Drain MITSUBISHI LANCER EVOLUTION 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1143 of 1449

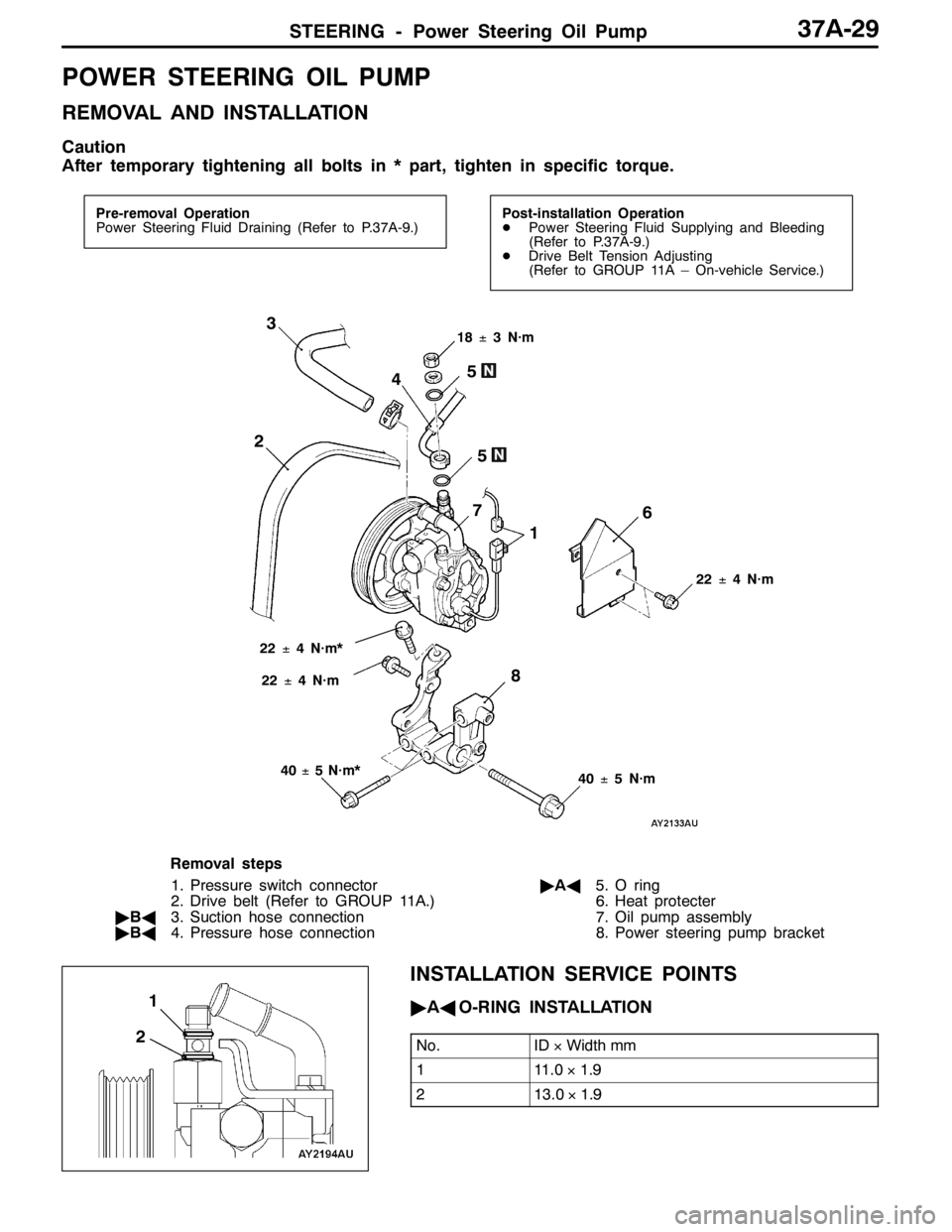

STEERING - Power Steering Oil Pump37A-29

POWER STEERING OIL PUMP

REMOVAL AND INSTALLATION

Caution

After temporary tightening all bolts in * part, tighten in specific torque.

Pre-removal Operation

Power Steering Fluid Draining (Refer to P.37A-9.)Post-installation Operation

DPower Steering Fluid Supplying and Bleeding

(Refer to P.37A-9.)

DDrive Belt Tension Adjusting

(Refer to GROUP 11A – On-vehicle Service.)

