engine oil MITSUBISHI LANCER EVOLUTION X 2008 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 60 of 241

BASE ENGINE

ENGINE MECHANICAL11A-16

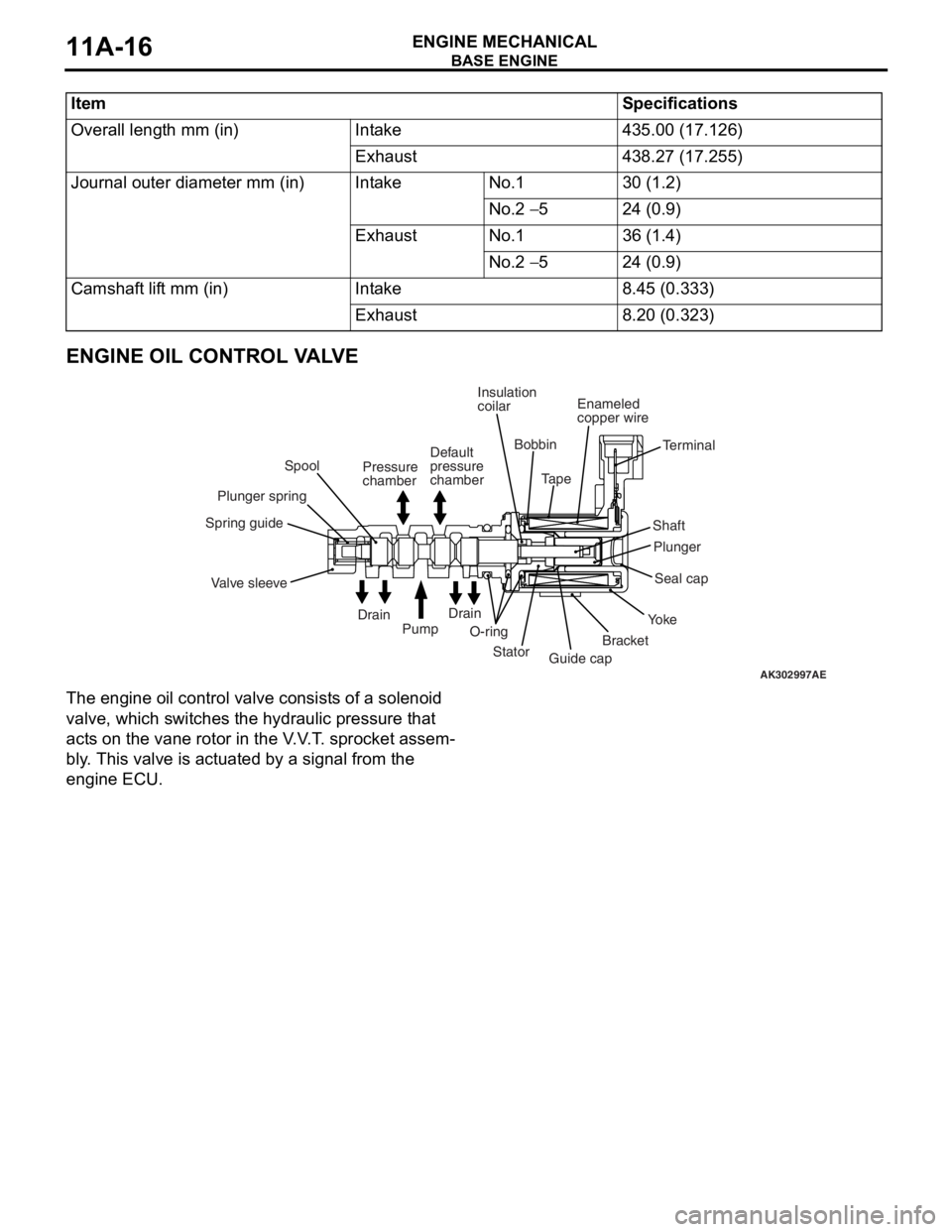

ENGINE OIL CONTROL VALVE

The engine oil control valve consists of a solenoid

valve, which switches the hydraulic pressure that

acts on the vane rotor in the V.V.T. sprocket assem

-

bly. This valve is actuated by a signal from the

engine ECU.

ItemSpecifications

Overall length mm (in)Intake435.00 (17.126)

Exhaust438.27 (17.255)

Journal outer diameter mm (in)IntakeNo.130 (1.2)

No.2 − 524 (0.9)

ExhaustNo.136 (1.4)

No.2 − 524 (0.9)

Camshaft lift mm (in)Intake8.45 (0.333)

Exhaust8.20 (0.323)

