battery MITSUBISHI LANCER EVOLUTION X 2008 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 125 of 241

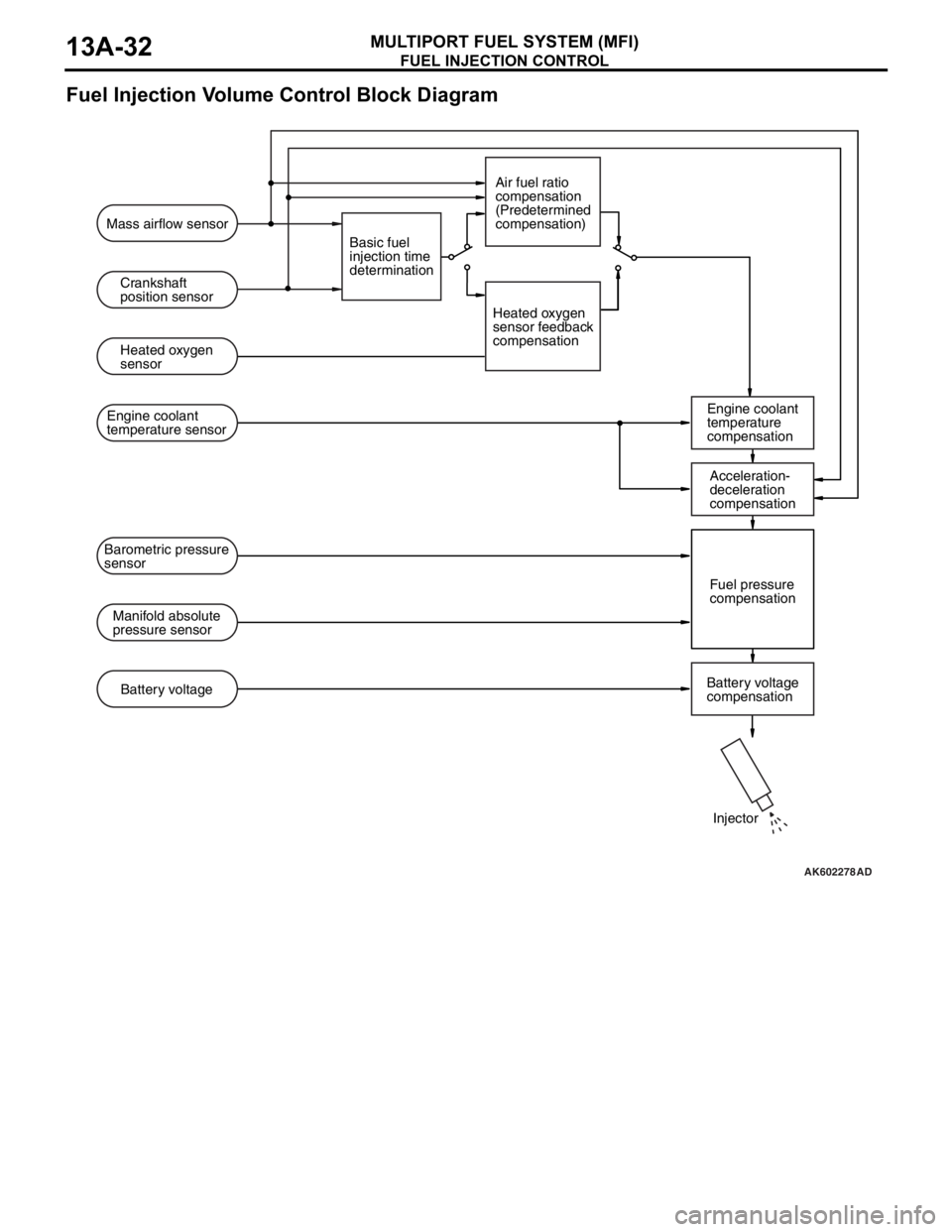

FUEL INJECTION CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-32

Fuel Injection Volume Control Block Diagram

.

AK602278AD

Mass airflow sensor

Crankshaft

position sensor

Heated oxygen

sensor

Engine coolant

temperature

compensation Engine coolant

temperature sensor

Manifold absolute

pressure sensorFuel pressure

compensation Barometric pressure

sensor

Battery voltage

compensation Battery voltageBasic fuel

injection time

determinationAir fuel ratio

compensation

(Predetermined

compensation)

Heated oxygen

sensor feedback

compensation

Injector Acceleration-

deceleration

compensation

Page 127 of 241

![MITSUBISHI LANCER EVOLUTION X 2008 User Guide FUEL INJECTION CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-34

[Injector drive time compensation]

After calculating the injector basic drive time, the ECM makes

the following compensations to control the o MITSUBISHI LANCER EVOLUTION X 2008 User Guide FUEL INJECTION CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-34

[Injector drive time compensation]

After calculating the injector basic drive time, the ECM makes

the following compensations to control the o](/img/19/57326/w960_57326-126.png)

FUEL INJECTION CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-34

[Injector drive time compensation]

After calculating the injector basic drive time, the ECM makes

the following compensations to control the optimum fuel injec

-

tion volume according to driving conditions.