22±4 N·m

8

40±5 N·m 18±3 N·m

3

45

2

5

22±4 N·m*

1 7

6

40±5 N·m* 22±4 N·m

Removal steps

1. Pressure switch connector

2. Drive belt (Refer to GROUP 11A.)

"BA3. Suction hose connection

"BA4. Pressure hose connection"AA5. O ring

6. Heat protecter

7. Oil pump assembly

8. Power steering pump bracket

INSTALLATION SERVICE POINTS

"AAO-RING INSTALLATION

No.ID×Width mm

111.0×1.9

213.0×1.9

21

Page 1145 of 1449

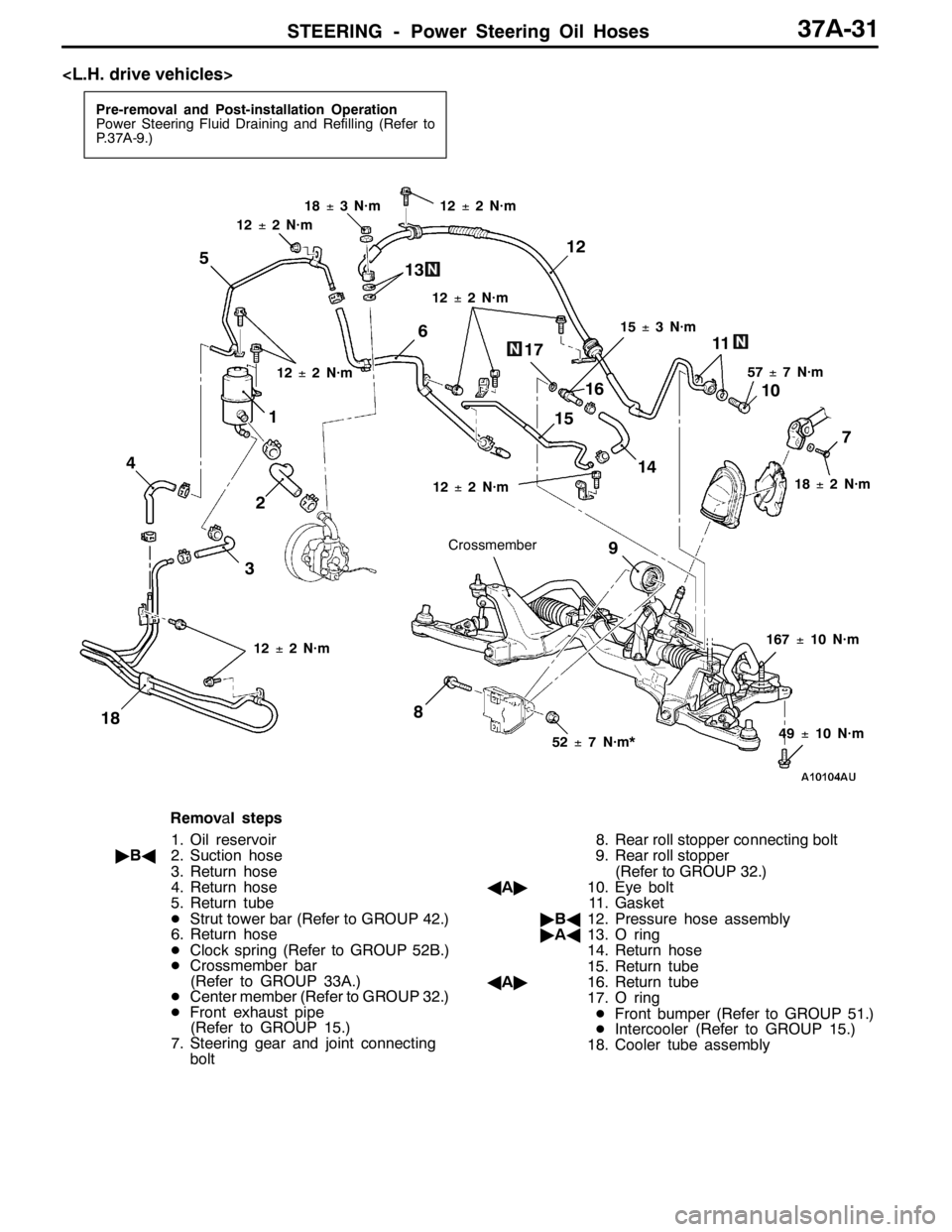

STEERING - Power Steering Oil Hoses37A-31

Pre-removal and Post-installation Operation

Power Steering Fluid Draining and Refilling (Refer to

P.37A-9.)

12±2 N·m

17

16

15

12

18±3 N·m

Crossmember

1

57±7 N·m

9

8 47

32 5

12±2 N·m15±3 N·m

18±2 N·m 12±2 N·m

49±10 N·m

52±7 N·m*

12±2 N·m

6

10

11

167±10 N·m

14 13

18

12±2 N·m

12±2 N·m

Removal steps

1. Oil reservoir

"BA2. Suction hose

3. Return hose

4. Return hose

5. Return tube

DStrut tower bar (Refer to GROUP 42.)

6. Return hose

DClock spring (Refer to GROUP 52B.)

DCrossmember bar

(Refer to GROUP 33A.)

DCenter member (Refer to GROUP 32.)

DFront exhaust pipe

(Refer to GROUP 15.)

7. Steering gear and joint connecting

bolt8. Rear roll stopper connecting bolt

9. Rear roll stopper

(Refer to GROUP 32.)

AA"10. Eye bolt

11. Gasket

"BA12. Pressure hose assembly

"AA13. O ring

14. Return hose

15. Return tube

AA"16. Return tube

17. O ring

DFront bumper (Refer to GROUP 51.)

DIntercooler (Refer to GROUP 15.)