AK302997AE

Spring guide

Valve sleevePlunger springSpool

O-ringInsulation

coilar

Stator

Guide capBracketYo k eSeal cap Plunger ShaftTerminal Bobbin

TapeEnameled

copper wire

Drain

Drain

Pump Pressure

chamberDefault

pressure

chamber

Page 61 of 241

BASE ENGINE

ENGINE MECHANICAL11A-17

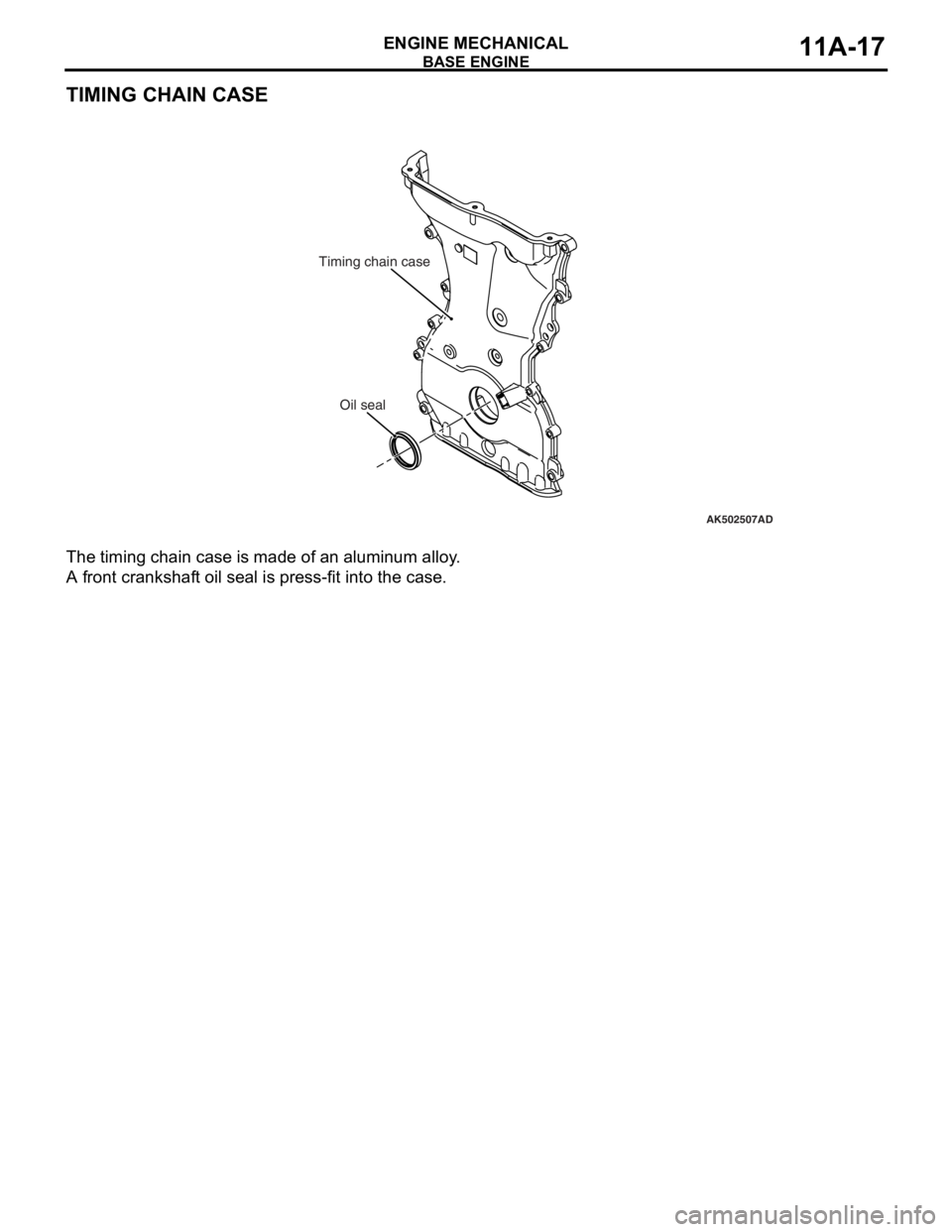

TIMING CHAIN CASE

The timing chain case is made of an aluminum alloy.

A front crankshaft oil seal is press-fit into the case.

