engine oil MITSUBISHI LANCER EVOLUTION X 2008 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 99 of 241

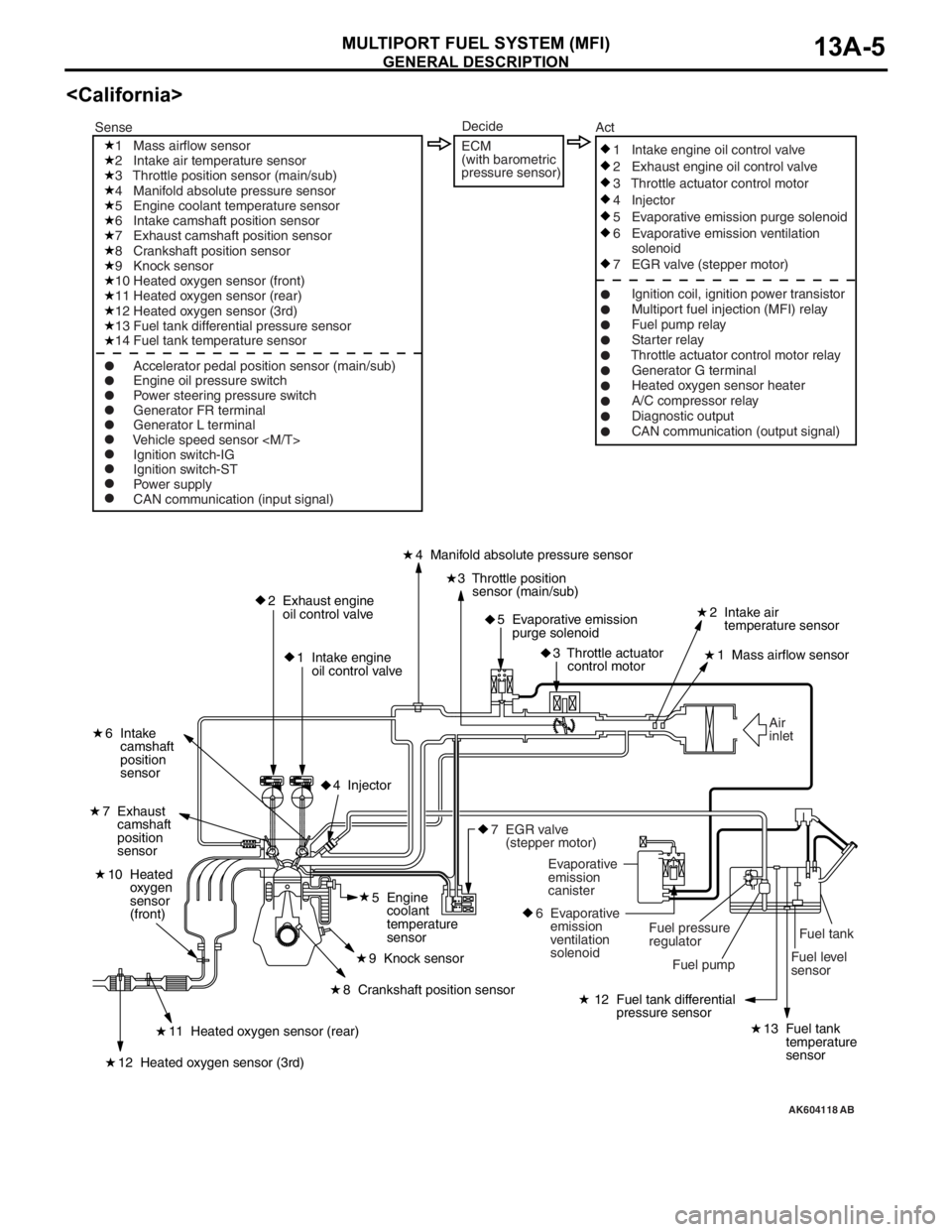

GENERAL DESCRIPTION

MULTIPORT FUEL SYSTEM (MFI)13A-5

AK604118

Fuel tank

Fuel level

sensor Air

inlet

2 Exhaust engine

oil control valve

1 Intake engine

oil control valve4 Manifold absolute pressure sensor

2 Intake air

temperature sensor

1 Mass airflow sensor

6 Intake

camshaft

position

sensor

7 Exhaust

camshaft

position

sensor

3 Throttle position

sensor (main/sub)

5 Evaporative emission

purge solenoid

3 Throttle actuator

control motor

12 Fuel tank differential

pressure sensor

13 Fuel tank

temperature

sensor11 Heated oxygen sensor (rear)

10 Heated

oxygen

sensor

(front)

12 Heated oxygen sensor (3rd)

8 Crankshaft position sensor5 Engine

coolant

temperature

sensor

9 Knock sensor

4 Injector

Fuel pump Fuel pressure

regulator Evaporative

emission

canister

6 Evaporative

emission

ventilation

solenoid

7 EGR valve

(stepper motor)

1 Mass airflow sensor

2 Intake air temperature sensor

3 Throttle position sensor (main/sub)

4 Manifold absolute pressure sensor

5 Engine coolant temperature sensor

6 Intake camshaft position sensor

7 Exhaust camshaft position sensor

8 Crankshaft position sensor

9 Knock sensor

10 Heated oxygen sensor (front)

11 Heated oxygen sensor (rear)

12 Heated oxygen sensor (3rd)

13 Fuel tank differential pressure sensor

14 Fuel tank temperature sensor

Ignition switch-IG

Ignition switch-ST

Power supply

CAN communication (input signal)1 Intake engine oil control valve

2 Exhaust engine oil control valve

3 Throttle actuator control motor

4 Injector

5 Evaporative emission purge solenoid

6 Evaporative emission ventilation

solenoid

7 EGR valve (stepper motor)

Ignition coil, ignition power transistor

Multiport fuel injection (MFI) relay

Fuel pump relay

Starter relay

Throttle actuator control motor relay

Generator G terminal

Heated oxygen sensor heater

A/C compressor relay

Diagnostic output

CAN communication (output signal) SenseAct

Engine oil pressure switch

Power steering pressure switch

Generator FR terminal

Generator L terminal

Vehicle speed sensor

Decide

ECM

(with barometric

pressure sensor)

