check oil MITSUBISHI LANCER EVOLUTION 2007 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 562 of 1449

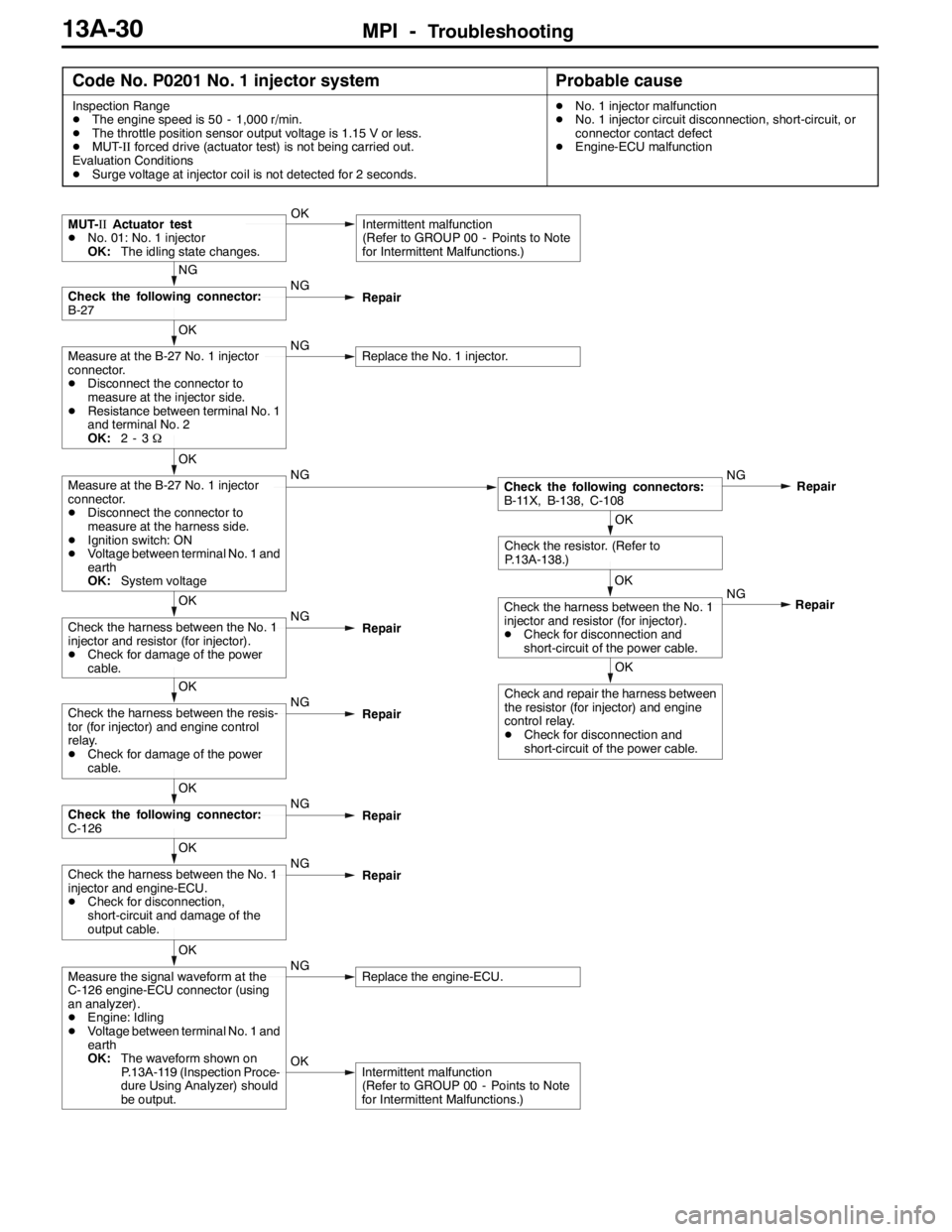

MPI -Troubleshooting13A-30

Code No. P0201 No. 1 injector systemProbable cause

Inspection Range

DThe engine speed is 50 - 1,000 r/min.

DThe throttle position sensor output voltage is 1.15 V or less.

DMUT-IIforced drive (actuator test) is not being carried out.

Evaluation Conditions

DSurge voltage at injector coil is not detected for 2 seconds.DNo. 1 injector malfunction

DNo. 1 injector circuit disconnection, short-circuit, or

connector contact defect

DEngine-ECU malfunction

OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Measure the signal waveform at the

C-126 engine-ECU connector (using

an analyzer).

DEngine: Idling

DVoltage between terminal No. 1 and

earth

OK:The waveform shown on

P.13A-119 (Inspection Proce-

dure Using Analyzer) should

be output.NGReplace the engine-ECU.

OK

Check the harness between the No. 1

injector and engine-ECU.

DCheck for disconnection,

short-circuit and damage of the

output cable.NG

Repair

OK

Check the following connector:

C-126NG

Repair

OK

Check the harness between the resis-

tor (for injector) and engine control

relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check the harness between the No. 1

injector and resistor (for injector).

DCheck for damage of the power

cable.NG

Repair

OK

Check and repair the harness between

the resistor (for injector) and engine

control relay.

DCheck for disconnection and

short-circuit of the power cable.NG

OK

Check the harness between the No. 1

injector and resistor (for injector).

DCheck for disconnection and

short-circuit of the power cable.Repair

OK

Check the resistor. (Refer to

P.13A-138.)

OK

Measure at the B-27 No. 1 injector

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1 and

earth

OK:System voltageNGCheck the following connectors:

B-11X, B-138, C-108NG

Repair

OK

Measure at the B-27 No. 1 injector

connector.

DDisconnect the connector to

measure at the injector side.

DResistance between terminal No. 1

and terminal No. 2

OK:2-3ΩNGReplace the No. 1 injector.

NG

Check the following connector:

B-27NG

Repair

MUT-IIActuator test

DNo. 01: No. 1 injector

OK:The idling state changes.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Page 563 of 1449