AK502507

Oil seal

AD

Timing chain case

Page 74 of 241

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-12

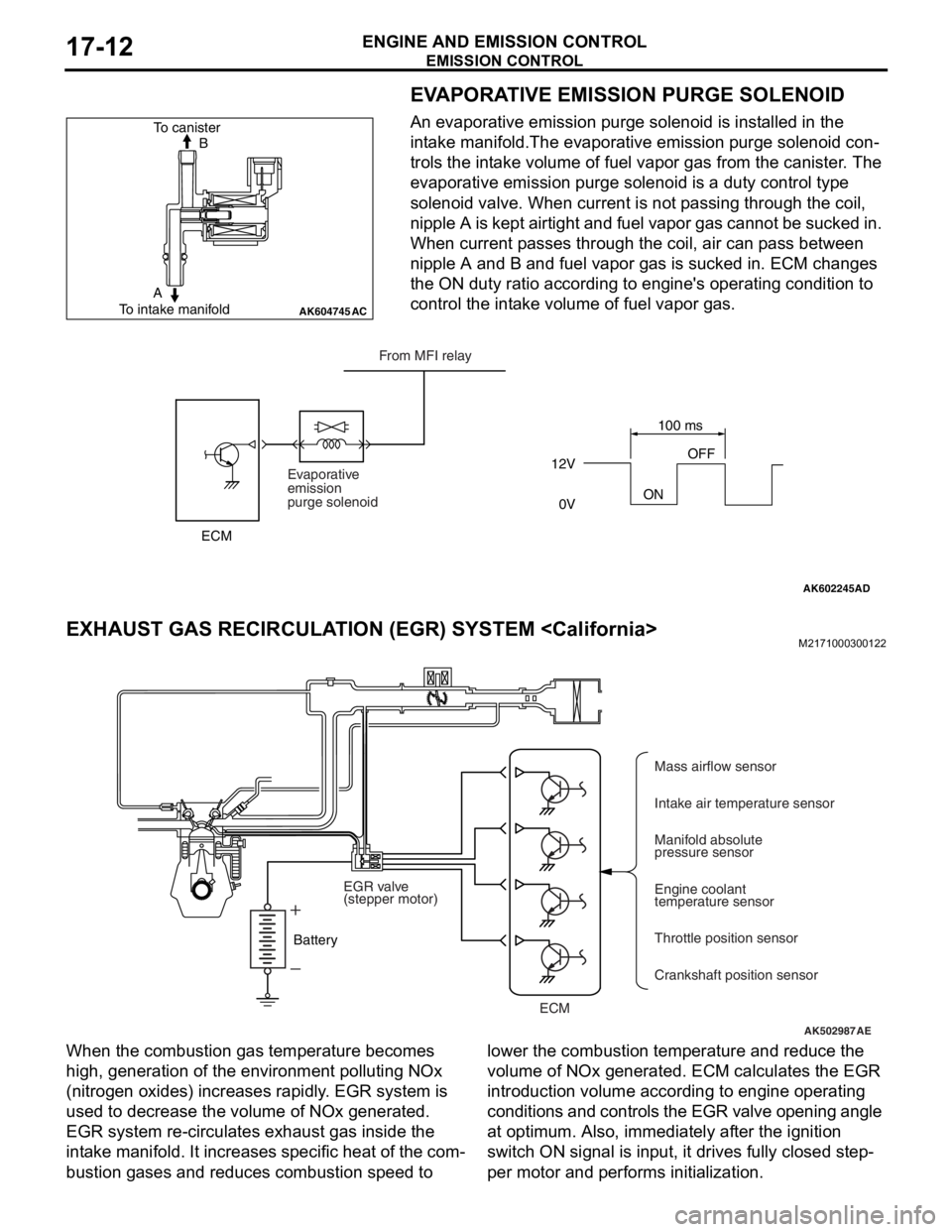

EVAPORATIVE EMISSION PURGE SOLENOID

An evaporative emission purge solenoid is installed in the

intake manifold.The evaporative emission purge solenoid con

-

trols the intake volume of fuel vapor gas from the canister. The

evaporative emission purge solenoid is a duty control type

solenoid valve. When current is not passing through the coil,

nipple A is kept airtight and fuel vapor gas cannot be sucked in.

When current passes through the coil, air can pass between

nipple A and B and fuel vapor gas is sucked in. ECM changes

the ON duty ratio according to engine's operating condition to

control the intake volume of fuel vapor gas.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

When the combustion gas temperature becomes

high, generation of the environment polluting NOx

(nitrogen oxides) increases rapidly. EGR system is

used to decrease the volume of NOx generated.

EGR system re-circulates exhaust gas inside the

intake manifold. It increases specific heat of the com

-

bustion gases and reduces combustion speed to lower the combustion temperature and reduce the

volume of NOx generated. ECM calculates the EGR

introduction volume according to engine operating

conditions and controls the EGR valve opening angle

at optimum. Also, immediately after the ignition

switch ON signal is input, it drives fully closed step

-

per motor and performs initialization.

AK604745AC

B To canister

To intake manifoldA

AK602245AD

12V

ONOFF

0V100 ms

Evaporative

emission

purge solenoidFrom MFI relay

ECM

AK502987AE

ECMMass airflow sensor

Intake air temperature sensor

Manifold absolute

pressure sensor

Engine coolant

temperature sensor

Throttle position sensor

Crankshaft position sensor BatteryEGR valve

(stepper motor)