AB

Page 100 of 241

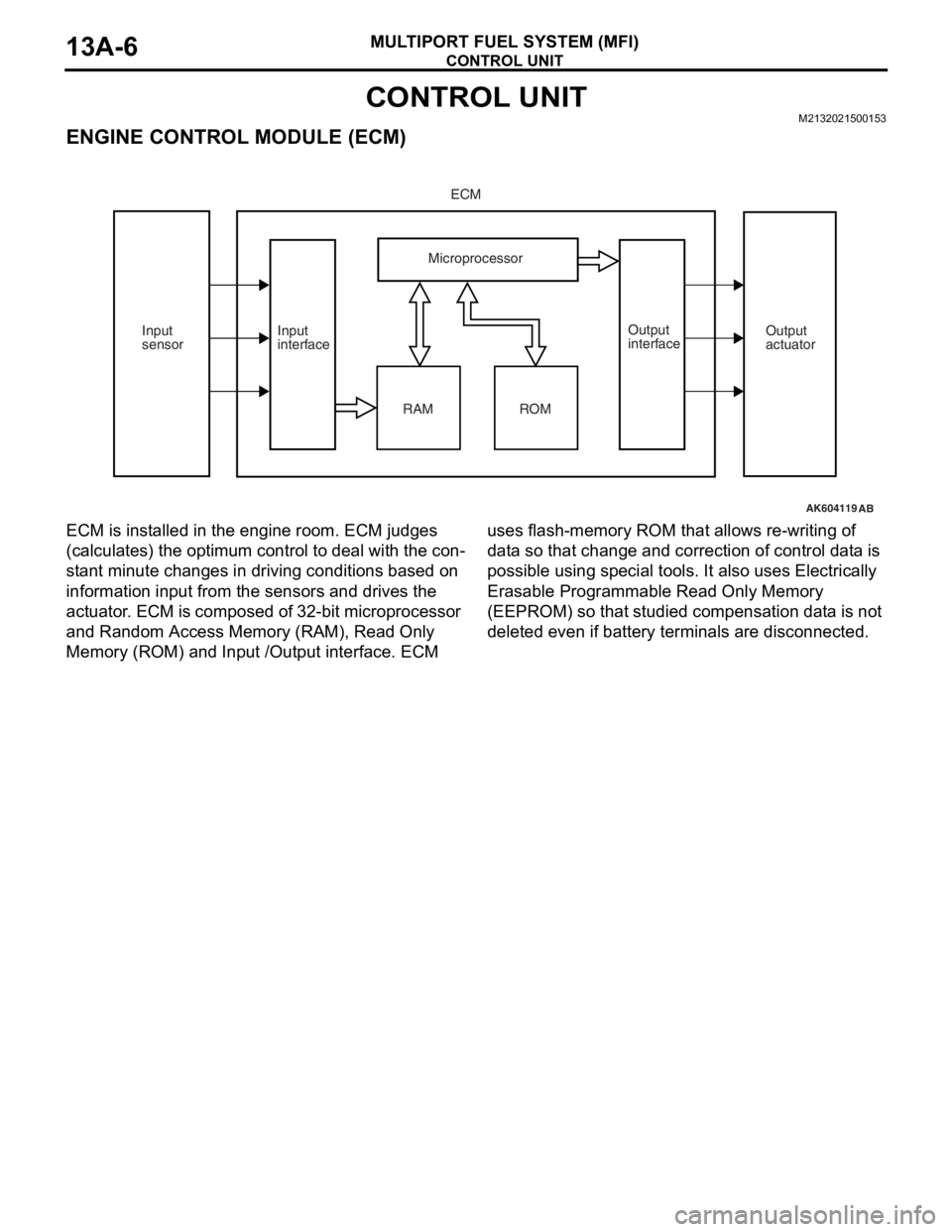

CONTROL UNIT

MULTIPORT FUEL SYSTEM (MFI)13A-6

CONTROL UNITM2132021500153

ENGINE CONTROL MODULE (ECM)

ECM is installed in the engine room. ECM judges

(calculates) the optimum control to deal with the con

-

stant minute changes in driving conditions based on

information input from the sensors and drives the

actuator. ECM is composed of 32-bit microprocessor

and Random Access Memory (RAM), Read Only

Memory (ROM) and Input /Output interface. ECM uses flash-memory ROM that allows re-writing of

data so that change and correction of control data is

possible using special tools. It also uses Electrically

Erasable Programmable Read Only Memory

(EEPROM) so that studied compensation data is not

deleted even if battery terminals are disconnected.

ECM CONNECTOR INPUT/OUTPUT PIN ARRANGEMENT

NOTE: *: California

AK604119

ECM

Microprocessor

RAM Input

interfaceOutput

interface Input

sensorOutput

actuator

AB

ROM

AK602565AC

1 2 3 4 5 6 7 8 9 10 11 1213 14 15 16

17 18 19 20 21 91

90

89

87

86

84 85

83 82

88 92 93 94

95 96 97 98 99

109

108

107 106

105

104

103

102

112 113 114 115 116 117 118

100 101

111

110

41

40

39

38

37

36

35

34

33 32

31

30

29

28

27

26

25

24

23

2260

59

58

57

56

55

54

53

52

51

50

49 48

47

46

45

44

43

4263

61 62 6471 72 73 74 75 76 77 78 79 80 81

1Intake engine oil control valve2No.1 injector

3No.2 injector4Ignition coil No.1 (ignition power transistor)

5Ignition coil No.2 (ignition power transistor)6Starter active signal

7Exhaust camshaft position sensor8Crankshaft position sensor

9Sensor supplied voltage10Throttle position sensor (main)

