ESP MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 7 of 241

ANTENNA

CHASSIS ELECTRICAL54A-26

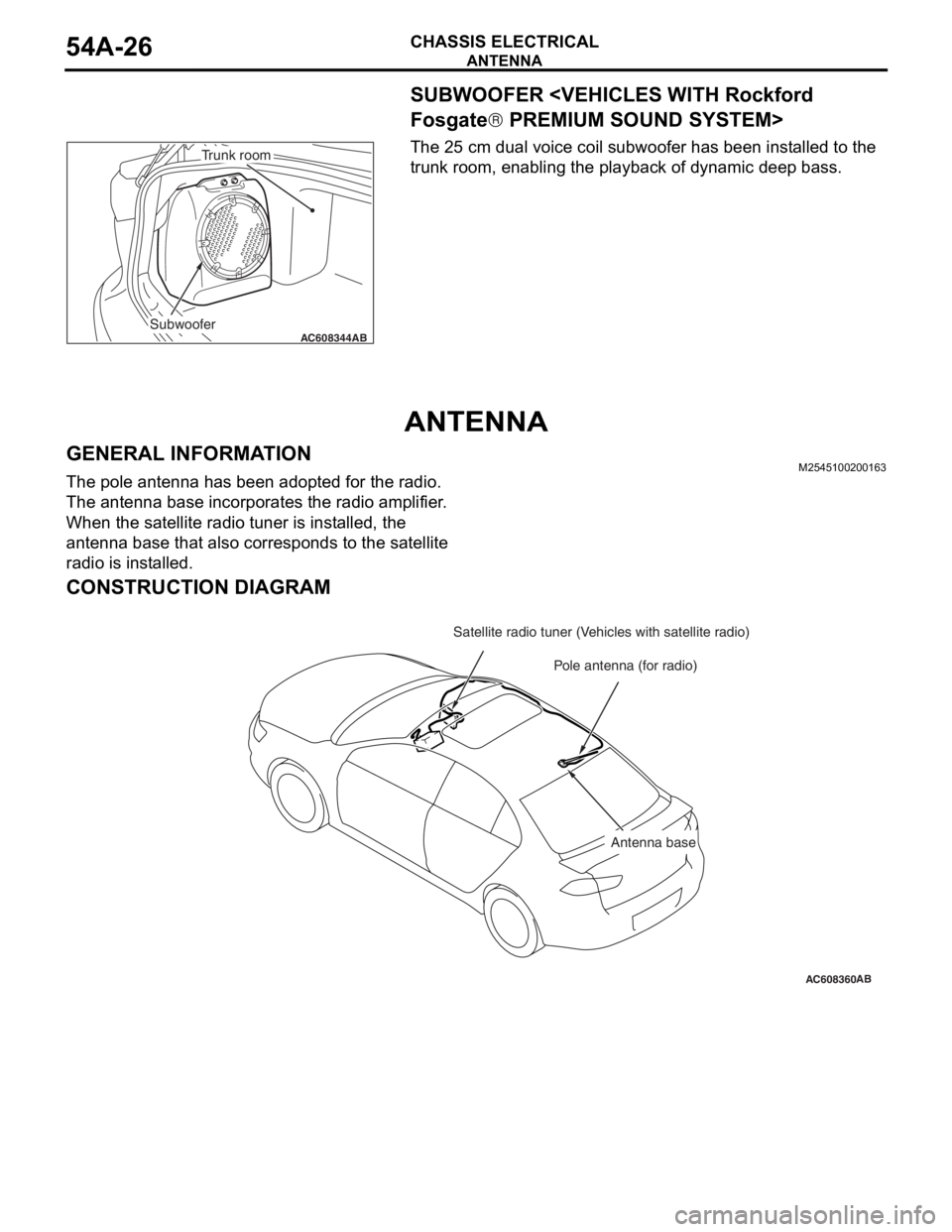

SUBWOOFER

® PREMIUM SOUND SYSTEM>

The 25 cm dual voice coil subwoofer has been installed to the

trunk room, enabling the playback of dynamic deep bass.

