Motor MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 36 of 241

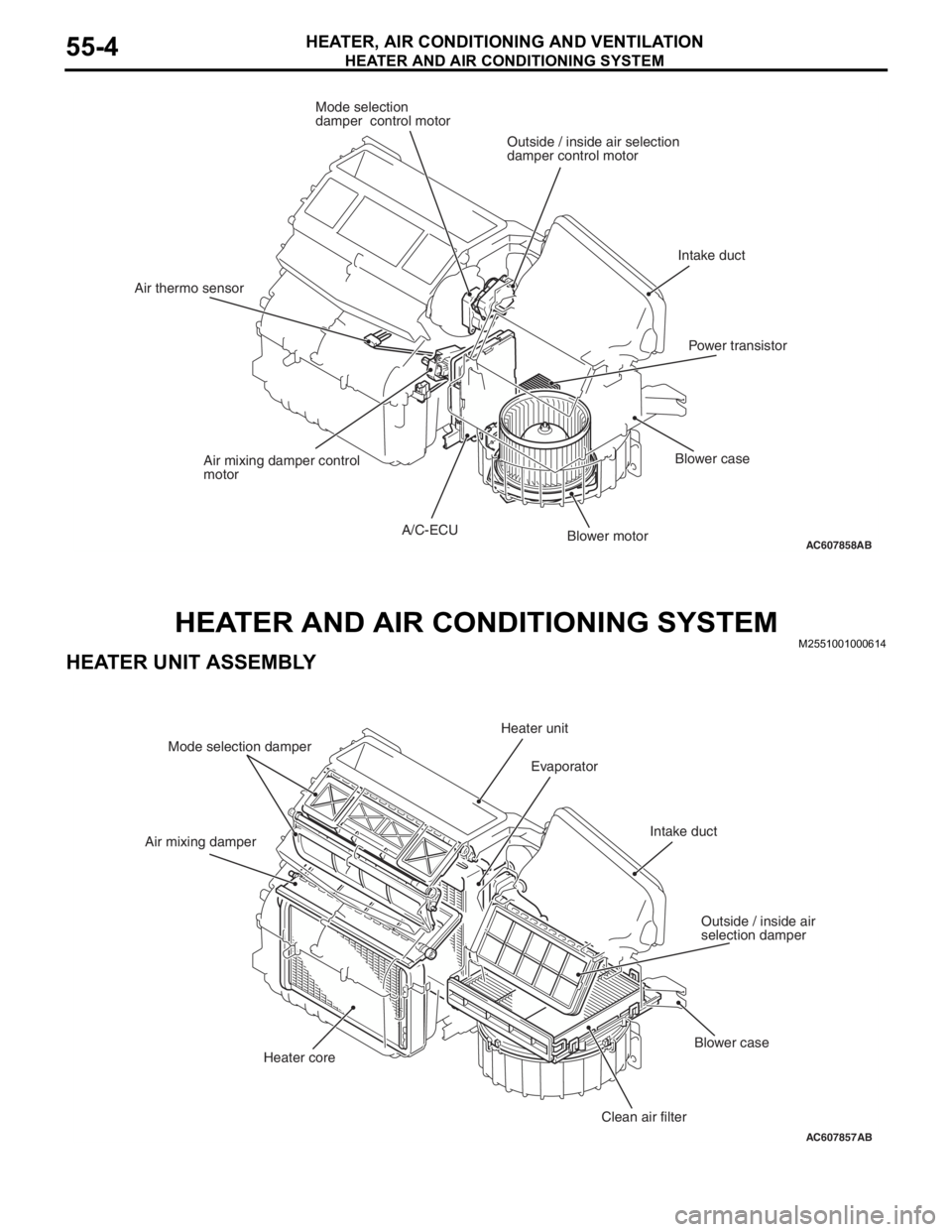

HEATER AND AIR CONDITIONING SYSTEM

HEATER, AIR CONDITIONING AND VENTILATION55-4

HEATER AND AIR CONDITIONING SYSTEMM2551001000614

HEATER UNIT ASSEMBLY

AC607858Blower motor Outside / inside air selection

damper control motor

Air mixing damper control

motor Air thermo sensorAB

Mode selection

damper control motor

A/C-ECUPower transistor Intake duct

Blower case

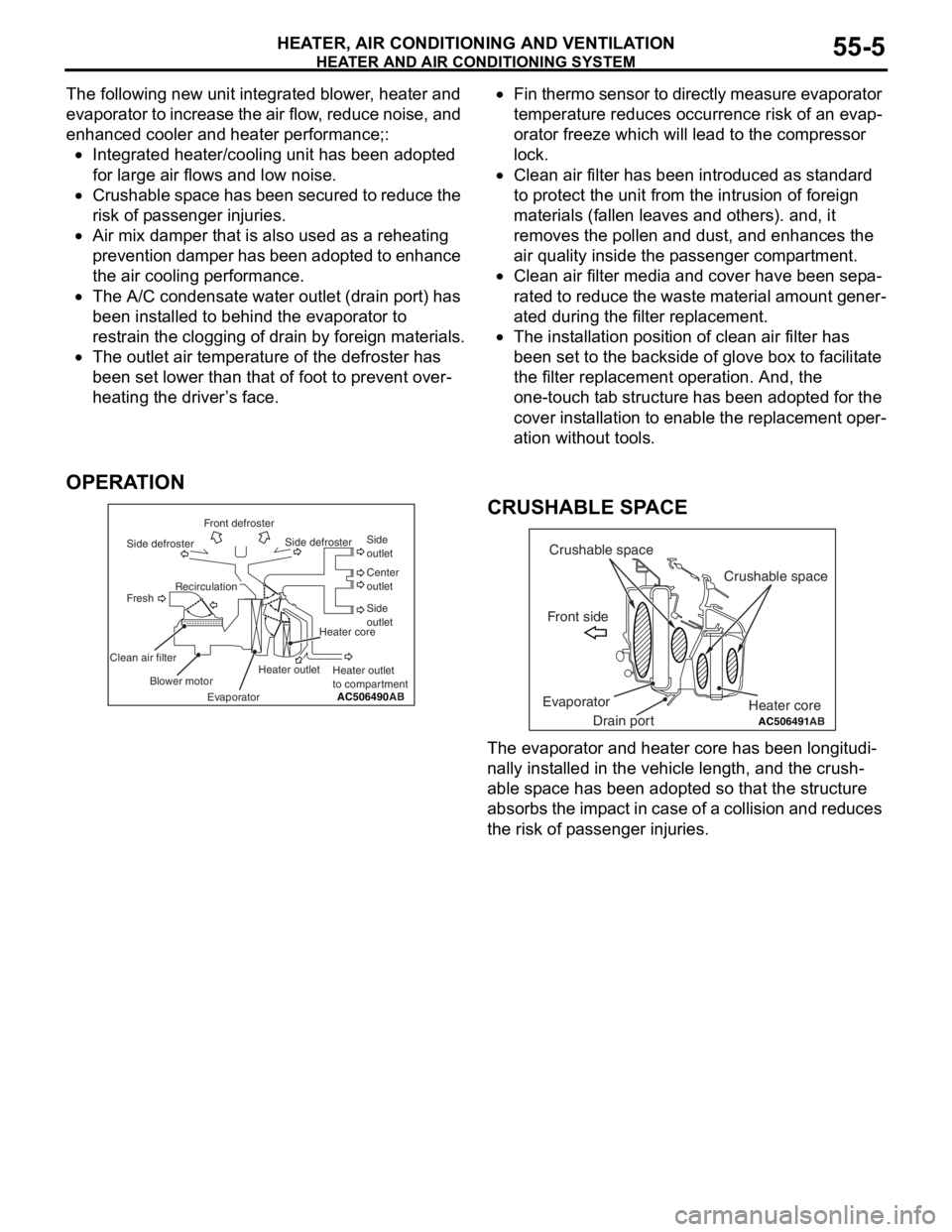

AC607857

Heater unit

Air mixing damper

Heater coreEvaporator Mode selection damper

Outside / inside air

selection damper

AB

Intake duct

Blower case

Clean air filter

Page 37 of 241

HEATER AND AIR CONDITIONING SYSTEM

HEATER, AIR CONDITIONING AND VENTILATION55-5

The following new unit integrated blower, heater and

evaporator to increase the air flow, reduce noise, and

enhanced cooler and heater performance;:

•Integrated heater/cooling unit has been adopted

for large air flows and low noise.

•Crushable space has been secured to reduce the

risk of passenger injuries.

•Air mix damper that is also used as a reheating

prevention damper has been adopted to enhance

the air cooling performance.

•The A/C condensate water outlet (drain port) has

been installed to behind the evaporator to

restrain the clogging of drain by foreign materials.

•The outlet air temperature of the defroster has

been set lower than that of foot to prevent over

-

heating the driver’s face.

•Fin thermo sensor to directly measure evaporator

temperature reduces occurrence risk of an evap

-

orator freeze which will lead to the compressor

lock.

•Clean air filter has been introduced as standard

to protect the unit from the intrusion of foreign

materials (fallen leaves and others). and, it

removes the pollen and dust, and enhances the

air quality inside the passenger compartment.

•Clean air filter media and cover have been sepa-

rated to reduce the waste material amount gener-

ated during the filter replacement.

•The installation position of clean air filter has

been set to the backside of glove box to facilitate

the filter replacement operation. And, the

one-touch tab structure has been adopted for the

cover installation to enable the replacement oper

-

ation without tools.

OPERATION

.

CRUSHABLE SPACE

The evaporator and heater core has been longitudi-

nally installed in the vehicle length, and the crush-

able space has been adopted so that the structure

absorbs the impact in case of a collision and reduces

the risk of passenger injuries.

