display MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 90 of 1449

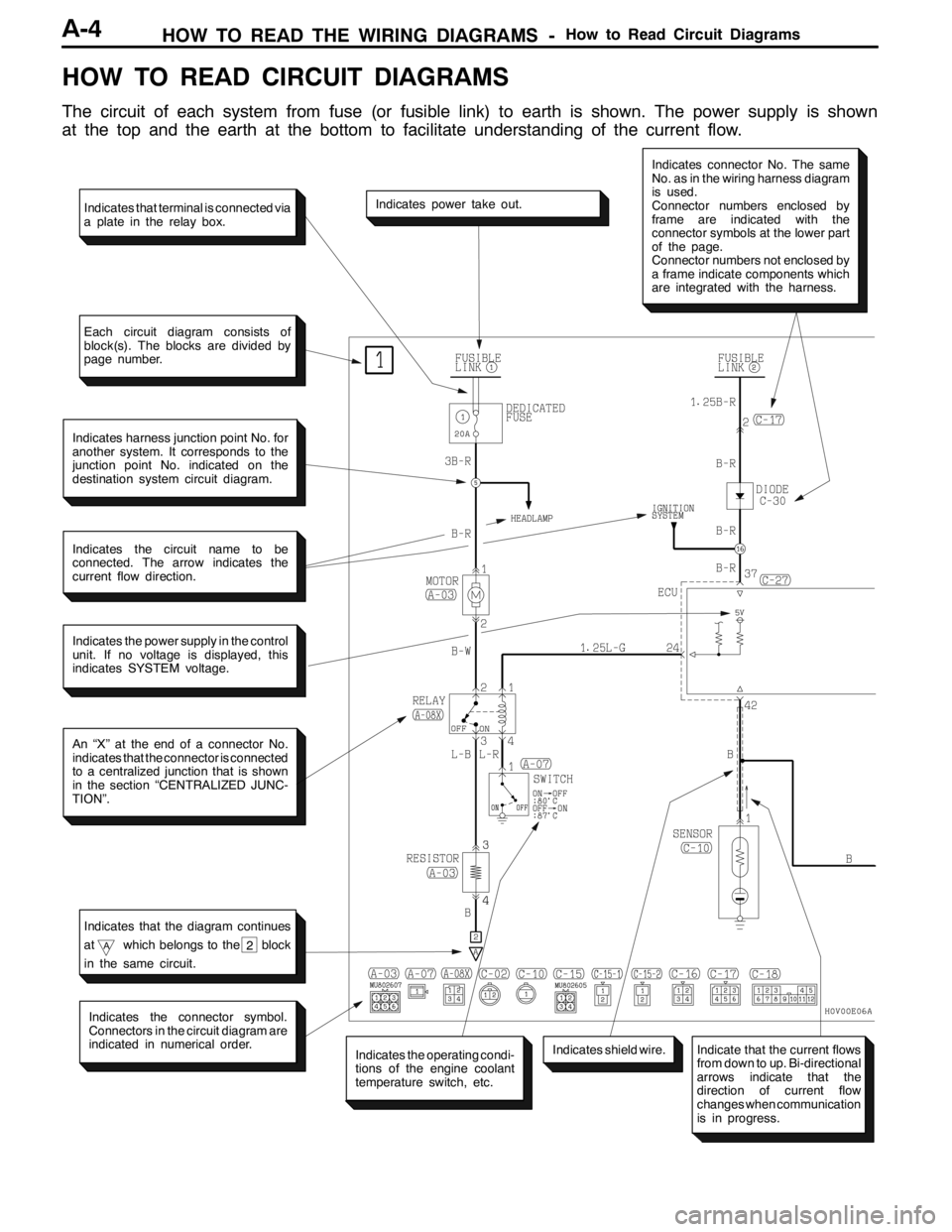

HOW TO READ THE WIRING DIAGRAMS -How to Read Circuit DiagramsA-4

HOW TO READ CIRCUIT DIAGRAMS

The circuit of each system from fuse (or fusible link) to earth is shown. The power supply is shown

at the top and the earth at the bottom to facilitate understanding of the current flow.

Indicates the power supply in the control

unit. If no voltage is displayed, this

indicates SYSTEM voltage.

Indicates power take out.

Indicates connector No. The same

No. as in the wiring harness diagram

is used.

Connector numbers enclosed by

frame are indicated with the

connector symbols at the lower part

of the page.

Connector numbers not enclosed by

a frame indicate components which

are integrated with the harness.

Indicates harness junction point No. for

another system. It corresponds to the

junction point No. indicated on the

destination system circuit diagram.

Indicates the circuit name to be

connected. The arrow indicates the

current flow direction.

An “X” at the end of a connector No.

indicates that the connector is connected

to a centralized junction that is shown

in the section “CENTRALIZED JUNC-

TION”.

Indicates the operating condi-

tions of the engine coolant

temperature switch, etc.

Indicates the connector symbol.

Connectors in the circuit diagram are

indicated in numerical order.

Indicates shield wire.

Indicates that terminal is connected via

a plate in the relay box.

Each circuit diagram consists of

block(s). The blocks are divided by

page number.

Indicates that the diagram continues

at

Awhich belongs to the block

in the same circuit.2

Indicate that the current flows

from down to up. Bi-directional

arrows indicate that the

direction of current flow

changes when communication

is in progress.