ANTENNA

GENERAL INFORMATIONM2545100200163

The pole antenna has been adopted for the radio.

The antenna base incorporates the radio amplifier.

When the satellite radio tuner is installed, the

antenna base that also corresponds to the satellite

radio is installed.

CONSTRUCTION DIAGRAM

AC608344ABSubwoofer

Trunk room

AC608360

Pole antenna (for radio)

AB

Satellite radio tuner (Vehicles with satellite radio)

Antenna base

Page 9 of 241

MITSUBISHI MULTI COMMUNICATION SYSTEM (MMCS)

CHASSIS ELECTRICAL54A-28

Navigation function

The storage of very large map data is now possible,

and the following contents have been adopted.

•Map type navigation

•NAVTEQ map database

•Map data stored in hard disc drive

•U.S. English, French, and Spanish are available

to select.

Audio and visual function

The following functions are in addition to the naviga-

tion function:

•Music server function

•DVD drive unit

•FM/AM radio

•MP3/WMA playback function

•Control by steering wheel audio remote comtrol

switch

•Integrated 4-ch power amplifier (MAX: 180 W)

•Correspond to Rockford Fosgate® premium

sound system

•Output of DVD video 5.1 channel data

•Connect with satellite radio tuner

Other function

The following functions are in addition to the naviga-

tion, audio and visual function:

•Clock display

•Connect with hands free unit

•A/C information display

•Outside temperature display

•Trip information display (Average fuel consump-

tion etc.)

•Function customize

SYSTEM BLOCK DIAGRAM

AC505476

AC608750 ZC3050180000

Audio and video

adopter Antenna

Steering wheel

audio remote control

switch

Speaker

*1: Controller Area Network Note:

*2: Universal Asynchronous Receiver Transmitter UART

communicationn

Sound Sound Voice Sound

Picture

Audio amplifierCAN box unitETACS-ECU Combination

meter

Audio visual navigation unitA/C-ECU

Hands-free

module

CAN

communication

AB

Page 34 of 241

GENERAL DESCRIPTION

HEATER, AIR CONDITIONING AND VENTILATION55-2

GENERAL DESCRIPTIONM2551001500040

The blower, heater, and evaporator have been inte-

grated with the heater and A/C system to achieve a

greater fan power and noise reduction.

FEATURES

.

ENHANCEMENTS IN COMFORT

•With the adoption of fully-automatic A/C, the out-

side/inside air circulation switching, air outlet, and

outlet air temperature are automatically con

-

trolled according to the ambient temperature,

solar radiation, and passenger compartment tem

-

perature so that the optimum air conditioner is

achieved.

•By the adoption of clean air filter, the air quality

inside the passenger compartment has been

enhanced.

.

ENHANCEMENTS IN OPERATION

PERFORMANCE

•Operability has been enhanced by the adoption

of large triple dial.

•Customise function has been added for the

enhanced convenience.

.

ENHANCEMENTS IN FUEL ECONOMY

•The high efficiency compressor with a 2-step pro-

file oil separator has been installed, thus enhanc-

ing the fuel economy.

•The idle-up speed is controlled in two steps to

secure the air cooling performance during sum

-

mer and to enhance the fuel economy in the sea-

sons with moderate temperature.

•Enhancement of fuel economy by the cooling fan

control depending on the refrigerant pressure and

vehicle speed.

.

ENHANCEMENT IN SAFETY

•A/C system is stopped when the air bags are

deployed.

•Crushable space has been adopted to heater unit

to reduce the risk of passenger injuries in case of

a collision.

.

GLOBAL ENVIRONMENT PROTECTION

•New refrigerant system (HFC134a) has been

adopted.

•By the optimisation of A/C system, the refrigerant

charging amount has been reduced.