Page 75 of 241

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-13

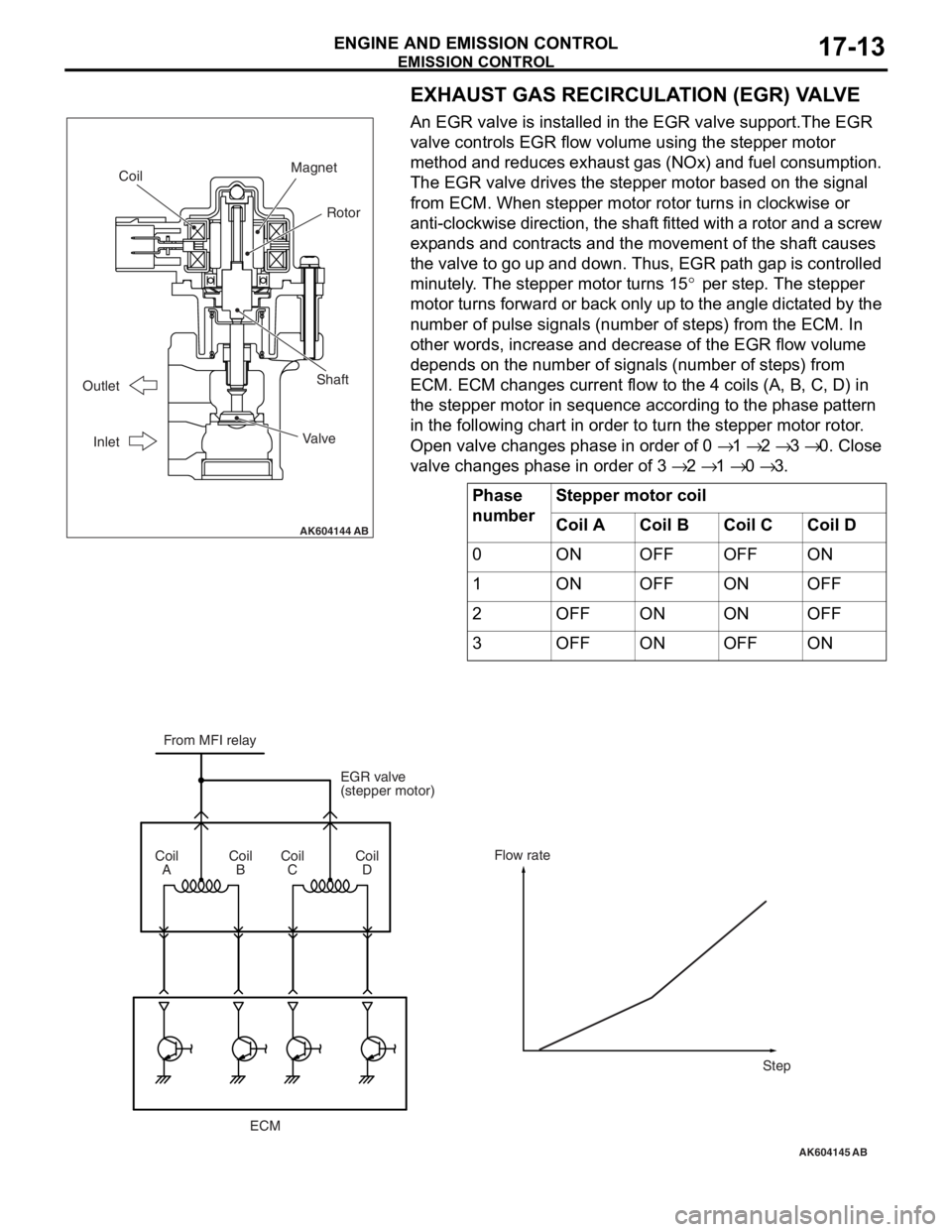

EXHAUST GAS RECIRCULATION (EGR) VALVE

An EGR valve is installed in the EGR valve support.The EGR

valve controls EGR flow volume using the stepper motor

method and reduces exhaust gas (NOx) and fuel consumption.

The EGR valve drives the stepper motor based on the signal

from ECM. When stepper motor rotor turns in clockwise or

anti-clockwise direction, the shaft fitted with a rotor and a screw

expands and contracts and the movement of the shaft causes

the valve to go up and down. Thus, EGR path gap is controlled

minutely. The stepper motor turns 15

° per step. The stepper

motor turns forward or back only up to the angle dictated by the

number of pulse signals (number of steps) from the ECM. In

other words, increase and decrease of the EGR flow volume

depends on the number of signals (number of steps) from

ECM. ECM changes current flow to the 4 coils (A, B, C, D) in

the stepper motor in sequence according to the phase pattern

in the following chart in order to turn the stepper motor rotor.

Open valve changes phase in order of 0

→ 1 → 2 → 3 → 0. Close

valve changes phase in order of 3

→ 2 → 1 → 0 → 3.

Phase

numberStepper motor coil

Coil ACoil BCoil CCoil D

0ONOFFOFFON

1ONOFFONOFF

2OFFONONOFF

3OFFONOFFON

AK604144

Coil

Shaft

Valve Outlet

Inlet

Rotor

Magnet

AB

AK604145

From MFI relay

EGR valve

(stepper motor)