List of main compensations for fuel injection control

.

[Fuel limit control during deceleration]

ECM limits fuel when decelerating downhill to prevent exces-

sive rise of catalytic converter temperature and to improve fuel

efficiency.

.

[Fuel-cut control when over-run]

When engine speed exceeds a prescribed limit (6,600 r/min),

ECM cuts fuel supply to prevent overrunning and thus protect

the engine. Also, if engine speed exceeds 4,000 r/min for 15

seconds while vehicle is stationary (no load), it cuts fuel supply

and controls the throttle valve opening angle to protect the

engine.

CompensationsContent

Heated oxygen sensor feedback compensationThe heated oxygen sensor signal is used for

making the compensation to get air-fuel ratio with

best cleaning efficiency of the 3-way catalytic

converter. This compensation might not be made

sometimes in order to improve drivability,

depending on driving conditions. (Air-fuel ratio

compensation is made.)

Air-fuel ratio compensationUnder driving conditions where heated oxygen

sensor feedback compensation is not performed,

compensation is made based on pre-set map

values that vary according to engine speed and

intake air volume.

Engine coolant temperature compensationCompensation is made according to the engine

coolant temperature. The lower the engine coolant

temperature, the greater the fuel injection volume.

Acceleration/ Deceleration compensationCompensation is made according to change in

intake air volume. During acceleration, fuel injection

volume is increased. Also, during deceleration, fuel

injection volume is decreased.

Fuel injection compensationCompensation is made according to the pressure

difference between atmospheric pressure and

manifold absolute pressure. The greater the

difference in pressure, the shorter the injector drive

time.

Battery voltage compensationCompensation is made depending on battery

voltage. The lower the battery voltage, the greater

the injector drive signal time.

Learning value for fuel compensationCompensation amount is learned to compensate

feedback of heated oxygen sensor. This allows

system to compensate in accordance with engine

characteristics.