•Clean air filter media and its cover are separated

to reduce waste materials.

.

ENHANCEMENTS IN SERVICE QUALITY

•Reduction of refrigerant gas leakage and

enhancement in serviceability by incorporating

condenser and receiver

•Clean air filter is installed to the backside of glove

box to facilitate the filter replacement.

.

ENHANCEMENTS IN RESPONSIBILITY

Reliable information transmission is achieved by

connecting A/C-ECU and each ECU via CAN com

-

munication.

SPECIFICATIONS

ITEMSPECIFICATION

Air conditioning switch typeRotary type

Compressor typeMSC90CAS

Cooling output5.5 kw

Heating output5.7 kw

RefrigerantTy p eR134a (HFC-134a)

Charge quantity g (oz.)480 - 520 (16.9 - 18.3)

Page 47 of 241

BASE ENGINE

ENGINE MECHANICAL11A-3

BASE ENGINEM2112001001050

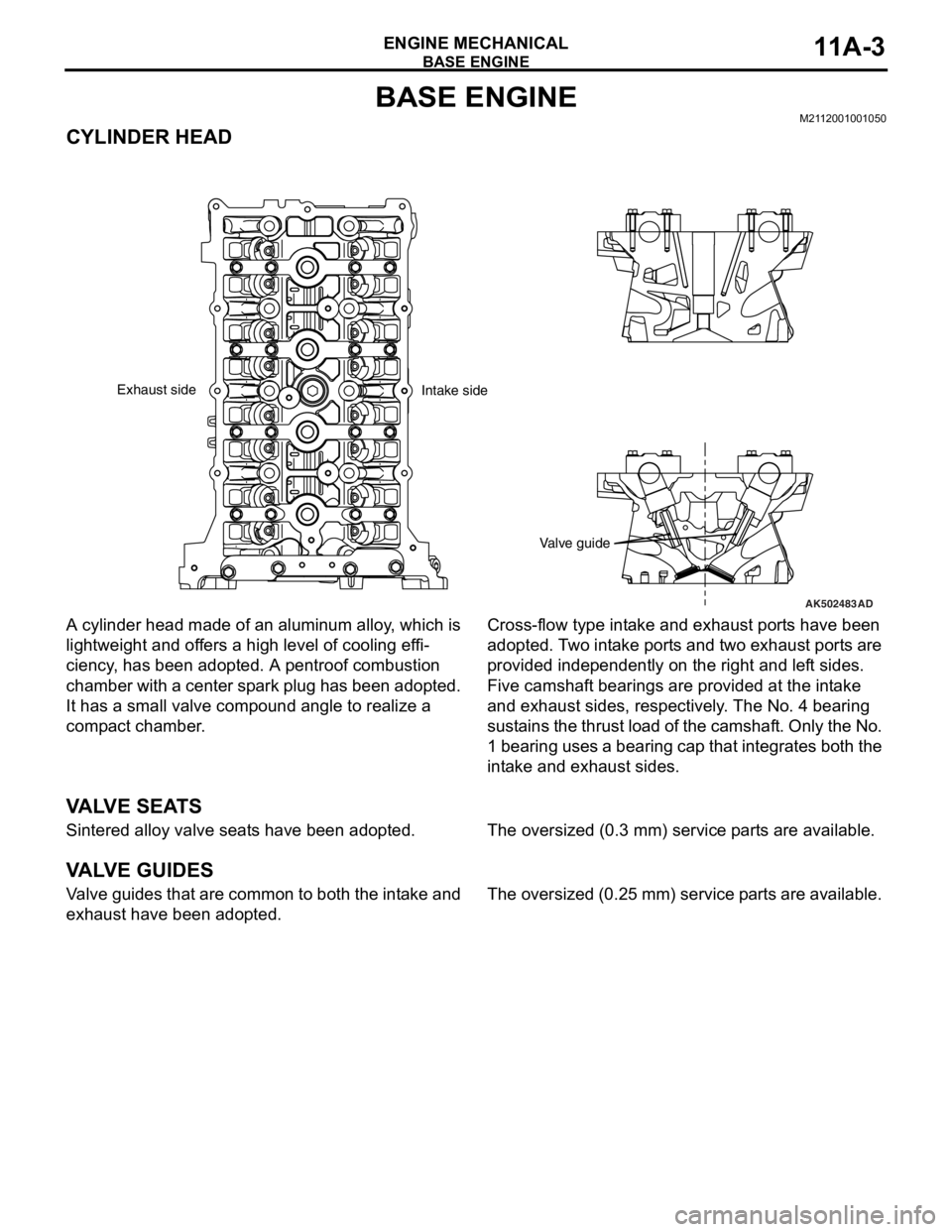

CYLINDER HEAD

A cylinder head made of an aluminum alloy, which is

lightweight and offers a high level of cooling effi

-

ciency, has been adopted. A pentroof combustion

chamber with a center spark plug has been adopted.

It has a small valve compound angle to realize a

compact chamber.

Cross-flow type intake and exhaust ports have been

adopted. Two intake ports and two exhaust ports are

provided independently on the right and left sides.

Five camshaft bearings are provided at the intake

and exhaust sides, respectively. The No. 4 bearing

sustains the thrust load of the camshaft. Only the No.

1 bearing uses a bearing cap that integrates both the

intake and exhaust sides.

VA LV E S E AT S

Sintered alloy valve seats have been adopted.The oversized (0.3 mm) service parts are available.

VA LV E G U I D E S

Valve guides that are common to both the intake and

exhaust have been adopted.The oversized (0.25 mm) service parts are available.