11Throttle position sensor (sub)12Power supply voltage applied to throttle

position sensor

13Throttle position sensor ground14Intake camshaft position sensor

Page 111 of 241

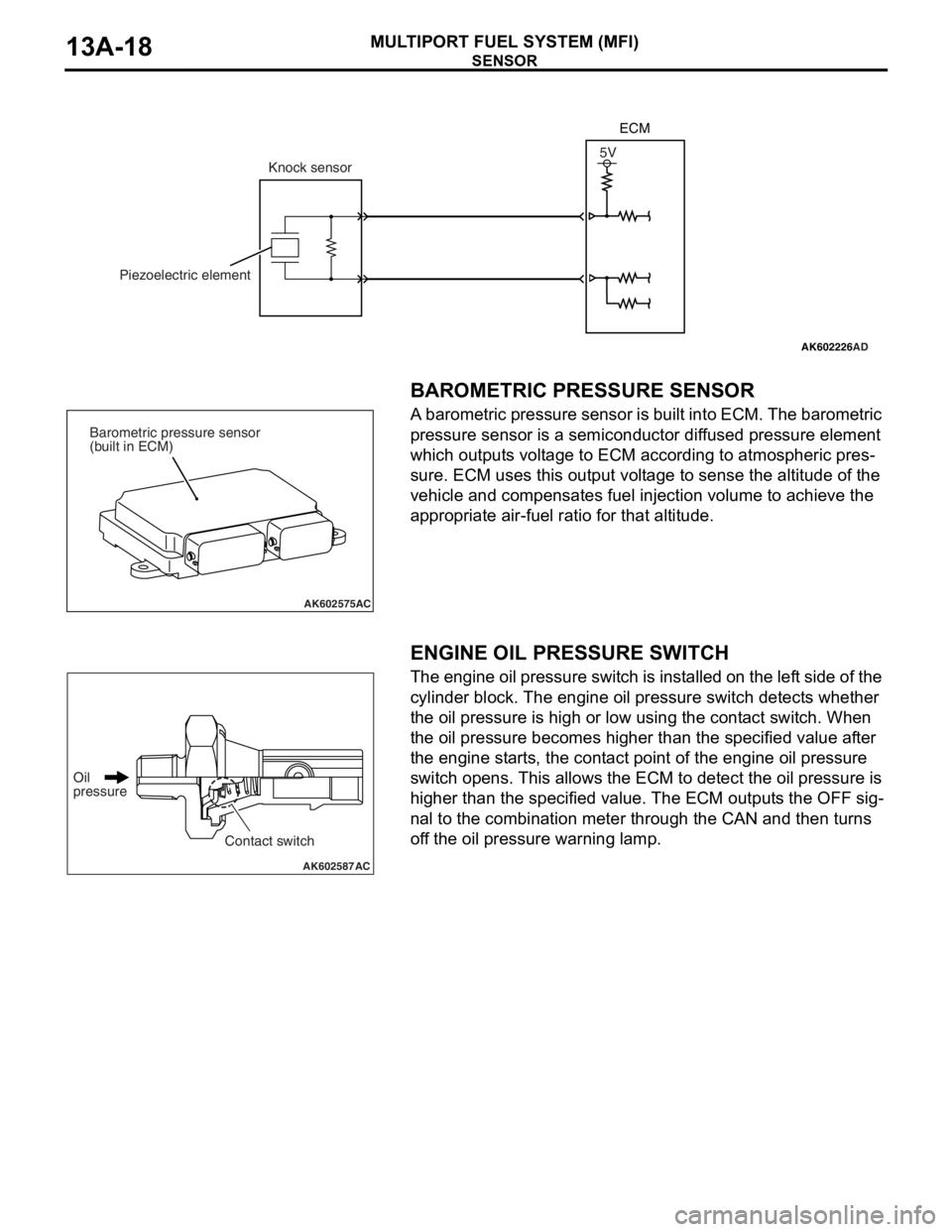

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-18

.

BAROMETRIC PRESSURE SENSOR

A barometric pressure sensor is built into ECM. The barometric

pressure sensor is a semiconductor diffused pressure element

which outputs voltage to ECM according to atmospheric pres

-

sure. ECM uses this output voltage to sense the altitude of the

vehicle and compensates fuel injection volume to achieve the

appropriate air-fuel ratio for that altitude.

.

ENGINE OIL PRESSURE SWITCH

The engine oil pressure switch is installed on the left side of the

cylinder block. The engine oil pressure switch detects whether

the oil pressure is high or low using the contact switch. When

the oil pressure becomes higher than the specified value after

the engine starts, the contact point of the engine oil pressure

switch opens. This allows the ECM to detect the oil pressure is

higher than the specified value. The ECM outputs the OFF sig

-

nal to the combination meter through the CAN and then turns

off the oil pressure warning lamp.

AK602226AD

5V

Knock sensor

Piezoelectric elementECM

AK602575AC

Barometric pressure sensor

(built in ECM)