Page 128 of 241

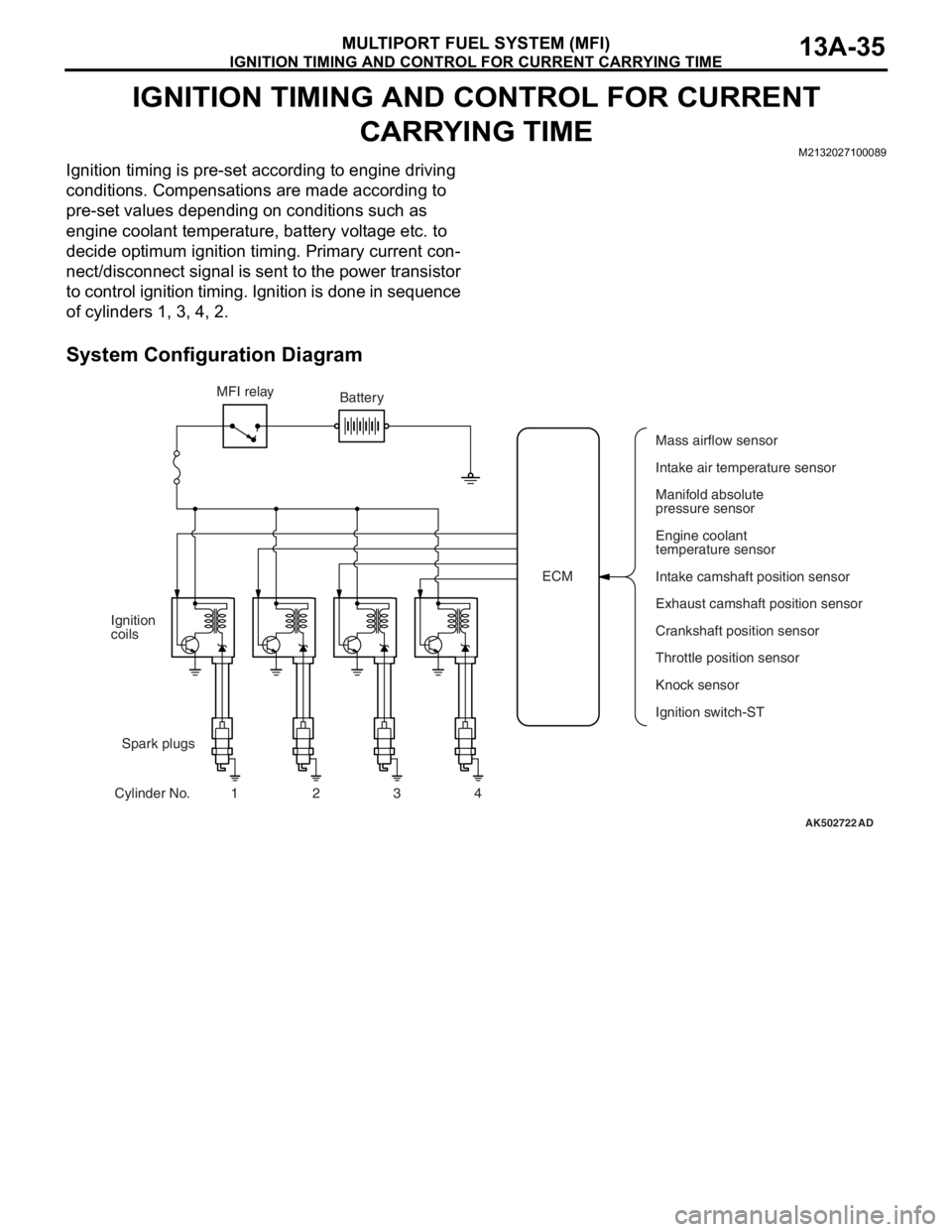

IGNITION TIMING AND CONTROL FOR CURRENT CARRYING TIME

MULTIPORT FUEL SYSTEM (MFI)13A-35

IGNITION TIMING AND CONTROL FOR CURRENT

CARRYING TIME

M2132027100089

Ignition timing is pre-set according to engine driving

conditions. Compensations are made according to

pre-set values depending on conditions such as

engine coolant temperature, battery voltage etc. to

decide optimum ignition timing. Primary current con

-

nect/disconnect signal is sent to the power transistor

to control ignition timing. Ignition is done in sequence

of cylinders 1, 3, 4, 2.

System Configuration Diagram

AK502722AD

ECM MFI relay

Spark plugs Ignition

coils

Cylinder No. 1 2 3 4Battery

Mass airflow sensor

Intake air temperature sensor

Manifold absolute

pressure sensor

Engine coolant

temperature sensor

Intake camshaft position sensor

Exhaust camshaft position sensor

Crankshaft position sensor

Knock sensor

Ignition switch-ST Throttle position sensor

Page 130 of 241

![MITSUBISHI LANCER EVOLUTION X 2008 User Guide IGNITION TIMING AND CONTROL FOR CURRENT CARRYING TIME

MULTIPORT FUEL SYSTEM (MFI)13A-37

2. Spark-advance control and current carrying

time control

.

[During start]

ECM initiates ignition at fixed ign MITSUBISHI LANCER EVOLUTION X 2008 User Guide IGNITION TIMING AND CONTROL FOR CURRENT CARRYING TIME

MULTIPORT FUEL SYSTEM (MFI)13A-37

2. Spark-advance control and current carrying

time control

.

[During start]

ECM initiates ignition at fixed ign](/img/19/57326/w960_57326-129.png)

IGNITION TIMING AND CONTROL FOR CURRENT CARRYING TIME

MULTIPORT FUEL SYSTEM (MFI)13A-37

2. Spark-advance control and current carrying

time control

.

[During start]

ECM initiates ignition at fixed ignition timing (5° BTDC) syn-

chronized with the crankshaft position sensor signal.

.

[During normal operation]

After determining the basic spark-advance based on the intake

air volume and engine speed, ECM makes compensations

based on input from various sensors to control the optimum

spark-advance and current carrying time.

List of main compensations for spark-advance control and current carrying time control

.

[Control for checking ignition timing]

During basic ignition timing set mode for M.U.T.-III actuator test

function, sparking is done with fixed ignition timing (5

° BTDC)

synchronized with crankshaft position sensor signal.

CompensationsContent

Intake air temperature compensationCompensation is made according to intake air

temperature. The higher the intake air temperature

the greater the delay in ignition timing.

Engine coolant temperature compensationCompensation is made according to engine coolant

temperature. The lower the engine coolant

temperature the greater the advance in ignition

timing.

Knocking compensationCompensation is made according to generation of

knocking. The greater the knocking the greater the

delay in ignition timing.

Stable idle compensationCompensation is made according to change in idle

speed. In case engine speed becomes lower than

target speed, ignition timing is advanced.

Delay compensation when changing shiftDuring change of shift, sparking is delayed

compared to normal ignition timing to reduce

engine output torque and absorb the shock of the

shift change.

Battery voltage compensationCompensation is made depending on battery

voltage. The lower the battery voltage the greater

the current carrying time and when battery voltage

is high current carrying time is shortened.

