oil level MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 100 of 1449

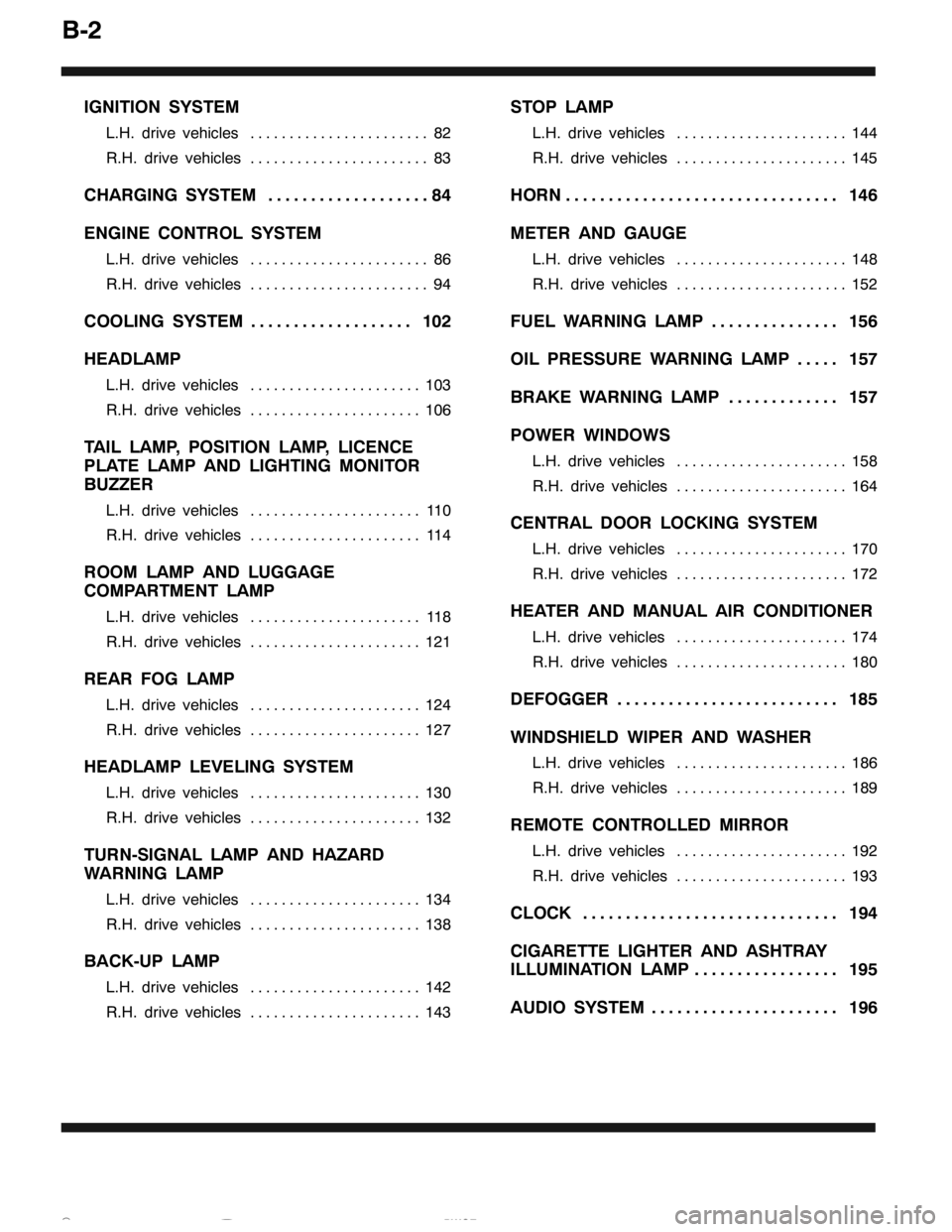

B-2

S

PWGEE

IGNITION SYSTEM

L.H. drive vehicles 82.......................

R.H. drive vehicles 83.......................

CHARGING SYSTEM 84...................

ENGINE CONTROL SYSTEM

L.H. drive vehicles 86.......................

R.H. drive vehicles 94.......................

COOLING SYSTEM 102...................

HEADLAMP

L.H. drive vehicles 103......................

R.H. drive vehicles 106......................

TAIL LAMP, POSITION LAMP, LICENCE

PLATE LAMP AND LIGHTING MONITOR

BUZZER

L.H. drive vehicles 110......................

R.H. drive vehicles 114......................

ROOM LAMP AND LUGGAGE

COMPARTMENT LAMP

L.H. drive vehicles 118......................

R.H. drive vehicles 121......................

REAR FOG LAMP

L.H. drive vehicles 124......................

R.H. drive vehicles 127......................

HEADLAMP LEVELING SYSTEM

L.H. drive vehicles 130......................

R.H. drive vehicles 132......................

TURN-SIGNAL LAMP AND HAZARD

WARNING LAMP

L.H. drive vehicles 134......................

R.H. drive vehicles 138......................

BACK-UP LAMP

L.H. drive vehicles 142......................

R.H. drive vehicles 143......................

STOP LAMP

L.H. drive vehicles 144......................

R.H. drive vehicles 145......................

HORN 146................................

METER AND GAUGE

L.H. drive vehicles 148......................

R.H. drive vehicles 152......................

FUEL WARNING LAMP 156...............

OIL PRESSURE WARNING LAMP 157.....

BRAKE WARNING LAMP 157.............

POWER WINDOWS

L.H. drive vehicles 158......................

R.H. drive vehicles 164......................

CENTRAL DOOR LOCKING SYSTEM

L.H. drive vehicles 170......................

R.H. drive vehicles 172......................

HEATER AND MANUAL AIR CONDITIONER

L.H. drive vehicles 174......................

