fuel MITSUBISHI LANCER EVOLUTION 2007 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 535 of 1449

MPI -General Information13A-3

GENERAL INFORMATION

The Multipoint Fuel Injection System consists

of sensors which detect the engine conditions,

the engine-ECU which controls the system

based on signals from these sensors, and

actuators which operate under the control of

the engine-ECU. The engine-ECU carries outactivities such as fuel injection control, idle

speed control and ignition timing control. In

addition, the engine-ECU is equipped with

several diagnosis modes which simplify

troubleshooting when a problem develops.

FUEL INJECTION CONTROL

The injector drive times and injector timing are

controlled so that the optimum air/fuel mixture

is supplied to the engine to correspond to the

continually-changing engine operation condi-

tions.

A single injector is mounted at the intake port

of each cylinder. Fuel is sent under pressure

from the fuel tank by the fuel pump, with the

pressure being regulated by the fuel pressure

regulator. The fuel thus regulated is distributed

to each of the injectors.

Fuel injection is normally carried out once for

each cylinder for every two rotations of the

crankshaft. The firing order is 1-3-4-2. This iscalled sequential fuel injection. The

engine-ECU provides a richer air/fuel mixture

by carrying out “open-loop” control when the

engine is cold or operating under high load

conditions in order to maintain engine

performance. In addition, when the engine is

warm or operating under normal conditions,

the engine-ECU controls the air/fuel mixture

by using the oxygen sensor signal to carry out

“closed-loop” control in order to obtain the

theoretical air/fuel mixture ratio that provides

the maximum cleaning performance from the

three way catalyst.

IDLE AIR CONTROL

The idle speed is kept at the optimum speed

by controlling the amount of air that bypasses

the throttle valve in accordance with changes

in idling conditions and engine load during

idling. The engine-ECU drives the idle speed

control motor to keep the engine running at

the pre-set idle target speed in accordance

with the engine coolant temperature and airconditioner load. In addition, when the air

conditioner switch is turned off and on while

the engine is idling, the idle speed control motor

operates to adjust the throttle valve bypass

air amount in accordance with the engine load

conditions in order to avoid fluctuations in the

engine speed.

IGNITION TIMING CONTROL

The power transistor located in the ignition

primary circuit turns ON and OFF to control

the primary current flow to the ignition coil. This

controls the ignition timing in order to provide

the optimum ignition timing with respect to theengine operating conditions. The ignition timing

is determined by the engine-ECU from the

engine speed, intake air volume, engine coolant

temperature and barometric pressure.

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in one

of the sensors or actuators related to

emission control, the engine warning lamp

(check engine lamp) illuminates as a

warning to the driver.

DWhen an abnormality is detected in one

of the sensors or actuators, a diagnosis

code corresponding to the abnormality is

output.DThe RAM data inside the engine-ECU that

is related to the sensors and actuators can

be read by means of the MUT-II. In addition,

the actuators can be force-driven under

certain circumstances.

Page 536 of 1449

MPI -General Information13A-4

OTHER CONTROL FUNCTIONS

1. Fuel Pump Control

Turns the fuel pump relay ON so that current

is supplied to the fuel pump while the engine

is cranking or running.

2. A/C Relay Control

Turns the compressor clutch of the A/C

ON and OFF.3. Fan Motor Control

The revolutions of the radiator fan and

condenser fan are controlled in response to

the engine coolant temperature and vehicle

speed.

4. Purge Control Solenoid Valve Control

Refer to GROUP 17.

5. EGR Control Solenoid Valve Control

Refer to GROUP 17.