Page 138 of 241

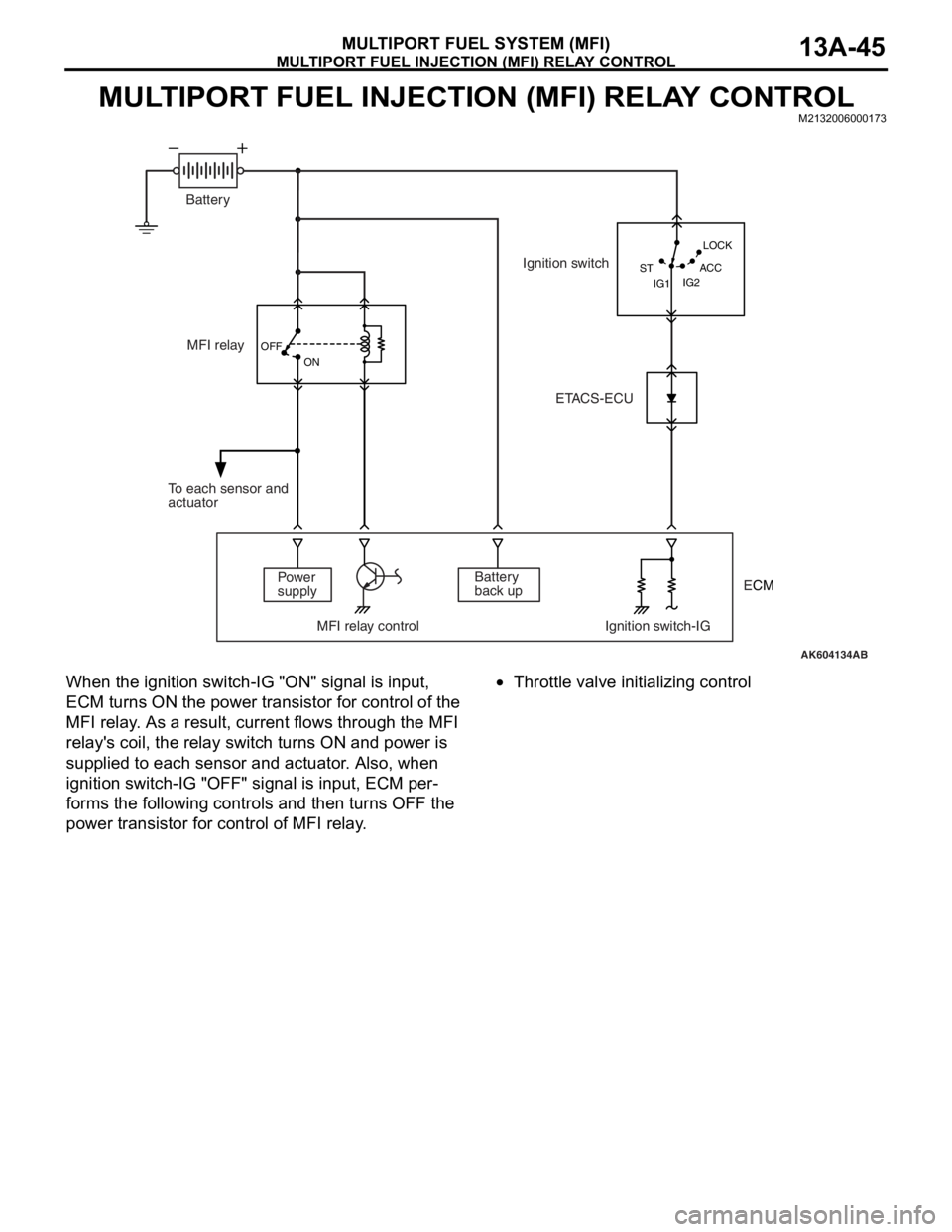

MULTIPORT FUEL INJECTION (MFI) RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-45

MULTIPORT FUEL INJECTION (MFI) RELAY CONTROLM2132006000173

When the ignition switch-IG "ON" signal is input,

ECM turns ON the power transistor for control of the

MFI relay. As a result, current flows through the MFI

relay's coil, the relay switch turns ON and power is

supplied to each sensor and actuator. Also, when

ignition switch-IG "OFF" signal is input, ECM per

-

forms the following controls and then turns OFF the

power transistor for control of MFI relay.

