transmission MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1 of 1449

00

11

12

13

14

15

16

17

21

22

25

26

27

31

32

33

34

35

36

37

42

51

52

54

55

General........................

Engine .........................

Engine Lubrication .............

Fuel ...........................

Engine Cooling .................

Intake and Exhaust ............

Engine Electrical ...............

Engine and Emission Control ....

Clutch .........................

Manual Transmission ...........

Propeller Shaft .................

Front Axle ......................

Rear Axle ......................

Wheel and Tyre .................

Power Plant Mount ..............

Front Suspension ...............

Rear Suspension ...............

Service Brakes .................

Parking Brakes .................

Steering ........................

Body ...........................

Exterior ........................

Chassis Electrical ..............

Electrical Wiring ................

Body Repair ....................

WORKSHOP

MANUAL

FOREWORD

This Workshop Manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and

installation. Use the following manuals in

combination with this manual as required.

TECHNICAL INFORMATION MANUAL N0104CT9A

All information, illustrations and product

descriptions contained in this manual are current

as at the time of publication. We, however, reserve

the right to make changes at any time without prior

notice or obligation.

The EVOLUTION-VII is sold exclusively through

RALLIART Inc. Since the EVOLUTION-VII is a

rally-based model, it will not be warranted and will

not be homologated for general production.

Therefore, any service matters on the

EVOLUTION-VII should be inquired to RALLIART

Inc. as usual.

EMitsubishi Motors Corporation May 2001

Interior and Supplemental

Restraint System (SRS) ........

Heater, Air Conditioner and

Ventilation .....................

