Motor MITSUBISHI LANCER EVOLUTION X 2008 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 80 of 241

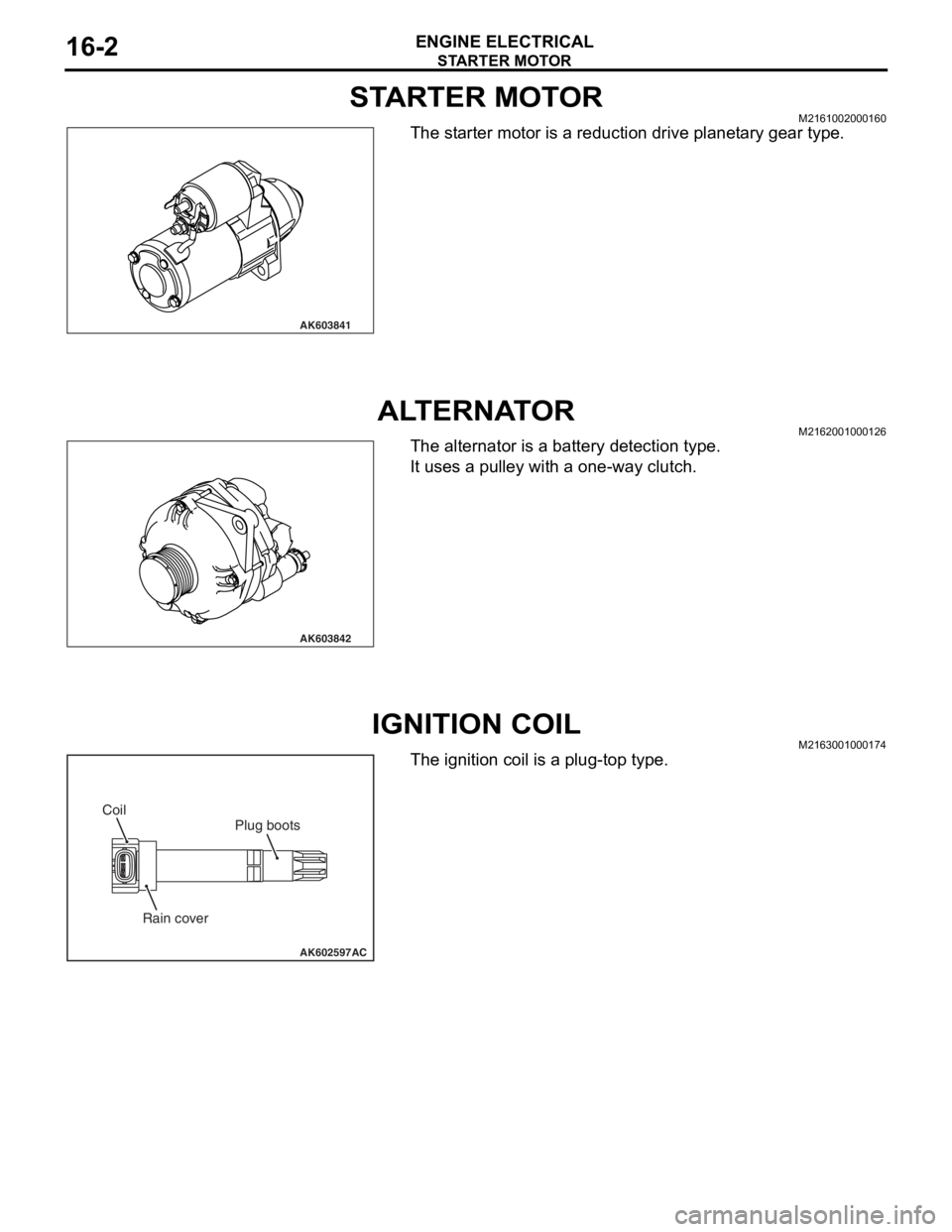

STARTER MOTOR

ENGINE ELECTRICAL16-2

STARTER MOTORM2161002000160

The starter motor is a reduction drive planetary gear type.

ALTERNATORM2162001000126

The alternator is a battery detection type.

It uses a pulley with a one-way clutch.

IGNITION COILM2163001000174

The ignition coil is a plug-top type.

AK603841

AK603842

AK602597

Plug boots

Rain cover Coil

AC

Page 88 of 241

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATIONM2140000100780

The cooling system is a water-cooled pressurized,

forced circulation type which offers the following fea

-

tures.

•To stabilize engine coolant temperature, the ther-

mostat is located at the coolant inlet port from the

radiator.

•To improve engine cooling performance and save

weight, a plastic tank and aluminum radiator fins

are used.

SPECIFICATIONS

CONSTRUCTION DIAGRAM

ItemSpecification

Cooling methodWater-cooled pressurized, forced

circulation with electrical fan

RadiatorTy p ePressurized corrugate type

Performance kJ/h (kcal/h)222,480 (53,148)

Water pumpTy p eCentrifugal impeller

Drive methodDrive belt

ThermostatTy p eWax pellet with jiggle valve

Valve open temperature °C (°F)82 (180)