•Throttle valve initializing control

AK604134AB OFF

ON

IG2 STLOCK

ACC

IG1

MFI relay

Power

supply

MFI relay control Ignition switch-IGBattery

back up To each sensor and

actuatorIgnition switch

ETACS-ECU Battery

ECM

Page 139 of 241

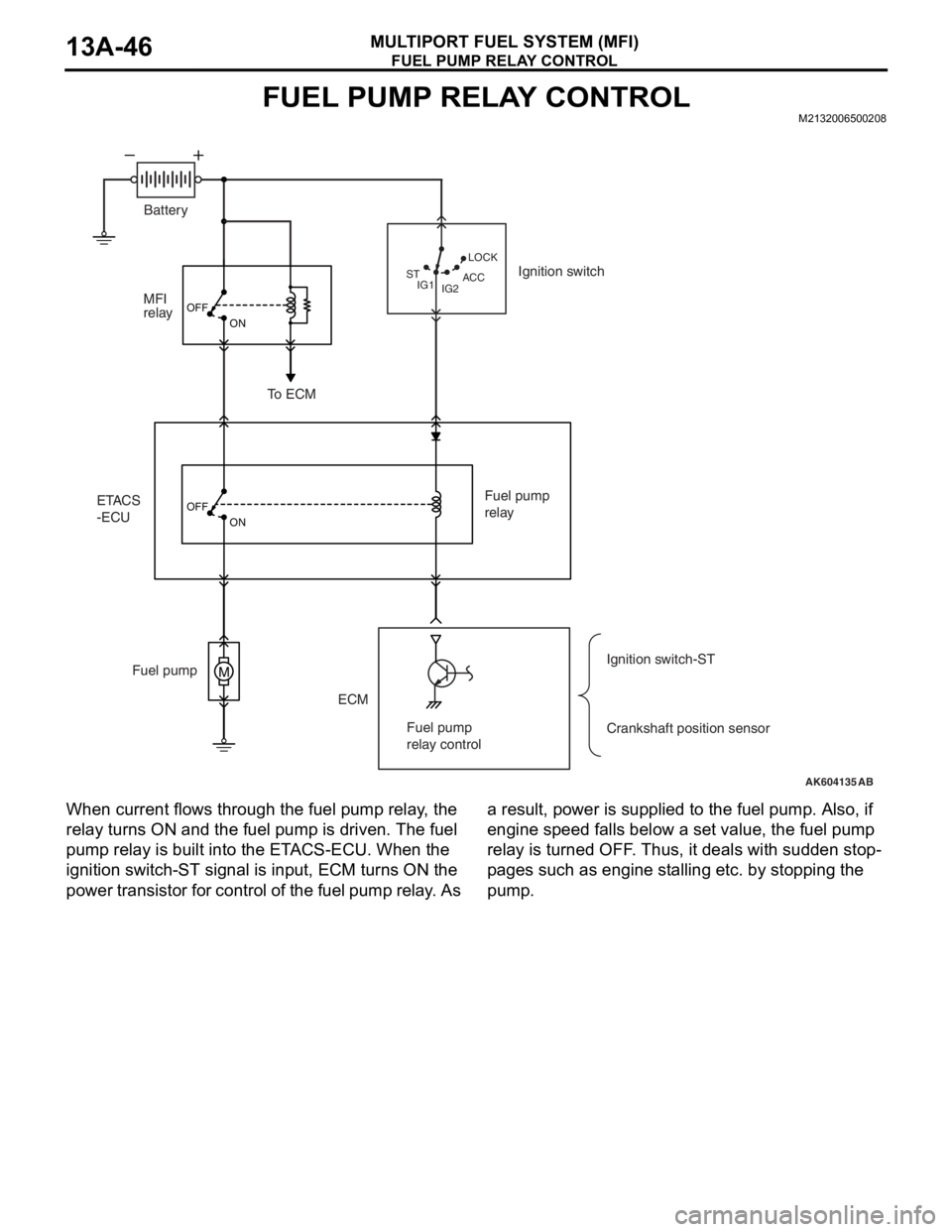

FUEL PUMP RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-46

FUEL PUMP RELAY CONTROLM2132006500208

When current flows through the fuel pump relay, the

relay turns ON and the fuel pump is driven. The fuel

pump relay is built into the ETACS-ECU. When the

ignition switch-ST signal is input, ECM turns ON the

power transistor for control of the fuel pump relay. As a result, power is supplied to the fuel pump. Also, if

engine speed falls below a set value, the fuel pump

relay is turned OFF. Thus, it deals with sudden stop

-

pages such as engine stalling etc. by stopping the

pump.