AC506490AB Front defroster

Side defrosterSide defrosterSide

outlet

Side

outlet Center

outlet

Heater core

Heater outlet

to compartment Recirculation

Fresh

Clean air filter

Blower motor

EvaporatorHeater outlet

AC506491

Crushable space

Crushable space

Front side

Drain port EvaporatorHeater coreAB

Page 46 of 241

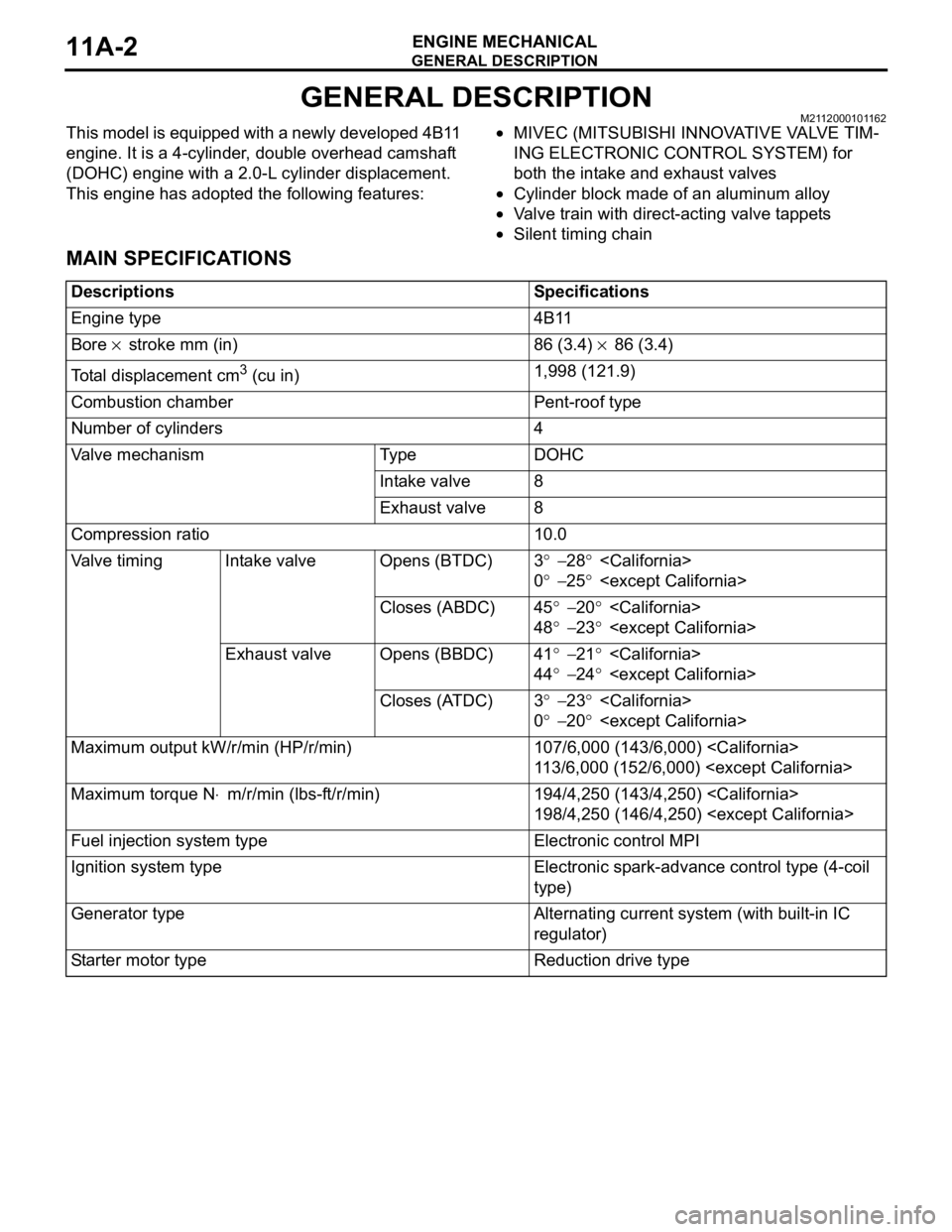

GENERAL DESCRIPTION

ENGINE MECHANICAL11A-2

GENERAL DESCRIPTIONM2112000101162

This model is equipped with a newly developed 4B11

engine. It is a 4-cylinder, double overhead camshaft

(DOHC) engine with a 2.0-L cylinder displacement.

This engine has adopted the following features:

•MIVEC (MITSUBISHI INNOVATIVE VALVE TIM-

ING ELECTRONIC CONTROL SYSTEM) for

both the intake and exhaust valves

•Cylinder block made of an aluminum alloy

•Valve train with direct-acting valve tappets

•Silent timing chain

MAIN SPECIFICATIONS

DescriptionsSpecifications

Engine type4B11

Bore × stroke mm (in)86 (3.4) × 86 (3.4)

Total displacement cm3 (cu in)1,998 (121.9)

Combustion chamberPent-roof type

Number of cylinders4

Valve mechanismTy p eDOHC

Intake valve8

Exhaust valve8

Compression ratio10.0

Va l v e t i m i n gIntake valveOpens (BTDC)3° − 28°

0° − 25°

Closes (ABDC)45° − 20°

48° − 23°

Exhaust valveOpens (BBDC)41° − 21°

44° − 24°

Closes (ATDC)3° − 23°

0° − 20°

Maximum output kW/r/min (HP/r/min)107/6,000 (143/6,000)

113/6,000 (152/6,000)

Maximum torque N⋅m/r/min (lbs-ft/r/min)194/4,250 (143/4,250)

198/4,250 (146/4,250)

Fuel injection system typeElectronic control MPI

Ignition system typeElectronic spark-advance control type (4-coil

type)

Generator typeAlternating current system (with built-in IC

regulator)

