Serpentine MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 422 of 1449

ENGINE -Crankshaft Pulley/Camshaft and Camshaft Oil Seal11A-16

REMOVAL SERVICE POINT

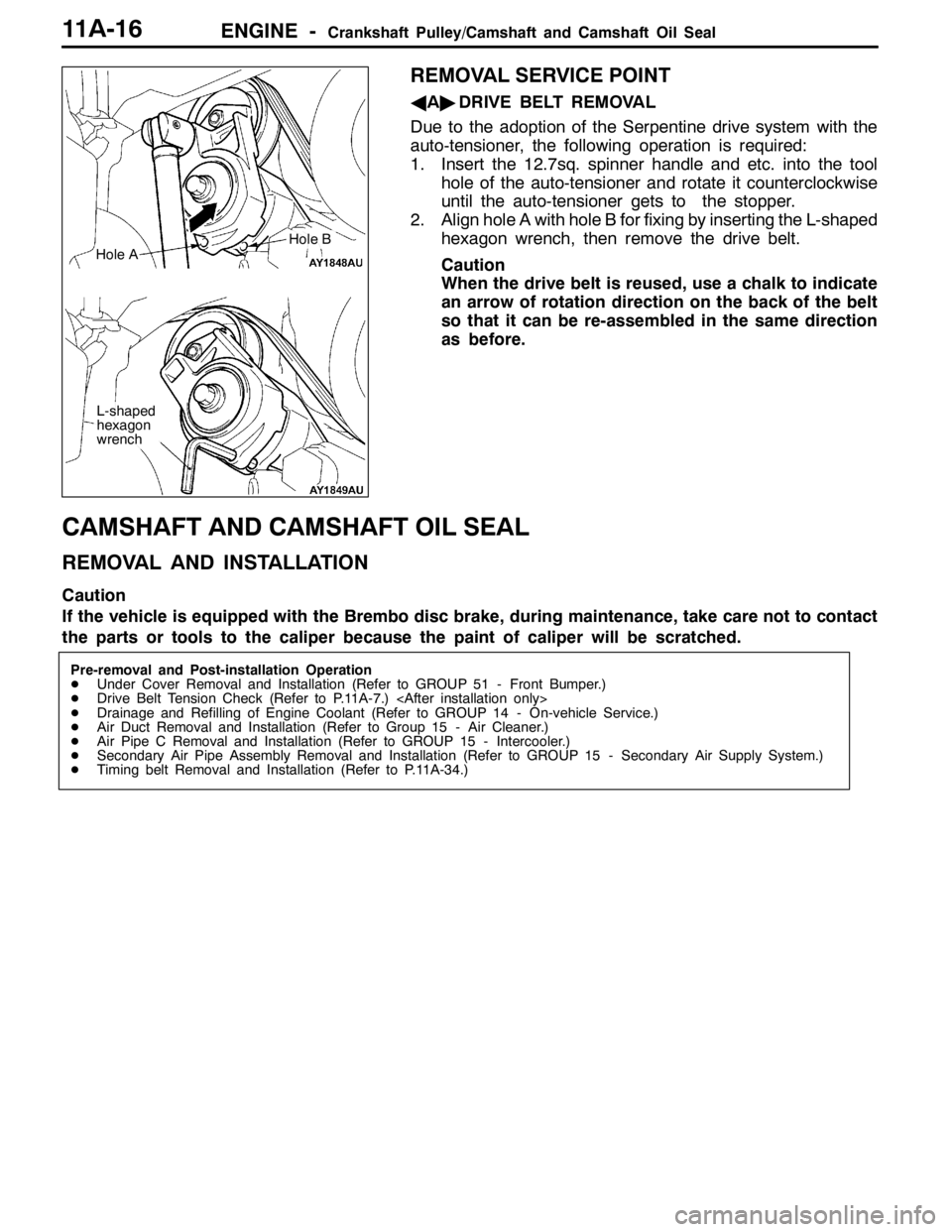

AA"DRIVE BELT REMOVAL

Due to the adoption of the Serpentine drive system with the

auto-tensioner, the following operation is required:

1. Insert the 12.7sq. spinner handle and etc. into the tool

hole of the auto-tensioner and rotate it counterclockwise

until the auto-tensioner gets to the stopper.

