sensor MITSUBISHI LANCER EVOLUTION X 2008 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 132 of 241

THROTTLE VALVE OPENING ANGLE CONTROL AND IDLE SPEED CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-39

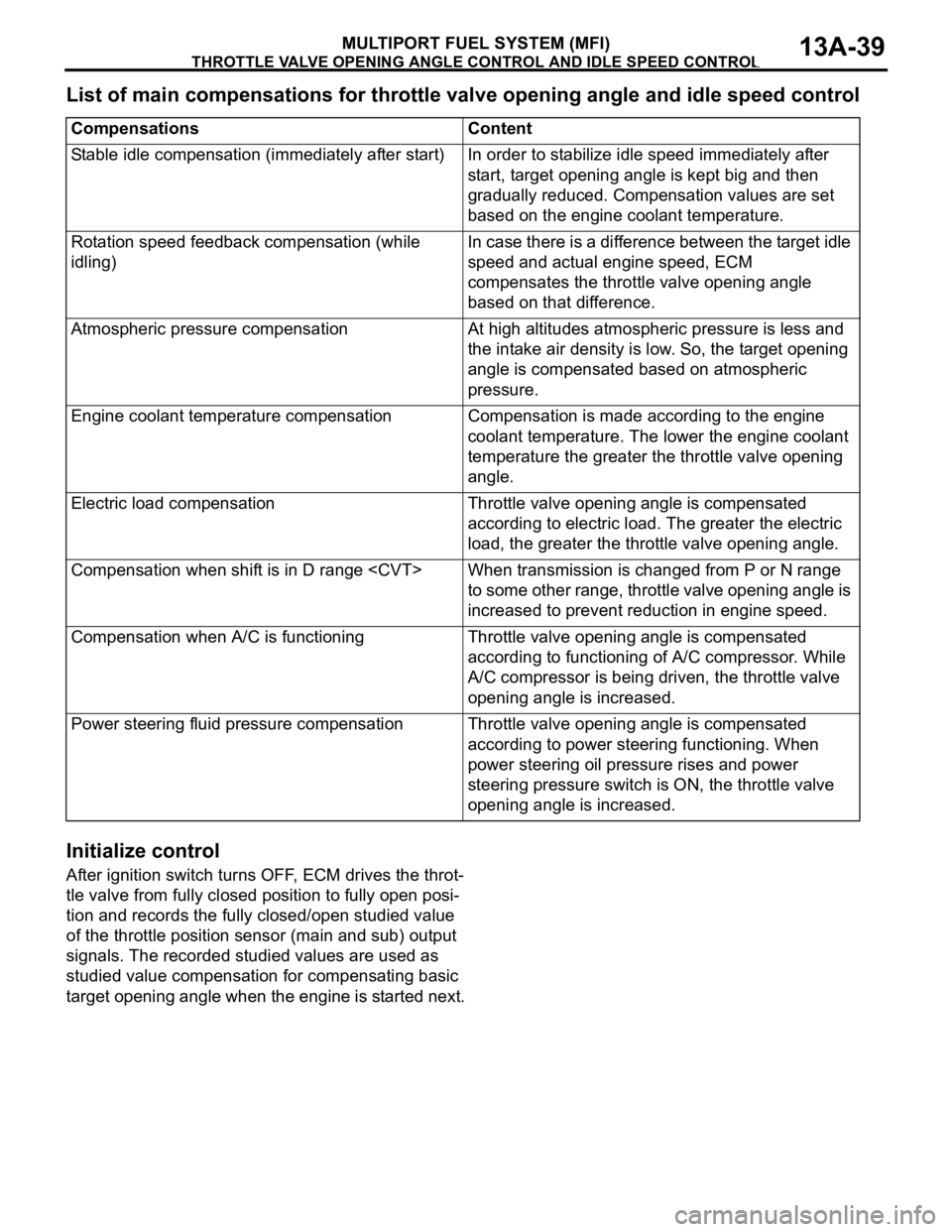

List of main compensations for throttle valve opening angle and idle speed control

Initialize control

After ignition switch turns OFF, ECM drives the throt-

tle valve from fully closed position to fully open posi-

tion and records the fully closed/open studied value

of the throttle position sensor (main and sub) output

signals. The recorded studied values are used as

studied value compensation for compensating basic

target opening angle when the engine is started next.

CompensationsContent

Stable idle compensation (immediately after start)In order to stabilize idle speed immediately after

start, target opening angle is kept big and then

gradually reduced. Compensation values are set

based on the engine coolant temperature.

Rotation speed feedback compensation (while

idling)In case there is a difference between the target idle

speed and actual engine speed, ECM

compensates the throttle valve opening angle

based on that difference.

Atmospheric pressure compensationAt high altitudes atmospheric pressure is less and

the intake air density is low. So, the target opening

angle is compensated based on atmospheric

pressure.

Engine coolant temperature compensationCompensation is made according to the engine

coolant temperature. The lower the engine coolant

temperature the greater the throttle valve opening

angle.

Electric load compensationThrottle valve opening angle is compensated

according to electric load. The greater the electric

load, the greater the throttle valve opening angle.

Compensation when shift is in D range

to some other range, throttle valve opening angle is

increased to prevent reduction in engine speed.

Compensation when A/C is functioningThrottle valve opening angle is compensated

according to functioning of A/C compressor. While

A/C compressor is being driven, the throttle valve

opening angle is increased.

Power steering fluid pressure compensationThrottle valve opening angle is compensated

according to power steering functioning. When

power steering oil pressure rises and power

steering pressure switch is ON, the throttle valve

opening angle is increased.

