ignition MITSUBISHI LANCER EVOLUTION X 2008 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 114 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-21

.

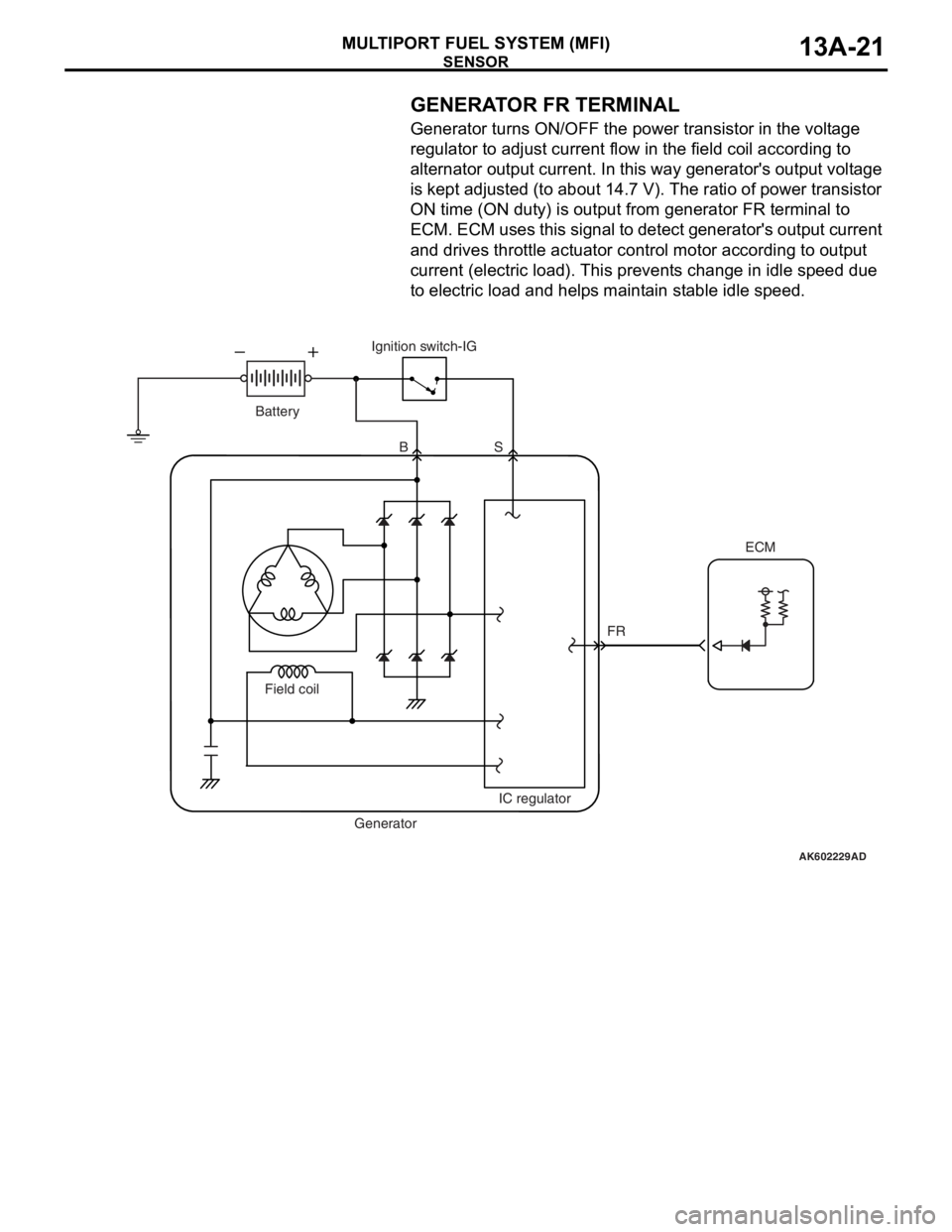

GENERATOR FR TERMINAL

Generator turns ON/OFF the power transistor in the voltage

regulator to adjust current flow in the field coil according to

alternator output current. In this way generator's output voltage

is kept adjusted (to about 14.7 V). The ratio of power transistor

ON time (ON duty) is output from generator FR terminal to

ECM. ECM uses this signal to detect generator's output current

and drives throttle actuator control motor according to output

current (electric load). This prevents change in idle speed due

to electric load and helps maintain stable idle speed.

.