2. Align hole A with hole B for fixing by inserting the L-shaped

hexagon wrench, then remove the drive belt.

Caution

When the drive belt is reused, use a chalk to indicate

an arrow of rotation direction on the back of the belt

so that it can be re-assembled in the same direction

as before.

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

Pre-removal and Post-installation Operation

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DDrive Belt Tension Check (Refer to P.11A-7.)

DDrainage and Refilling of Engine Coolant (Refer to GROUP 14 - On-vehicle Service.)

DAir Duct Removal and Installation (Refer to Group 15 - Air Cleaner.)

DAir Pipe C Removal and Installation (Refer to GROUP 15 - Intercooler.)

DSecondary Air Pipe Assembly Removal and Installation (Refer to GROUP 15 - Secondary Air Supply System.)

DTiming belt Removal and Installation (Refer to P.11A-34.)

Hole A

L-shaped

hexagon

wrench

Hole B

Page 452 of 1449

ENGINE -Engine Assembly11A-46

REMOVAL SERVICE POINTS

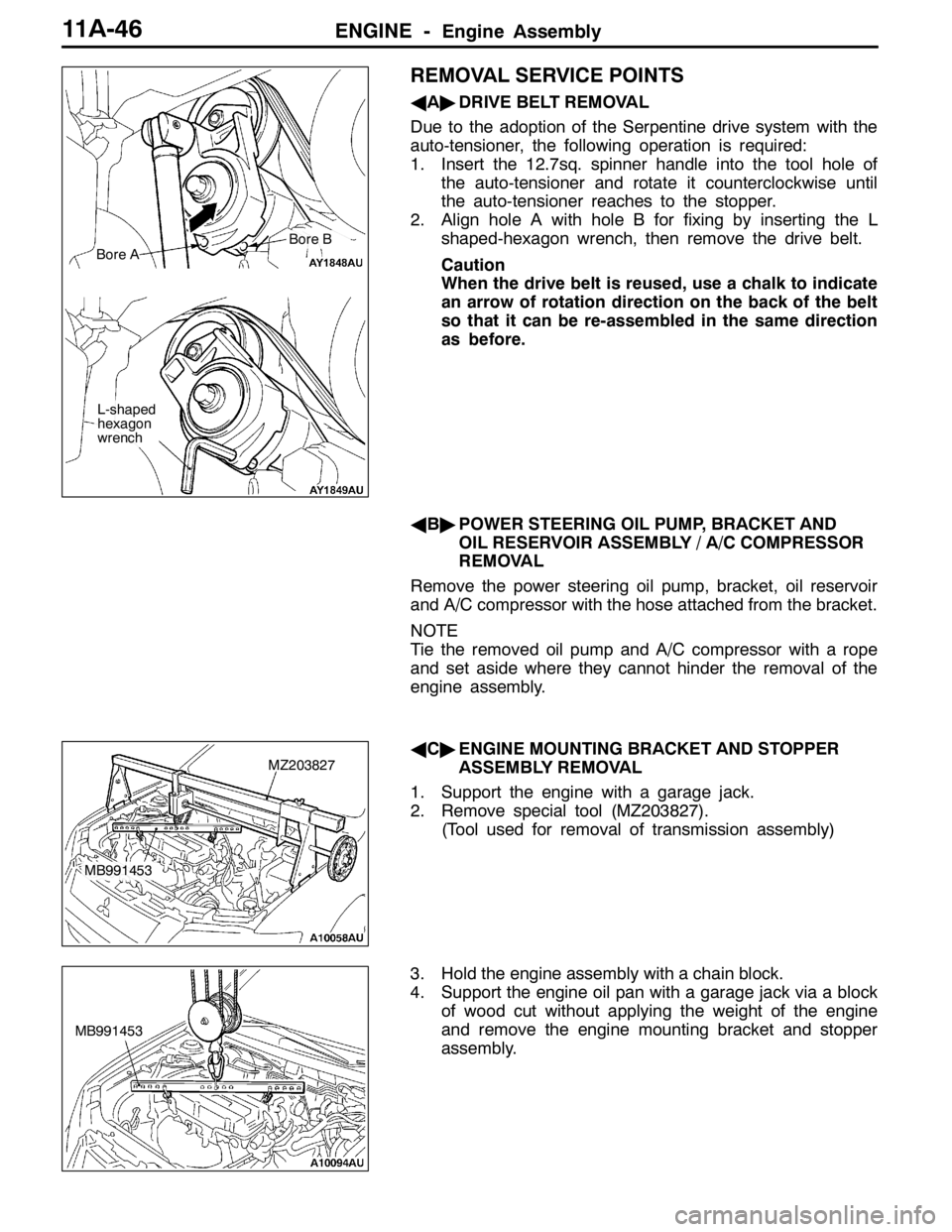

AA"DRIVE BELT REMOVAL

Due to the adoption of the Serpentine drive system with the

auto-tensioner, the following operation is required:

1. Insert the 12.7sq. spinner handle into the tool hole of

the auto-tensioner and rotate it counterclockwise until

the auto-tensioner reaches to the stopper.

2. Align hole A with hole B for fixing by inserting the L

