oil level MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 960 of 1449

REAR AXLE -Troubleshooting

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection

procedure No.Reference

page

Communication between MUT-IIand the whole system is not possible.1Refer to

GROUP22

Communication between MUT-IIand 4WD-ECU is not possible.2

GROUP22.

3 ACD mode indicator lamps do not light up when the ignition key is turned to “ON”

(engine stationary).3

3 ACD mode indicator lamps remain lit up after the engine has started.4

AYC is inoperative.

Unable to start or accelerate on slippery road surfaces.527B-14

Rear tires are noisy during low-speed cornering.

Vehicle skews.627B-15

Noise is produced from the torque transfer differential during turning.727B-15

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

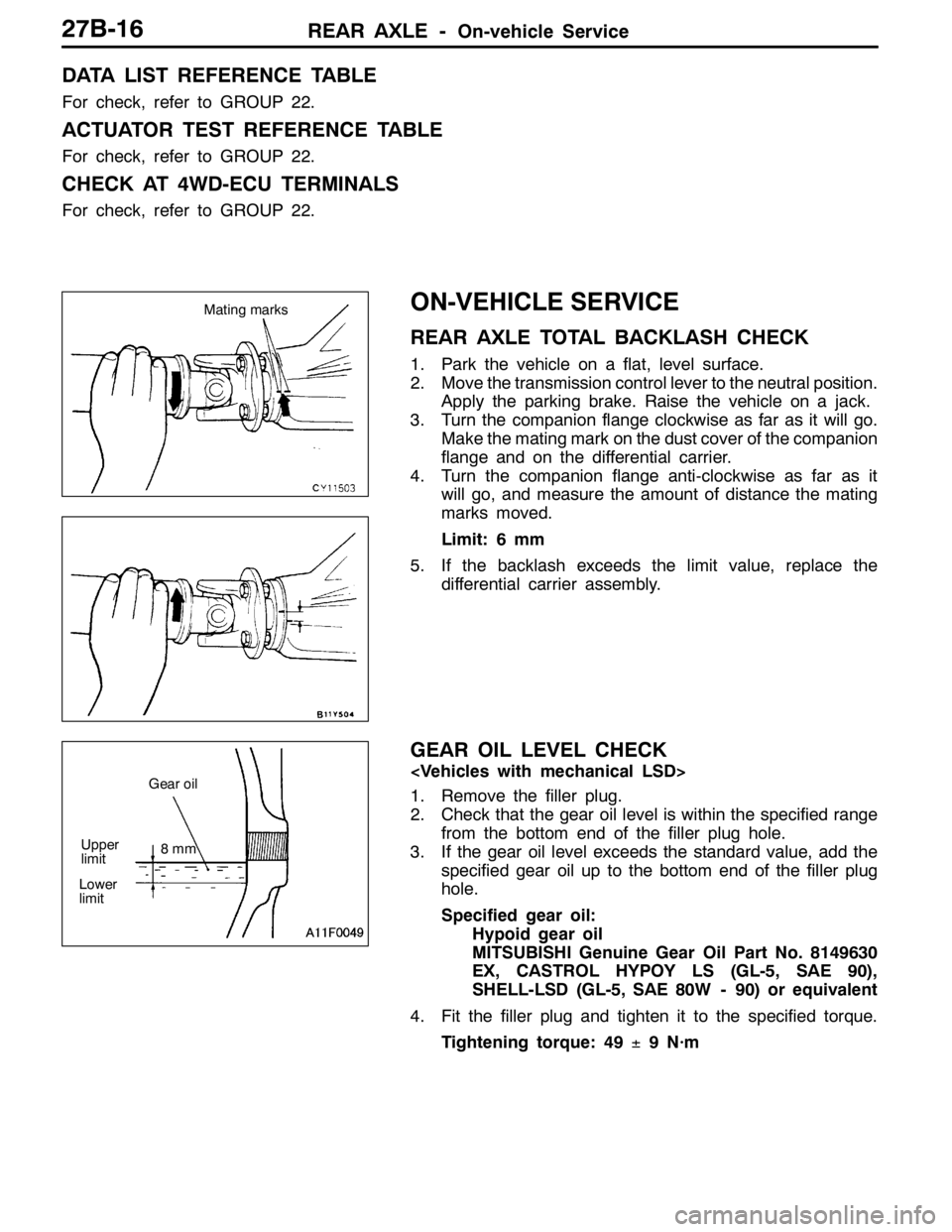

INSPECTION PROCEDURE 5

AYC is inoperative.

Unable to start or accelerate on slippery road surfaces.

Probable cause

The hydraulic oil level is probably low, there is an oil leak, the hydraulic unit is defective,

or the torque transfer differential is defective.DLow hydraulic oil level

DOil leak

DDefective hydraulic unit

DDefective torque transfer differential

NOTE

This symptom is limited only when the diagnosis code is correct.

NG

Replace the hydraulic unit. (Refer to

P.27B-61.)

NG

Add fluid. (Refer to P.27B-19.)

OKRepair

Check the trouble symptom.NO

Replace the torque transfer differential.

OK

Is foreign matter trapped in the hydrau-

lic line?YES

Repair

OK

Check the fluid level.

(Refer to P.27B-19.)Check the hydraulic pressure line for

leak.

OK

Add gear oil. (Refer to P.27B-16.)

OK

Check hydraulic pressure.

(Refer to P.27-21.)NGBleed the system of air.

(Refer to P.27-19.)

Check the gear oil level. (Refer to

P.27B-16.)NGCheck for oil leak.NG

Repair

Check the AYC for operation.