Page 11 of 1449

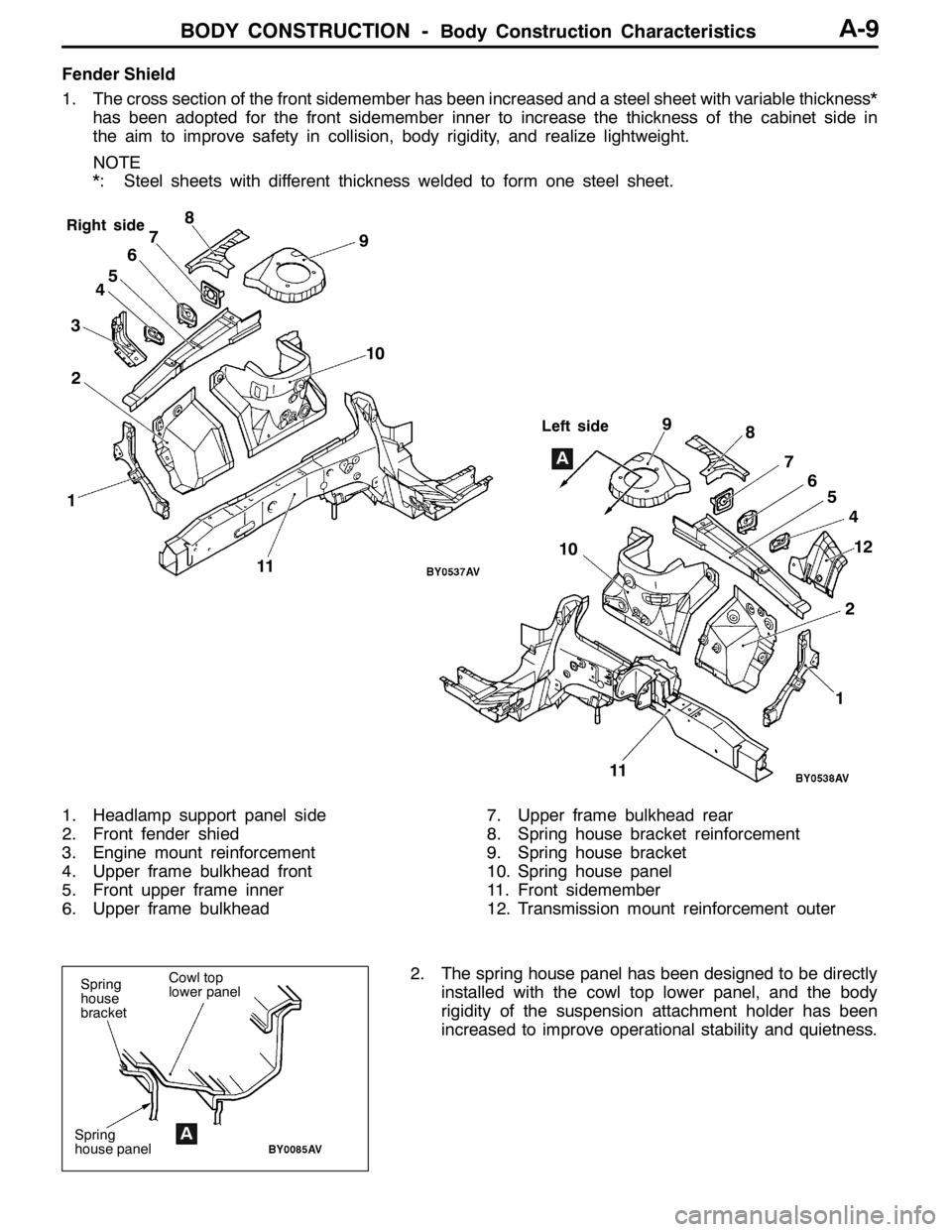

BODY CONSTRUCTION -Body Construction CharacteristicsA-9

Fender Shield

1. The cross section of the front sidemember has been increased and a steel sheet with variable thickness*

has been adopted for the front sidemember inner to increase the thickness of the cabinet side in

the aim to improve safety in collision, body rigidity, and realize lightweight.

NOTE

*: Steel sheets with different thickness welded to form one steel sheet.

12 345678

9

1112

Right side

Left side

10

10

124 5 6 7 8 9

A

11

1. Headlamp support panel side

2. Front fender shied

3. Engine mount reinforcement

4. Upper frame bulkhead front

5. Front upper frame inner

6. Upper frame bulkhead7. Upper frame bulkhead rear

8. Spring house bracket reinforcement

9. Spring house bracket

10. Spring house panel

11. Front sidemember

12. Transmission mount reinforcement outer

2. The spring house panel has been designed to be directly

installed with the cowl top lower panel, and the body

rigidity of the suspension attachment holder has been

increased to improve operational stability and quietness.