Page 98 of 1449

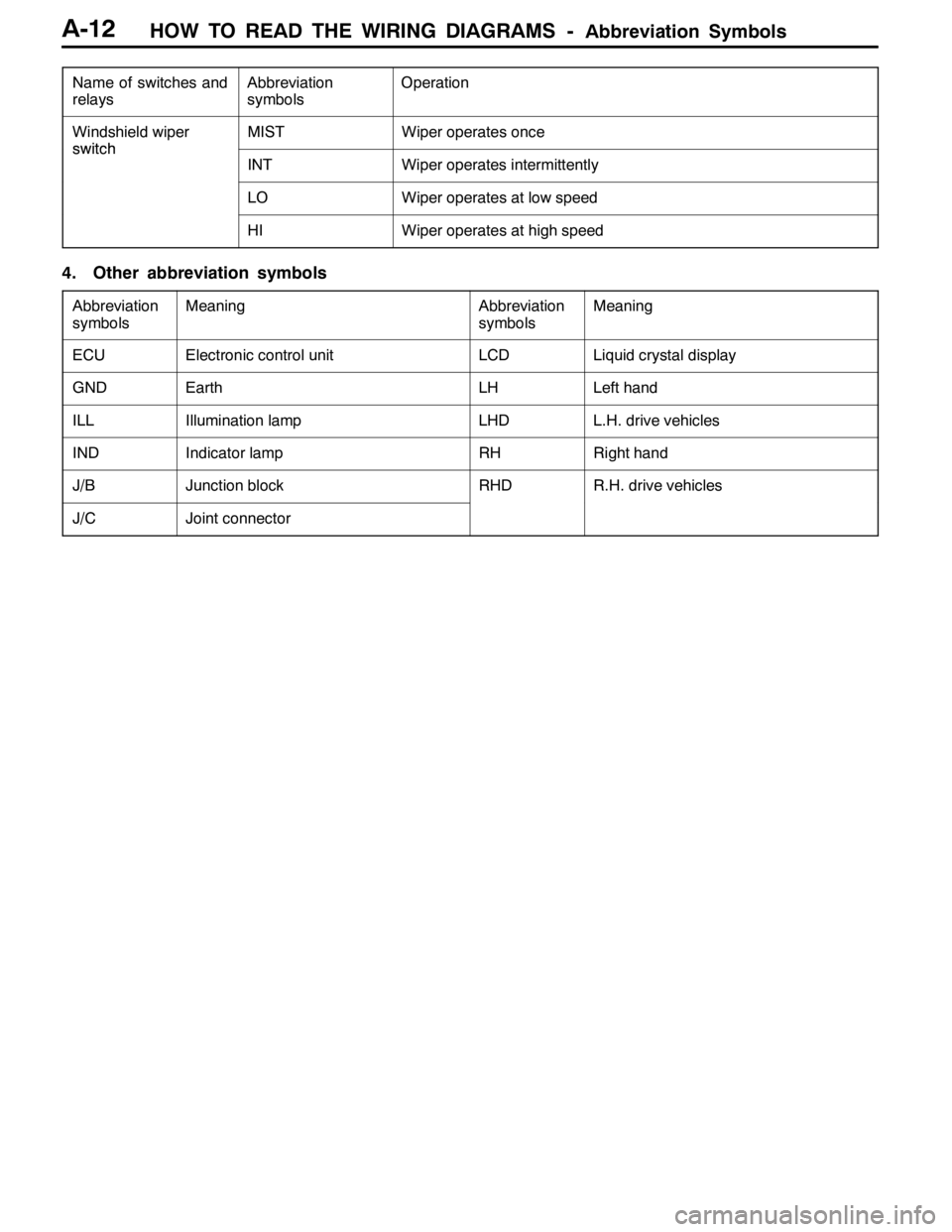

HOW TO READ THE WIRING DIAGRAMS -Abbreviation SymbolsA-12

Name of switches and

relaysOperation Abbreviation

symbols

Windshield wiper

switch

MISTWiper operates once

switch

INTWiper operates intermittently

LOWiper operates at low speed

HIWiper operates at high speed

4. Other abbreviation symbols

Abbreviation

symbolsMeaningAbbreviation

symbolsMeaning

ECUElectronic control unitLCDLiquid crystal display

GNDEarthLHLeft hand

ILLIllumination lampLHDL.H. drive vehicles

INDIndicator lampRHRight hand

J/BJunction blockRHDR.H. drive vehicles

J/CJoint connector

Page 384 of 1449

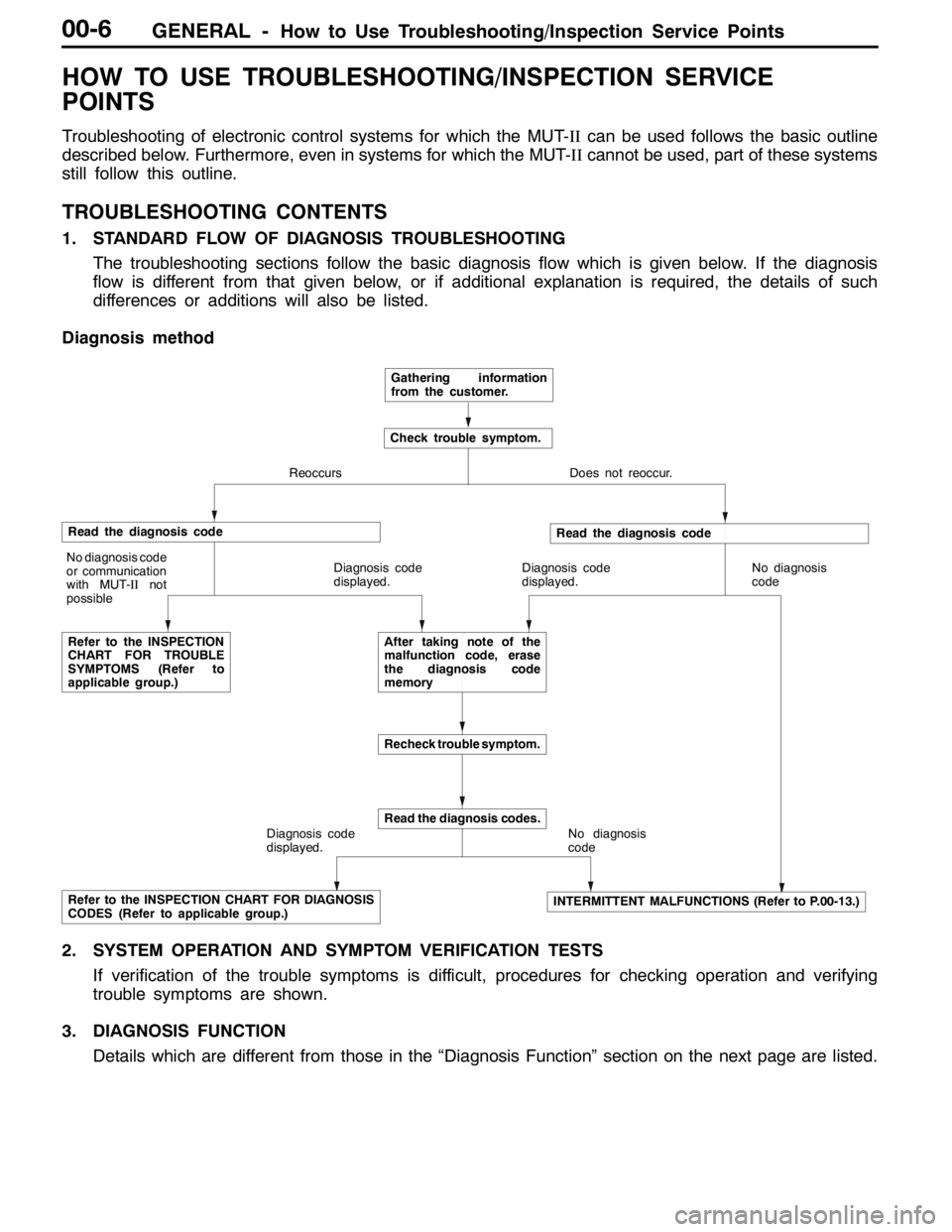

GENERAL -How to Use Troubleshooting/Inspection Service Points00-6

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE

POINTS

Troubleshooting of electronic control systems for which the MUT-IIcan be used follows the basic outline

described below. Furthermore, even in systems for which the MUT-IIcannot be used, part of these systems

still follow this outline.

TROUBLESHOOTING CONTENTS

1. STANDARD FLOW OF DIAGNOSIS TROUBLESHOOTING

The troubleshooting sections follow the basic diagnosis flow which is given below. If the diagnosis

flow is different from that given below, or if additional explanation is required, the details of such

differences or additions will also be listed.

Diagnosis method

Gathering information

from the customer.

Check trouble symptom.

Reoccurs Does not reoccur.

Read the diagnosis code

No diagnosis code

or communication

with MUT-IInot

possible

Refer to the INSPECTION

CHART FOR TROUBLE

SYMPTOMS (Refer to

applicable group.)Diagnosis code

displayed.

Read the diagnosis code

Diagnosis code

displayed.No diagnosis

code

After taking note of the

malfunction code, erase

the diagnosis code

memory

Recheck trouble symptom.

Diagnosis code

displayed.

Read the diagnosis codes.

No diagnosis

code

Refer to the INSPECTION CHART FOR DIAGNOSIS

CODES (Refer to applicable group.)INTERMITTENT MALFUNCTIONS (Refer to P.00-13.)

2. SYSTEM OPERATION AND SYMPTOM VERIFICATION TESTS

If verification of the trouble symptoms is difficult, procedures for checking operation and verifying

trouble symptoms are shown.

3. DIAGNOSIS FUNCTION

Details which are different from those in the “Diagnosis Function” section on the next page are listed.