AK602229AD

FR BS

Field coil

IC regulator

GeneratorIgnition switch-IG

Battery

ECM

Page 115 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-22

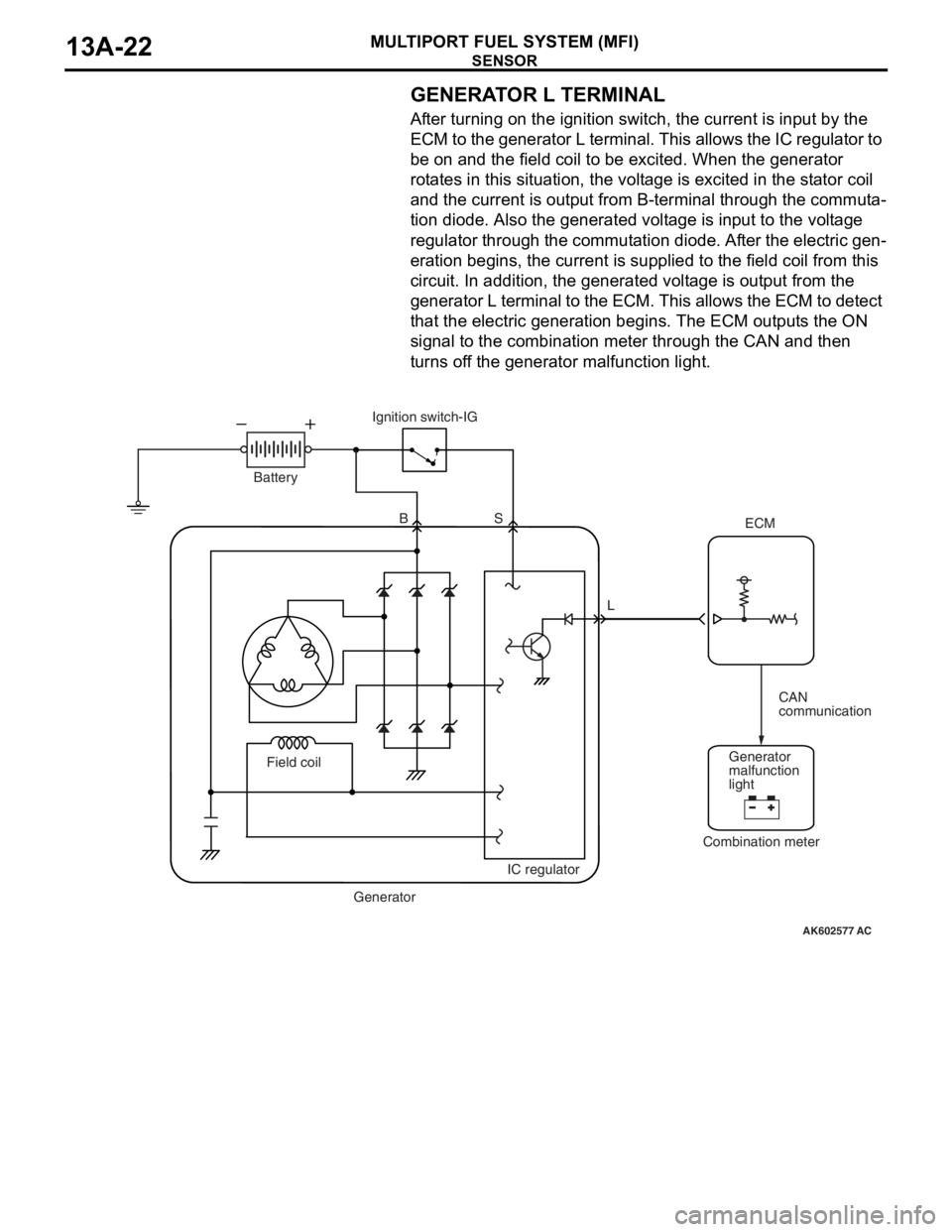

GENERATOR L TERMINAL

After turning on the ignition switch, the current is input by the

ECM to the generator L terminal. This allows the IC regulator to

be on and the field coil to be excited. When the generator

rotates in this situation, the voltage is excited in the stator coil

and the current is output from B-terminal through the commuta

-

tion diode. Also the generated voltage is input to the voltage

regulator through the commutation diode. After the electric gen

-

eration begins, the current is supplied to the field coil from this

circuit. In addition, the generated voltage is output from the

generator L terminal to the ECM. This allows the ECM to detect

that the electric generation begins. The ECM outputs the ON

signal to the combination meter through the CAN and then

turns off the generator malfunction light.

AK602577

L BS

AC

Battery

GeneratorIC regulator Ignition switch-IG

CAN

communication

Generator

malfunction

light

Combination meterECM

Field coil

Page 118 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-25

IGNITION COIL

Refer to GROUP 16 − Ignition Coil P.16-2.

EXHAUST GAS RECIRCULATION (EGR) VALVE

Refer to GROUP 17 − Emission Control − Exhaust Gas Recircu-

lation (EGR) System P.17-12.

EVAPORATIVE EMISSION PURGE SOLENOID

Refer to GROUP 17 − Emission Control − Evaporative Emission

Control System

P.17-11.