Starter motor typeReduction drive type

Page 65 of 241

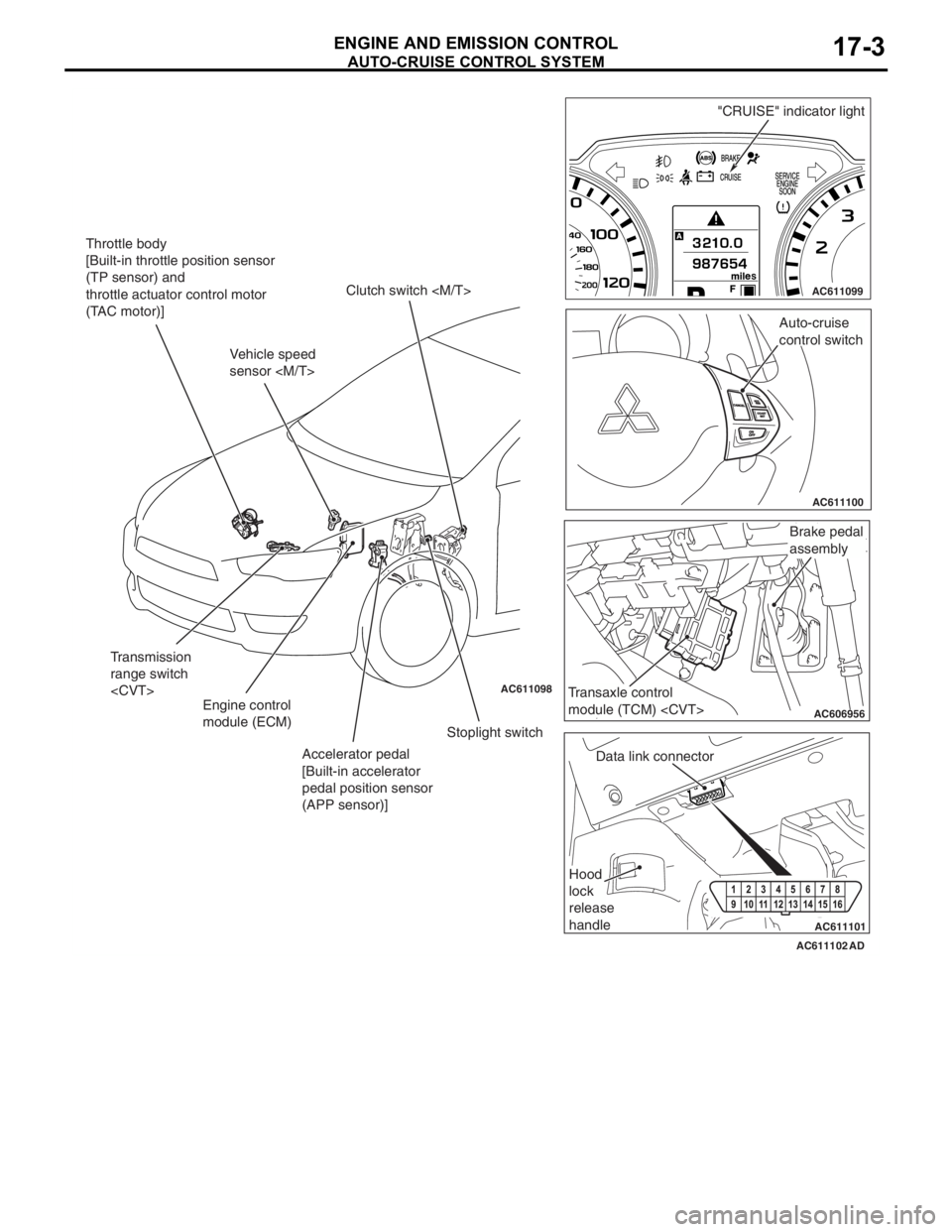

AUTO-CRUISE CONTROL SYSTEM

ENGINE AND EMISSION CONTROL17-3

AC611102 AC611098

AC611099

AC611100

AC606956

AC611101

Auto-cruise

control switch

Data link connector

Hood

lock

release

handle

AD

Clutch switch

Stoplight switch

Accelerator pedal

[Built-in accelerator

pedal position sensor

(APP sensor)] Engine control

module (ECM)"CRUISE" indicator light

Transaxle control

module (TCM)

Brake pedal

assembly

Throttle body

[Built-in throttle position sensor

(TP sensor) and

throttle actuator control motor

(TAC motor)]

Transmission

range switch

Vehicle speed

sensor

Page 66 of 241

AUTO-CRUISE CONTROL SYSTEM

ENGINE AND EMISSION CONTROL17-4

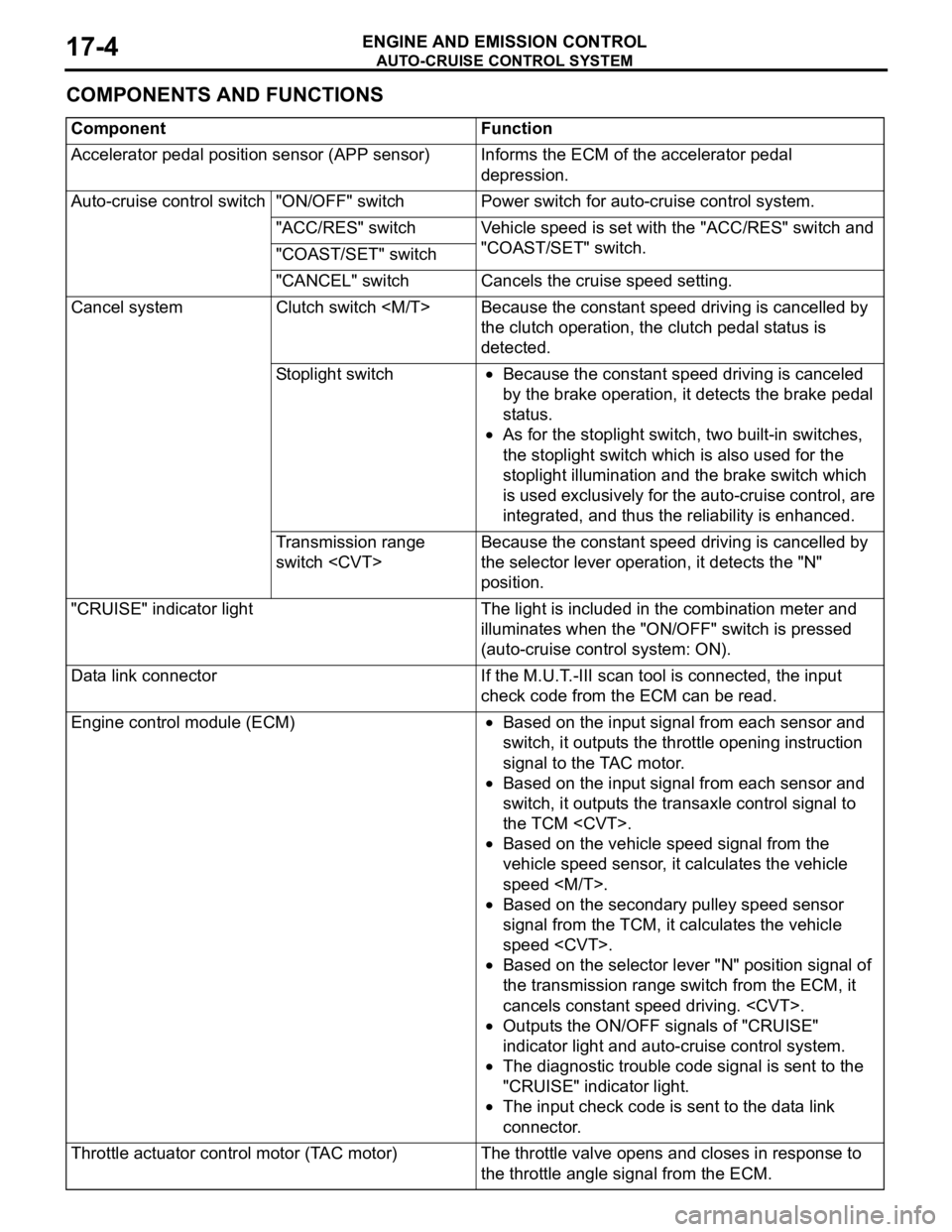

COMPONENTS AND FUNCTIONS

ComponentFunction

Accelerator pedal position sensor (APP sensor)Informs the ECM of the accelerator pedal

depression.