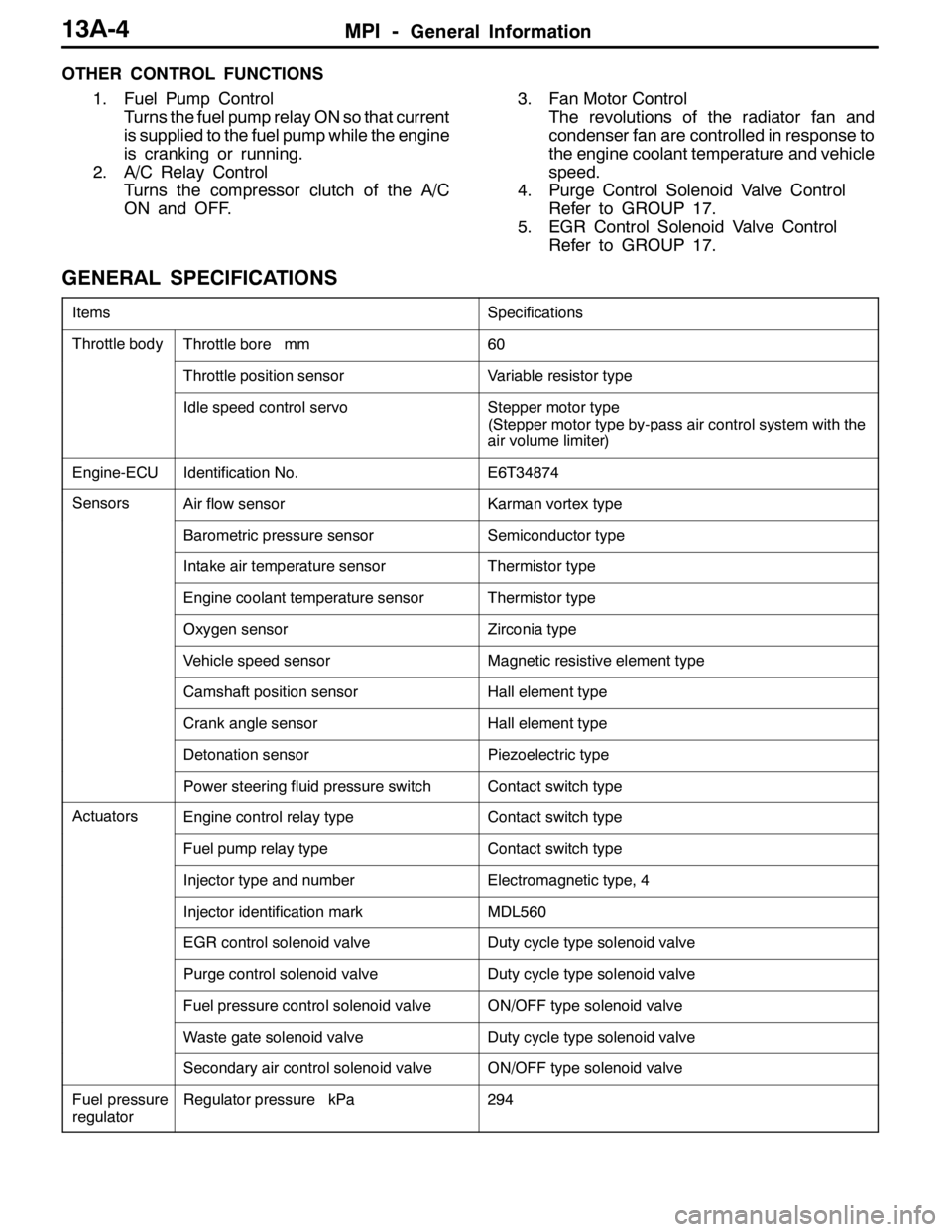

GENERAL SPECIFICATIONS

ItemsSpecifications

Throttle bodyThrottle bore mm60

Throttle position sensorVariable resistor type

Idle speed control servoStepper motor type

(Stepper motor type by-pass air control system with the

air volume limiter)

Engine-ECUIdentification No.E6T34874

SensorsAir flow sensorKarman vortex type

Barometric pressure sensorSemiconductor type

Intake air temperature sensorThermistor type

Engine coolant temperature sensorThermistor type

Oxygen sensorZirconia type

Vehicle speed sensorMagnetic resistive element type

Camshaft position sensorHall element type

Crank angle sensorHall element type

Detonation sensorPiezoelectric type

Power steering fluid pressure switchContact switch type

ActuatorsEngine control relay typeContact switch type

Fuel pump relay typeContact switch type

Injector type and numberElectromagnetic type, 4

Injector identification markMDL560

EGR control solenoid valveDuty cycle type solenoid valve

Purge control solenoid valveDuty cycle type solenoid valve

Fuel pressure control solenoid valveON/OFF type solenoid valve

Waste gate solenoid valveDuty cycle type solenoid valve

Secondary air control solenoid valveON/OFF type solenoid valve

Fuel pressure

regulatorRegulator pressure kPa294

Page 537 of 1449

MPI -General Information13A-5

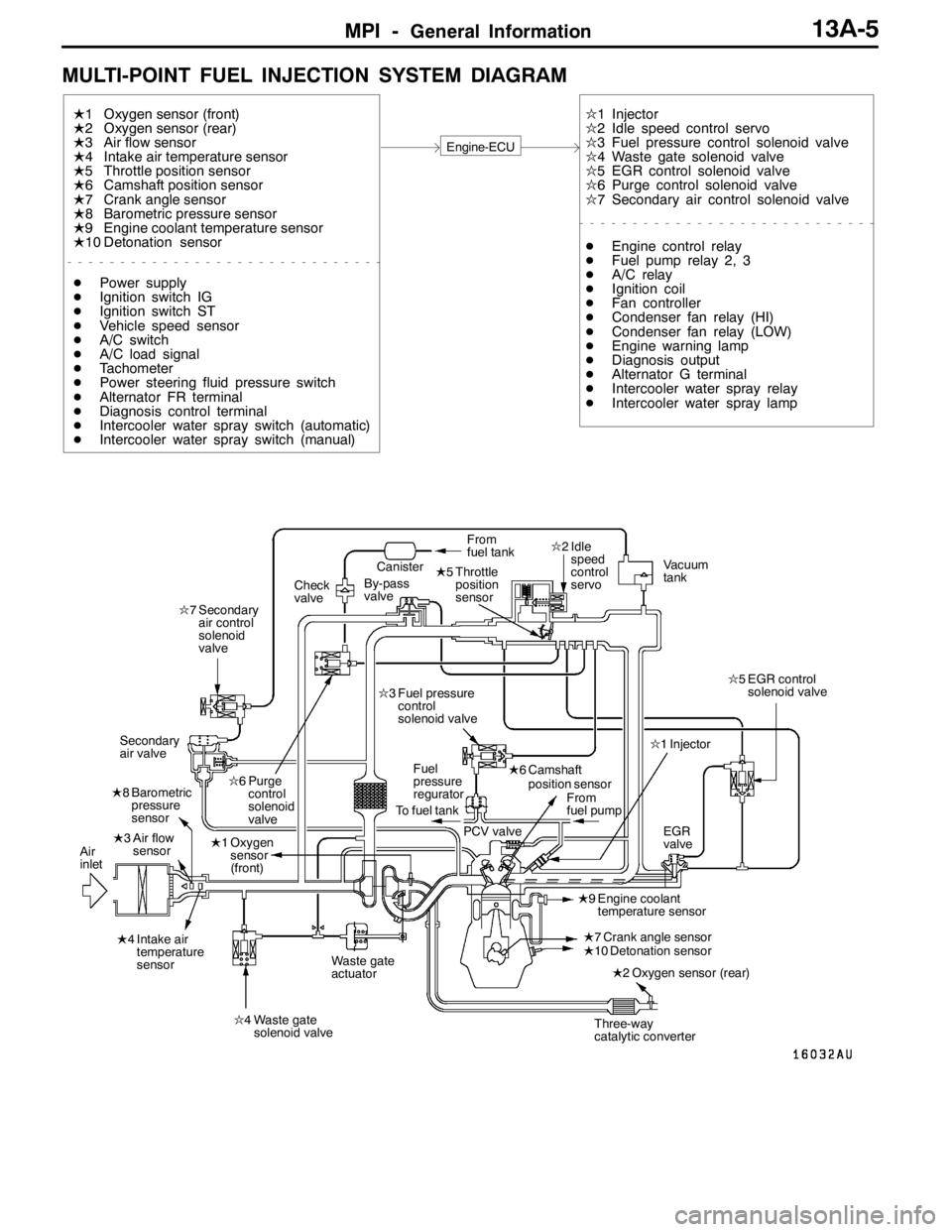

MULTI-POINT FUEL INJECTION SYSTEM DIAGRAM

L1 Oxygen sensor (front)