(Refer to P.27B-20.)Check the trouble symptom. OKOK

NGNormal

NGNG

Page 961 of 1449

REAR AXLE -Troubleshooting

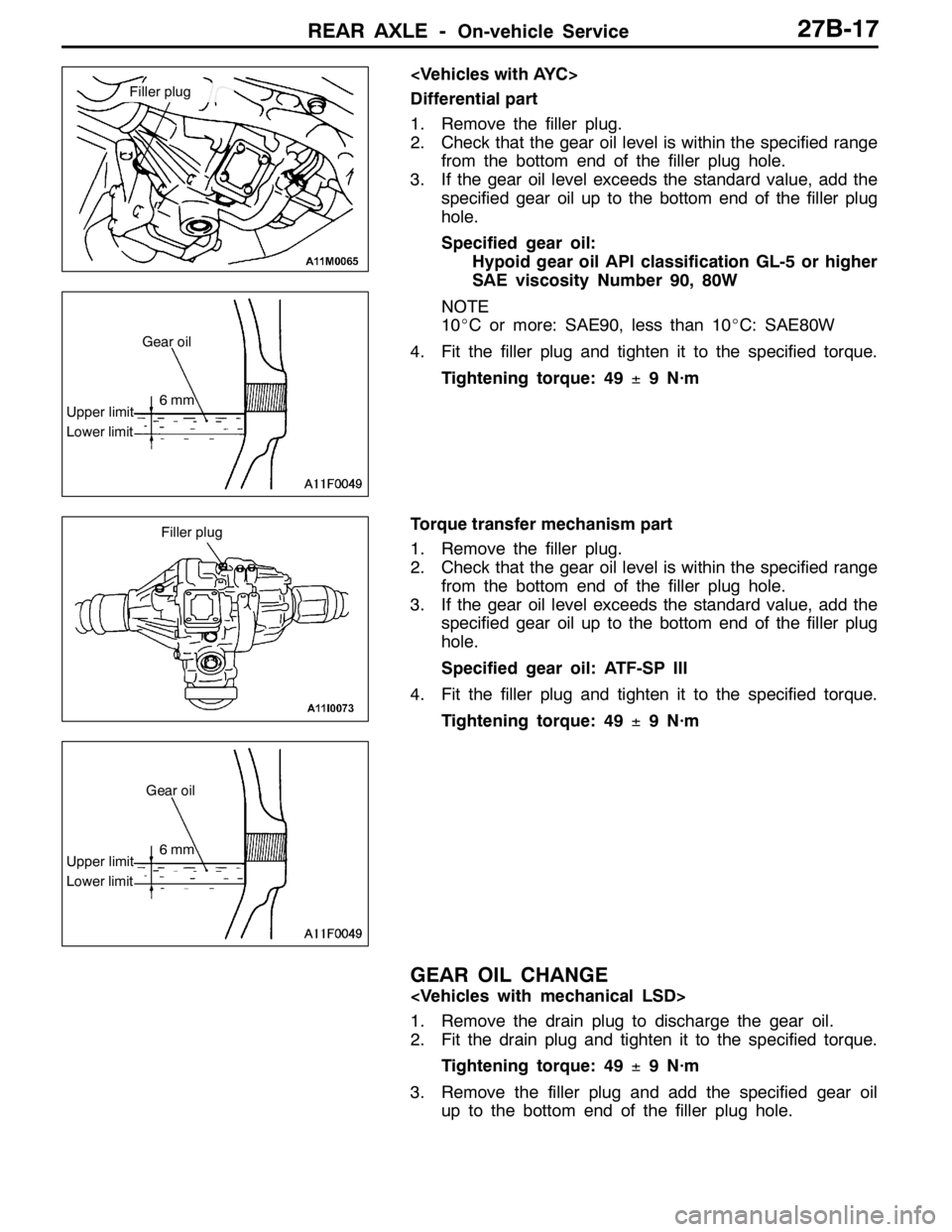

INSPECTION PROCEDURE 6

Rear tires are noisy during low-speed cornering.

Vehicle skews.

Probable cause

The hydraulic unit or torque transfer differential is probably defective.DDefective hydraulic unit

DDefective torque transfer differential

NOTE

This symptom is limited only when the diagnosis code is correct.

NG

Replace the hydraulic unit. (Refer to

P.27B-61.)

NG

Add fluid. (Refer to P.27B-19.)

OKRepair

Check the trouble symptom.NO

Replace the torque transfer differential.

OK

Is foreign matter trapped in the hydrau-

lic line?YES

Repair

Check the fluid level.

(Refer to P.27B-19.)Check the hydraulic pressure line for

leak.

OK

Check hydraulic pressure.

(Refer to P.27-21.)NGBleed the system of air.

(Refer to P.27-19.)

Check the AYC for operation.

(Refer to P.27B-20.)Check the trouble symptom. OK

NG

NGNG

INSPECTION PROCEDURE 7

Noise is produced from the torque transfer differential

during turning

Probable cause

The torque transfer differential is probably defective.DDefective torque transfer differential

NOTE

This symptom is limited only when the diagnosis code is correct.

NG

Replace the gear oil of the torque transfer differential. (Refer to

P.27B-17.)

Replace the gear oil of the torque transfer differential. (Refer to

P.27B-17.)Normal

Replace the gear oil of the torque transfer differential. (Refer to

P.27B-17.)

Replace the torque transfer differential.

Check the trouble symptom.

OKNG

NG

MUT-IIActuator test

DNo. 06 Clutch operation check (left side) 5 times

DNo. 07 Clutch operation check (right side) 5 times

DSteering wheel on neutral position

DDrive straight in 20 km/h or less

MUT-IIActuator test

DNo. 06 Clutch operation check (left side) 5 times

DNo. 07 Clutch operation check (right side) 5 times

DSteering wheel on neutral position

DDrive straight in 20 km/h or less

Check the trouble symptom.

Normal

Page 962 of 1449

REAR AXLE -On-vehicle Service27B-16

DATA LIST REFERENCE TABLE

For check, refer to GROUP 22.

ACTUATOR TEST REFERENCE TABLE

For check, refer to GROUP 22.

CHECK AT 4WD-ECU TERMINALS

For check, refer to GROUP 22.

