battery MITSUBISHI LANCER EVOLUTION X 2008 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 144 of 241

GENERATOR CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-51

GENERATOR CONTROLM2132025000172

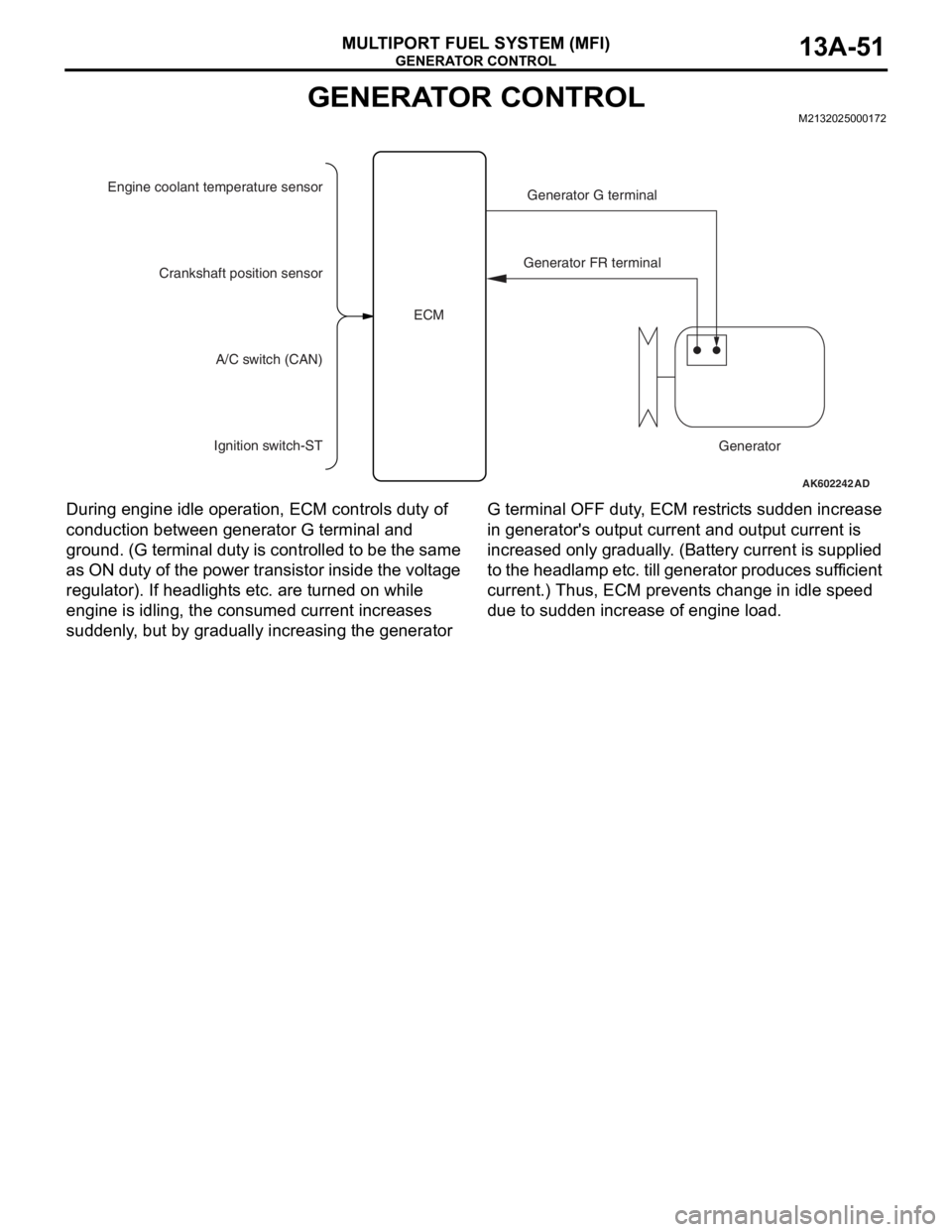

During engine idle operation, ECM controls duty of

conduction between generator G terminal and

ground. (G terminal duty is controlled to be the same

as ON duty of the power transistor inside the voltage

regulator). If headlights etc. are turned on while

engine is idling, the consumed current increases

suddenly, but by gradually increasing the generator G terminal OFF duty, ECM restricts sudden increase

in generator's output current and output current is

increased only gradually. (Battery current is supplied

to the headlamp etc. till generator produces sufficient

current.) Thus, ECM prevents change in idle speed

due to sudden increase of engine load.