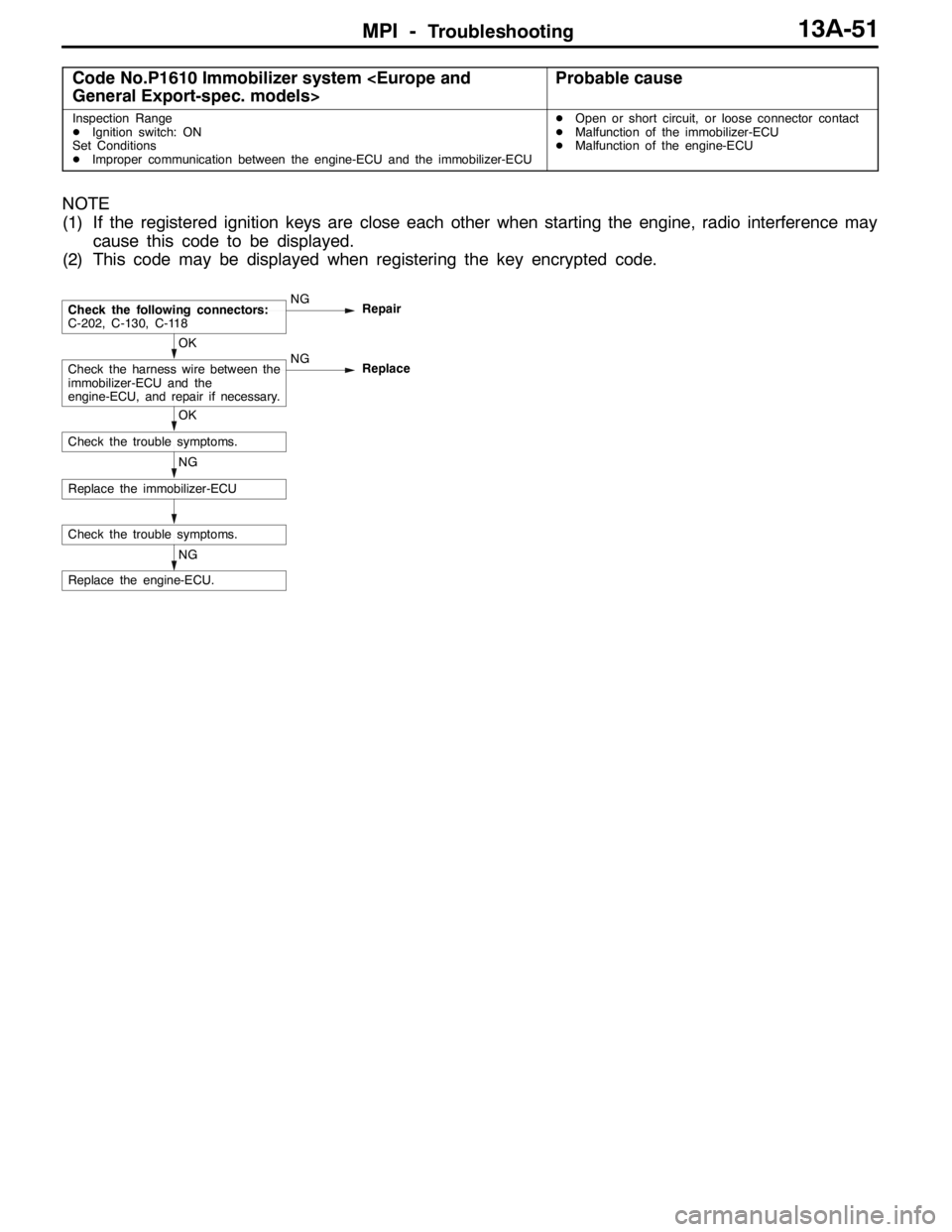

Page 583 of 1449

MPI -Troubleshooting13A-51

Code No.P1610 Immobilizer system

Inspection Range

DIgnition switch: ON

Set Conditions

DImproper communication between the engine-ECU and the immobilizer-ECUDOpen or short circuit, or loose connector contact

DMalfunction of the immobilizer-ECU

DMalfunction of the engine-ECU

NOTE

(1) If the registered ignition keys are close each other when starting the engine, radio interference may

cause this code to be displayed.

(2) This code may be displayed when registering the key encrypted code.

NG

Replace the engine-ECU.

Check the trouble symptoms.

NG

Replace the immobilizer-ECU

OK

Check the trouble symptoms.

OK

Check the harness wire between the

immobilizer-ECU and the

engine-ECU, and repair if necessary.NG

Replace

Check the following connectors:

C-202, C-130, C-118NG

Repair

Page 587 of 1449

MPI -Troubleshooting13A-55

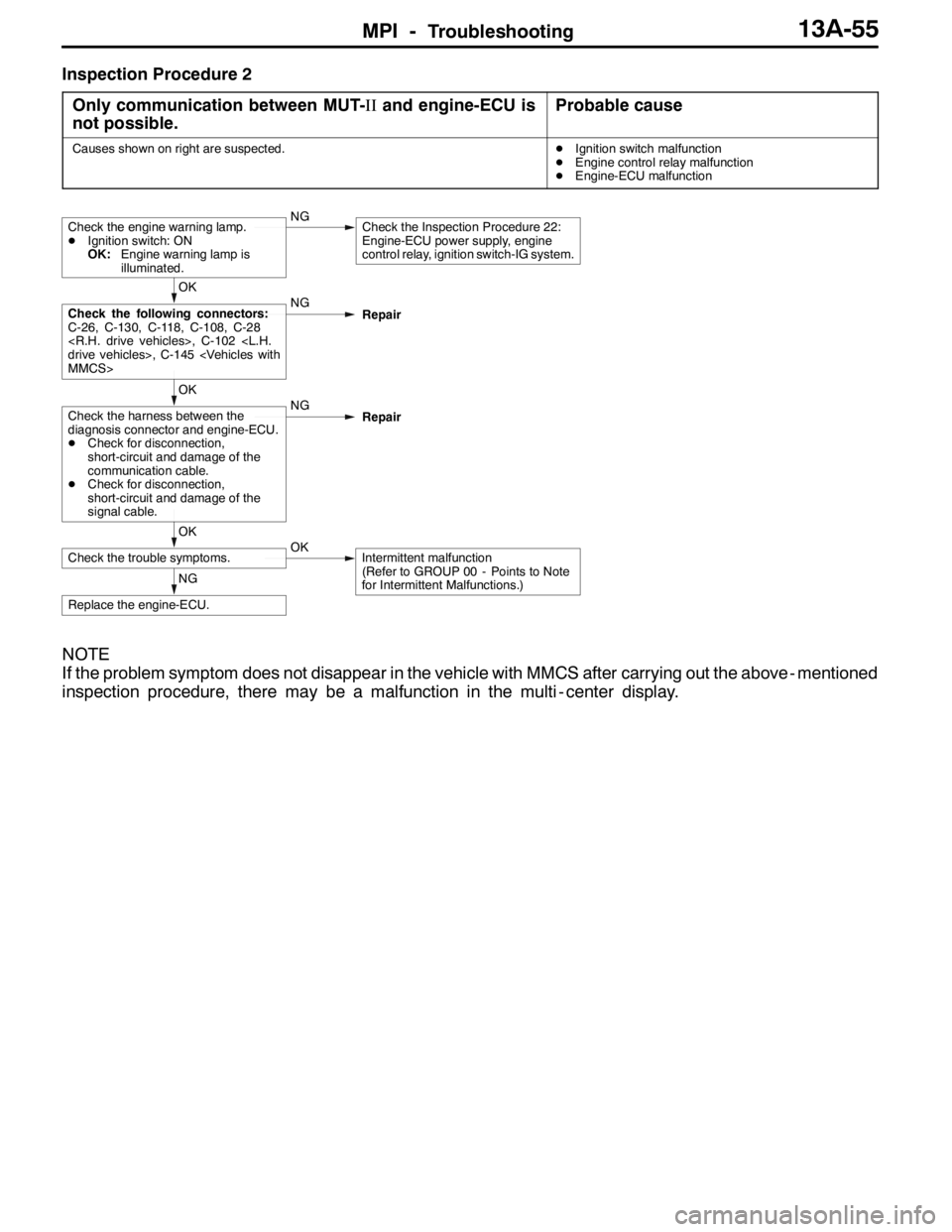

Inspection Procedure 2

Only communication between MUT-IIand engine-ECU is

not possible.

Probable cause

Causes shown on right are suspected.DIgnition switch malfunction

DEngine control relay malfunction

DEngine-ECU malfunction

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Check the harness between the

diagnosis connector and engine-ECU.

DCheck for disconnection,

short-circuit and damage of the

communication cable.

DCheck for disconnection,

short-circuit and damage of the

signal cable.NG

Repair

OK

Check the following connectors:

C-26, C-130, C-118, C-108, C-28

Repair

Check the engine warning lamp.