ON-VEHICLE SERVICE

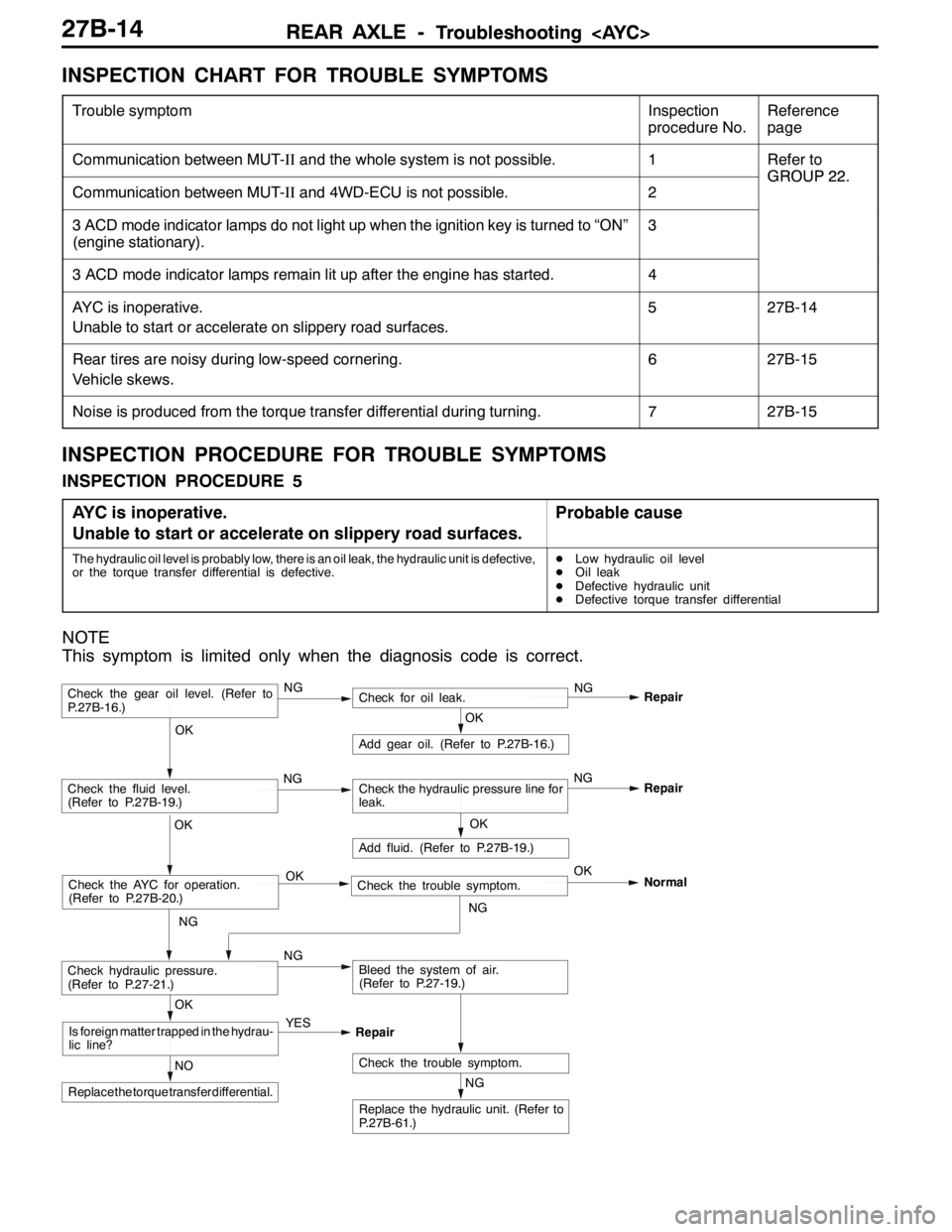

REAR AXLE TOTAL BACKLASH CHECK

1. Park the vehicle on a flat, level surface.

2. Move the transmission control lever to the neutral position.

Apply the parking brake. Raise the vehicle on a jack.

3. Turn the companion flange clockwise as far as it will go.

Make the mating mark on the dust cover of the companion

flange and on the differential carrier.

4. Turn the companion flange anti-clockwise as far as it

will go, and measure the amount of distance the mating

marks moved.

Limit: 6 mm

5. If the backlash exceeds the limit value, replace the

differential carrier assembly.

GEAR OIL LEVEL CHECK

1. Remove the filler plug.

2. Check that the gear oil level is within the specified range

from the bottom end of the filler plug hole.

3. If the gear oil level exceeds the standard value, add the

specified gear oil up to the bottom end of the filler plug

hole.

Specified gear oil:

Hypoid gear oil

MITSUBISHI Genuine Gear Oil Part No. 8149630

EX, CASTROL HYPOY LS (GL-5, SAE 90),

SHELL-LSD (GL-5, SAE 80W - 90) or equivalent

4. Fit the filler plug and tighten it to the specified torque.

Tightening torque: 49±9 N·m

Mating marks

Upper

limit

Lower

limit

Gear oil

8mm

Page 963 of 1449

REAR AXLE -On-vehicle Service27B-17

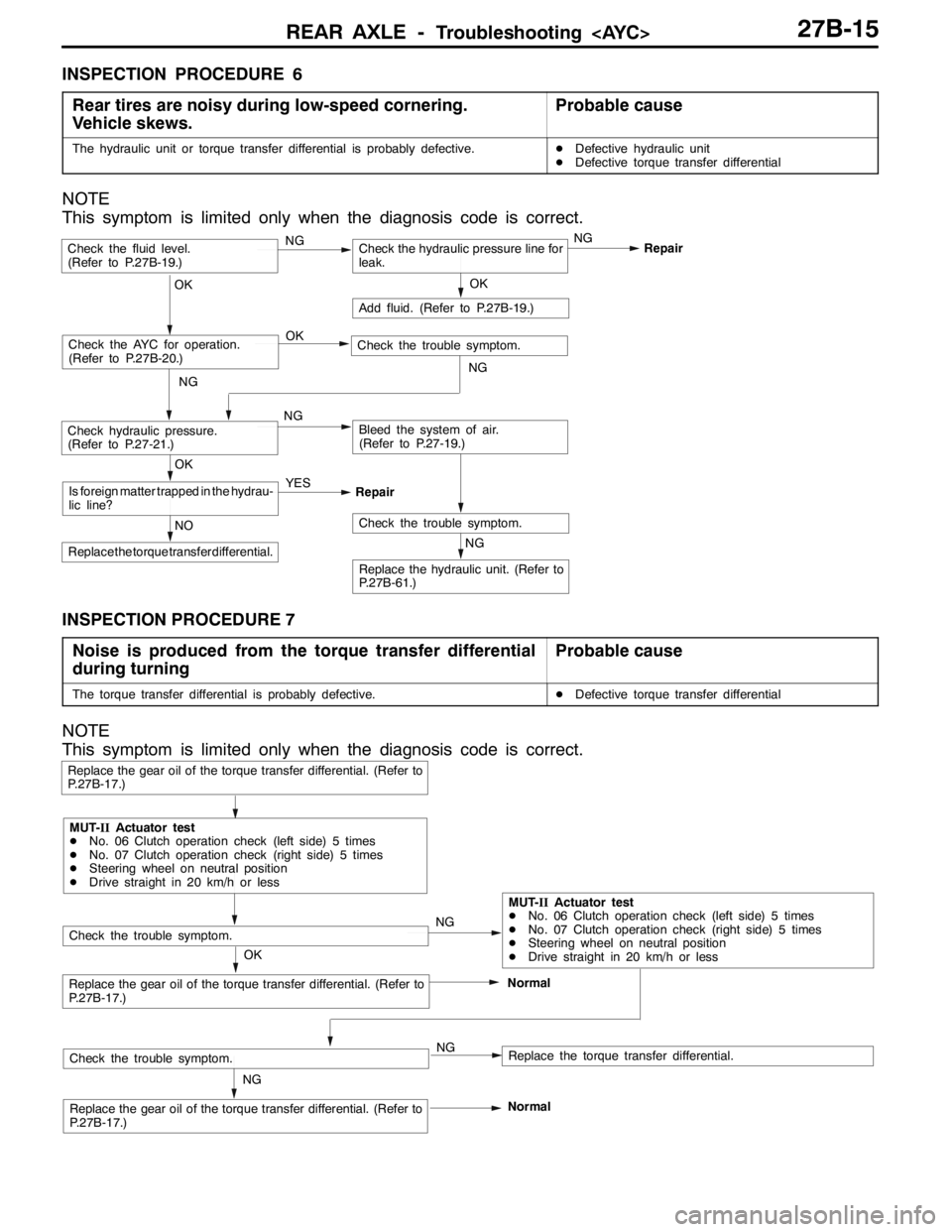

Differential part

1. Remove the filler plug.

2. Check that the gear oil level is within the specified range

from the bottom end of the filler plug hole.

3. If the gear oil level exceeds the standard value, add the

specified gear oil up to the bottom end of the filler plug

hole.

Specified gear oil:

Hypoid gear oil API classification GL-5 or higher

SAE viscosity Number 90, 80W

NOTE

10_C or more: SAE90, less than 10_C: SAE80W

4. Fit the filler plug and tighten it to the specified torque.

Tightening torque: 49±9 N·m

Torque transfer mechanism part

1. Remove the filler plug.

2. Check that the gear oil level is within the specified range

from the bottom end of the filler plug hole.

3. If the gear oil level exceeds the standard value, add the

specified gear oil up to the bottom end of the filler plug

hole.

Specified gear oil: ATF-SP III

4. Fit the filler plug and tighten it to the specified torque.

Tightening torque: 49±9 N·m

GEAR OIL CHANGE

1. Remove the drain plug to discharge the gear oil.

2. Fit the drain plug and tighten it to the specified torque.

Tightening torque: 49±9 N·m

3. Remove the filler plug and add the specified gear oil

up to the bottom end of the filler plug hole.

Filler plug

Upper limit

Lower limitGear oil

6mm

Filler plug

Upper limit

Lower limitGear oil

6mm

Page 965 of 1449

REAR AXLE -On-vehicle Service27B-19

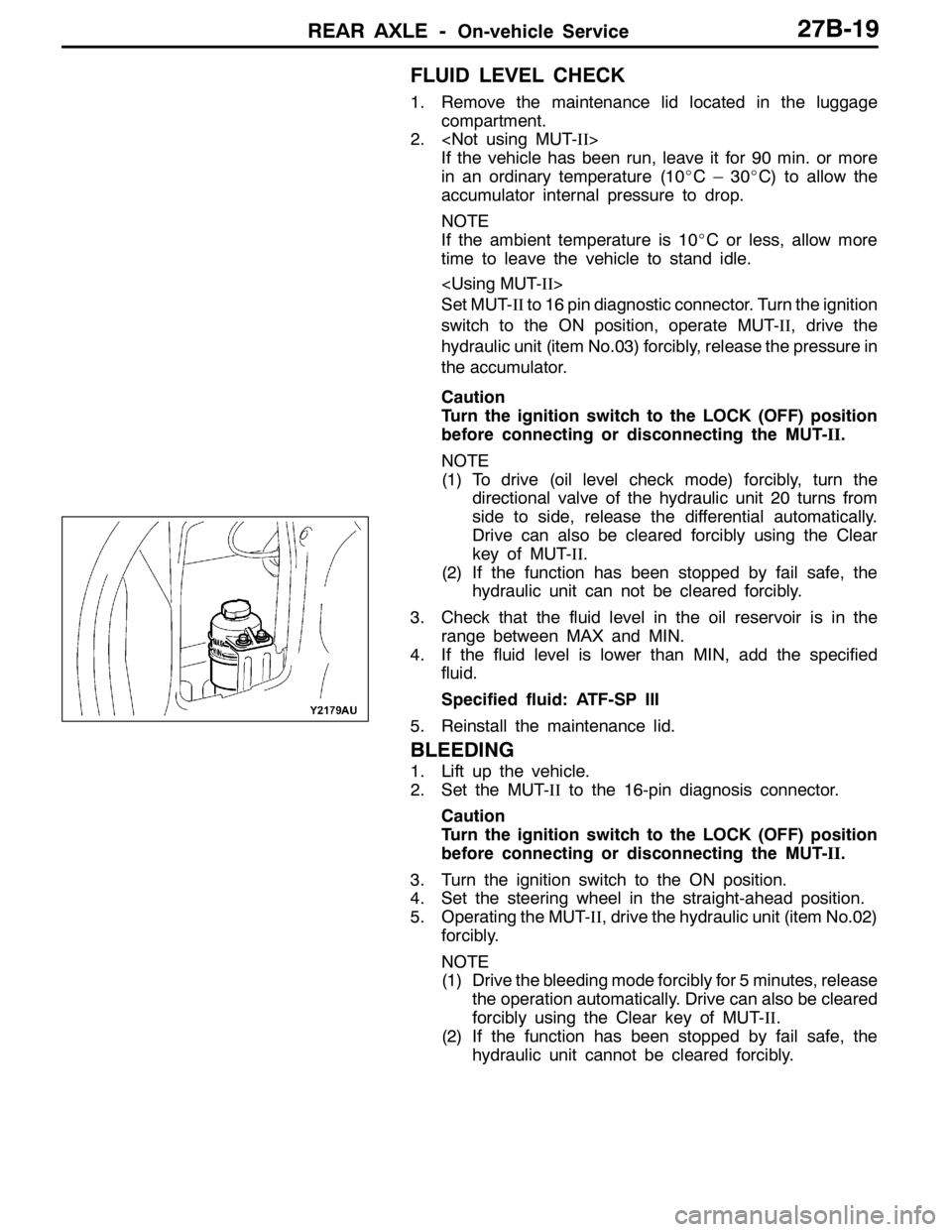

FLUID LEVEL CHECK

1. Remove the maintenance lid located in the luggage

compartment.