AK602242 AD

Engine coolant temperature sensor

Generator G terminal

Generator FR terminal

Generator Crankshaft position sensor

A/C switch (CAN)

Ignition switch-STECM

Page 145 of 241

EVAPORATIVE EMISSION CONTROL SYSTEM INCORRECT PURGE FLOW MONITOR

MULTIPORT FUEL SYSTEM (MFI)13A-52

EVAPORATIVE EMISSION CONTROL SYSTEM INCORRECT

PURGE FLOW MONITOR

M2132027200019

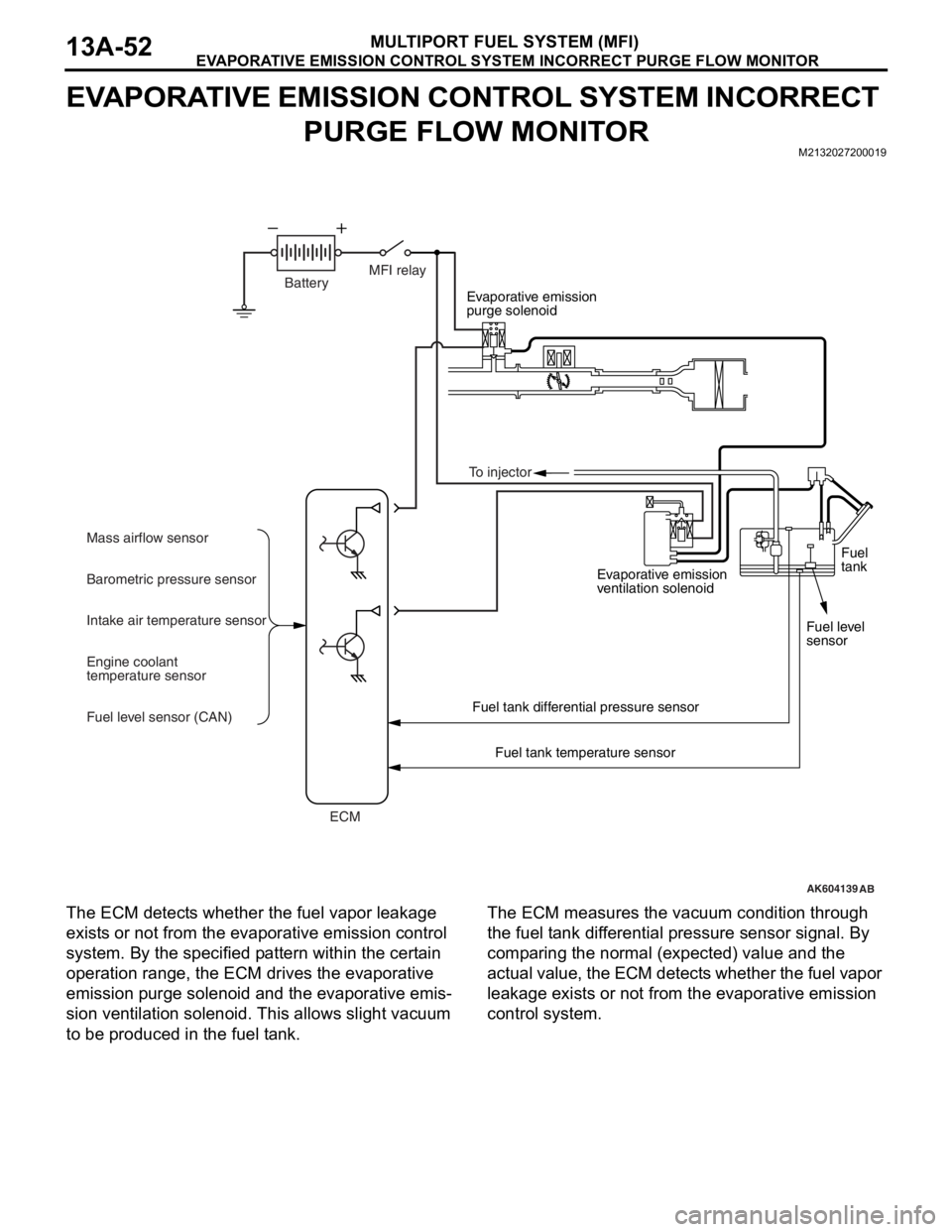

The ECM detects whether the fuel vapor leakage

exists or not from the evaporative emission control

system. By the specified pattern within the certain

operation range, the ECM drives the evaporative

emission purge solenoid and the evaporative emis

-

sion ventilation solenoid. This allows slight vacuum

to be produced in the fuel tank.

The ECM measures the vacuum condition through

the fuel tank differential pressure sensor signal. By

comparing the normal (expected) value and the

actual value, the ECM detects whether the fuel vapor

leakage exists or not from the evaporative emission

control system.