AC608448

Condenser fan motor Radiator assemblyRadiator upper hose

assembly

Radiator condenser

tank assembly Radiator fan motor

Cooling fan shroud

Radiator lower hose Transmission oil

cooler line hose

and tube assembly

AB

Page 97 of 241

GENERAL DESCRIPTION

MULTIPORT FUEL SYSTEM (MFI)13A-3

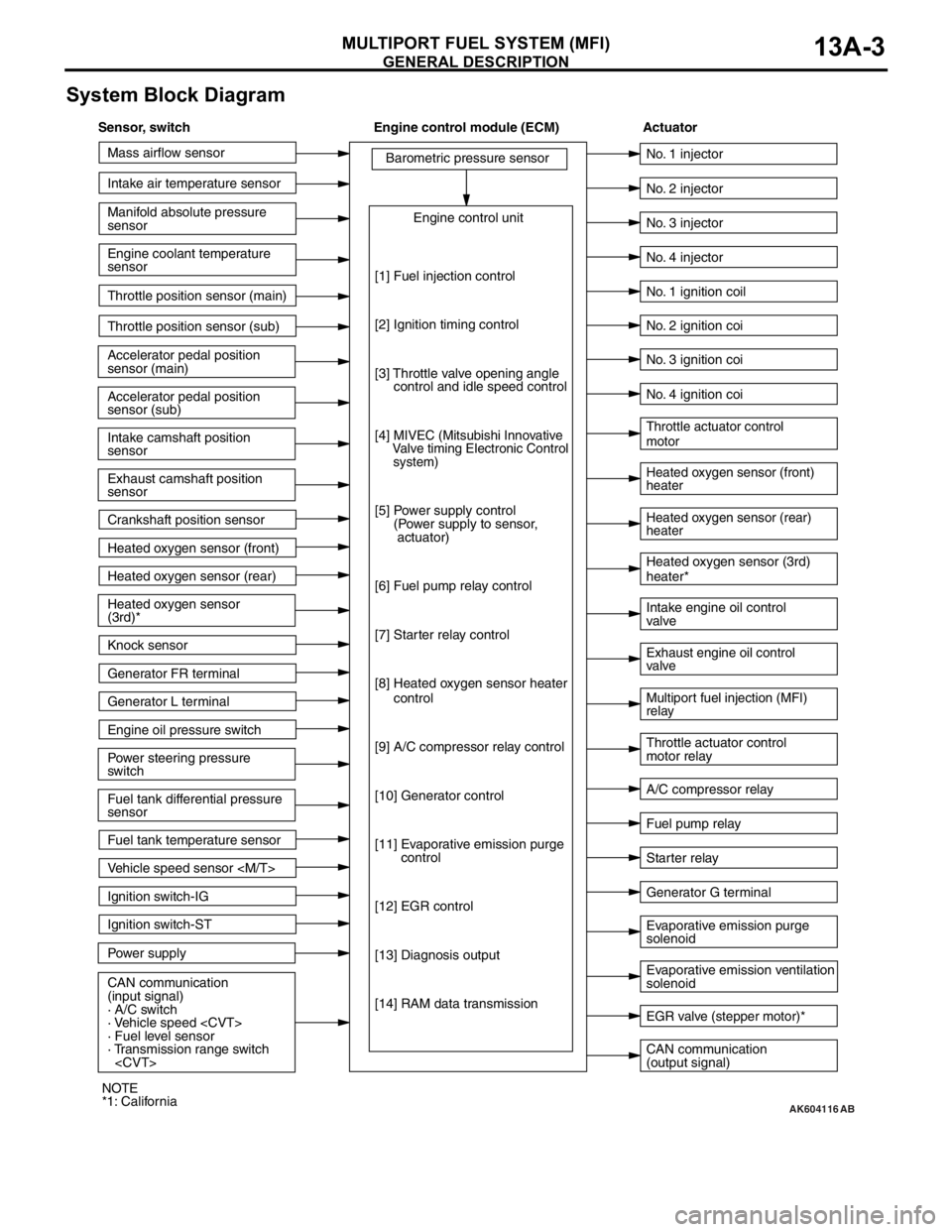

System Block Diagram

AK604116

Mass airflow sensor

Intake air temperature sensor

Intake camshaft position

sensor

Exhaust camshaft position

sensor

Crankshaft position sensor Throttle position sensor (main)

Throttle position sensor (sub)

Accelerator pedal position

sensor (sub) Accelerator pedal position

sensor (main) Engine coolant temperature

sensor Manifold absolute pressure

sensor

Heated oxygen sensor (front)

Heated oxygen sensor (rear)

Power steering pressure

switch Engine oil pressure switch Generator L terminal

Ignition switch-ST

Power supply Ignition switch-IG

CAN communication

(input signal)

· A/C switch

· Vehicle speed

· Fuel level sensor

· Transmission range switch

sensor Heated oxygen sensor

(3rd)*

Knock sensor

Generator FR terminal

Fuel tank temperature sensor

Vehicle speed sensor

[1] Fuel injection control

[2] Ignition timing control

[3] Throttle valve opening angle

control and idle speed control

[4]

MIVEC (Mitsubishi Innovative

Valve timing Electronic Control

system)

[5] Power supply control

(Power supply to sensor,

actuator)

[6] Fuel pump relay control

[7] Starter relay control

[8] Heated oxygen sensor heater

control

[9] A/C compressor relay control

[10] Generator control

[11] Evaporative emission purge

control

[12] EGR control

[13] Diagnosis output

[14] RAM data transmission

CAN communication

(output signal) Intake engine oil control

valve

A/C compressor relay No. 2 injector

No. 3 injector

No. 4 injector

Heated oxygen sensor (front)

heater

Heated oxygen sensor (rear)

heater Throttle actuator control

motor

Throttle actuator control

motor relay No. 1 injector

No. 1 ignition coil

No. 2 ignition coi

No. 3 ignition coi

No. 4 ignition coi

Fuel pump relay

Generator G terminal Heated oxygen sensor (3rd)

heater*

Multiport fuel injection (MFI)