Spring

house

bracket

Spring

house panelA

Cowl top

lower panel

Page 13 of 1449

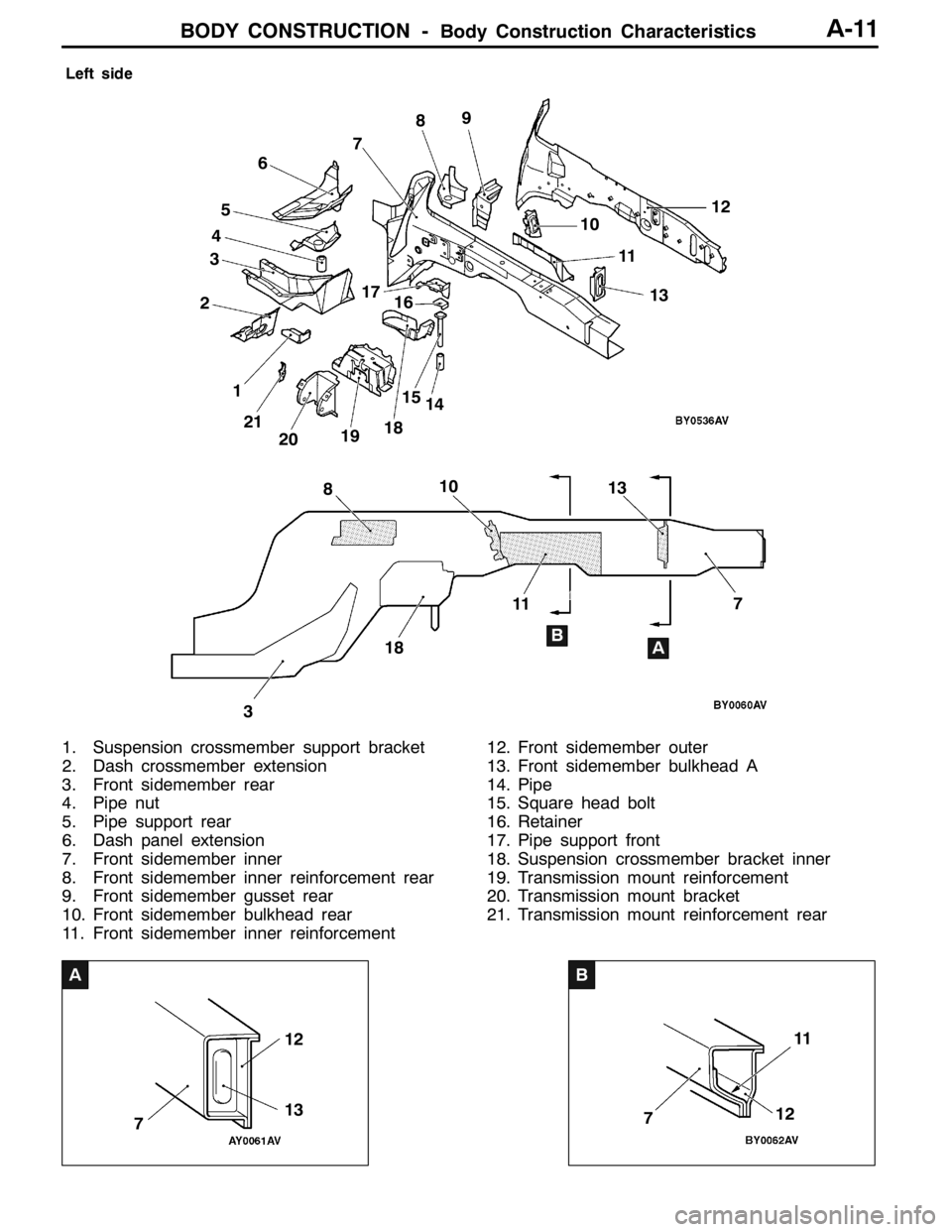

BODY CONSTRUCTION -Body Construction Characteristics

A

713

12

B

11

712

A-11

Left side

23

7 8 456789

10

11

AB

310

1112

13

14 15 16 17

18

19

20 21 1

13

18

1. Suspension crossmember support bracket

2. Dash crossmember extension

3. Front sidemember rear

4. Pipe nut

5. Pipe support rear

6. Dash panel extension

7. Front sidemember inner

8. Front sidemember inner reinforcement rear

9. Front sidemember gusset rear

10. Front sidemember bulkhead rear

11. Front sidemember inner reinforcement12. Front sidemember outer

13. Front sidemember bulkhead A

14. Pipe

15. Square head bolt

16. Retainer

17. Pipe support front

18. Suspension crossmember bracket inner

19. Transmission mount reinforcement

20. Transmission mount bracket

21. Transmission mount reinforcement rear

Page 89 of 1449

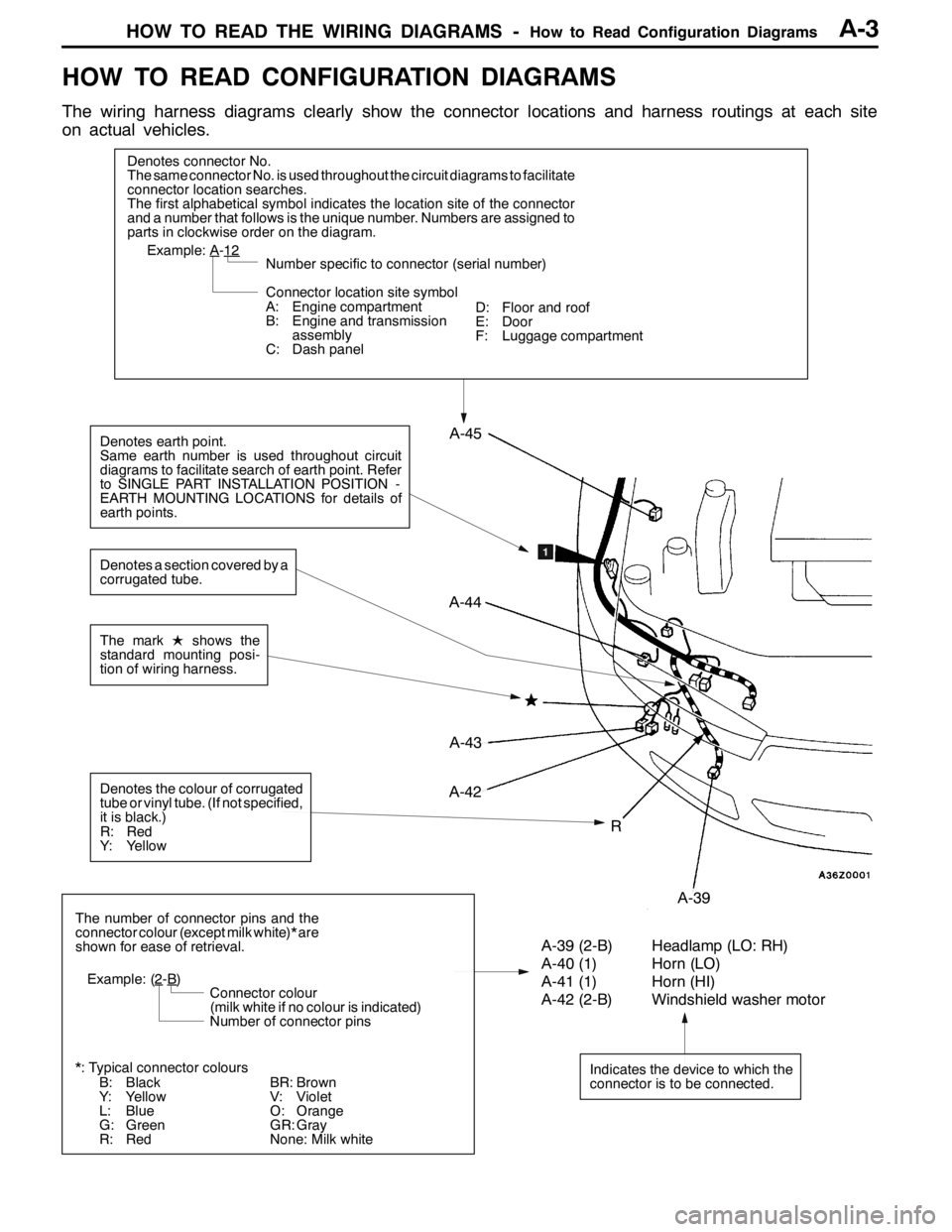

HOW TO READ THE WIRING DIAGRAMS -How to Read Configuration DiagramsA-3

HOW TO READ CONFIGURATION DIAGRAMS

The wiring harness diagrams clearly show the connector locations and harness routings at each site

on actual vehicles.

Denotes connector No.

The same connector No. is used throughout the circuit diagrams to facilitate

connector location searches.

The first alphabetical symbol indicates the location site of the connector

and a number that follows is the unique number. Numbers are assigned to

parts in clockwise order on the diagram.

A-43

Example: A-12

Number specific to connector (serial number)

Connector location site symbol

A: Engine compartment

B: Engine and transmission

assembly