AK604139

Evaporative emission

purge solenoid

Evaporative emission

ventilation solenoid

Fuel tank differential pressure sensor

Fuel tank temperature sensor

AB

BatteryMFI relay

ECM Mass airflow sensor

Barometric pressure sensor

Intake air temperature sensor

Engine coolant

temperature sensor

Fuel level sensor (CAN)Fuel

tank

Fuel level

sensor To injector

Page 180 of 241

FRONT SEAT ASSEMBLY

TSB Revision

INTERIOR52A-19

INSPECTIONM1522005500287

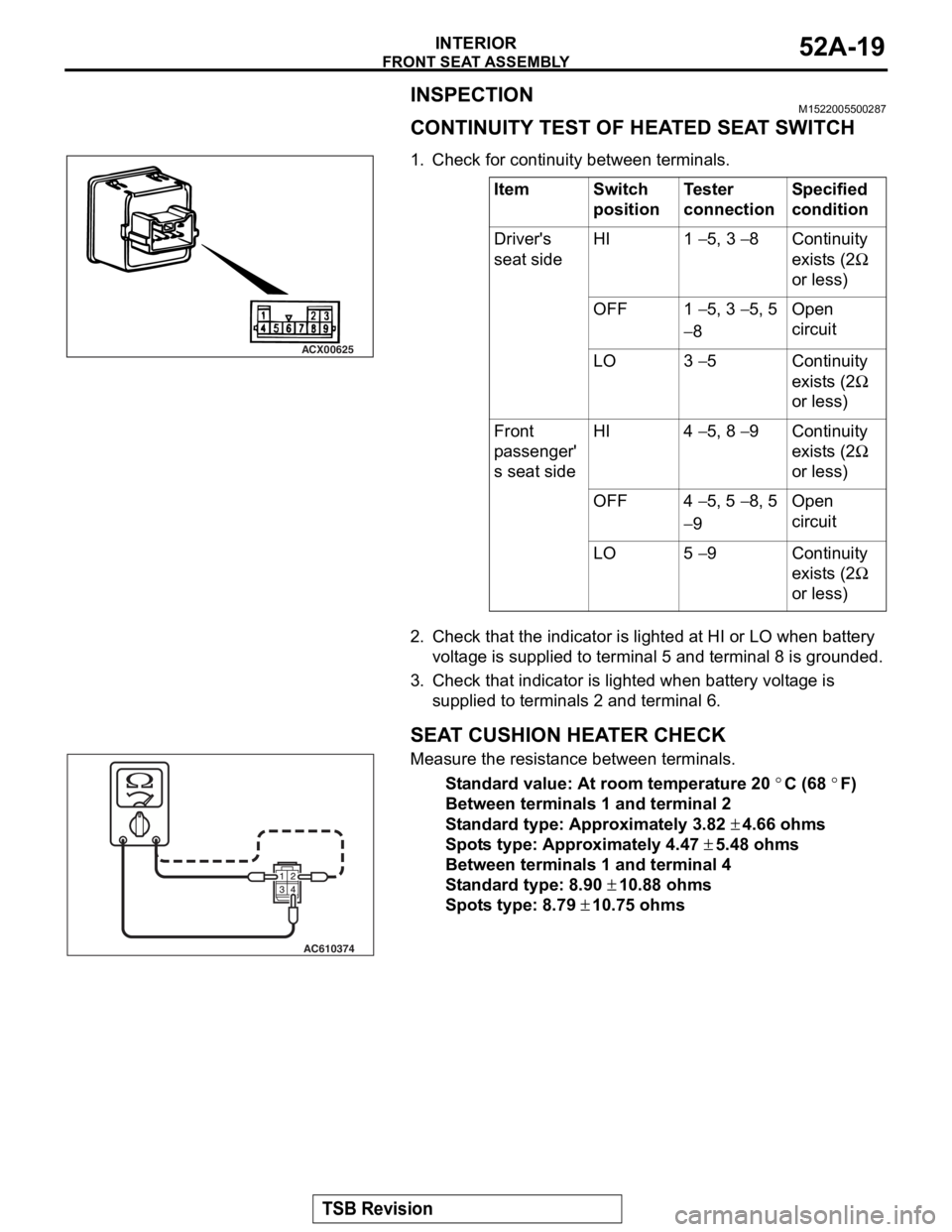

CONTINUITY TEST OF HEATED SEAT SWITCH

.1. Check for continuity between terminals.

2. Check that the indicator is lighted at HI or LO when battery voltage is supplied to terminal 5 and terminal 8 is grounded.

3. Check that indicator is lighted when battery voltage is

supplied to terminal s 2 and terminal 6.

.

SEAT CUSHION HEATER CHECK

Measure the resistance between terminals.

Standard value: At room temperature 20 °C (68 °F)

Between terminals 1 and terminal 2

Standard type: Approximately 3.82 ± 4.66 ohms

Spots type: Approximately 4.47 ± 5.48 ohms

Between terminals 1 and terminal 4

Standard type: 8.90 ± 10.88 ohms

Spots type: 8.79 ± 10.75 ohms

.

ItemSwitch

positionTester

connectionSpecified

condition

Driver's

seat sideHI1 − 5, 3 − 8Continuity

exists (2

Ω

or less)

OFF1 − 5, 3 − 5, 5

− 8

Open

circuit

LO3 − 5Continuity

exists (2

Ω

or less)

Front

passenger'

s seat sideHI4 − 5, 8 − 9Continuity

exists (2

Ω

or less)

OFF4 − 5, 5 − 8, 5

− 9

Open

circuit

LO5 − 9Continuity

exists (2

Ω

or less)