L2 Oxygen sensor (rear)

L3 Air flow sensor

L4 Intake air temperature sensor

L5 Throttle position sensor

L6 Camshaft position sensor

L7 Crank angle sensor

L8 Barometric pressure sensor

L9 Engine coolant temperature sensor

L10 Detonation sensor

Engine-ECU

l1 Injector

l2 Idle speed control servo

l3 Fuel pressure control solenoid valve

l4 Waste gate solenoid valve

l5 EGR control solenoid valve

l6 Purge control solenoid valve

l7 Secondary air control solenoid valve

DPower supply

DIgnition switch IG

DIgnition switch ST

DVehicle speed sensor

DA/C switch

DA/C load signal

DTachometer

DPower steering fluid pressure switch

DAlternator FR terminal

DDiagnosis control terminal

DIntercooler water spray switch (automatic)

DIntercooler water spray switch (manual)DEngine control relay

DFuel pump relay 2, 3

DA/C relay

DIgnition coil

DFan controller

DCondenser fan relay (HI)

DCondenser fan relay (LOW)

DEngine warning lamp

DDiagnosis output

DAlternator G terminal

DIntercooler water spray relay

DIntercooler water spray lamp

L1 Oxygen

sensor

(front)

L4 Intake air

temperature

sensorL5 Throttle

position

sensor

L6 Camshaft

position sensorl1 Injector l2 Idle

speed

control

servo

l6 Purge

control

solenoid

valve

Three-way

catalytic converter Canister

Air

inletVacuum

tank

Fuel

pressure

reguratorFrom

fuel tank

To fuel tank

PCV valveFrom

fuel pump

Waste gate

actuatorL2 Oxygen sensor (rear) Check

valveBy-pass

valve

l5 EGR control

solenoid valve

l4 Waste gate

solenoid valve L8 Barometric

pressure

sensor

L3 Air flow

sensorl7 Secondary

air control

solenoid

valve

Secondary

air valvel3 Fuel pressure

control

solenoid valve

EGR

valve

L9 Engine coolant

temperature sensor

L7 Crank angle sensor

L10 Detonation sensor

Page 538 of 1449

MPI -Service Specifications/Sealant13A-6

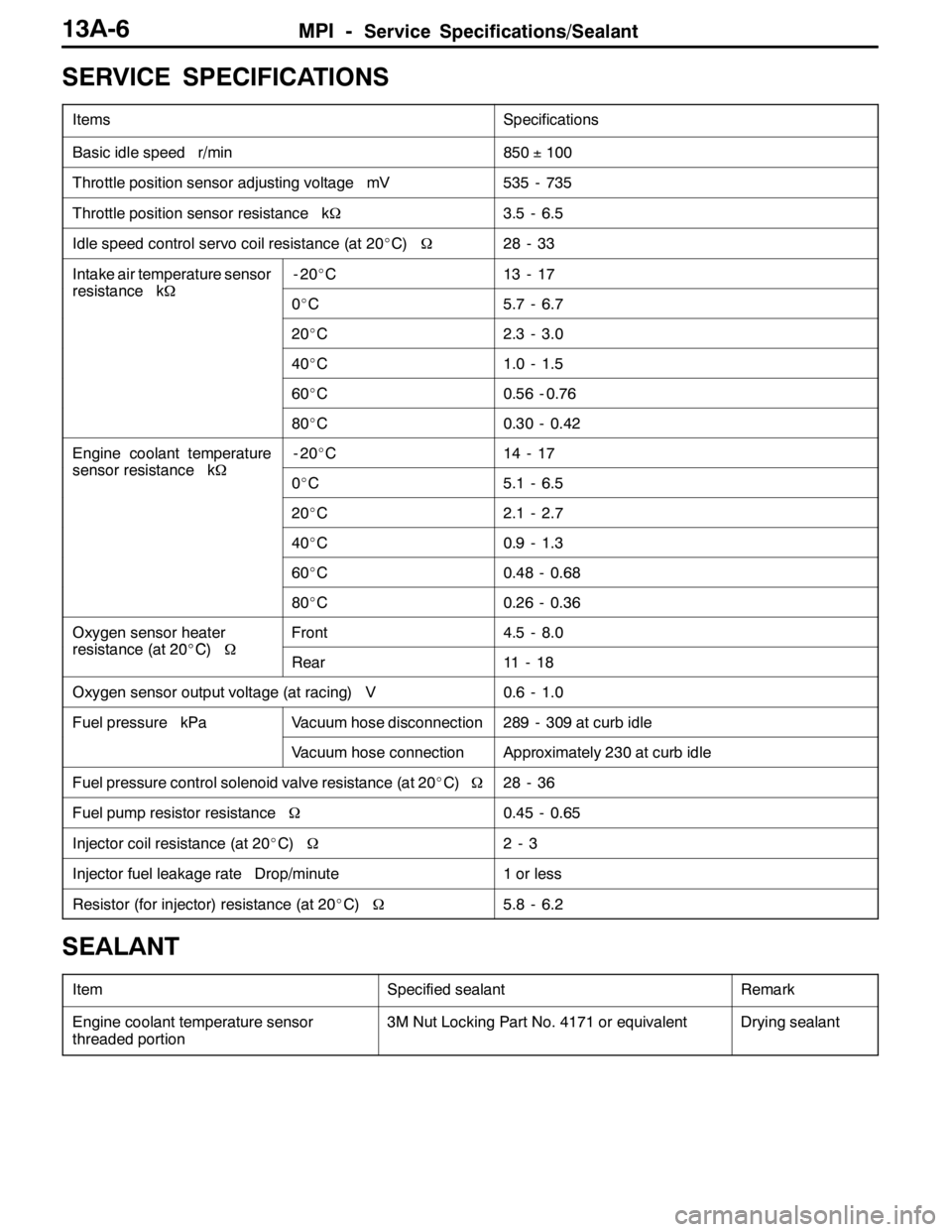

SERVICE SPECIFICATIONS

ItemsSpecifications

Basic idle speed r/min850±100

Throttle position sensor adjusting voltage mV535 - 735

Throttle position sensor resistance kΩ3.5 - 6.5