relay Exhaust engine oil control

valve

Evaporative emission ventilation

solenoid Evaporative emission purge

solenoid

EGR valve (stepper motor)*

Starter relay

AB

Sensor, switch Engine control module (ECM) Actuator

NOTE

*1: California

Page 98 of 241

GENERAL DESCRIPTION

MULTIPORT FUEL SYSTEM (MFI)13A-4

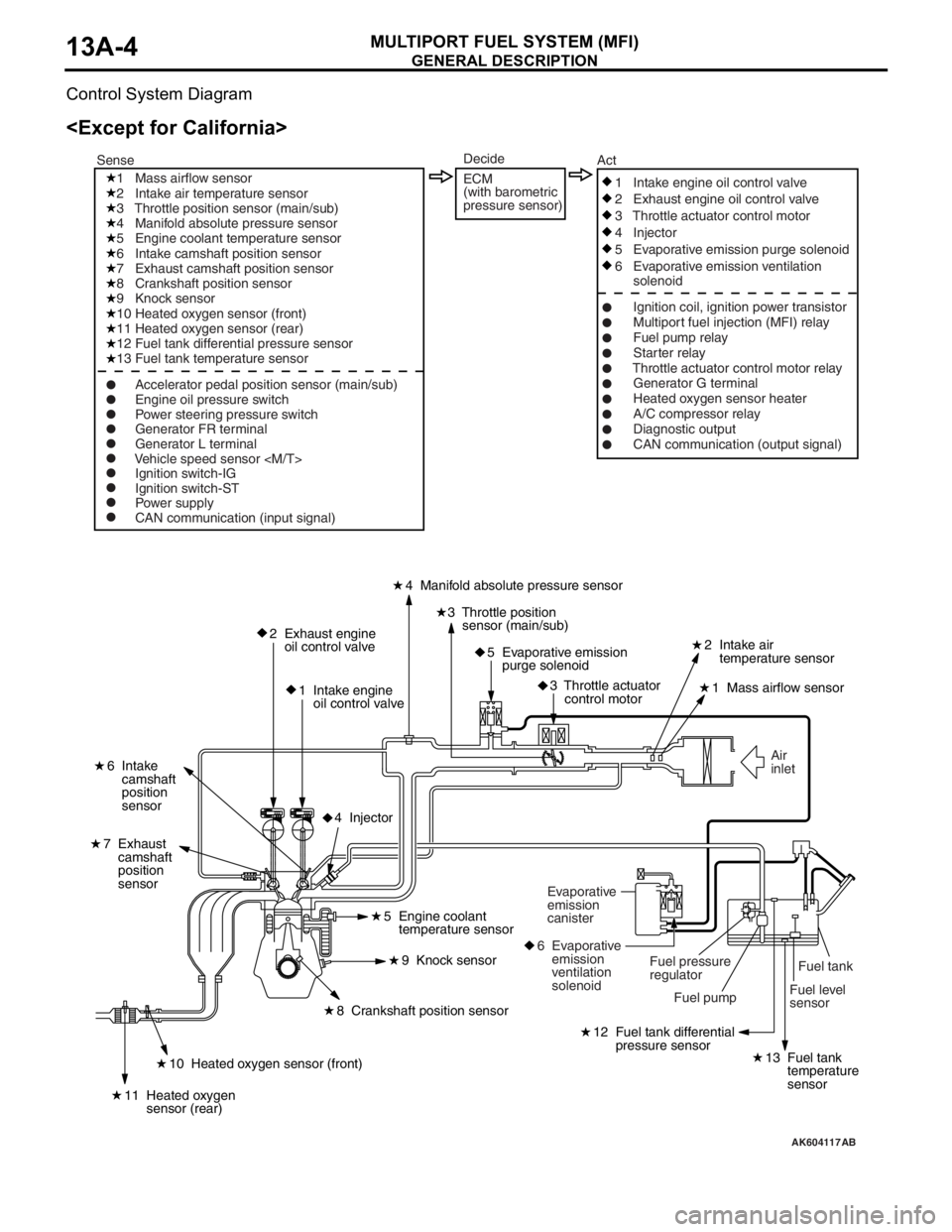

Control System Diagram

AK604117

Fuel level

sensorFuel tank Air

inlet

2 Exhaust engine

oil control valve

1 Intake engine

oil control valve4 Manifold absolute pressure sensor

2 Intake air

temperature sensor

1 Mass airflow sensor

6 Intake

camshaft

position

sensor

7 Exhaust

camshaft

position

sensor

3 Throttle position

sensor (main/sub)

5 Evaporative emission

purge solenoid

3 Throttle actuator

control motor

12 Fuel tank differential

pressure sensor

13 Fuel tank

temperature

sensor10 Heated oxygen sensor (front)

11 Heated oxygen

sensor (rear)

8 Crankshaft position sensor5 Engine coolant

temperature sensor

9 Knock sensor

4 Injector

Fuel pump Fuel pressure

regulator Evaporative

emission

canister

6 Evaporative

emission

ventilation

solenoid

1 Mass airflow sensor

2 Intake air temperature sensor

3 Throttle position sensor (main/sub)

4 Manifold absolute pressure sensor

5 Engine coolant temperature sensor

6 Intake camshaft position sensor

7 Exhaust camshaft position sensor

8 Crankshaft position sensor

9 Knock sensor

10 Heated oxygen sensor (front)

11 Heated oxygen sensor (rear)

12 Fuel tank differential pressure sensor

13 Fuel tank temperature sensor

Ignition switch-IG

Ignition switch-ST

Power supply

CAN communication (input signal)1 Intake engine oil control valve

2 Exhaust engine oil control valve

3 Throttle actuator control motor

4 Injector

5 Evaporative emission purge solenoid

6 Evaporative emission ventilation

solenoid

Ignition coil, ignition power transistor

Multiport fuel injection (MFI) relay

Fuel pump relay

Starter relay

Throttle actuator control motor relay

Generator G terminal

Heated oxygen sensor heater

A/C compressor relay

Diagnostic output

CAN communication (output signal) SenseAct

Engine oil pressure switch

Power steering pressure switch

Generator FR terminal

Generator L terminal

Vehicle speed sensor

Decide

ECM

(with barometric

pressure sensor)