DIgnition switch: ON

OK:Engine warning lamp is

illuminated.NGCheck the Inspection Procedure 22:

Engine-ECU power supply, engine

control relay, ignition switch-IG system.

NOTE

If the problem symptom does not disappear in the vehicle with MMCS after carrying out the above - mentioned

inspection procedure, there may be a malfunction in the multi - center display.

Page 638 of 1449

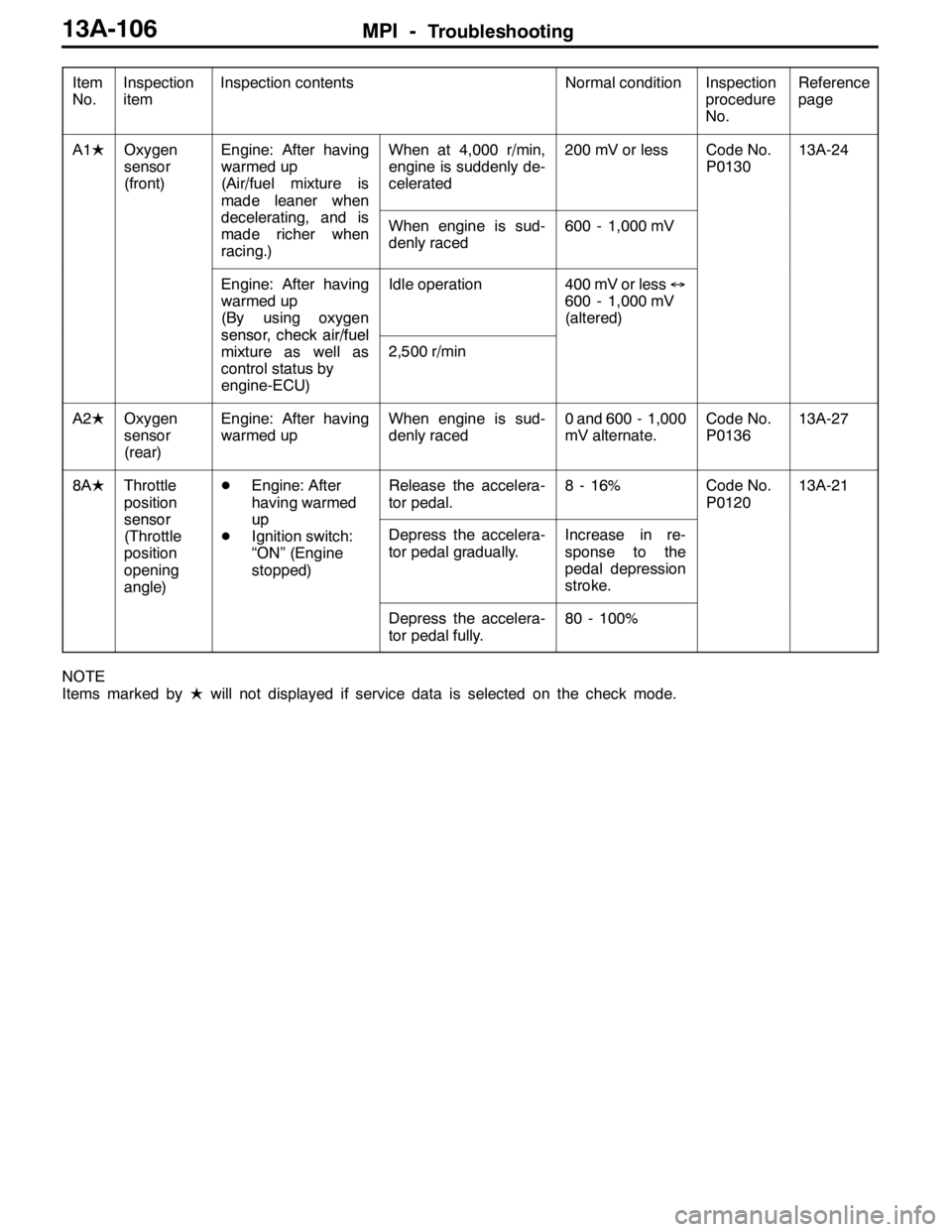

MPI -Troubleshooting13A-106

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Inspection

item

A1LOxygen

sensor

(front)Engine: After having

warmed up

(Air/fuel mixture is

made leaner whenWhen at 4,000 r/min,

engine is suddenly de-

celerated200 mV or lessCode No.

P013013A-24

madeleanerwhen

decelerating, and is

made richer when

racing.)When engine is sud-

denly raced600 - 1,000 mV

Engine: After having

warmed up

(By using oxygen

sensorcheckair/fuel

Idle operation400 mV or less↔

600 - 1,000 mV

(altered)

sensor, checkair/fuel

mixture as well as

control status by

engine-ECU)2,500 r/min

A2LOxygen

sensor

(rear)Engine: After having

warmed upWhen engine is sud-

denly raced0 and 600 - 1,000

mV alternate.Code No.

P013613A-27

8ALThrottle

position

sensor

DEngine: After

having warmed

up

Release the accelera-

tor pedal.8 - 16%Code No.

P012013A-21

sensor

(Throttle

position

opening

angle)up

DIgnition switch:

“ON” (Engine

stopped)Depress the accelera-

tor pedal gradually.Increase in re-

sponse to the

pedal depression

stroke.

Depress the accelera-

tor pedal fully.80 - 100%

NOTE

Items marked byLwill not displayed if service data is selected on the check mode.