Page 133 of 241

MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)

MULTIPORT FUEL SYSTEM (MFI)13A-40

MIVEC (Mitsubishi Innovative Valve Timing Electronic

Control System)

M2132023500212

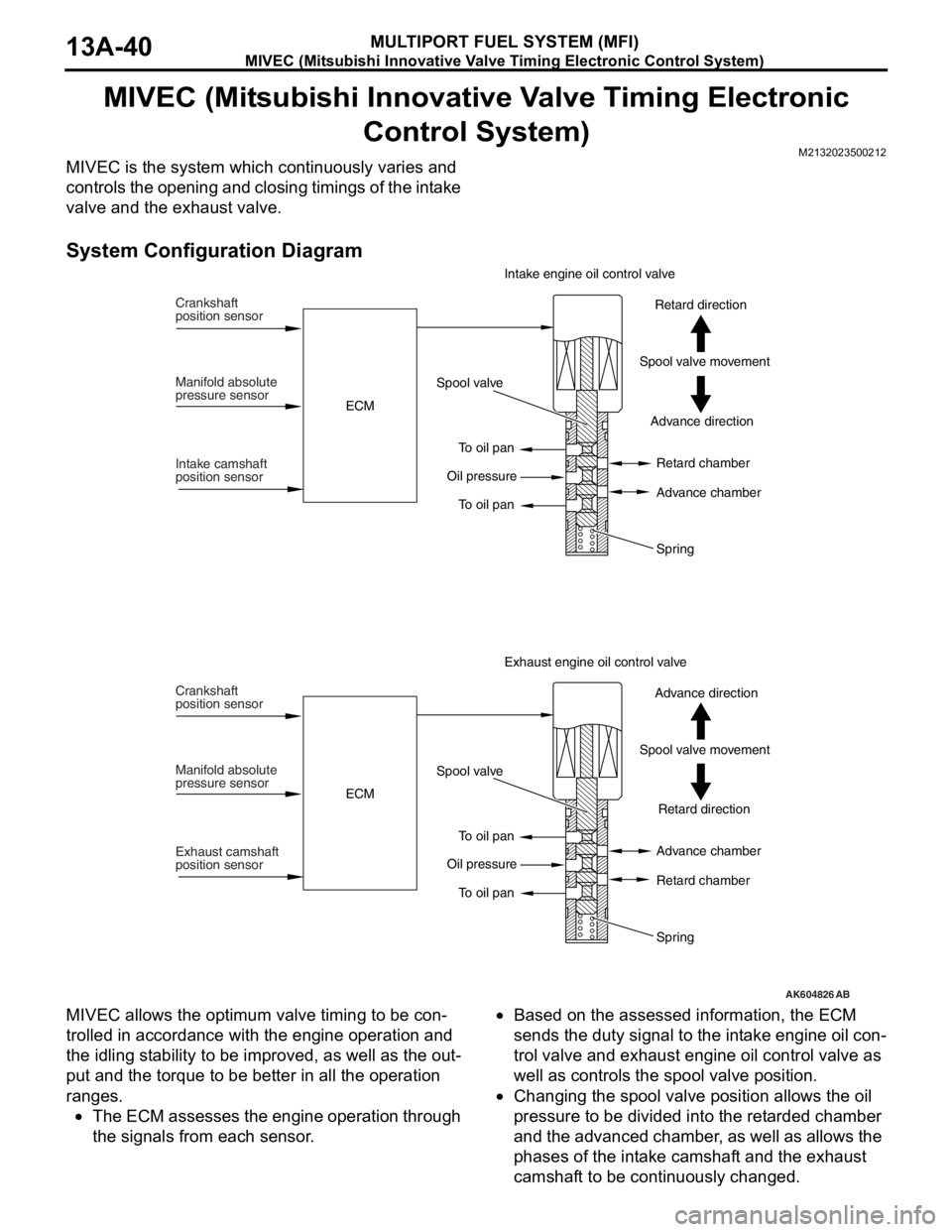

MIVEC is the system which continuously varies and

controls the opening and closing timings of the intake

valve and the exhaust valve.

System Configuration Diagram

MIVEC allows the optimum valve timing to be con-

trolled in accordance with the engine operation and

the idling stability to be improved, as well as the out

-

put and the torque to be better in all the operation

ranges.

•The ECM assesses the engine operation through

the signals from each sensor.

•Based on the assessed information, the ECM

sends the duty signal to the intake engine oil con

-

trol valve and exhaust engine oil control valve as

well as controls the spool valve position.

•Changing the spool valve position allows the oil

pressure to be divided into the retarded chamber

and the advanced chamber, as well as allows the

phases of the intake camshaft and the exhaust

camshaft to be continuously changed.

AK604826AB

Crankshaft

position sensor

Manifold absolute

pressure sensor

Intake camshaft

position sensorECMSpool valve

To oil pan

To oil pan Oil pressureAdvance direction Spool valve movementRetard direction Intake engine oil control valve

Retard chamber

Advance chamber

Spring

Crankshaft

position sensor

Manifold absolute

pressure sensor

Exhaust camshaft

position sensorECMSpool valve

To oil pan

To oil pan Oil pressureRetard direction Spool valve movementAdvance direction Exhaust engine oil control valve

Advance chamber

Retard chamber

Spring

Page 134 of 241

MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)