AB

Page 99 of 241

GENERAL DESCRIPTION

MULTIPORT FUEL SYSTEM (MFI)13A-5

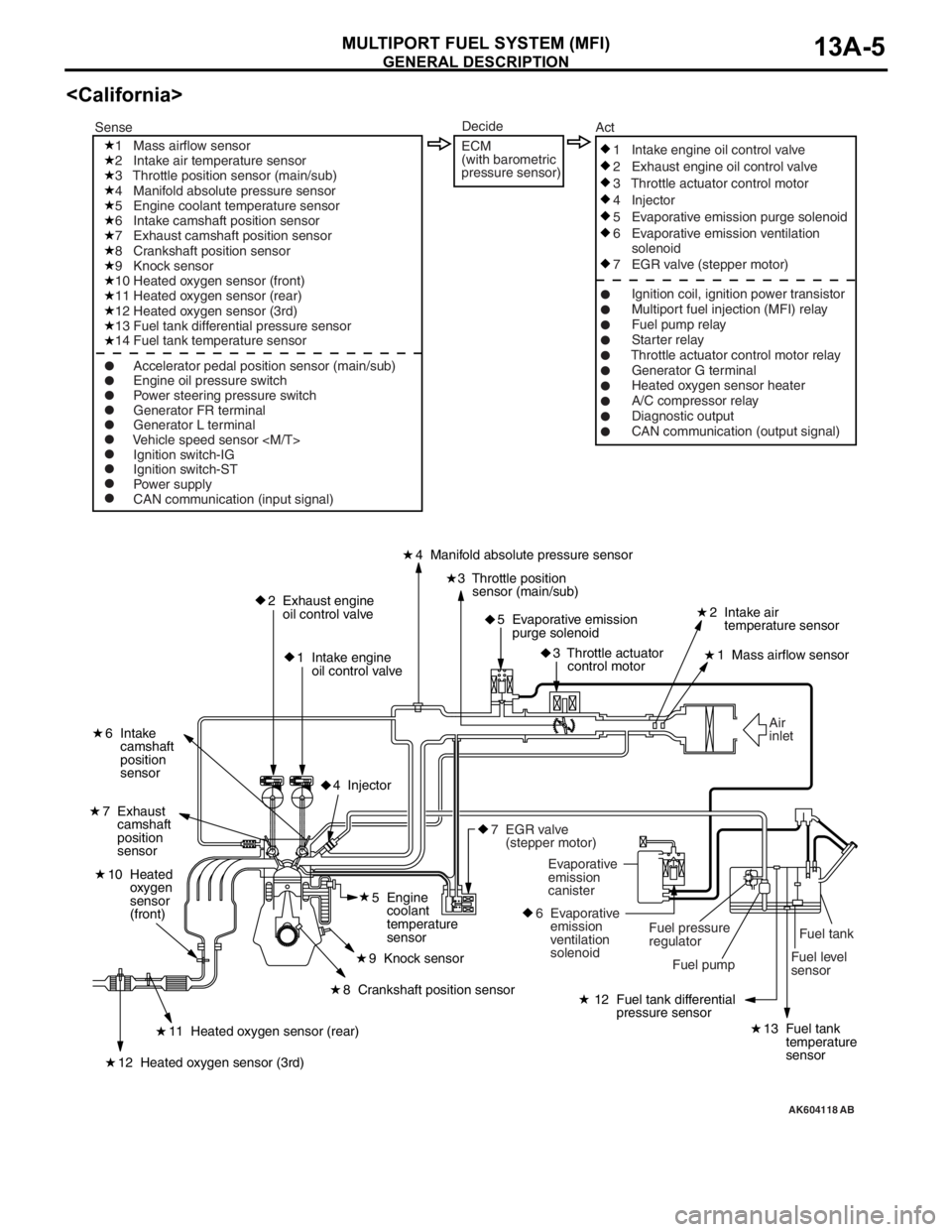

AK604118

Fuel tank

Fuel level

sensor Air

inlet

2 Exhaust engine

oil control valve

1 Intake engine

oil control valve4 Manifold absolute pressure sensor

2 Intake air

temperature sensor

1 Mass airflow sensor

6 Intake

camshaft

position

sensor

7 Exhaust

camshaft

position

sensor

3 Throttle position

sensor (main/sub)

5 Evaporative emission

purge solenoid

3 Throttle actuator

control motor

12 Fuel tank differential

pressure sensor

13 Fuel tank

temperature

sensor11 Heated oxygen sensor (rear)

10 Heated

oxygen

sensor

(front)

12 Heated oxygen sensor (3rd)

8 Crankshaft position sensor5 Engine

coolant

temperature

sensor

9 Knock sensor

4 Injector

Fuel pump Fuel pressure

regulator Evaporative

emission

canister

6 Evaporative

emission

ventilation

solenoid

7 EGR valve

(stepper motor)

1 Mass airflow sensor

2 Intake air temperature sensor

3 Throttle position sensor (main/sub)

4 Manifold absolute pressure sensor

5 Engine coolant temperature sensor

6 Intake camshaft position sensor

7 Exhaust camshaft position sensor

8 Crankshaft position sensor

9 Knock sensor

10 Heated oxygen sensor (front)

11 Heated oxygen sensor (rear)

12 Heated oxygen sensor (3rd)

13 Fuel tank differential pressure sensor

14 Fuel tank temperature sensor

Ignition switch-IG

Ignition switch-ST

Power supply

CAN communication (input signal)1 Intake engine oil control valve

2 Exhaust engine oil control valve

3 Throttle actuator control motor

4 Injector

5 Evaporative emission purge solenoid

6 Evaporative emission ventilation

solenoid

7 EGR valve (stepper motor)

Ignition coil, ignition power transistor

Multiport fuel injection (MFI) relay

Fuel pump relay

Starter relay

Throttle actuator control motor relay

Generator G terminal

Heated oxygen sensor heater

A/C compressor relay

Diagnostic output

CAN communication (output signal) SenseAct

Engine oil pressure switch

Power steering pressure switch

Generator FR terminal

Generator L terminal

Vehicle speed sensor

Decide

ECM

(with barometric

pressure sensor)