AK602587AC

Oil

pressure

Contact switch

Page 112 of 241

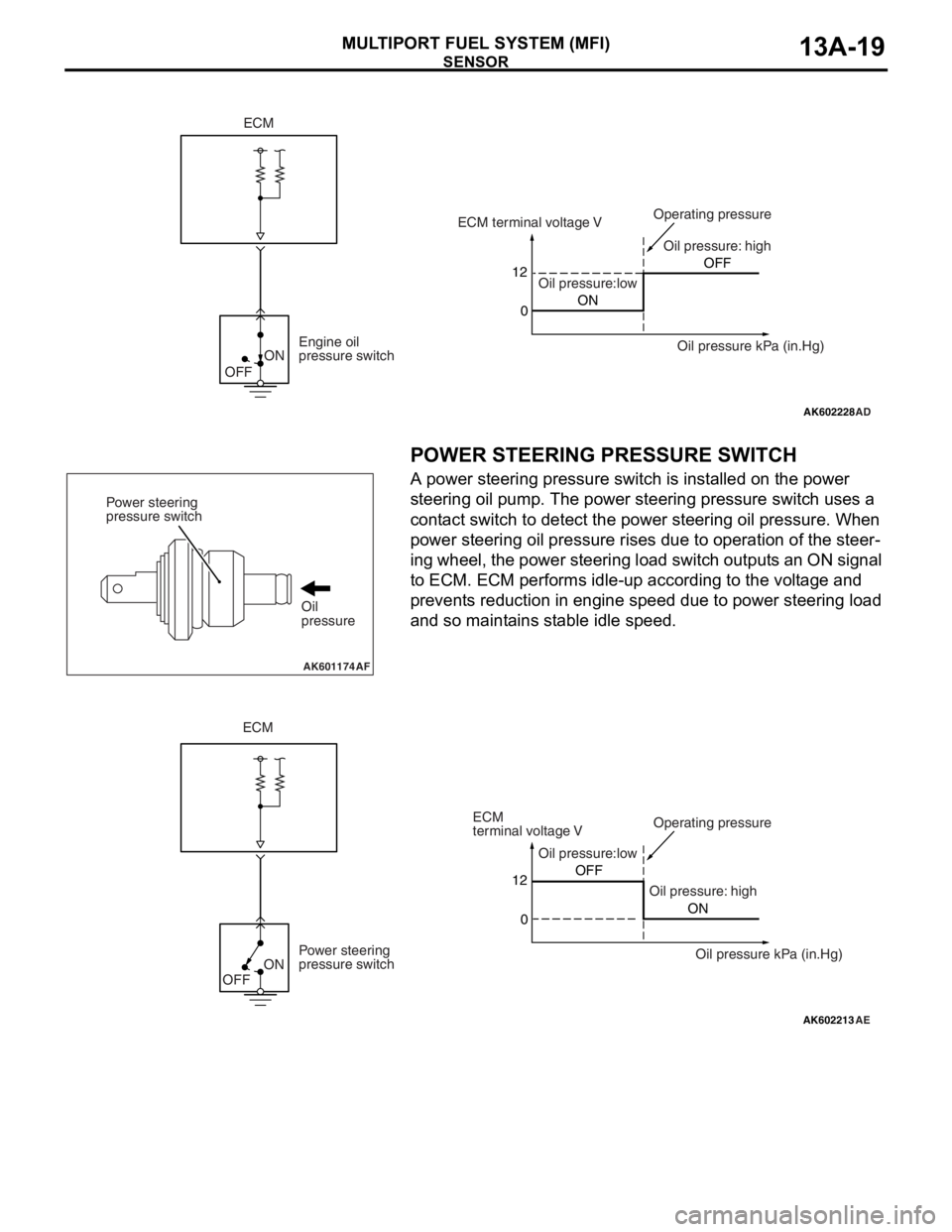

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-19

.

POWER STEERING PRESSURE SWITCH

A power steering pressure switch is installed on the power

steering oil pump. The power steering pressure switch uses a

contact switch to detect the power steering oil pressure. When

power steering oil pressure rises due to operation of the steer

-

ing wheel, the power steering load switch outputs an ON signal

to ECM. ECM performs idle-up according to the voltage and

prevents reduction in engine speed due to power steering load

and so maintains stable idle speed.

.

AK602228

ON

OFF

AD

12

0ONOFF ECM terminal voltage V

Oil pressure:lowOil pressure: high Operating pressure

Oil pressure kPa (in.Hg) Engine oil

pressure switch

ECM

AK601174AF

Power steering

pressure switch

Oil

pressure

AK602213

ON

OFF

AE

Oil pressure:low

Oil pressure: highOperating pressure

Power steering

pressure switch12

0OFF

ON

ECM

ECM

terminal voltage V

Oil pressure kPa (in.Hg)

Page 118 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-25

IGNITION COIL

Refer to GROUP 16 − Ignition Coil P.16-2.

EXHAUST GAS RECIRCULATION (EGR) VALVE

Refer to GROUP 17 − Emission Control − Exhaust Gas Recircu-

lation (EGR) System P.17-12.

EVAPORATIVE EMISSION PURGE SOLENOID

Refer to GROUP 17 − Emission Control − Evaporative Emission

Control System

P.17-11.