Idle speed control servo coil resistance (at 20_C)Ω28 - 33

Intake air temperature sensor

resistancekΩ

-20_C13 - 17

resistance kΩ0_C5.7 - 6.7

20_C2.3 - 3.0

40_C1.0 - 1.5

60_C0.56 - 0.76

80_C0.30 - 0.42

Engine coolant temperature

sensorresistancekΩ

-20_C14 - 17

sensor resistance kΩ0_C5.1 - 6.5

20_C2.1 - 2.7

40_C0.9 - 1.3

60_C0.48 - 0.68

80_C0.26 - 0.36

Oxygen sensor heater

resistance(at20_C)Ω

Front4.5 - 8.0

resistance (at 20_C)ΩRear11 - 1 8

Oxygen sensor output voltage (at racing) V0.6 - 1.0

Fuel pressure kPaVacuum hose disconnection289 - 309 at curb idle

Vacuum hose connectionApproximately 230 at curb idle

Fuel pressure control solenoid valve resistance (at 20_C)Ω28 - 36

Fuel pump resistor resistanceΩ0.45 - 0.65

Injector coil resistance (at 20_C)Ω2-3

Injector fuel leakage rate Drop/minute1 or less

Resistor (for injector) resistance (at 20_C)Ω5.8 - 6.2

SEALANT

ItemSpecified sealantRemark

Engine coolant temperature sensor

threaded portion3M Nut Locking Part No. 4171 or equivalentDrying sealant

Page 540 of 1449

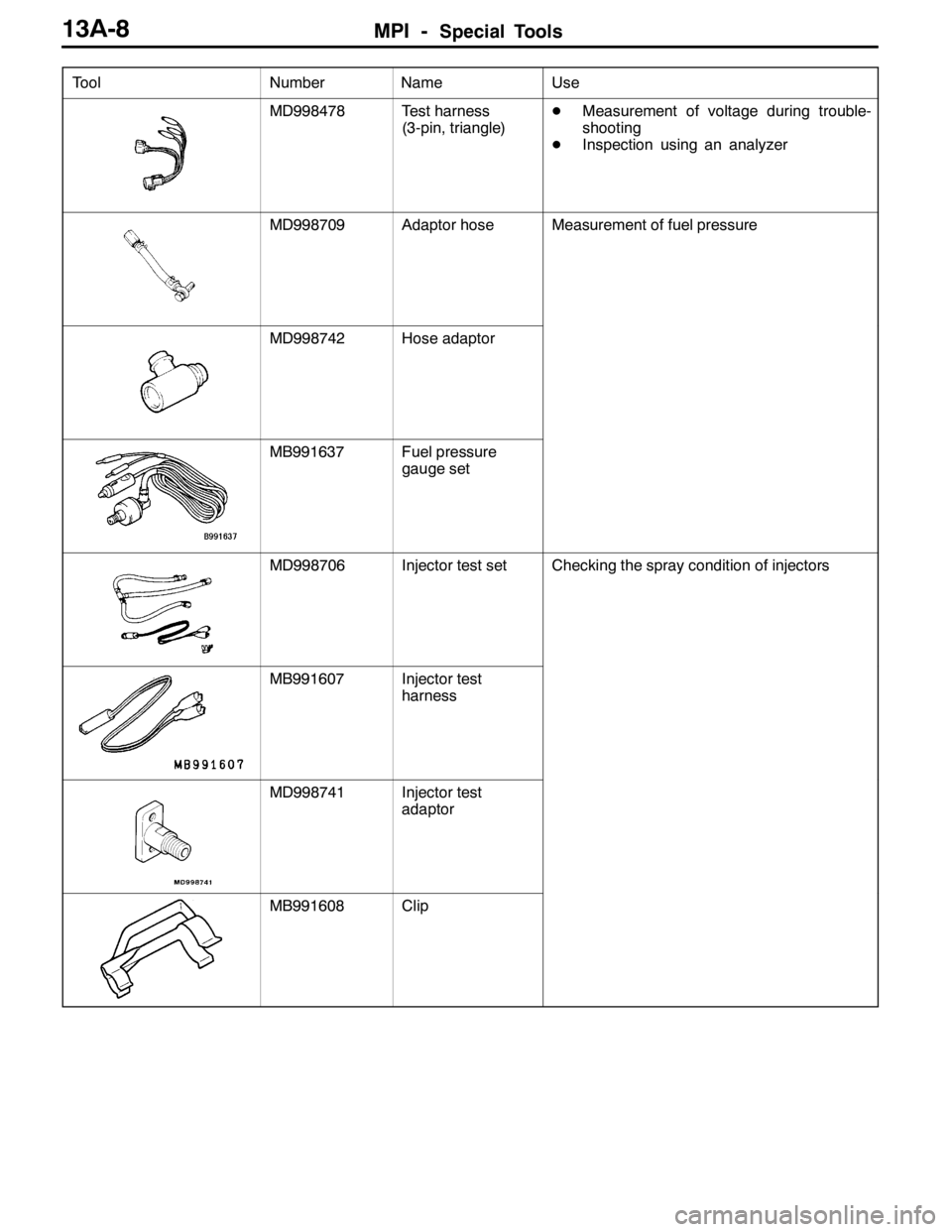

MPI -Special Tools13A-8

Tool UseName Number

MD998478Test harness

(3-pin, triangle)DMeasurement of voltage during trouble-

shooting

DInspection using an analyzer

MD998709Adaptor hoseMeasurement of fuel pressure

MD998742Hose adaptor

MB991637Fuel pressure

gauge set

MD998706Injector test setChecking the spray condition of injectors

MB991607Injector test

harness

MD998741Injector test

adaptor

MB991608Clip

Page 542 of 1449

MPI -TroubleshootingMPI -Troubleshooting13A-10

Code No. Diagnosis item

P0443Purge control solenoid valve system

P0500Vehicle speed sensor system

P0505Idle speed control system

P0551Power steering fluid pressure switch

P1104Waste gate solenoid valve system

P1105Fuel pressure control solenoid valve system

NOTE

If the engine warning lamp illuminates because of a malfunction of the engine-ECU, communication between

MUT-IIand the engine-ECU is impossible. In this case, the diagnosis code cannot be read.