AB

Page 103 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-10

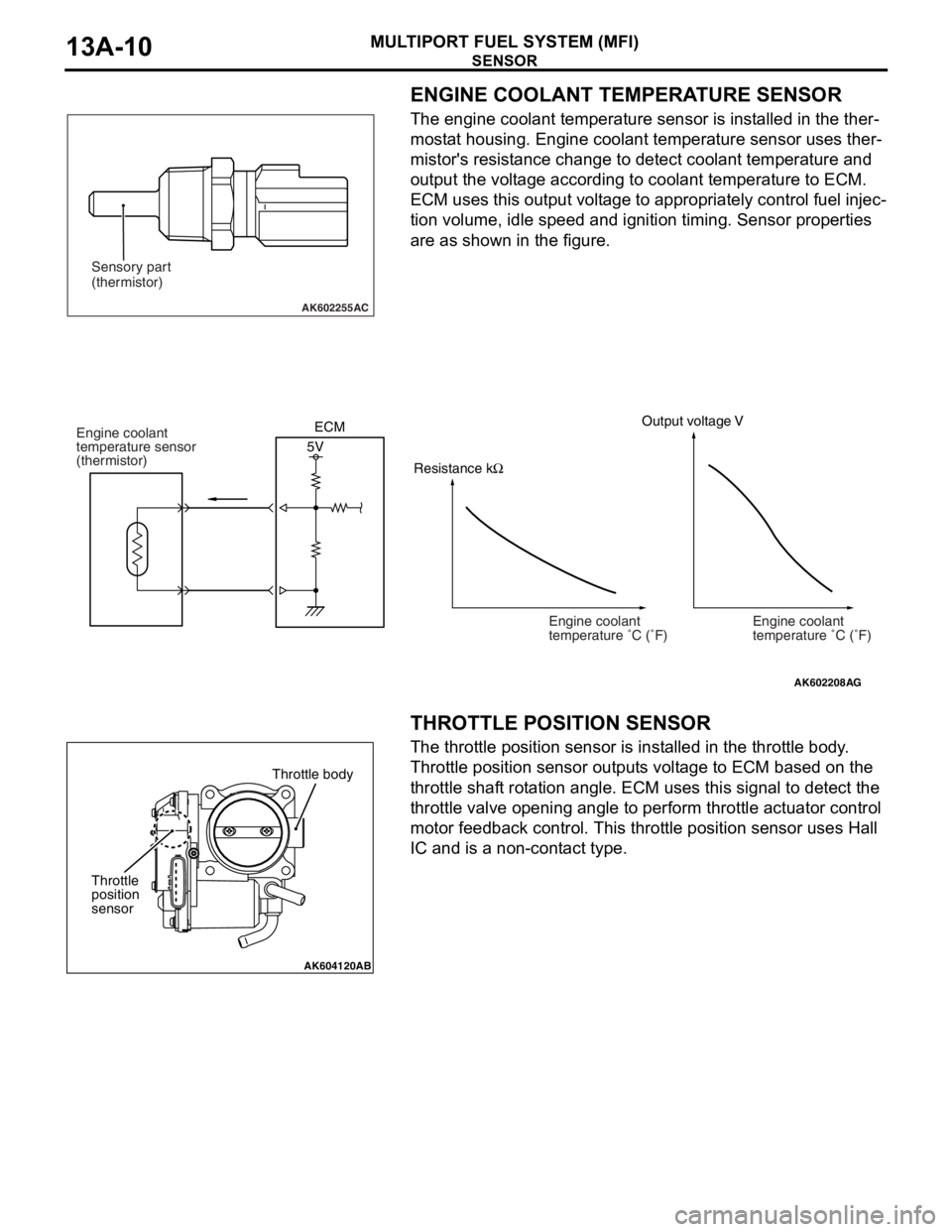

ENGINE COOLANT TEMPERATURE SENSOR

The engine coolant temperature sensor is installed in the ther-

mostat housing. Engine coolant temperature sensor uses ther-

mistor's resistance change to detect coolant temperature and

output the voltage according to coolant temperature to ECM.

ECM uses this output voltage to appropriately control fuel injec

-

tion volume, idle speed and ignition timing. Sensor properties

are as shown in the figure.

.

THROTTLE POSITION SENSOR

The throttle position sensor is installed in the throttle body.

Throttle position sensor outputs voltage to ECM based on the

throttle shaft rotation angle. ECM uses this signal to detect the

throttle valve opening angle to perform throttle actuator control

motor feedback control. This throttle position sensor uses Hall

IC and is a non-contact type.

.

AK602255AC

Sensory part

(thermistor)

AK602208

Engine coolant

temperature �C (�F)

AG

Output voltage V

5V Engine coolant

temperature sensor

(thermistor)

