compression ratio MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 46 of 241

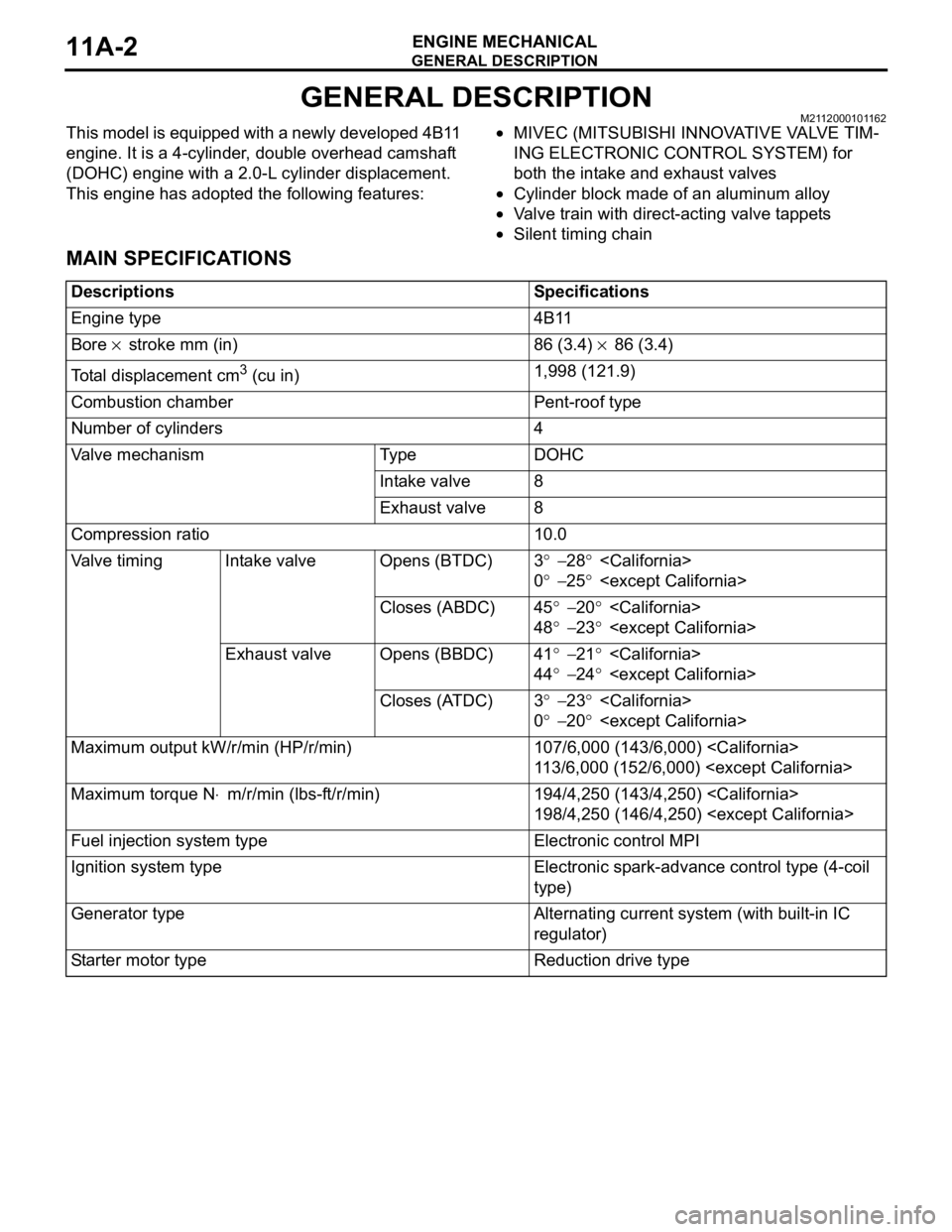

GENERAL DESCRIPTION

ENGINE MECHANICAL11A-2

GENERAL DESCRIPTIONM2112000101162

This model is equipped with a newly developed 4B11

engine. It is a 4-cylinder, double overhead camshaft

(DOHC) engine with a 2.0-L cylinder displacement.

This engine has adopted the following features:

•MIVEC (MITSUBISHI INNOVATIVE VALVE TIM-

ING ELECTRONIC CONTROL SYSTEM) for

both the intake and exhaust valves

•Cylinder block made of an aluminum alloy

•Valve train with direct-acting valve tappets

•Silent timing chain

MAIN SPECIFICATIONS

DescriptionsSpecifications

Engine type4B11

Bore × stroke mm (in)86 (3.4) × 86 (3.4)

Total displacement cm3 (cu in)1,998 (121.9)

Combustion chamberPent-roof type

Number of cylinders4

Valve mechanismTy p eDOHC

Intake valve8

Exhaust valve8

Compression ratio10.0

Va l v e t i m i n gIntake valveOpens (BTDC)3° − 28°

0° − 25°

Closes (ABDC)45° − 20°

48° − 23°

Exhaust valveOpens (BBDC)41° − 21°

44° − 24°

Closes (ATDC)3° − 23°

0° − 20°

Maximum output kW/r/min (HP/r/min)107/6,000 (143/6,000)

