air filter MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 34 of 241

GENERAL DESCRIPTION

HEATER, AIR CONDITIONING AND VENTILATION55-2

GENERAL DESCRIPTIONM2551001500040

The blower, heater, and evaporator have been inte-

grated with the heater and A/C system to achieve a

greater fan power and noise reduction.

FEATURES

.

ENHANCEMENTS IN COMFORT

•With the adoption of fully-automatic A/C, the out-

side/inside air circulation switching, air outlet, and

outlet air temperature are automatically con

-

trolled according to the ambient temperature,

solar radiation, and passenger compartment tem

-

perature so that the optimum air conditioner is

achieved.

•By the adoption of clean air filter, the air quality

inside the passenger compartment has been

enhanced.

.

ENHANCEMENTS IN OPERATION

PERFORMANCE

•Operability has been enhanced by the adoption

of large triple dial.

•Customise function has been added for the

enhanced convenience.

.

ENHANCEMENTS IN FUEL ECONOMY

•The high efficiency compressor with a 2-step pro-

file oil separator has been installed, thus enhanc-

ing the fuel economy.

•The idle-up speed is controlled in two steps to

secure the air cooling performance during sum

-

mer and to enhance the fuel economy in the sea-

sons with moderate temperature.

•Enhancement of fuel economy by the cooling fan

control depending on the refrigerant pressure and

vehicle speed.

.

ENHANCEMENT IN SAFETY

•A/C system is stopped when the air bags are

deployed.

•Crushable space has been adopted to heater unit

to reduce the risk of passenger injuries in case of

a collision.

.

GLOBAL ENVIRONMENT PROTECTION

•New refrigerant system (HFC134a) has been

adopted.

•By the optimisation of A/C system, the refrigerant

charging amount has been reduced.

•Clean air filter media and its cover are separated

to reduce waste materials.

.

ENHANCEMENTS IN SERVICE QUALITY

•Reduction of refrigerant gas leakage and

enhancement in serviceability by incorporating

condenser and receiver

•Clean air filter is installed to the backside of glove

box to facilitate the filter replacement.

.

ENHANCEMENTS IN RESPONSIBILITY

Reliable information transmission is achieved by

connecting A/C-ECU and each ECU via CAN com

-

munication.