AK502483

Valve guide

AD

Exhaust side

Intake side

Page 66 of 241

AUTO-CRUISE CONTROL SYSTEM

ENGINE AND EMISSION CONTROL17-4

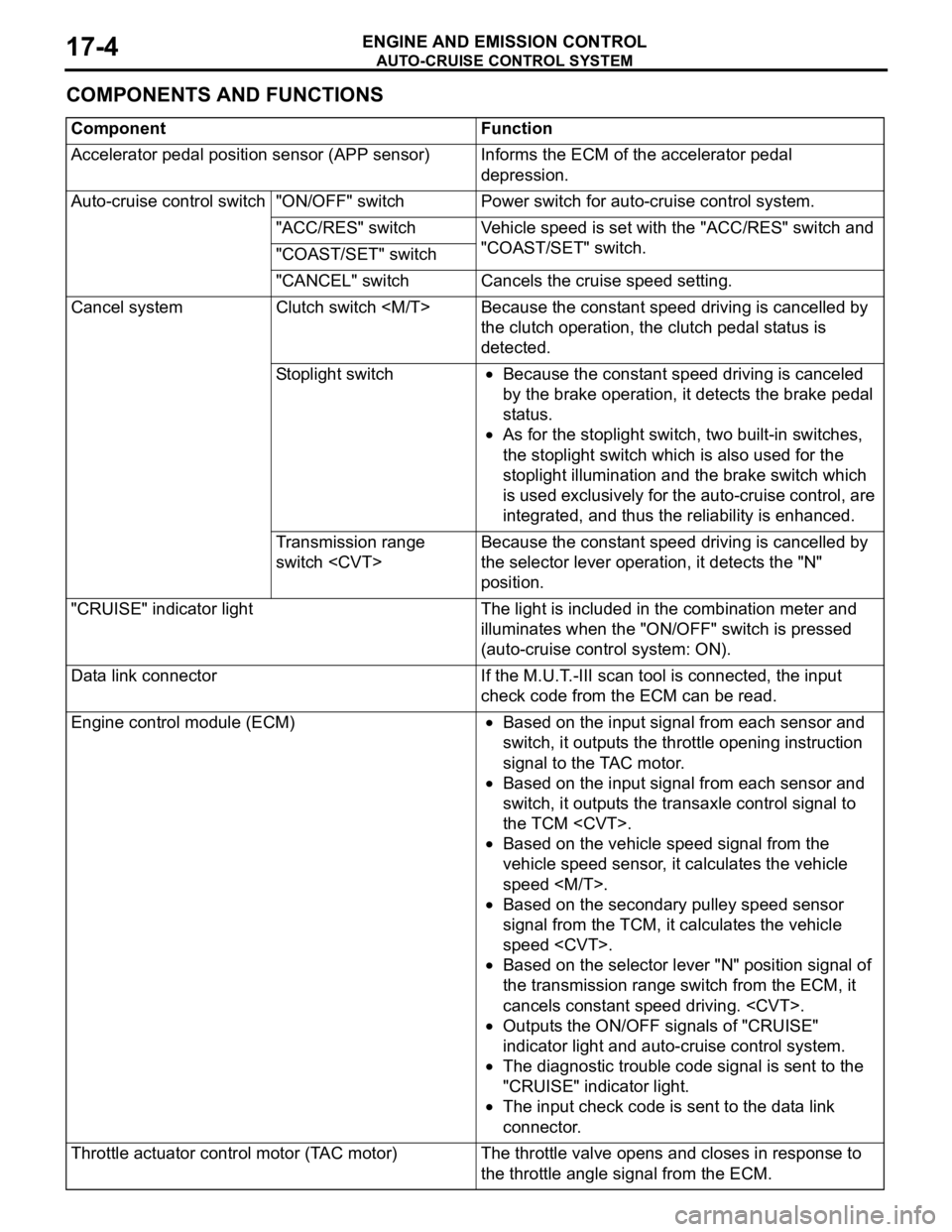

COMPONENTS AND FUNCTIONS

ComponentFunction

Accelerator pedal position sensor (APP sensor)Informs the ECM of the accelerator pedal

depression.

Auto-cruise control switch"ON/OFF" switchPower switch for auto-cruise control system.

"ACC/RES" switchVehicle speed is set with the "ACC/RES" switch and

"COAST/SET" switch.

"COAST/SET" switch

"CANCEL" switchCancels the cruise speed setting.

Cancel systemClutch switch

the clutch operation, the clutch pedal status is

detected.

Stoplight switch•Because the constant speed driving is canceled

by the brake operation, it detects the brake pedal

status.

•As for the stoplight switch, two built-in switches,

the stoplight switch which is also used for the

stoplight illumination and the brake switch which

is used exclusively for the auto-cruise control, are

integrated, and thus the reliability is enhanced.

Transmission range

switch

the selector lever operation, it detects the "N"

position.

"CRUISE" indicator lightThe light is included in the combination meter and

illuminates when the "ON/OFF" switch is pressed

(auto-cruise control system: ON).

Data link connectorIf the M.U.T.-III scan tool is connected, the input

check code from the ECM can be read.

Engine control module (ECM)•Based on the input signal from each sensor and

switch, it outputs the throttle opening instruction

signal to the TAC motor.

•Based on the input signal from each sensor and

switch, it outputs the transaxle control signal to

the TCM

•Based on the vehicle speed signal from the

vehicle speed sensor, it calculates the vehicle

speed

•Based on the secondary pulley speed sensor

signal from the TCM, it calculates the vehicle

speed

•Based on the selector lever "N" position signal of

the transmission range switch from the ECM, it

cancels constant speed driving.

•Outputs the ON/OFF signals of "CRUISE"

indicator light and auto-cruise control system.

•The diagnostic trouble code signal is sent to the

"CRUISE" indicator light.

•The input check code is sent to the data link

connector.

Throttle actuator control motor (TAC motor)The throttle valve opens and closes in response to

the throttle angle signal from the ECM.