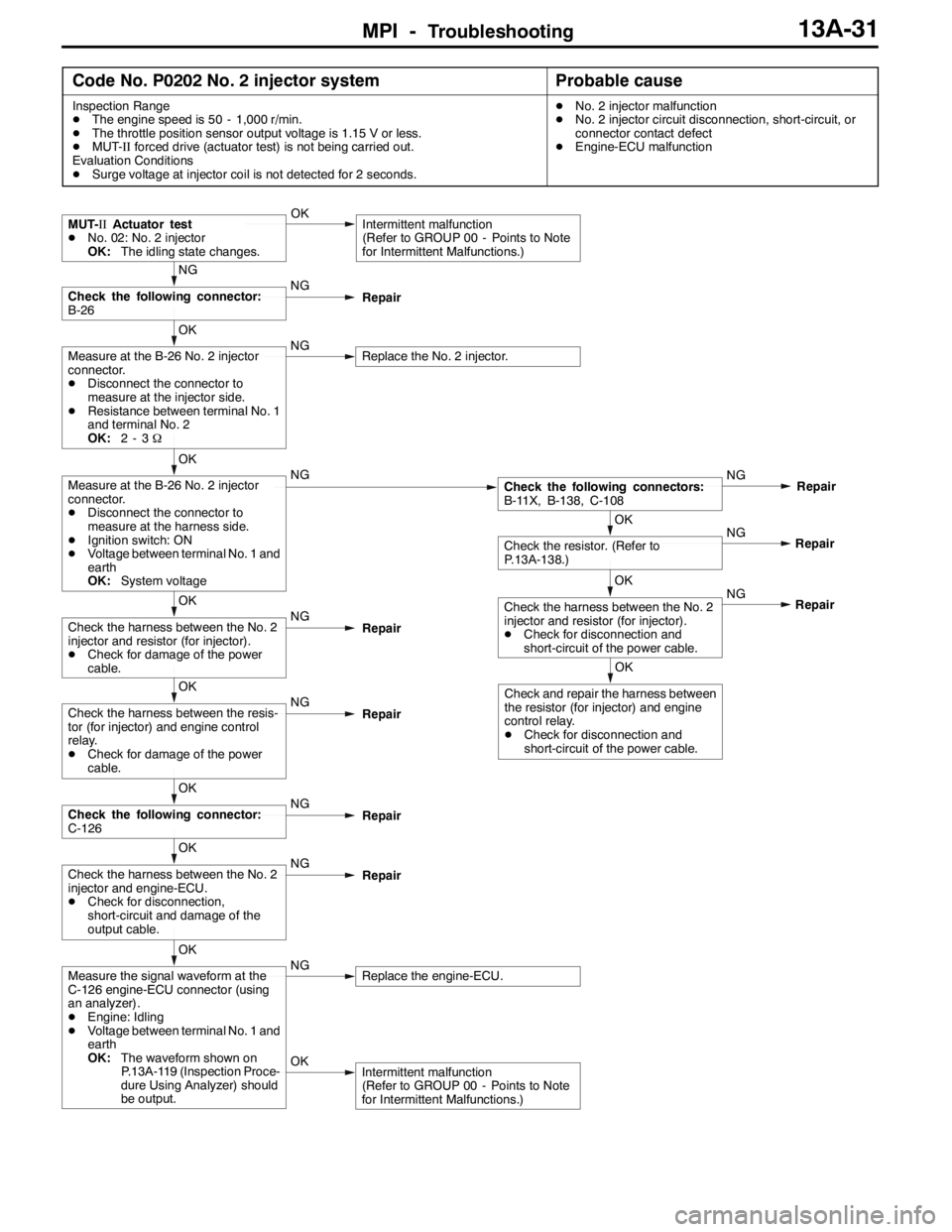

MPI -Troubleshooting13A-31

Code No. P0202 No. 2 injector systemProbable cause

Inspection Range

DThe engine speed is 50 - 1,000 r/min.

DThe throttle position sensor output voltage is 1.15 V or less.

DMUT-IIforced drive (actuator test) is not being carried out.

Evaluation Conditions

DSurge voltage at injector coil is not detected for 2 seconds.DNo. 2 injector malfunction

DNo. 2 injector circuit disconnection, short-circuit, or

connector contact defect

DEngine-ECU malfunction

OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Measure the signal waveform at the

C-126 engine-ECU connector (using

an analyzer).

DEngine: Idling

DVoltage between terminal No. 1 and

earth

OK:The waveform shown on

P.13A-119 (Inspection Proce-

dure Using Analyzer) should

be output.NGReplace the engine-ECU.

OK

Check the harness between the No. 2

injector and engine-ECU.

DCheck for disconnection,

short-circuit and damage of the

output cable.NG

Repair

OK

Check the following connector:

C-126NG

Repair

OK

Check the harness between the resis-

tor (for injector) and engine control

relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check and repair the harness between

the resistor (for injector) and engine

control relay.

DCheck for disconnection and

short-circuit of the power cable.NG

OK

Check the harness between the No. 2

injector and resistor (for injector).

DCheck for disconnection and

short-circuit of the power cable.Repair NG

OK

Check the resistor. (Refer to

P.13A-138.)Repair

OK

Check the harness between the No. 2

injector and resistor (for injector).

DCheck for damage of the power

cable.NG

Repair

OK

Measure at the B-26 No. 2 injector

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1 and

earth

OK:System voltageNGCheck the following connectors:

B-11X, B-138, C-108NG

Repair

OK

Measure at the B-26 No. 2 injector

connector.

DDisconnect the connector to

measure at the injector side.

DResistance between terminal No. 1

and terminal No. 2

OK:2-3ΩNGReplace the No. 2 injector.

NG

Check the following connector:

B-26NG

Repair

MUT-IIActuator test

DNo. 02: No. 2 injector

OK:The idling state changes.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Page 564 of 1449