ECM Coil

ACoil

BCoil

CCoil

DFlow rate

Step

AB

Page 79 of 241

16-1

GROUP 16

ENGINE

ELECTRICAL

CONTENTS

STARTER MOTOR . . . . . . . . . . . . . .16-2

ALTERNATOR . . . . . . . . . . . . . . . . . .16-2

IGNITION COIL . . . . . . . . . . . . . . . . . .16-2

SPARK PLUG . . . . . . . . . . . . . . . . . . .16-3

Page 80 of 241

STARTER MOTOR

ENGINE ELECTRICAL16-2

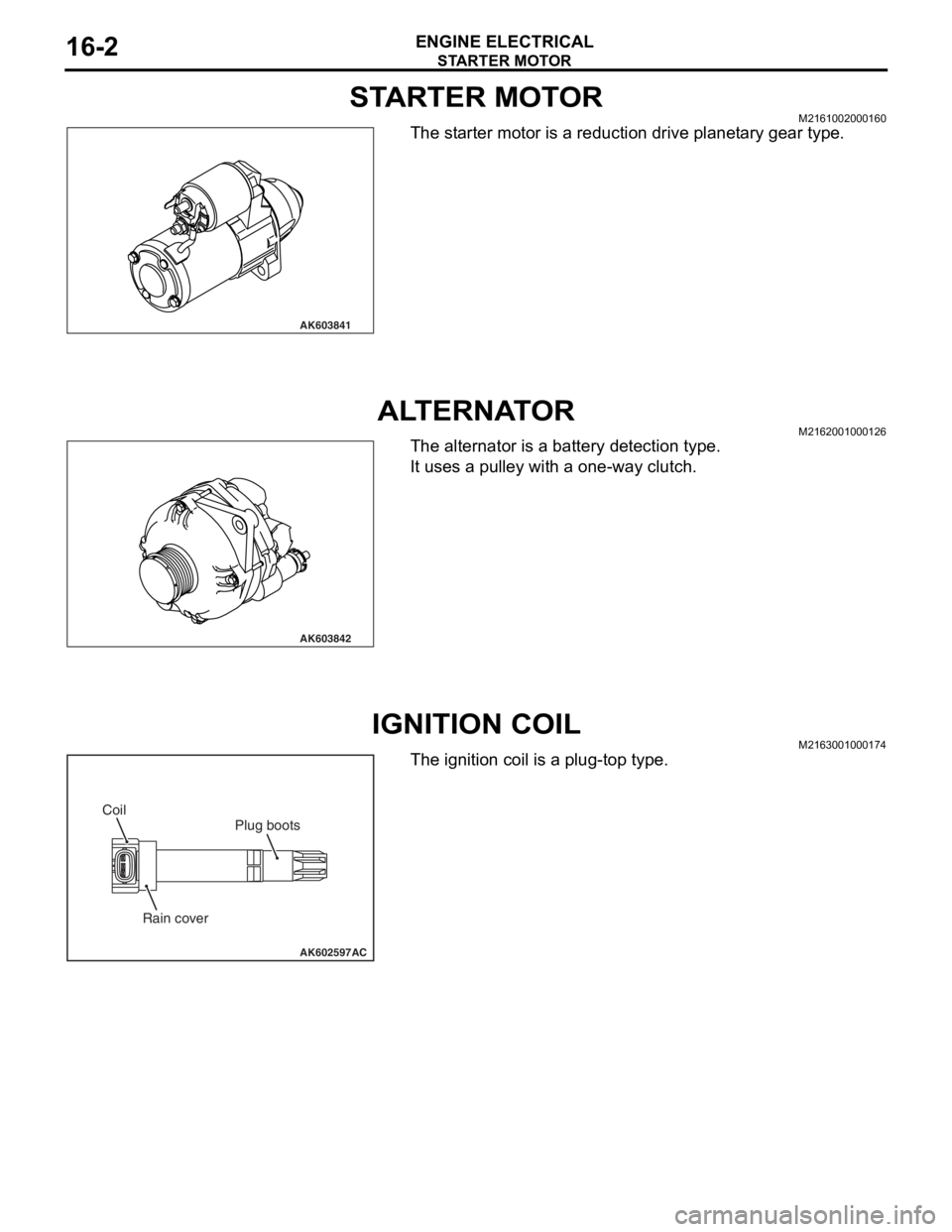

STARTER MOTORM2161002000160

The starter motor is a reduction drive planetary gear type.

ALTERNATORM2162001000126

The alternator is a battery detection type.

It uses a pulley with a one-way clutch.

IGNITION COILM2163001000174

The ignition coil is a plug-top type.

AK603841

AK603842

AK602597

Plug boots

Rain cover Coil

AC

Page 88 of 241

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATIONM2140000100780

The cooling system is a water-cooled pressurized,

forced circulation type which offers the following fea

-

tures.

•To stabilize engine coolant temperature, the ther-

mostat is located at the coolant inlet port from the

radiator.

•To improve engine cooling performance and save

weight, a plastic tank and aluminum radiator fins

are used.

SPECIFICATIONS

CONSTRUCTION DIAGRAM

ItemSpecification

Cooling methodWater-cooled pressurized, forced

circulation with electrical fan

RadiatorTy p ePressurized corrugate type

Performance kJ/h (kcal/h)222,480 (53,148)

Water pumpTy p eCentrifugal impeller

Drive methodDrive belt

ThermostatTy p eWax pellet with jiggle valve

Valve open temperature °C (°F)82 (180)