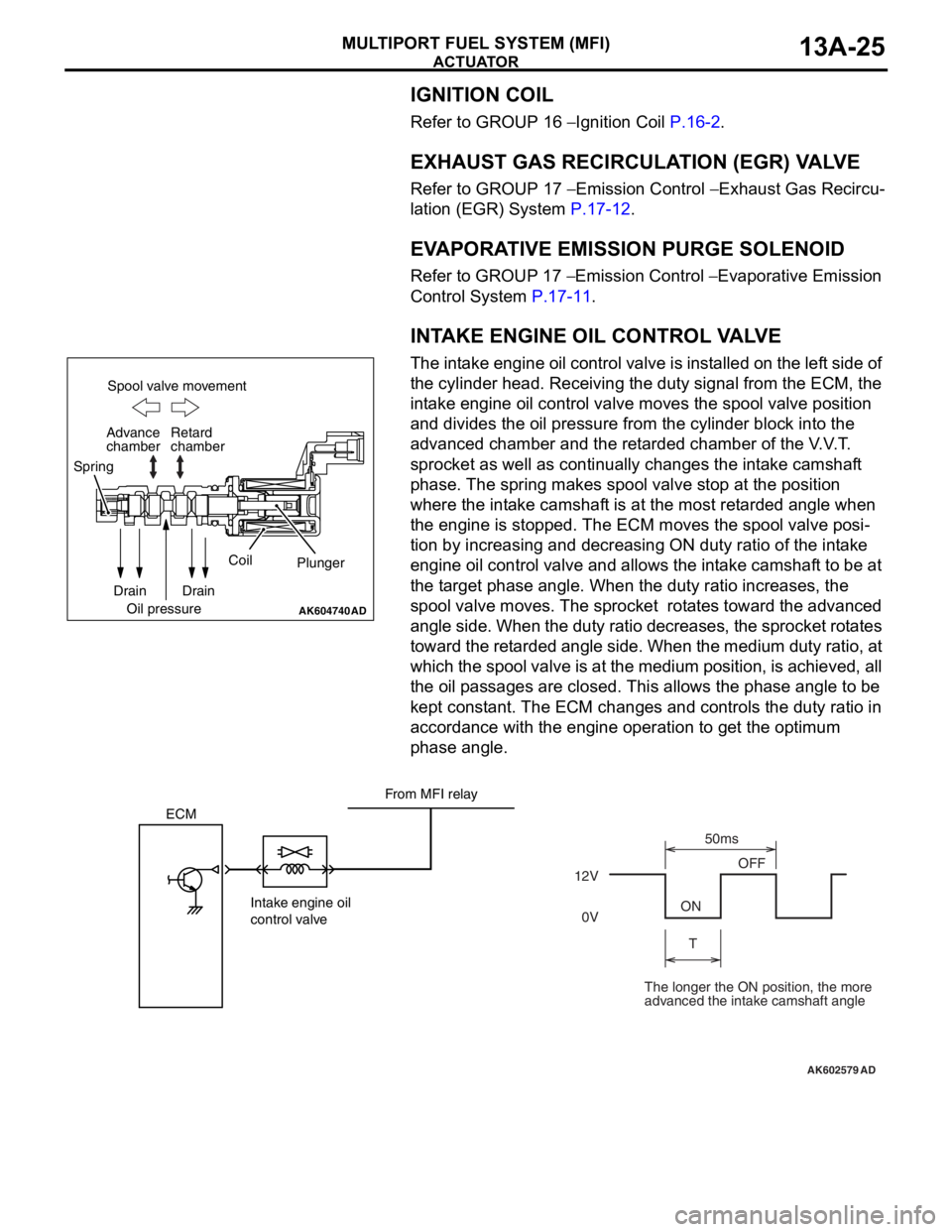

INTAKE ENGINE OIL CONTROL VALVE

The intake engine oil control valve is installed on the left side of

the cylinder head. Receiving the duty signal from the ECM, the

intake engine oil control valve moves the spool valve position

and divides the oil pressure from the cylinder block into the

advanced chamber and the retarded chamber of the V.V.T.

sprocket as well as continually changes the intake camshaft

phase. The spring makes spool valve stop at the position

where the intake camshaft is at the most retarded angle when

the engine is stopped. The ECM moves the spool valve posi

-

tion by increasing and decreasing ON duty ratio of the intake

engine oil control valve and allows the intake camshaft to be at

the target phase angle. When the duty ratio increases, the

spool valve moves. The sprocket rotates toward the advanced

angle side. When the duty ratio decreases, the sprocket rotates

toward the retarded angle side. When the medium duty ratio, at

which the spool valve is at the medium position, is achieved, all

the oil passages are closed. This allows the phase angle to be

kept constant. The ECM changes and controls the duty ratio in

accordance with the engine operation to get the optimum

phase angle.