MULTIPORT FUEL SYSTEM (MFI)13A-41

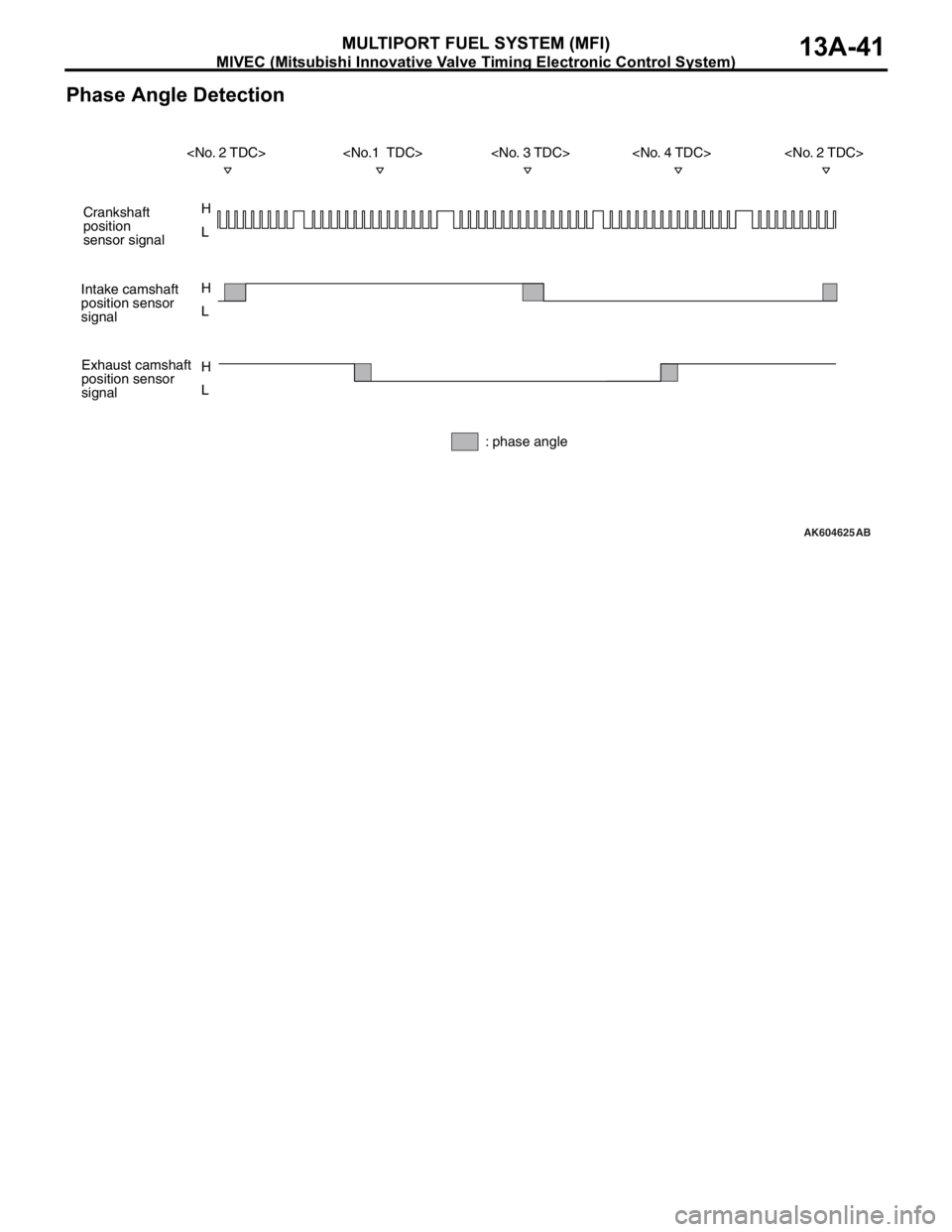

Phase Angle Detection

AK604625

H

L H

L

H

L

AB

Crankshaft

position

sensor signal

Intake camshaft

position sensor

signal

Exhaust camshaft

position sensor

signal

: phase angle

Page 135 of 241

MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)