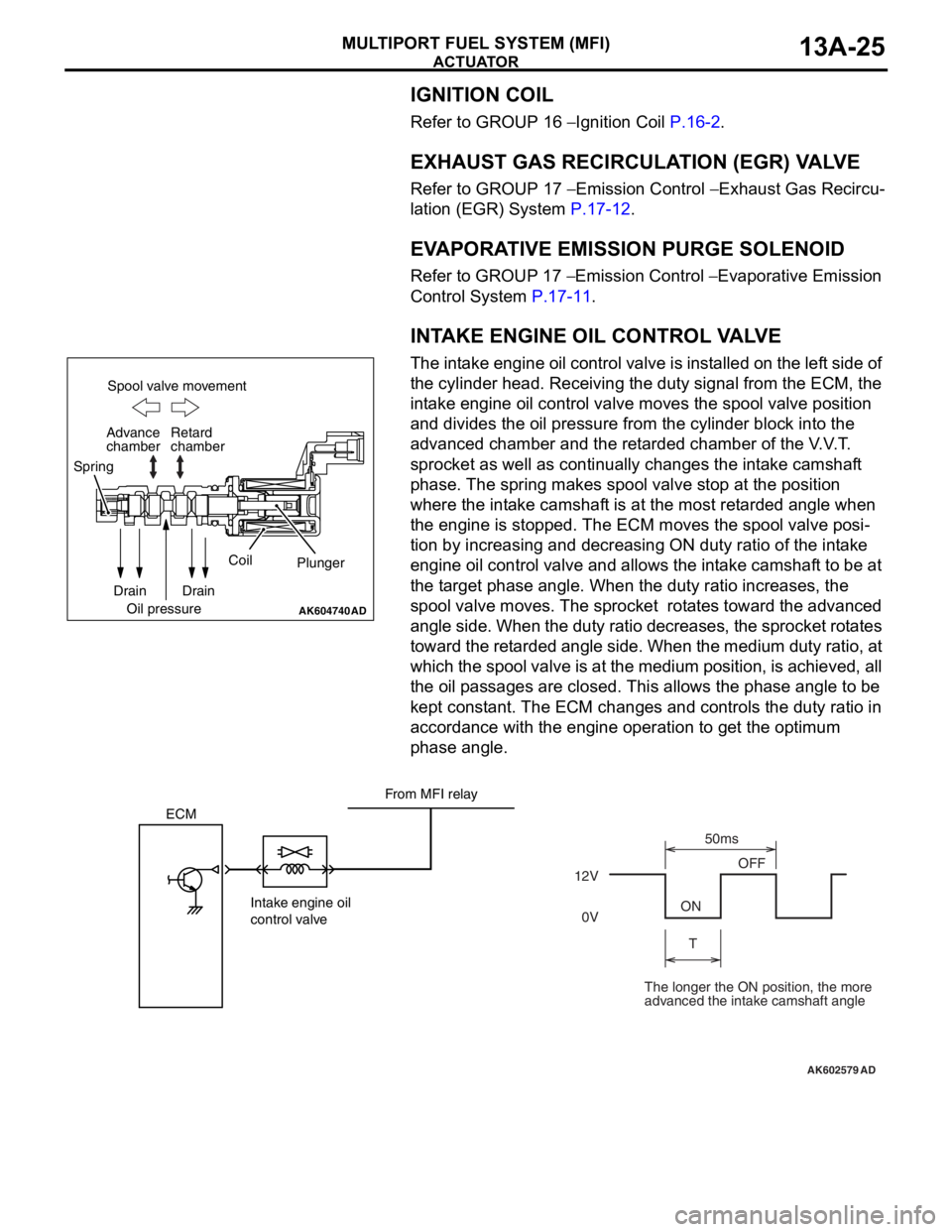

INTAKE ENGINE OIL CONTROL VALVE

The intake engine oil control valve is installed on the left side of

the cylinder head. Receiving the duty signal from the ECM, the

intake engine oil control valve moves the spool valve position

and divides the oil pressure from the cylinder block into the

advanced chamber and the retarded chamber of the V.V.T.

sprocket as well as continually changes the intake camshaft

phase. The spring makes spool valve stop at the position

where the intake camshaft is at the most retarded angle when

the engine is stopped. The ECM moves the spool valve posi

-

tion by increasing and decreasing ON duty ratio of the intake

engine oil control valve and allows the intake camshaft to be at

the target phase angle. When the duty ratio increases, the

spool valve moves. The sprocket rotates toward the advanced

angle side. When the duty ratio decreases, the sprocket rotates

toward the retarded angle side. When the medium duty ratio, at

which the spool valve is at the medium position, is achieved, all

the oil passages are closed. This allows the phase angle to be

kept constant. The ECM changes and controls the duty ratio in

accordance with the engine operation to get the optimum

phase angle.