Engine coolant

temperature �C (�F) ECM

Resistance kΩ

AK604120AB

Throttle body

Throttle

position

sensor

Page 104 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-11

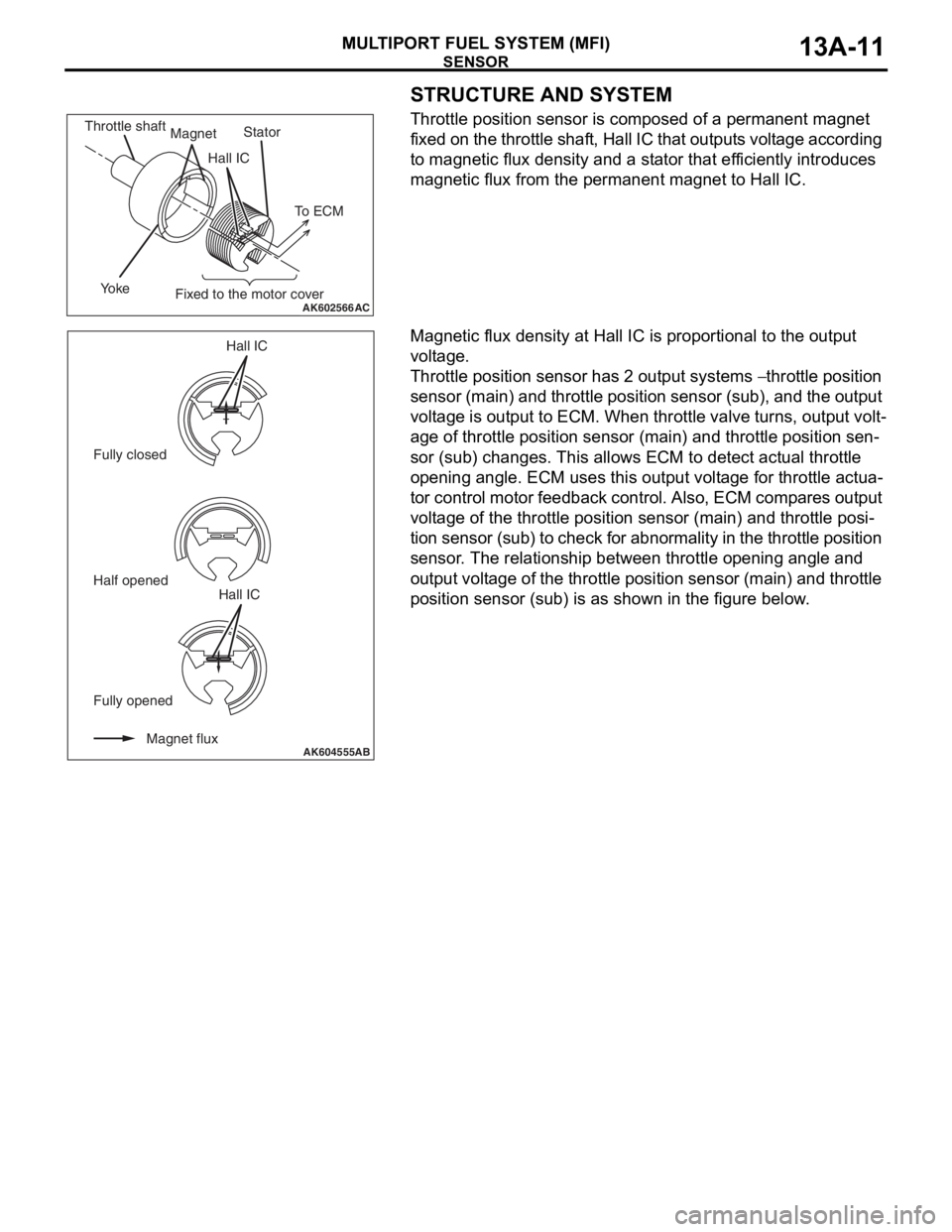

STRUCTURE AND SYSTEM

Throttle position sensor is composed of a permanent magnet

fixed on the throttle shaft, Hall IC that outputs voltage according

to magnetic flux density and a stator that efficiently introduces

magnetic flux from the permanent magnet to Hall IC.

Magnetic flux density at Hall IC is proportional to the output

voltage.

Throttle position sensor has 2 output systems − throttle position

sensor (main) and throttle position sensor (sub), and the output

voltage is output to ECM. When throttle valve turns, output volt

-

age of throttle position sensor (main) and throttle position sen-

sor (sub) changes. This allows ECM to detect actual throttle

opening angle. ECM uses this output voltage for throttle actua

-

tor control motor feedback control. Also, ECM compares output

voltage of the throttle position sensor (main) and throttle posi

-

tion sensor (sub) to check for abnormality in the throttle position

sensor. The relationship between throttle opening angle and

output voltage of the throttle position sensor (main) and throttle

position sensor (sub) is as shown in the figure below.

AK602566AC

Hall ICStator

Yo k e

Fixed to the motor cover Magnet Throttle shaft

To ECM

AK604555Magnet flux Fully opened Fully closedHall IC

Half opened

Hall ICAB

Page 114 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-21

.

