roof MITSUBISHI LANCER EVOLUTION 2007 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1167 of 1449

BODY -DoorsBODY -Doors42-19

DOORS

SERVICE SPECIFICATIONS

ItemsStandard value

Door outside handle play mmFront2.3±2.1py

Rear1.3±1.7

Power window operating current (power supply 14.5±0.5 V, 25_C) A5±1

Door inside handle play mmFront9.6±9.2py

Rear9.0±9.2

ADHESIVE

ItemsSpecified sealantRemark

Waterproof film3M ATD Part No. 8625 or equivalentRibbon sealer

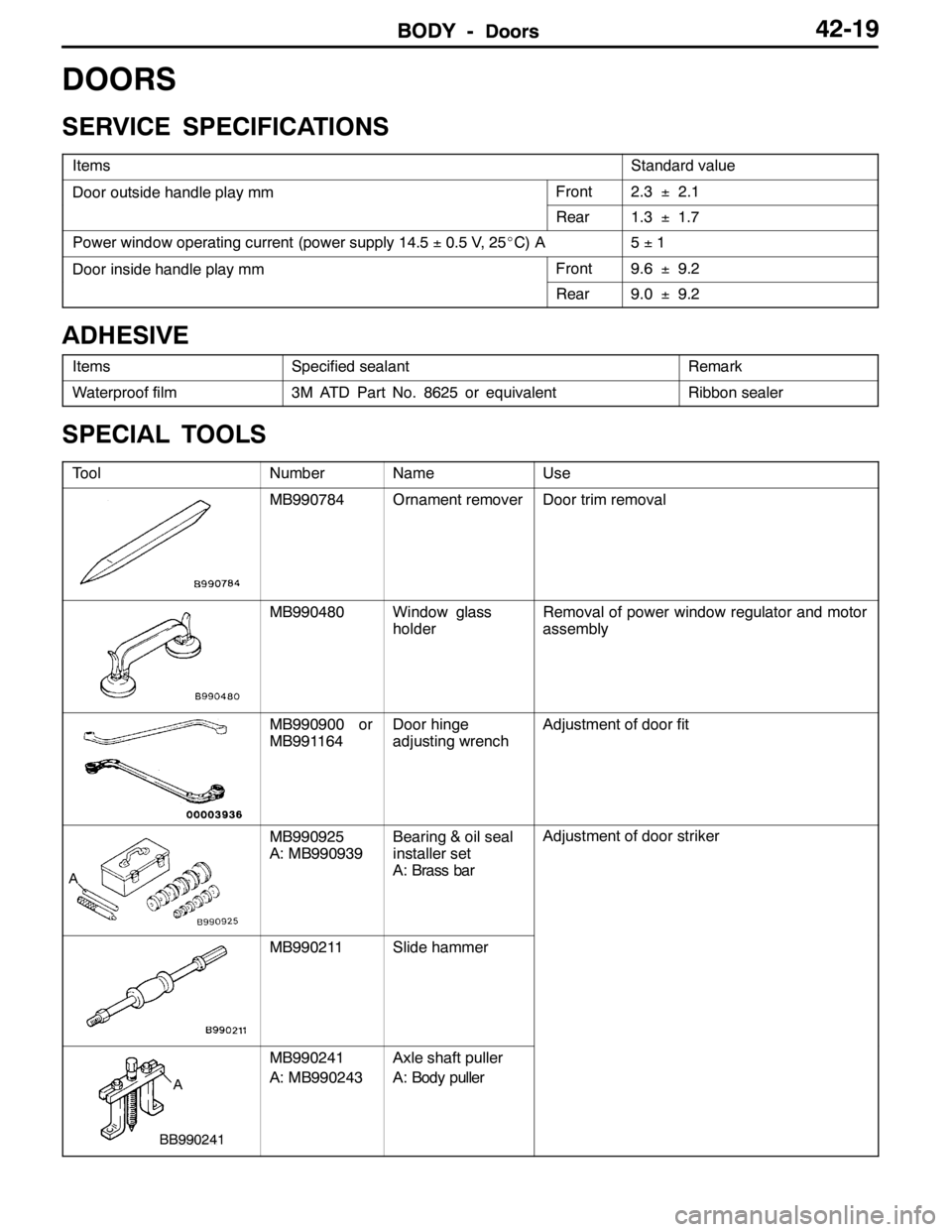

SPECIAL TOOLS

ToolNumberNameUse

MB990784Ornament removerDoor trim removal

MB990480Window glass

holderRemoval of power window regulator and motor

assembly

MB990900 or

MB991164Door hinge

adjusting wrenchAdjustment of door fit

A

MB990925

A: MB990939Bearing & oil seal

installer set

A: Brass barAdjustment of door striker

MB990211Slide hammer

A

BB990241

MB990241

A: MB990243Axle shaft puller

A: Body puller

Page 1169 of 1449

BODY -Doors42-21

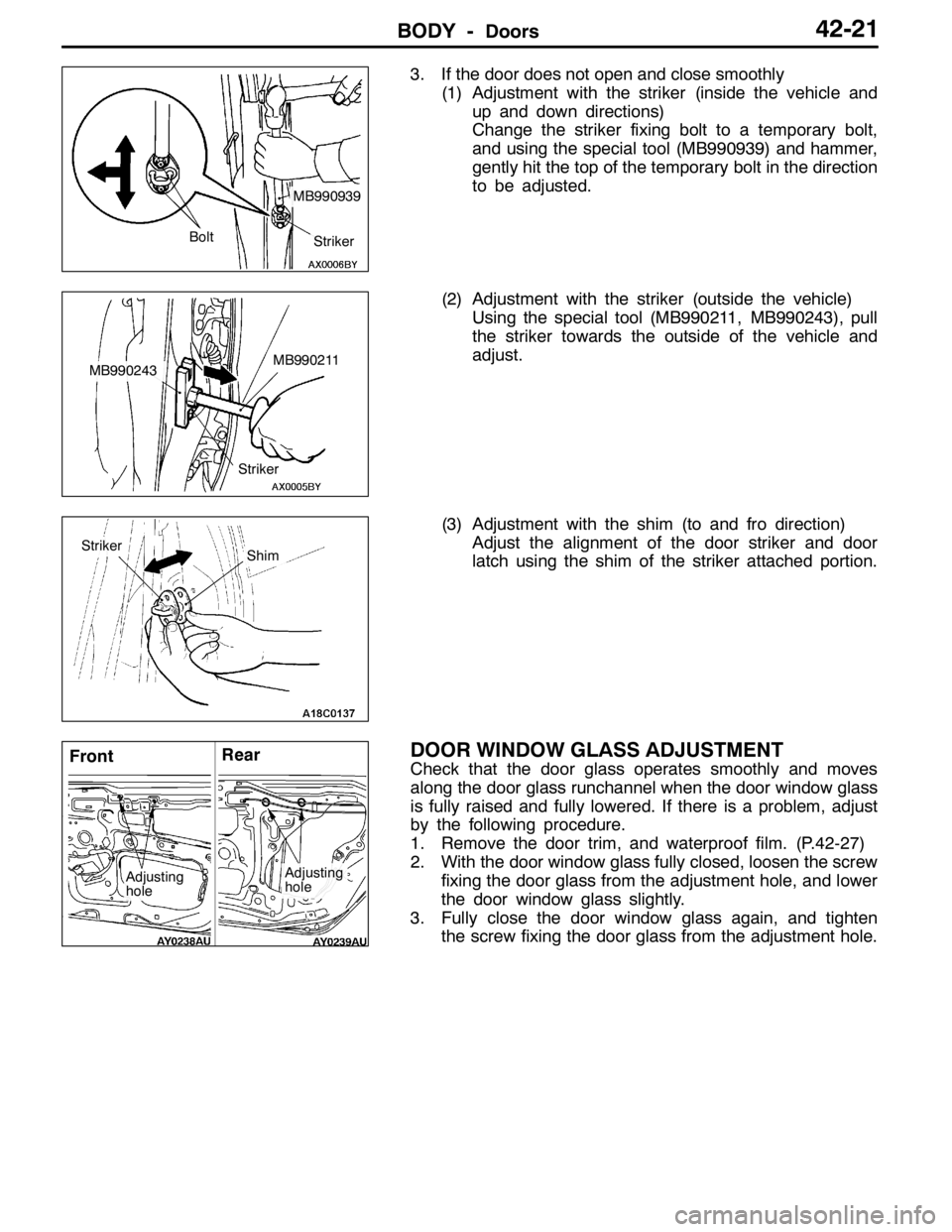

3. If the door does not open and close smoothly

(1) Adjustment with the striker (inside the vehicle and

up and down directions)

Change the striker fixing bolt to a temporary bolt,

and using the special tool (MB990939) and hammer,

gently hit the top of the temporary bolt in the direction

to be adjusted.

(2) Adjustment with the striker (outside the vehicle)

Using the special tool (MB990211, MB990243), pull

the striker towards the outside of the vehicle and

adjust.

(3) Adjustment with the shim (to and fro direction)

Adjust the alignment of the door striker and door

latch using the shim of the striker attached portion.

DOOR WINDOW GLASS ADJUSTMENT

Check that the door glass operates smoothly and moves

along the door glass runchannel when the door window glass

is fully raised and fully lowered. If there is a problem, adjust

by the following procedure.

1. Remove the door trim, and waterproof film. (P.42-27)

2. With the door window glass fully closed, loosen the screw

fixing the door glass from the adjustment hole, and lower

the door window glass slightly.

3. Fully close the door window glass again, and tighten

the screw fixing the door glass from the adjustment hole.