AK604740AD

Spool valve movement

Retard

chamber

Spring

Drain

Oil pressureCoil

Plunger

Drain Advance

chamber

AK602579

ECM

Intake engine oil

control valve12VOFF

ON

T50ms

0V

AD

From MFI relay

The longer the ON position, the more

advanced the intake camshaft angle

Page 121 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-28

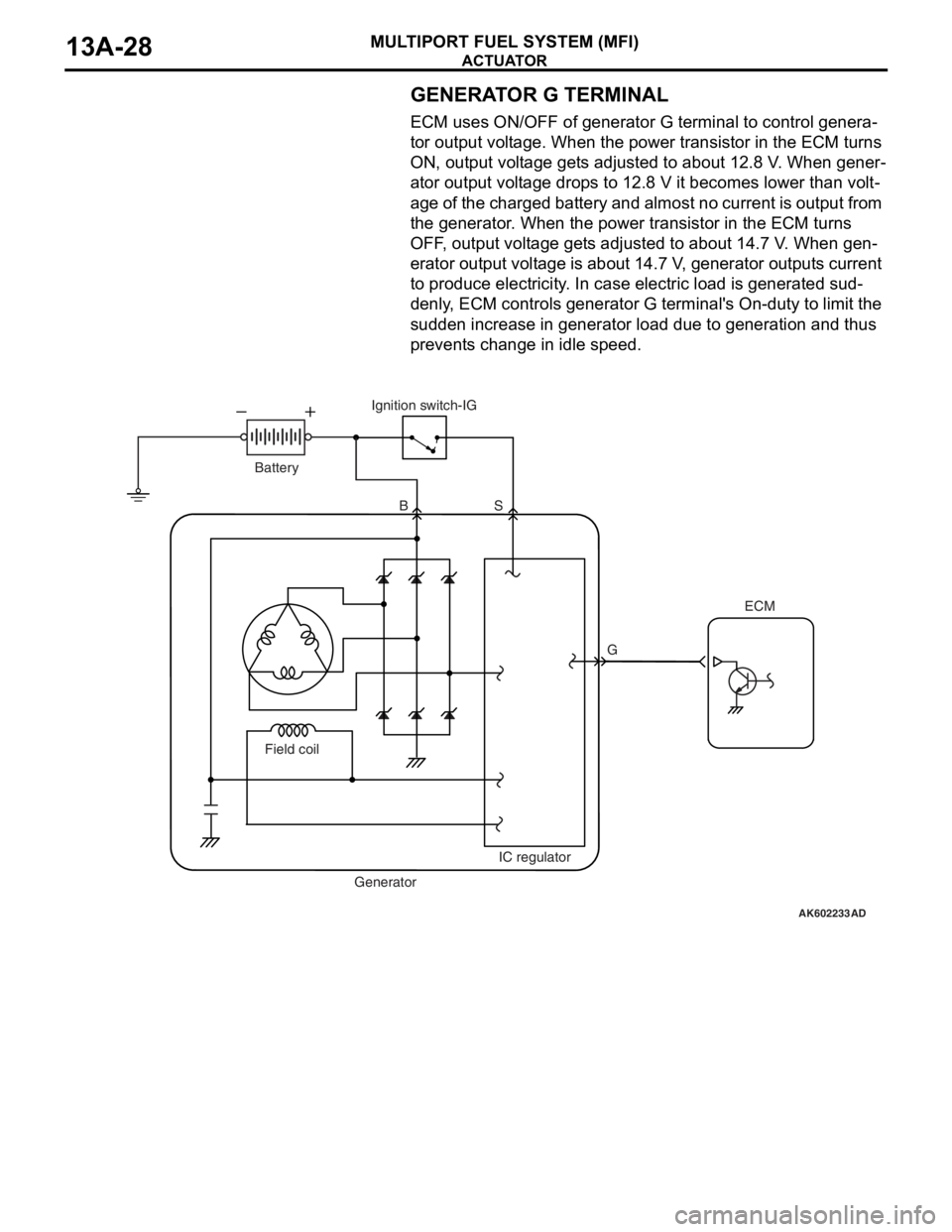

GENERATOR G TERMINAL

ECM uses ON/OFF of generator G terminal to control genera-

tor output voltage. When the power transistor in the ECM turns

ON, output voltage gets adjusted to about 12.8 V. When gener

-

ator output voltage drops to 12.8 V it becomes lower than volt-

age of the charged battery and almost no current is output from

the generator. When the power transistor in the ECM turns

OFF, output voltage gets adjusted to about 14.7 V. When gen

-

erator output voltage is about 14.7 V, generator outputs current

to produce electricity. In case electric load is generated sud

-

denly, ECM controls generator G terminal's On-duty to limit the

sudden increase in generator load due to generation and thus

prevents change in idle speed.