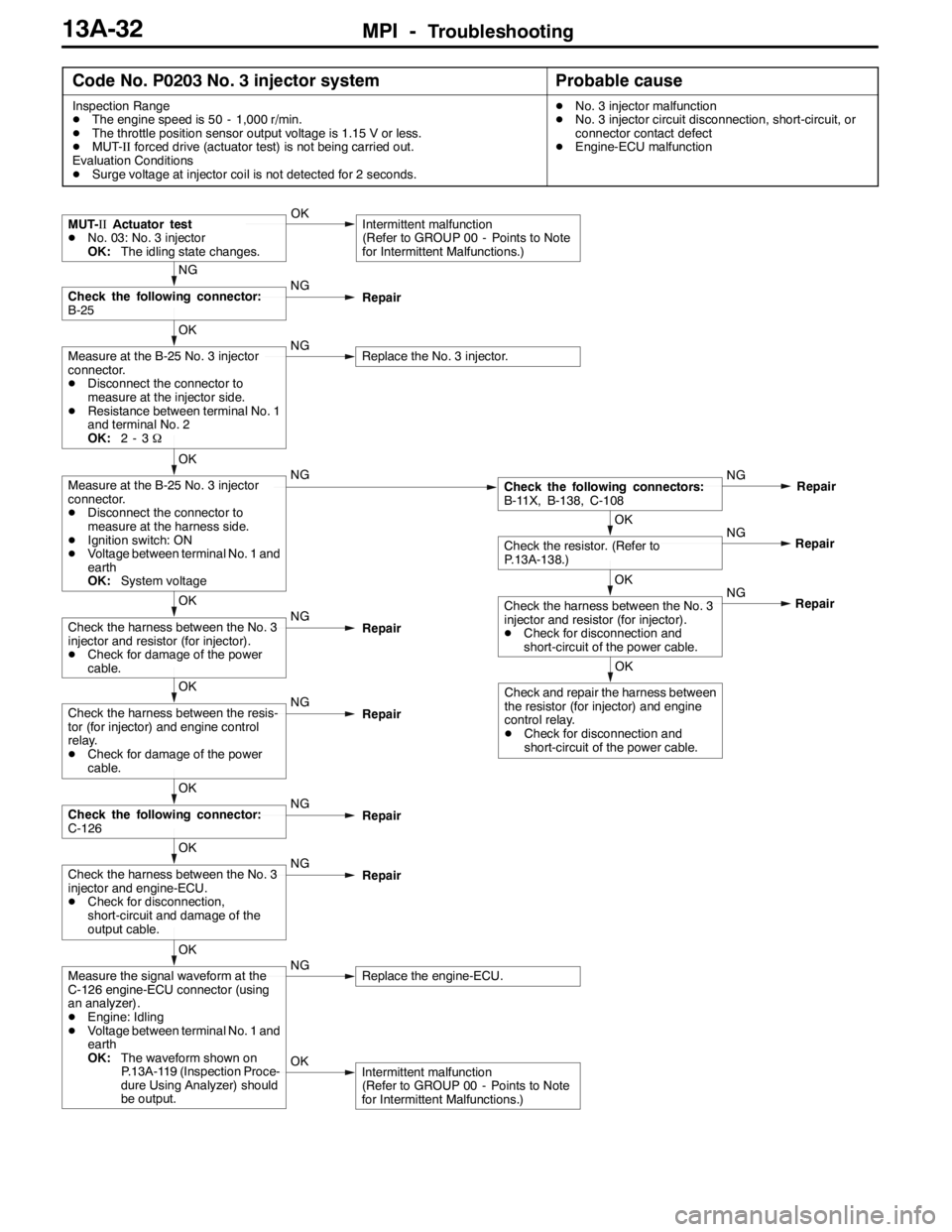

MPI -Troubleshooting13A-32

Code No. P0203 No. 3 injector systemProbable cause

Inspection Range

DThe engine speed is 50 - 1,000 r/min.

DThe throttle position sensor output voltage is 1.15 V or less.

DMUT-IIforced drive (actuator test) is not being carried out.

Evaluation Conditions

DSurge voltage at injector coil is not detected for 2 seconds.DNo. 3 injector malfunction

DNo. 3 injector circuit disconnection, short-circuit, or

connector contact defect

DEngine-ECU malfunction

OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Measure the signal waveform at the

C-126 engine-ECU connector (using

an analyzer).

DEngine: Idling

DVoltage between terminal No. 1 and

earth

OK:The waveform shown on

P.13A-119 (Inspection Proce-

dure Using Analyzer) should

be output.NGReplace the engine-ECU.

OK

Check the harness between the No. 3

injector and engine-ECU.

DCheck for disconnection,

short-circuit and damage of the

output cable.NG

Repair

OK

Check the following connector:

C-126NG

Repair

OK

Check the harness between the resis-

tor (for injector) and engine control

relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check and repair the harness between

the resistor (for injector) and engine

control relay.

DCheck for disconnection and

short-circuit of the power cable.NG

OK

Check the harness between the No. 3

injector and resistor (for injector).

DCheck for disconnection and

short-circuit of the power cable.Repair NG

OK

Check the resistor. (Refer to

P.13A-138.)Repair

OK

Check the harness between the No. 3

injector and resistor (for injector).

DCheck for damage of the power

cable.NG

Repair

OK

Measure at the B-25 No. 3 injector

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1 and

earth

OK:System voltageNGCheck the following connectors:

B-11X, B-138, C-108NG

Repair

OK

Measure at the B-25 No. 3 injector

connector.

DDisconnect the connector to

measure at the injector side.

DResistance between terminal No. 1

and terminal No. 2

OK:2-3ΩNGReplace the No. 3 injector.

NG

Check the following connector:

B-25NG

Repair

MUT-IIActuator test

DNo. 03: No. 3 injector

OK:The idling state changes.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Page 565 of 1449

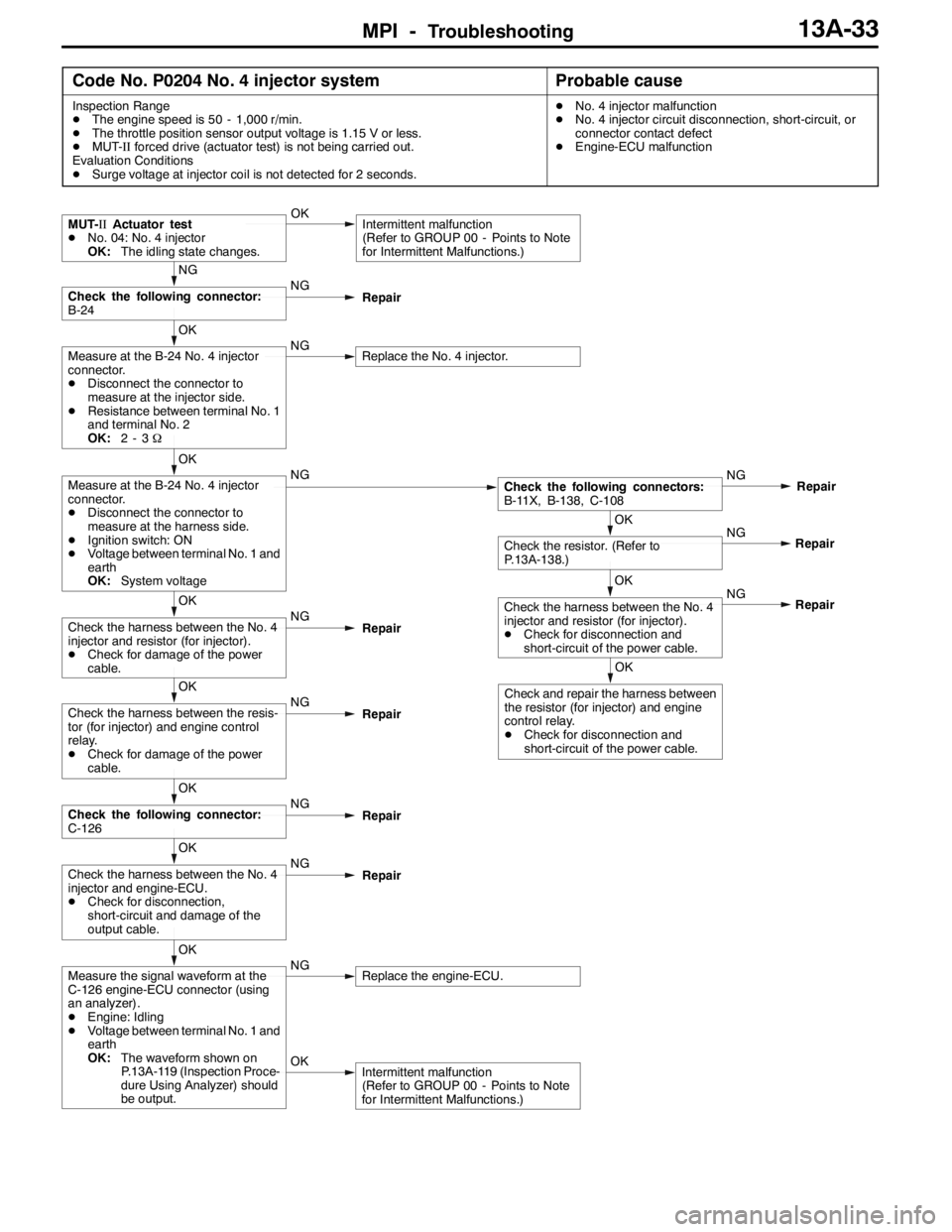

MPI -Troubleshooting13A-33

Code No. P0204 No. 4 injector systemProbable cause

Inspection Range

DThe engine speed is 50 - 1,000 r/min.