MB990939

Striker Bolt

MB990211MB990243

Striker

StrikerShim

FrontRear

Adjusting

holeAdjusting

hole

Page 1170 of 1449

BODY -Doors42-22

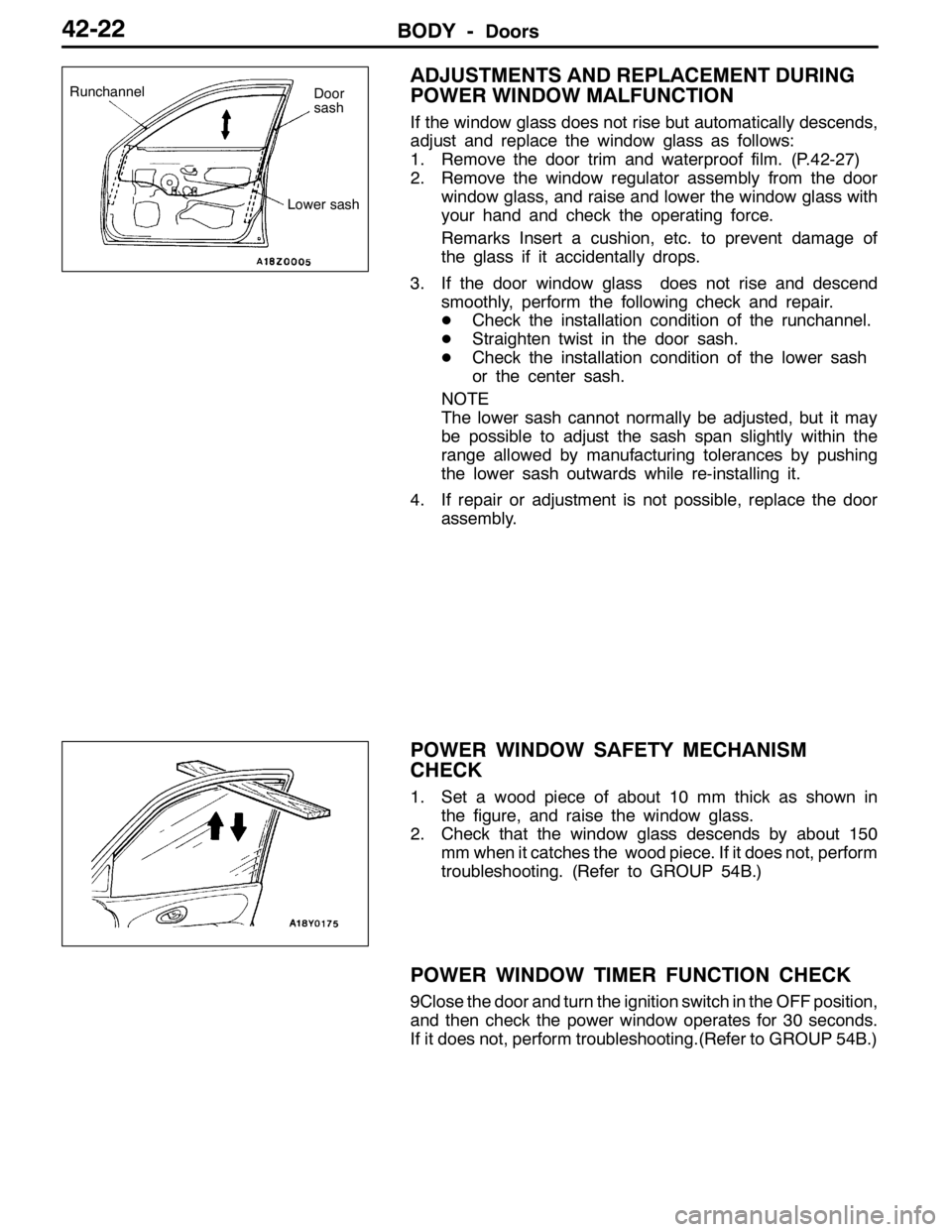

ADJUSTMENTS AND REPLACEMENT DURING

POWER WINDOW MALFUNCTION

If the window glass does not rise but automatically descends,

adjust and replace the window glass as follows:

1. Remove the door trim and waterproof film. (P.42-27)

2. Remove the window regulator assembly from the door

window glass, and raise and lower the window glass with

your hand and check the operating force.

Remarks Insert a cushion, etc. to prevent damage of

the glass if it accidentally drops.

3. If the door window glass does not rise and descend

smoothly, perform the following check and repair.

DCheck the installation condition of the runchannel.

DStraighten twist in the door sash.

DCheck the installation condition of the lower sash

or the center sash.

NOTE

The lower sash cannot normally be adjusted, but it may

be possible to adjust the sash span slightly within the

range allowed by manufacturing tolerances by pushing

the lower sash outwards while re-installing it.

4. If repair or adjustment is not possible, replace the door

assembly.

POWER WINDOW SAFETY MECHANISM

CHECK

1. Set a wood piece of about 10 mm thick as shown in

the figure, and raise the window glass.

2. Check that the window glass descends by about 150

mm when it catches the wood piece. If it does not, perform

troubleshooting. (Refer to GROUP 54B.)

POWER WINDOW TIMER FUNCTION CHECK

9Close the door and turn the ignition switch in the OFF position,

and then check the power window operates for 30 seconds.

If it does not, perform troubleshooting.(Refer to GROUP 54B.)