AC608448

Condenser fan motor Radiator assemblyRadiator upper hose

assembly

Radiator condenser

tank assembly Radiator fan motor

Cooling fan shroud

Radiator lower hose Transmission oil

cooler line hose

and tube assembly

AB

Page 89 of 241

WATER PASSAGE

ENGINE COOLING14-3

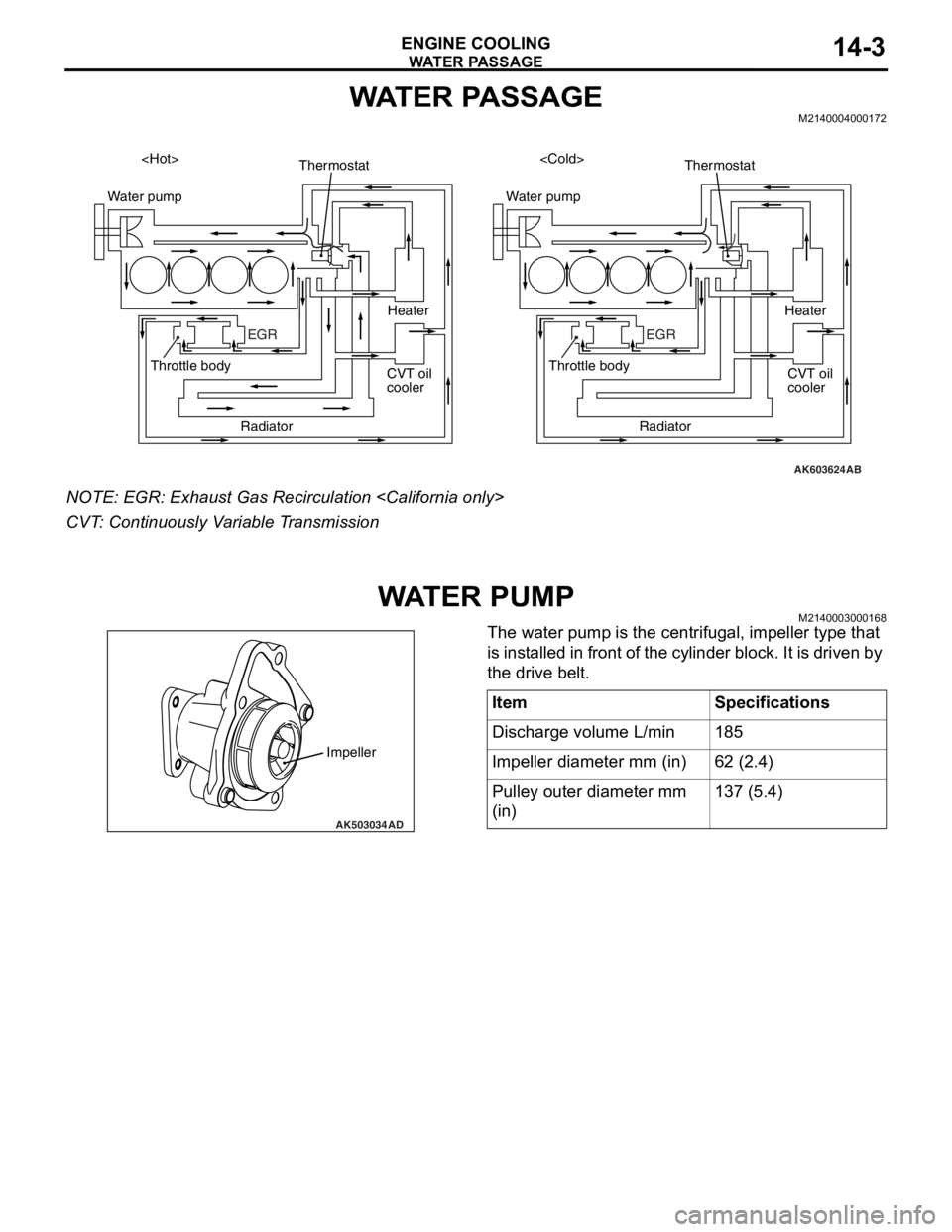

WATER PASSAGEM2140004000172

NOTE: EGR: Exhaust Gas Recirculation

CVT: Continuously Variable Transmission

WAT E R P U M PM2140003000168

The water pump is the centrifugal, impeller type that

is installed in front of the cylinder block. It is driven by

the drive belt.

AK603624

Water pump

EGR

AB

Thermostat

Radiator Throttle body

CVT oil

coolerHeater

Water pump

EGR

Thermostat

Radiator Throttle body

CVT oil

cooler Heater

AK503034

Impeller

AD

ItemSpecifications

Discharge volume L/min185

Impeller diameter mm (in)62 (2.4)

Pulley outer diameter mm

(in)137 (5.4)