AK602233AD

Field coil

IC regulator

GeneratorG Ignition switch-IG

Battery

BS

ECM

Page 122 of 241

FUEL INJECTION CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-29

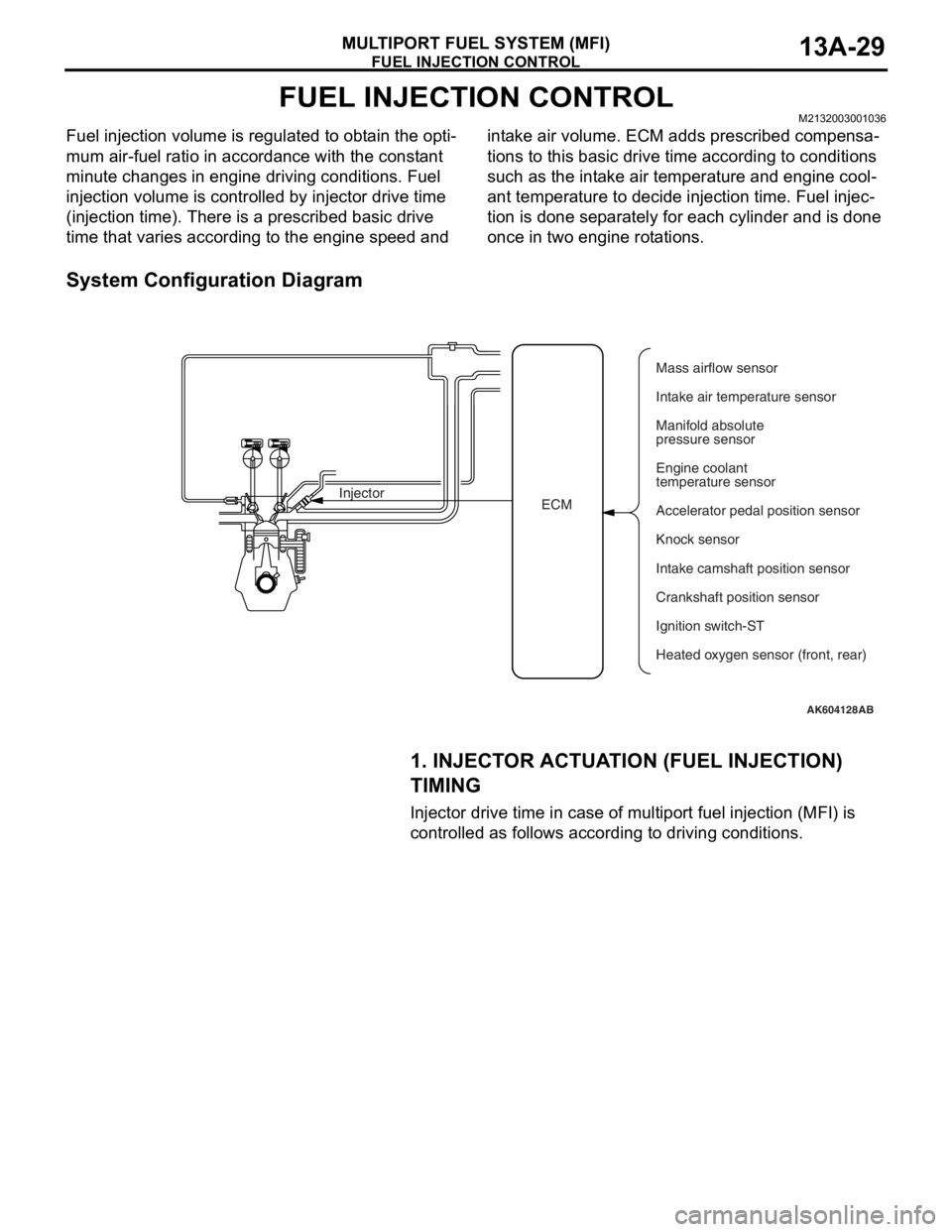

FUEL INJECTION CONTROLM2132003001036

Fuel injection volume is regulated to obtain the opti-

mum air-fuel ratio in accordance with the constant

minute changes in engine driving conditions. Fuel

injection volume is controlled by injector drive time

(injection time). There is a prescribed basic drive

time that varies according to the engine speed and intake air volume. ECM adds prescribed compensa

-

tions to this basic drive time according to conditions

such as the intake air temperature and engine cool

-

ant temperature to decide injection time. Fuel injec-

tion is done separately for each cylinder and is done

once in two engine rotations.

System Configuration Diagram

1. INJECTOR ACTUATION (FUEL INJECTION)

TIMING

Injector drive time in case of multiport fuel injection (MFI) is

controlled as follows according to driving conditions.