Runchannel

Door

sash

Lower sash

Page 1175 of 1449

BODY -Doors42-27

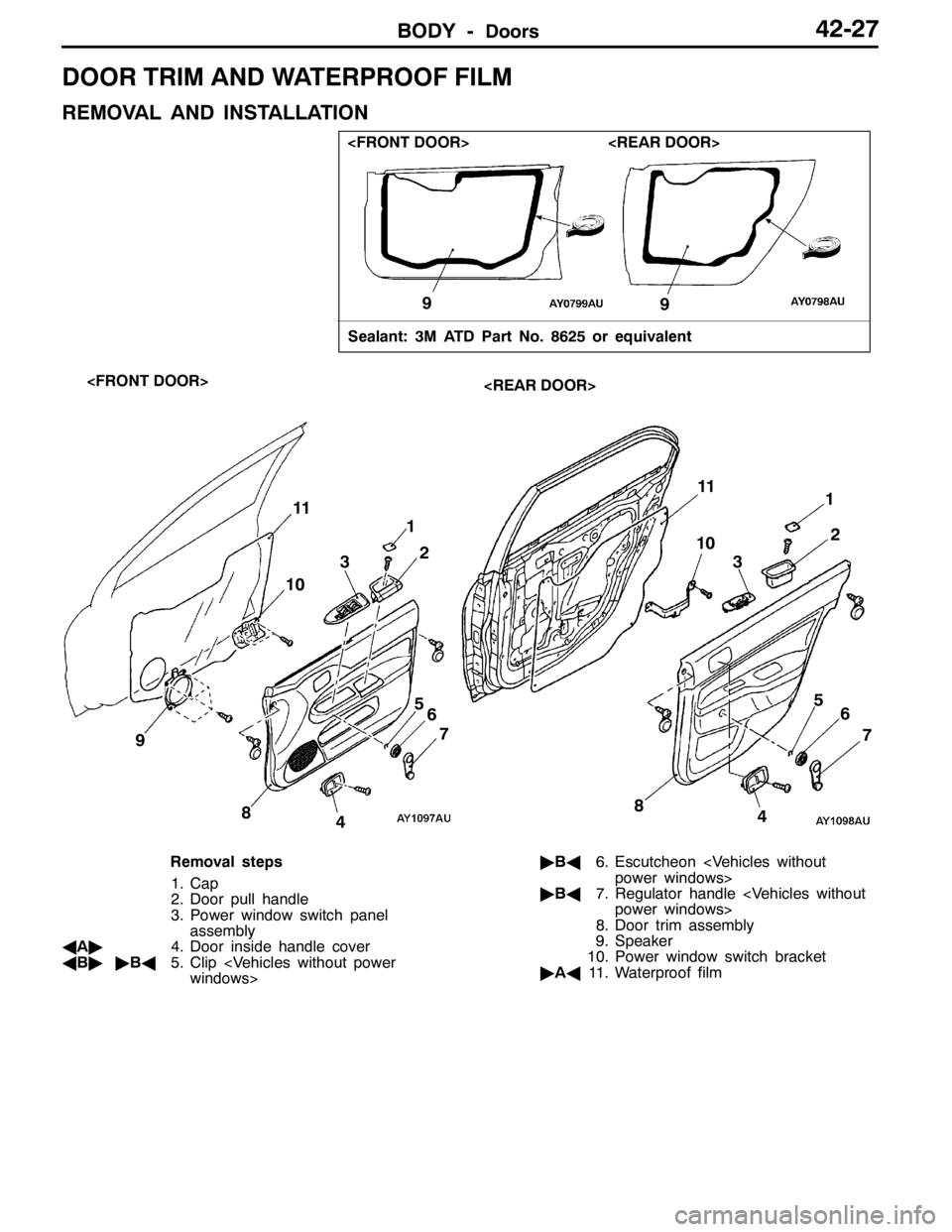

DOOR TRIM AND WATERPROOF FILM

REMOVAL AND INSTALLATION

7

91

1011

6 9

9

3

521

2

4 8

4 87 6 5 11

103

Sealant: 3M ATD Part No. 8625 or equivalent

Removal steps

1. Cap

2. Door pull handle

3. Power window switch panel

assembly

AA"4. Door inside handle cover

AB""BA5. Clip

"BA7. Regulator handle

8. Door trim assembly

9. Speaker

10. Power window switch bracket

"AA11. Waterproof film

Page 1179 of 1449

BODY -Doors42-31

INSTALLATION SERVICE POINTS

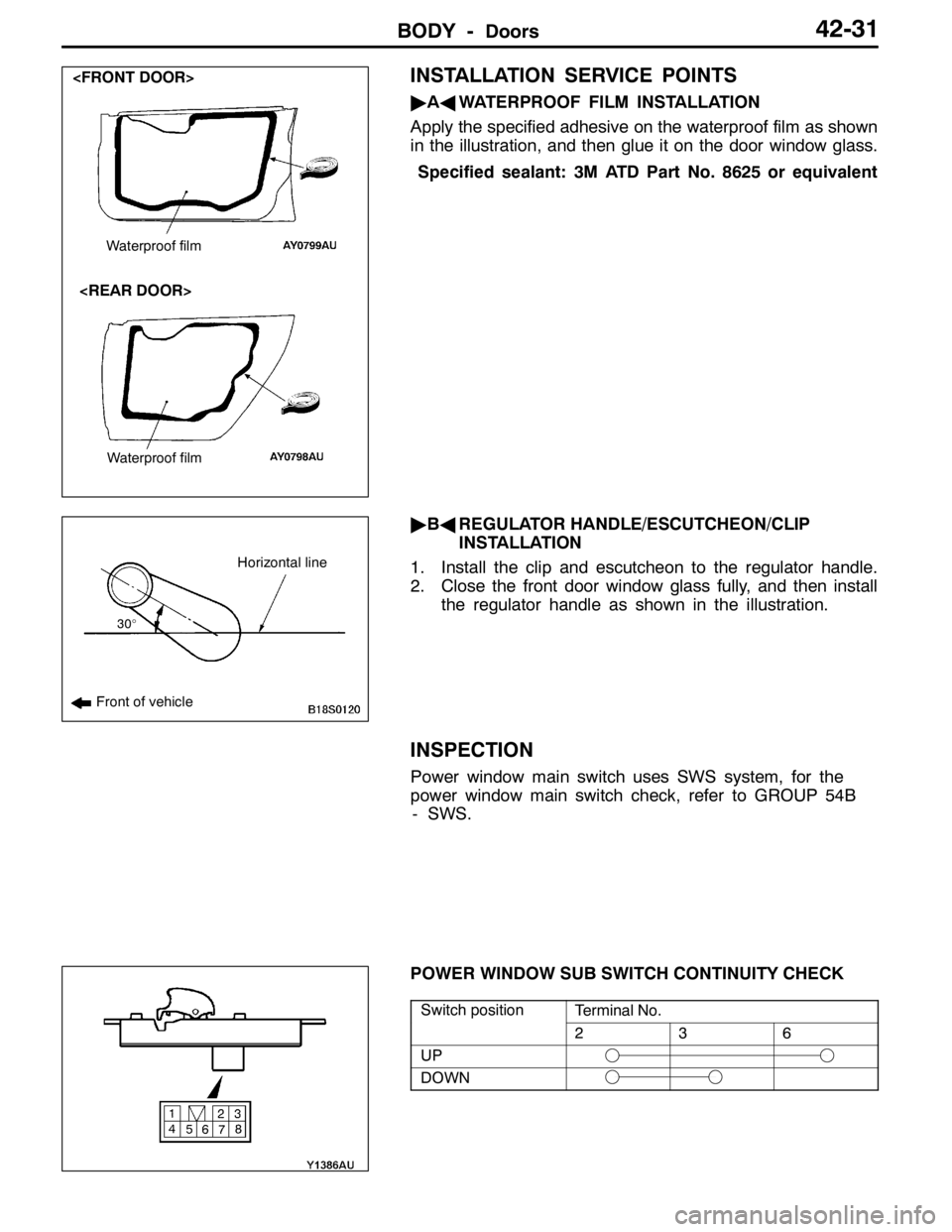

"AAWATERPROOF FILM INSTALLATION

Apply the specified adhesive on the waterproof film as shown

in the illustration, and then glue it on the door window glass.

Specified sealant: 3M ATD Part No. 8625 or equivalent

"BAREGULATOR HANDLE/ESCUTCHEON/CLIP

INSTALLATION

1. Install the clip and escutcheon to the regulator handle.

2. Close the front door window glass fully, and then install

the regulator handle as shown in the illustration.

INSPECTION

Power window main switch uses SWS system, for the

power window main switch check, refer to GROUP 54B

- SWS.