18. Cooler tube assembly

Page 1146 of 1449

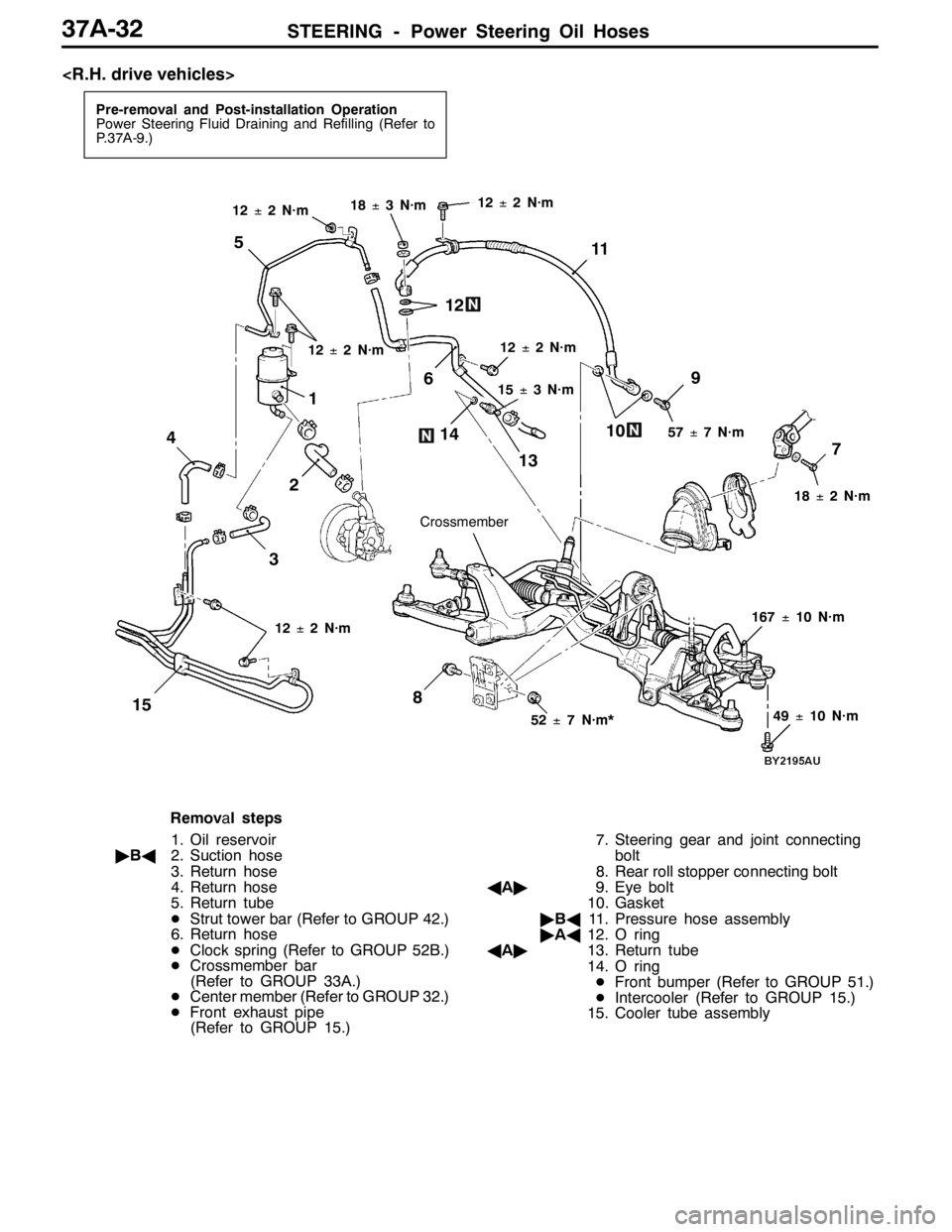

STEERING - Power Steering Oil Hoses37A-32

Pre-removal and Post-installation Operation

Power Steering Fluid Draining and Refilling (Refer to

P.37A-9.)

12±2 N·m

15

12

18±3 N·m

Crossmember

1

57±7 N·m

9

8 4

7

32 5

12±2 N·m

15±3 N·m

18±2 N·m 12±2 N·m

49±10 N·m

52±7 N·m*

12±2 N·m

6

10

11

167±10 N·m

14

13

12±2 N·m

Removal steps

1. Oil reservoir

"BA2. Suction hose

3. Return hose

4. Return hose

5. Return tube

DStrut tower bar (Refer to GROUP 42.)

6. Return hose

DClock spring (Refer to GROUP 52B.)

DCrossmember bar

(Refer to GROUP 33A.)

DCenter member (Refer to GROUP 32.)

DFront exhaust pipe

(Refer to GROUP 15.)7. Steering gear and joint connecting

bolt

8. Rear roll stopper connecting bolt

AA"9. Eye bolt

10. Gasket

"BA11. Pressure hose assembly

"AA12. O ring

AA"13. Return tube

14. O ring

DFront bumper (Refer to GROUP 51.)

DIntercooler (Refer to GROUP 15.)

15. Cooler tube assembly

Page 1341 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-21

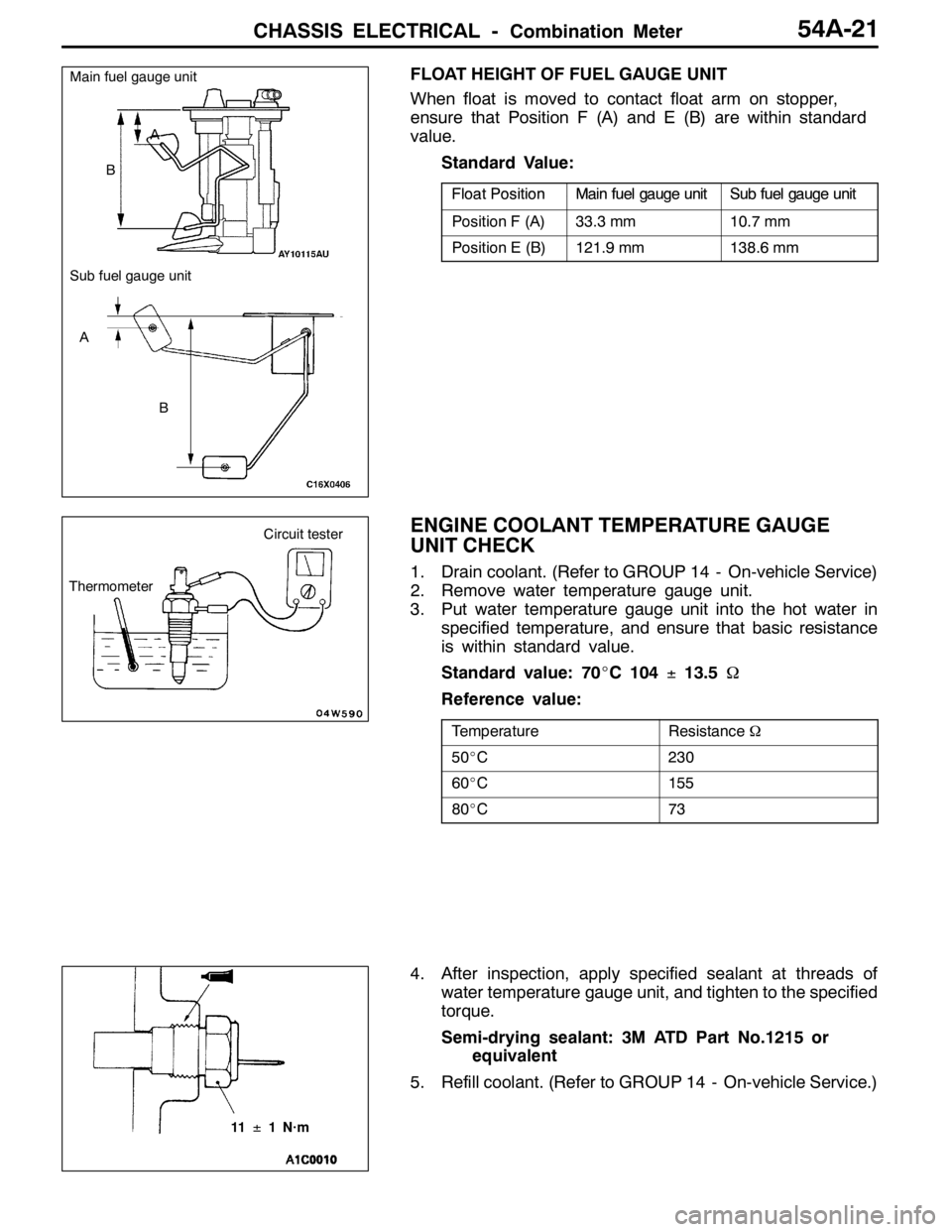

FLOAT HEIGHT OF FUEL GAUGE UNIT

When float is moved to contact float arm on stopper,

ensure that Position F (A) and E (B) are within standard

value.