Auto-cruise control switch"ON/OFF" switchPower switch for auto-cruise control system.

"ACC/RES" switchVehicle speed is set with the "ACC/RES" switch and

"COAST/SET" switch.

"COAST/SET" switch

"CANCEL" switchCancels the cruise speed setting.

Cancel systemClutch switch

the clutch operation, the clutch pedal status is

detected.

Stoplight switch•Because the constant speed driving is canceled

by the brake operation, it detects the brake pedal

status.

•As for the stoplight switch, two built-in switches,

the stoplight switch which is also used for the

stoplight illumination and the brake switch which

is used exclusively for the auto-cruise control, are

integrated, and thus the reliability is enhanced.

Transmission range

switch

the selector lever operation, it detects the "N"

position.

"CRUISE" indicator lightThe light is included in the combination meter and

illuminates when the "ON/OFF" switch is pressed

(auto-cruise control system: ON).

Data link connectorIf the M.U.T.-III scan tool is connected, the input

check code from the ECM can be read.

Engine control module (ECM)•Based on the input signal from each sensor and

switch, it outputs the throttle opening instruction

signal to the TAC motor.

•Based on the input signal from each sensor and

switch, it outputs the transaxle control signal to

the TCM

•Based on the vehicle speed signal from the

vehicle speed sensor, it calculates the vehicle

speed

•Based on the secondary pulley speed sensor

signal from the TCM, it calculates the vehicle

speed

•Based on the selector lever "N" position signal of

the transmission range switch from the ECM, it

cancels constant speed driving.

•Outputs the ON/OFF signals of "CRUISE"

indicator light and auto-cruise control system.

•The diagnostic trouble code signal is sent to the

"CRUISE" indicator light.

•The input check code is sent to the data link

connector.

Throttle actuator control motor (TAC motor)The throttle valve opens and closes in response to

the throttle angle signal from the ECM.

Page 67 of 241

AUTO-CRUISE CONTROL SYSTEM

ENGINE AND EMISSION CONTROL17-5

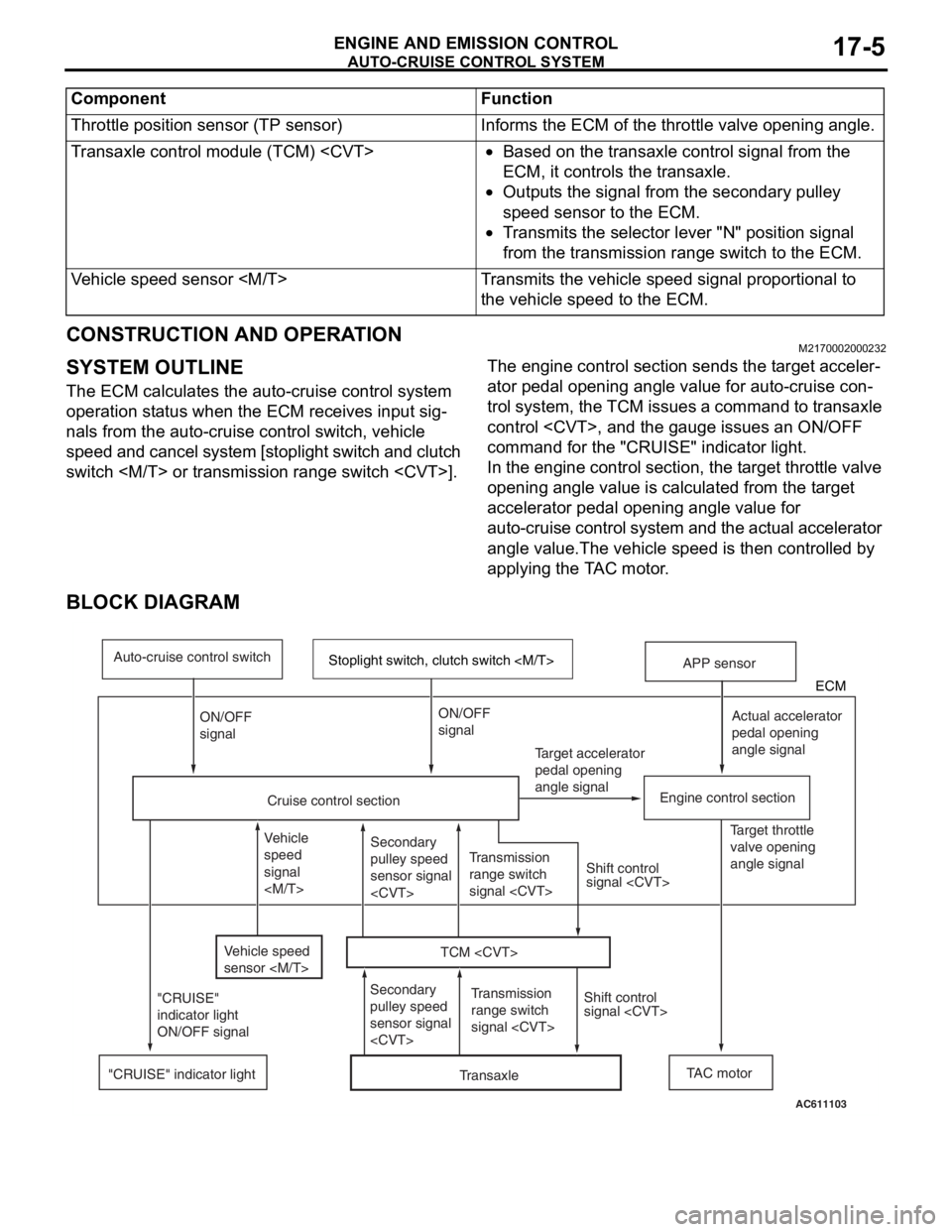

CONSTRUCTION AND OPERATIONM2170002000232

SYSTEM OUTLINE

The ECM calculates the auto-cruise control system

operation status when the ECM receives input sig

-

nals from the auto-cruise control switch, vehicle

speed and cancel system [stoplight switch and clutch

switch

-

ator pedal opening angle value for auto-cruise con-

trol system, the TCM issues a command to transaxle

control

command for the "CRUISE" indicator light.