AK604128AB

ECM InjectorMass airflow sensor

Intake air temperature sensor

Manifold absolute

pressure sensor

Engine coolant

temperature sensor

Accelerator pedal position sensor

Knock sensor

Intake camshaft position sensor

Ignition switch-ST

Heated oxygen sensor (front, rear) Crankshaft position sensor

Page 128 of 241

IGNITION TIMING AND CONTROL FOR CURRENT CARRYING TIME

MULTIPORT FUEL SYSTEM (MFI)13A-35

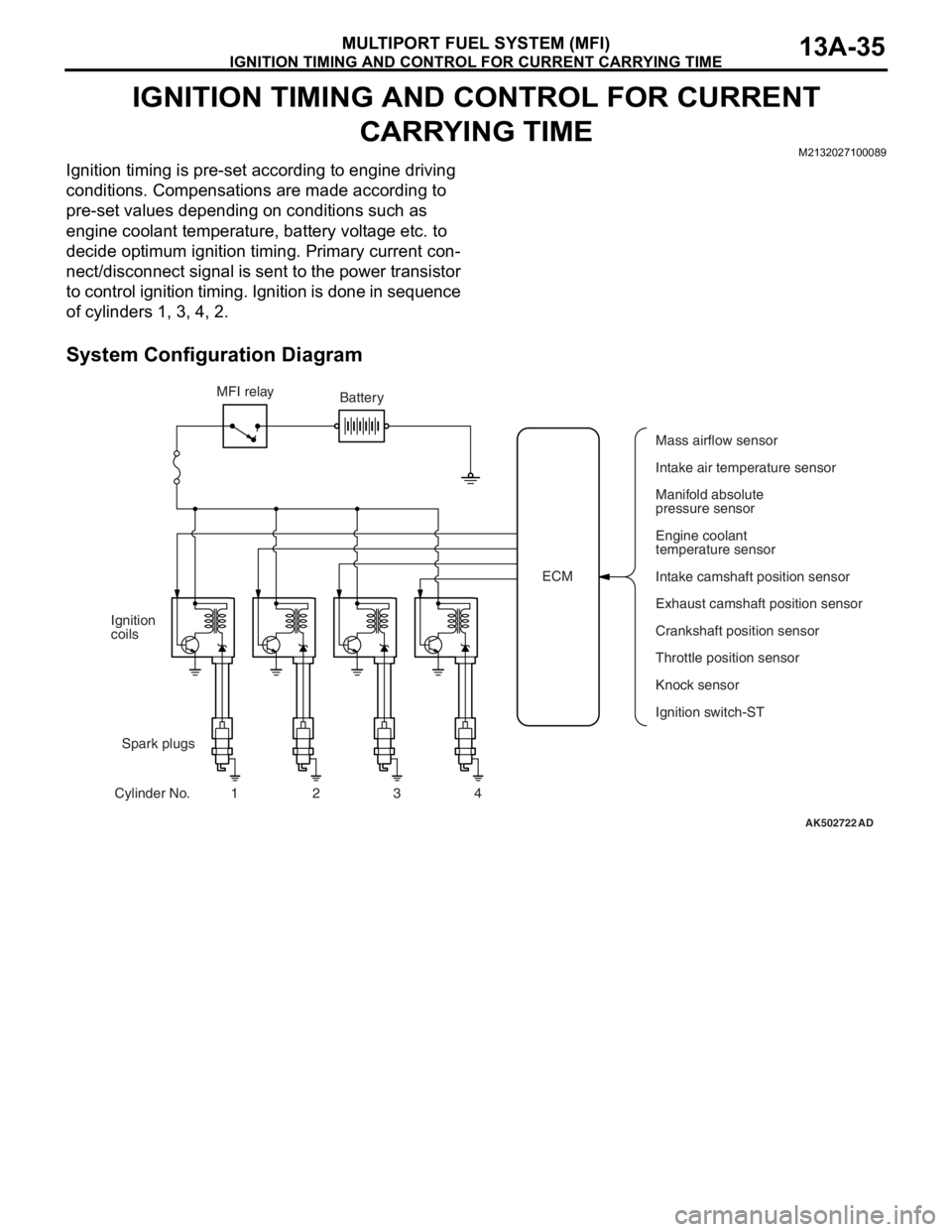

IGNITION TIMING AND CONTROL FOR CURRENT

CARRYING TIME

M2132027100089

Ignition timing is pre-set according to engine driving

conditions. Compensations are made according to

pre-set values depending on conditions such as

engine coolant temperature, battery voltage etc. to

decide optimum ignition timing. Primary current con

-

nect/disconnect signal is sent to the power transistor

to control ignition timing. Ignition is done in sequence

of cylinders 1, 3, 4, 2.