ACX00625

AC610374

Page 181 of 241

FRONT SEAT ASSEMBLY

TSB Revision

INTERIOR52A-20

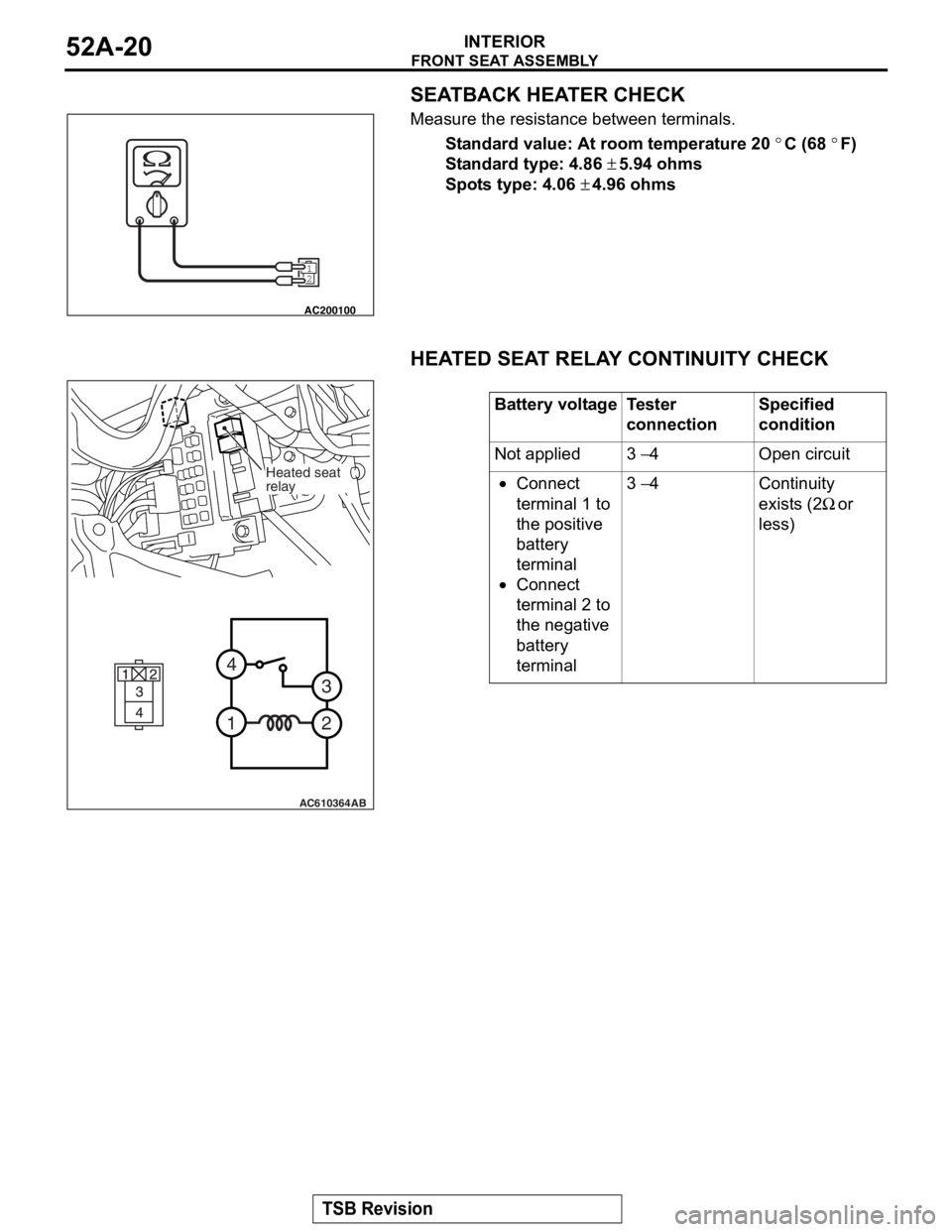

SEATBACK HEATER CHECK

Measure the resistance between terminals.