In the engine control section, the target throttle valve

opening angle value is calculated from the target

accelerator pedal opening angle value for

auto-cruise control system and the actual accelerator

angle value.The vehicle speed is then controlled by

applying the TAC motor.

BLOCK DIAGRAM

Throttle position sensor (TP sensor)Informs the ECM of the throttle valve opening angle.

Transaxle control module (TCM)

ECM, it controls the transaxle.

•Outputs the signal from the secondary pulley

speed sensor to the ECM.

•Transmits the selector lever "N" position signal

from the transmission range switch to the ECM.

Vehicle speed sensor

the vehicle speed to the ECM.

Component Function

TAC motor Target accelerator

pedal opening

angle signal

Engine control section

Cruise control section"CRUISE" indicator light

AC611103

Actual accelerator

pedal opening

angle signal

Shift control

signal

Target throttle

valve opening

angle signal

Auto-cruise control switch

ECM

Stoplight switch, clutch switch

TCM

"CRUISE"

indicator light

ON/OFF signal

APP sensor

Transmission

range switch

signal

signal

TransaxleTransmission

range switch

signal

Secondary

pulley speed

sensor signal

signalON/OFF

signal

Vehicle speed

sensor

Vehicle

speed

signal

pulley speed

sensor signal

Page 71 of 241

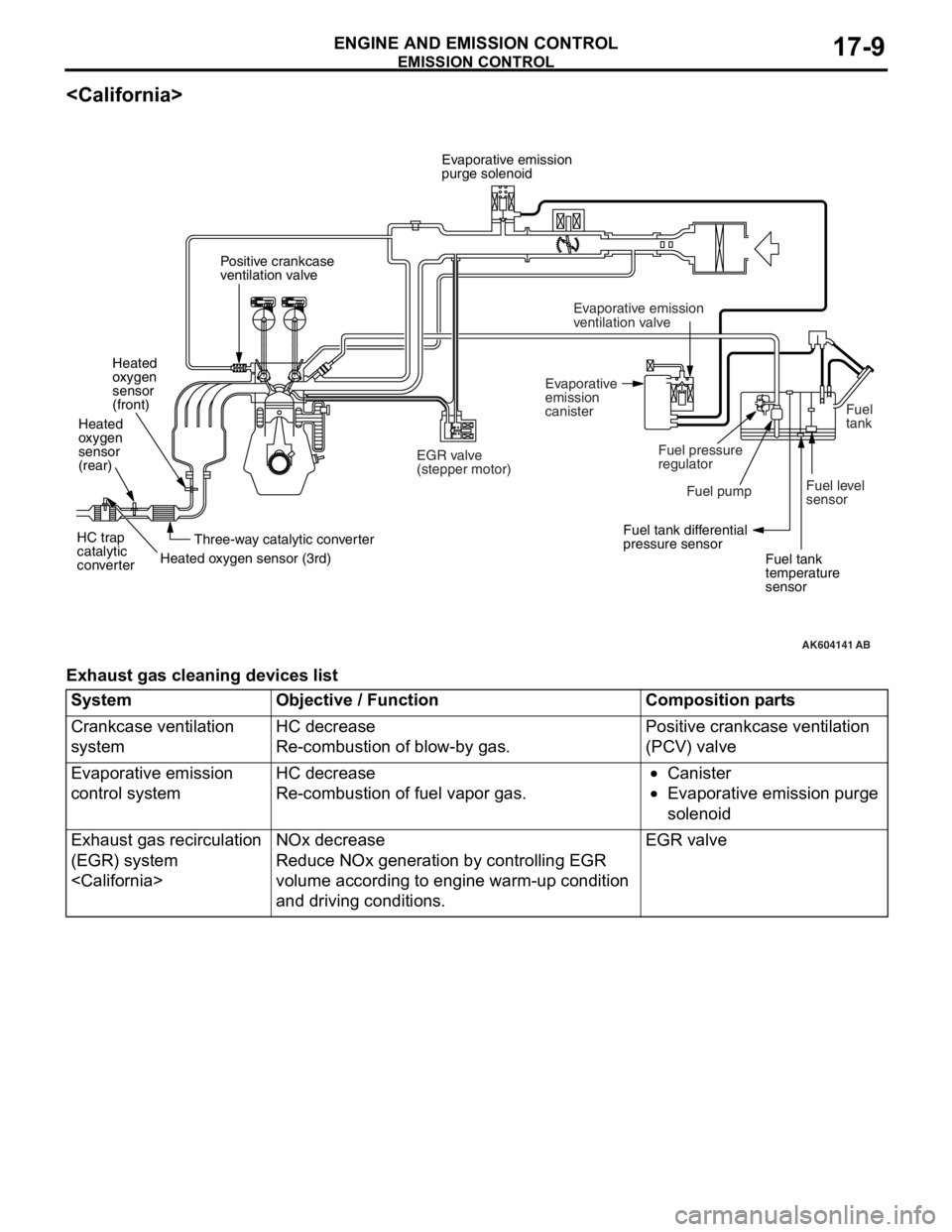

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-9

Exhaust gas cleaning devices list

AK604141

Three-way catalytic converter Heated

oxygen

sensor

(front)

Heated

oxygen

sensor

(rear)

HC trap

catalytic

converterHeated oxygen sensor (3rd)Positive crankcase

ventilation valve

EGR valve

(stepper motor)

AB

Fuel level

sensorFuel

tank

Fuel tank differential

pressure sensor

Fuel tank

temperature

sensor Fuel pump Fuel pressure

regulator Evaporative emission

purge solenoid

Evaporative

emission

canisterEvaporative emission

ventilation valve

SystemObjective / FunctionComposition parts

Crankcase ventilation

systemHC decrease

Re-combustion of blow-by gas.