R.H. drive vehicles 180......................

DEFOGGER 185..........................

WINDSHIELD WIPER AND WASHER

L.H. drive vehicles 186......................

R.H. drive vehicles 189......................

REMOTE CONTROLLED MIRROR

L.H. drive vehicles 192......................

R.H. drive vehicles 193......................

CLOCK 194..............................

CIGARETTE LIGHTER AND ASHTRAY

ILLUMINATION LAMP 195.................

AUDIO SYSTEM 196......................

Page 112 of 1449

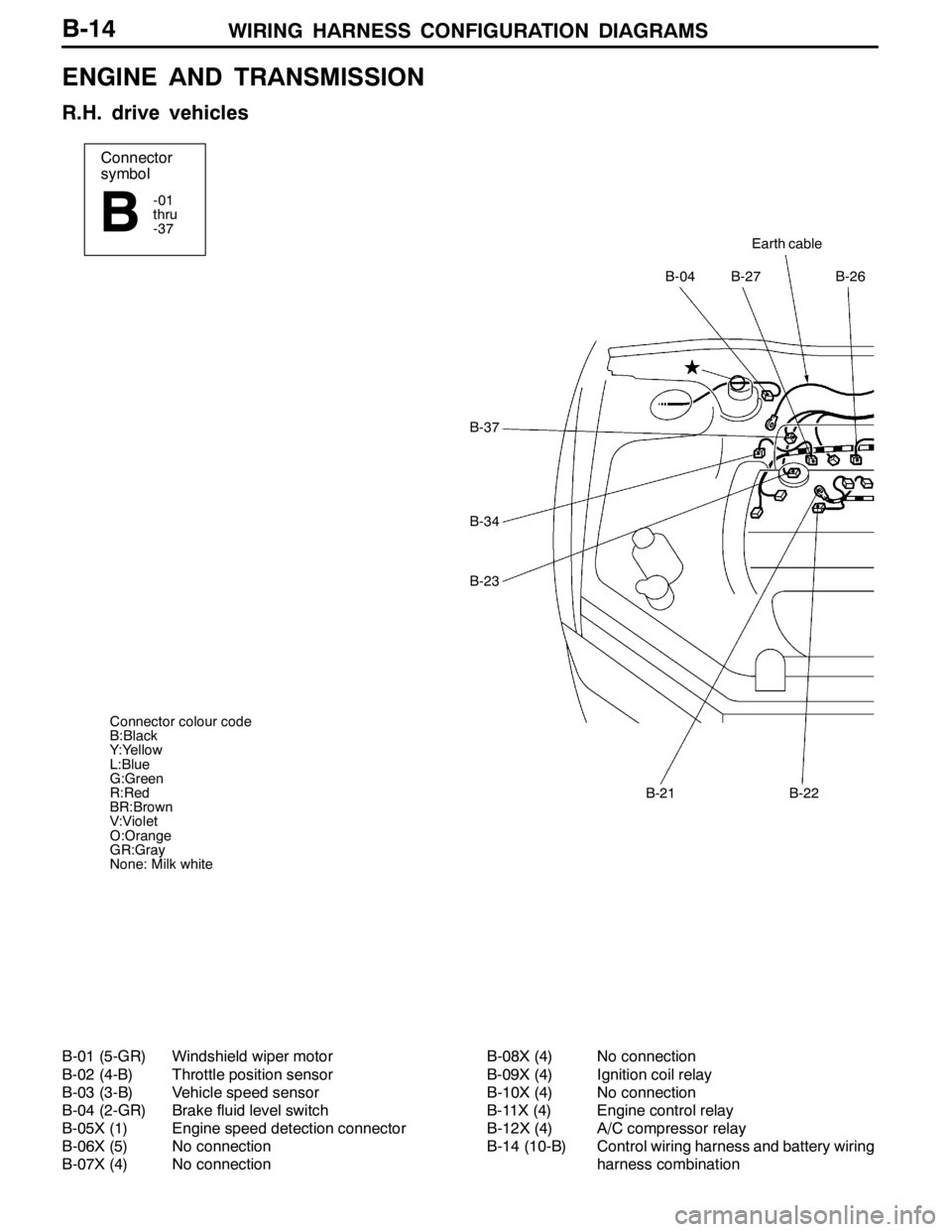

WIRING HARNESS CONFIGURATION DIAGRAMS

Connector

symbol

-01

thru

-37

B

Earth cable

B-27B-26B-04

B-22B-21

B-37

B-34

B-23

Connector colour code

B:Black

Y:Yellow

L:Blue

G:Green

R:Red

BR:Brown

V:Violet

O:Orange

GR:Gray

None: Milk white

B-14

ENGINE AND TRANSMISSION

R.H. drive vehicles

B-01 (5-GR) Windshield wiper motor

B-02 (4-B) Throttle position sensor

B-03 (3-B) Vehicle speed sensor

B-04 (2-GR) Brake fluid level switch

B-05X (1) Engine speed detection connector

B-06X (5) No connection

B-07X (4) No connectionB-08X (4) No connection

B-09X (4) Ignition coil relay

B-10X (4) No connection

B-11X (4) Engine control relay

B-12X (4) A/C compressor relay

B-14 (10-B) Control wiring harness and battery wiring

harness combination

Page 253 of 1449

CIRCUIT DIAGRAMSB-155

FUEL WARNING LAMP (See P.B-156.)

OIL PRESSURE WARNING LAMP (See P.B-157.)

BRAKE WARNING LAMP (See P.B-157.)

OPERATION

DWhen the ignition switch is at the “ON” position,

the fuel gauge unit resistance is small when

the fuel level is high, and the fuel gauge unit

resistance is large when the fuel level is low.