AK604135

M

OFF

ON

OFF

ON

AB IG2 STLOCK

ACC

IG1

ETACS

-ECUMFI

relay

ECM Fuel pumpFuel pump

relay

Crankshaft position sensor Ignition switch

To ECM

Ignition switch-ST Battery

Fuel pump

relay control

Page 140 of 241

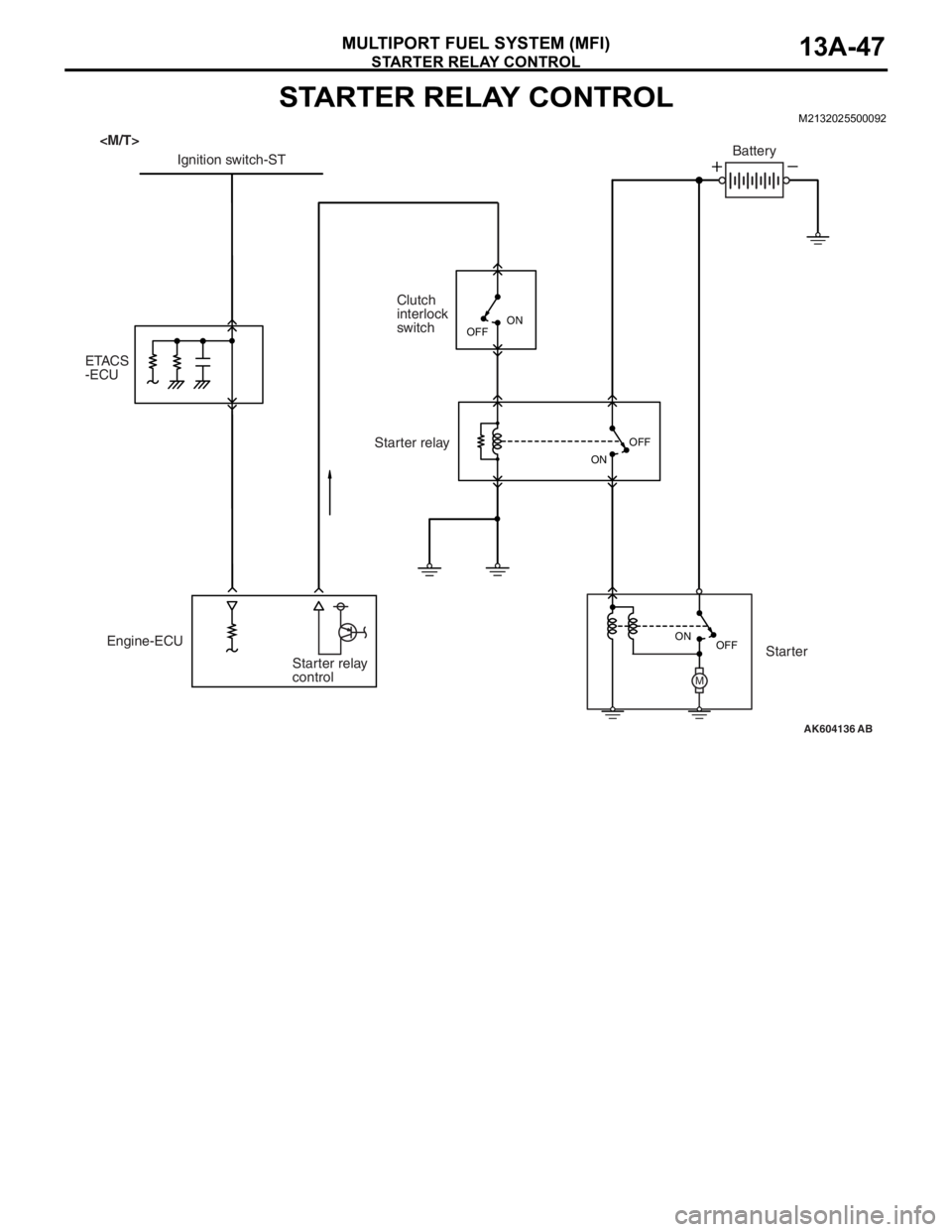

STARTER RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-47

STARTER RELAY CONTROLM2132025500092

AK604136

M

AB OFF ON OFF

ON

Engine-ECU

Starter relay

controlClutch

interlock

switch

ETACS

-ECUIgnition switch-STBattery

Starter relay

Starter

OFFON

Page 141 of 241

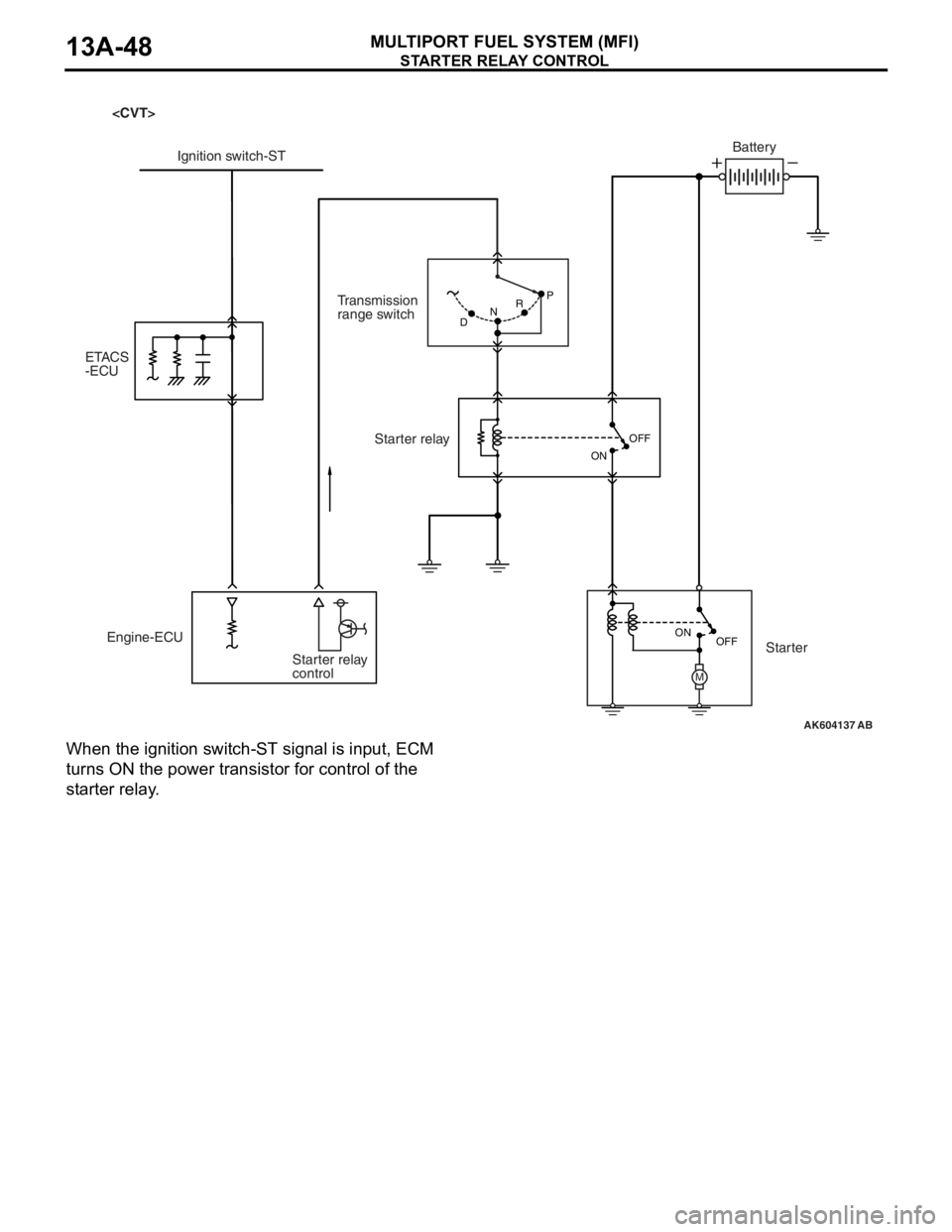

STARTER RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-48

When the ignition switch-ST signal is input, ECM

turns ON the power transistor for control of the

starter relay.

AK604137

M

AB P

DNR

OFF ON OFF

ON

Engine-ECU

Starter relay

