roof MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 3 of 1449

A-1

BODY

CONSTRUCTION

CONTENTS

BODY COMPONENTS 2...................

BODY MAIN CROSS-SECTIONAL VIEWS 4.

MAINTENANCE, SERVICEABILITY 6........

BODY CONSTRUCTION

CHARACTERISTICS 8.....................

FRONT BODY 8...........................

SIDE BODY 13.............................

REAR BODY 15............................

ROOF 16...................................UNDER BODY 17...........................

DOOR 20..................................

SILENCER APPLICATION LOCATIONS 21..

LOCATIONS USING URETHANE FOAM

AND FOAM

MATERIAL 22.............................

STIFFENER AND DUMP SHEET

APPLICATION

LOCATIONS 24............................

Page 5 of 1449

BODY CONSTRUCTION -Body ComponentsA-3

1. Headlamp support panel

2. Hood lock stay

3. Front end crossmember

4. Front end upper bar

5. Headlamp support panel side

6. Front fender shield

7. Front upper frame inner

8. Upper frame bulkhead front

9. Upper frame bulkhead

10. Upper frame bulkhead rear

11. Front sidemember inner

12. Engine mount bracket

13. Front sidemember rear

14. Front sidemember outer

15. Spring house panel

16. Dash panel

17. Dash panel silencer

18. Dash panel reinforcement

19. Upper frame to front pillar brace

20. Upper frame extension outer

21. Upper frame extension inner

22. Cowl top lower panel

23. Cowl top inner panel

24. Cowl top upper panel

25. Front deck crossmember

26. Hood inner panel

27. Hood outer panel

28. Front roof rail

29. Front roof bow

30. Roof panel

31. Rear roof bow

32. Rear roof rail

33. Seat back plate

34. Rear seat back panel

35. Rear shelf panel

36. Rear seat back brace

37. Trunk lid outer panel

38. Trunk lid inner panel

39. Trunk lid hinge