Page 648 of 1449

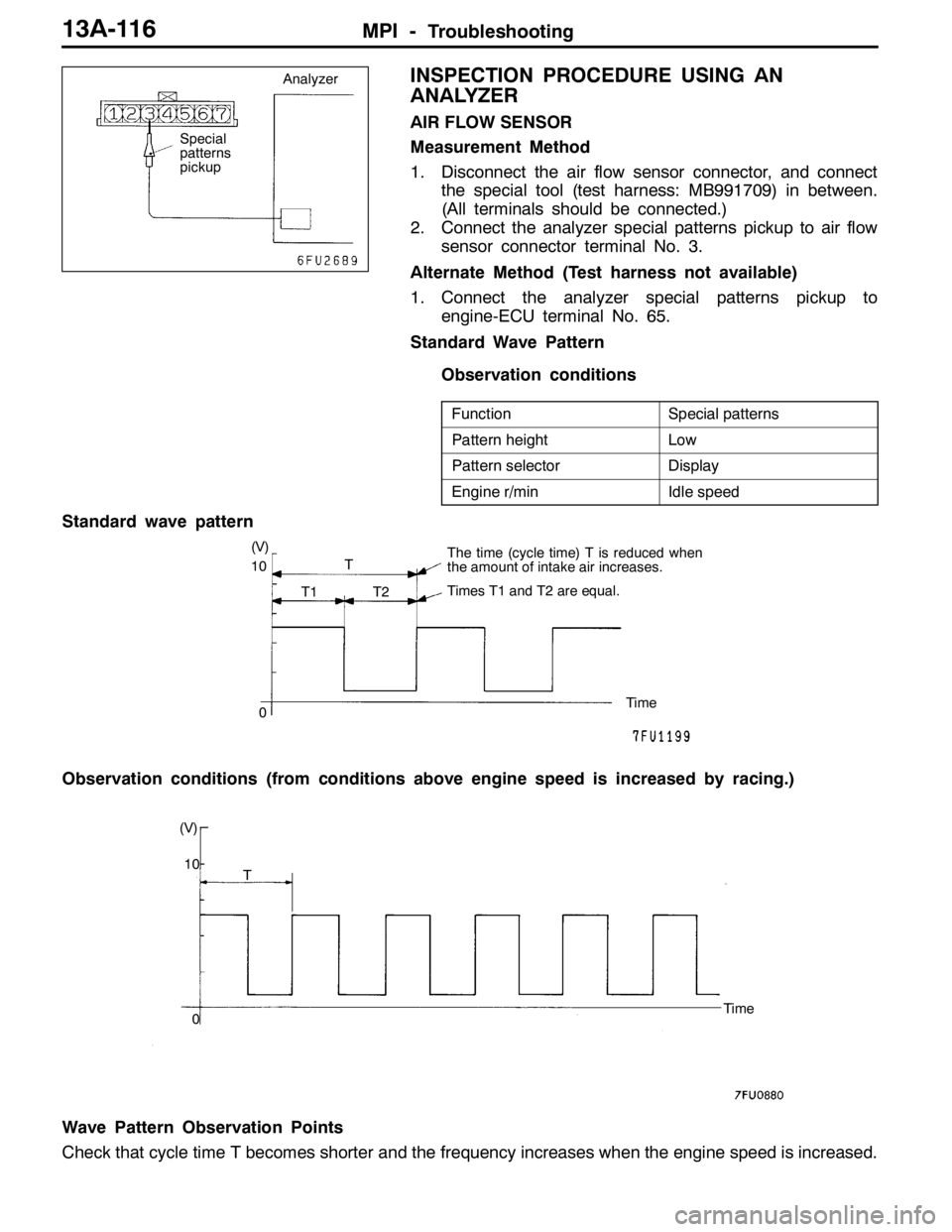

MPI -Troubleshooting13A-116

INSPECTION PROCEDURE USING AN

ANALYZER

AIR FLOW SENSOR

Measurement Method

1. Disconnect the air flow sensor connector, and connect

the special tool (test harness: MB991709) in between.

(All terminals should be connected.)

2. Connect the analyzer special patterns pickup to air flow

sensor connector terminal No. 3.

Alternate Method (Test harness not available)

1. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 65.

Standard Wave Pattern

Observation conditions

FunctionSpecial patterns

Pattern heightLow

Pattern selectorDisplay

Engine r/minIdle speed

Standard wave pattern

(V)

10

0The time (cycle time) T is reduced when

the amount of intake air increases.

Times T1 and T2 are equal.

Time T

T1 T2

Observation conditions (from conditions above engine speed is increased by racing.)

Time (V)

10

0T

Wave Pattern Observation Points

Check that cycle time T becomes shorter and the frequency increases when the engine speed is increased.