DThe throttle position sensor output voltage is 1.15 V or less.

DMUT-IIforced drive (actuator test) is not being carried out.

Evaluation Conditions

DSurge voltage at injector coil is not detected for 2 seconds.DNo. 4 injector malfunction

DNo. 4 injector circuit disconnection, short-circuit, or

connector contact defect

DEngine-ECU malfunction

OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Measure the signal waveform at the

C-126 engine-ECU connector (using

an analyzer).

DEngine: Idling

DVoltage between terminal No. 1 and

earth

OK:The waveform shown on

P.13A-119 (Inspection Proce-

dure Using Analyzer) should

be output.NGReplace the engine-ECU.

OK

Check the harness between the No. 4

injector and engine-ECU.

DCheck for disconnection,

short-circuit and damage of the

output cable.NG

Repair

OK

Check the following connector:

C-126NG

Repair

OK

Check the harness between the resis-

tor (for injector) and engine control

relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check and repair the harness between

the resistor (for injector) and engine

control relay.

DCheck for disconnection and

short-circuit of the power cable.NG

OK

Check the harness between the No. 4

injector and resistor (for injector).

DCheck for disconnection and

short-circuit of the power cable.Repair NG

OK

Check the resistor. (Refer to

P.13A-138.)Repair

OK

Check the harness between the No. 4

injector and resistor (for injector).

DCheck for damage of the power

cable.NG

Repair

OK

Measure at the B-24 No. 4 injector

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1 and

earth

OK:System voltageNGCheck the following connectors:

B-11X, B-138, C-108NG

Repair

OK

Measure at the B-24 No. 4 injector

connector.

DDisconnect the connector to

measure at the injector side.

DResistance between terminal No. 1

and terminal No. 2

OK:2-3ΩNGReplace the No. 4 injector.

NG

Check the following connector:

B-24NG

Repair

MUT-IIActuator test

DNo. 04: No. 4 injector

OK:The idling state changes.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Page 571 of 1449

MPI -Troubleshooting13A-39

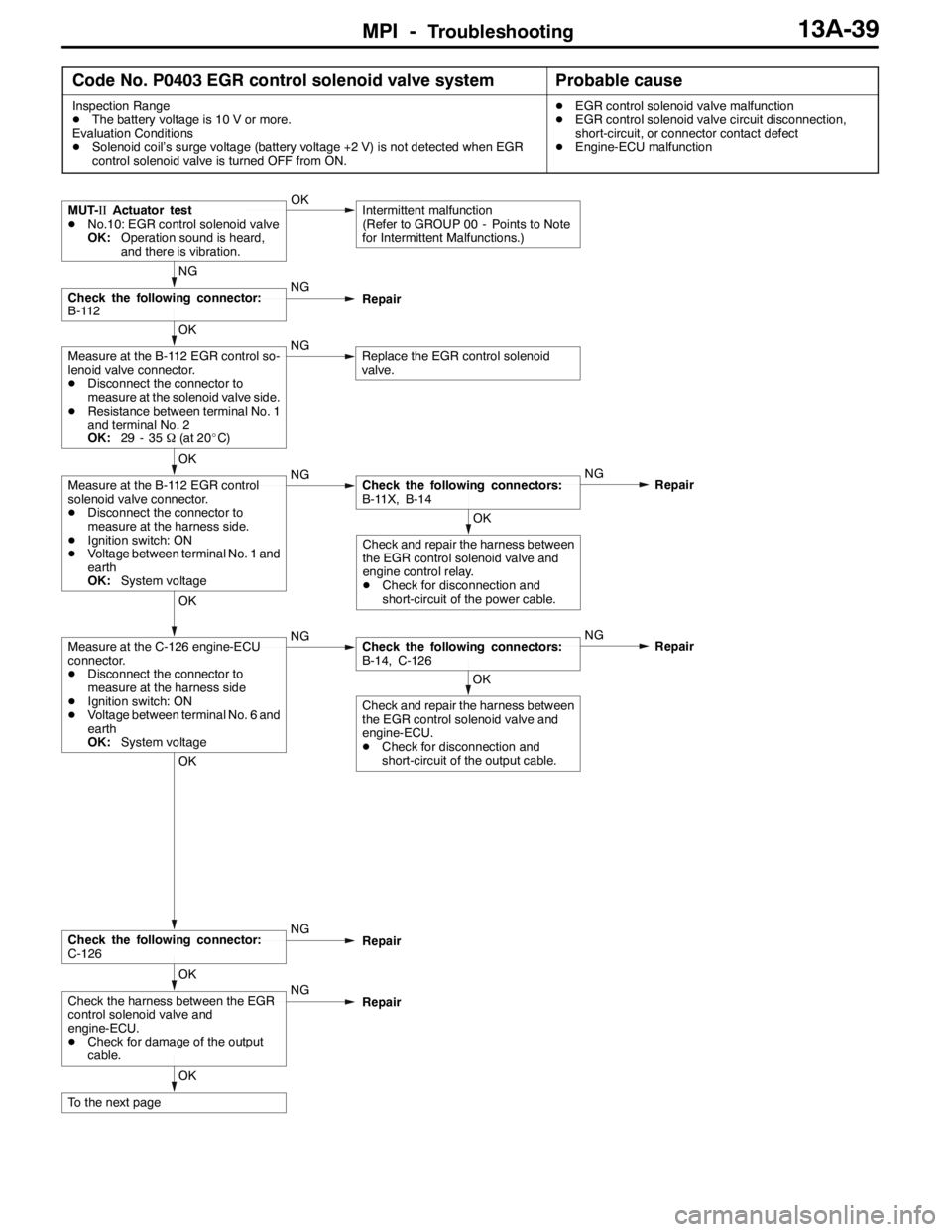

Code No. P0403 EGR control solenoid valve systemProbable cause

Inspection Range

DThe battery voltage is 10 V or more.

Evaluation Conditions

DSolenoid coil’s surge voltage (battery voltage +2 V) is not detected when EGR

control solenoid valve is turned OFF from ON.DEGR control solenoid valve malfunction

DEGR control solenoid valve circuit disconnection,

short-circuit, or connector contact defect

DEngine-ECU malfunction

OK

To the next page

OK

Check the harness between the EGR

control solenoid valve and

engine-ECU.

DCheck for damage of the output

cable.NG

Repair

OK

Check the following connector:

C-126NG

Repair

OK

Check and repair the harness between

the EGR control solenoid valve and

engine-ECU.

DCheck for disconnection and

short-circuit of the output cable.

OK

Measure at the C-126 engine-ECU

connector.

DDisconnect the connector to

measure at the harness side

DIgnition switch: ON

DVoltage between terminal No. 6 and

earth

OK:System voltageNGCheck the following connectors:

B-14, C-126NG

Repair

OK

Check and repair the harness between

the EGR control solenoid valve and

engine control relay.

DCheck for disconnection and

short-circuit of the power cable.

OK

Measure at the B-112 EGR control

solenoid valve connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1 and

earth

OK:System voltageNGCheck the following connectors:

B-11X, B-14NG

Repair

OK

Measure at the B-112 EGR control so-

lenoid valve connector.