When this resistance rises above a specified

value, the fuel warning lamp illuminates to notify

the driver that the fuel level is low.

DWhen the lubrication system fails after engine

starting, resulting in the oil pressure failing to

build up, the oil pressure switch turns on

causing the oil pressure warning lamp to

illuminate.

DWhen the brake fluid level goes down below

a predetermined level with the ignition switch

in the “ON” position, the brake fluid level switch

is activated or the parking brake switch is turned

on, causing the brake warning lamp to

illuminate.TROUBLESHOOTING HINTS

1. No warning lamps illuminate.

DCheck multi-purpose fuse No.(2).

2. Some warning lamps do not illuminate.

DCheck lamp valve.

DCheck the switches and the gauge unit.

Page 358 of 1449

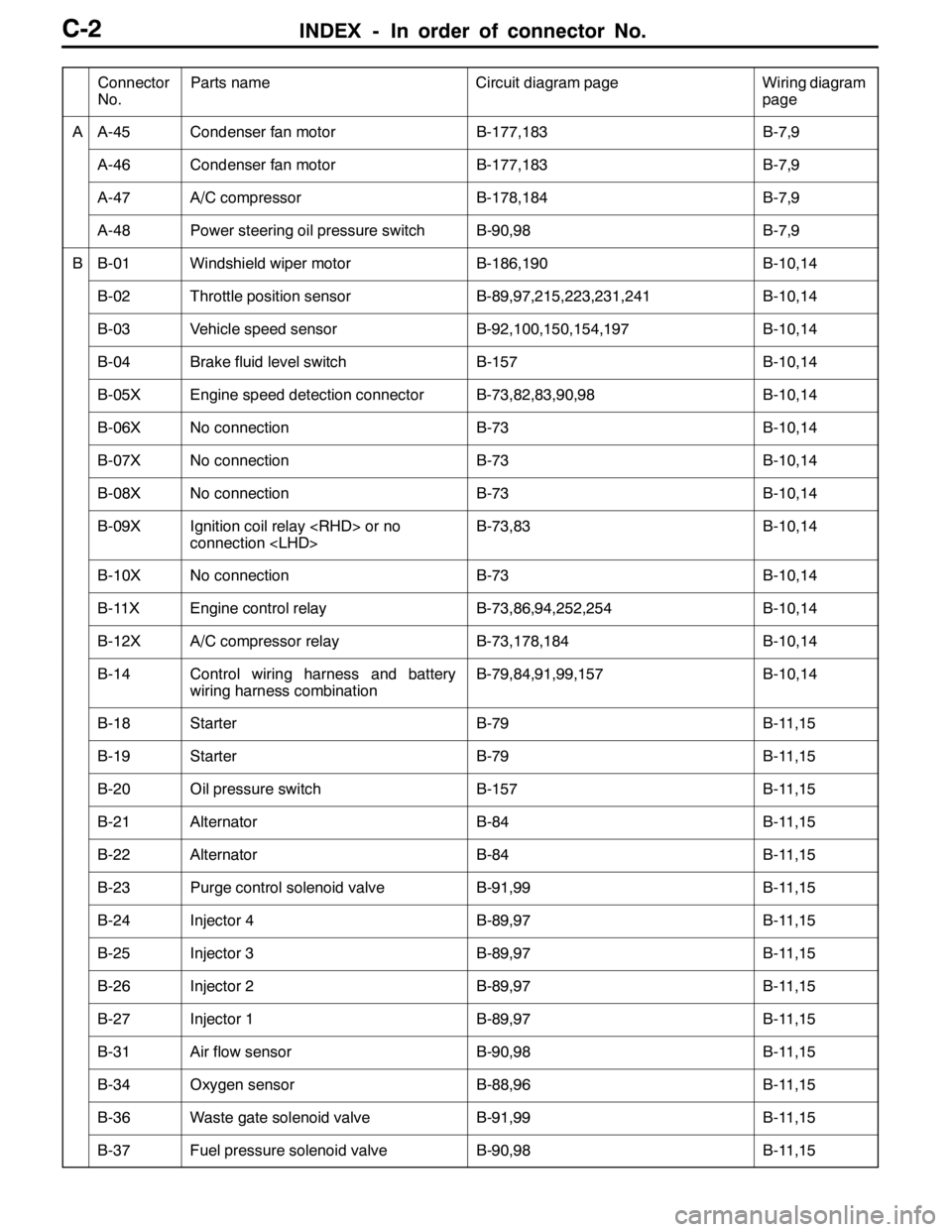

INDEX - In order of connector No.C-2

Wiring diagram

page Circuit diagram page Parts name Connector

No.