40. Quarter inner extension rear

41. Quarter corner panel42. Rear combination lamp housing

43. Side roof rail inner

44. Front pillar inner upper

45. Front pillar inner lower

46. Center pillar inner

47. Side outer panel

48. Rear wheel house inner panel

49. Quarter inner panel

50. Rear floor side brace

51. Quarter outer extension lower

52. Fuel filler door

53. Rear license plate bracket

54. Rear end panel outer

55. Rear end panel inner

56. Rear door outer panel

57. Rear door side door beam

58. Rear door inner panel

59. Front door outer panel

60. Front door side door beam

61. Front door inner panel

62. Fender panel

63. Front floor crossmember rear

64. Front floor crossmember front

65. Front floor side sill inner

66. Front floor sidemember

67. Backbone reinforcement

68. Installment panel center bracket reinforcement

69. Front floor pan

70. Front floor extension panel rear

71. Rear floor extension

72. Rear floor pan

73. Seat back plate extension

74. Jack bracket

75. Spare tire bracket

76. Towing hook reinforcement

77. Rear floor sidemember extension

78. Crossmember center support

79. Rear floor crossmember

80. Rear floor sidemember

81. Rear seat back reinforcement

Page 6 of 1449

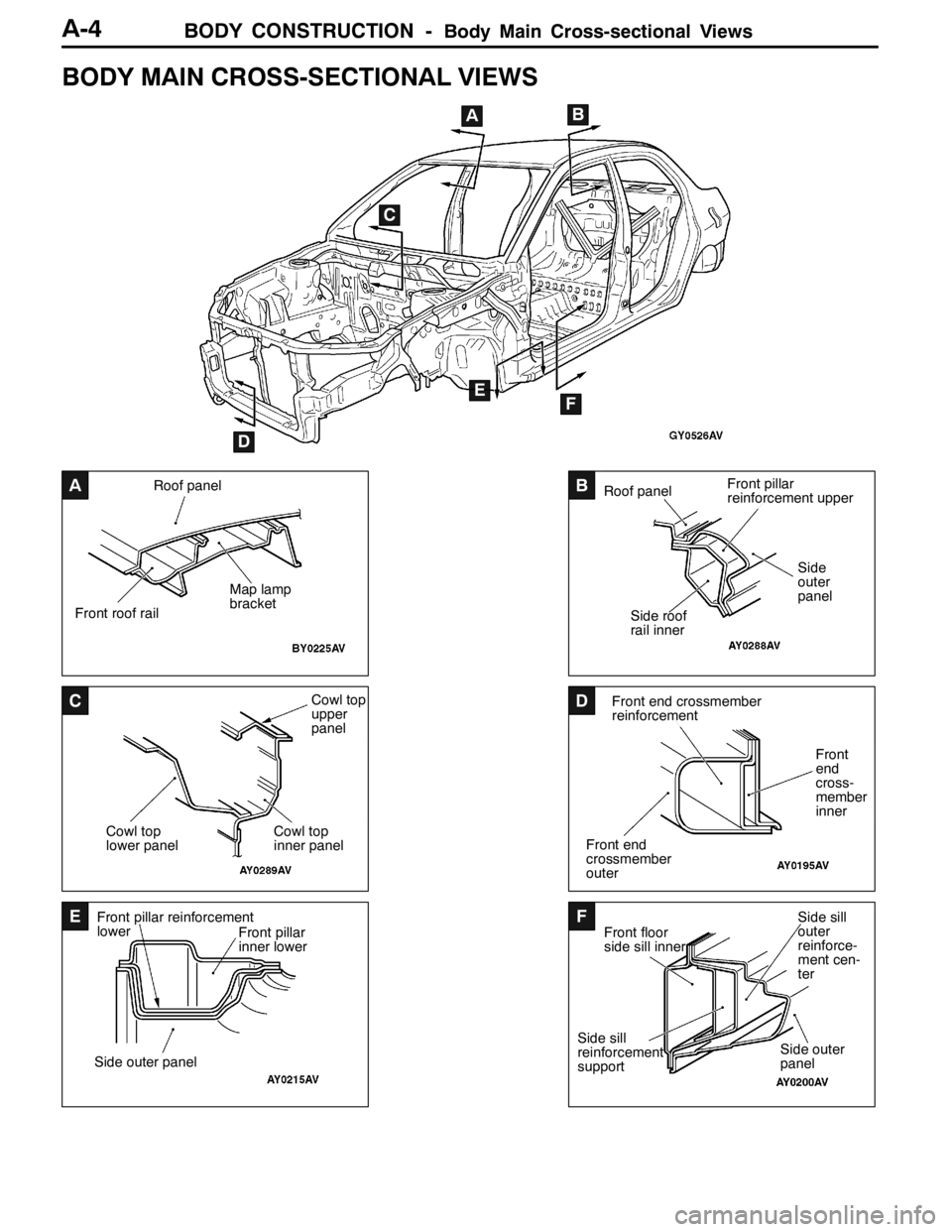

BODY CONSTRUCTION -Body Main Cross-sectional Views

ARoof panel

Map lamp

bracket

Front roof railB

Side

outer

panel

Front pillar

reinforcement upper

Side roof

rail inner Roof panel

CCowl top

upper

panel

Cowl top

inner panel Cowl top

lower panel

Front end crossmember

reinforcement

Front

end

cross-

member

inner

Front end

crossmember

outer

D

EFront pillar reinforcement

lower

Front pillar

inner lower

Side outer panel

F

Side outer

panel Front floor

side sill inner