DDisconnect the connector to

measure at the solenoid valve side.

DResistance between terminal No. 1

and terminal No. 2

OK:29 - 35Ω(at 20_C)NGReplace the EGR control solenoid

valve.

NG

Check the following connector:

B-112NG

Repair

MUT-IIActuator test

DNo.10: EGR control solenoid valve

OK:Operation sound is heard,

and there is vibration.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Page 573 of 1449

MPI -Troubleshooting13A-41

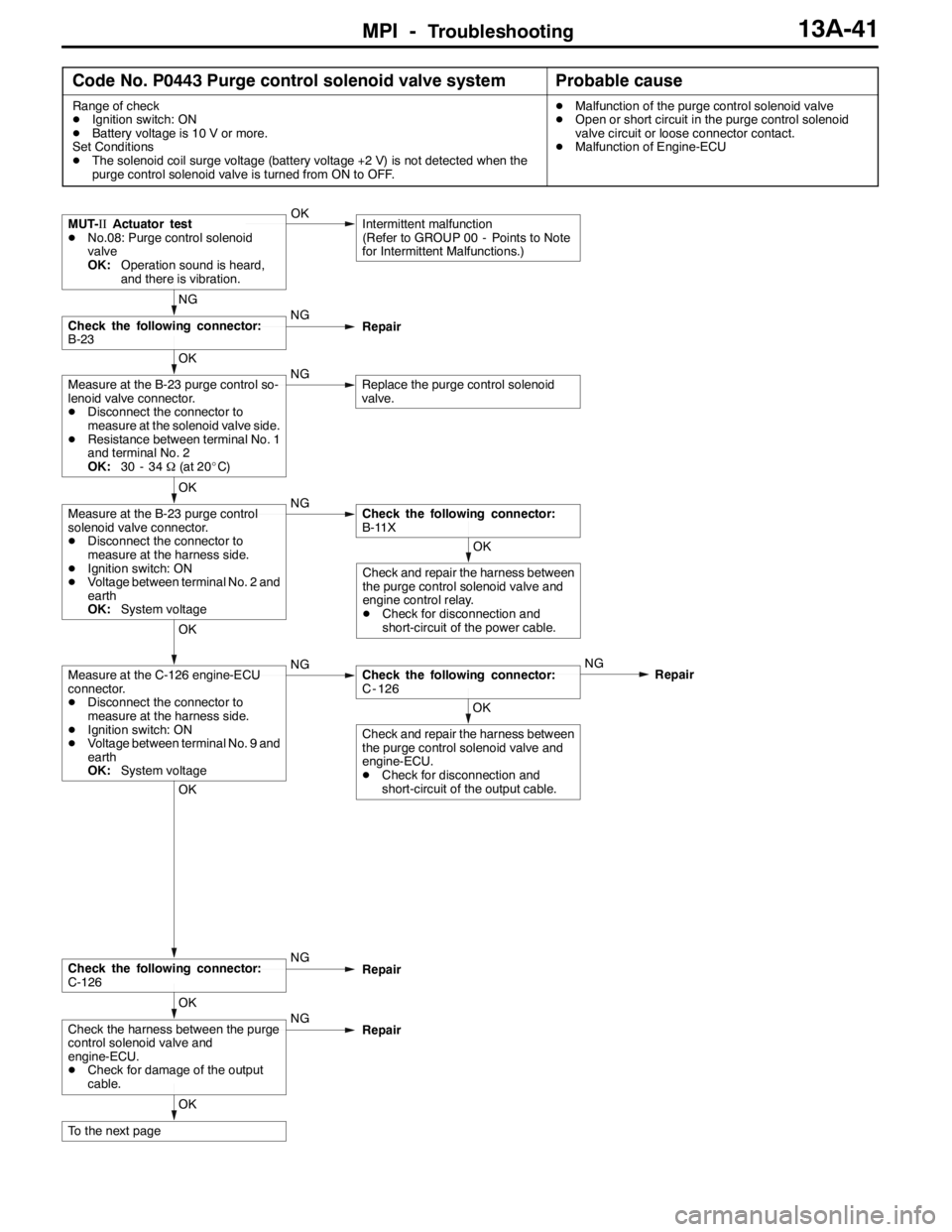

Code No. P0443 Purge control solenoid valve systemProbable cause

Range of check

DIgnition switch: ON

DBattery voltage is 10 V or more.

Set Conditions

DThe solenoid coil surge voltage (battery voltage +2 V) is not detected when the

purge control solenoid valve is turned from ON to OFF.DMalfunction of the purge control solenoid valve

DOpen or short circuit in the purge control solenoid

valve circuit or loose connector contact.

DMalfunction of Engine-ECU

OK

To the next page

OK

Check the harness between the purge

control solenoid valve and

engine-ECU.

DCheck for damage of the output

cable.NG

Repair

OK

Check the following connector:

C-126NG

Repair

OK

Check and repair the harness between

the purge control solenoid valve and

engine-ECU.

DCheck for disconnection and

short-circuit of the output cable.

OK

Measure at the C-126 engine-ECU

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 9 and

earth

OK:System voltageNGCheck the following connector:

C - 126NG

Repair

OK

Check and repair the harness between

the purge control solenoid valve and

engine control relay.

DCheck for disconnection and

short-circuit of the power cable.

OK

Measure at the B-23 purge control

solenoid valve connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 2 and

earth

OK:System voltageNGCheck the following connector:

B-11X

OK

Measure at the B-23 purge control so-

lenoid valve connector.

DDisconnect the connector to

measure at the solenoid valve side.

DResistance between terminal No. 1

and terminal No. 2

OK:30 - 34Ω(at 20_C)NGReplace the purge control solenoid

valve.

NG

Check the following connector:

B-23NG

Repair

MUT-IIActuator test

DNo.08: Purge control solenoid

valve

OK:Operation sound is heard,

and there is vibration.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Page 579 of 1449