MULTIPORT FUEL SYSTEM (MFI)13A-42

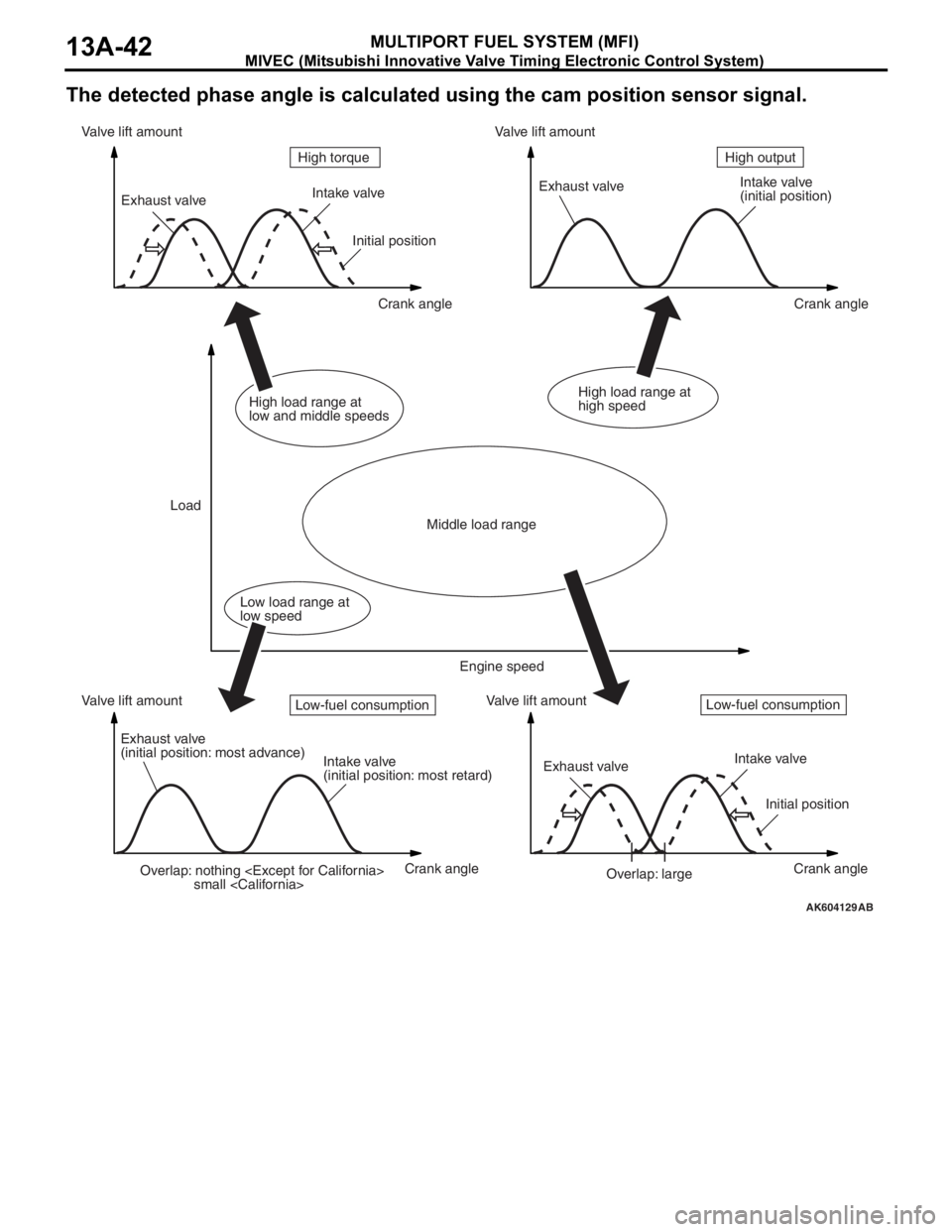

The detected phase angle is calculated using the cam position sensor signal.

AK604129AB

Overlap: nothing

small

(initial position)

Exhaust valve

(initial position: most advance)

Intake valve

(initial position: most retard)Exhaust valveIntake valve

Initial position

Overlap: large Initial position

Crank angle Crank angle

Crank angle Crank angle Valve lift amount Valve lift amountValve lift amount Valve lift amount

LoadHigh output High torque

Middle load range

Low load range at

low speedHigh load range at

low and middle speedsHigh load range at

high speed

Engine speed

Low-fuel consumptionLow-fuel consumption

Page 138 of 241

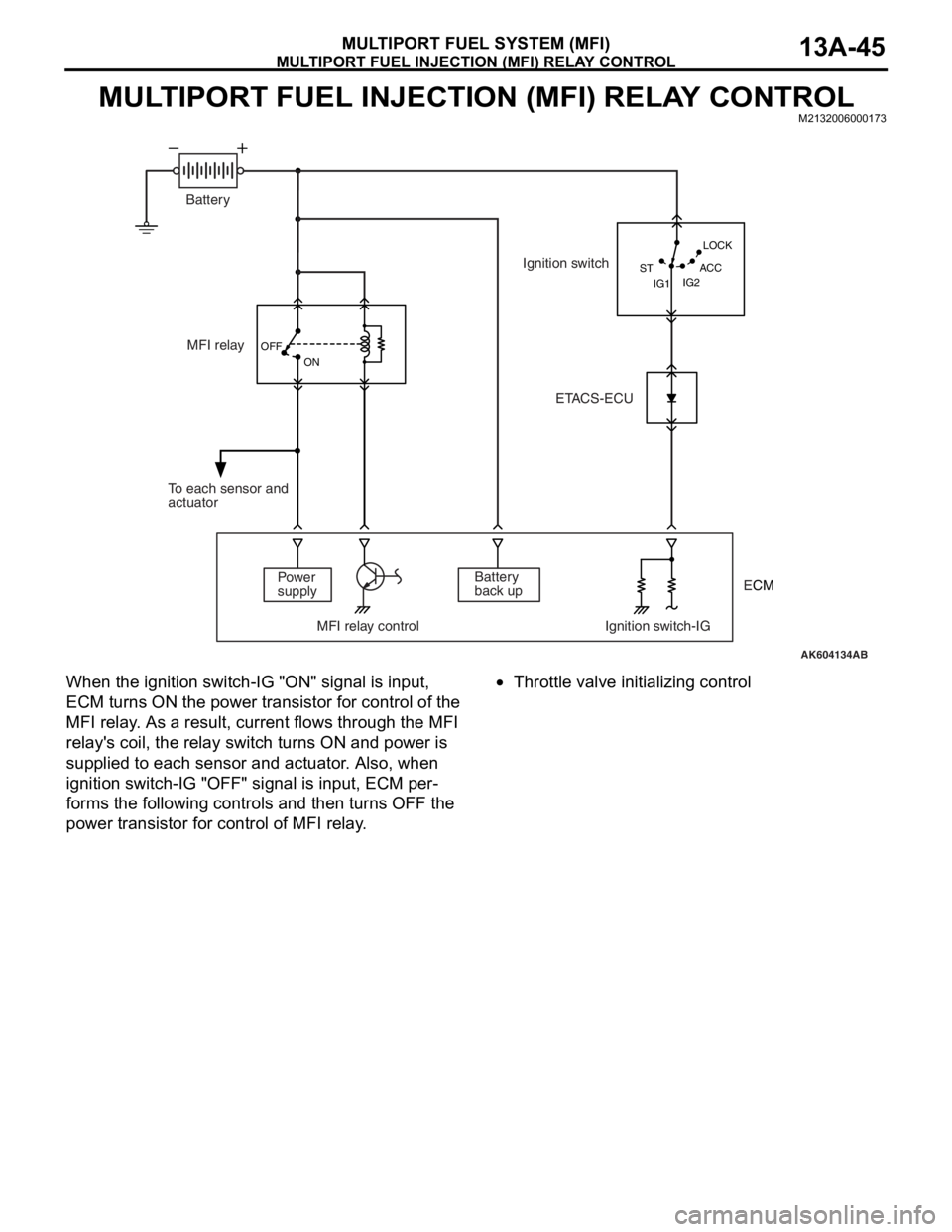

MULTIPORT FUEL INJECTION (MFI) RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-45