Analyzer

Special

patterns

pickup

Page 650 of 1449

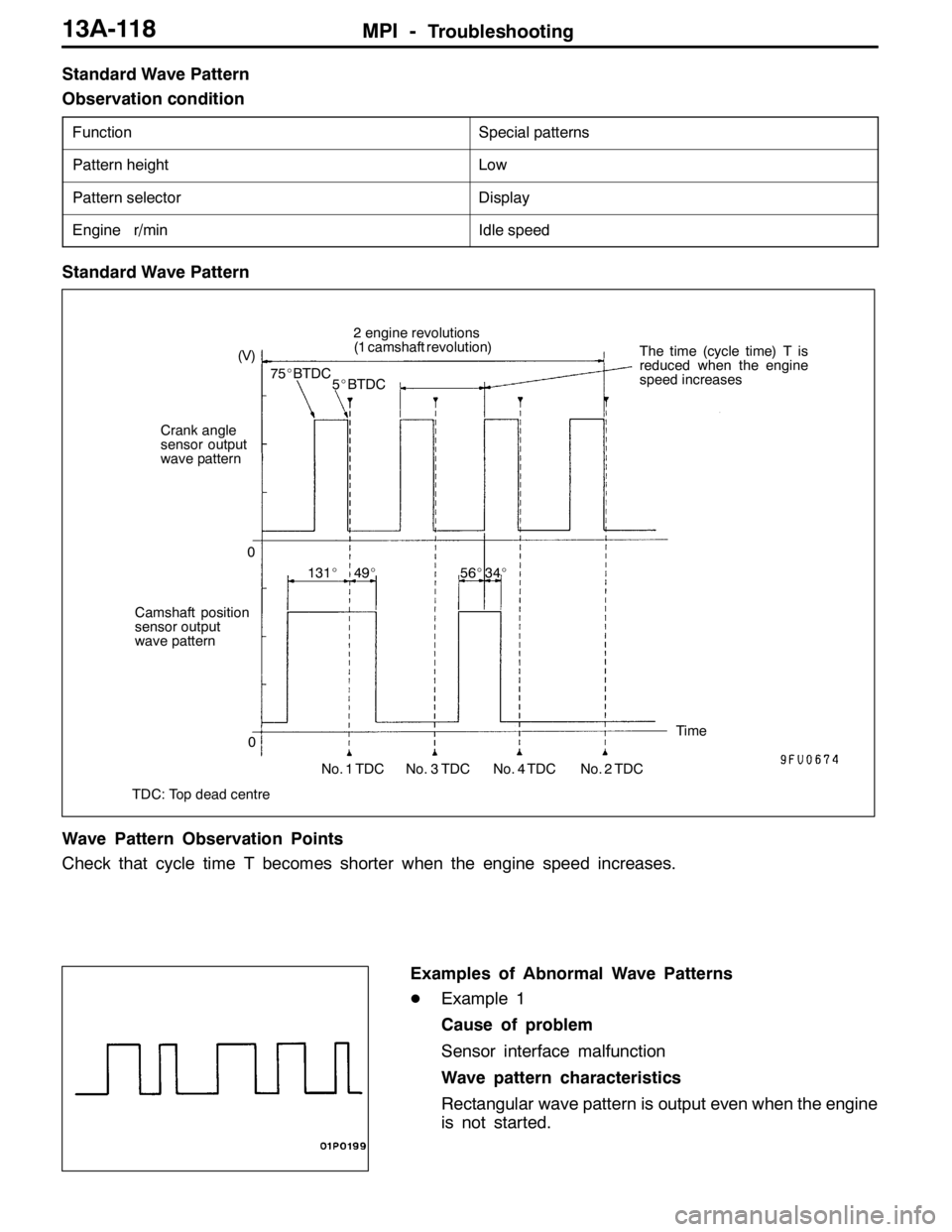

MPI -Troubleshooting13A-118

Standard Wave Pattern

Observation condition

FunctionSpecial patterns

Pattern heightLow

Pattern selectorDisplay

Engine r/minIdle speed

Standard Wave Pattern

Crank angle

sensor output

wave pattern(V)

75_BTDC2 engine revolutions

(1 camshaft revolution)

5_BTDCThe time (cycle time) T is

reduced when the engine

speed increases

0

Camshaft position

sensor output

wave pattern

TDC: Top dead centre131_49_

No. 1 TDC No. 3 TDC No. 4 TDC No. 2 TDCTime

056_34_

Wave Pattern Observation Points

Check that cycle time T becomes shorter when the engine speed increases.

Examples of Abnormal Wave Patterns

DExample 1

Cause of problem

Sensor interface malfunction

Wave pattern characteristics

Rectangular wave pattern is output even when the engine

is not started.

Page 651 of 1449

MPI -Troubleshooting13A-119

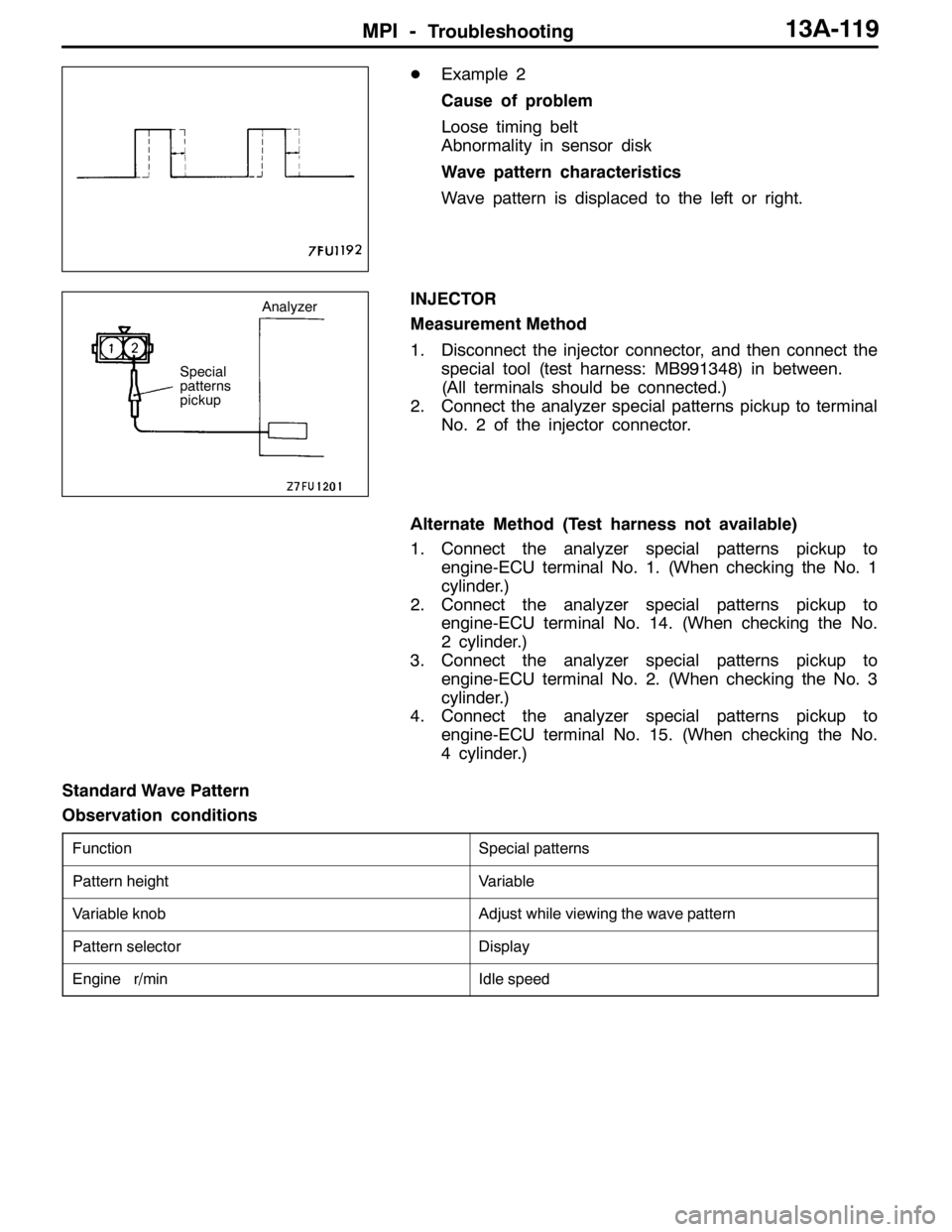

DExample 2

Cause of problem

Loose timing belt

Abnormality in sensor disk

Wave pattern characteristics

Wave pattern is displaced to the left or right.