METHOD OF READING AND ERASING DIAGNOSIS

CODES

Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.

INSPECTION USING MUT-IIDATA LIST AND ACTUATOR

TESTING

1. Carry out inspection by means of the data list and the

actuator test function. If there is an abnormality, check

and repair the chassis harnesses and components.

2. After repairing, re-check using the MUT-IIand check that

the abnormal input and output have returned to normal

as a result of the repairs.

3. Erase the diagnosis code memory.

4. Remove the MUT-II, and then start the engine again and

carry out a road test to confirm that the problem has

disappeared.

Page 543 of 1449

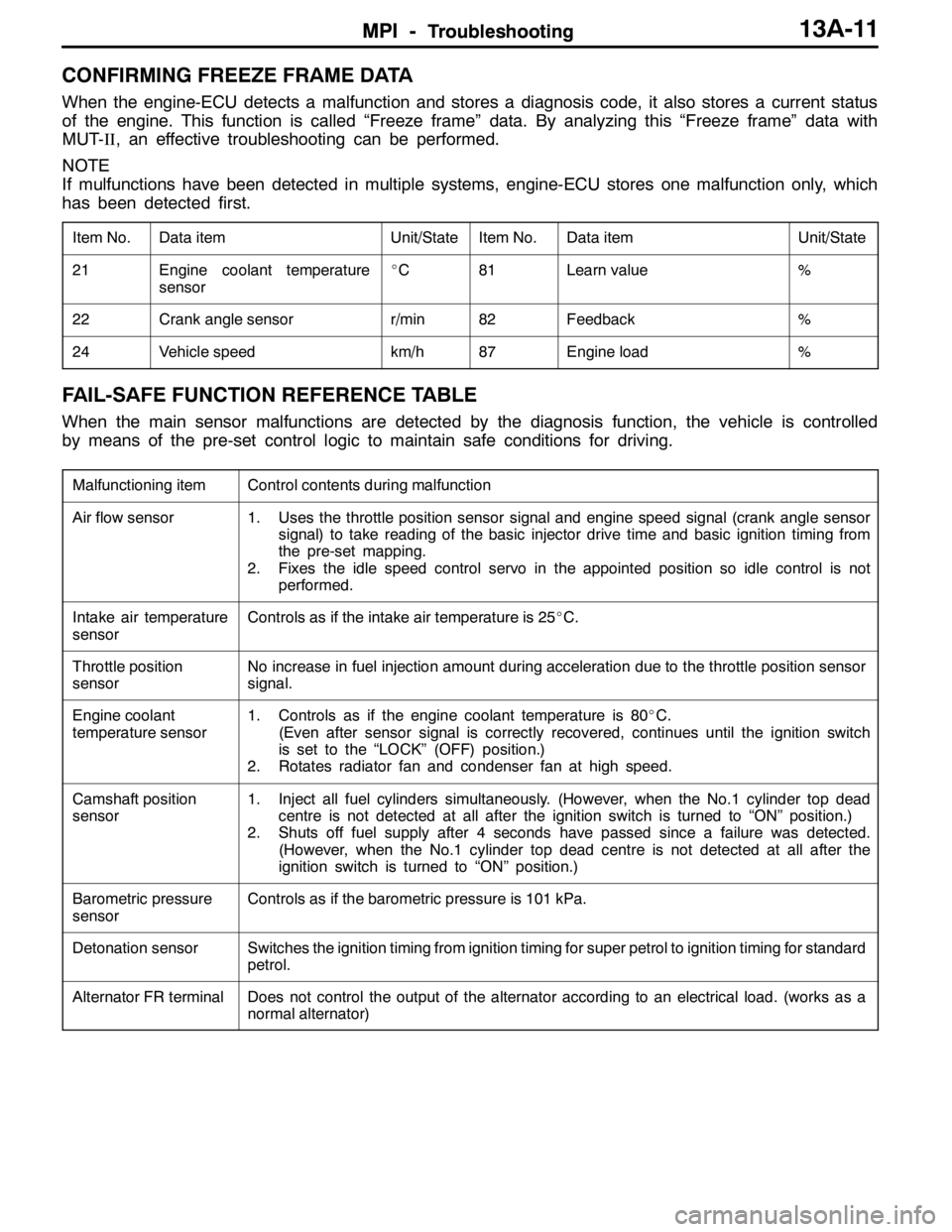

MPI -TroubleshootingMPI -Troubleshooting13A-11

CONFIRMING FREEZE FRAME DATA

When the engine-ECU detects a malfunction and stores a diagnosis code, it also stores a current status

of the engine. This function is called “Freeze frame” data. By analyzing this “Freeze frame” data with

MUT-II, an effective troubleshooting can be performed.

NOTE

If mulfunctions have been detected in multiple systems, engine-ECU stores one malfunction only, which

has been detected first.

Item No.Data itemUnit/StateItem No.Data itemUnit/State

21Engine coolant temperature

sensor_C81Learn value%

22Crank angle sensorr/min82Feedback%

24Vehicle speedkm/h87Engine load%

FAIL-SAFE FUNCTION REFERENCE TABLE

When the main sensor malfunctions are detected by the diagnosis function, the vehicle is controlled

by means of the pre-set control logic to maintain safe conditions for driving.