2.

If the vehicle has been run, leave it for 90 min. or more

in an ordinary temperature (10_C–30_C) to allow the

accumulator internal pressure to drop.

NOTE

If the ambient temperature is 10_C or less, allow more

time to leave the vehicle to stand idle.

Set MUT-IIto 16 pin diagnostic connector. Turn the ignition

switch to the ON position, operate MUT-II, drive the

hydraulic unit (item No.03) forcibly, release the pressure in

the accumulator.

Caution

Turn the ignition switch to the LOCK (OFF) position

before connecting or disconnecting the MUT-II.

NOTE

(1) To drive (oil level check mode) forcibly, turn the

directional valve of the hydraulic unit 20 turns from

side to side, release the differential automatically.

Drive can also be cleared forcibly using the Clear

key of MUT-II.

(2) If the function has been stopped by fail safe, the

hydraulic unit can not be cleared forcibly.

3. Check that the fluid level in the oil reservoir is in the

range between MAX and MIN.

4. If the fluid level is lower than MIN, add the specified

fluid.

Specified fluid: ATF-SP III

5. Reinstall the maintenance lid.

BLEEDING

1. Lift up the vehicle.

2. Set the MUT-IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the LOCK (OFF) position

before connecting or disconnecting the MUT-II.

3. Turn the ignition switch to the ON position.

4. Set the steering wheel in the straight-ahead position.

5. Operating the MUT-II, drive the hydraulic unit (item No.02)

forcibly.

NOTE

(1) Drive the bleeding mode forcibly for 5 minutes, release

the operation automatically. Drive can also be cleared

forcibly using the Clear key of MUT-II.

(2) If the function has been stopped by fail safe, the

hydraulic unit cannot be cleared forcibly.

Page 966 of 1449

REAR AXLE -On-vehicle Service27B-20

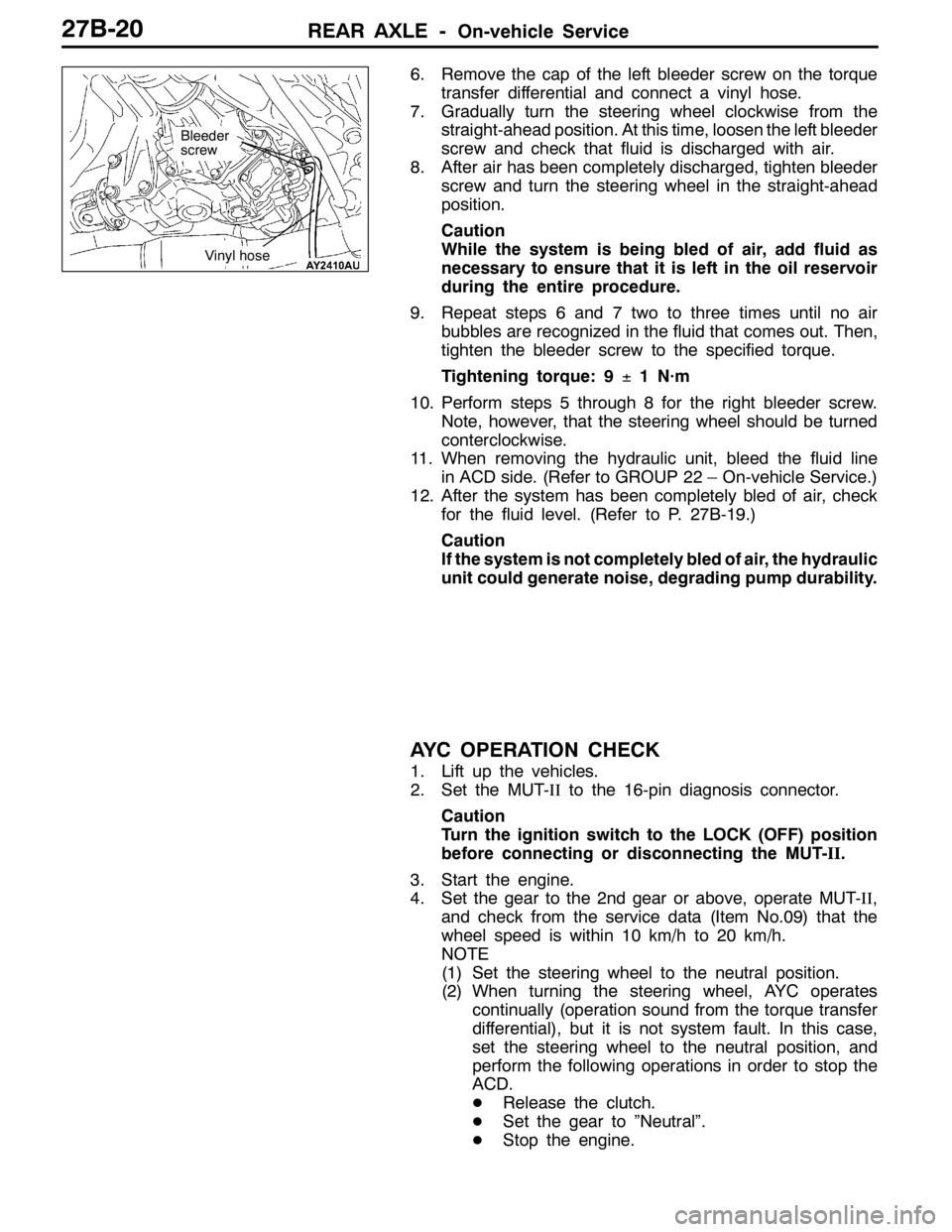

6. Remove the cap of the left bleeder screw on the torque

transfer differential and connect a vinyl hose.

7. Gradually turn the steering wheel clockwise from the

straight-ahead position. At this time, loosen the left bleeder

screw and check that fluid is discharged with air.

8. After air has been completely discharged, tighten bleeder

screw and turn the steering wheel in the straight-ahead

position.

Caution

While the system is being bled of air, add fluid as

necessary to ensure that it is left in the oil reservoir

during the entire procedure.

9. Repeat steps 6 and 7 two to three times until no air

bubbles are recognized in the fluid that comes out. Then,

tighten the bleeder screw to the specified torque.

Tightening torque: 9±1 N·m

10. Perform steps 5 through 8 for the right bleeder screw.

Note, however, that the steering wheel should be turned

conterclockwise.