MULTIPORT FUEL INJECTION (MFI) RELAY CONTROLM2132006000173

When the ignition switch-IG "ON" signal is input,

ECM turns ON the power transistor for control of the

MFI relay. As a result, current flows through the MFI

relay's coil, the relay switch turns ON and power is

supplied to each sensor and actuator. Also, when

ignition switch-IG "OFF" signal is input, ECM per

-

forms the following controls and then turns OFF the

power transistor for control of MFI relay.

•Throttle valve initializing control

AK604134AB OFF

ON

IG2 STLOCK

ACC

IG1

MFI relay

Power

supply

MFI relay control Ignition switch-IGBattery

back up To each sensor and

actuatorIgnition switch

ETACS-ECU Battery

ECM

Page 139 of 241

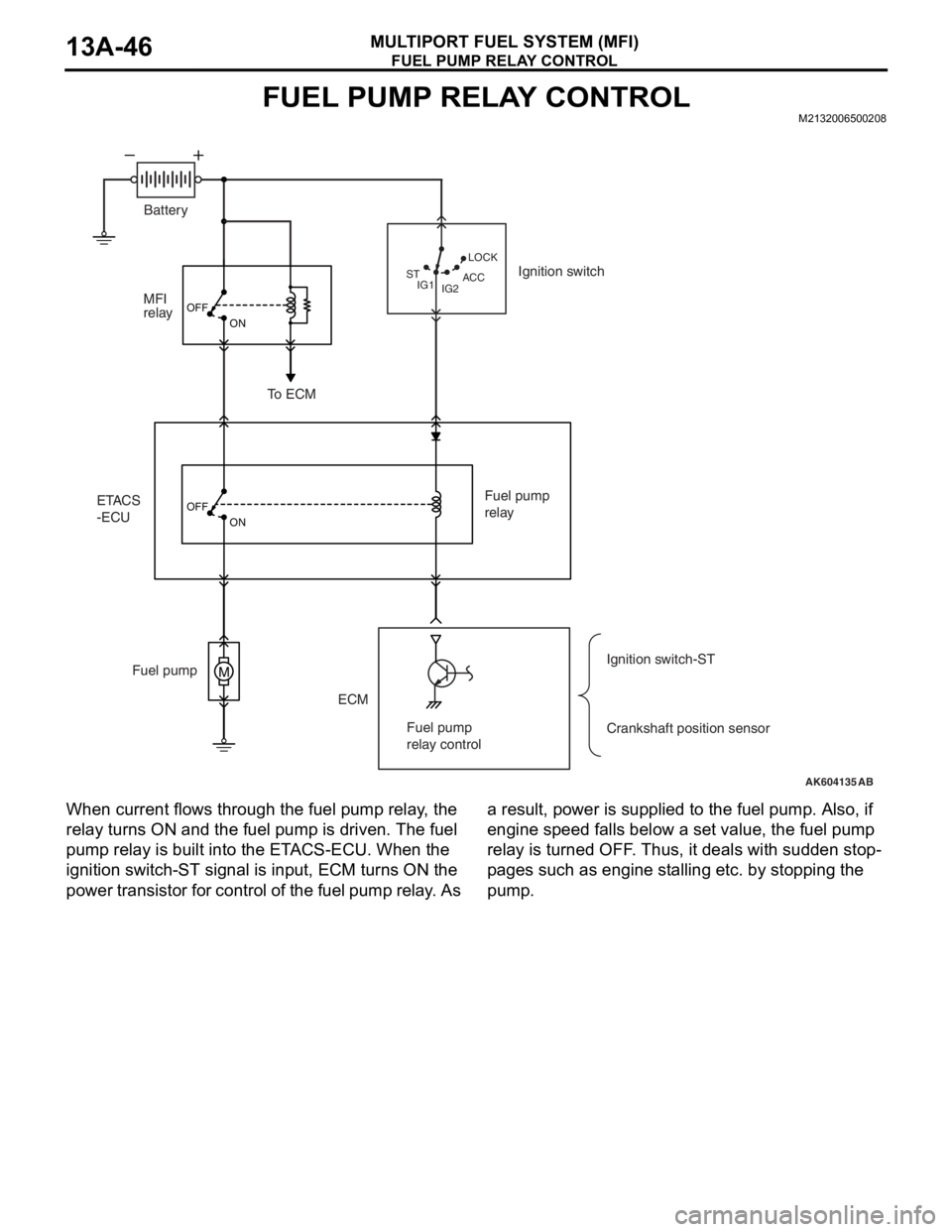

FUEL PUMP RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-46

FUEL PUMP RELAY CONTROLM2132006500208

When current flows through the fuel pump relay, the

relay turns ON and the fuel pump is driven. The fuel

pump relay is built into the ETACS-ECU. When the

ignition switch-ST signal is input, ECM turns ON the

power transistor for control of the fuel pump relay. As a result, power is supplied to the fuel pump. Also, if

engine speed falls below a set value, the fuel pump

relay is turned OFF. Thus, it deals with sudden stop

-

pages such as engine stalling etc. by stopping the

pump.