Standard Value:

FloatPositionMainfuelgaugeunitSubfuelgaugeunitFloatPositionMainfuelgaugeunitSubfuelgaugeunit

Position F (A)33.3 mm10.7 mm

Position E (B)121.9 mm138.6 mm

ENGINE COOLANT TEMPERATURE GAUGE

UNIT CHECK

1. Drain coolant. (Refer to GROUP 14 - On-vehicle Service)

2. Remove water temperature gauge unit.

3. Put water temperature gauge unit into the hot water in

specified temperature, and ensure that basic resistance

is within standard value.

Standard value: 70_C 104±13.5Ω

Reference value:

TemperatureResistanceΩ

50_C230

60_C155

80_C73

4. After inspection, apply specified sealant at threads of

water temperature gauge unit, and tighten to the specified

torque.

Semi-drying sealant: 3M ATD Part No.1215 or

equivalent

5. Refill coolant. (Refer to GROUP 14 - On-vehicle Service.)

Main fuel gauge unit

Sub fuel gauge unit

A

B

A

B

ThermometerCircuit tester

11±1 N·m

Page 1416 of 1449

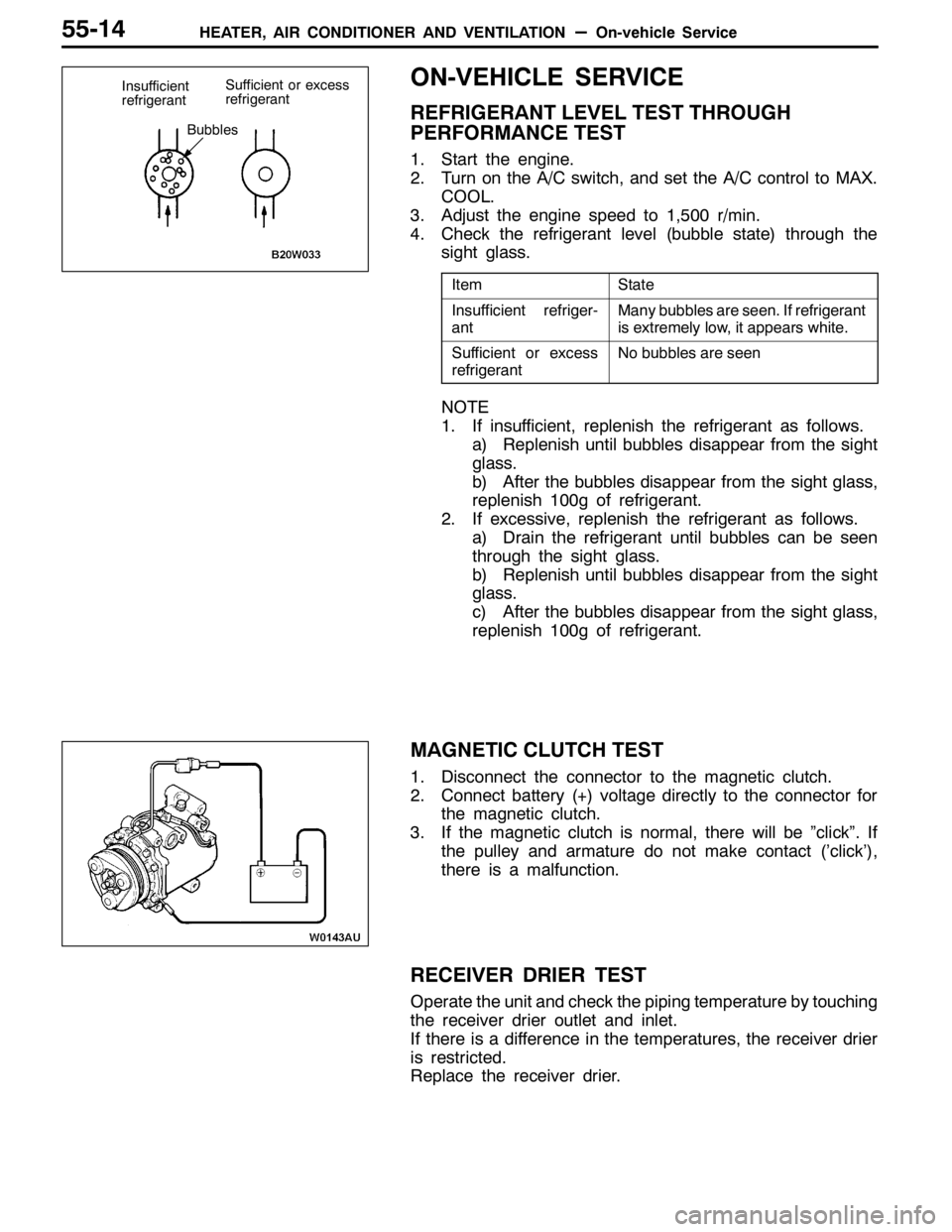

HEATER, AIR CONDITIONER AND VENTILATION–On-vehicle Service55-14

ON-VEHICLE SERVICE

REFRIGERANT LEVEL TEST THROUGH

PERFORMANCE TEST

1. Start the engine.

2. Turn on the A/C switch, and set the A/C control to MAX.

COOL.

3. Adjust the engine speed to 1,500 r/min.

4. Check the refrigerant level (bubble state) through the

sight glass.

ItemState

Insufficient refriger-

antMany bubbles are seen. If refrigerant

is extremely low, it appears white.