Side sill

reinforcement

supportSide sill

outer

reinforce-

ment cen-

ter

A-4

BODY MAIN CROSS-SECTIONAL VIEWS

C

AB

D

EF

Page 7 of 1449

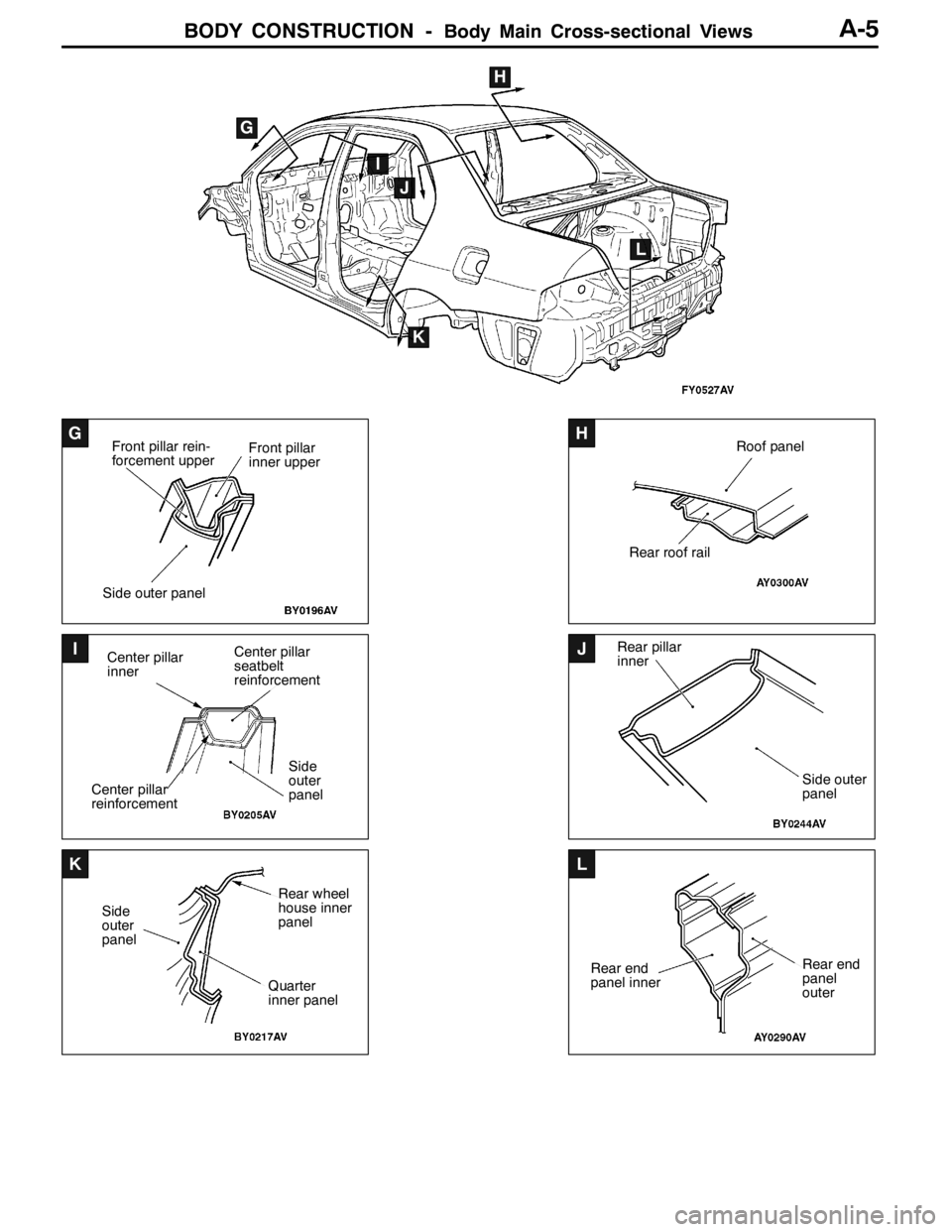

BODY CONSTRUCTION -Body Main Cross-sectional Views

GFront pillar

inner upperFront pillar rein-

forcement upper

Side outer panelH

Rear roof railRoof panel

I

Center pillar

reinforcement

Center pillar

seatbelt

reinforcement Center pillar

inner

Side

outer

panelRear pillar

innerJ

Side outer

panel

K

Rear wheel

house inner

panel Side

outer

panel

Quarter

inner panel

Rear end

panel

outer

L

Rear end

panel inner

A-5

G

H

I

J

K

L

Page 15 of 1449

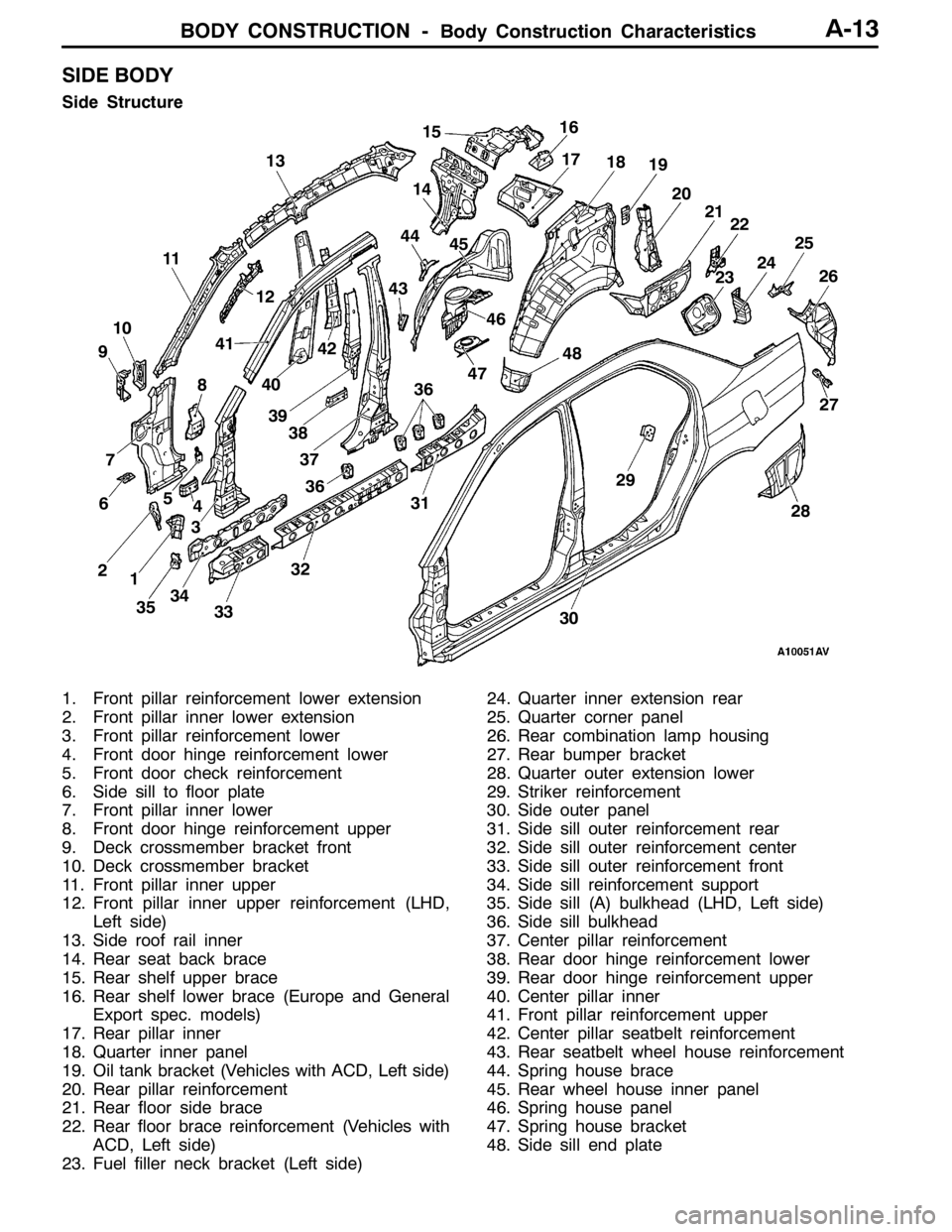

BODY CONSTRUCTION -Body Construction CharacteristicsA-13

SIDE BODY

Side Structure

1 2710

4 5

68 911

1213

1415

320 17

18

19 16

2425

26 22

23 21

27

28

3231

30 33 3438

37 41

40

39

36

3529 424344

45

3646

4748

1. Front pillar reinforcement lower extension

2. Front pillar inner lower extension

3. Front pillar reinforcement lower

4. Front door hinge reinforcement lower

5. Front door check reinforcement

6. Side sill to floor plate

7. Front pillar inner lower

8. Front door hinge reinforcement upper

9. Deck crossmember bracket front

10. Deck crossmember bracket

11. Front pillar inner upper

12. Front pillar inner upper reinforcement (LHD,

Left side)

13. Side roof rail inner

14. Rear seat back brace

15. Rear shelf upper brace

16. Rear shelf lower brace (Europe and General

Export spec. models)

17. Rear pillar inner

18. Quarter inner panel

19. Oil tank bracket (Vehicles with ACD, Left side)

20. Rear pillar reinforcement

21. Rear floor side brace

22. Rear floor brace reinforcement (Vehicles with

ACD, Left side)