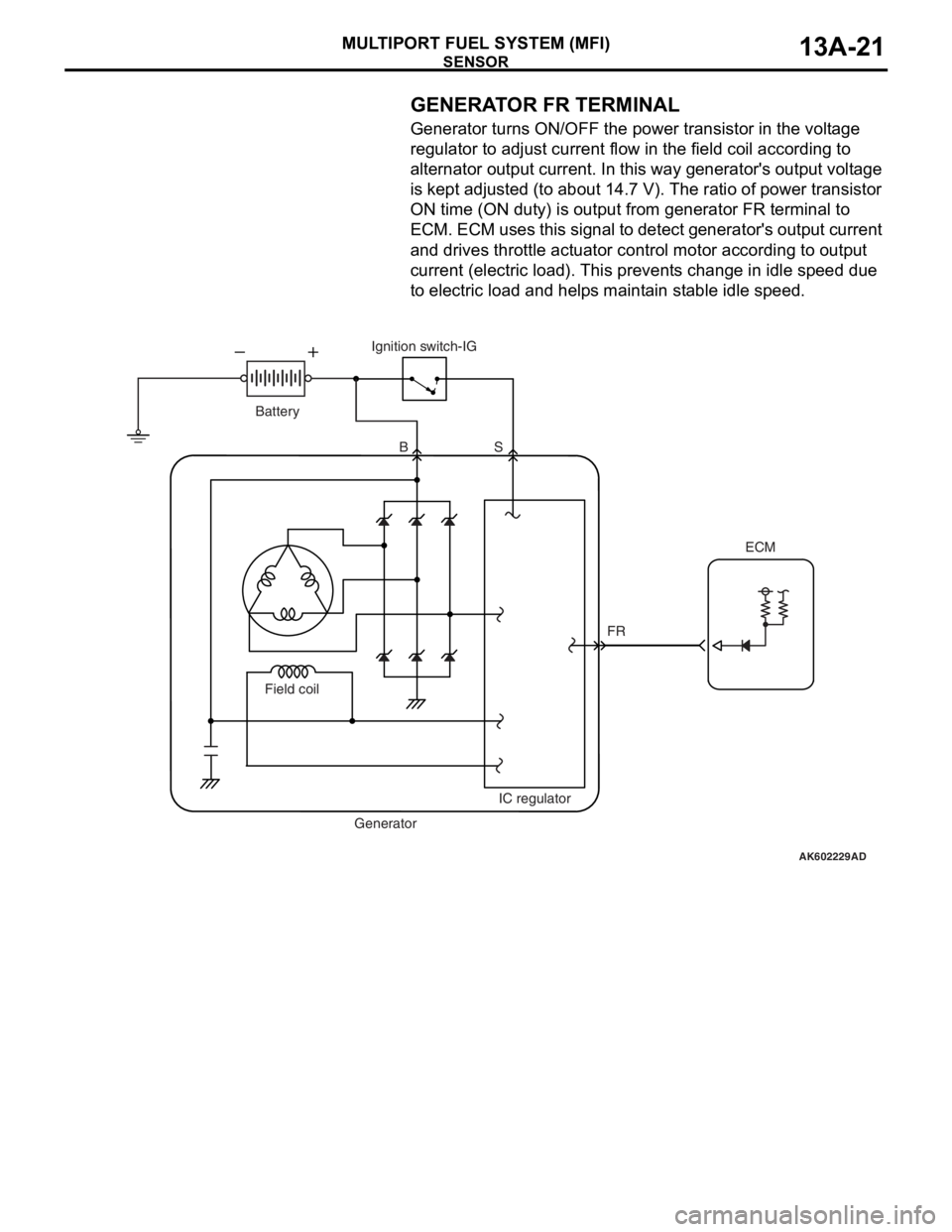

GENERATOR FR TERMINAL

Generator turns ON/OFF the power transistor in the voltage

regulator to adjust current flow in the field coil according to

alternator output current. In this way generator's output voltage

is kept adjusted (to about 14.7 V). The ratio of power transistor

ON time (ON duty) is output from generator FR terminal to

ECM. ECM uses this signal to detect generator's output current

and drives throttle actuator control motor according to output

current (electric load). This prevents change in idle speed due

to electric load and helps maintain stable idle speed.

.

AK602229AD

FR BS

Field coil

IC regulator

GeneratorIgnition switch-IG

Battery

ECM

Page 117 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-24

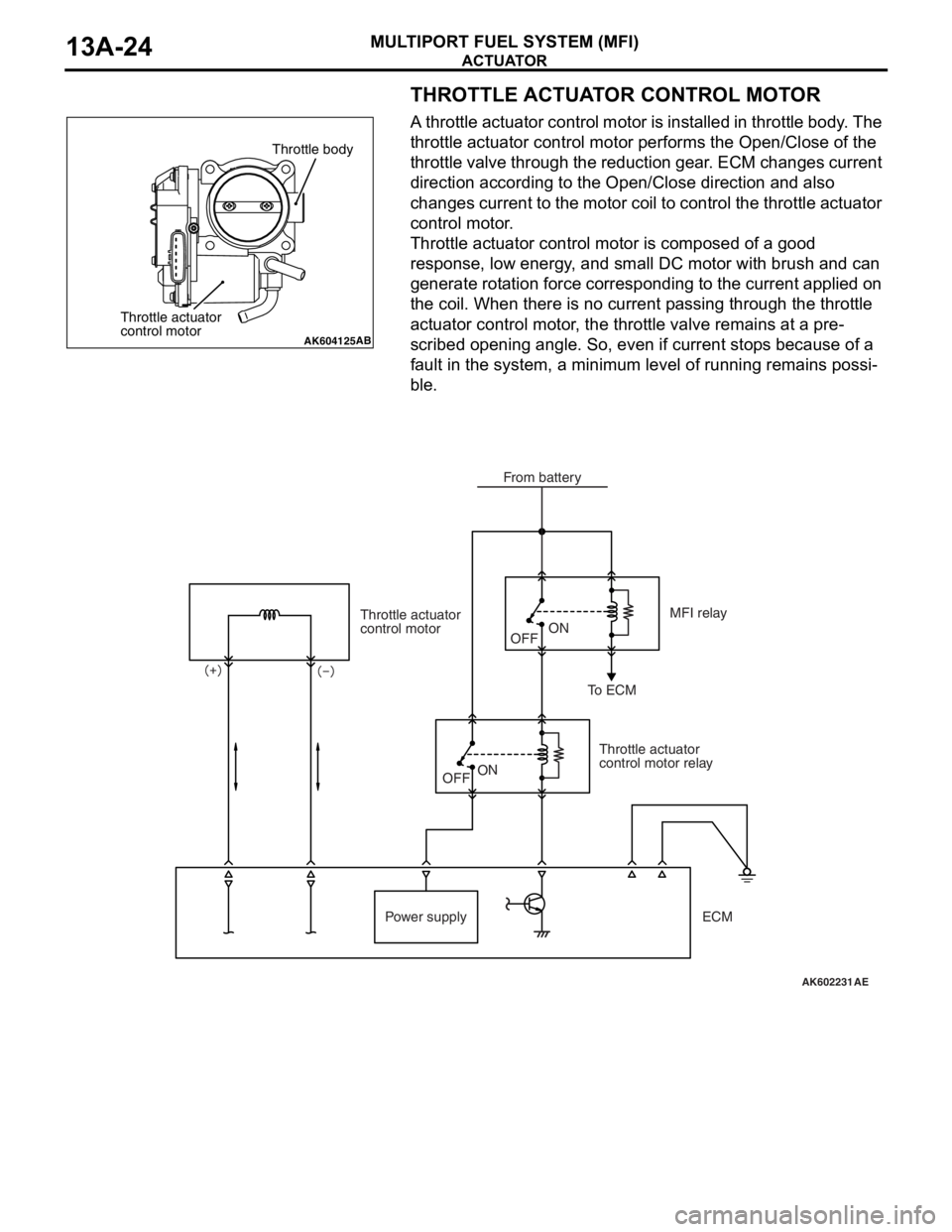

THROTTLE ACTUATOR CONTROL MOTOR

A throttle actuator control motor is installed in throttle body. The

throttle actuator control motor performs the Open/Close of the

throttle valve through the reduction gear. ECM changes current

direction according to the Open/Close direction and also

changes current to the motor coil to control the throttle actuator

control motor.