System Configuration Diagram

AK502722AD

ECM MFI relay

Spark plugs Ignition

coils

Cylinder No. 1 2 3 4Battery

Mass airflow sensor

Intake air temperature sensor

Manifold absolute

pressure sensor

Engine coolant

temperature sensor

Intake camshaft position sensor

Exhaust camshaft position sensor

Crankshaft position sensor

Knock sensor

Ignition switch-ST Throttle position sensor

Page 129 of 241

IGNITION TIMING AND CONTROL FOR CURRENT CARRYING TIME

MULTIPORT FUEL SYSTEM (MFI)13A-36

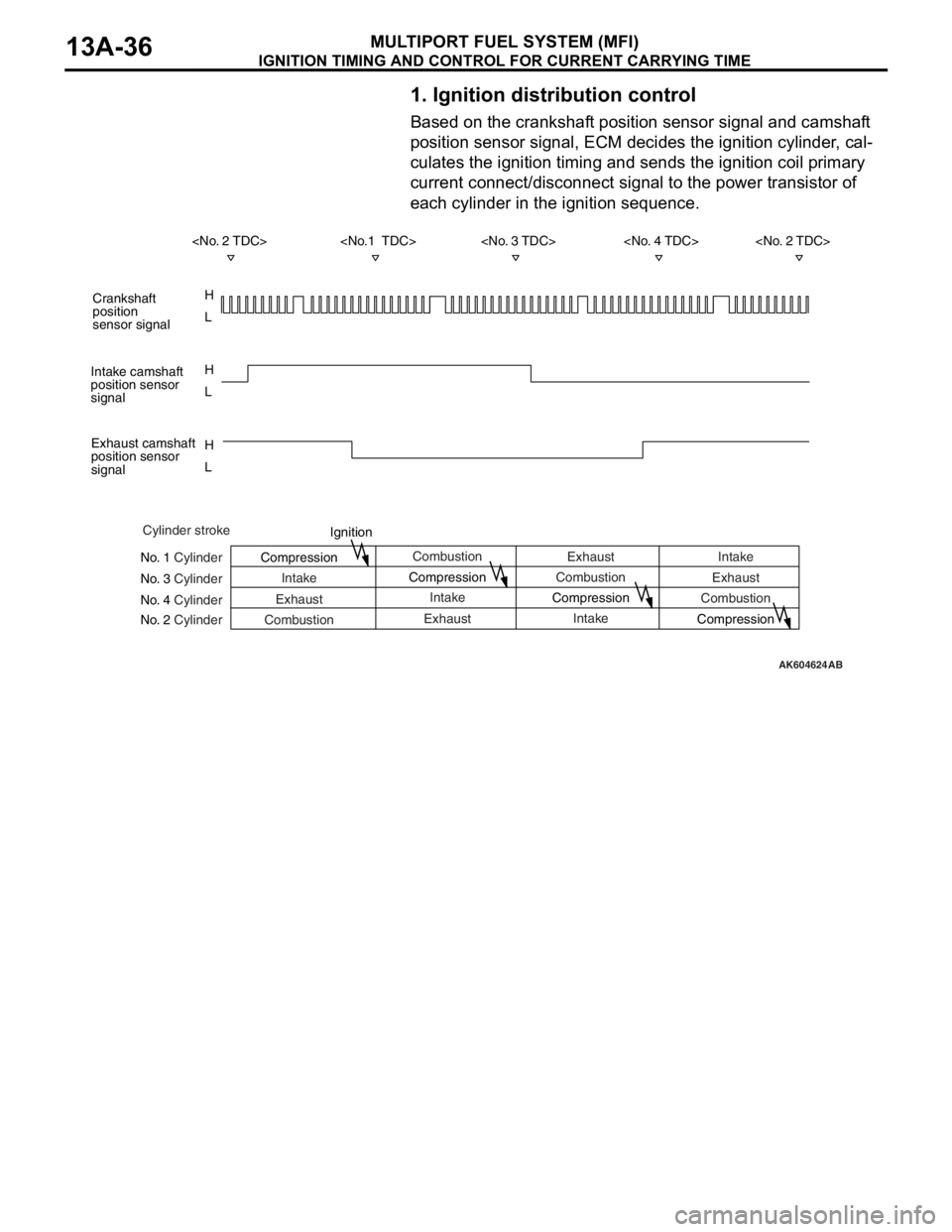

1. Ignition distribution control

Based on the crankshaft position sensor signal and camshaft

position sensor signal, ECM decides the ignition cylinder, cal

-

culates the ignition timing and sends the ignition coil primary

current connect/disconnect signal to the power transistor of

each cylinder in the ignition sequence.

AK604624

Exhaust

AB

Cylinder stroke

No. 1 Cylinder

No. 3 Cylinder

No. 4 Cylinder

No. 2 CylinderCombustion

Intake

Exhaust

Combustion CompressionIgnition

Intake

Exhaust CompressionCombustion

Intake CompressionIntake

Exhaust

Combustion

Compression H

L

H

L

H

L Crankshaft

position

sensor signal

Intake camshaft

position sensor

signal

Exhaust camshaft

position sensor

signal

Page 130 of 241

![MITSUBISHI LANCER EVOLUTION X 2008 Owners Manual IGNITION TIMING AND CONTROL FOR CURRENT CARRYING TIME

MULTIPORT FUEL SYSTEM (MFI)13A-37

2. Spark-advance control and current carrying

time control

.

[During start]

ECM initiates ignition at fixed ign MITSUBISHI LANCER EVOLUTION X 2008 Owners Manual IGNITION TIMING AND CONTROL FOR CURRENT CARRYING TIME

MULTIPORT FUEL SYSTEM (MFI)13A-37

2. Spark-advance control and current carrying

time control

.

[During start]

ECM initiates ignition at fixed ign](/img/19/57326/w960_57326-129.png)

IGNITION TIMING AND CONTROL FOR CURRENT CARRYING TIME

MULTIPORT FUEL SYSTEM (MFI)13A-37

2. Spark-advance control and current carrying

time control

.

[During start]

ECM initiates ignition at fixed ignition timing (5° BTDC) syn-

chronized with the crankshaft position sensor signal.

.

[During normal operation]

After determining the basic spark-advance based on the intake

air volume and engine speed, ECM makes compensations

based on input from various sensors to control the optimum

spark-advance and current carrying time.

List of main compensations for spark-advance control and current carrying time control

.

[Control for checking ignition timing]

During basic ignition timing set mode for M.U.T.-III actuator test

function, sparking is done with fixed ignition timing (5

° BTDC)

synchronized with crankshaft position sensor signal.

CompensationsContent

Intake air temperature compensationCompensation is made according to intake air

temperature. The higher the intake air temperature

the greater the delay in ignition timing.

Engine coolant temperature compensationCompensation is made according to engine coolant

temperature. The lower the engine coolant

temperature the greater the advance in ignition

timing.

Knocking compensationCompensation is made according to generation of

knocking. The greater the knocking the greater the

delay in ignition timing.

Stable idle compensationCompensation is made according to change in idle

speed. In case engine speed becomes lower than

target speed, ignition timing is advanced.

Delay compensation when changing shiftDuring change of shift, sparking is delayed

compared to normal ignition timing to reduce

engine output torque and absorb the shock of the

shift change.

Battery voltage compensationCompensation is made depending on battery

voltage. The lower the battery voltage the greater

the current carrying time and when battery voltage

is high current carrying time is shortened.

Page 132 of 241

THROTTLE VALVE OPENING ANGLE CONTROL AND IDLE SPEED CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-39

List of main compensations for throttle valve opening angle and idle speed control

Initialize control

After ignition switch turns OFF, ECM drives the throt-

tle valve from fully closed position to fully open posi-

tion and records the fully closed/open studied value

of the throttle position sensor (main and sub) output

signals. The recorded studied values are used as

studied value compensation for compensating basic

target opening angle when the engine is started next.

CompensationsContent

Stable idle compensation (immediately after start)In order to stabilize idle speed immediately after

start, target opening angle is kept big and then

gradually reduced. Compensation values are set

based on the engine coolant temperature.

Rotation speed feedback compensation (while

idling)In case there is a difference between the target idle

speed and actual engine speed, ECM

compensates the throttle valve opening angle

based on that difference.

Atmospheric pressure compensationAt high altitudes atmospheric pressure is less and

the intake air density is low. So, the target opening

angle is compensated based on atmospheric

pressure.