controlTransmission

range switch Ignition switch-STBattery

Starter relay

Starter ETACS

-ECU

Page 142 of 241

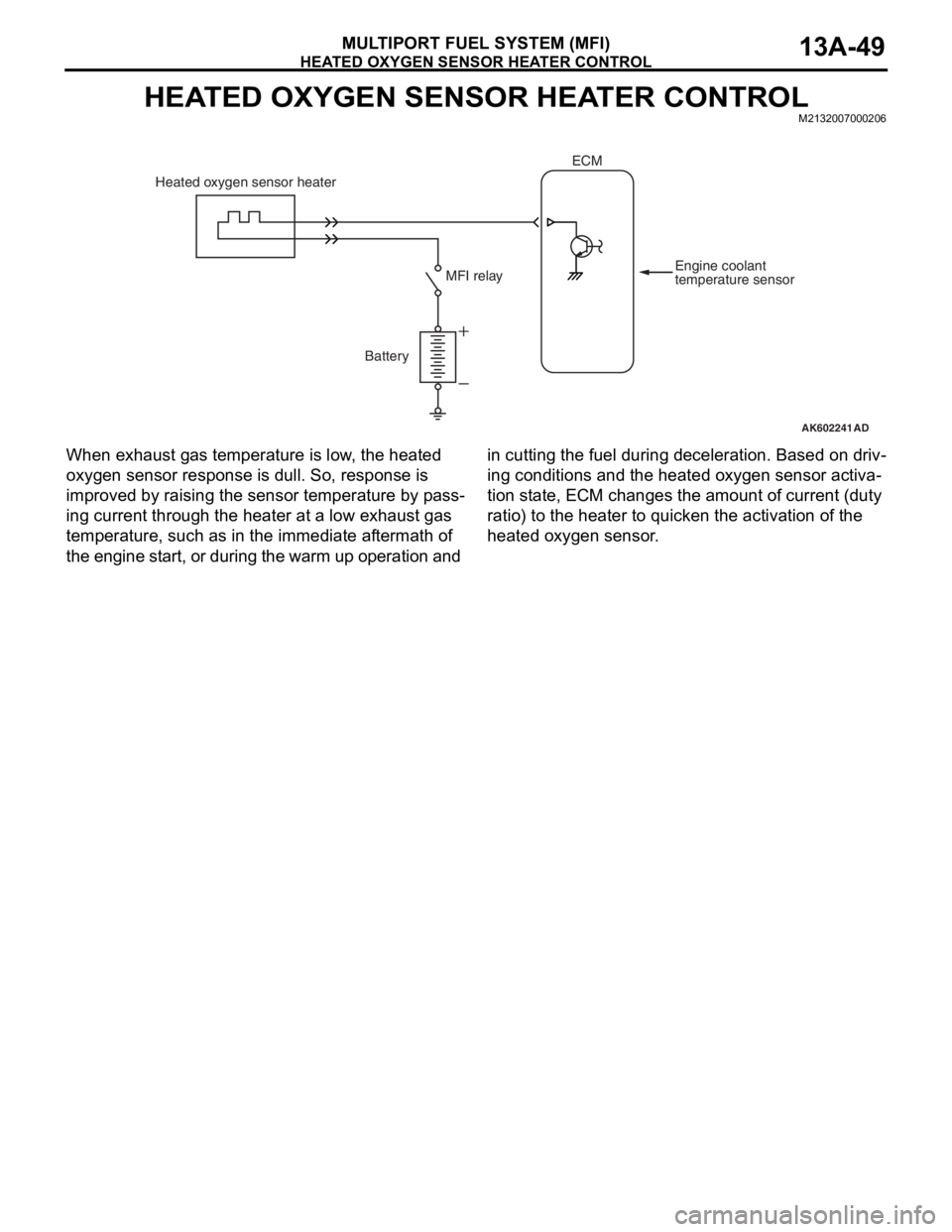

HEATED OXYGEN SENSOR HEATER CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-49

HEATED OXYGEN SENSOR HEATER CONTROLM2132007000206

When exhaust gas temperature is low, the heated

oxygen sensor response is dull. So, response is

improved by raising the sensor temperature by pass

-

ing current through the heater at a low exhaust gas

temperature, such as in the immediate aftermath of

the engine start, or during the warm up operation and in cutting the fuel during deceleration. Based on driv

-

ing conditions and the heated oxygen sensor activa-

tion state, ECM changes the amount of current (duty

ratio) to the heater to quicken the activation of the

heated oxygen sensor.