Page 117 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-24

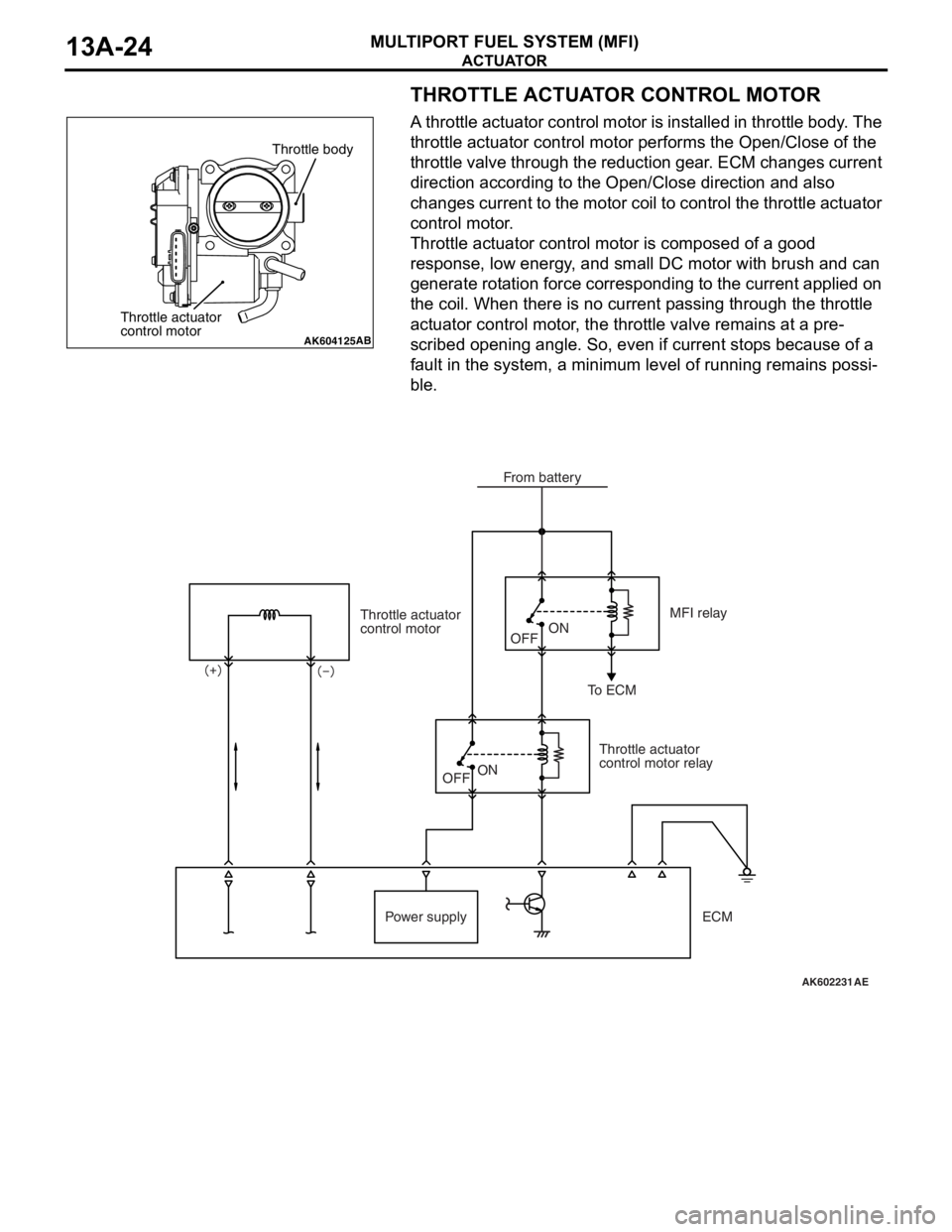

THROTTLE ACTUATOR CONTROL MOTOR

A throttle actuator control motor is installed in throttle body. The

throttle actuator control motor performs the Open/Close of the

throttle valve through the reduction gear. ECM changes current

direction according to the Open/Close direction and also

changes current to the motor coil to control the throttle actuator

control motor.