Sufficient or excess

refrigerantNo bubbles are seen

NOTE

1. If insufficient, replenish the refrigerant as follows.

a) Replenish until bubbles disappear from the sight

glass.

b) After the bubbles disappear from the sight glass,

replenish 100g of refrigerant.

2. If excessive, replenish the refrigerant as follows.

a) Drain the refrigerant until bubbles can be seen

through the sight glass.

b) Replenish until bubbles disappear from the sight

glass.

c) After the bubbles disappear from the sight glass,

replenish 100g of refrigerant.

MAGNETIC CLUTCH TEST

1. Disconnect the connector to the magnetic clutch.

2. Connect battery (+) voltage directly to the connector for

the magnetic clutch.

3. If the magnetic clutch is normal, there will be ”click”. If

the pulley and armature do not make contact (’click’),

there is a malfunction.

RECEIVER DRIER TEST

Operate the unit and check the piping temperature by touching

the receiver drier outlet and inlet.

If there is a difference in the temperatures, the receiver drier

is restricted.

Replace the receiver drier.

Insufficient

refrigerantSufficient or excess

refrigerant

Bubbles

Page 1430 of 1449

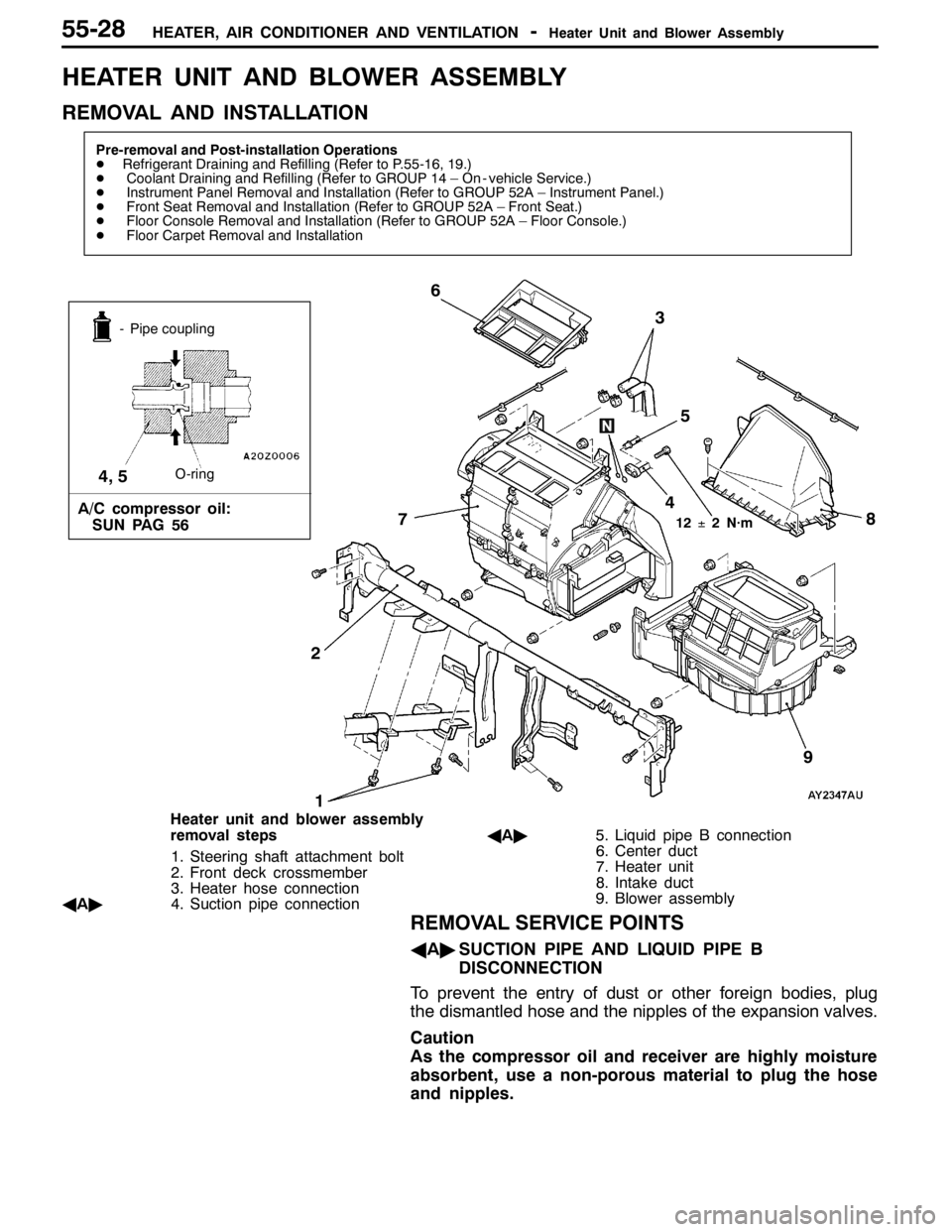

HEATER, AIR CONDITIONER AND VENTILATION-Heater Unit and Blower Assembly55-28

HEATER UNIT AND BLOWER ASSEMBLY

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operations

DRefrigerant Draining and Refilling (Refer to P.55-16, 19.)

DCoolant Draining and Refilling (Refer to GROUP 14 – On - vehicle Service.)

DInstrument Panel Removal and Installation (Refer to GROUP 52A – Instrument Panel.)

DFront Seat Removal and Installation (Refer to GROUP 52A – Front Seat.)

DFloor Console Removal and Installation (Refer to GROUP 52A – Floor Console.)

DFloor Carpet Removal and Installation

13

5 6

2

12±2 N·m

- Pipe coupling

O-ring

A/C compressor oil:

SUN PAG 56

4, 5

9

7

4

8

Heater unit and blower assembly

removal steps

1. Steering shaft attachment bolt

2. Front deck crossmember

3. Heater hose connection

AA"4. Suction pipe connectionAA"5. Liquid pipe B connection

6. Center duct

7. Heater unit

8. Intake duct

9. Blower assembly

REMOVAL SERVICE POINTS

AA"SUCTION PIPE AND LIQUID PIPE B

DISCONNECTION

To prevent the entry of dust or other foreign bodies, plug

the dismantled hose and the nipples of the expansion valves.