Throttle actuator control motor is composed of a good

response, low energy, and small DC motor with brush and can

generate rotation force corresponding to the current applied on

the coil. When there is no current passing through the throttle

actuator control motor, the throttle valve remains at a pre

-

scribed opening angle. So, even if current stops because of a

fault in the system, a minimum level of running remains possi

-

ble.

AK604125AB

Throttle body

Throttle actuator

control motor

AK602231

Throttle actuator

control motor

Throttle actuator

control motor relayMFI relay

To ECM

Power supplyOFFON

OFF

ON

AE

From battery

ECM

Page 131 of 241

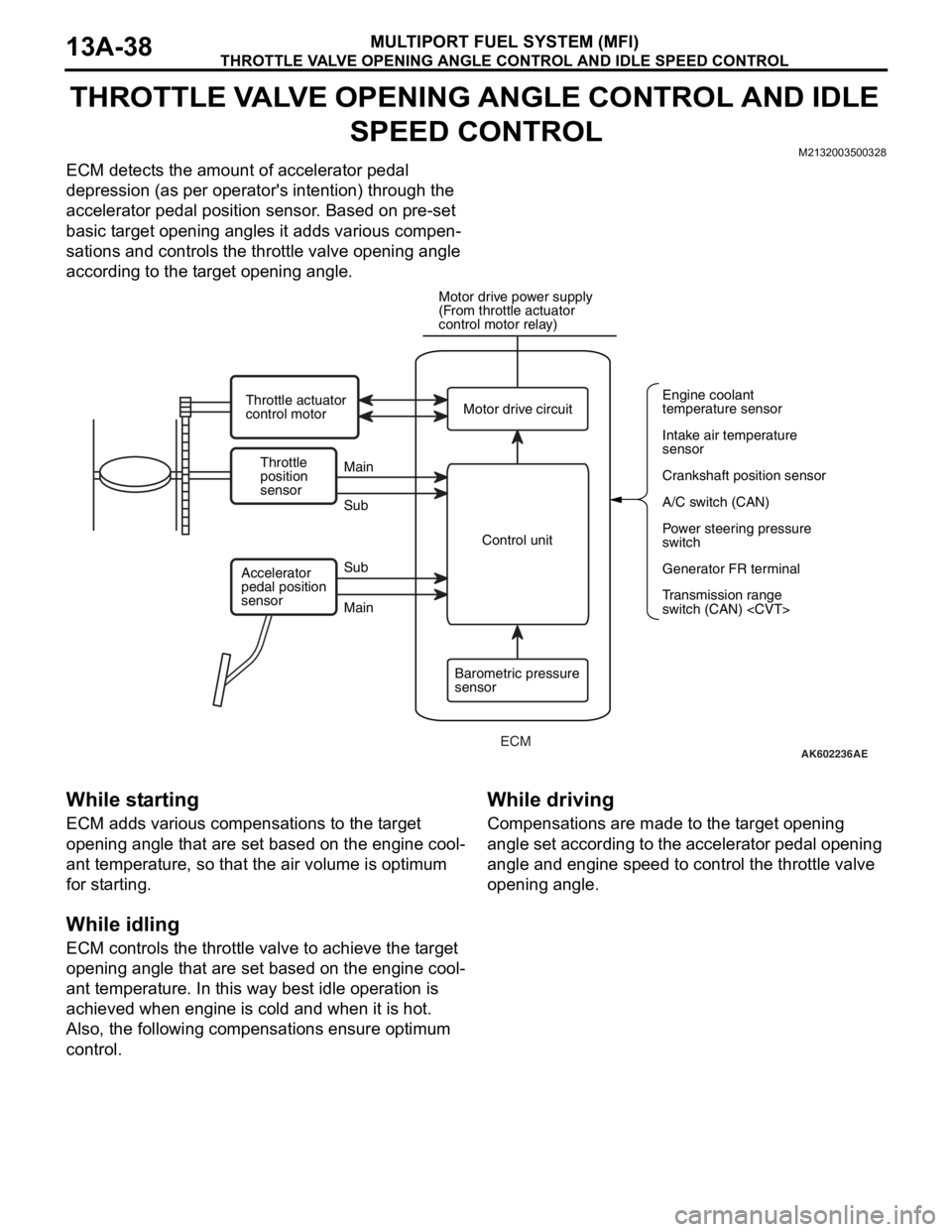

THROTTLE VALVE OPENING ANGLE CONTROL AND IDLE SPEED CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-38

THROTTLE VALVE OPENING ANGLE CONTROL AND IDLE

SPEED CONTROL

M2132003500328

ECM detects the amount of accelerator pedal

depression (as per operator's intention) through the

accelerator pedal position sensor. Based on pre-set

basic target opening angles it adds various compen

-

sations and controls the throttle valve opening angle

according to the target opening angle.

While starting

ECM adds various compensations to the target

opening angle that are set based on the engine cool

-

ant temperature, so that the air volume is optimum

for starting.

While idling

ECM controls the throttle valve to achieve the target

opening angle that are set based on the engine cool

-

ant temperature. In this way best idle operation is

achieved when engine is cold and when it is hot.

Also, the following compensations ensure optimum

control.

While driving

Compensations are made to the target opening

angle set according to the accelerator pedal opening

angle and engine speed to control the throttle valve

opening angle.

AK602236AE

Throttle

position

sensorMain

Main Sub

SubMotor drive circuit

A/C switch (CAN) Engine coolant

temperature sensor

Intake air temperature

sensor

Crankshaft position sensor

Power steering pressure

switch

Generator FR terminal

Transmission range

switch (CAN)

(From throttle actuator

control motor relay)

Throttle actuator

control motor

Control unit

Barometric pressure

sensor Accelerator

pedal position

sensor

ECM