AK604740AD

Spool valve movement

Retard

chamber

Spring

Drain

Oil pressureCoil

Plunger

Drain Advance

chamber

AK602579

ECM

Intake engine oil

control valve12VOFF

ON

T50ms

0V

AD

From MFI relay

The longer the ON position, the more

advanced the intake camshaft angle

Page 119 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-26

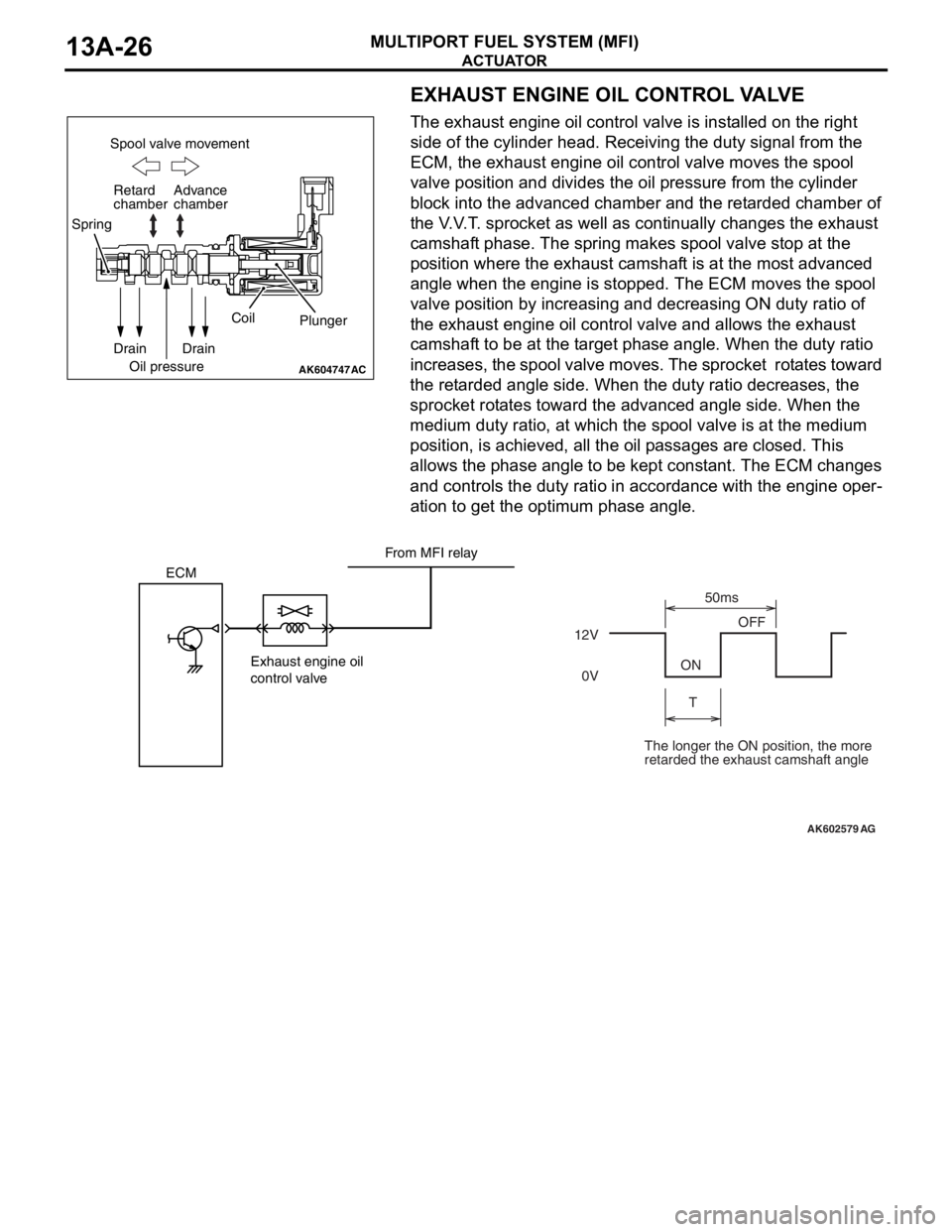

EXHAUST ENGINE OIL CONTROL VALVE

The exhaust engine oil control valve is installed on the right

side of the cylinder head. Receiving the duty signal from the

ECM, the exhaust engine oil control valve moves the spool

valve position and divides the oil pressure from the cylinder

block into the advanced chamber and the retarded chamber of

the V.V.T. sprocket as well as continually changes the exhaust

camshaft phase. The spring makes spool valve stop at the

position where the exhaust camshaft is at the most advanced

angle when the engine is stopped. The ECM moves the spool

valve position by increasing and decreasing ON duty ratio of

the exhaust engine oil control valve and allows the exhaust

camshaft to be at the target phase angle. When the duty ratio

increases, the spool valve moves. The sprocket rotates toward

the retarded angle side. When the duty ratio decreases, the

sprocket rotates toward the advanced angle side. When the

medium duty ratio, at which the spool valve is at the medium

position, is achieved, all the oil passages are closed. This

allows the phase angle to be kept constant. The ECM changes

and controls the duty ratio in accordance with the engine oper

-

ation to get the optimum phase angle.

AK604747

Spool valve movement

Retard

chamber

Spring

Drain

Oil pressureCoil

Plunger

Drain Advance

chamber

AC

AK602579

ECM

Exhaust engine oil

control valve12VOFF

ON

T50ms

0V

AG

From MFI relay

The longer the ON position, the more

retarded the exhaust camshaft angle

Page 120 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-27

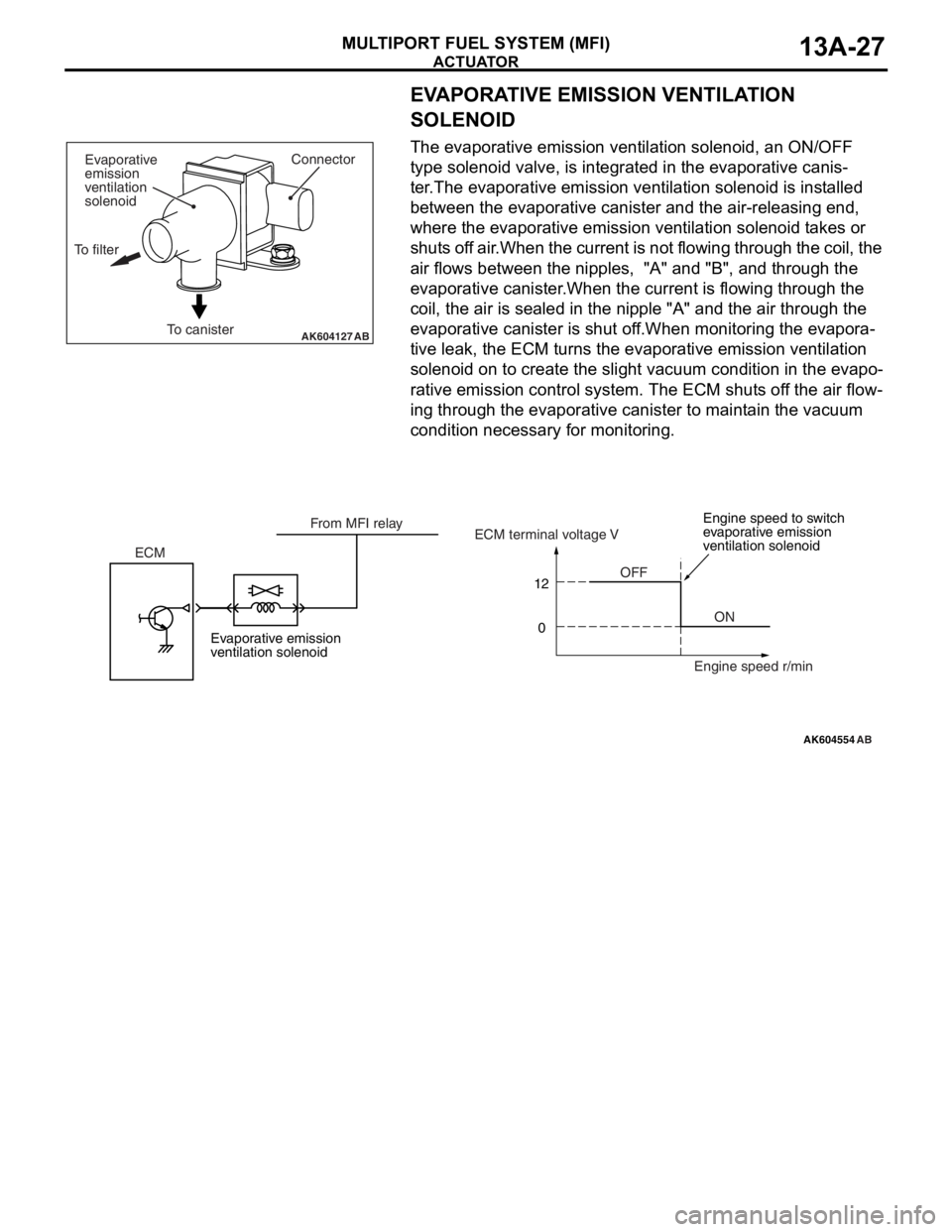

EVAPORATIVE EMISSION VENTILATION

SOLENOID

The evaporative emission ventilation solenoid, an ON/OFF

type solenoid valve, is integrated in the evaporative canis

-

ter.The evaporative emission ventilation solenoid is installed

between the evaporative canister and the air-releasing end,

where the evaporative emission ventilation solenoid takes or

shuts off air.When the current is not flowing through the coil, the

air flows between the nipples, "A" and "B", and through the

evaporative canister.When the current is flowing through the

coil, the air is sealed in the nipple "A" and the air through the

evaporative canister is shut off.When monitoring the evapora

-

tive leak, the ECM turns the evaporative emission ventilation

solenoid on to create the slight vacuum condition in the evapo

-

rative emission control system. The ECM shuts off the air flow-

ing through the evaporative canister to maintain the vacuum

condition necessary for monitoring.