MPI -Troubleshooting13A-47

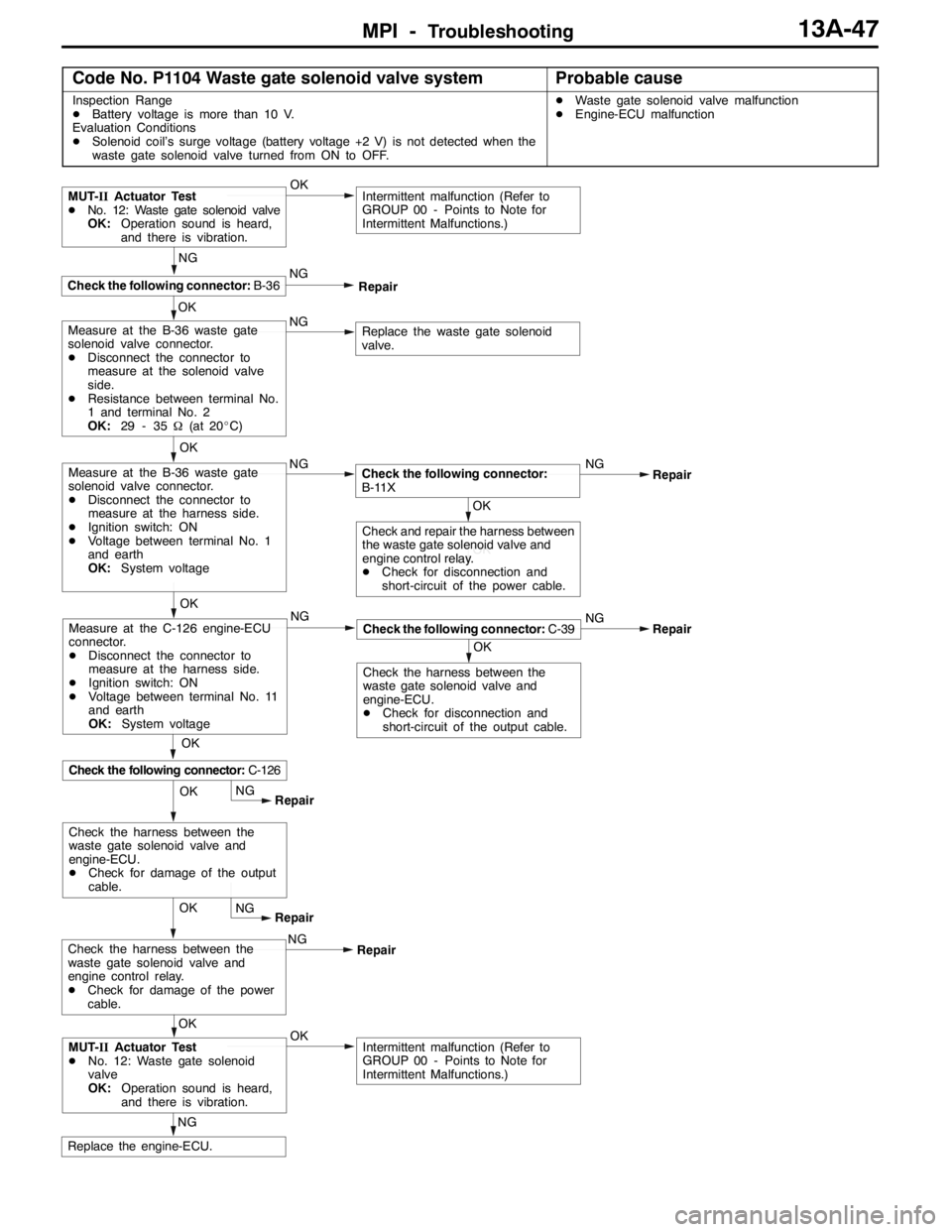

Code No. P1104 Waste gate solenoid valve systemProbable cause

Inspection Range

DBattery voltage is more than 10 V.

Evaluation Conditions

DSolenoid coil’s surge voltage (battery voltage +2 V) is not detected when the

waste gate solenoid valve turned from ON to OFF.DWaste gate solenoid valve malfunction

DEngine-ECU malfunction

OK

NG

Replace the engine-ECU.

OKIntermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)MUT-IIActuator Test

DNo. 12: Waste gate solenoid

valve

OK:Operation sound is heard,

and there is vibration.OKNG

Repair

OK

NG

Intermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)

OK

Check the following connector:B-36

MUT-IIActuator Test

DNo. 12: Waste gate solenoid valve

OK:Operation sound is heard,

and there is vibration.

NG

Repair

NGNG

Repair

OK

Check the harness between the

waste gate solenoid valve and

engine-ECU.

DCheck for disconnection and

short-circuit of the output cable.

Check the following connector:C-39

OK

Check the following connector:C-126

Measure at the C-126 engine-ECU

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 11

and earth

OK:System voltageNG

Replace the waste gate solenoid

valve.Measure at the B-36 waste gate

solenoid valve connector.

DDisconnect the connector to

measure at the solenoid valve

side.

DResistance between terminal No.

1 and terminal No. 2

OK:29 - 35Ω(at 20_C)

OK

NG

Measure at the B-36 waste gate

solenoid valve connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1

and earth

OK:System voltage

OKNG

Repair

OK

OK

Check and repair the harness between

the waste gate solenoid valve and

engine control relay.

DCheck for disconnection and

short-circuit of the power cable.

Check the following connector:

B-11X

NG

RepairCheck the harness between the

waste gate solenoid valve and

engine control relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check the harness between the

waste gate solenoid valve and

engine-ECU.

DCheck for damage of the output

cable.