Standard value: At room temperature 20 °C (68 °F)

Standard type: 4.86 ± 5.94 ohms

Spots type: 4.06 ± 4.96 ohms

HEATED SEAT RELAY CONTINUITY CHECK

12

AC200100

Battery voltageTester

connectionSpecified

condition

Not applied3 − 4Open circuit

•Connect

terminal 1 to

the positive

battery

terminal

•Connect

terminal 2 to

the negative

battery

terminal

3 − 4Continuity

exists (2

Ω or

less)

AC610364

2

3

4

1

AB

Heated seat

relay

Page 189 of 241

FRONT SEAT BELT

TSB Revision

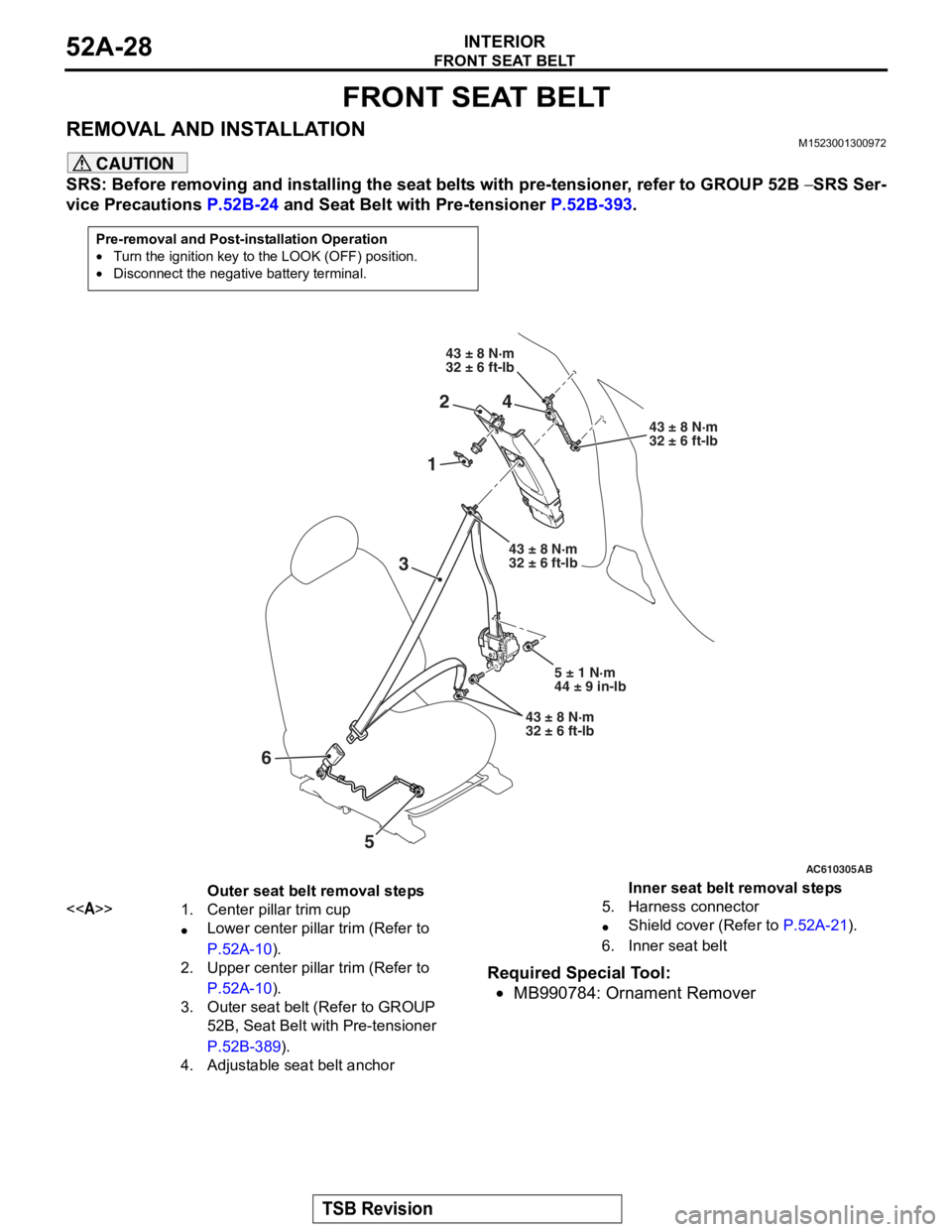

INTERIOR52A-28

FRONT SEAT BELT

REMOVAL AND INSTALLATIONM1523001300972

CAUTION

SRS: Before removing and installing the seat belts with pre-tensioner, refer to GROUP 52B − SRS Ser-

vice Precautions P.52B-24 and Seat Belt with Pre-tensioner P.52B-393.