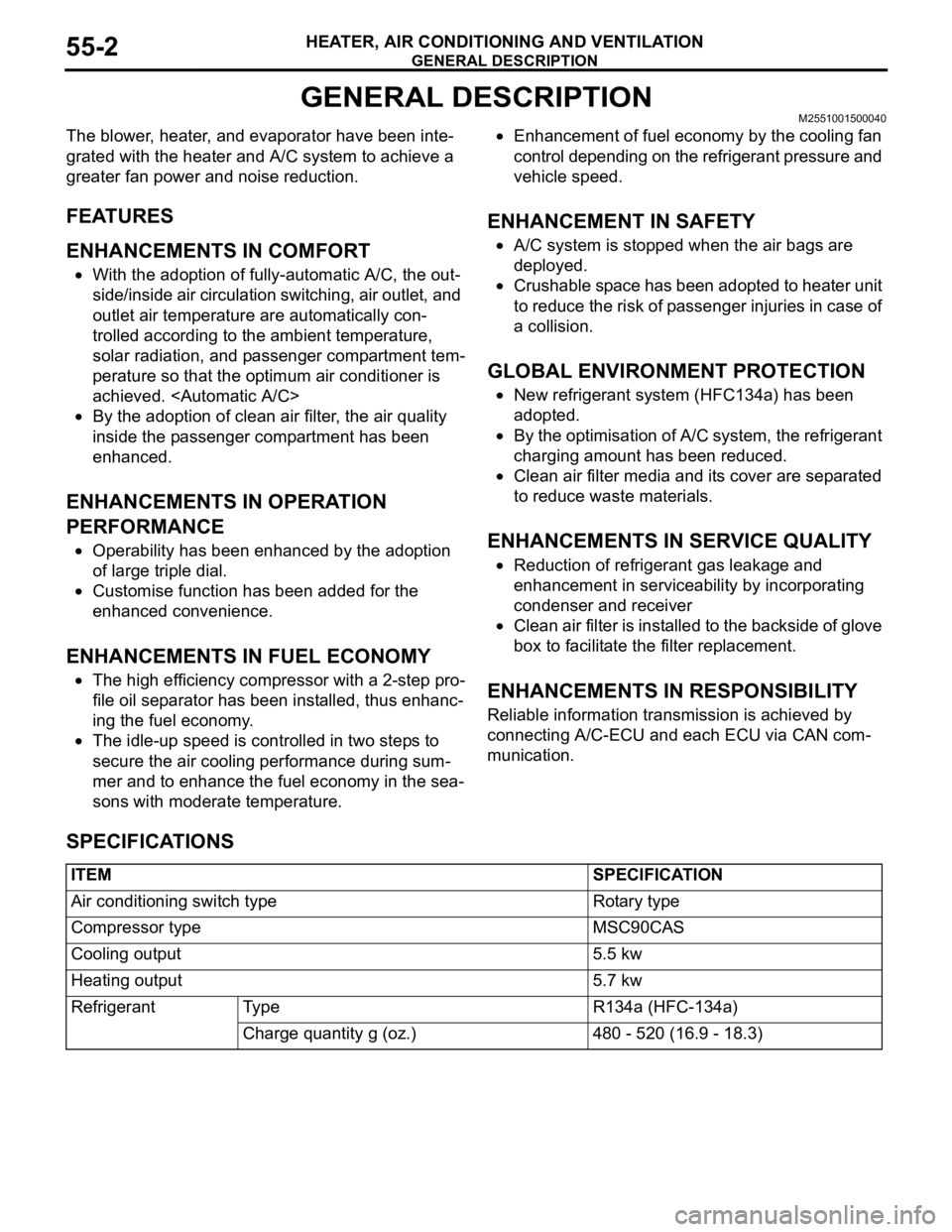

SPECIFICATIONS

ITEMSPECIFICATION

Air conditioning switch typeRotary type

Compressor typeMSC90CAS

Cooling output5.5 kw

Heating output5.7 kw

RefrigerantTy p eR134a (HFC-134a)

Charge quantity g (oz.)480 - 520 (16.9 - 18.3)