Page 97 of 241

GENERAL DESCRIPTION

MULTIPORT FUEL SYSTEM (MFI)13A-3

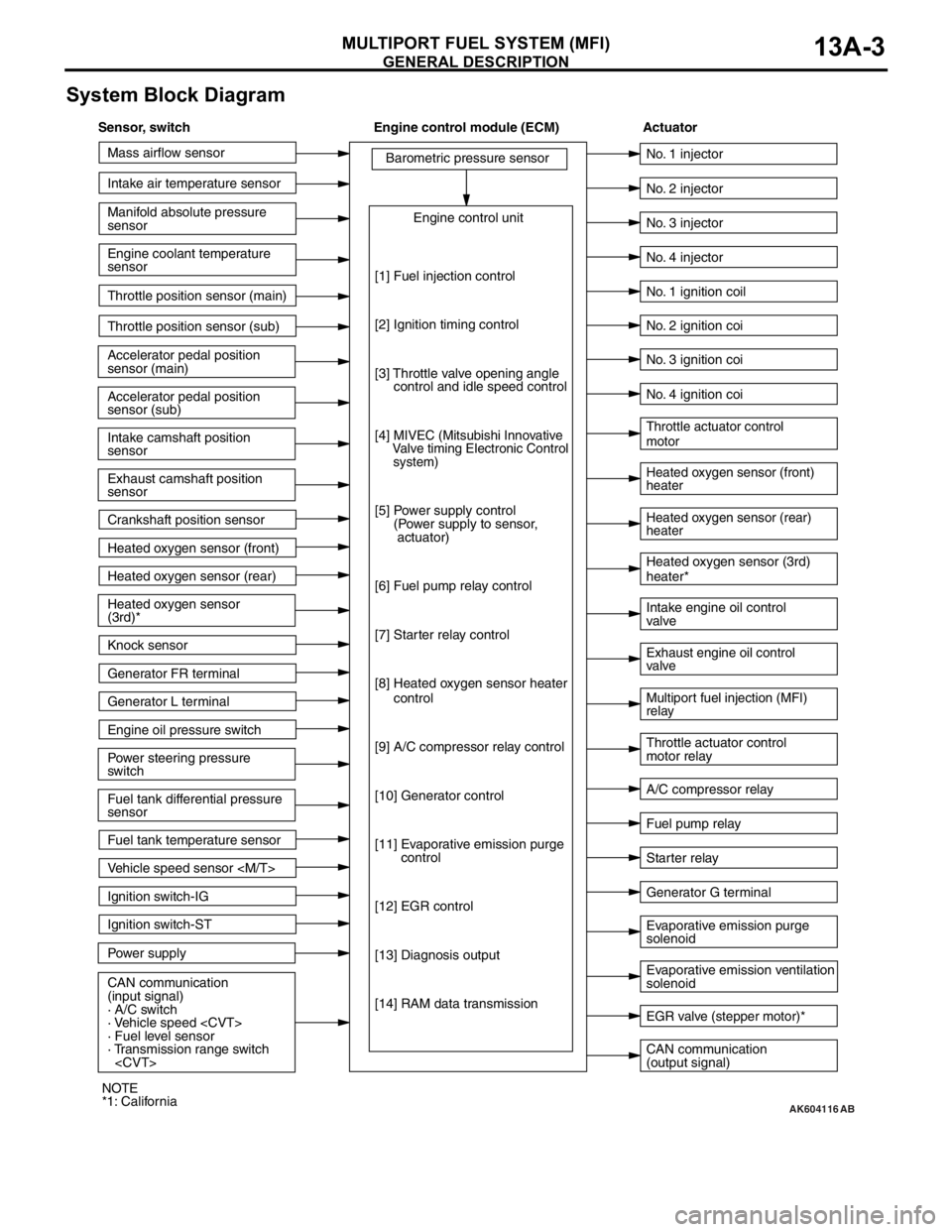

System Block Diagram

AK604116

Mass airflow sensor

Intake air temperature sensor

Intake camshaft position

sensor

Exhaust camshaft position

sensor

Crankshaft position sensor Throttle position sensor (main)

Throttle position sensor (sub)

Accelerator pedal position

sensor (sub) Accelerator pedal position

sensor (main) Engine coolant temperature

sensor Manifold absolute pressure

sensor

Heated oxygen sensor (front)

Heated oxygen sensor (rear)

Power steering pressure

switch Engine oil pressure switch Generator L terminal

Ignition switch-ST

Power supply Ignition switch-IG

CAN communication

(input signal)

· A/C switch

· Vehicle speed

· Fuel level sensor

· Transmission range switch

sensor Heated oxygen sensor

(3rd)*

Knock sensor

Generator FR terminal

Fuel tank temperature sensor

Vehicle speed sensor

[1] Fuel injection control

[2] Ignition timing control

[3] Throttle valve opening angle

control and idle speed control

[4]

MIVEC (Mitsubishi Innovative

Valve timing Electronic Control

system)

[5] Power supply control

(Power supply to sensor,

actuator)

[6] Fuel pump relay control

[7] Starter relay control

[8] Heated oxygen sensor heater

control

[9] A/C compressor relay control

[10] Generator control

[11] Evaporative emission purge

control

[12] EGR control

[13] Diagnosis output

[14] RAM data transmission

CAN communication

(output signal) Intake engine oil control

valve

A/C compressor relay No. 2 injector

No. 3 injector

No. 4 injector

Heated oxygen sensor (front)

heater

Heated oxygen sensor (rear)

heater Throttle actuator control

motor

Throttle actuator control

motor relay No. 1 injector

No. 1 ignition coil

No. 2 ignition coi

No. 3 ignition coi

No. 4 ignition coi

Fuel pump relay

Generator G terminal Heated oxygen sensor (3rd)

heater*

Multiport fuel injection (MFI)