11. When removing the hydraulic unit, bleed the fluid line

in ACD side. (Refer to GROUP 22 – On-vehicle Service.)

12. After the system has been completely bled of air, check

for the fluid level. (Refer to P. 27B-19.)

Caution

If the system is not completely bled of air, the hydraulic

unit could generate noise, degrading pump durability.

AYC OPERATION CHECK

1. Lift up the vehicles.

2. Set the MUT-IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the LOCK (OFF) position

before connecting or disconnecting the MUT-II.

3. Start the engine.

4. Set the gear to the 2nd gear or above, operate MUT-II,

and check from the service data (Item No.09) that the

wheel speed is within 10 km/h to 20 km/h.

NOTE

(1) Set the steering wheel to the neutral position.

(2) When turning the steering wheel, AYC operates

continually (operation sound from the torque transfer

differential), but it is not system fault. In this case,

set the steering wheel to the neutral position, and

perform the following operations in order to stop the

ACD.

DRelease the clutch.

DSet the gear to ”Neutral”.

DStop the engine.

Bleeder

screw

Vinyl hose

Page 968 of 1449

REAR AXLE -On-vehicle Service27B-22

8. If the measured value exceeds the standard value, replace

the hydraulic unit.

9. Connect the hydraulic unit and the hydraulic unit hose

assembly, and connect the torque transfer differential and

hydraulic unit hose assembly, tighten the flare nut in

specified torque.

Tightening torque: 34±5 N·m (Thread is not lubricated)

26±4 N·m (Thread is lubricated)

10. Supply the specified fluid up to the MAX level of the

oil reservoir, and bleed.

Specified fluid: ATF-SP III

Quantity: 1 L

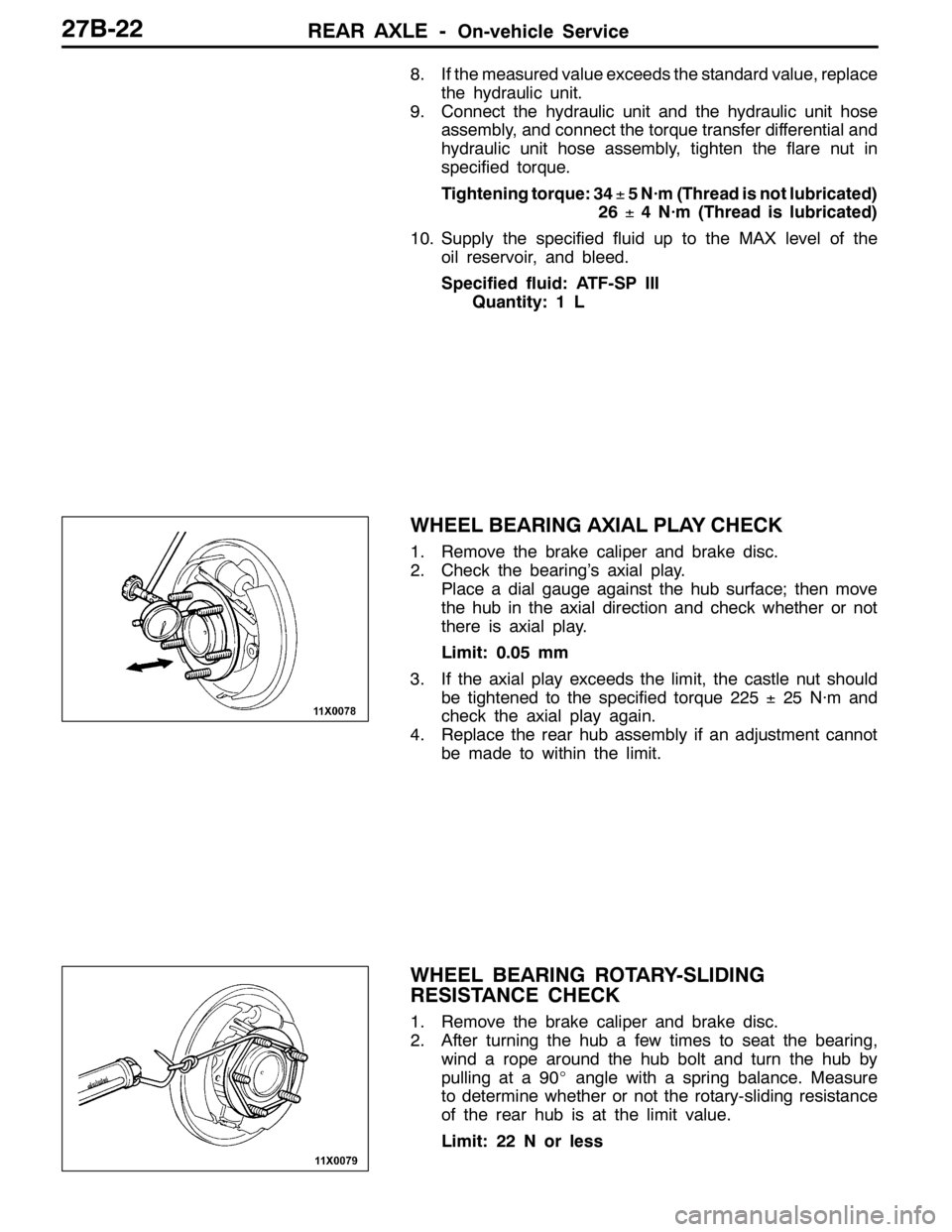

WHEEL BEARING AXIAL PLAY CHECK

1. Remove the brake caliper and brake disc.

2. Check the bearing’s axial play.

Place a dial gauge against the hub surface; then move

the hub in the axial direction and check whether or not

there is axial play.

Limit: 0.05 mm

3. If the axial play exceeds the limit, the castle nut should

be tightened to the specified torque 225±25 N·m and

check the axial play again.

4. Replace the rear hub assembly if an adjustment cannot

be made to within the limit.

WHEEL BEARING ROTARY-SLIDING

RESISTANCE CHECK

1. Remove the brake caliper and brake disc.

2. After turning the hub a few times to seat the bearing,

wind a rope around the hub bolt and turn the hub by

pulling at a 90_angle with a spring balance. Measure

to determine whether or not the rotary-sliding resistance

of the rear hub is at the limit value.