Required Special Tool:

•MB990784: Ornament Remover

Pre-removal and Post-installation Operation

•Turn the ignition key to the LOOK (OFF) position.

•Disconnect the negative battery terminal.

AC608130

AC610305

AC608130

1

43 ± 8 N·m

32 ± 6 ft-lb

43 ± 8 N·m

32 ± 6 ft-lb

AB

3

24

5

43 ± 8 N·m

32 ± 6 ft-lb

5 ± 1 N·m

44 ± 9 in-lb

43 ± 8 N·m

32 ± 6 ft-lb

6

Outer seat belt removal steps

<>1.Center pillar trim cup

•Lower center pillar trim (Refer to

P.52A-10).

2.Upper center pillar trim (Refer to

P.52A-10).

3.Outer seat belt (Refer to GROUP

52B, Seat Belt with Pre-tensioner

P.52B-389).

4.Adjustable seat belt anchor

Inner seat belt removal steps

5.Harness connector

•Shield cover (Refer to P.52A-21).

6.Inner seat belt

Page 220 of 241

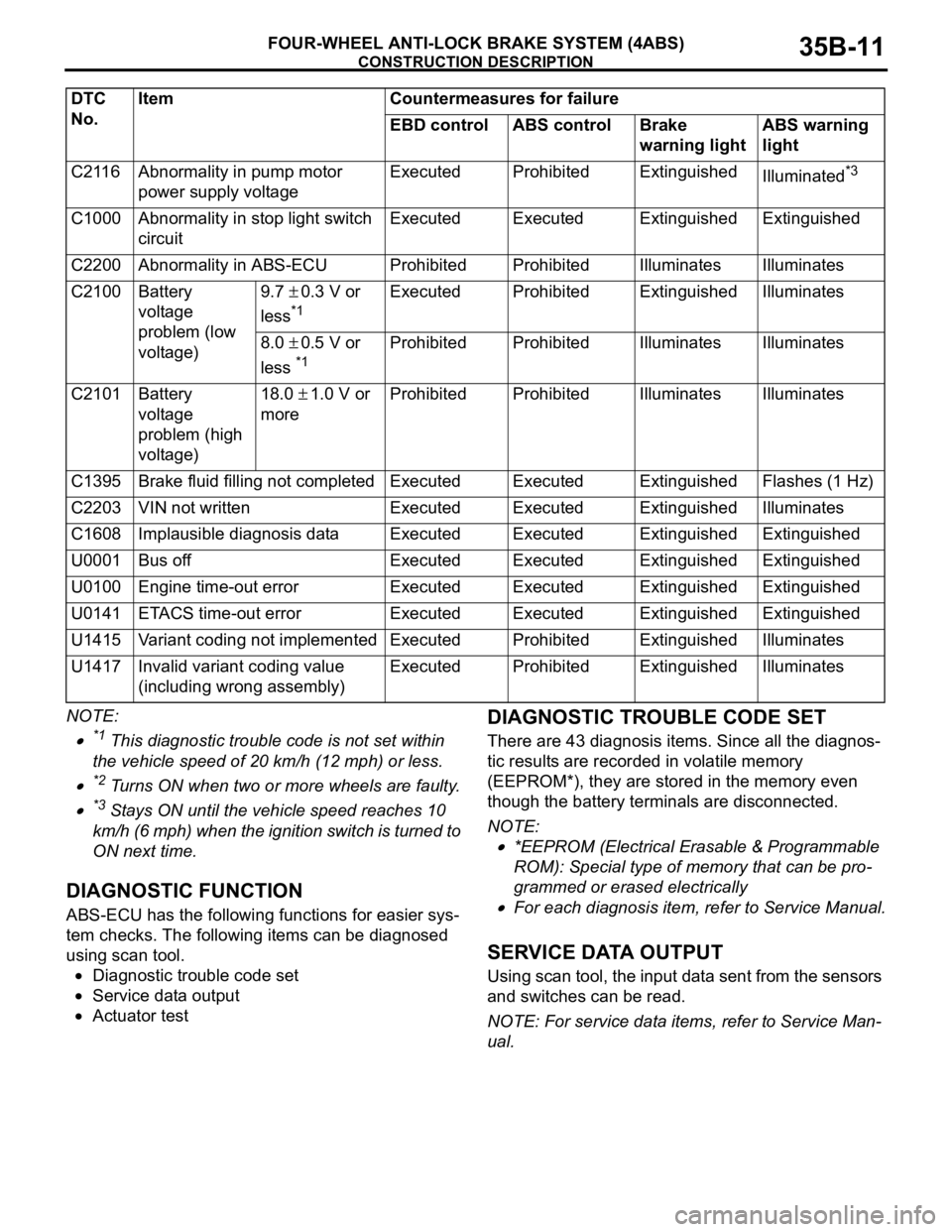

CONSTRUCTION DESCRIPTION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-11

NOTE: .

•*1 This diagnostic trouble code is not set within

the vehicle speed of 20 km/h (12 mph) or less.

•*2 Turns ON when two or more wheels are faulty.

•*3 Stays ON until the vehicle speed reaches 10

km/h (6 mph) when the ignition switch is turned to

ON next time.

DIAGNOSTIC FUNCTION

ABS-ECU has the following functions for easier sys-

tem checks. The following items can be diagnosed

using scan tool.

•Diagnostic trouble code set

•Service data output

•Actuator test.

DIAGNOSTIC TROUBLE CODE SET

There are 43 diagnosis items. Since all the diagnos-

tic results are recorded in volatile memory

(EEPROM*), they are stored in the memory even

though the battery terminals are disconnected.