23. Fuel filler neck bracket (Left side)24. Quarter inner extension rear

25. Quarter corner panel

26. Rear combination lamp housing

27. Rear bumper bracket

28. Quarter outer extension lower

29. Striker reinforcement

30. Side outer panel

31. Side sill outer reinforcement rear

32. Side sill outer reinforcement center

33. Side sill outer reinforcement front

34. Side sill reinforcement support

35. Side sill (A) bulkhead (LHD, Left side)

36. Side sill bulkhead

37. Center pillar reinforcement

38. Rear door hinge reinforcement lower

39. Rear door hinge reinforcement upper

40. Center pillar inner

41. Front pillar reinforcement upper

42. Center pillar seatbelt reinforcement

43. Rear seatbelt wheel house reinforcement

44. Spring house brace

45. Rear wheel house inner panel

46. Spring house panel

47. Spring house bracket

48. Side sill end plate

Page 16 of 1449

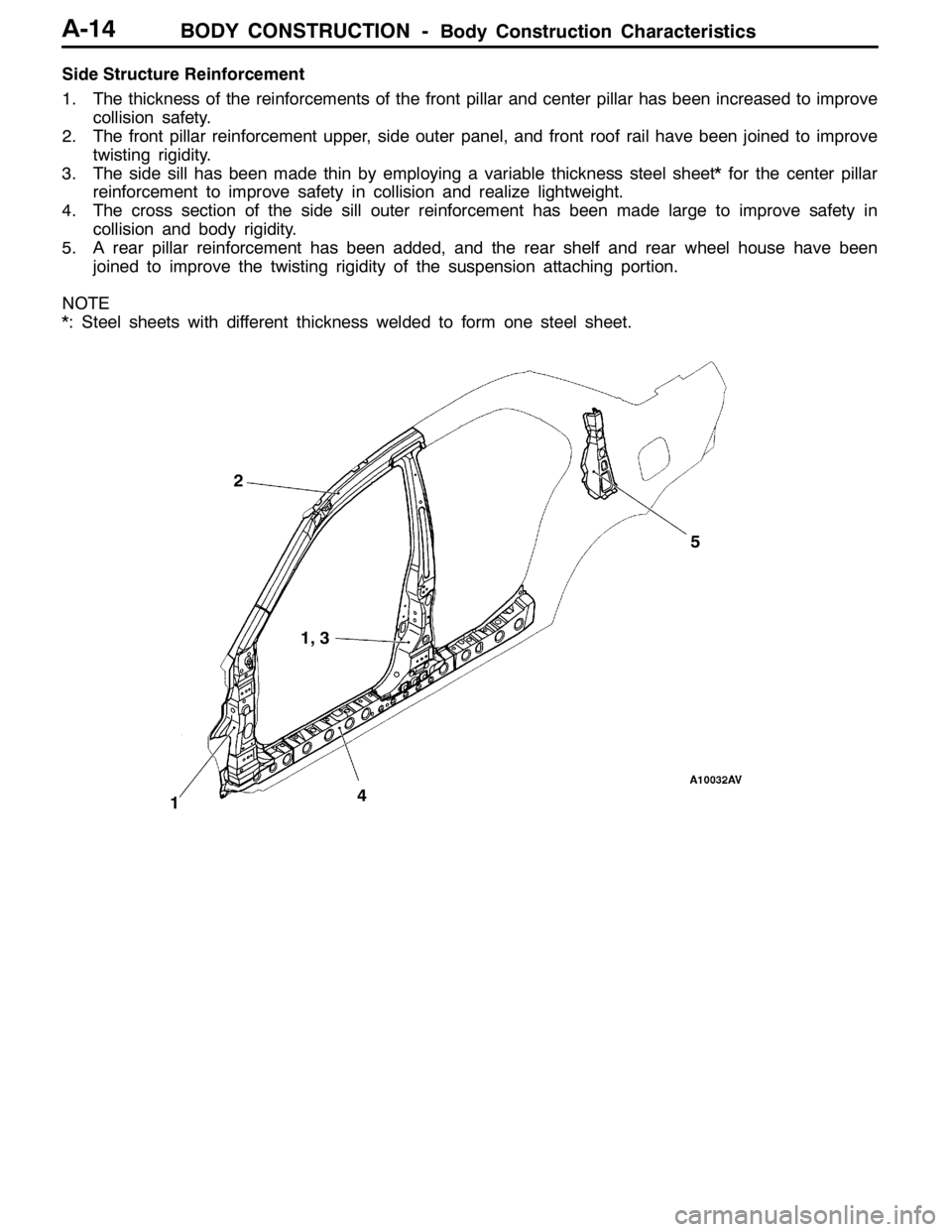

BODY CONSTRUCTION -Body Construction CharacteristicsA-14

Side Structure Reinforcement

1. The thickness of the reinforcements of the front pillar and center pillar has been increased to improve

collision safety.

2. The front pillar reinforcement upper, side outer panel, and front roof rail have been joined to improve

twisting rigidity.

3. The side sill has been made thin by employing a variable thickness steel sheet* for the center pillar

reinforcement to improve safety in collision and realize lightweight.

4. The cross section of the side sill outer reinforcement has been made large to improve safety in

collision and body rigidity.

5. A rear pillar reinforcement has been added, and the rear shelf and rear wheel house have been

joined to improve the twisting rigidity of the suspension attaching portion.

NOTE

*: Steel sheets with different thickness welded to form one steel sheet.