Throttle actuator control motor is composed of a good

response, low energy, and small DC motor with brush and can

generate rotation force corresponding to the current applied on

the coil. When there is no current passing through the throttle

actuator control motor, the throttle valve remains at a pre

-

scribed opening angle. So, even if current stops because of a

fault in the system, a minimum level of running remains possi

-

ble.

AK604125AB

Throttle body

Throttle actuator

control motor

AK602231

Throttle actuator

control motor

Throttle actuator

control motor relayMFI relay

To ECM

Power supplyOFFON

OFF

ON

AE

From battery

ECM

Page 142 of 241

HEATED OXYGEN SENSOR HEATER CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-49

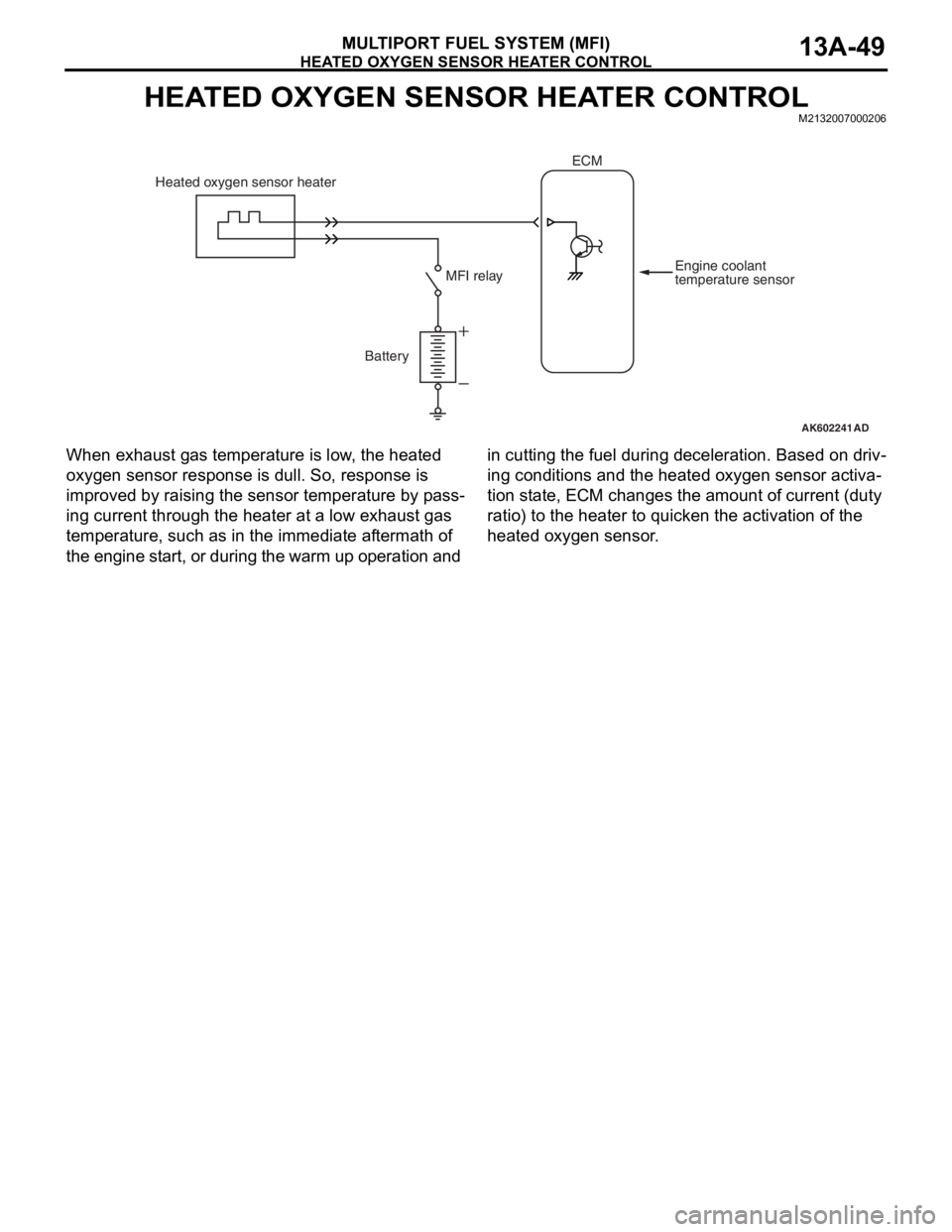

HEATED OXYGEN SENSOR HEATER CONTROLM2132007000206

When exhaust gas temperature is low, the heated

oxygen sensor response is dull. So, response is

improved by raising the sensor temperature by pass

-

ing current through the heater at a low exhaust gas

temperature, such as in the immediate aftermath of

the engine start, or during the warm up operation and in cutting the fuel during deceleration. Based on driv

-

ing conditions and the heated oxygen sensor activa-

tion state, ECM changes the amount of current (duty

ratio) to the heater to quicken the activation of the

heated oxygen sensor.

AK602241AD

Battery Heated oxygen sensor heater

Engine coolant

temperature sensor MFI relay

ECM

Page 162 of 241

52A-1

GROUP 52A

INTERIOR

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .52A-2

SPECIAL TOOL . . . . . . . . . . . . . . . . .52A-2

INSTRUMENT PANEL ASSEMBLY*.52A-2

REMOVAL AND INSTALLATION . . . . . . . . 52A-2