C: Dash panel

Denotes earth point.

Same earth number is used throughout circuit

diagrams to facilitate search of earth point. Refer

to SINGLE PART INSTALLATION POSITION -

EARTH MOUNTING LOCATIONS for details of

earth points.

Indicates the device to which the

connector is to be connected.

A-39 (2-B) Headlamp (LO: RH)

A-40 (1) Horn (LO)

A-41 (1) Horn (HI)

A-42 (2-B) Windshield washer motor

The number of connector pins and the

connector colour (except milk white)* are

shown for ease of retrieval.

Example: (2

-B)

Connector colour

(milk white if no colour is indicated)

Number of connector pins

*: Typical connector colours

B: Black

Y: Yellow

L: Blue

G: Green

R: Red

The markLshows the

standard mounting posi-

tion of wiring harness.

R

A-44

A-45

A-42

A-39

Denotes the colour of corrugated

tube or vinyl tube. (If not specified,

it is black.)

R: Red

Y: Yellow

Denotes a section covered by a

corrugated tube.

BR: Brown

V: Violet

O: Orange

GR: Gray

None: Milk whiteD: Floor and roof

E: Door

F: Luggage compartment

Page 99 of 1449

B-1

ELECTRICAL

WIRING

CONTENTS

WIRING HARNESS CONFIGURATION

DIAGRAMS 4.........................

OVERALL WIRING DIAGRAM

L.H. drive vehicles 4........................

R.H. drive vehicles 5........................

ENGINE COMPARTMENT

L.H. drive vehicles 6........................

R.H. drive vehicles 8........................

ENGINE AND TRANSMISSION

L.H. drive vehicles 10.......................

R.H. drive vehicles 14.......................

DASH PANEL

L.H. drive vehicles 18.......................

R.H. drive vehicles 24.......................

FLOOR AND ROOF

L.H. drive vehicles 30.......................