11, 3

45 2

Page 18 of 1449

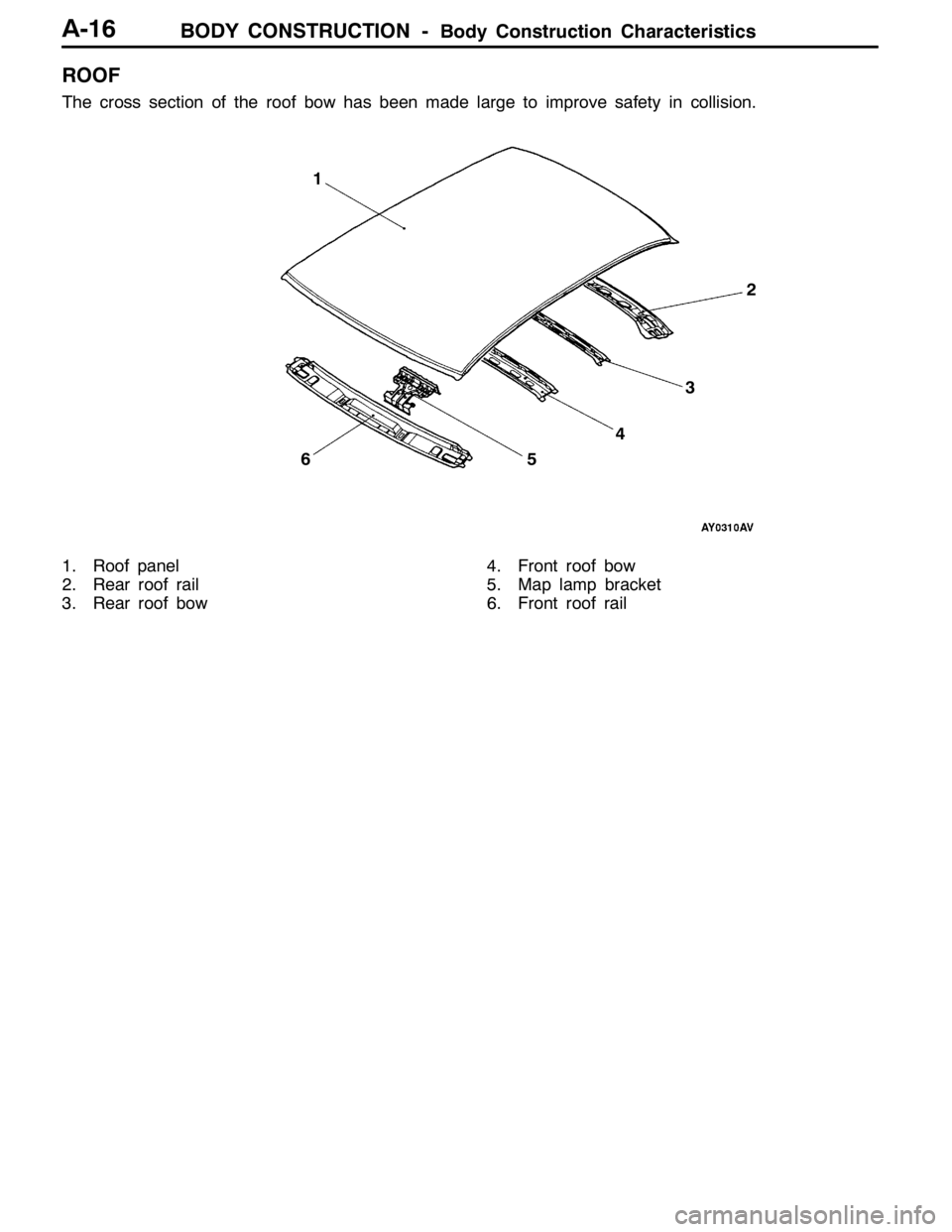

BODY CONSTRUCTION -Body Construction CharacteristicsA-16

ROOF

The cross section of the roof bow has been made large to improve safety in collision.