Malfunctioning itemControl contents during malfunction

Air flow sensor1. Uses the throttle position sensor signal and engine speed signal (crank angle sensor

signal) to take reading of the basic injector drive time and basic ignition timing from

the pre-set mapping.

2. Fixes the idle speed control servo in the appointed position so idle control is not

performed.

Intake air temperature

sensorControls as if the intake air temperature is 25_C.

Throttle position

sensorNo increase in fuel injection amount during acceleration due to the throttle position sensor

signal.

Engine coolant

temperature sensor1. Controls as if the engine coolant temperature is 80_C.

(Even after sensor signal is correctly recovered, continues until the ignition switch

is set to the “LOCK” (OFF) position.)

2. Rotates radiator fan and condenser fan at high speed.

Camshaft position

sensor1. Inject all fuel cylinders simultaneously. (However, when the No.1 cylinder top dead

centre is not detected at all after the ignition switch is turned to “ON” position.)

2. Shuts off fuel supply after 4 seconds have passed since a failure was detected.

(However, when the No.1 cylinder top dead centre is not detected at all after the

ignition switch is turned to “ON” position.)

Barometric pressure

sensorControls as if the barometric pressure is 101 kPa.

Detonation sensorSwitches the ignition timing from ignition timing for super petrol to ignition timing for standard

petrol.

Alternator FR terminalDoes not control the output of the alternator according to an electrical load. (works as a

normal alternator)