AA-45Condenser fan motorB-177,183B-7,9

A-46Condenser fan motorB-177,183B-7,9

A-47A/C compressorB-178,184B-7,9

A-48Power steering oil pressure switchB-90,98B-7,9

BB-01Windshield wiper motorB-186,190B-10,14

B-02Throttle position sensorB-89,97,215,223,231,241B-10,14

B-03Vehicle speed sensorB-92,100,150,154,197B-10,14

B-04Brake fluid level switchB-157B-10,14

B-05XEngine speed detection connectorB-73,82,83,90,98B-10,14

B-06XNo connectionB-73B-10,14

B-07XNo connectionB-73B-10,14

B-08XNo connectionB-73B-10,14

B-09XIgnition coil relay

connection

B-10XNo connectionB-73B-10,14

B-11XEngine control relayB-73,86,94,252,254B-10,14

B-12XA/C compressor relayB-73,178,184B-10,14

B-14Control wiring harness and battery

wiring harness combinationB-79,84,91,99,157B-10,14

B-18StarterB-79B-11,15

B-19StarterB-79B-11,15

B-20Oil pressure switchB-157B-11,15

B-21AlternatorB-84B-11,15

B-22AlternatorB-84B-11,15

B-23Purge control solenoid valveB-91,99B-11,15

B-24Injector 4B-89,97B-11,15

B-25Injector 3B-89,97B-11,15

B-26Injector 2B-89,97B-11,15

B-27Injector 1B-89,97B-11,15

B-31Air flow sensorB-90,98B-11,15

B-34Oxygen sensorB-88,96B-11,15

B-36Waste gate solenoid valveB-91,99B-11,15

B-37Fuel pressure solenoid valveB-90,98B-11,15

Page 371 of 1449

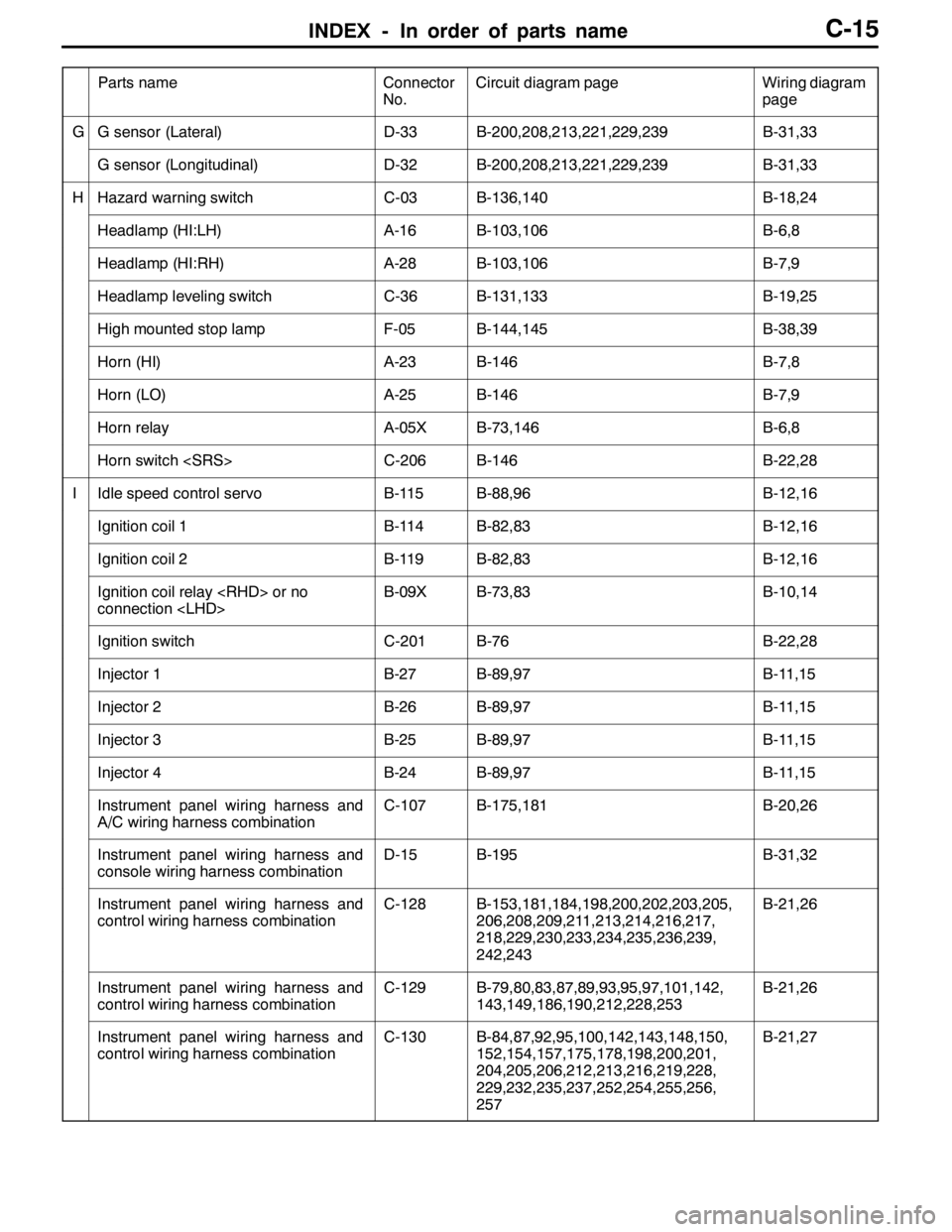

INDEX - In order of parts nameC-15

Wiring diagram

page Circuit diagram page Connector

No. Parts name

GG sensor (Lateral)D-33B-200,208,213,221,229,239B-31,33

G sensor (Longitudinal)D-32B-200,208,213,221,229,239B-31,33

HHazard warning switchC-03B-136,140B-18,24

Headlamp (HI:LH)A-16B-103,106B-6,8

Headlamp (HI:RH)A-28B-103,106B-7,9

Headlamp leveling switchC-36B-131,133B-19,25

High mounted stop lampF-05B-144,145B-38,39

Horn (HI)A-23B-146B-7,8

Horn (LO)A-25B-146B-7,9

Horn relayA-05XB-73,146B-6,8

Horn switch

IIdle speed control servoB-115B-88,96B-12,16

Ignition coil 1B-114B-82,83B-12,16

Ignition coil 2B-119B-82,83B-12,16

Ignition coil relay

connection

Ignition switchC-201B-76B-22,28

Injector 1B-27B-89,97B-11,15

Injector 2B-26B-89,97B-11,15

Injector 3B-25B-89,97B-11,15

Injector 4B-24B-89,97B-11,15

Instrument panel wiring harness and

A/C wiring harness combinationC-107B-175,181B-20,26

Instrument panel wiring harness and

console wiring harness combinationD-15B-195B-31,32

Instrument panel wiring harness and

control wiring harness combinationC-128B-153,181,184,198,200,202,203,205,

206,208,209,211,213,214,216,217,

218,229,230,233,234,235,236,239,

242,243B-21,26

Instrument panel wiring harness and

control wiring harness combinationC-129B-79,80,83,87,89,93,95,97,101,142,

143,149,186,190,212,228,253B-21,26

Instrument panel wiring harness and

control wiring harness combinationC-130B-84,87,92,95,100,142,143,148,150,

152,154,157,175,178,198,200,201,

204,205,206,212,213,216,219,228,

229,232,235,237,252,254,255,256,

257B-21,27

Page 419 of 1449

ENGINE -On-vehicle Service11A-13

(2) If there is a problem with the lash adjusters, the noise

will almost never disappear, even if the engine has

been run at idle to let it warm up.

The only case where the noise might disappear is