Engine coolant temperature compensationCompensation is made according to the engine

coolant temperature. The lower the engine coolant

temperature the greater the throttle valve opening

angle.

Electric load compensationThrottle valve opening angle is compensated

according to electric load. The greater the electric

load, the greater the throttle valve opening angle.

Compensation when shift is in D range

to some other range, throttle valve opening angle is

increased to prevent reduction in engine speed.

Compensation when A/C is functioningThrottle valve opening angle is compensated

according to functioning of A/C compressor. While

A/C compressor is being driven, the throttle valve

opening angle is increased.

Power steering fluid pressure compensationThrottle valve opening angle is compensated

according to power steering functioning. When

power steering oil pressure rises and power

steering pressure switch is ON, the throttle valve

opening angle is increased.

Page 138 of 241

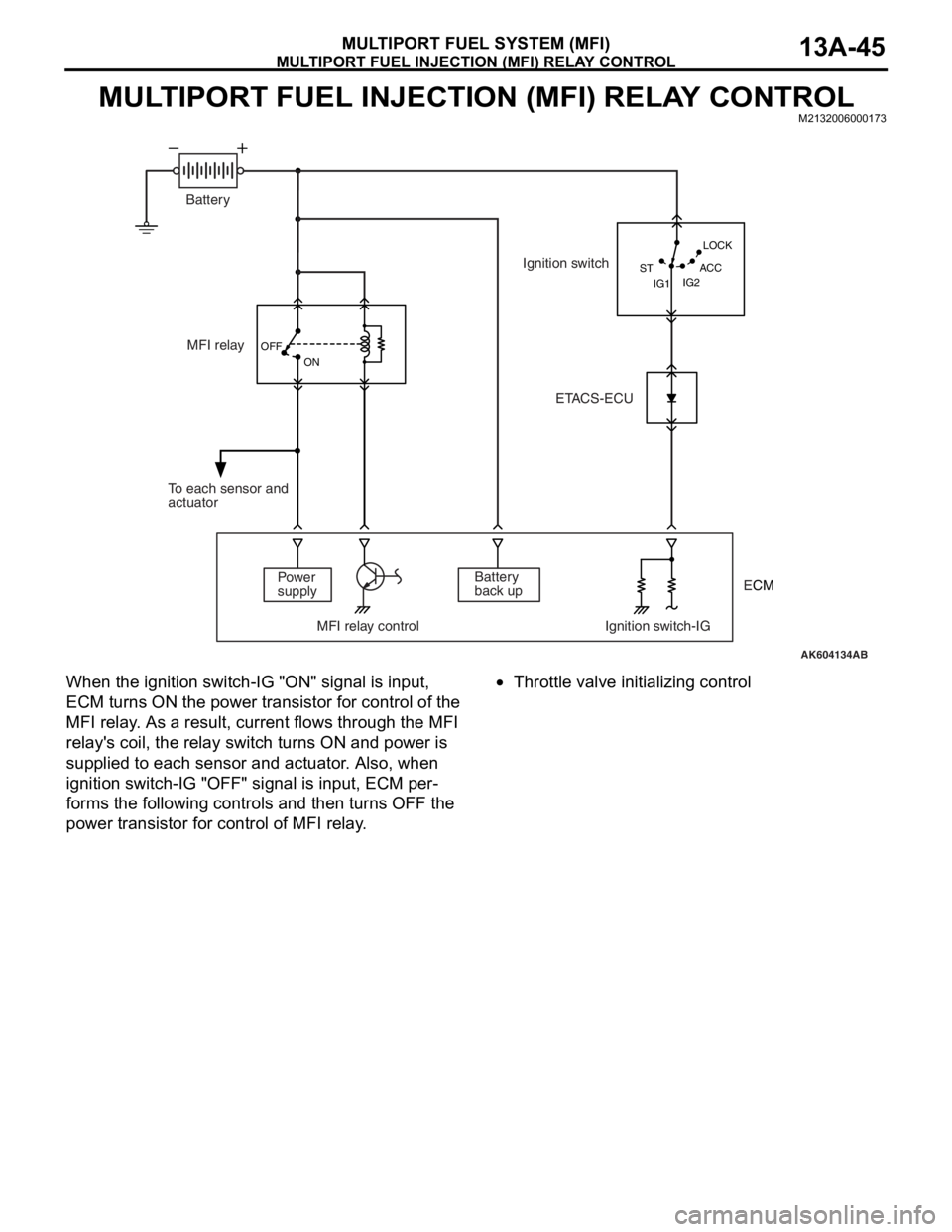

MULTIPORT FUEL INJECTION (MFI) RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-45

MULTIPORT FUEL INJECTION (MFI) RELAY CONTROLM2132006000173

When the ignition switch-IG "ON" signal is input,

ECM turns ON the power transistor for control of the

MFI relay. As a result, current flows through the MFI

relay's coil, the relay switch turns ON and power is

supplied to each sensor and actuator. Also, when

ignition switch-IG "OFF" signal is input, ECM per

-

forms the following controls and then turns OFF the

power transistor for control of MFI relay.

•Throttle valve initializing control

AK604134AB OFF

ON

IG2 STLOCK

ACC

IG1

MFI relay

Power

supply

MFI relay control Ignition switch-IGBattery

back up To each sensor and

actuatorIgnition switch

ETACS-ECU Battery

ECM