AK602241AD

Battery Heated oxygen sensor heater

Engine coolant

temperature sensor MFI relay

ECM

Page 143 of 241

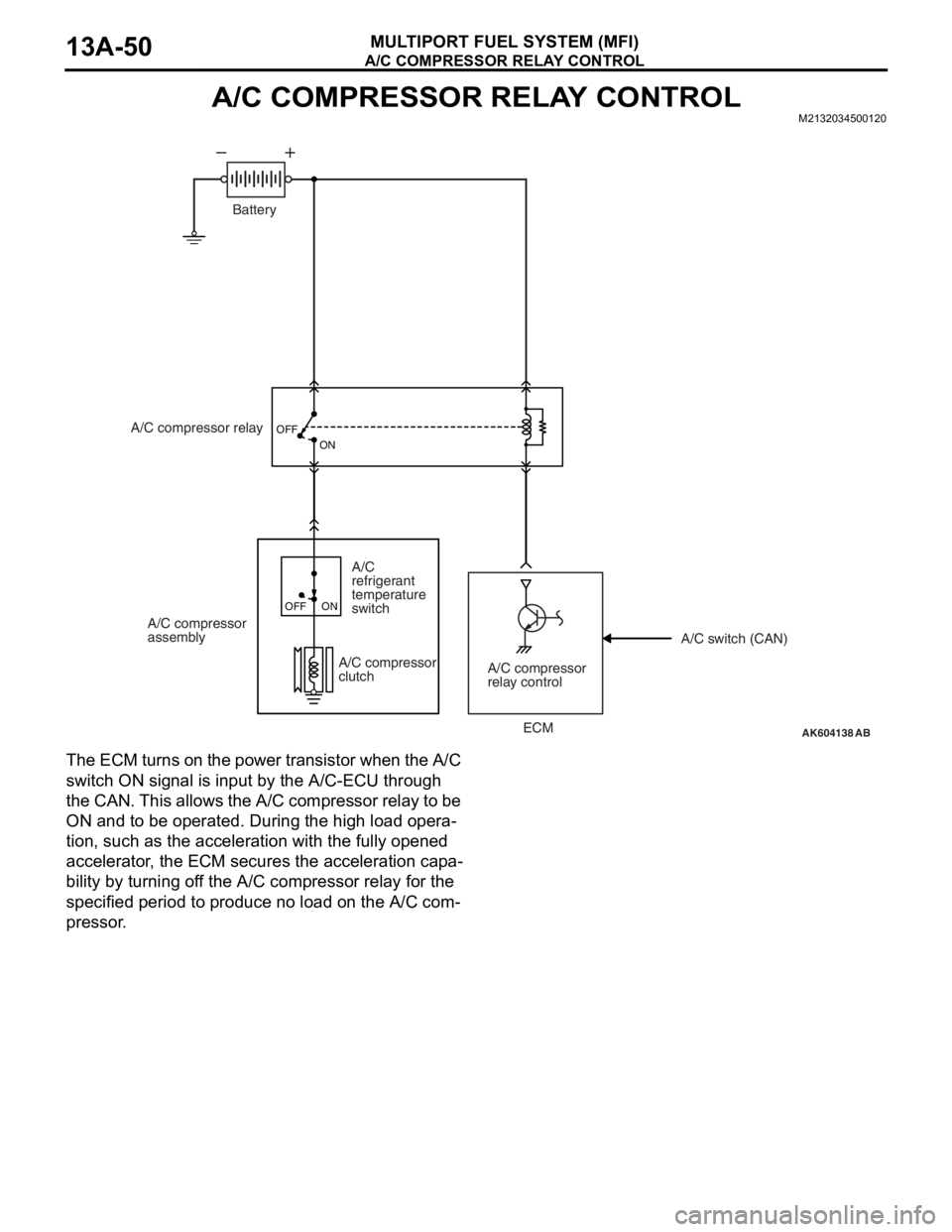

A/C COMPRESSOR RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-50

A/C COMPRESSOR RELAY CONTROLM2132034500120

The ECM turns on the power transistor when the A/C

switch ON signal is input by the A/C-ECU through

the CAN. This allows the A/C compressor relay to be

ON and to be operated. During the high load opera

-

tion, such as the acceleration with the fully opened

accelerator, the ECM secures the acceleration capa

-

bility by turning off the A/C compressor relay for the

specified period to produce no load on the A/C com

-

pressor.

AK604138

OFF

ON

AB

Battery

A/C compressor relay

A/C compressor

assembly

A/C compressor

relay control A/C compressor

clutch

A/C

refrigerant

temperature

switch

OFF ON

A/C switch (CAN)

ECM