Page 580 of 1449

MPI -Troubleshooting13A-48

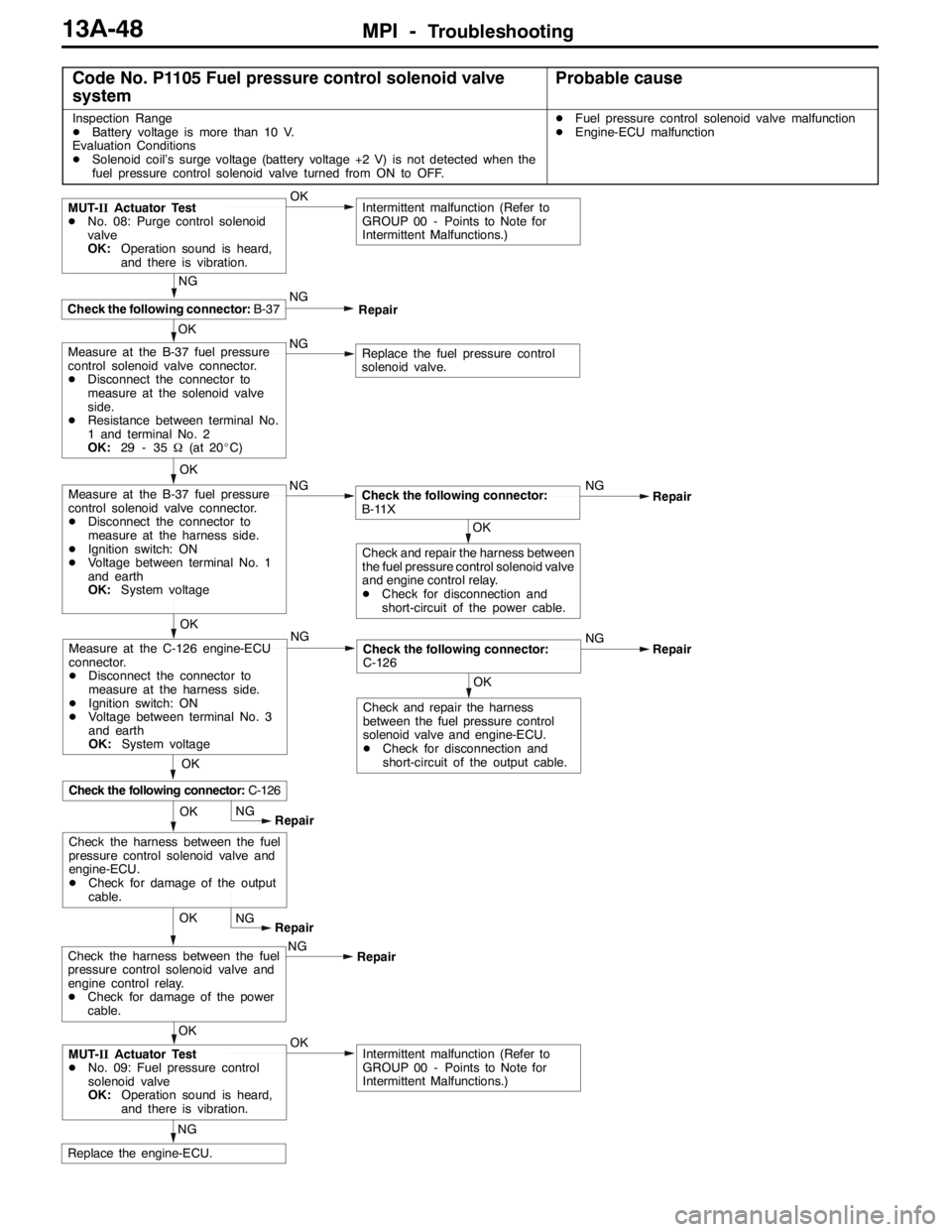

Code No. P1105 Fuel pressure control solenoid valve

systemProbable cause

Inspection Range

DBattery voltage is more than 10 V.

Evaluation Conditions

DSolenoid coil’s surge voltage (battery voltage +2 V) is not detected when the

fuel pressure control solenoid valve turned from ON to OFF.DFuel pressure control solenoid valve malfunction

DEngine-ECU malfunction

OK

NG

Replace the engine-ECU.

OKIntermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)MUT-IIActuator Test

DNo. 09: Fuel pressure control

solenoid valve

OK:Operation sound is heard,

and there is vibration.OKNG

Repair

OK

NG

Intermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)

OK

Check the following connector:B-37

MUT-IIActuator Test

DNo. 08: Purge control solenoid

valve

OK:Operation sound is heard,

and there is vibration.

NG

Repair

NGNG

Repair

OK

OK

Check and repair the harness

between the fuel pressure control

solenoid valve and engine-ECU.

DCheck for disconnection and

short-circuit of the output cable.

Check the following connector:

C-126

OK

Check the following connector:C-126

Measure at the C-126 engine-ECU

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 3

and earth

OK:System voltageNG

Replace the fuel pressure control

solenoid valve.Measure at the B-37 fuel pressure

control solenoid valve connector.

DDisconnect the connector to

measure at the solenoid valve

side.

DResistance between terminal No.

1 and terminal No. 2

OK:29 - 35Ω(at 20_C)

OK

NG

Measure at the B-37 fuel pressure

control solenoid valve connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1

and earth

OK:System voltage

OKNG

Repair

OK

OKCheck and repair the harness between

the fuel pressure control solenoid valve

and engine control relay.

DCheck for disconnection and

short-circuit of the power cable.

Check the following connector:

B-11X

NG

RepairCheck the harness between the fuel

pressure control solenoid valve and

engine control relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check the harness between the fuel

pressure control solenoid valve and

engine-ECU.

DCheck for damage of the output

cable.

Page 584 of 1449

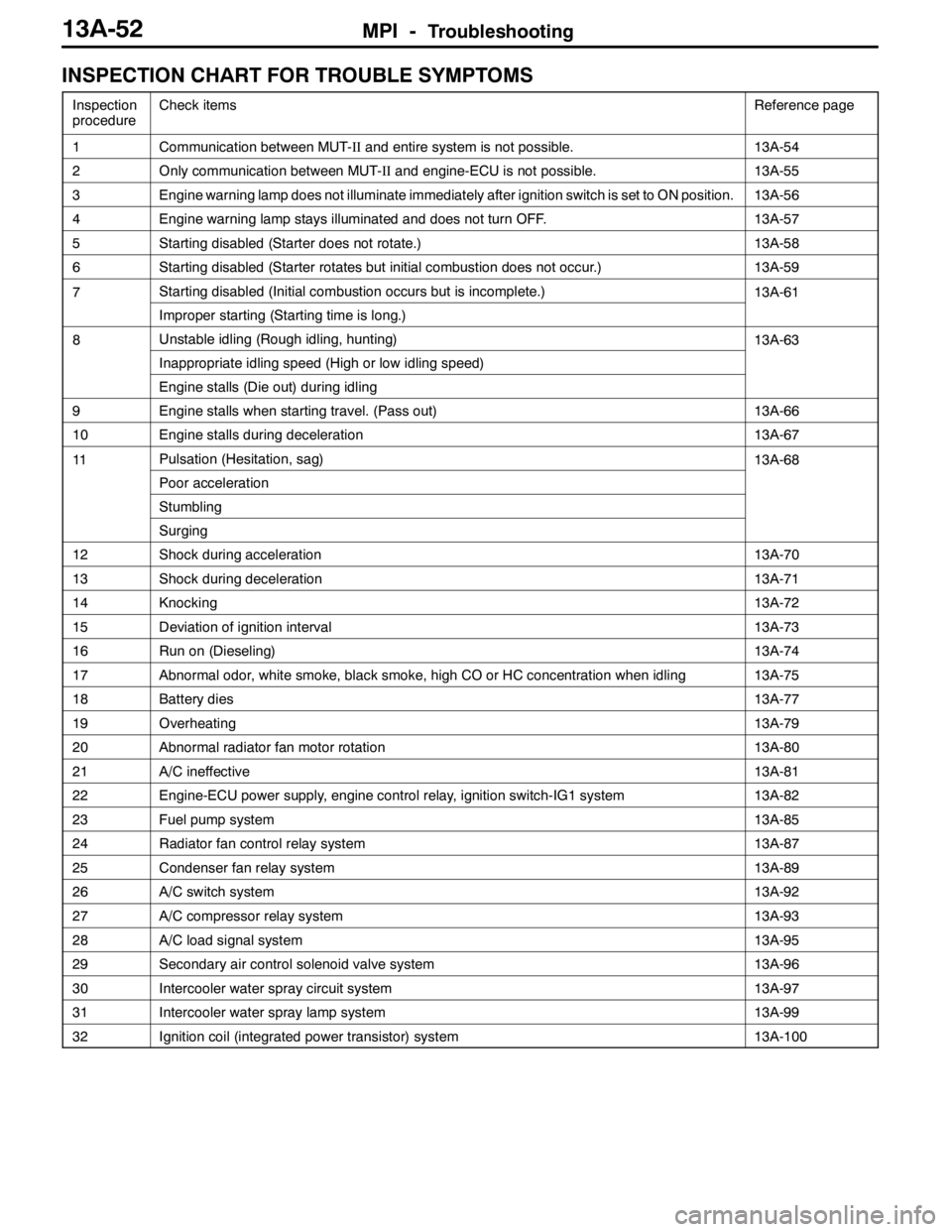

MPI -Troubleshooting13A-52

INSPECTION CHART FOR TROUBLE SYMPTOMS

Inspection

procedureCheck itemsReference page

1Communication between MUT-IIand entire system is not possible.13A-54

2Only communication between MUT-IIand engine-ECU is not possible.13A-55

3Engine warning lamp does not illuminate immediately after ignition switch is set to ON position.13A-56

4Engine warning lamp stays illuminated and does not turn OFF.13A-57

5Starting disabled (Starter does not rotate.)13A-58

6Starting disabled (Starter rotates but initial combustion does not occur.)13A-59

7Starting disabled (Initial combustion occurs but is incomplete.)13A-61

Improper starting (Starting time is long.)