POWER WINDOW SUB SWITCH CONTINUITY CHECK

Switch positionTerminal No.p

236

UP

DOWN

Waterproof film

Waterproof film

Front of vehicle

30_

Horizontal line

Page 1180 of 1449

BODY -Doors42-32

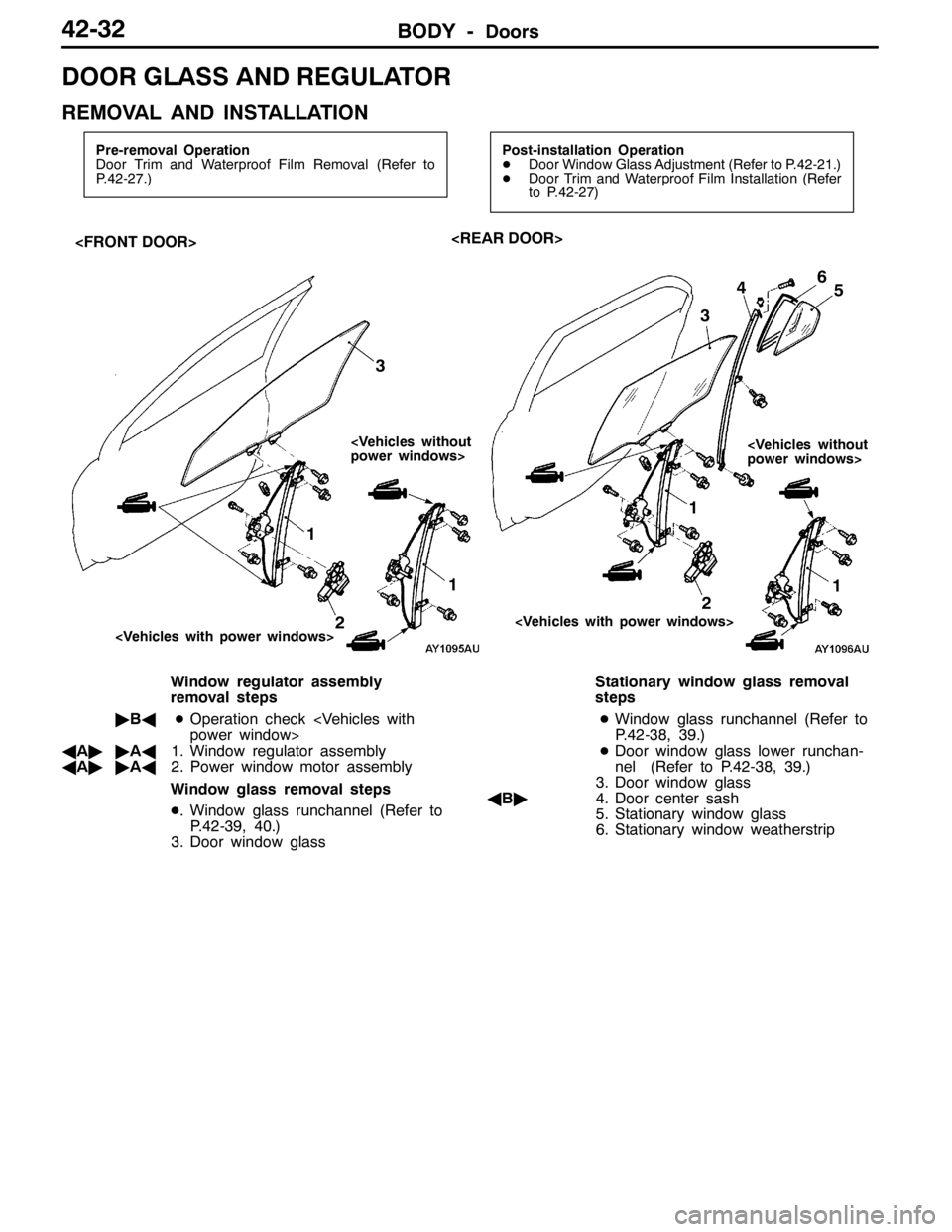

DOOR GLASS AND REGULATOR

REMOVAL AND INSTALLATION

Pre-removal Operation

Door Trim and Waterproof Film Removal (Refer to

P.42-27.)Post-installation Operation

DDoor Window Glass Adjustment (Refer to P.42-21.)

DDoor Trim and Waterproof Film Installation (Refer

to P.42-27)

1

23

1

34

25 6

1 1

Window regulator assembly

removal steps

"BADOperation check

AA""AA1. Window regulator assembly

AA""AA2. Power window motor assembly

Window glass removal steps

D. Window glass runchannel (Refer to

P.42-39, 40.)

3. Door window glassStationary window glass removal

steps

DWindow glass runchannel (Refer to

P.42-38, 39.)

DDoor window glass lower runchan-

nel (Refer to P.42-38, 39.)