Page 544 of 1449

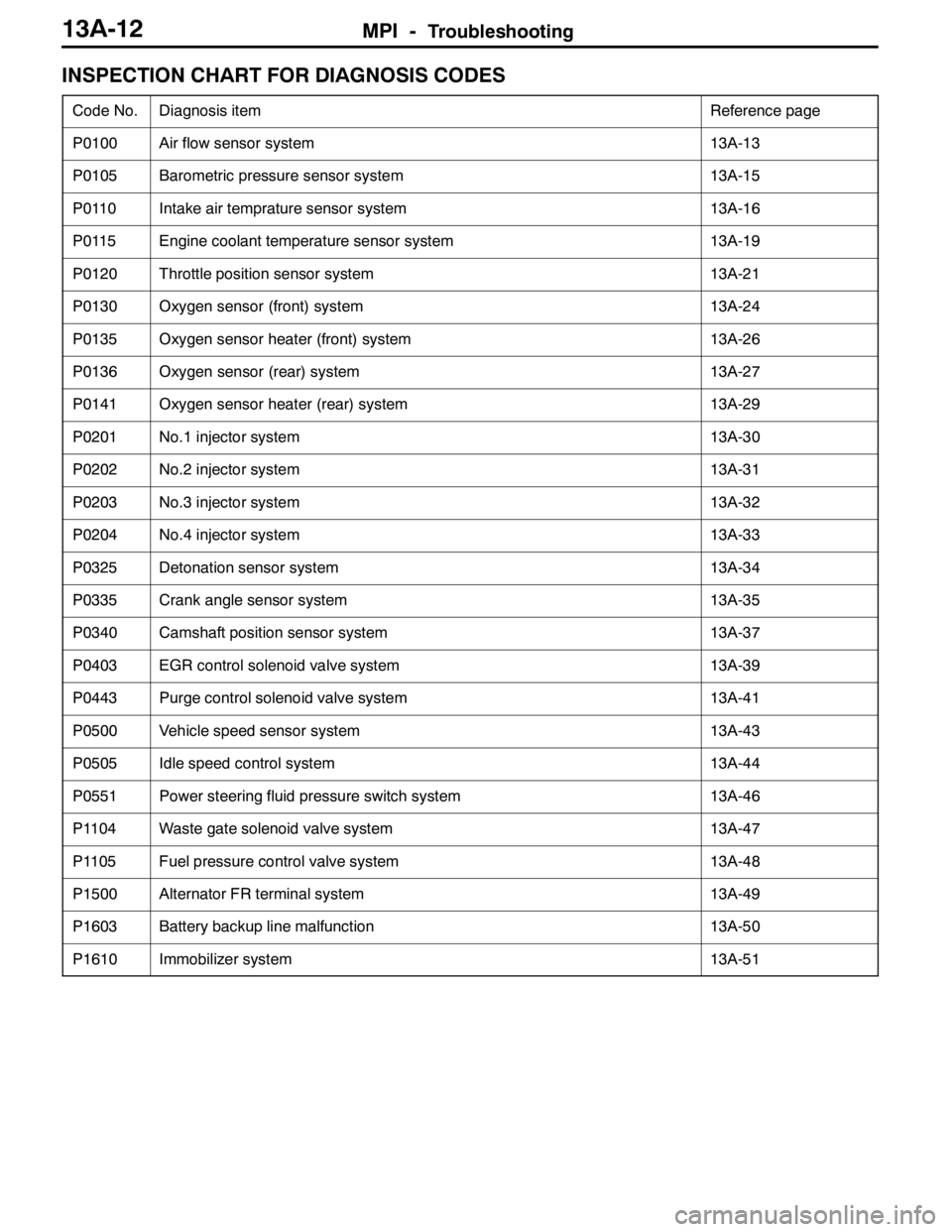

MPI -Troubleshooting13A-12

INSPECTION CHART FOR DIAGNOSIS CODES

Code No.Diagnosis itemReference page

P0100Air flow sensor system13A-13

P0105Barometric pressure sensor system13A-15

P0110Intake air temprature sensor system13A-16

P0115Engine coolant temperature sensor system13A-19

P0120Throttle position sensor system13A-21

P0130Oxygen sensor (front) system13A-24

P0135Oxygen sensor heater (front) system13A-26

P0136Oxygen sensor (rear) system13A-27

P0141Oxygen sensor heater (rear) system13A-29

P0201No.1 injector system13A-30

P0202No.2 injector system13A-31

P0203No.3 injector system13A-32

P0204No.4 injector system13A-33

P0325Detonation sensor system13A-34

P0335Crank angle sensor system13A-35

P0340Camshaft position sensor system13A-37

P0403EGR control solenoid valve system13A-39

P0443Purge control solenoid valve system13A-41

P0500Vehicle speed sensor system13A-43

P0505Idle speed control system13A-44

P0551Power steering fluid pressure switch system13A-46

P1104Waste gate solenoid valve system13A-47

P1105Fuel pressure control valve system13A-48

P1500Alternator FR terminal system13A-49

P1603Battery backup line malfunction13A-50

P1610Immobilizer system13A-51

Page 580 of 1449

MPI -Troubleshooting13A-48

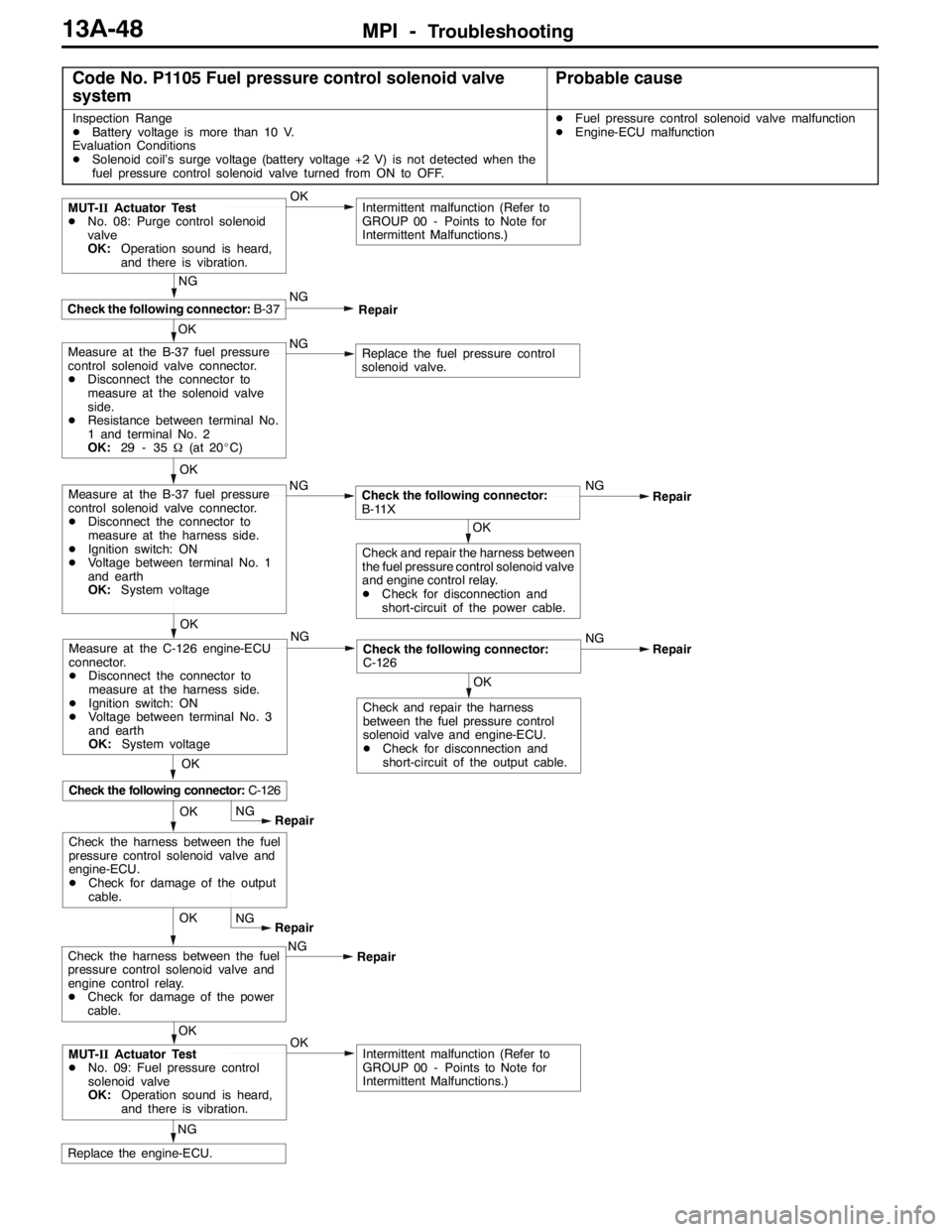

Code No. P1105 Fuel pressure control solenoid valve

systemProbable cause

Inspection Range

DBattery voltage is more than 10 V.

Evaluation Conditions

DSolenoid coil’s surge voltage (battery voltage +2 V) is not detected when the

fuel pressure control solenoid valve turned from ON to OFF.DFuel pressure control solenoid valve malfunction

DEngine-ECU malfunction

OK

NG

Replace the engine-ECU.

OKIntermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)MUT-IIActuator Test

DNo. 09: Fuel pressure control

solenoid valve

OK:Operation sound is heard,

and there is vibration.OKNG

Repair

OK

NG

Intermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)

OK

Check the following connector:B-37

MUT-IIActuator Test

DNo. 08: Purge control solenoid

valve

OK:Operation sound is heard,

and there is vibration.

NG

Repair

NGNG

Repair

OK

OK

Check and repair the harness

between the fuel pressure control

solenoid valve and engine-ECU.

DCheck for disconnection and

short-circuit of the output cable.

Check the following connector:

C-126

OK

Check the following connector:C-126

Measure at the C-126 engine-ECU

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 3

and earth

OK:System voltageNG

Replace the fuel pressure control

solenoid valve.Measure at the B-37 fuel pressure

control solenoid valve connector.

DDisconnect the connector to

measure at the solenoid valve

side.

DResistance between terminal No.

1 and terminal No. 2

OK:29 - 35Ω(at 20_C)

OK

NG

Measure at the B-37 fuel pressure

control solenoid valve connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1

and earth

OK:System voltage

OKNG

Repair

OK

OKCheck and repair the harness between

the fuel pressure control solenoid valve

and engine control relay.