AK604135

M

OFF

ON

OFF

ON

AB IG2 STLOCK

ACC

IG1

ETACS

-ECUMFI

relay

ECM Fuel pumpFuel pump

relay

Crankshaft position sensor Ignition switch

To ECM

Ignition switch-ST Battery

Fuel pump

relay control

Page 142 of 241

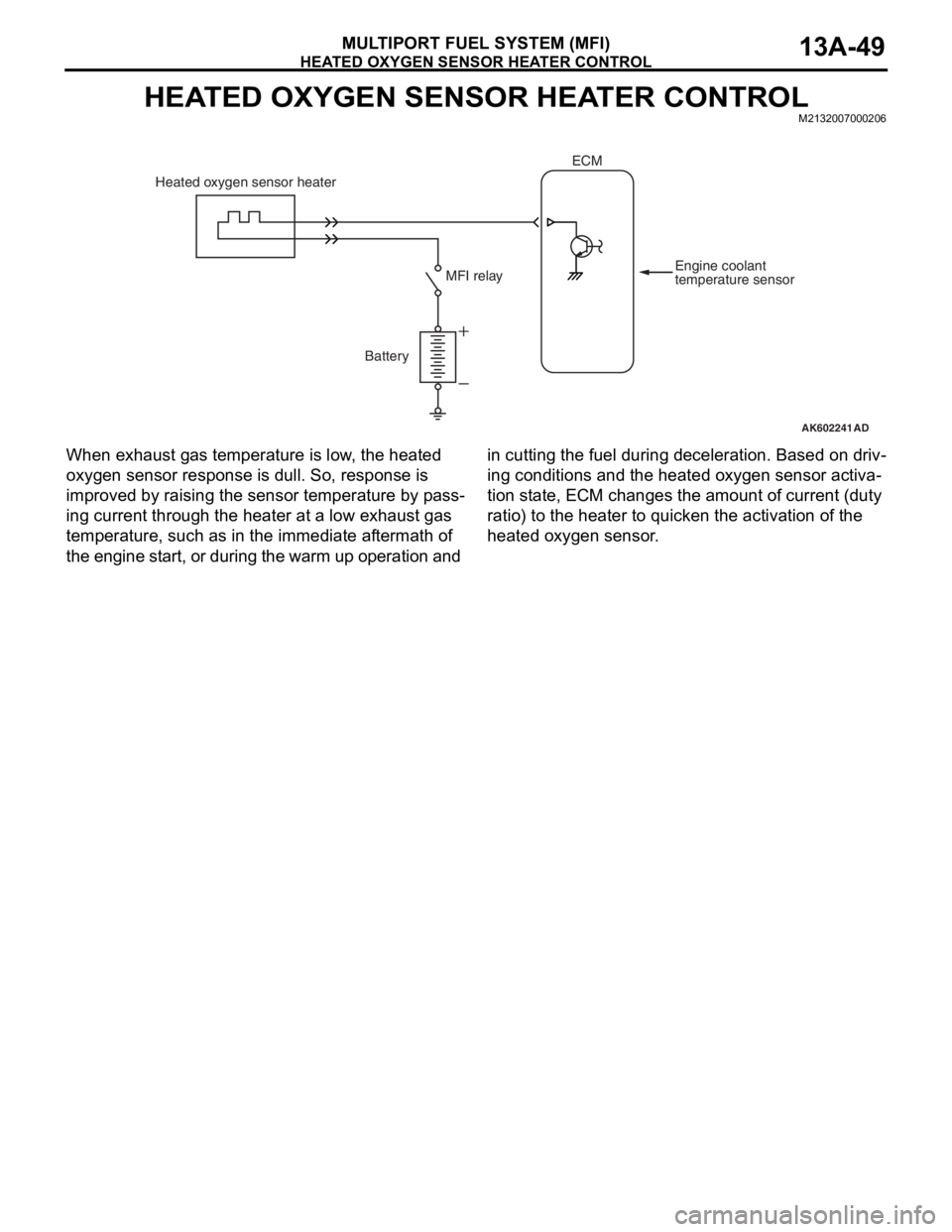

HEATED OXYGEN SENSOR HEATER CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-49

HEATED OXYGEN SENSOR HEATER CONTROLM2132007000206

When exhaust gas temperature is low, the heated

oxygen sensor response is dull. So, response is

improved by raising the sensor temperature by pass

-

ing current through the heater at a low exhaust gas

temperature, such as in the immediate aftermath of

the engine start, or during the warm up operation and in cutting the fuel during deceleration. Based on driv

-

ing conditions and the heated oxygen sensor activa-

tion state, ECM changes the amount of current (duty

ratio) to the heater to quicken the activation of the

heated oxygen sensor.