AK604127ABTo canisterConnector

Evaporative

emission

ventilation

solenoid

To filter

AK604554

12

0

AB

OFF

ON ECMECM terminal voltage V

Engine speed r/min From MFI relay

Evaporative emission

ventilation solenoidEngine speed to switch

evaporative emission

ventilation solenoid

Page 128 of 241

IGNITION TIMING AND CONTROL FOR CURRENT CARRYING TIME

MULTIPORT FUEL SYSTEM (MFI)13A-35

IGNITION TIMING AND CONTROL FOR CURRENT

CARRYING TIME

M2132027100089

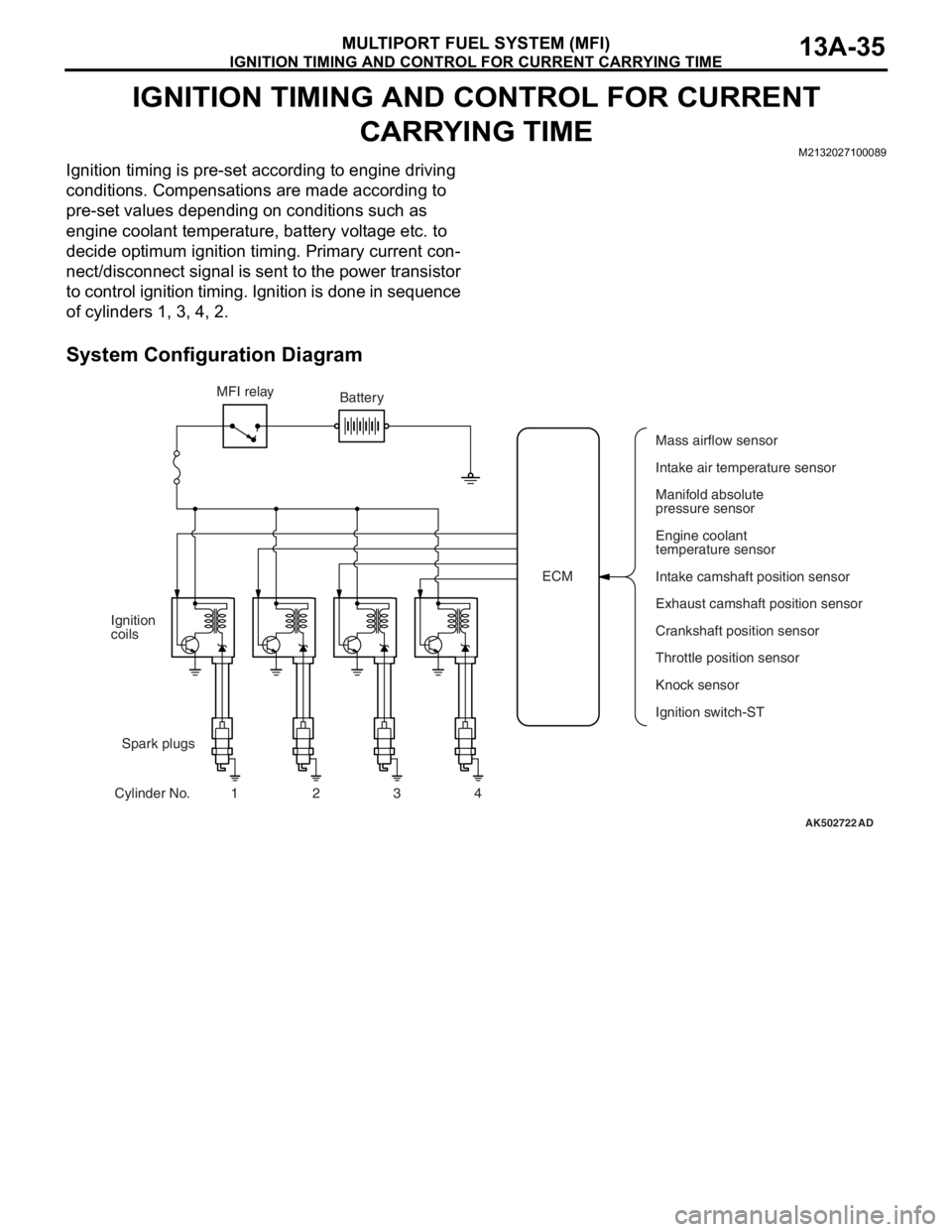

Ignition timing is pre-set according to engine driving

conditions. Compensations are made according to

pre-set values depending on conditions such as

engine coolant temperature, battery voltage etc. to

decide optimum ignition timing. Primary current con

-

nect/disconnect signal is sent to the power transistor

to control ignition timing. Ignition is done in sequence

of cylinders 1, 3, 4, 2.

System Configuration Diagram

AK502722AD

ECM MFI relay

Spark plugs Ignition

coils

Cylinder No. 1 2 3 4Battery

Mass airflow sensor

Intake air temperature sensor

Manifold absolute

pressure sensor

Engine coolant

temperature sensor

Intake camshaft position sensor

Exhaust camshaft position sensor

Crankshaft position sensor

Knock sensor

Ignition switch-ST Throttle position sensor

Page 132 of 241

THROTTLE VALVE OPENING ANGLE CONTROL AND IDLE SPEED CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-39

List of main compensations for throttle valve opening angle and idle speed control

Initialize control

After ignition switch turns OFF, ECM drives the throt-

tle valve from fully closed position to fully open posi-

tion and records the fully closed/open studied value

of the throttle position sensor (main and sub) output

signals. The recorded studied values are used as

studied value compensation for compensating basic

target opening angle when the engine is started next.

CompensationsContent

Stable idle compensation (immediately after start)In order to stabilize idle speed immediately after

start, target opening angle is kept big and then

gradually reduced. Compensation values are set

based on the engine coolant temperature.

Rotation speed feedback compensation (while

idling)In case there is a difference between the target idle

speed and actual engine speed, ECM

compensates the throttle valve opening angle

based on that difference.