8Unstable idling (Rough idling, hunting)13A-63

Inappropriate idling speed (High or low idling speed)

Engine stalls (Die out) during idling

9Engine stalls when starting travel. (Pass out)13A-66

10Engine stalls during deceleration13A-67

11Pulsation (Hesitation, sag)13A-68

Poor acceleration

Stumbling

Surging

12Shock during acceleration13A-70

13Shock during deceleration13A-71

14Knocking13A-72

15Deviation of ignition interval13A-73

16Run on (Dieseling)13A-74

17Abnormal odor, white smoke, black smoke, high CO or HC concentration when idling13A-75

18Battery dies13A-77

19Overheating13A-79

20Abnormal radiator fan motor rotation13A-80

21A/C ineffective13A-81

22Engine-ECU power supply, engine control relay, ignition switch-IG1 system13A-82

23Fuel pump system13A-85

24Radiator fan control relay system13A-87

25Condenser fan relay system13A-89

26A/C switch system13A-92

27A/C compressor relay system13A-93

28A/C load signal system13A-95

29Secondary air control solenoid valve system13A-96

30Intercooler water spray circuit system13A-97

31Intercooler water spray lamp system13A-99

32Ignition coil (integrated power transistor) system13A-100

Page 591 of 1449

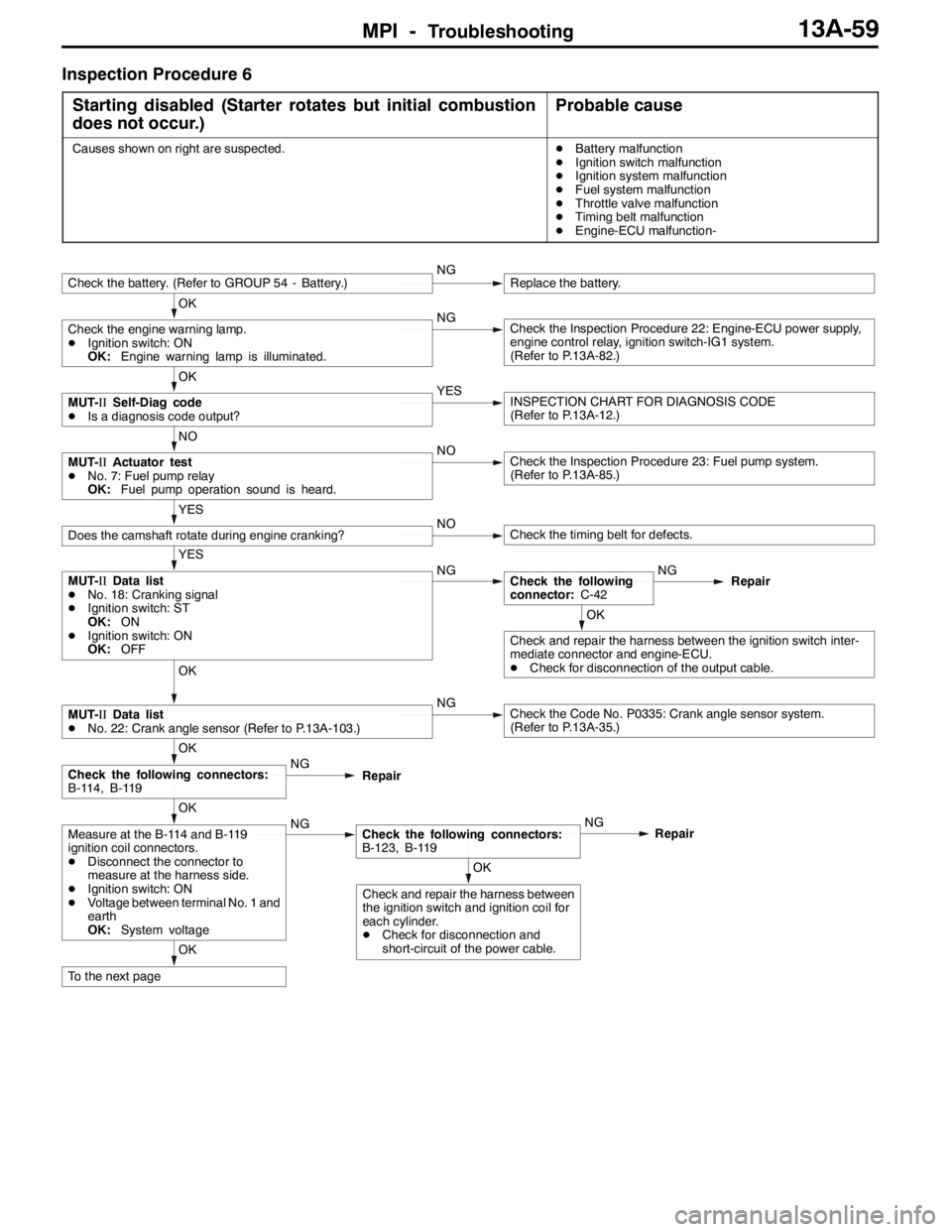

MPI -Troubleshooting13A-59

Inspection Procedure 6

Starting disabled (Starter rotates but initial combustion

does not occur.)

Probable cause

Causes shown on right are suspected.DBattery malfunction

DIgnition switch malfunction

DIgnition system malfunction

DFuel system malfunction

DThrottle valve malfunction

DTiming belt malfunction

DEngine-ECU malfunction-

OK

To the next page

OK

Check and repair the harness between

the ignition switch and ignition coil for

each cylinder.

DCheck for disconnection and

short-circuit of the power cable.

OK

Measure at the B-114 and B-119

ignition coil connectors.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1 and

earth

OK:System voltageNGCheck the following connectors:

B-123, B-119NG

Repair

OK

Check the following connectors:

B-114, B-119NG

Repair

OK

MUT-IIData list

DNo. 22: Crank angle sensor (Refer to P.13A-103.)NGCheck the Code No. P0335: Crank angle sensor system.

(Refer to P.13A-35.)

OK

Check and repair the harness between the ignition switch inter-

mediate connector and engine-ECU.

DCheck for disconnection of the output cable.

YES

MUT-IIData list

DNo. 18: Cranking signal

DIgnition switch: ST

OK:ON

DIgnition switch: ON

OK:OFFNGCheck the following

connector:C-42NG

Repair

YES

Does the camshaft rotate during engine cranking?NOCheck the timing belt for defects.

NO

MUT-IIActuator test

DNo. 7: Fuel pump relay

OK:Fuel pump operation sound is heard.NOCheck the Inspection Procedure 23: Fuel pump system.

(Refer to P.13A-85.)

OK

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

OK

Check the engine warning lamp.

DIgnition switch: ON

OK:Engine warning lamp is illuminated.NGCheck the Inspection Procedure 22: Engine-ECU power supply,

engine control relay, ignition switch-IG1 system.

(Refer to P.13A-82.)

Check the battery. (Refer to GROUP 54 - Battery.)NGReplace the battery.