3. Door window glass

AB"4. Door center sash

5. Stationary window glass

6. Stationary window weatherstrip

Page 1183 of 1449

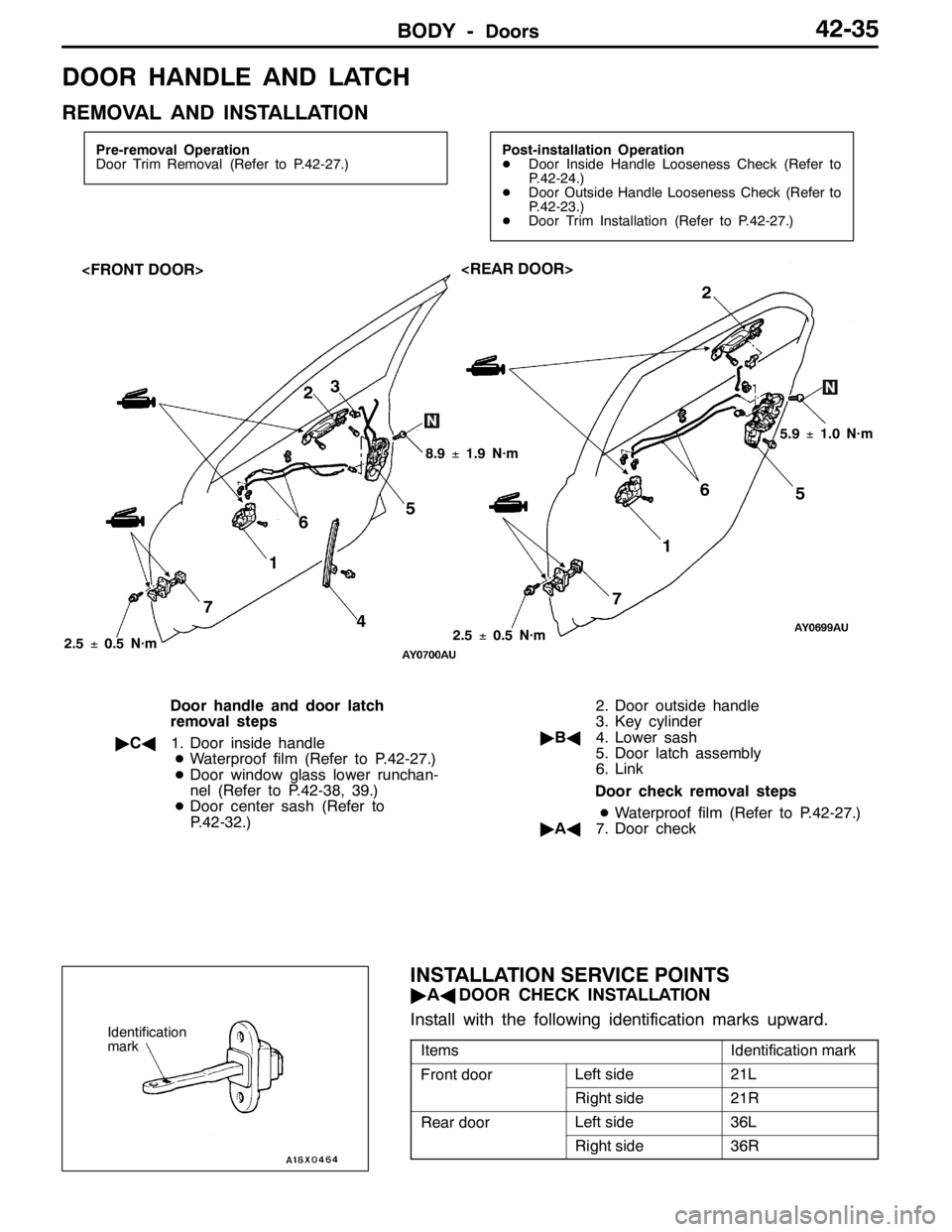

BODY -Doors42-35

DOOR HANDLE AND LATCH

REMOVAL AND INSTALLATION

Pre-removal Operation

Door Trim Removal (Refer to P.42-27.)Post-installation Operation

DDoor Inside Handle Looseness Check (Refer to

P.42-24.)

DDoor Outside Handle Looseness Check (Refer to

P.42-23.)

DDoor Trim Installation (Refer to P.42-27.)

3

5

4 72

6

1

5.9±1.0 N·m

8.9±1.9 N·m

2

1

75 6

2.5±0.5 N·m

2.5±0.5 N·m

Door handle and door latch

removal steps

"CA1. Door inside handle

DWaterproof film (Refer to P.42-27.)

DDoor window glass lower runchan-

nel (Refer to P.42-38, 39.)

DDoor center sash (Refer to

P.42-32.)2. Door outside handle

3. Key cylinder

"BA4. Lower sash

5. Door latch assembly

6. Link

Door check removal steps

DWaterproof film (Refer to P.42-27.)

"AA7. Door check

INSTALLATION SERVICE POINTS

"AADOOR CHECK INSTALLATION

Install with the following identification marks upward.