R.H. drive vehicles 32.......................

DOOR

L.H. drive vehicles 34.......................

R.H. drive vehicles 36.......................

LUGGAGE COMPARTMENT

L.H. drive vehicles 38.......................

R.H. drive vehicles 39.......................

SINGLE PART INSTALLATION

POSITION 40.........................

RELAY 40.................................

ECU 41...................................

SENSOR 43...............................

SOLENOID VALVE 46......................

INSPECTION CONNECTOR AND SPARE

CONNECTOR 47...........................

FUSIBLE LINK AND FUSE 48..............

EARTH CABLE 49.........................

EARTH 50.................................

CIRCUIT DIAGRAMS 54...............

J/B 54....................................

J/C

L.H. drive vehicles 56.......................

R.H. drive vehicles 62.......................

CENTRALIZED JUNCTION 68..............

POWER DISTRIBUTION SYSTEM 74........

STARTING SYSTEM 79....................

Page 108 of 1449

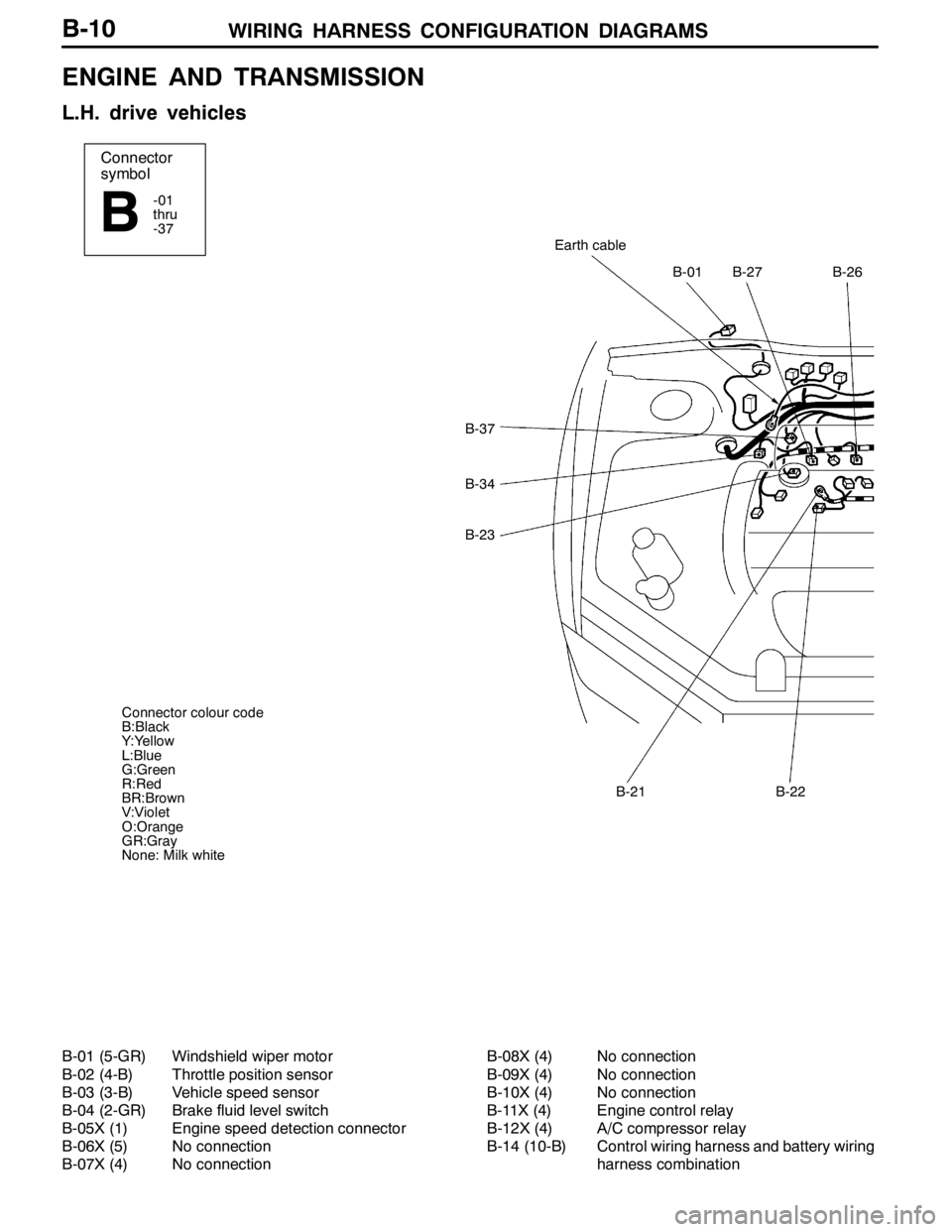

WIRING HARNESS CONFIGURATION DIAGRAMS

Connector

symbol

-01

thru

-37

B

B-37

B-34

B-23

B-01B-27B-26

Earth cable

B-21B-22

Connector colour code

B:Black

Y:Yellow

L:Blue

G:Green

R:Red

BR:Brown

V:Violet

O:Orange

GR:Gray

None: Milk white

B-10

ENGINE AND TRANSMISSION

L.H. drive vehicles

B-01 (5-GR) Windshield wiper motor

B-02 (4-B) Throttle position sensor

B-03 (3-B) Vehicle speed sensor

B-04 (2-GR) Brake fluid level switch

B-05X (1) Engine speed detection connector

B-06X (5) No connection