Atmospheric pressure compensationAt high altitudes atmospheric pressure is less and

the intake air density is low. So, the target opening

angle is compensated based on atmospheric

pressure.

Engine coolant temperature compensationCompensation is made according to the engine

coolant temperature. The lower the engine coolant

temperature the greater the throttle valve opening

angle.

Electric load compensationThrottle valve opening angle is compensated

according to electric load. The greater the electric

load, the greater the throttle valve opening angle.

Compensation when shift is in D range

to some other range, throttle valve opening angle is

increased to prevent reduction in engine speed.

Compensation when A/C is functioningThrottle valve opening angle is compensated

according to functioning of A/C compressor. While

A/C compressor is being driven, the throttle valve

opening angle is increased.

Power steering fluid pressure compensationThrottle valve opening angle is compensated

according to power steering functioning. When

power steering oil pressure rises and power

steering pressure switch is ON, the throttle valve

opening angle is increased.

Page 133 of 241

MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)

MULTIPORT FUEL SYSTEM (MFI)13A-40

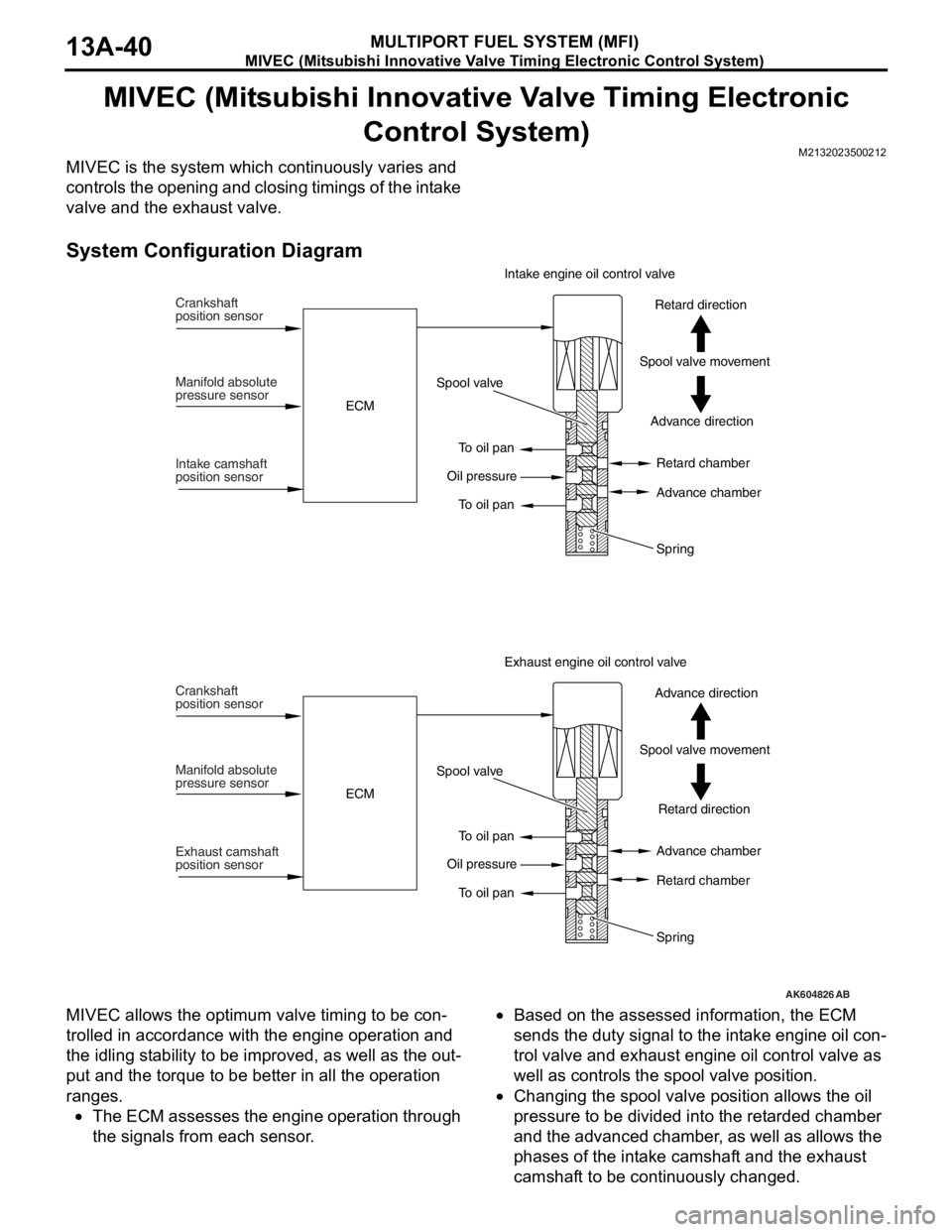

MIVEC (Mitsubishi Innovative Valve Timing Electronic

Control System)

M2132023500212

MIVEC is the system which continuously varies and

controls the opening and closing timings of the intake

valve and the exhaust valve.

System Configuration Diagram

MIVEC allows the optimum valve timing to be con-

trolled in accordance with the engine operation and

the idling stability to be improved, as well as the out

-

put and the torque to be better in all the operation

ranges.

•The ECM assesses the engine operation through

the signals from each sensor.

•Based on the assessed information, the ECM

sends the duty signal to the intake engine oil con

-

trol valve and exhaust engine oil control valve as

well as controls the spool valve position.

•Changing the spool valve position allows the oil

pressure to be divided into the retarded chamber

and the advanced chamber, as well as allows the

phases of the intake camshaft and the exhaust

camshaft to be continuously changed.

AK604826AB

Crankshaft

position sensor

Manifold absolute

pressure sensor

Intake camshaft

position sensorECMSpool valve

To oil pan

To oil pan Oil pressureAdvance direction Spool valve movementRetard direction Intake engine oil control valve

Retard chamber

Advance chamber

Spring

Crankshaft

position sensor

Manifold absolute

pressure sensor

Exhaust camshaft

position sensorECMSpool valve

To oil pan

To oil pan Oil pressureRetard direction Spool valve movementAdvance direction Exhaust engine oil control valve

Advance chamber

Retard chamber

Spring