Positive crankcase ventilation

(PCV) valve

Evaporative emission

control systemHC decrease

Re-combustion of fuel vapor gas.

•Canister

•Evaporative emission purge

solenoid

Exhaust gas recirculation

(EGR) system

Reduce NOx generation by controlling EGR

volume according to engine warm-up condition

and driving conditions.

EGR valve

Page 74 of 241

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-12

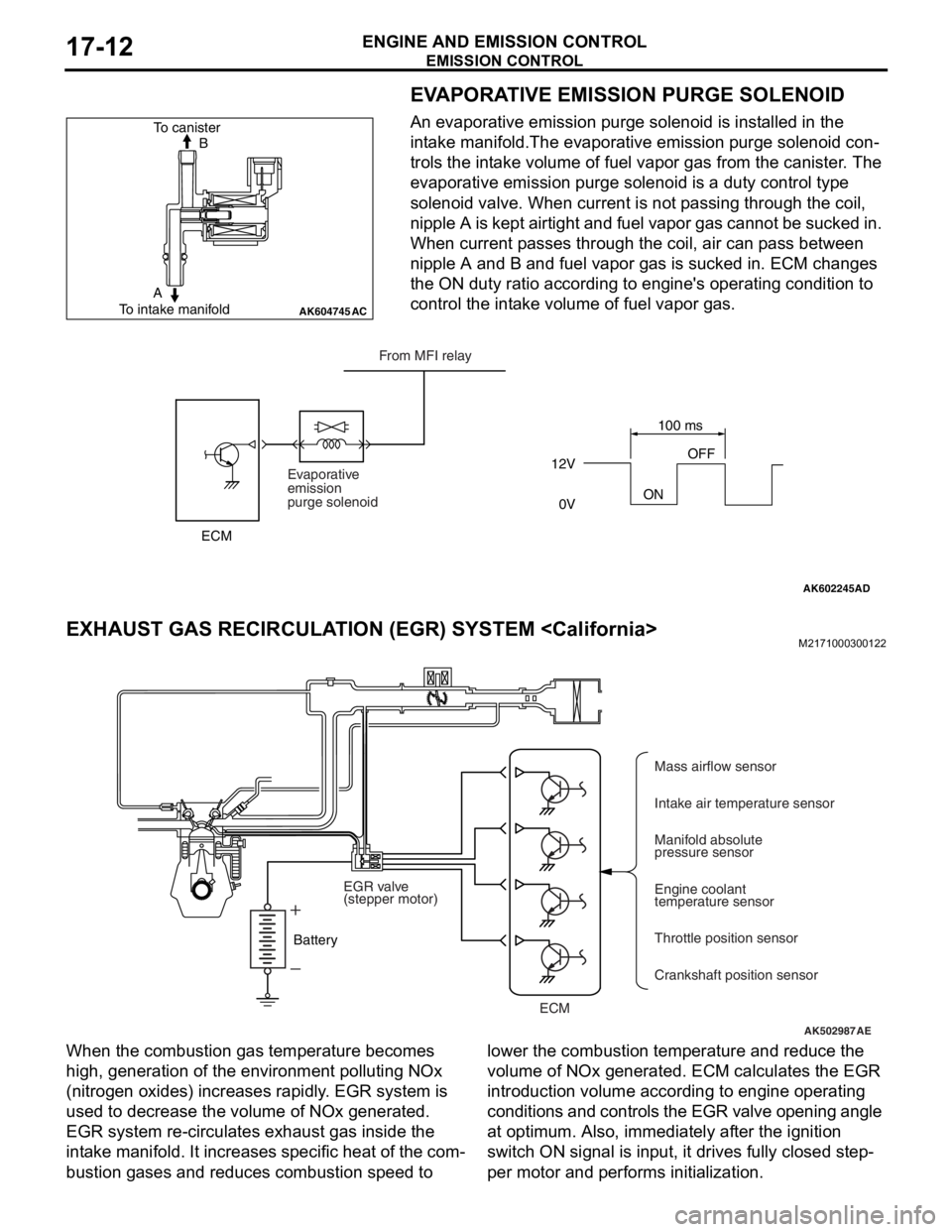

EVAPORATIVE EMISSION PURGE SOLENOID

An evaporative emission purge solenoid is installed in the

intake manifold.The evaporative emission purge solenoid con

-

trols the intake volume of fuel vapor gas from the canister. The

evaporative emission purge solenoid is a duty control type

solenoid valve. When current is not passing through the coil,

nipple A is kept airtight and fuel vapor gas cannot be sucked in.

When current passes through the coil, air can pass between

nipple A and B and fuel vapor gas is sucked in. ECM changes

the ON duty ratio according to engine's operating condition to

control the intake volume of fuel vapor gas.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

When the combustion gas temperature becomes

high, generation of the environment polluting NOx

(nitrogen oxides) increases rapidly. EGR system is

used to decrease the volume of NOx generated.

EGR system re-circulates exhaust gas inside the

intake manifold. It increases specific heat of the com

-

bustion gases and reduces combustion speed to lower the combustion temperature and reduce the

volume of NOx generated. ECM calculates the EGR

introduction volume according to engine operating

conditions and controls the EGR valve opening angle

at optimum. Also, immediately after the ignition

switch ON signal is input, it drives fully closed step

-

per motor and performs initialization.