Limit: 22 N or less

Page 1072 of 1449

ABS <4WD> -General Information35B-2

GENERAL INFORMATION

ABS has been adopted as optional equipment in

RS-IIto maintain directional stability and steering

performance during sudden braking or braking on

slippery road surfaces.

The ABS control method is a 4-sensor, 4-channel

method which provides independent control for all

wheels.

Following system for Lancer EVOLUTION-VII has

been modified from Lancer EVOLUTION-VI Tommi

Makinen Edition.DBy adding lateral G sensor, longitudinal G

sensor and steering wheel sensor, optimized

ABS control at the time of cornering.

DBy inputting parking brake switch signal to

ABS-ECU with pulling parking brake lever, ABS

control has been optimized.

DABS-ECU outputs ABS signal to 4WD-ECU.

DG sensor (lateral), steering wheel sensor and

parking brake switch have been added to the

diagnosis and service data.

DABS-ECU connector has been changed.

EBD CONTROL

In ABS, electronic control method is used by which

the rear wheel brake hydraulic pressure during

braking is regulated by rear wheel control solenoid

valves in accordance with the vehicle’s rate of

deceleration and the front and rear wheel slippage

which are calculated from the each wheel speed

sensor’s signal. EBD control is a control system

which provides a high level of control for both vehicle

braking force and vehicle stability. The system has

the following features:

DBecause the system provides the optimum rear

wheel braking force regardless of the vehicleladen condition and the condition of the road

surface, the system reduces the required pedal

depression force, particularly when the vehicle

is heavily laden or driving on road surfaces

with high frictional coefficients.

DBecause the duty placed on the front brakes

has been reduced, the increases in pad

temperature can be controlled to improve the

wear resistance characteristics of the pad,

during front brakes applying.

DControl valves such as the proportioning valve

are no longer required.

SPECIFICATIONS

ItemSpecifications

ABS control method4-sensor, 4-channel

No. of ABS rotor teethFront43

Rear43

ABS speed sensorTypeMagnet coil typep

Gap between sensor and rotor mm0.85

Page 1115 of 1449

37A-1

STEERING

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 4.................

LUBRICANTS 4..............................

SEALANT 4..................................

SPECIAL TOOLS 4...........................

ON-VEHICLE SERVICE 7.....................

Steering Wheel Free Play Check 7..............

Steering Angle Check 7........................

Tie Rod End Ball Joint Turning Torque Check 7..

Stationary Steering Effort Check 8...............

Checking Steering Wheel Return to Centre 8.....

Drive Belt Tension Check 8.....................Power Steering Fluid Level Check 9.............

Power Steering Fluid Replacement 9.............

Power Steering System Bleeding 9..............

Oil Pump Pressure Test 10.....................

Power Steering Oil Pressure Switch Check 11....

Ball Joint Dust Cover Check 11.................

STEERING WHEEL* 12.......................

STEERING SHAFT* 14.......................

POWER STEERING GEAR BOX AND

LINKAGE* 16................................

POWER STEERING OIL PUMP 29............

POWER STEERING OIL HOSES 30...........

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring and interconnecting

wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are

indicated in the table of contents by an asterisk (*).

Page 1123 of 1449

STEERING -On-vehicle Service37A-9

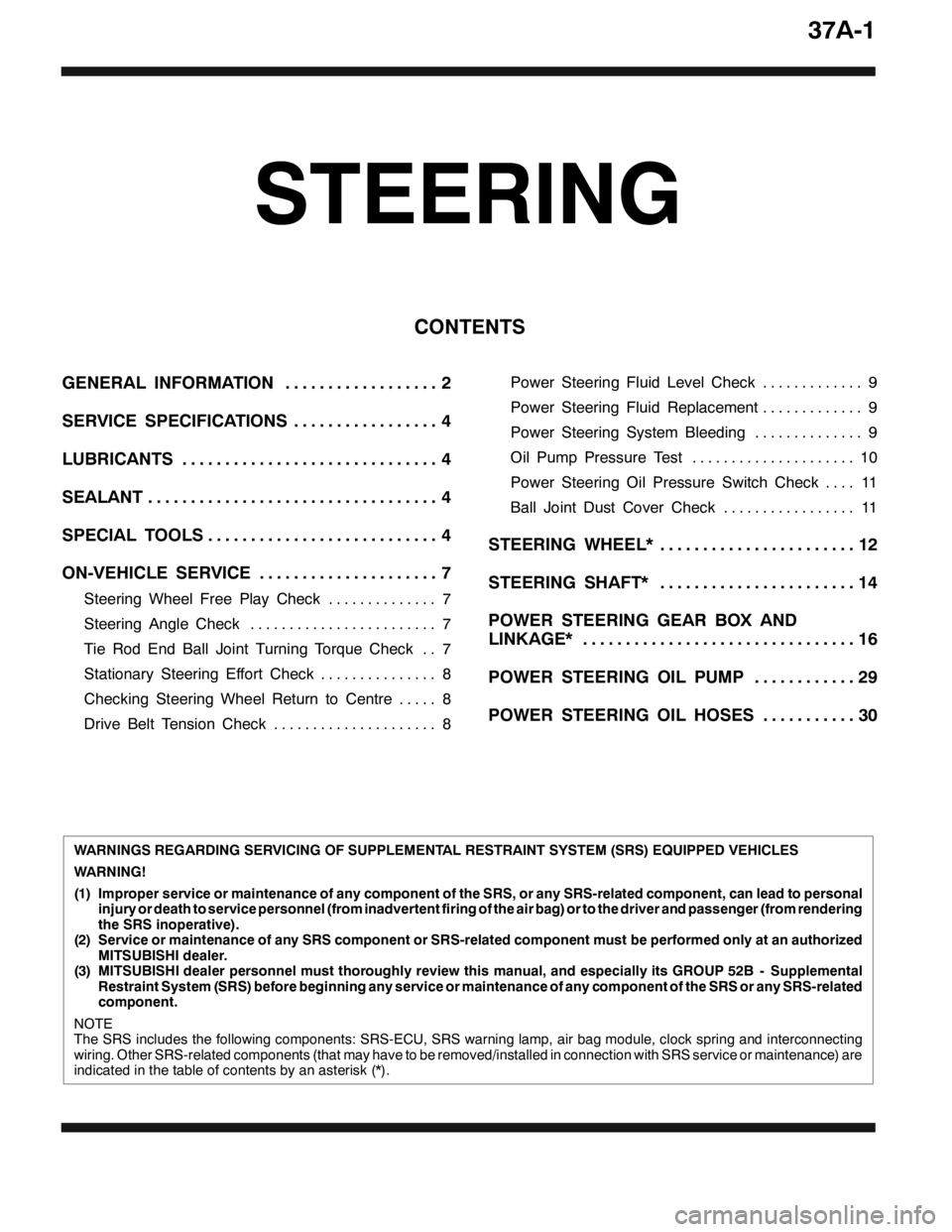

POWER STEERING FLUID LEVEL CHECK

1. Park the vehicle on a flat, level surface, start the engine,

and then turn the steering wheel several times to raise

the temperature of the fluid to approximately 50 - 60_C.