Page 36 of 241

HEATER AND AIR CONDITIONING SYSTEM

HEATER, AIR CONDITIONING AND VENTILATION55-4

HEATER AND AIR CONDITIONING SYSTEMM2551001000614

HEATER UNIT ASSEMBLY

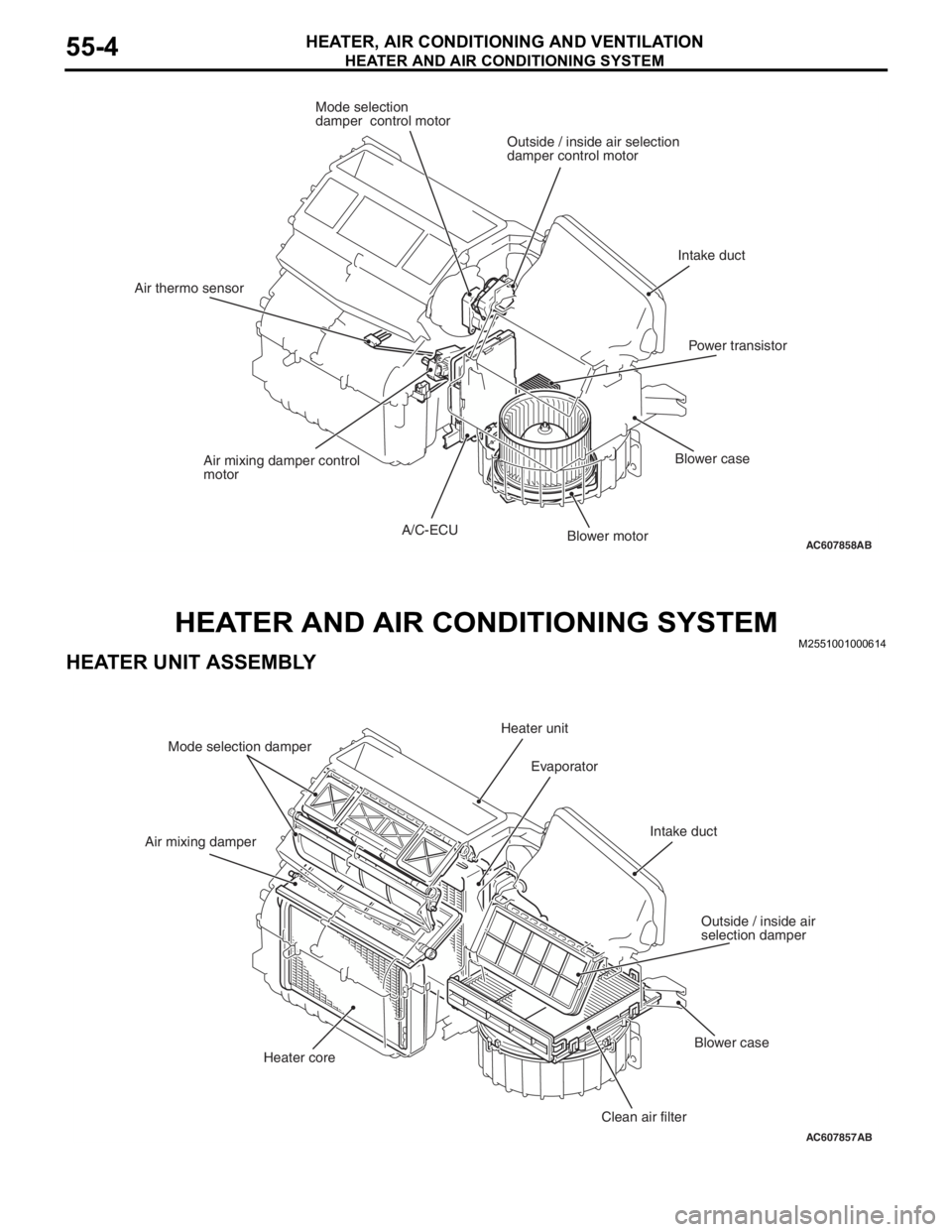

AC607858Blower motor Outside / inside air selection

damper control motor

Air mixing damper control

motor Air thermo sensorAB

Mode selection

damper control motor

A/C-ECUPower transistor Intake duct

Blower case

AC607857

Heater unit

Air mixing damper

Heater coreEvaporator Mode selection damper

Outside / inside air

selection damper

AB

Intake duct

Blower case

Clean air filter

Page 37 of 241

HEATER AND AIR CONDITIONING SYSTEM

HEATER, AIR CONDITIONING AND VENTILATION55-5

The following new unit integrated blower, heater and

evaporator to increase the air flow, reduce noise, and

enhanced cooler and heater performance;:

•Integrated heater/cooling unit has been adopted

for large air flows and low noise.

•Crushable space has been secured to reduce the

risk of passenger injuries.

•Air mix damper that is also used as a reheating

prevention damper has been adopted to enhance

the air cooling performance.

•The A/C condensate water outlet (drain port) has

been installed to behind the evaporator to

restrain the clogging of drain by foreign materials.

•The outlet air temperature of the defroster has

been set lower than that of foot to prevent over

-

heating the driver’s face.

•Fin thermo sensor to directly measure evaporator

temperature reduces occurrence risk of an evap

-

orator freeze which will lead to the compressor

lock.

•Clean air filter has been introduced as standard

to protect the unit from the intrusion of foreign

materials (fallen leaves and others). and, it

removes the pollen and dust, and enhances the

air quality inside the passenger compartment.

•Clean air filter media and cover have been sepa-

rated to reduce the waste material amount gener-

ated during the filter replacement.

•The installation position of clean air filter has

been set to the backside of glove box to facilitate

the filter replacement operation. And, the

one-touch tab structure has been adopted for the

cover installation to enable the replacement oper

-

ation without tools.