AK604745AC

B To canister

To intake manifoldA

AK602245AD

12V

ONOFF

0V100 ms

Evaporative

emission

purge solenoidFrom MFI relay

ECM

AK502987AE

ECMMass airflow sensor

Intake air temperature sensor

Manifold absolute

pressure sensor

Engine coolant

temperature sensor

Throttle position sensor

Crankshaft position sensor BatteryEGR valve

(stepper motor)

Page 75 of 241

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-13

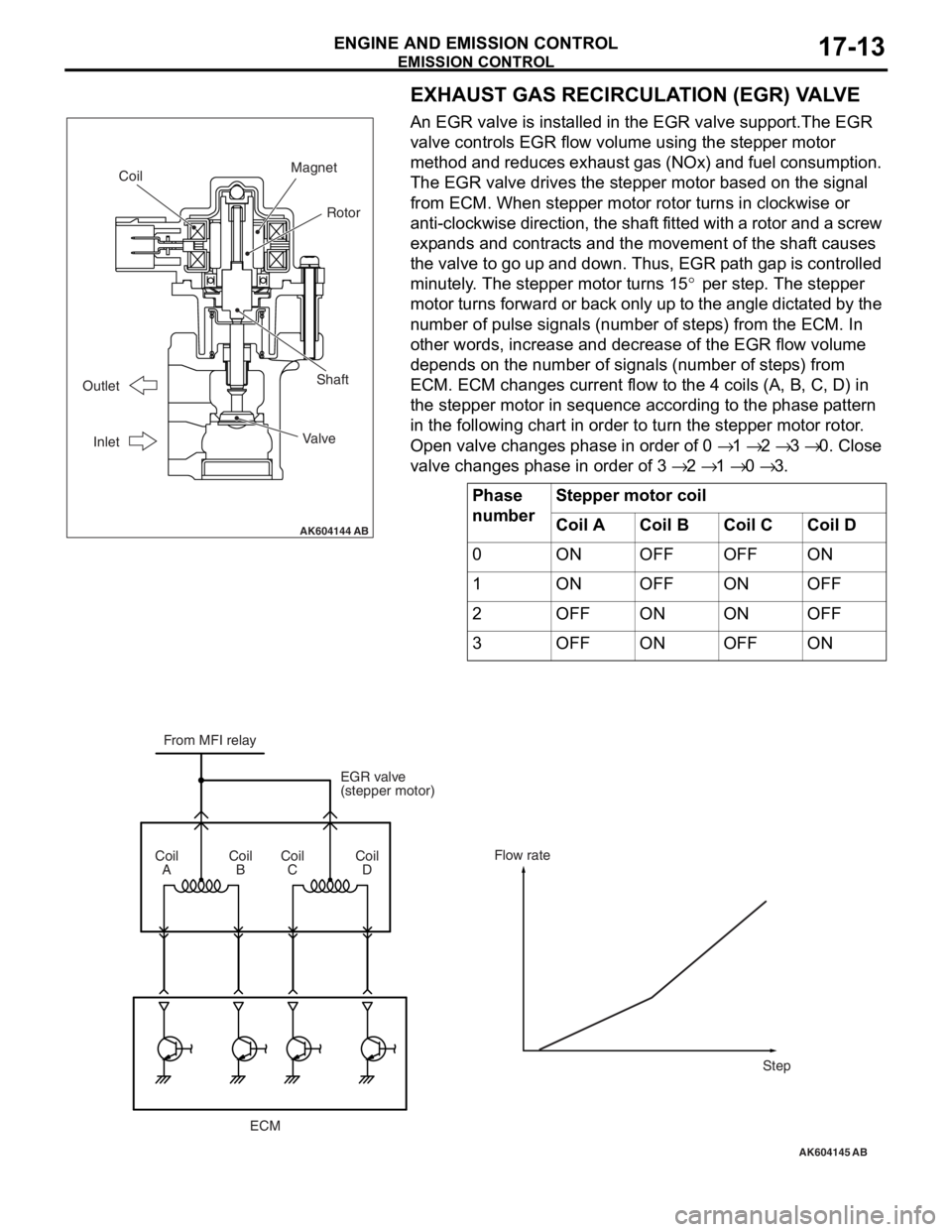

EXHAUST GAS RECIRCULATION (EGR) VALVE

An EGR valve is installed in the EGR valve support.The EGR

valve controls EGR flow volume using the stepper motor

method and reduces exhaust gas (NOx) and fuel consumption.

The EGR valve drives the stepper motor based on the signal

from ECM. When stepper motor rotor turns in clockwise or

anti-clockwise direction, the shaft fitted with a rotor and a screw

expands and contracts and the movement of the shaft causes

the valve to go up and down. Thus, EGR path gap is controlled

minutely. The stepper motor turns 15

° per step. The stepper

motor turns forward or back only up to the angle dictated by the

number of pulse signals (number of steps) from the ECM. In

other words, increase and decrease of the EGR flow volume

depends on the number of signals (number of steps) from

ECM. ECM changes current flow to the 4 coils (A, B, C, D) in

the stepper motor in sequence according to the phase pattern

in the following chart in order to turn the stepper motor rotor.

Open valve changes phase in order of 0

→ 1 → 2 → 3 → 0. Close

valve changes phase in order of 3

→ 2 → 1 → 0 → 3.

Phase

numberStepper motor coil

Coil ACoil BCoil CCoil D

0ONOFFOFFON

1ONOFFONOFF

2OFFONONOFF

3OFFONOFFON

AK604144

Coil

Shaft

Valve Outlet

Inlet

Rotor

Magnet

AB

AK604145

From MFI relay

EGR valve

(stepper motor)

ECM Coil

ACoil

BCoil

CCoil

DFlow rate

Step

AB

Page 79 of 241

16-1

GROUP 16

ENGINE

ELECTRICAL

CONTENTS

STARTER MOTOR . . . . . . . . . . . . . .16-2

ALTERNATOR . . . . . . . . . . . . . . . . . .16-2

IGNITION COIL . . . . . . . . . . . . . . . . . .16-2

SPARK PLUG . . . . . . . . . . . . . . . . . . .16-3