GLOVE BOX . . . . . . . . . . . . . . . . . . .52A-5

REMOVAL AND INSTALLATION . . . . . . . . 52A-5

INSTRUMENT CENTER PANEL . . . .52A-6

REMOVAL AND INSTLLATION . . . . . . . . . 52A-6

INSTRUMENT LOWER PANEL. . . . .52A-7

REMOVAL AND INSTALLATION . . . . . . . . 52A-7

FLOOR CONSOLE ASSEMBLY . . . .52A-8

REMOVAL AND INSTALLATION . . . . . . . . 52A-8

TRIMS. . . . . . . . . . . . . . . . . . . . . . . . .52A-10

REMOVAL AND INSTALLATION . . . . . . . . 52A-10

DOOR TRIM . . . . . . . . . . . . . . . . . . . .52A-13

REMOVAL AND INSTALLATION . . . . . . . . 52A-13

HEADLINING . . . . . . . . . . . . . . . . . . .52A-15

REMOVAL AND INSTALLATION . . . . . . . . 52A-15

INSIDE REAR VIEW MIRROR . . . . . .52A-17

FRONT SEAT ASSEMBLY* . . . . . . . .52A-17

REMOVAL AND INSTALLATION . . . . . . . . 52A-17

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 52A-19

DISASSEMBLY AND ASSEMBLY . . . . . . . 52A-21

REAR SEAT ASSEMBLY . . . . . . . . . .52A-23

REMOVAL AND INSTALLATION . . . . . . . . 52A-23

DISASSEMBLY AND ASSEMBLY . . . . . . . 52A-26

FRONT SEAT BELT* . . . . . . . . . . . . .52A-28

REMOVAL AND INSTALLATION . . . . . . . . 52A-28

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 52A-29

REAR SEAT BELT . . . . . . . . . . . . . . .52A-31

REMOVAL AND INSTALLATION . . . . . . . . 52A-31

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of an y component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and

passenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, driver’s and

passenger’s (front) air bag modules, knee air bag module, side-airbag module, curtain air bag module, side impact sensors,

seat belt pre-tensioners, clock spring, and interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).