Caution

As the compressor oil and receiver are highly moisture

absorbent, use a non-porous material to plug the hose

and nipples.

Page 1431 of 1449

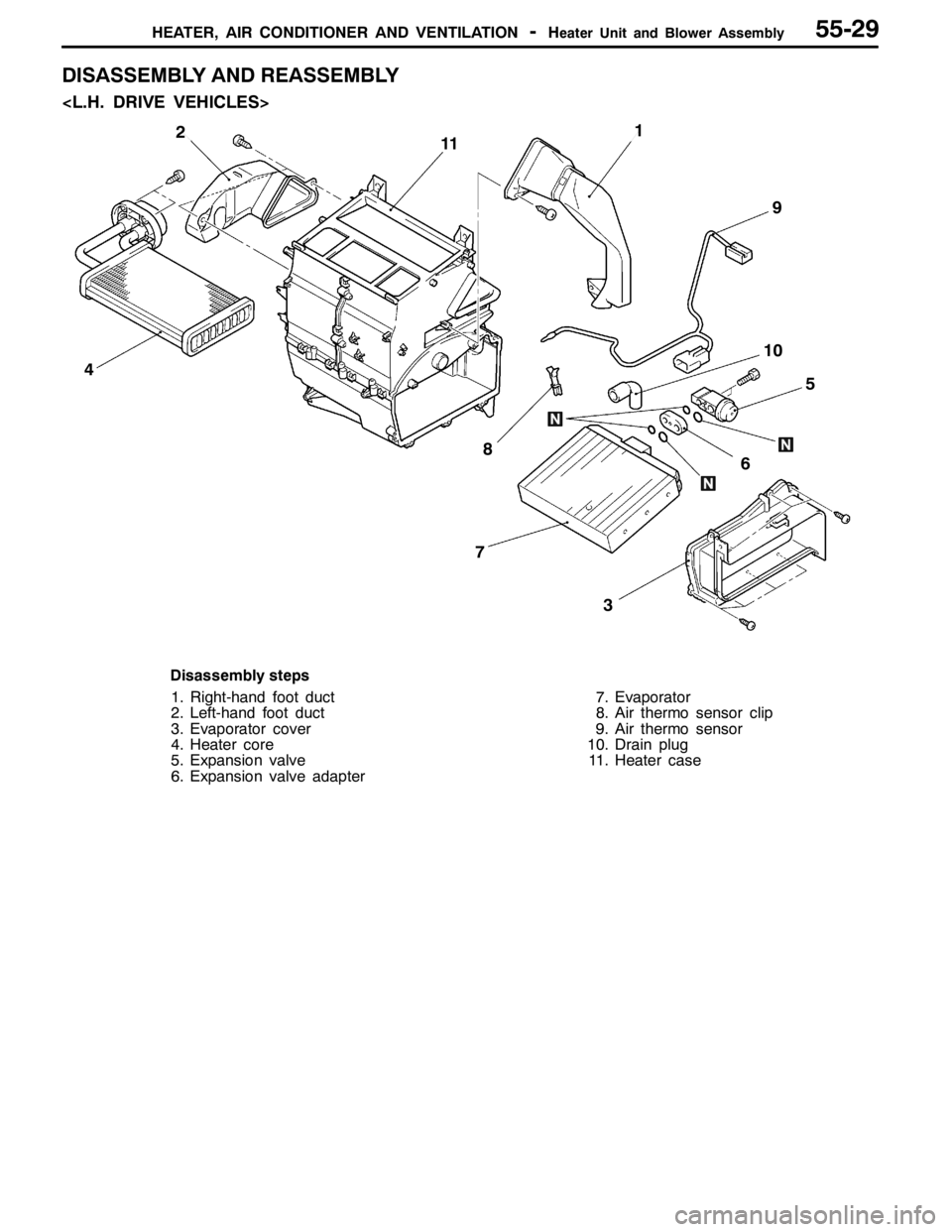

HEATER, AIR CONDITIONER AND VENTILATION-Heater Unit and Blower Assembly55-29

DISASSEMBLY AND REASSEMBLY

3 7

1

65 4

89

10211

Disassembly steps

1. Right-hand foot duct

2. Left-hand foot duct

3. Evaporator cover

4. Heater core

5. Expansion valve

6. Expansion valve adapter7. Evaporator

8. Air thermo sensor clip

9. Air thermo sensor

10. Drain plug

11. Heater case

Page 1432 of 1449

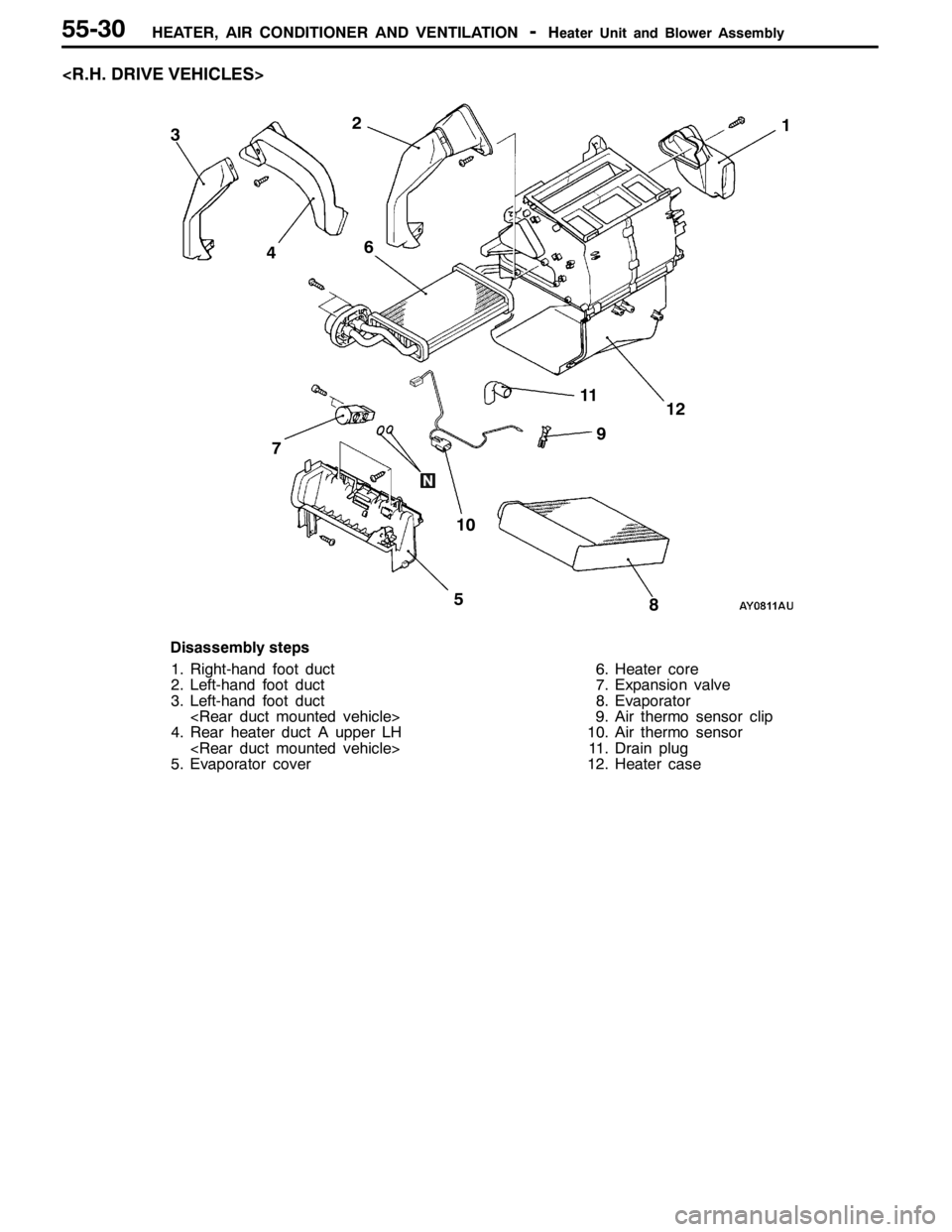