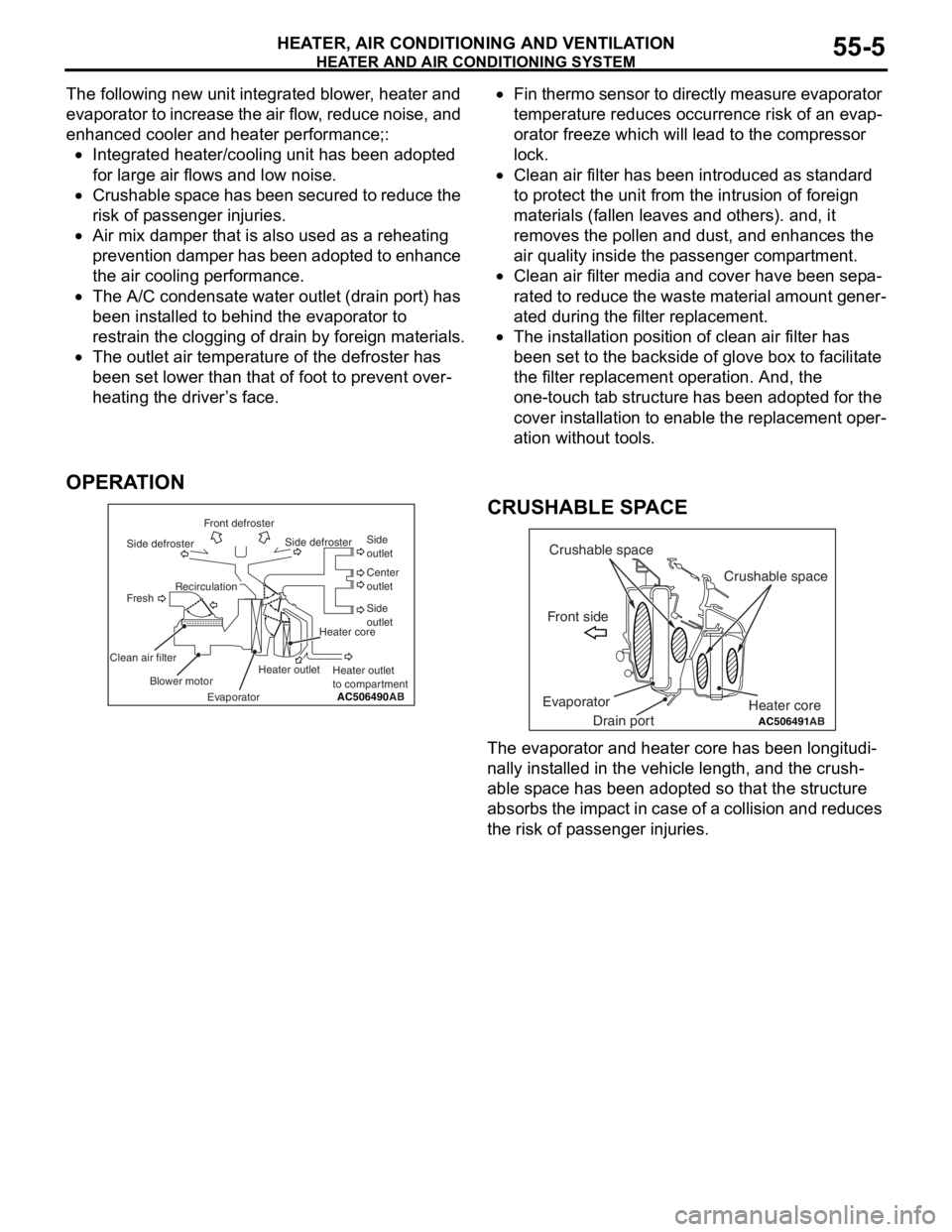

OPERATION

.

CRUSHABLE SPACE

The evaporator and heater core has been longitudi-

nally installed in the vehicle length, and the crush-

able space has been adopted so that the structure

absorbs the impact in case of a collision and reduces

the risk of passenger injuries.