B-07X (4) No connectionB-08X (4) No connection

B-09X (4) No connection

B-10X (4) No connection

B-11X (4) Engine control relay

B-12X (4) A/C compressor relay

B-14 (10-B) Control wiring harness and battery wiring

harness combination

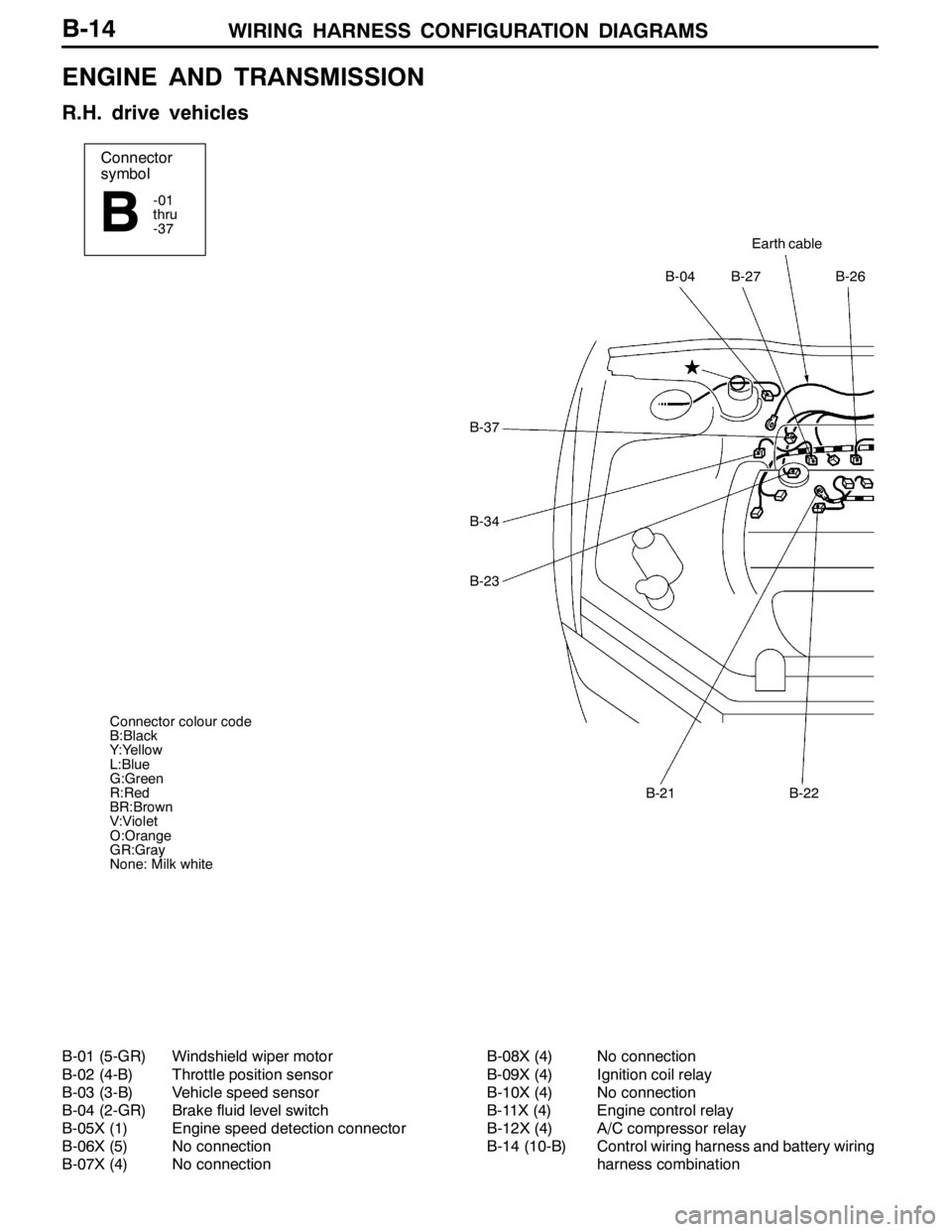

Page 112 of 1449

WIRING HARNESS CONFIGURATION DIAGRAMS

Connector

symbol

-01

thru

-37

B

Earth cable

B-27B-26B-04

B-22B-21

B-37

B-34

B-23

Connector colour code

B:Black

Y:Yellow

L:Blue

G:Green

R:Red

BR:Brown

V:Violet

O:Orange

GR:Gray

None: Milk white

B-14

ENGINE AND TRANSMISSION

R.H. drive vehicles

B-01 (5-GR) Windshield wiper motor

B-02 (4-B) Throttle position sensor

B-03 (3-B) Vehicle speed sensor

B-04 (2-GR) Brake fluid level switch

B-05X (1) Engine speed detection connector

B-06X (5) No connection

B-07X (4) No connectionB-08X (4) No connection

B-09X (4) Ignition coil relay

B-10X (4) No connection

B-11X (4) Engine control relay

B-12X (4) A/C compressor relay

B-14 (10-B) Control wiring harness and battery wiring

harness combination

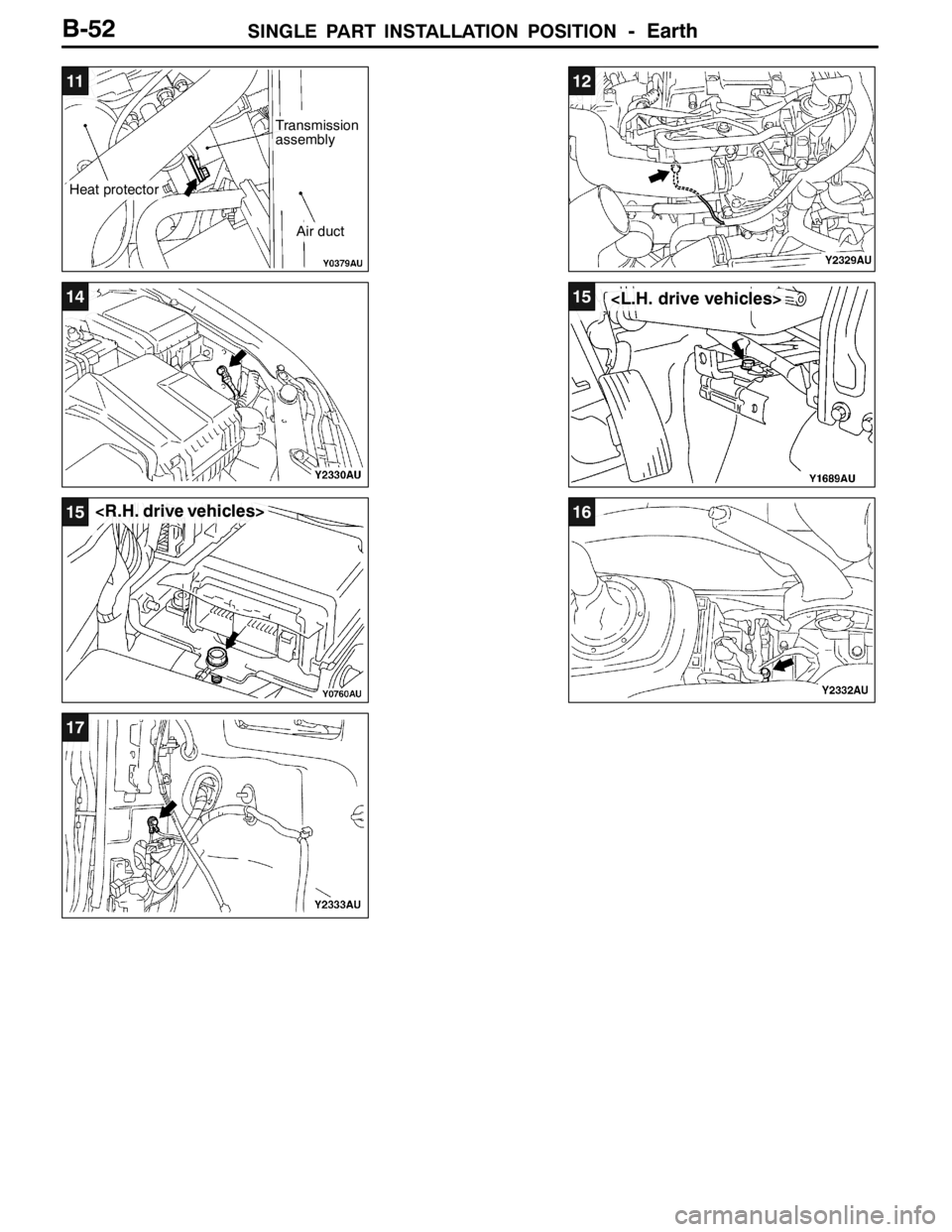

Page 150 of 1449

SINGLE PART INSTALLATION POSITION- Earth

11

Heat protector

Transmission

assembly

Air duct

12

1415

15

17

B-52

Page 380 of 1449

GENERAL -How to Use This Manual00-2

HOW TO USE THIS MANUAL

SCOPE OF MAINTENANCE, REPAIR

AND SERVICING EXPLANATIONS

This manual provides explanations, etc. concerning

procedures for the inspection, maintenance, repair

and servicing of the subject model. Note, however,

that for engine and transmission-related component