AK602241AD

Battery Heated oxygen sensor heater

Engine coolant

temperature sensor MFI relay

ECM

Page 144 of 241

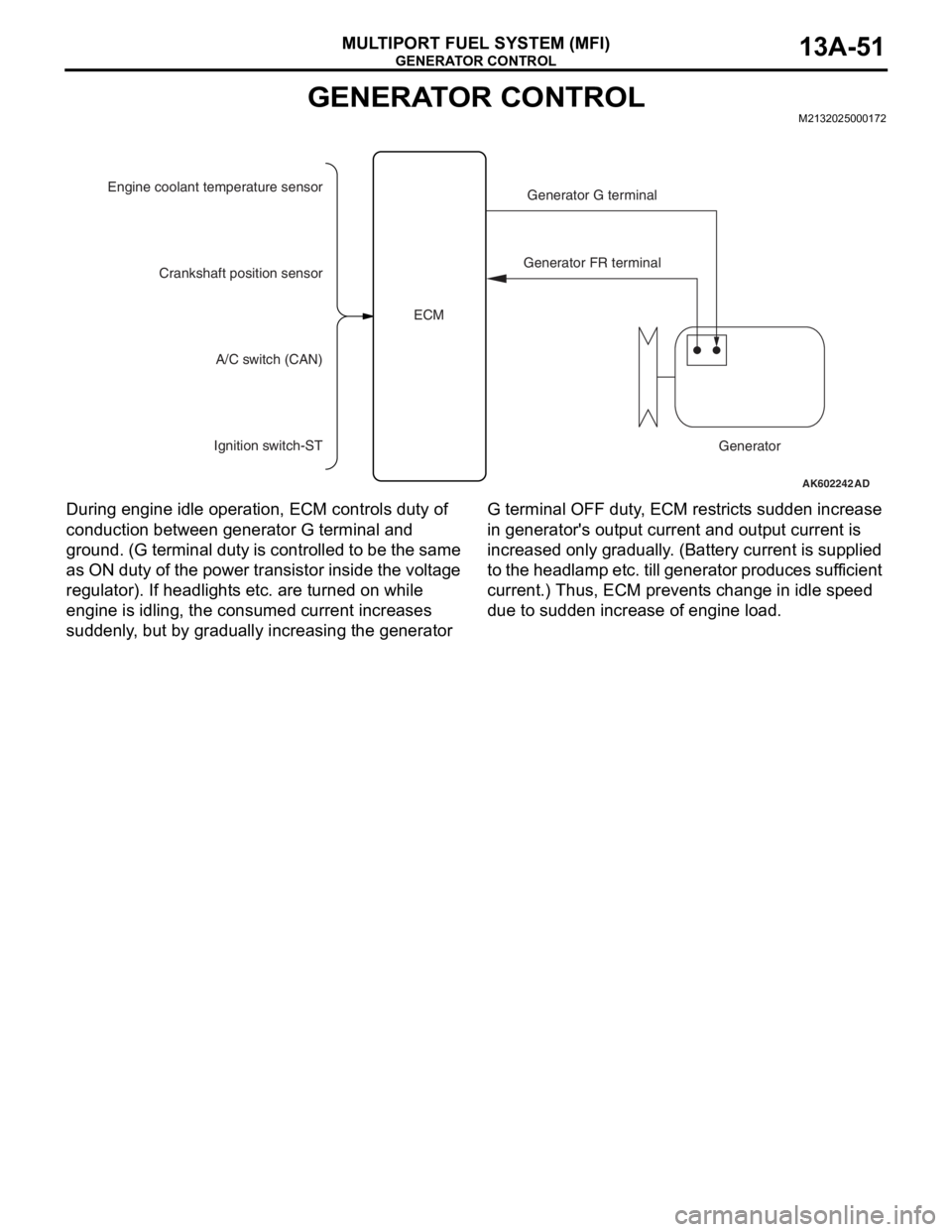

GENERATOR CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-51

GENERATOR CONTROLM2132025000172

During engine idle operation, ECM controls duty of

conduction between generator G terminal and

ground. (G terminal duty is controlled to be the same

as ON duty of the power transistor inside the voltage

regulator). If headlights etc. are turned on while

engine is idling, the consumed current increases

suddenly, but by gradually increasing the generator G terminal OFF duty, ECM restricts sudden increase

in generator's output current and output current is

increased only gradually. (Battery current is supplied

to the headlamp etc. till generator produces sufficient

current.) Thus, ECM prevents change in idle speed

due to sudden increase of engine load.

AK602242 AD

Engine coolant temperature sensor

Generator G terminal

Generator FR terminal

Generator Crankshaft position sensor

A/C switch (CAN)