INJECTOR

Measurement Method

1. Disconnect the injector connector, and then connect the

special tool (test harness: MB991348) in between.

(All terminals should be connected.)

2. Connect the analyzer special patterns pickup to terminal

No. 2 of the injector connector.

Alternate Method (Test harness not available)

1. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 1. (When checking the No. 1

cylinder.)

2. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 14. (When checking the No.

2 cylinder.)

3. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 2. (When checking the No. 3

cylinder.)

4. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 15. (When checking the No.

4 cylinder.)

Standard Wave Pattern

Observation conditions

FunctionSpecial patterns

Pattern heightVariable

Variable knobAdjust while viewing the wave pattern

Pattern selectorDisplay

Engine r/minIdle speed

Special

patterns

pickupAnalyzer

Page 652 of 1449

MPI -Troubleshooting13A-120

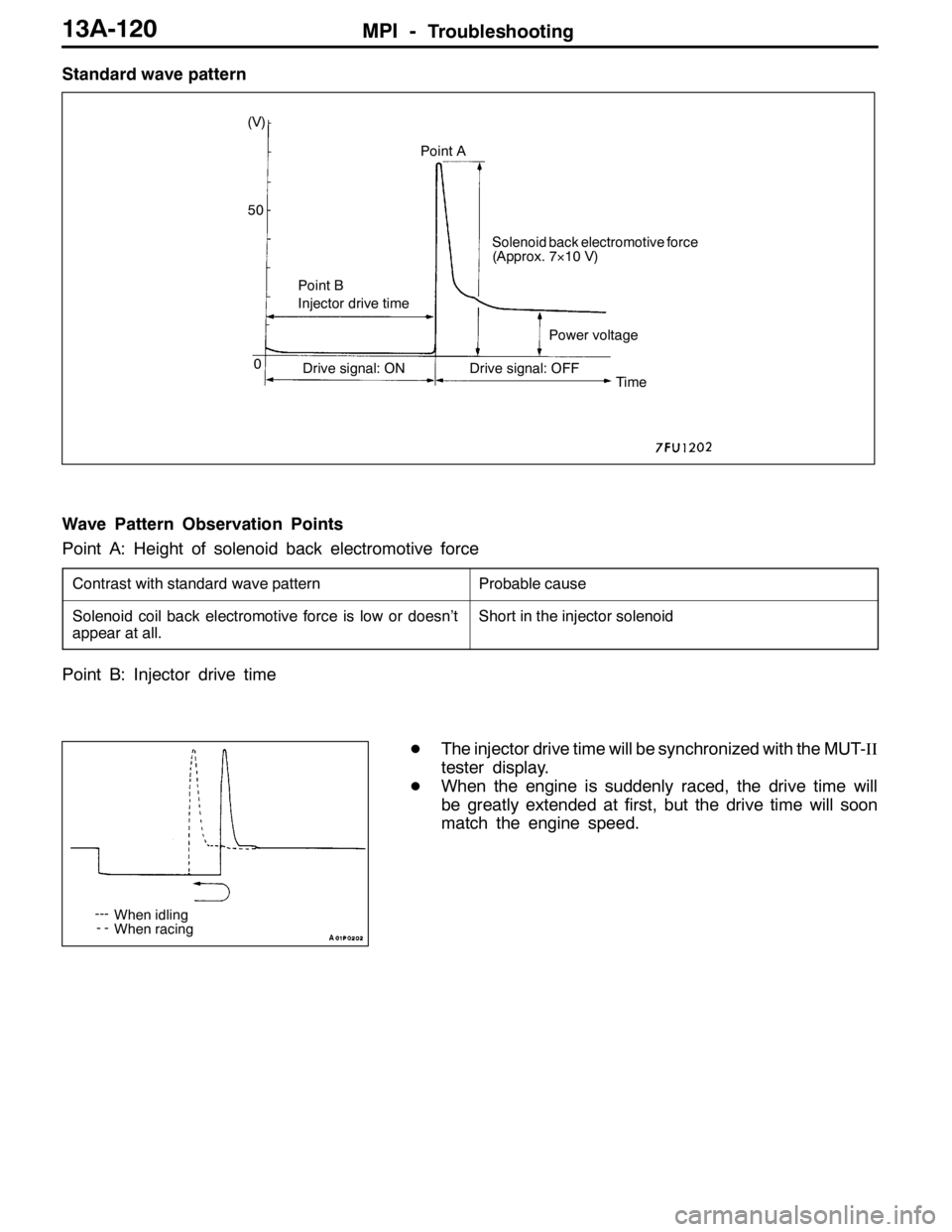

Standard wave pattern

(V)

Point A

Point BSolenoid back electromotive force

(Approx. 7×10 V)

Injector drive time

Power voltage

Drive signal: ON Drive signal: OFF

Time 50

0

Wave Pattern Observation Points

Point A: Height of solenoid back electromotive force

Contrast with standard wave patternProbable cause

Solenoid coil back electromotive force is low or doesn’t

appear at all.Short in the injector solenoid

Point B: Injector drive time

DThe injector drive time will be synchronized with the MUT-II

tester display.

DWhen the engine is suddenly raced, the drive time will

be greatly extended at first, but the drive time will soon

match the engine speed.

When idling

When racing ---

--