relay Exhaust engine oil control

valve

Evaporative emission ventilation

solenoid Evaporative emission purge

solenoid

EGR valve (stepper motor)*

Starter relay

AB

Sensor, switch Engine control module (ECM) Actuator

NOTE

*1: California

Page 98 of 241

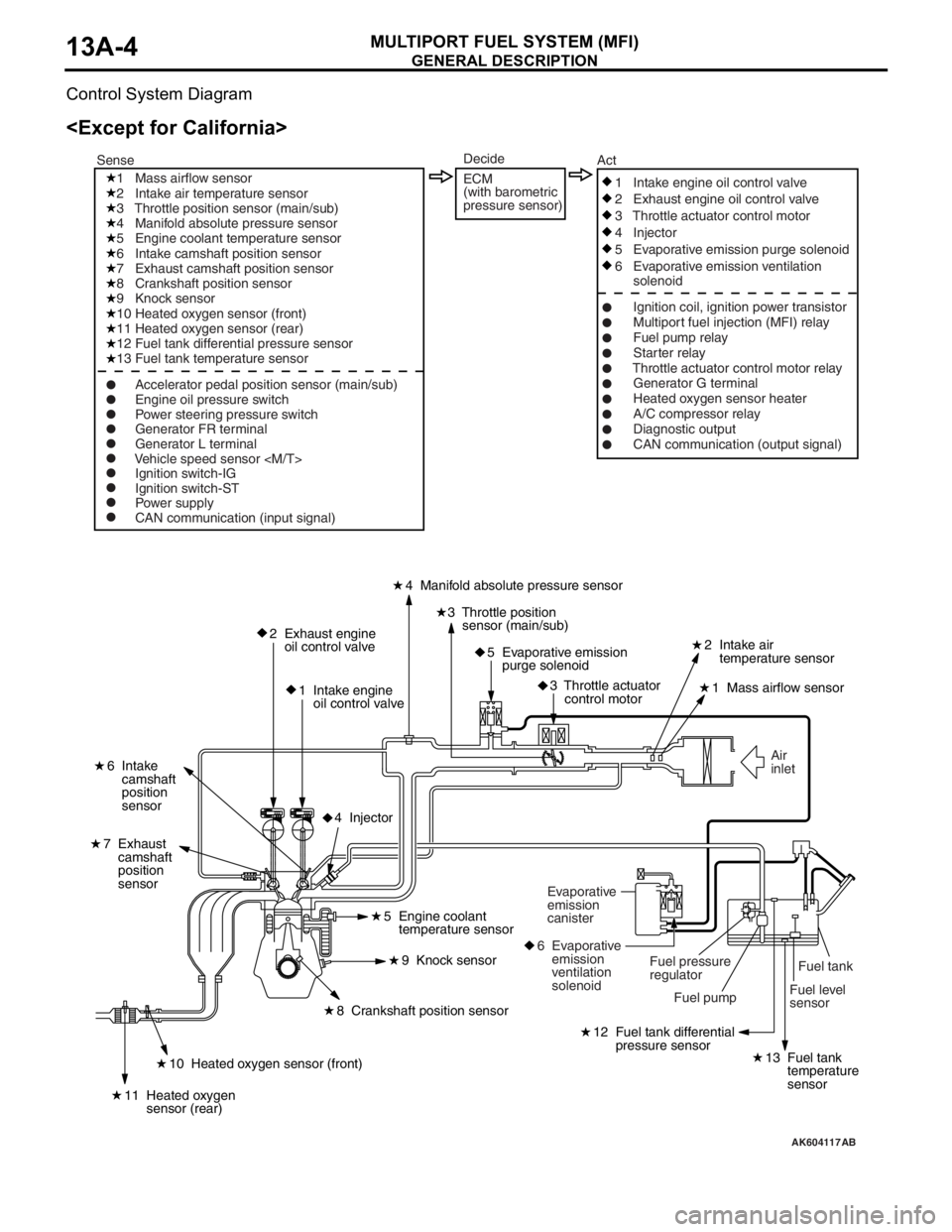

GENERAL DESCRIPTION

MULTIPORT FUEL SYSTEM (MFI)13A-4

Control System Diagram

AK604117

Fuel level

sensorFuel tank Air

inlet

2 Exhaust engine

oil control valve

1 Intake engine

oil control valve4 Manifold absolute pressure sensor

2 Intake air

temperature sensor

1 Mass airflow sensor

6 Intake

camshaft

position

sensor

7 Exhaust

camshaft

position

sensor

3 Throttle position

sensor (main/sub)

5 Evaporative emission

purge solenoid

3 Throttle actuator

control motor

12 Fuel tank differential

pressure sensor

13 Fuel tank

temperature

sensor10 Heated oxygen sensor (front)

11 Heated oxygen

sensor (rear)

8 Crankshaft position sensor5 Engine coolant

temperature sensor

9 Knock sensor

4 Injector

Fuel pump Fuel pressure

regulator Evaporative

emission

canister

6 Evaporative

emission

ventilation

solenoid

1 Mass airflow sensor

2 Intake air temperature sensor

3 Throttle position sensor (main/sub)

4 Manifold absolute pressure sensor

5 Engine coolant temperature sensor

6 Intake camshaft position sensor

7 Exhaust camshaft position sensor

8 Crankshaft position sensor

9 Knock sensor

10 Heated oxygen sensor (front)

11 Heated oxygen sensor (rear)

12 Fuel tank differential pressure sensor

13 Fuel tank temperature sensor

Ignition switch-IG

Ignition switch-ST

Power supply

CAN communication (input signal)1 Intake engine oil control valve

2 Exhaust engine oil control valve

3 Throttle actuator control motor

4 Injector

5 Evaporative emission purge solenoid

6 Evaporative emission ventilation

solenoid

Ignition coil, ignition power transistor

Multiport fuel injection (MFI) relay

Fuel pump relay

Starter relay

Throttle actuator control motor relay

Generator G terminal

Heated oxygen sensor heater

A/C compressor relay

Diagnostic output

CAN communication (output signal) SenseAct

Engine oil pressure switch

Power steering pressure switch

Generator FR terminal

Generator L terminal

Vehicle speed sensor

Decide

ECM

(with barometric

pressure sensor)

AB