if the oil in the engine has not been looked after

properly and oil sludge has caused the lash adjusters

to stick.

1. Start the engine.

2. Check that the noise occurs immediately after the engine

is started, and that the noise changes in accordance

with changes in the engine speed.

If the noise does not occur immediately after the engine

is started, or if it does not change in accordance with

the engine speed, the problem is not being caused by

the lash adjusters, so check for some other cause of

the problem. Moreover, if the noise does not change in

accordance with the engine speed, the cause of the

problem is probably not with the engine. (In these cases,

the lash adjusters are normal.)

3. While the engine is idling, check that the noise level does

not change when the engine load is varied.

If the noise level changes, the cause of the noise is

probably parts striking because of worn crankshaft

bearings or connecting rod bearings. (In such cases, the

lash adjusters are normal.)

4. After the engine has warmed up, run it at idle and check

if any noise can be heard.

If the noise has become smaller or disappeared, oil sludge

could make the lash adjusters stick. Clean the lash

adjusters. (Refer to the Engine Workshop Manual.) If not

improved, go to step 5.

5. Bleed air from the lash adjusters.

6. If the noise has not disappeared even after the air

bleeding, clean the lash adjusters.

(Refer to GROUP 11B - Rocker Arms and Camshaft.)

NOTE

(1) If the vehicle is parked on a slope for a long period

of time, the amount of oil inside the lash adjuster

will decrease, and air may get into the high pressure

chamber when starting the engine.

(2) After parking the vehicle for long periods, the oil drains

out of the oil passage, and it takes time for the oil

to be supplied to the lash adjuster, so air can get

into the high pressure chamber.

(3) If either of the above situations occur, the abnormal

noise can be eliminated by bleeding the air from inside

the lash adjusters.

Page 420 of 1449

ENGINE -On-vehicle Service11A-14

1. Check the engine oil and replenish or replace the oil

if necessary.

NOTE

(1) If there is a only small amount of oil, air will be drawn

in through the oil screen and will get into the oil

passage.

(2) If the amount of oil is greater than normal, then the

oil will being mixed by the crankshaft and a large

amount of air may get mixed into the oil.

(3) If the oil is degenerated, air and oil will not separate

easily in oil, and the amount of air mixed into the

oil will increase.

(4) If the air which has been mixed in with the oil due

to any of the above reasons gets into the high pressure

chamber of the lash adjuster, the air inside the high

pressure chamber will be compressed when the valve

is open and the lash adjuster will over-compress,

resulting in abnormal noise when the valve closes.

This is the same effect as if the valve clearance is

adjusted to be too large by mistake. If the air inside

the lash adjusters is then released, the operation

of the lash adjusters will return to normal.