HEATER, AIR CONDITIONER AND VENTILATION-Heater Unit and Blower Assembly55-30

3

42

59

1

8 76

1011

12

Disassembly steps

1. Right-hand foot duct

2. Left-hand foot duct

3. Left-hand foot duct

4. Rear heater duct A upper LH

5. Evaporator cover6. Heater core

7. Expansion valve

8. Evaporator

9. Air thermo sensor clip

10. Air thermo sensor

11. Drain plug

12. Heater case

Page 1436 of 1449

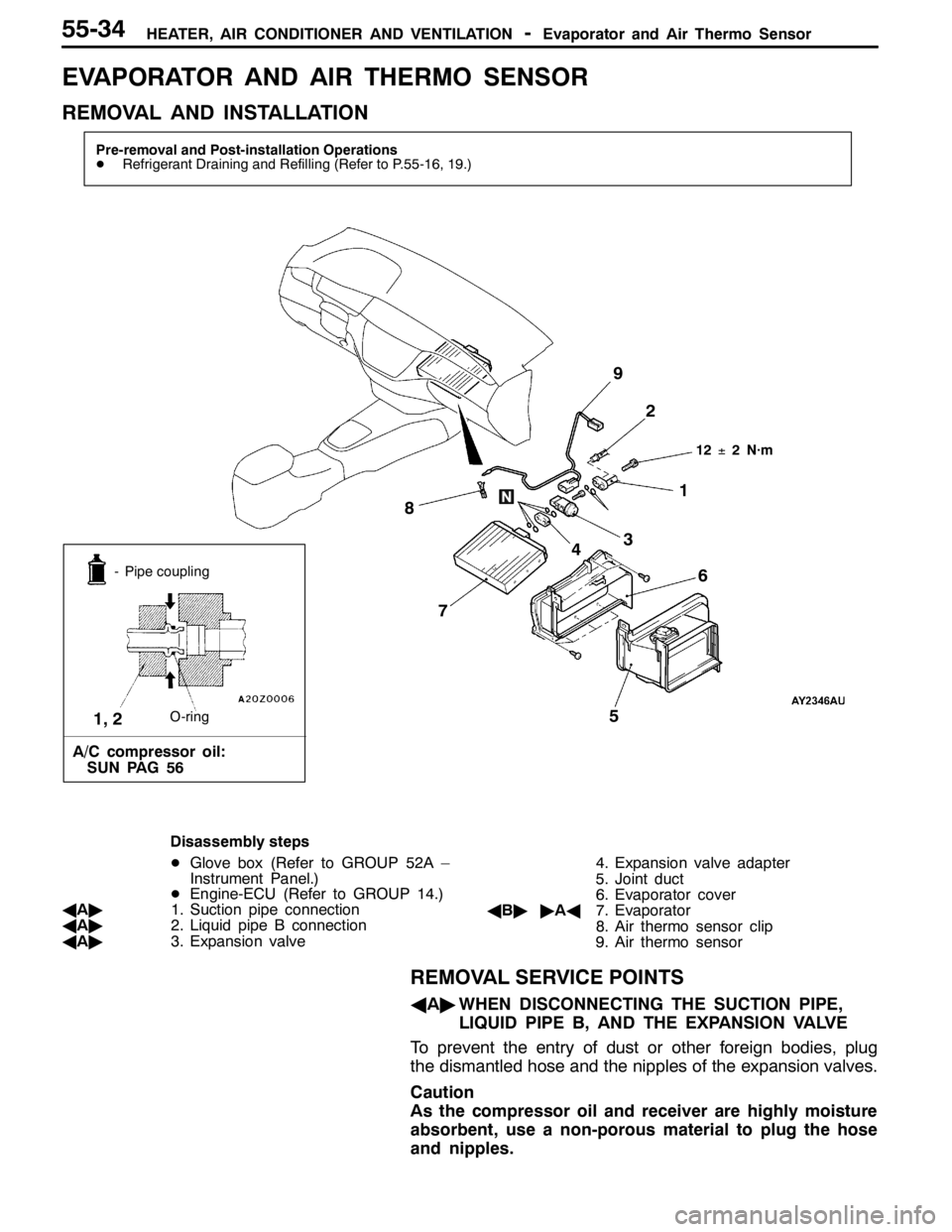

HEATER, AIR CONDITIONER AND VENTILATION-Evaporator and Air Thermo Sensor55-34

EVAPORATOR AND AIR THERMO SENSOR

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operations

DRefrigerant Draining and Refilling (Refer to P.55-16, 19.)