1

2

3

4

5 6

1. Roof panel

2. Rear roof rail

3. Rear roof bow4. Front roof bow

5. Map lamp bracket

6. Front roof rail

Page 24 of 1449

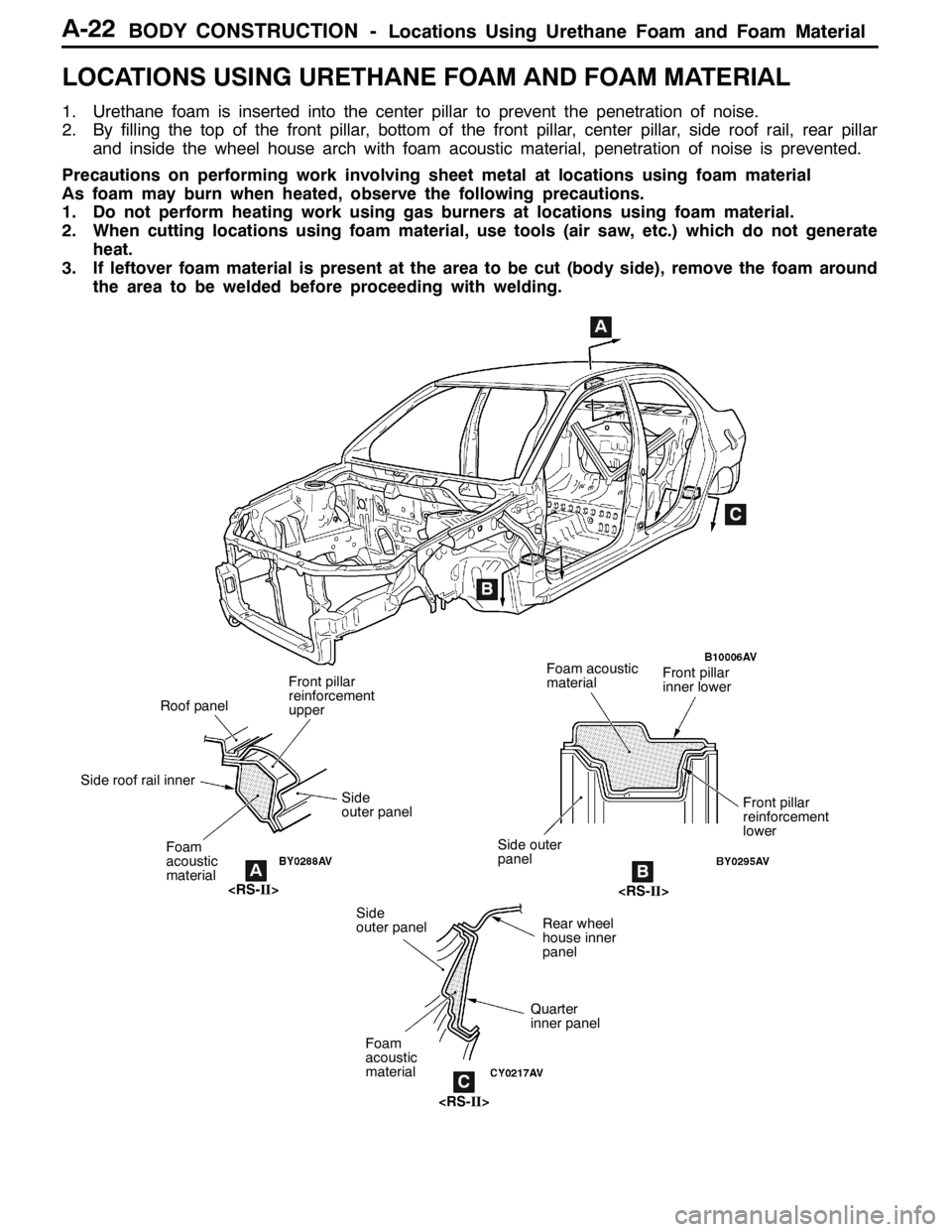

BODY CONSTRUCTION -Locations Using Urethane Foam and Foam MaterialA-22

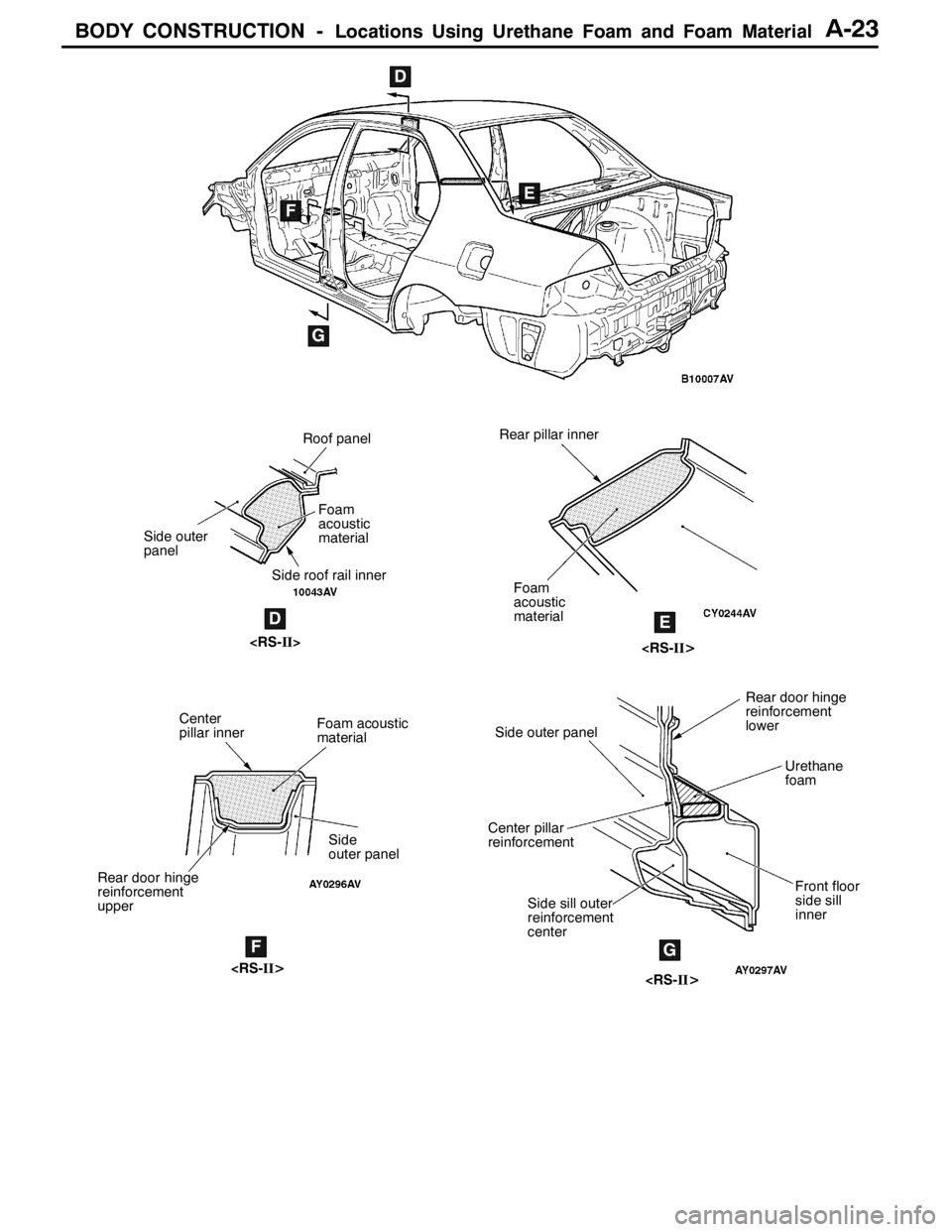

LOCATIONS USING URETHANE FOAM AND FOAM MATERIAL

1. Urethane foam is inserted into the center pillar to prevent the penetration of noise.

2. By filling the top of the front pillar, bottom of the front pillar, center pillar, side roof rail, rear pillar

and inside the wheel house arch with foam acoustic material, penetration of noise is prevented.

Precautions on performing work involving sheet metal at locations using foam material

As foam may burn when heated, observe the following precautions.

1. Do not perform heating work using gas burners at locations using foam material.

2. When cutting locations using foam material, use tools (air saw, etc.) which do not generate

heat.

3. If leftover foam material is present at the area to be cut (body side), remove the foam around

the area to be welded before proceeding with welding.