shaped-hexagon wrench, then remove the drive belt.

Caution

When the drive belt is reused, use a chalk to indicate

an arrow of rotation direction on the back of the belt

so that it can be re-assembled in the same direction

as before.

AB"POWER STEERING OIL PUMP, BRACKET AND

OIL RESERVOIR ASSEMBLY / A/C COMPRESSOR

REMOVAL

Remove the power steering oil pump, bracket, oil reservoir

and A/C compressor with the hose attached from the bracket.

NOTE

Tie the removed oil pump and A/C compressor with a rope

and set aside where they cannot hinder the removal of the

engine assembly.

AC"ENGINE MOUNTING BRACKET AND STOPPER

ASSEMBLY REMOVAL

1. Support the engine with a garage jack.

2. Remove special tool (MZ203827).

(Tool used for removal of transmission assembly)

3. Hold the engine assembly with a chain block.

4. Support the engine oil pan with a garage jack via a block

of wood cut without applying the weight of the engine

and remove the engine mounting bracket and stopper

assembly.

Bore A

L-shaped

hexagon

wrench

Bore B

MZ203827

MB991453

MB991453

Page 744 of 1449

ENGINE ELECTRICAL -Charging System16-12

REMOVAL SERVICE POINTS

AA"DELIVERY PIPE, INJECTOR, AND FUEL

PRESSURE REGULATOR ASSEMBLY REMOVAL

After loosening the installed parts, set the related parts

aside to make some space for removing the alternator.