NOTE: .

•*EEPROM (Electrical Erasable & Programmable

ROM): Special type of memory that can be pro

-

grammed or erased electrically

•For each diagnosis item, refer to Service Manual.

.

SERVICE DATA OUTPUT

Using scan tool, the input data sent from the sensors

and switches can be read.

NOTE: For service data items, refer to Service Man-

ual.

.

C2116Abnormality in pump motor

power supply voltageExecutedProhibitedExtinguishedIlluminated*3

C1000Abnormality in stop light switch

circuitExecutedExecutedExtinguishedExtinguished

C2200Abnormality in ABS-ECUProhibitedProhibitedIlluminatesIlluminates

C2100Battery

voltage

problem (low

voltage)9.7 ± 0.3 V or

less

*1

ExecutedProhibitedExtinguishedIlluminates

8.0 ± 0.5 V or

less

*1

ProhibitedProhibitedIlluminatesIlluminates

C2101Battery

voltage

problem (high

voltage)18.0 ± 1.0 V or

moreProhibitedProhibitedIlluminatesIlluminates

C1395Brake fluid filling not completedExecutedExecutedExtinguishedFlashes (1 Hz)

C2203VIN not writtenExecutedExecutedExtinguishedIlluminates

C1608Implausible diagnosis dataExecutedExecutedExtinguishedExtinguished

U0001Bus offExecutedExecutedExtinguishedExtinguished

U0100Engine time-out errorExecutedExecutedExtinguishedExtinguished

U0141ETACS time-out errorExecutedExecutedExtinguishedExtinguished

U1415Variant coding not implementedExecutedProhibitedExtinguishedIlluminates

U1417Invalid variant coding value

(including wrong assembly)ExecutedProhibitedExtinguishedIlluminates

DTC

No.Item Countermeasures for failure

EBD control ABS control Brake

warning lightABS warning

light