2. With the engine running, turn the wheel all the way to

the left and right several times.

3. Check the fluid in the oil reservoir for foaming or milkiness.

Check the difference of the fluid level when the engine

is stopped, and while it is running. If the change of the

fluid level is 5 mm or more, air bleeding should be done.

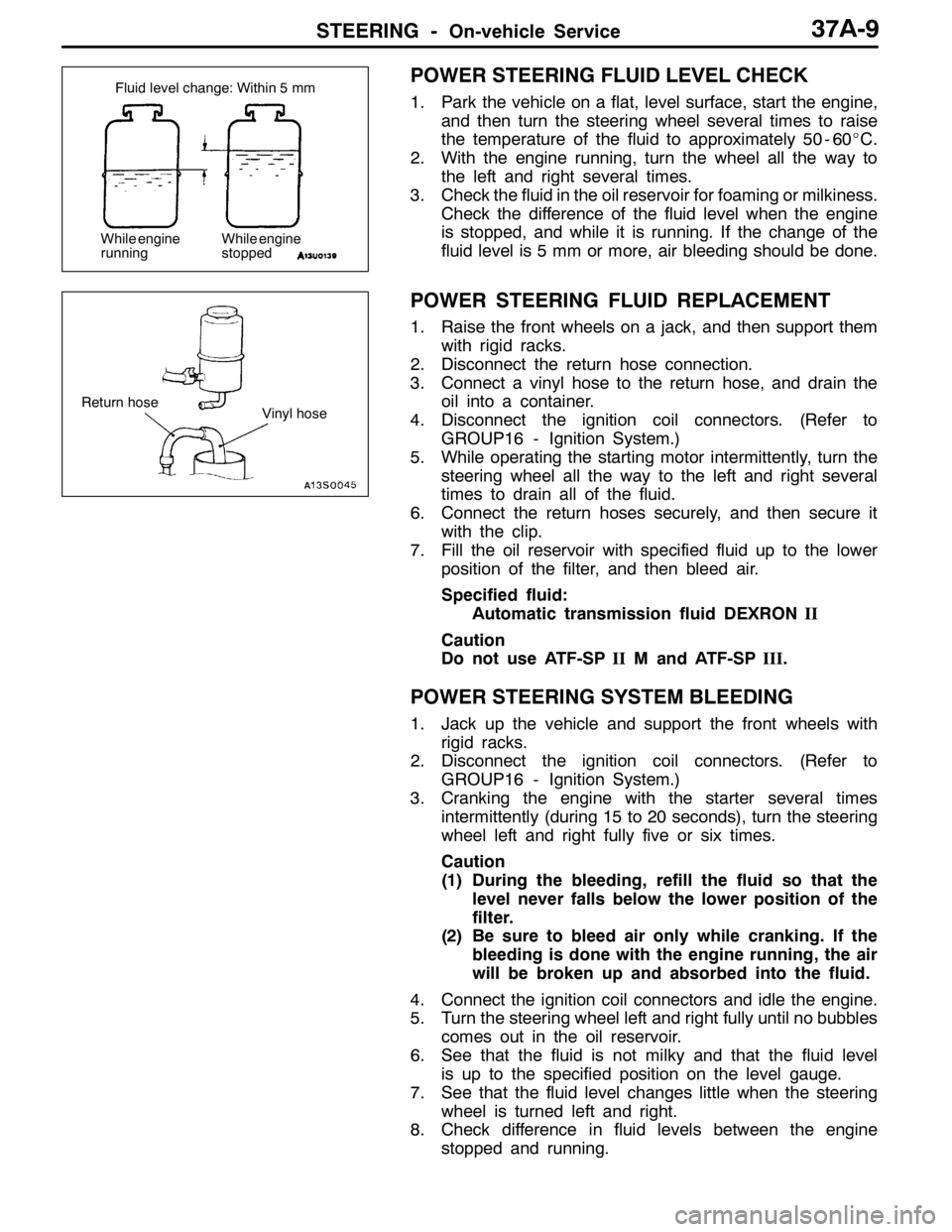

POWER STEERING FLUID REPLACEMENT

1. Raise the front wheels on a jack, and then support them

with rigid racks.

2. Disconnect the return hose connection.

3. Connect a vinyl hose to the return hose, and drain the

oil into a container.

4. Disconnect the ignition coil connectors. (Refer to

GROUP16 - Ignition System.)

5. While operating the starting motor intermittently, turn the

steering wheel all the way to the left and right several

times to drain all of the fluid.

6. Connect the return hoses securely, and then secure it

with the clip.

7. Fill the oil reservoir with specified fluid up to the lower

position of the filter, and then bleed air.

Specified fluid:

Automatic transmission fluid DEXRONII

Caution

Do not use ATF-SPIIM and ATF-SPIII.

POWER STEERING SYSTEM BLEEDING

1. Jack up the vehicle and support the front wheels with

rigid racks.

2. Disconnect the ignition coil connectors. (Refer to

GROUP16 - Ignition System.)

3. Cranking the engine with the starter several times

intermittently (during 15 to 20 seconds), turn the steering

wheel left and right fully five or six times.

Caution

(1) During the bleeding, refill the fluid so that the

level never falls below the lower position of the

filter.

(2) Be sure to bleed air only while cranking. If the

bleeding is done with the engine running, the air

will be broken up and absorbed into the fluid.

4. Connect the ignition coil connectors and idle the engine.

5. Turn the steering wheel left and right fully until no bubbles

comes out in the oil reservoir.

6. See that the fluid is not milky and that the fluid level

is up to the specified position on the level gauge.

7. See that the fluid level changes little when the steering

wheel is turned left and right.

8. Check difference in fluid levels between the engine

stopped and running.

Fluid level change: Within 5 mm

While engine

runningWhile engine

stopped

Return hose

Vinyl hose