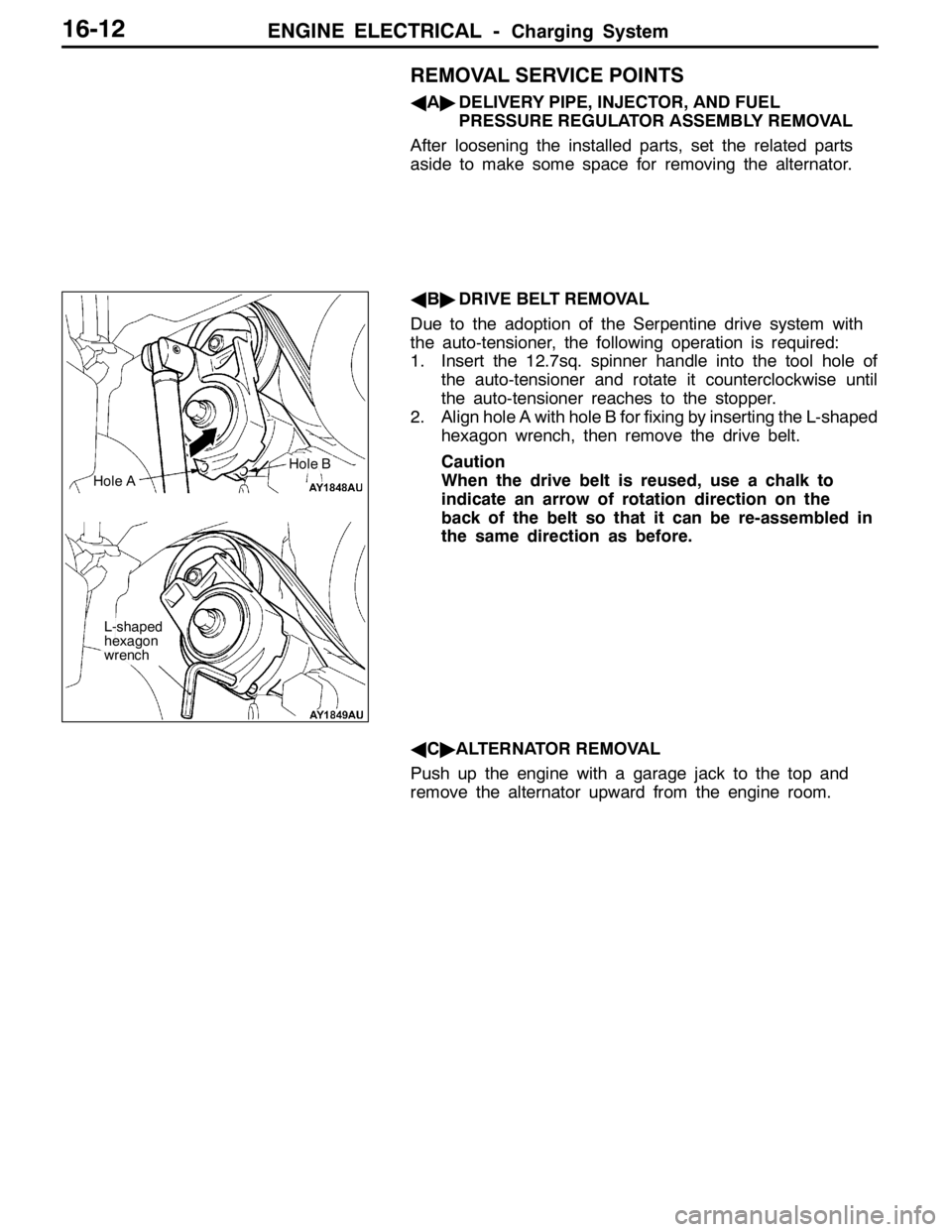

AB"DRIVE BELT REMOVAL

Due to the adoption of the Serpentine drive system with

the auto-tensioner, the following operation is required:

1. Insert the 12.7sq. spinner handle into the tool hole of

the auto-tensioner and rotate it counterclockwise until

the auto-tensioner reaches to the stopper.

2. Align hole A with hole B for fixing by inserting the L-shaped

hexagon wrench, then remove the drive belt.

Caution

When the drive belt is reused, use a chalk to

indicate an arrow of rotation direction on the

back of the belt so that it can be re-assembled in

the same direction as before.

AC"ALTERNATOR REMOVAL

Push up the engine with a garage jack to the top and

remove the alternator upward from the engine room.