ItemsIdentification mark

Front doorLeft side21L

Right side21R

Rear doorLeft side36L

Right side36R

Identification

mark

Page 1200 of 1449

EXTERIOR -Rear Bumper / Side Air Dam, Molding and Garnish51-8

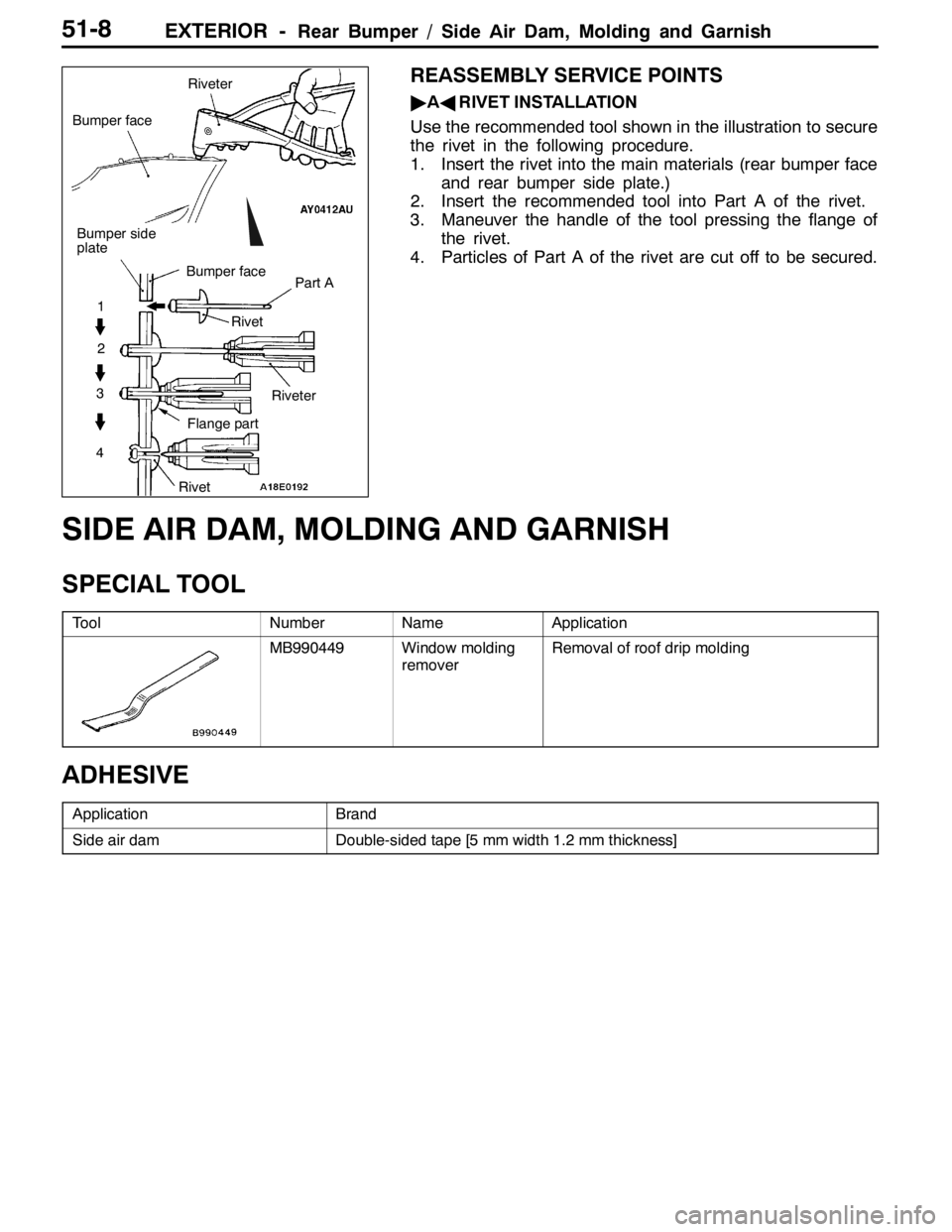

REASSEMBLY SERVICE POINTS

"AARIVET INSTALLATION

Use the recommended tool shown in the illustration to secure

the rivet in the following procedure.

1. Insert the rivet into the main materials (rear bumper face

and rear bumper side plate.)

2. Insert the recommended tool into Part A of the rivet.

3. Maneuver the handle of the tool pressing the flange of

the rivet.

4. Particles of Part A of the rivet are cut off to be secured.

SIDE AIR DAM, MOLDING AND GARNISH

SPECIAL TOOL

ToolNumberNameApplication

MB990449Window molding

removerRemoval of roof drip molding

ADHESIVE

ApplicationBrand

Side air damDouble-sided tape [5 mm width 1.2 mm thickness]