AC506490AB Front defroster

Side defrosterSide defrosterSide

outlet

Side

outlet Center

outlet

Heater core

Heater outlet

to compartment Recirculation

Fresh

Clean air filter

Blower motor

EvaporatorHeater outlet

AC506491

Crushable space

Crushable space

Front side

Drain port EvaporatorHeater coreAB

Page 120 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-27

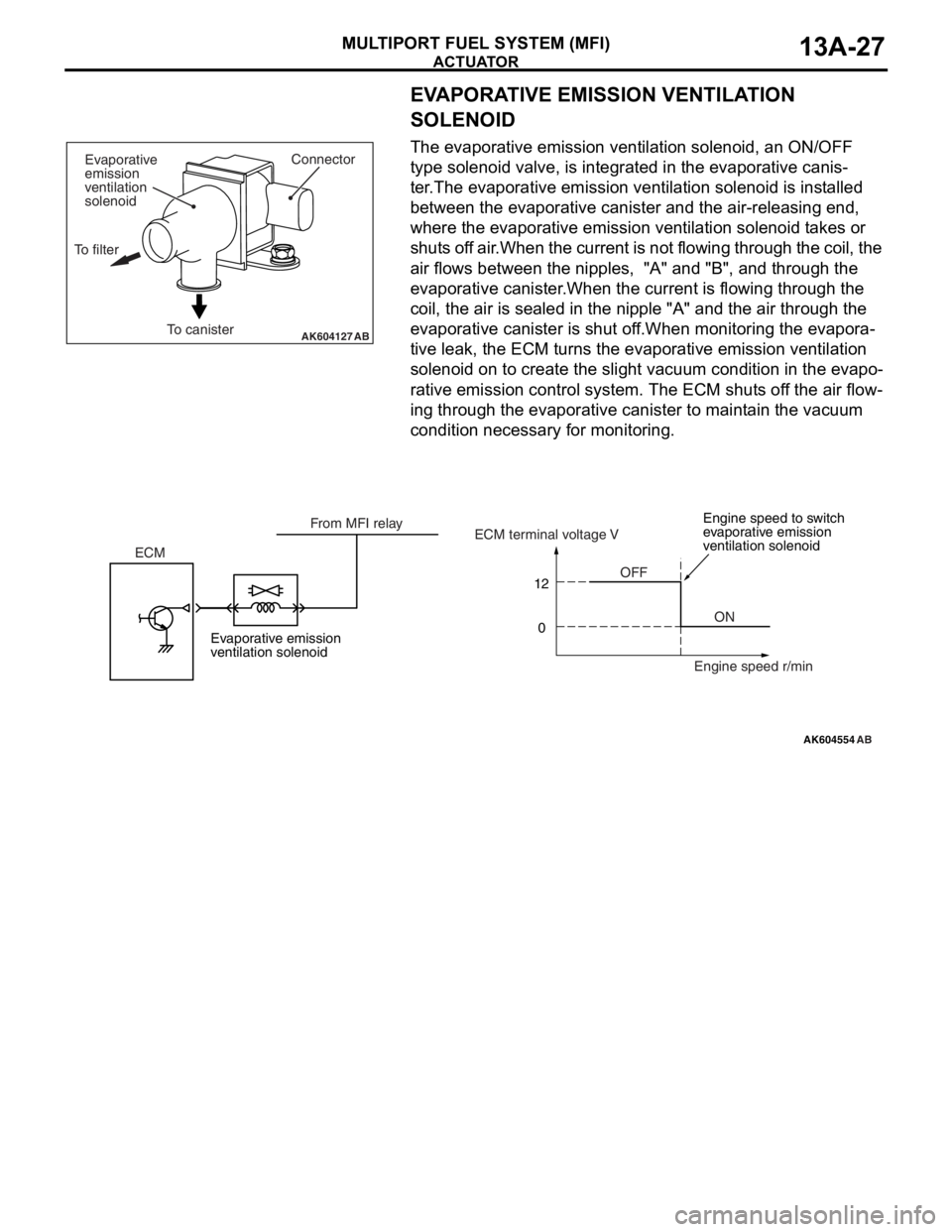

EVAPORATIVE EMISSION VENTILATION

SOLENOID

The evaporative emission ventilation solenoid, an ON/OFF

type solenoid valve, is integrated in the evaporative canis

-

ter.The evaporative emission ventilation solenoid is installed

between the evaporative canister and the air-releasing end,

where the evaporative emission ventilation solenoid takes or

shuts off air.When the current is not flowing through the coil, the

air flows between the nipples, "A" and "B", and through the

evaporative canister.When the current is flowing through the

coil, the air is sealed in the nipple "A" and the air through the

evaporative canister is shut off.When monitoring the evapora

-

tive leak, the ECM turns the evaporative emission ventilation

solenoid on to create the slight vacuum condition in the evapo

-

rative emission control system. The ECM shuts off the air flow-

ing through the evaporative canister to maintain the vacuum

condition necessary for monitoring.

AK604127ABTo canisterConnector

Evaporative

emission

ventilation

solenoid

To filter

AK604554

12

0

AB

OFF

ON ECMECM terminal voltage V

Engine speed r/min From MFI relay

Evaporative emission

ventilation solenoidEngine speed to switch

evaporative emission

ventilation solenoid