Hole A

L-shaped

hexagon

wrench

Hole B

Page 1439 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Compressor55-37

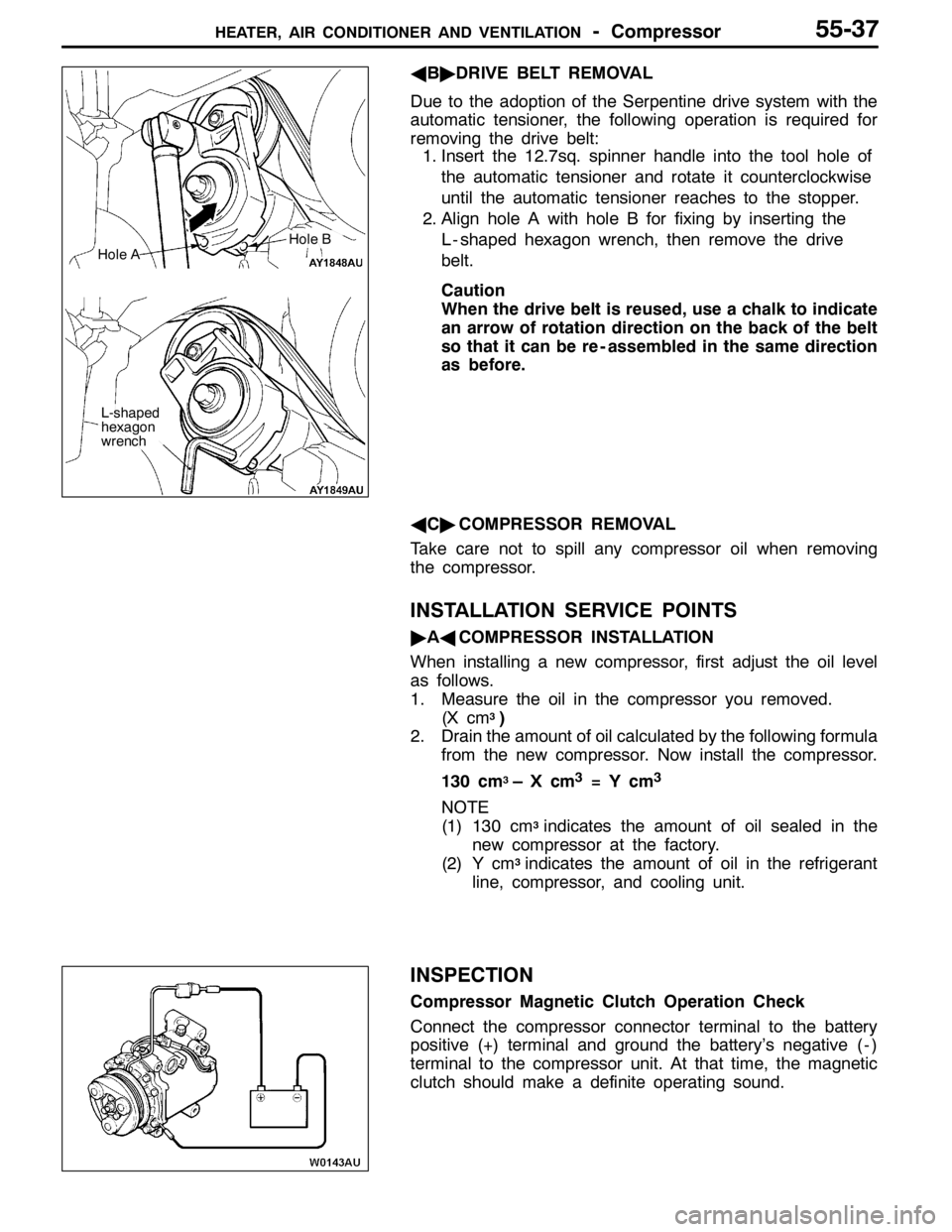

AB"DRIVE BELT REMOVAL

Due to the adoption of the Serpentine drive system with the

automatic tensioner, the following operation is required for

removing the drive belt:

1. Insert the 12.7sq. spinner handle into the tool hole of

the automatic tensioner and rotate it counterclockwise

until the automatic tensioner reaches to the stopper.

2. Align hole A with hole B for fixing by inserting the

L - shaped hexagon wrench, then remove the drive

belt.

Caution

When the drive belt is reused, use a chalk to indicate

an arrow of rotation direction on the back of the belt

so that it can be re - assembled in the same direction

as before.

AC"COMPRESSOR REMOVAL

Take care not to spill any compressor oil when removing

the compressor.

INSTALLATION SERVICE POINTS

"AACOMPRESSOR INSTALLATION

When installing a new compressor, first adjust the oil level

as follows.

1. Measure the oil in the compressor you removed.

(X cm

3)

2. Drain the amount of oil calculated by the following formula

from the new compressor. Now install the compressor.

130 cm

3–Xcm3=Ycm3

NOTE

(1) 130 cm3indicates the amount of oil sealed in the

new compressor at the factory.

(2) Y cm

3indicates the amount of oil in the refrigerant

line, compressor, and cooling unit.

INSPECTION

Compressor Magnetic Clutch Operation Check

Connect the compressor connector terminal to the battery

positive (+) terminal and ground the battery’s negative ( - )

terminal to the compressor unit. At that time, the magnetic

clutch should make a definite operating sound.

Hole A

L-shaped

hexagon

wrench

Hole B