1 2

3

4

56

7 8

12±2 N·m

- Pipe coupling

O-ring

A/C compressor oil:

SUN PAG 56

1, 2

9

Disassembly steps

DGlove box (Refer to GROUP 52A –

Instrument Panel.)

DEngine-ECU (Refer to GROUP 14.)

AA"1. Suction pipe connection

AA"2. Liquid pipe B connection

AA"3. Expansion valve4. Expansion valve adapter

5. Joint duct

6. Evaporator cover

AB""AA7. Evaporator

8. Air thermo sensor clip

9. Air thermo sensor

REMOVAL SERVICE POINTS

AA"WHEN DISCONNECTING THE SUCTION PIPE,

LIQUID PIPE B, AND THE EXPANSION VALVE

To prevent the entry of dust or other foreign bodies, plug

the dismantled hose and the nipples of the expansion valves.

Caution

As the compressor oil and receiver are highly moisture

absorbent, use a non-porous material to plug the hose

and nipples.

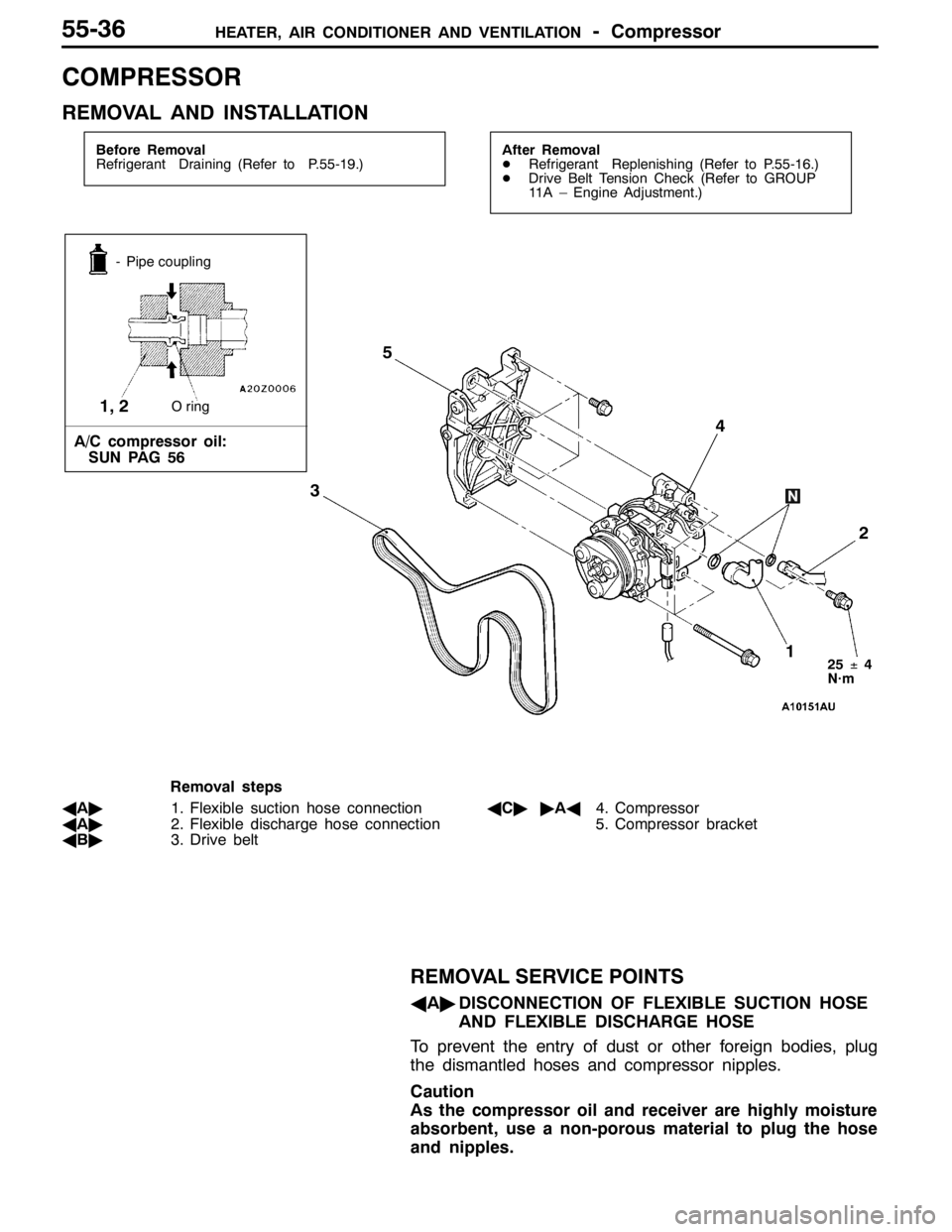

Page 1438 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Compressor55-36

COMPRESSOR

REMOVAL AND INSTALLATION

Before Removal

Refrigerant Draining (Refer to P.55-19.)After Removal

DRefrigerant Replenishing (Refer to P.55-16.)

DDrive Belt Tension Check (Refer to GROUP

11A – Engine Adjustment.)

25±4

N·m

2 4

1

- Pipe coupling

O ring

A/C compressor oil:

SUN PAG 56

1, 2

5

3

Removal steps

AA"1. Flexible suction hose connection

AA"2. Flexible discharge hose connection

AB"3. Drive beltAC""AA4. Compressor

5. Compressor bracket

REMOVAL SERVICE POINTS

AA"DISCONNECTION OF FLEXIBLE SUCTION HOSE

AND FLEXIBLE DISCHARGE HOSE

To prevent the entry of dust or other foreign bodies, plug

the dismantled hoses and compressor nipples.

Caution

As the compressor oil and receiver are highly moisture

absorbent, use a non-porous material to plug the hose

and nipples.