parts, this manual covers only on-vehicle

inspections, adjustments, and the removal and

installation procedures for major components.

For detailed information concerning the inspection,

checking, adjustment, disassembly and reassembly

of the engine, transmission and major components

after they have been removed from the vehicle,

please refer to separate manuals covering the

engine and the transmission.

ON-VEHICLE SERVICE

“On-vehicle Service” is procedures for performing

inspections and adjustments of particularly

important locations with regard to the construction

and for maintenance and servicing, but other

inspection (for looseness, play, cracking, damage,

etc.) must also be performed.

INSPECTION

Under this title are presented inspection and

checking procedures to be performed by using

special tools and measuring instruments and by

feeling, but, for actual maintenance and servicing

procedures, visual inspections should always be

performed as well.

INDICATION OF DESTINATION

General Export and GCC are used for convenience

to indicate destination.

NOTE

(1) “General Export” means territories other than

Europe, GCC, Australia, New Zealand, the

U.S.A. and Canada.

(2) “GCC” indicates countries that are members

of the (Persian) Gulf Cooperation Council of

nations.

(3) In some instances, vehicles with other

specifications may be shipped to some

countries.

DEFINITION OF TERMS

STANDARD VALUE

Indicates the value used as the standard for judging

the quality of a part or assembly on inspection

or the value to which the part or assembly is

corrected and adjusted. It is given by tolerance.

LIMIT

Shows the standard for judging the quality of a

part or assembly on inspection and means the

maximum or minimum value within which the part

or assembly must be kept functionally or in strength.

It is a value established outside the range of

standard value.

REFERENCE VALUE

Indicates the adjustment value prior to starting the

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be

completed in a shorter time).

CAUTION

Indicates the presentation of information particularly

vital to the worker during the performance of

maintenance and servicing procedures in order to

avoid the possibility of injury to the worker, or

damage to component parts, or a reduction of

component or vehicle function or performance, etc.

INDICATION OF TIGHTENING TORQUE

Tightening torques (units: N·m) are set to take into

account the central value and the allowable

tolerance. The central value is the target value,

and the allowable tolerance provides the checking

range for tightening torques. If bolts and nuts are

not provided with tightening torques, refer to

P.00-28.

Page 381 of 1449

GENERAL -How to Use This Manual00-3

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.

MPI: Indicates the multipoint injection, or engine equipped with the multipoint injection.

DOHC: Indicates an engine with the double overhead camshaft, or a model equipped with such an

engine.

M/T: Indicates the manual transmission, or models equipped with the manual transmission.

A/C: Indicates the air conditioner.