Riveter

Bumper side

plate

Part A

Riveter

Rivet

Flange part

1

2

3

4Bumper face

Rivet

Bumper face

Page 1201 of 1449

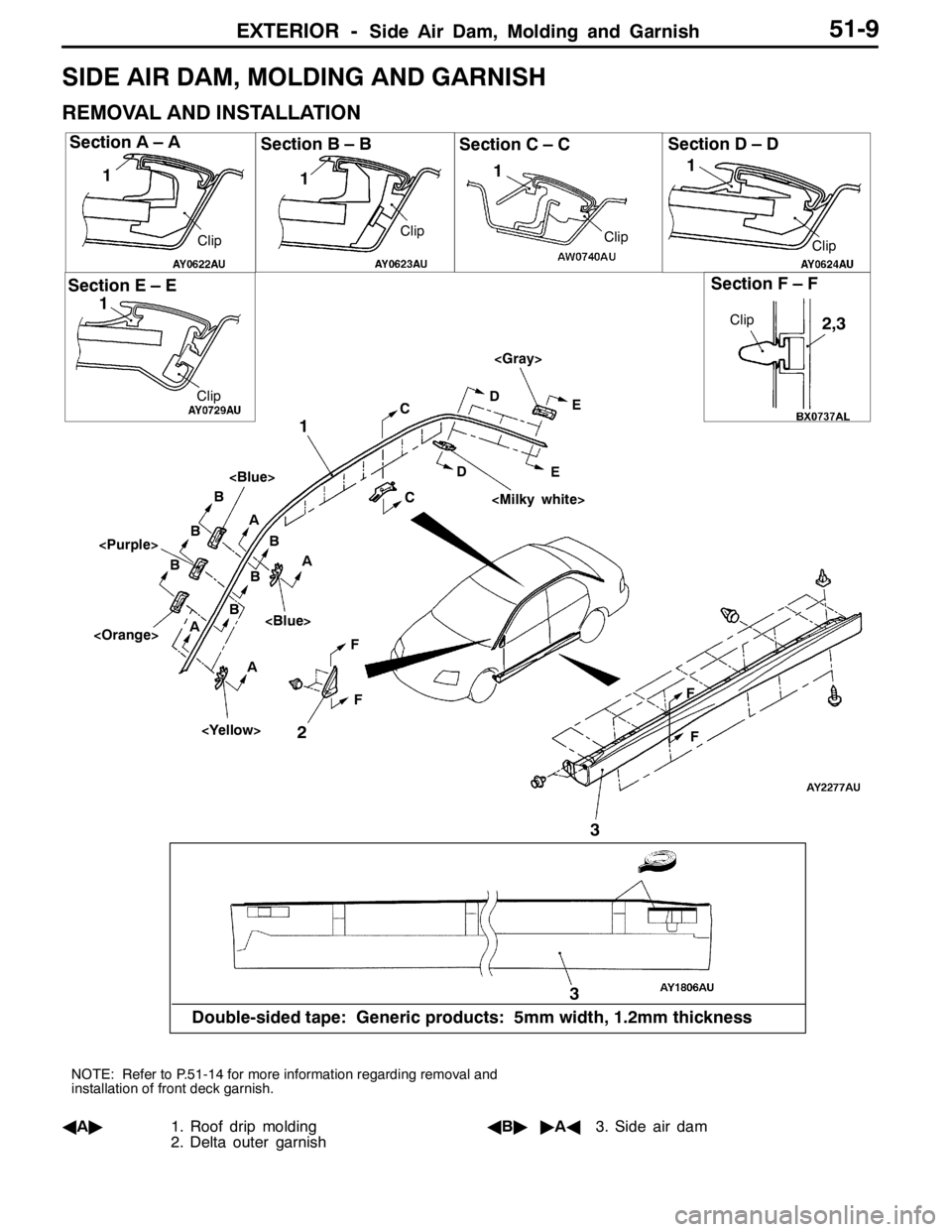

EXTERIOR -Side Air Dam, Molding and Garnish51-9

SIDE AIR DAM, MOLDING AND GARNISH

REMOVAL AND INSTALLATION

11

ClipClip

Clip

1

Section A – A

Section B – B

Section C – C

Section F – F

Clip2,3

1

Clip

Section D – D

1

2

3 1

Clip

Section E – E

NOTE: Refer to P.51-14 for more information regarding removal and

installation of front deck garnish.

F F

A AB BC CD

D

EE

F

F B

B

B BA

A

Double-sided tape: Generic products: 5mm width, 1.2mm thickness3

AA"1. Roof drip molding

2. Delta outer garnishAB""AA3. Side air dam

Page 1202 of 1449

EXTERIOR -Side Air Dam, Molding and Garnish51-10

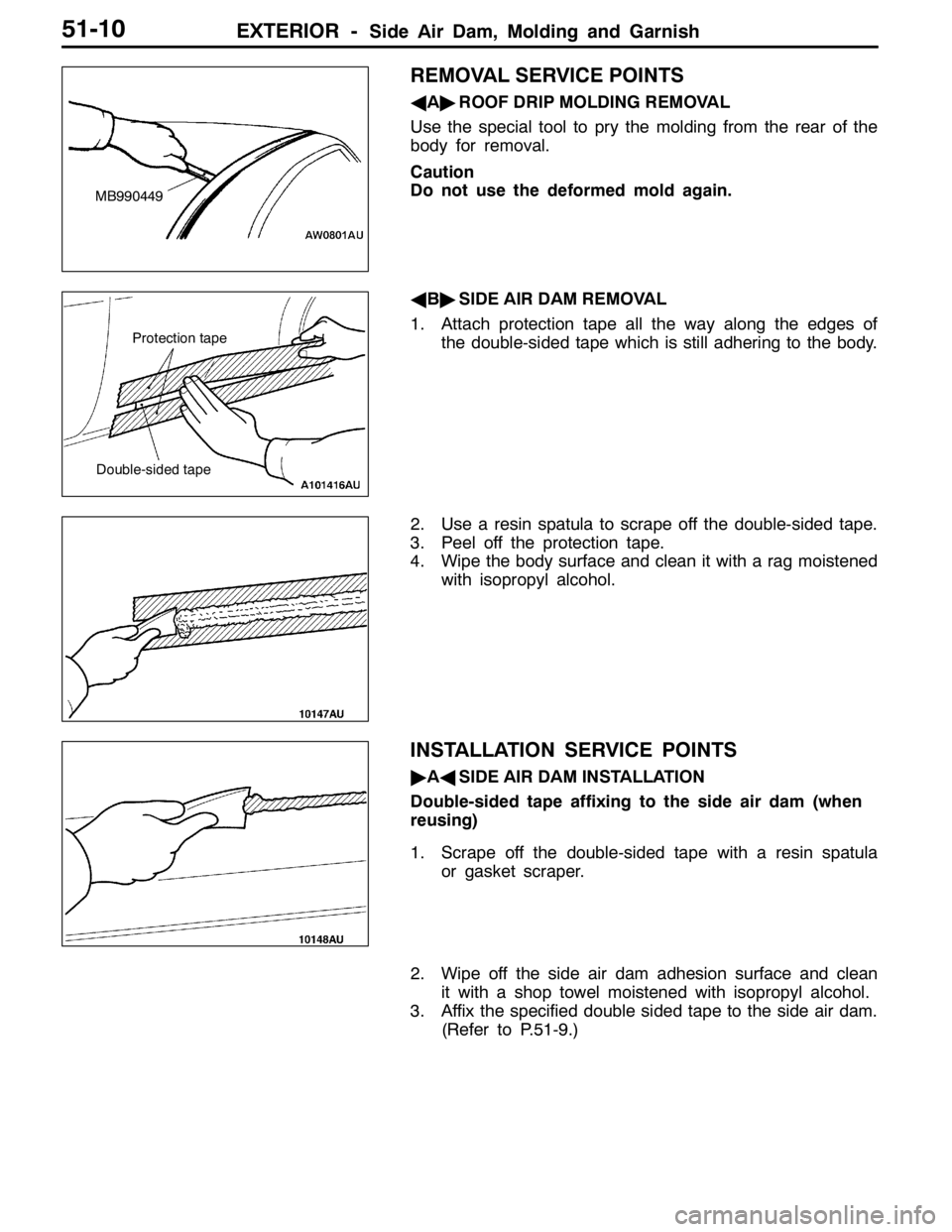

REMOVAL SERVICE POINTS

AA"ROOF DRIP MOLDING REMOVAL

Use the special tool to pry the molding from the rear of the

body for removal.

Caution

Do not use the deformed mold again.

AB"SIDE AIR DAM REMOVAL

1. Attach protection tape all the way along the edges of

the double-sided tape which is still adhering to the body.

2. Use a resin spatula to scrape off the double-sided tape.

3. Peel off the protection tape.

4. Wipe the body surface and clean it with a rag moistened

with isopropyl alcohol.

INSTALLATION SERVICE POINTS

"AASIDE AIR DAM INSTALLATION

Double-sided tape affixing to the side air dam (when

reusing)

1. Scrape off the double-sided tape with a resin spatula

or gasket scraper.

2. Wipe off the side air dam adhesion surface and clean

it with a shop towel moistened with isopropyl alcohol.

3. Affix the specified double sided tape to the side air dam.

(Refer to P.51-9.)

MB990449

Protection tape

Double-sided tape