DCheck for disconnection and

short-circuit of the power cable.

Check the following connector:

B-11X

NG

RepairCheck the harness between the fuel

pressure control solenoid valve and

engine control relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check the harness between the fuel

pressure control solenoid valve and

engine-ECU.

DCheck for damage of the output

cable.

Page 584 of 1449

MPI -Troubleshooting13A-52

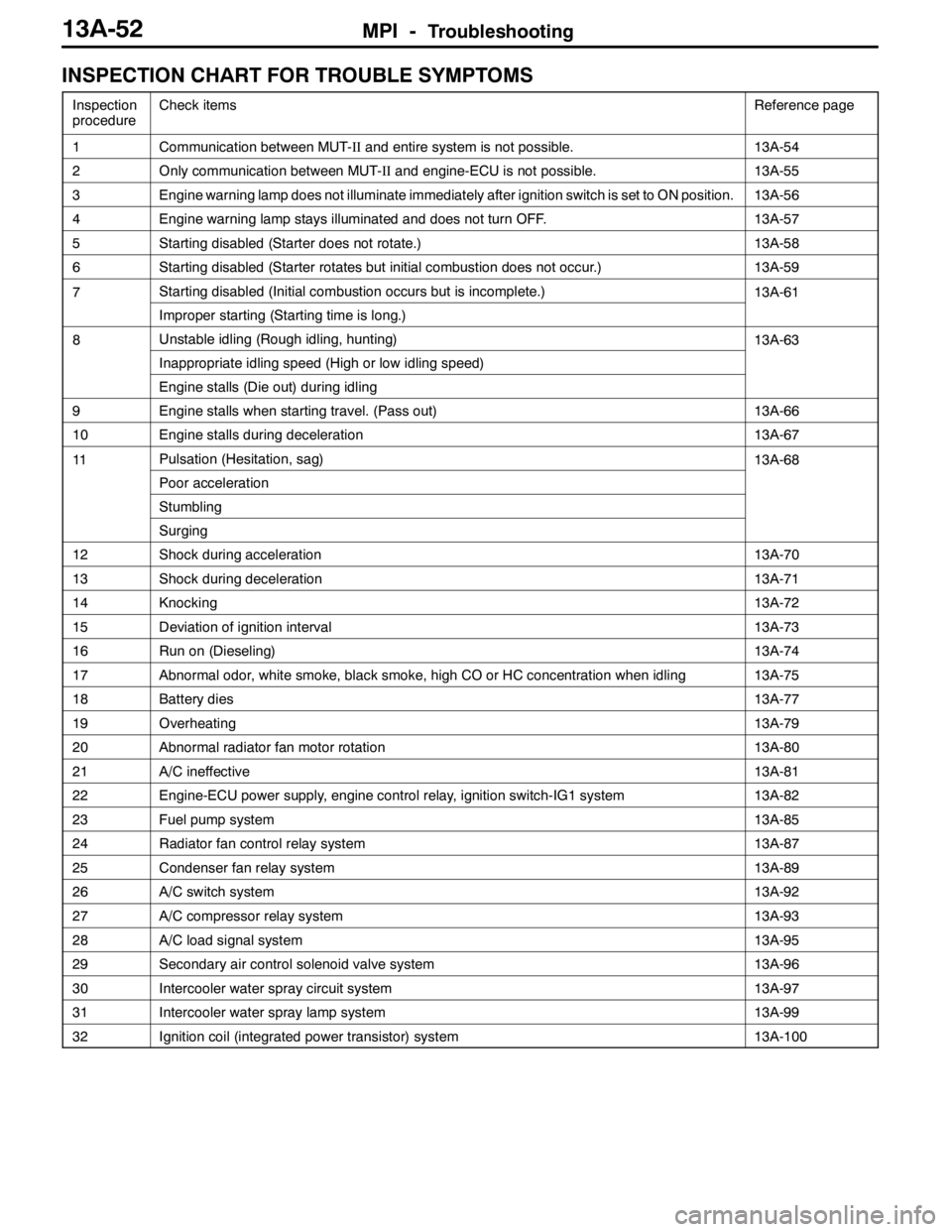

INSPECTION CHART FOR TROUBLE SYMPTOMS

Inspection

procedureCheck itemsReference page

1Communication between MUT-IIand entire system is not possible.13A-54

2Only communication between MUT-IIand engine-ECU is not possible.13A-55

3Engine warning lamp does not illuminate immediately after ignition switch is set to ON position.13A-56

4Engine warning lamp stays illuminated and does not turn OFF.13A-57

5Starting disabled (Starter does not rotate.)13A-58

6Starting disabled (Starter rotates but initial combustion does not occur.)13A-59

7Starting disabled (Initial combustion occurs but is incomplete.)13A-61

Improper starting (Starting time is long.)

8Unstable idling (Rough idling, hunting)13A-63

Inappropriate idling speed (High or low idling speed)

Engine stalls (Die out) during idling

9Engine stalls when starting travel. (Pass out)13A-66

10Engine stalls during deceleration13A-67

11Pulsation (Hesitation, sag)13A-68

Poor acceleration

Stumbling

Surging

12Shock during acceleration13A-70

13Shock during deceleration13A-71

14Knocking13A-72

15Deviation of ignition interval13A-73

16Run on (Dieseling)13A-74

17Abnormal odor, white smoke, black smoke, high CO or HC concentration when idling13A-75

18Battery dies13A-77

19Overheating13A-79

20Abnormal radiator fan motor rotation13A-80

21A/C ineffective13A-81

22Engine-ECU power supply, engine control relay, ignition switch-IG1 system13A-82

23Fuel pump system13A-85

24Radiator fan control relay system13A-87

25Condenser fan relay system13A-89

26A/C switch system13A-92

27A/C compressor relay system13A-93

28A/C load signal system13A-95

29Secondary air control solenoid valve system13A-96

30Intercooler water spray circuit system13A-97

31Intercooler water spray lamp system13A-99

32Ignition coil (integrated power transistor) system13A-100