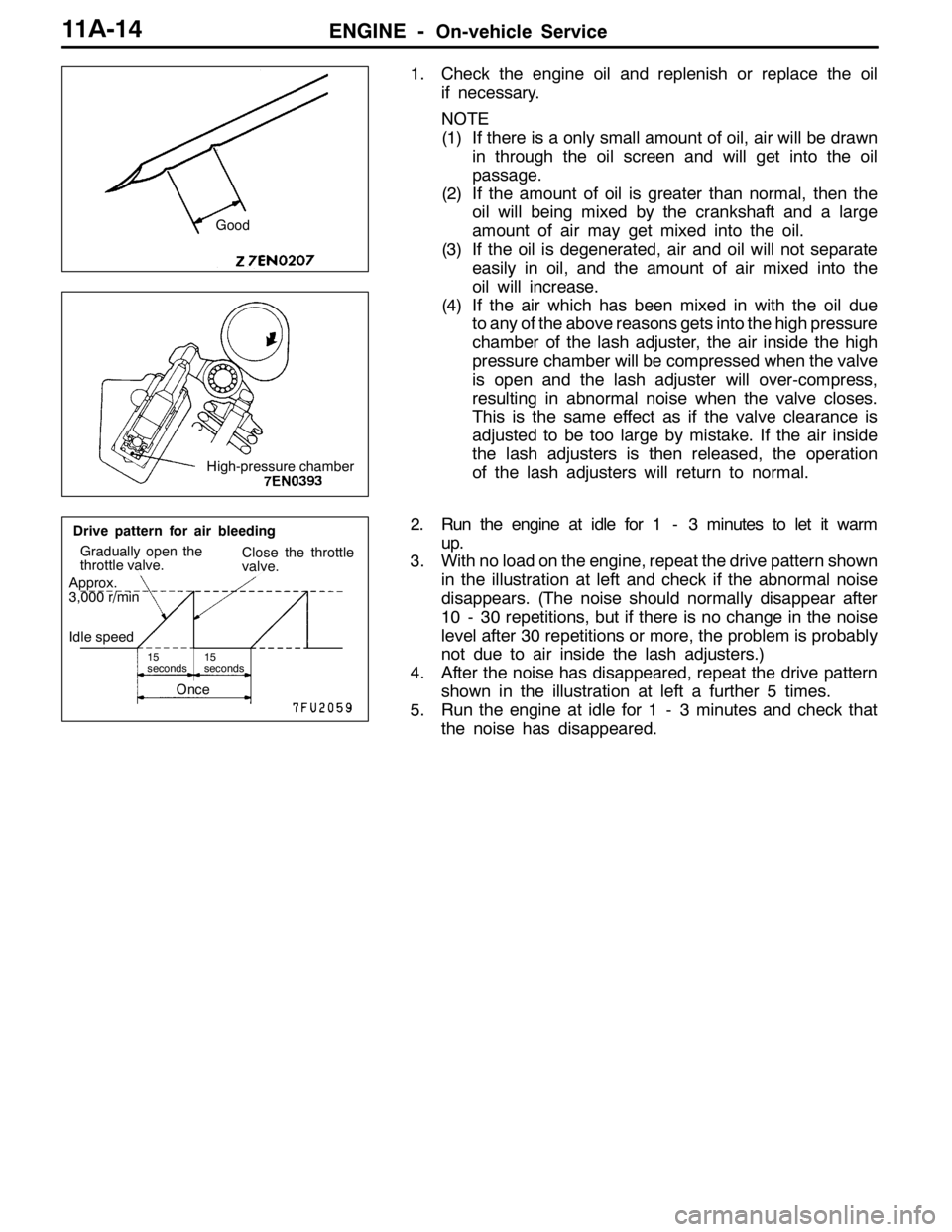

2. Run the engine at idle for 1 - 3 minutes to let it warm

up.

3. With no load on the engine, repeat the drive pattern shown

in the illustration at left and check if the abnormal noise

disappears. (The noise should normally disappear after

10 - 30 repetitions, but if there is no change in the noise

level after 30 repetitions or more, the problem is probably

not due to air inside the lash adjusters.)

4. After the noise has disappeared, repeat the drive pattern

shown in the illustration at left a further 5 times.

5. Run the engine at idle for 1 - 3 minutes and check that

the noise has disappeared.

Good

High-pressure chamber

Gradually open the

throttle valve.

Drive pattern for air bleeding

Close the throttle

valve.

Approx.

3,000 r/min

15

seconds15

seconds

Idle speed

Once

Page 435 of 1449

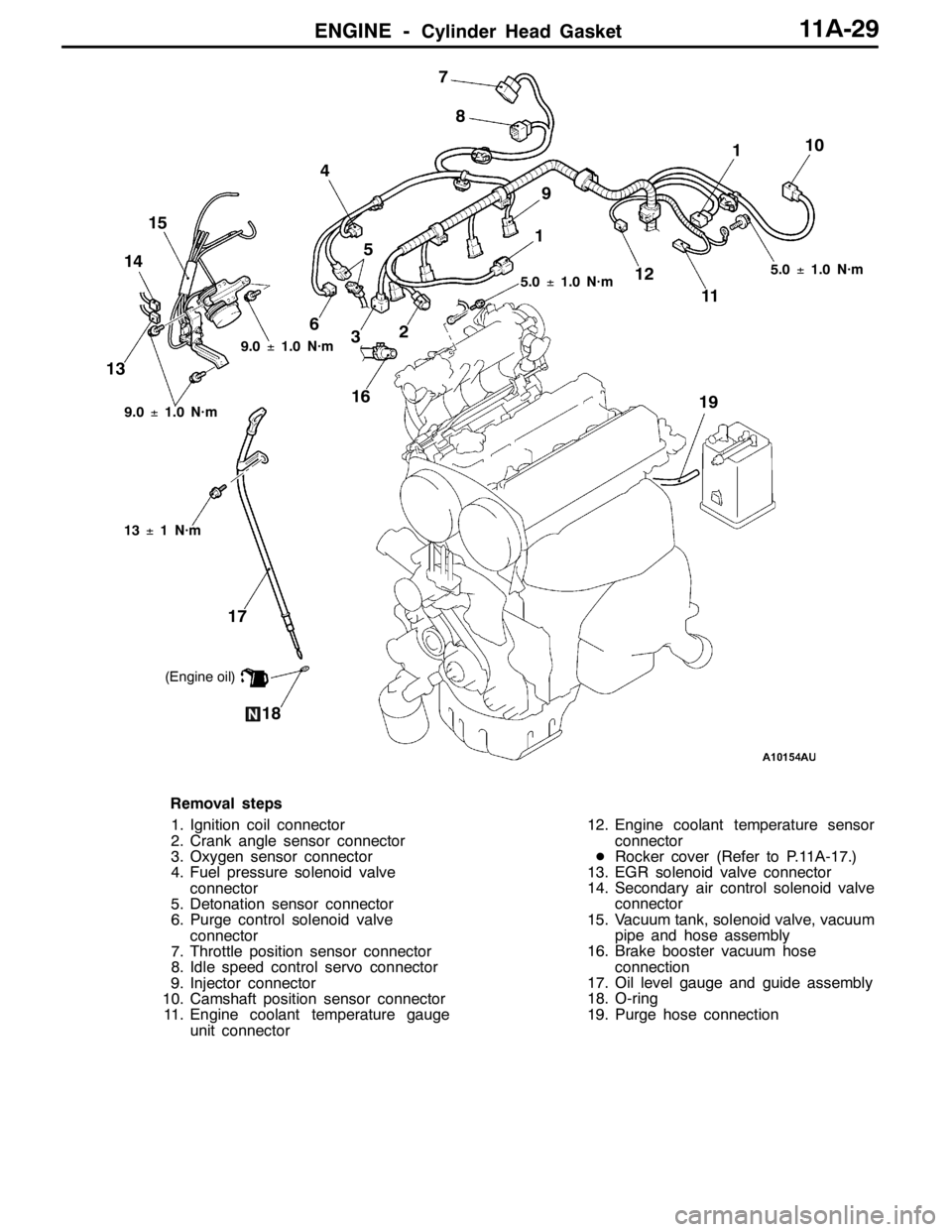

ENGINE -Cylinder Head Gasket11A-29

5.0±1.0 N·m

61

2

3 4

57

8

910

11 12

1314

13±1 N·m

15

16

17

5.0±1.0 N·m

1819

9.0±1.0 N·m

9.0±1.0 N·m

(Engine oil)