Ignition switch-STECM

Page 145 of 241

EVAPORATIVE EMISSION CONTROL SYSTEM INCORRECT PURGE FLOW MONITOR

MULTIPORT FUEL SYSTEM (MFI)13A-52

EVAPORATIVE EMISSION CONTROL SYSTEM INCORRECT

PURGE FLOW MONITOR

M2132027200019

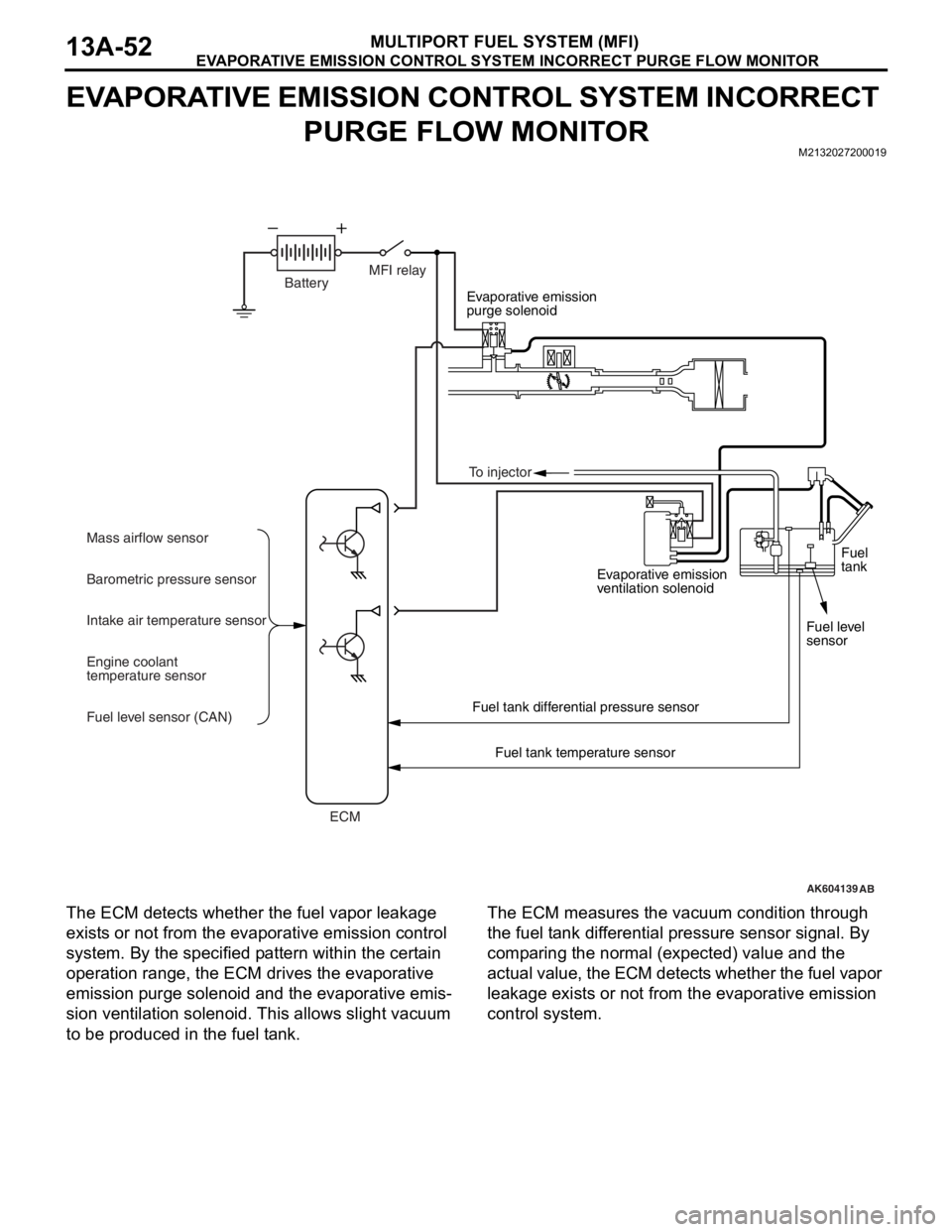

The ECM detects whether the fuel vapor leakage

exists or not from the evaporative emission control

system. By the specified pattern within the certain

operation range, the ECM drives the evaporative

emission purge solenoid and the evaporative emis

-

sion ventilation solenoid. This allows slight vacuum

to be produced in the fuel tank.

The ECM measures the vacuum condition through

the fuel tank differential pressure sensor signal. By

comparing the normal (expected) value and the

actual value, the ECM detects whether the fuel vapor

leakage exists or not from the evaporative emission

control system.

AK604139

Evaporative emission

purge solenoid

Evaporative emission

ventilation solenoid

Fuel tank differential pressure sensor

Fuel tank temperature sensor

AB

BatteryMFI relay

ECM Mass airflow sensor

Barometric pressure sensor

Intake air temperature sensor

Engine coolant

temperature sensor

Fuel level sensor (CAN)Fuel

tank

Fuel level

sensor To injector

Page 162 of 241

52A-1

GROUP 52A

INTERIOR

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .52A-2

SPECIAL TOOL . . . . . . . . . . . . . . . . .52A-2

INSTRUMENT PANEL ASSEMBLY*.52A-2

REMOVAL AND INSTALLATION . . . . . . . . 52A-2

GLOVE BOX . . . . . . . . . . . . . . . . . . .52A-5

REMOVAL AND INSTALLATION . . . . . . . . 52A-5

INSTRUMENT CENTER PANEL . . . .52A-6

REMOVAL AND INSTLLATION . . . . . . . . . 52A-6

INSTRUMENT LOWER PANEL. . . . .52A-7

REMOVAL AND INSTALLATION . . . . . . . . 52A-7

FLOOR CONSOLE ASSEMBLY . . . .52A-8

REMOVAL AND INSTALLATION . . . . . . . . 52A-8

TRIMS. . . . . . . . . . . . . . . . . . . . . . . . .52A-10

REMOVAL AND INSTALLATION . . . . . . . . 52A-10

DOOR TRIM . . . . . . . . . . . . . . . . . . . .52A-13

REMOVAL AND INSTALLATION . . . . . . . . 52A-13

HEADLINING . . . . . . . . . . . . . . . . . . .52A-15

REMOVAL AND INSTALLATION . . . . . . . . 52A-15

INSIDE REAR VIEW MIRROR . . . . . .52A-17

FRONT SEAT ASSEMBLY* . . . . . . . .52A-17

REMOVAL AND INSTALLATION . . . . . . . . 52A-17

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 52A-19

DISASSEMBLY AND ASSEMBLY . . . . . . . 52A-21

REAR SEAT ASSEMBLY . . . . . . . . . .52A-23

REMOVAL AND INSTALLATION . . . . . . . . 52A-23

DISASSEMBLY AND ASSEMBLY . . . . . . . 52A-26

FRONT SEAT BELT* . . . . . . . . . . . . .52A-28

REMOVAL AND INSTALLATION . . . . . . . . 52A-28

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 52A-29

REAR SEAT BELT . . . . . . . . . . . . . . .52A-31

REMOVAL AND INSTALLATION . . . . . . . . 52A-31

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of an y component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and

passenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, driver’s and

passenger’s (front) air bag modules, knee air bag module, side-airbag module, curtain air bag module, side impact sensors,

seat belt pre-tensioners, clock spring, and interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).