AB

C

A

B

C

Front pillar

inner lower

Foam

acoustic

material

Quarter

inner panel

Roof panel

Side roof rail inner

Rear wheel

house inner

panel

Front pillar

reinforcement

lower Side

outer panel

Front pillar

reinforcement

upper

Side outer

panel

Side

outer panelFoam acoustic

material

Foam

acoustic

material

Page 25 of 1449

BODY CONSTRUCTION -Locations Using Urethane Foam and Foam MaterialA-23

E

F

G

E

F

Side outer panel

Rear pillar inner

Side outer

panel

Rear door hinge

reinforcement

upperSide sill outer

reinforcement

center Center pillar

reinforcement

Front floor

side sill

inner Center

pillar inner

Side

outer panel

G

Foam acoustic

material

Foam

acoustic

material

Urethane

foam Rear door hinge

reinforcement

lower

D

D

Roof panel

Side roof rail inner

Foam

acoustic

material

Page 26 of 1449

BODY CONSTRUCTION -Stiffener and Dump Sheet Application LocationsA-24

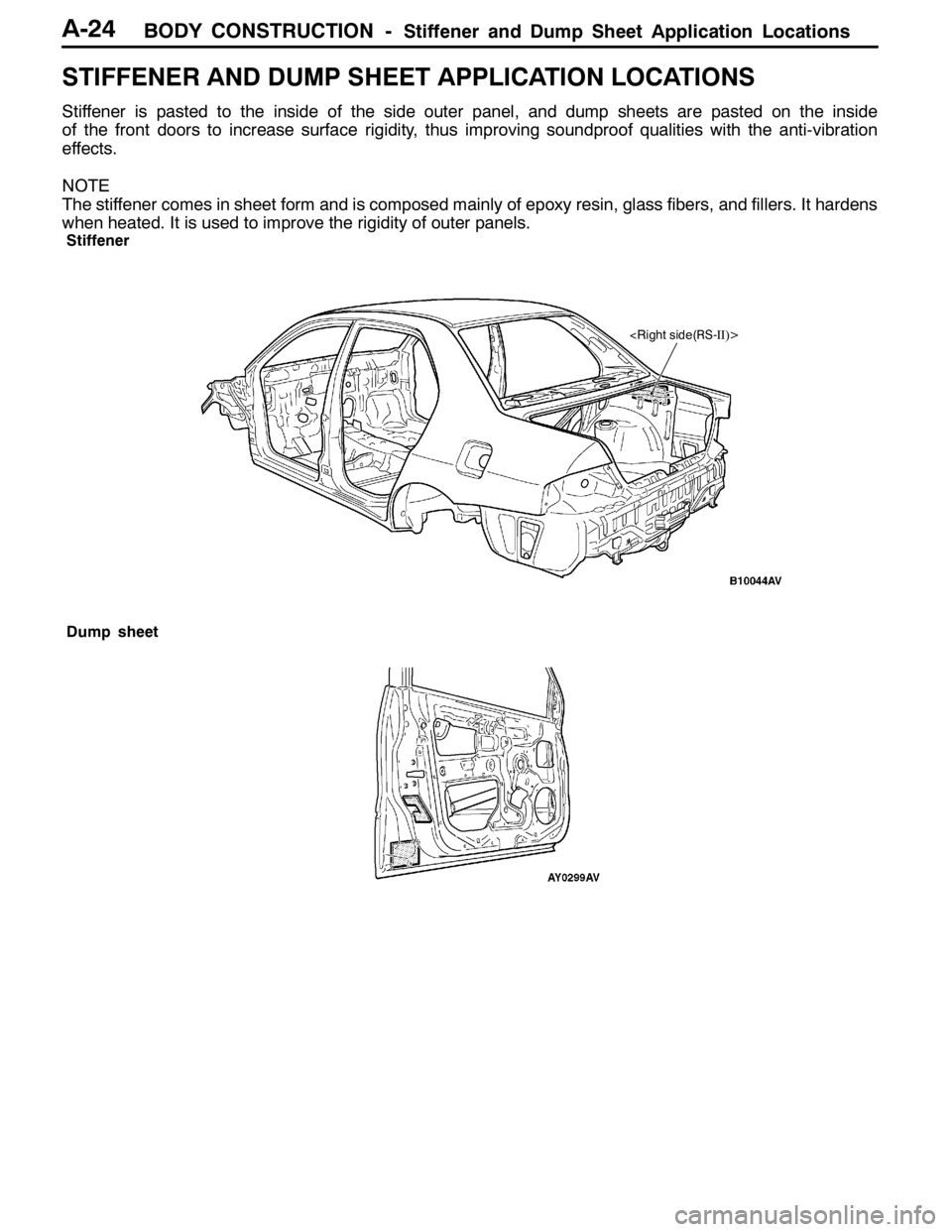

STIFFENER AND DUMP SHEET APPLICATION LOCATIONS

Stiffener is pasted to the inside of the side outer panel, and dump sheets are pasted on the inside

of the front doors to increase surface rigidity, thus improving soundproof qualities with the anti-vibration

effects.

NOTE

The stiffener comes in sheet form and is composed mainly of epoxy resin, glass fibers, and fillers. It hardens

when heated. It is used to improve the rigidity of outer panels.

Stiffener

Dump sheet