1

Removal steps

1. Ignition coil connector

2. Crank angle sensor connector

3. Oxygen sensor connector

4. Fuel pressure solenoid valve

connector

5. Detonation sensor connector

6. Purge control solenoid valve

connector

7. Throttle position sensor connector

8. Idle speed control servo connector

9. Injector connector

10. Camshaft position sensor connector

11. Engine coolant temperature gauge

unit connector12. Engine coolant temperature sensor

connector

DRocker cover (Refer to P.11A-17.)

13. EGR solenoid valve connector

14. Secondary air control solenoid valve

connector

15. Vacuum tank, solenoid valve, vacuum

pipe and hose assembly

16. Brake booster vacuum hose

connection

17. Oil level gauge and guide assembly

18. O-ring

19. Purge hose connection

Page 459 of 1449

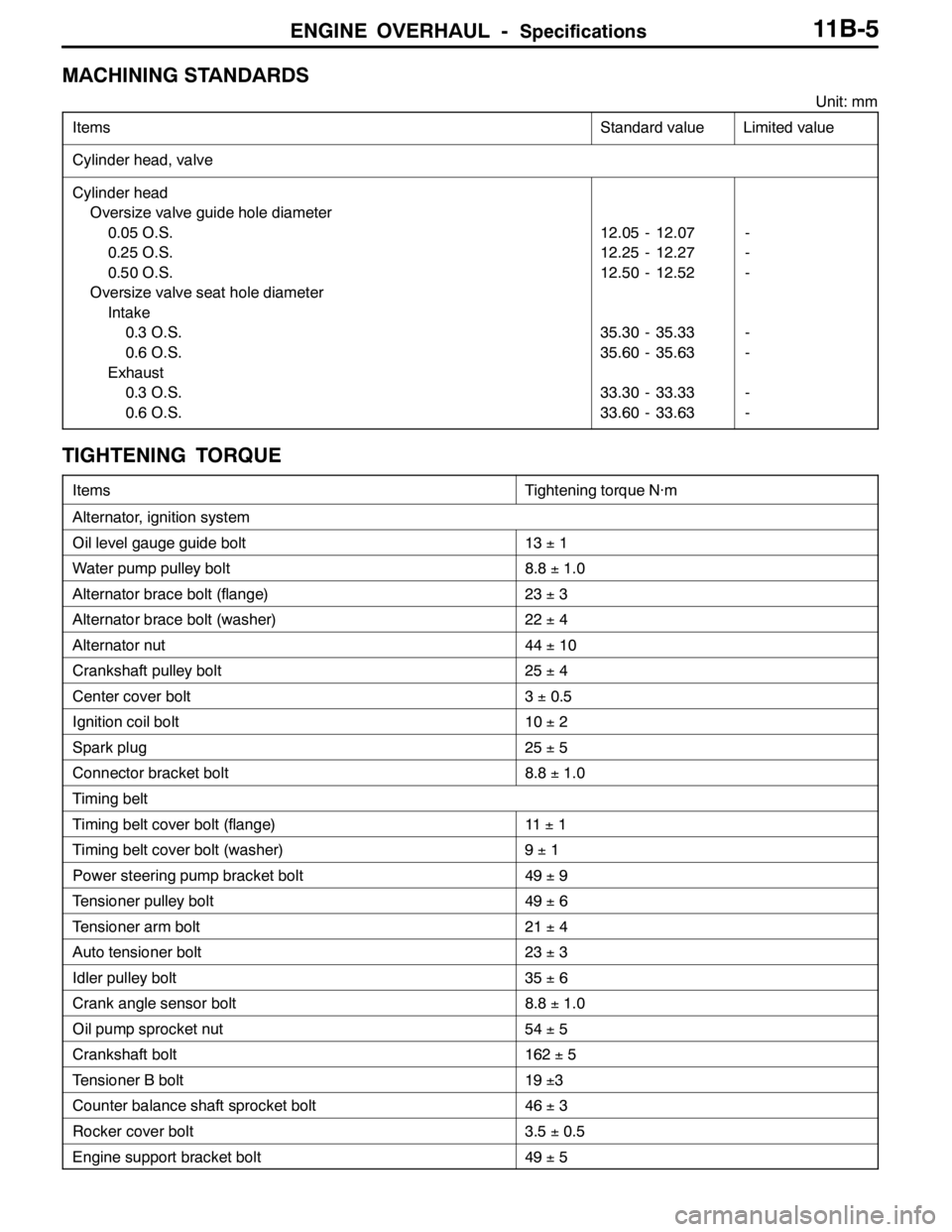

ENGINE OVERHAUL -Specifications11B-5

MACHINING STANDARDS

Unit: mm

Items

Standard valueLimited value

Cylinder head, valve

Cylinder head

Oversize valve guide hole diameter

0.05 O.S.

0.25 O.S.

0.50 O.S.

Oversize valve seat hole diameter

Intake

0.3 O.S.

0.6 O.S.

Exhaust

0.3 O.S.

0.6 O.S.

12.05 - 12.07

12.25 - 12.27

12.50 - 12.52

35.30 - 35.33

35.60 - 35.63

33.30 - 33.33

33.60 - 33.63-

-

-

-

-

-

-

TIGHTENING TORQUE

ItemsTightening torque N·m

Alternator, ignition system

Oil level gauge guide bolt13±1

Water pump pulley bolt8.8±1.0

Alternator brace bolt (flange)23±3

Alternator brace bolt (washer)22±4

Alternator nut44±10

Crankshaft pulley bolt25±4

Center cover bolt3±0.5

Ignition coil bolt10±2

Spark plug25±5

Connector bracket bolt8.8±1.0

Timing belt

Timing belt cover bolt (flange)11±1

Timing belt cover bolt (washer)9±1

Power steering pump bracket bolt49±9

Tensioner pulley bolt49±6

Tensioner arm bolt21±4

Auto tensioner bolt23±3

Idler pulley bolt35±6

Crank angle sensor bolt8.8±1.0

Oil pump sprocket nut54±5

Crankshaft bolt162±5

Tensioner B bolt19±3

Counter balance shaft sprocket bolt46±3

Rocker cover bolt3.5±0.5

Engine support bracket bolt49±5

Page 466 of 1449

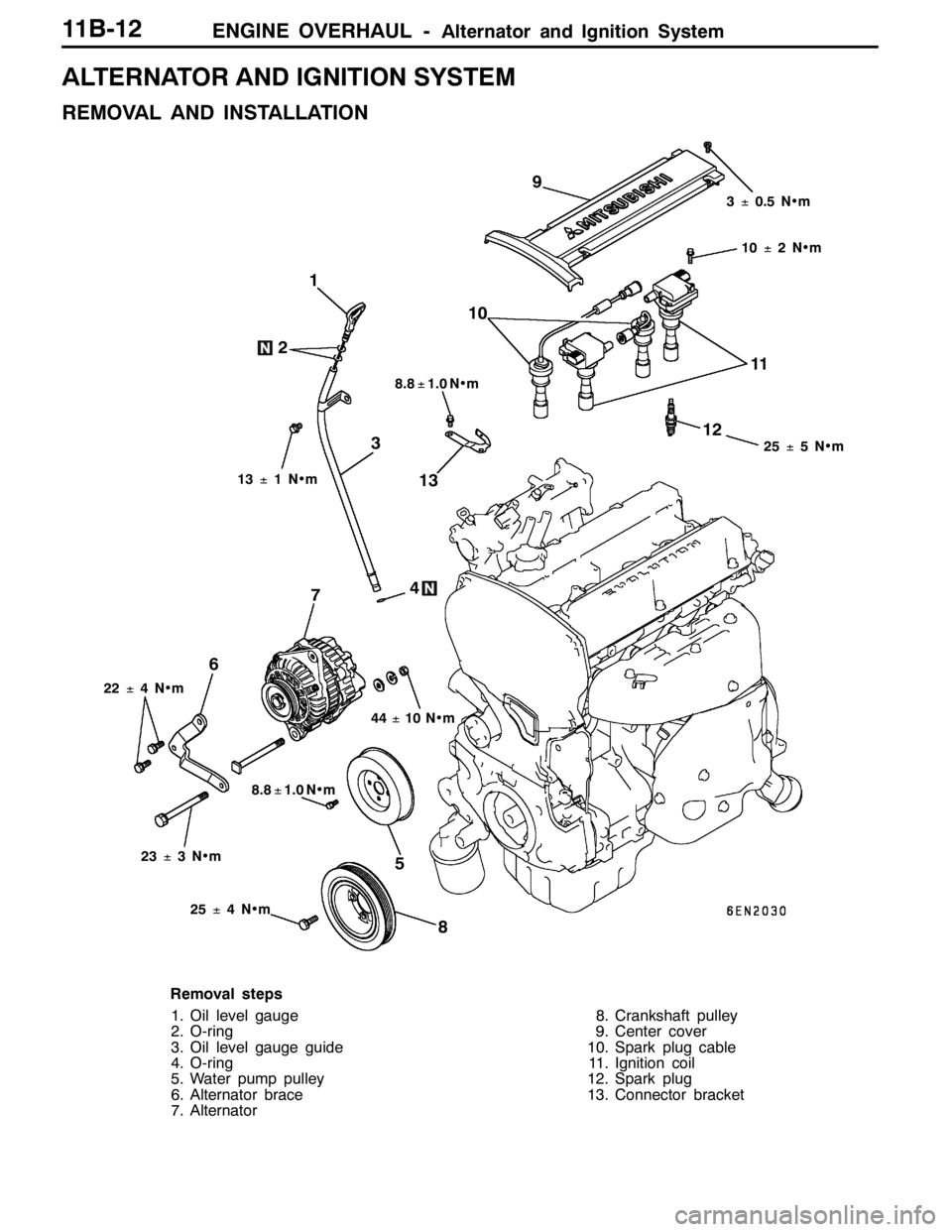

ENGINE OVERHAUL -Alternator and Ignition System11B-12

ALTERNATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION

1

13±1N•m

2

3

13

4

7

6

5

89

10

1211

22±4N•m8.8±1.0 N•m

25±5N•m 3±0.5 N•m

10±2N•m

8.8±1.0 N•m

23±3N•m

25±4N•m44±10 N•m

Removal steps

1. Oil level gauge

2. O-ring

3. Oil level gauge guide

4. O-ring

5. Water pump pulley

6. Alternator brace

7. Alternator8. Crankshaft pulley

9. Center cover

10. Spark plug cable

11. Ignition coil

12. Spark plug

13. Connector bracket