113/6,000 (152/6,000)

Maximum torque N⋅m/r/min (lbs-ft/r/min)194/4,250 (143/4,250)

198/4,250 (146/4,250)

Fuel injection system typeElectronic control MPI

Ignition system typeElectronic spark-advance control type (4-coil

type)

Generator typeAlternating current system (with built-in IC

regulator)

Starter motor typeReduction drive type

Page 123 of 241

FUEL INJECTION CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-30

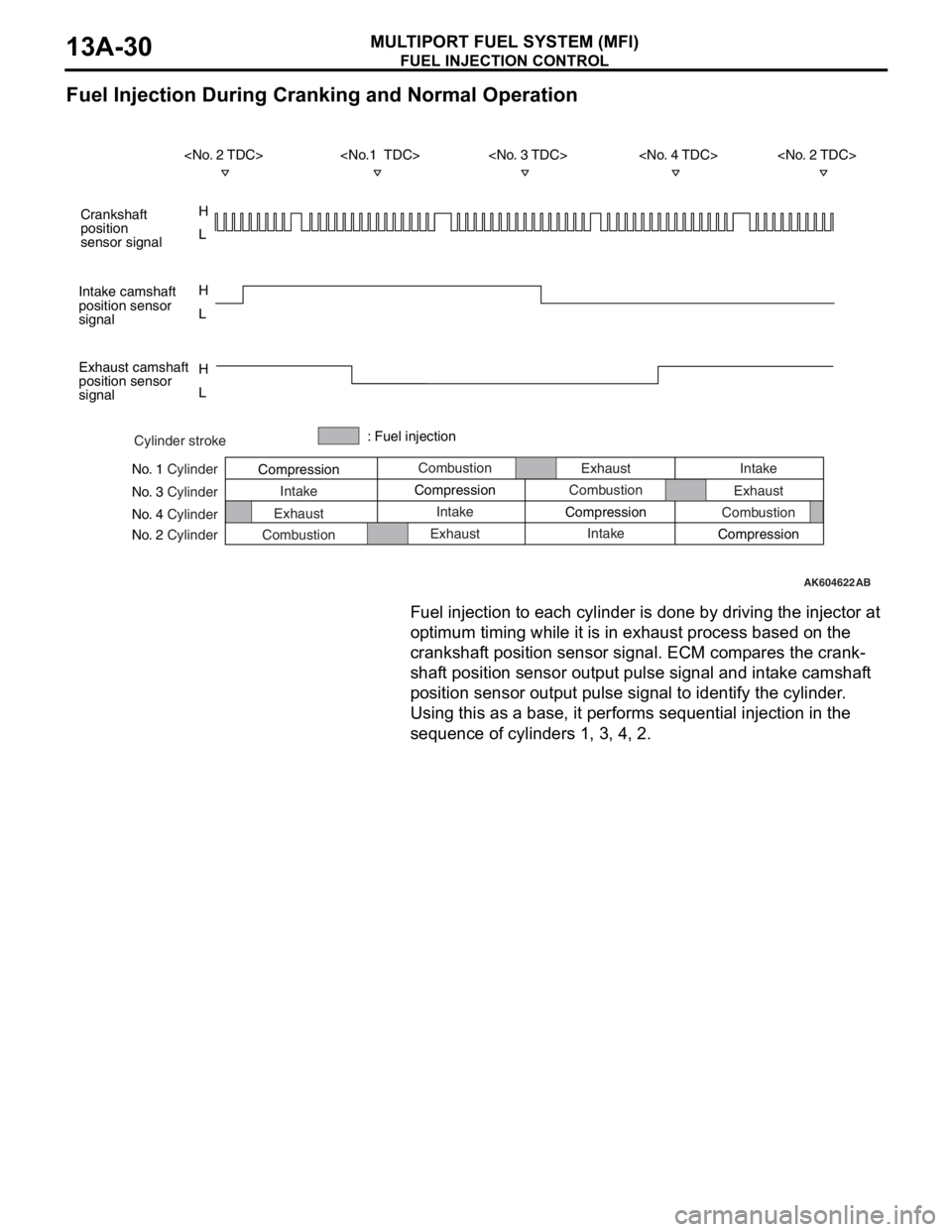

Fuel Injection During Cranking and Normal Operation

Fuel injection to each cylinder is done by driving the injector at

optimum timing while it is in exhaust process based on the

crankshaft position sensor signal. ECM compares the crank

-

shaft position sensor output pulse signal and intake camshaft

position sensor output pulse signal to identify the cylinder.

Using this as a base, it performs sequential injection in the

sequence of cylinders 1, 3, 4, 2.

AK604622AB

Cylinder stroke

No. 1 Cylinder

No. 3 Cylinder

No. 4 Cylinder

No. 2 CylinderCombustion

Intake

Exhaust

CombustionExhaust

Compression: Fuel injection

Intake

Exhaust CompressionCombustion

Intake CompressionIntake

Exhaust

Combustion

Compression

H

L H

L

H

L Crankshaft

position

sensor signal

Intake camshaft

position sensor

signal

Exhaust camshaft

position sensor

signal

Page 124 of 241

FUEL INJECTION CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-31

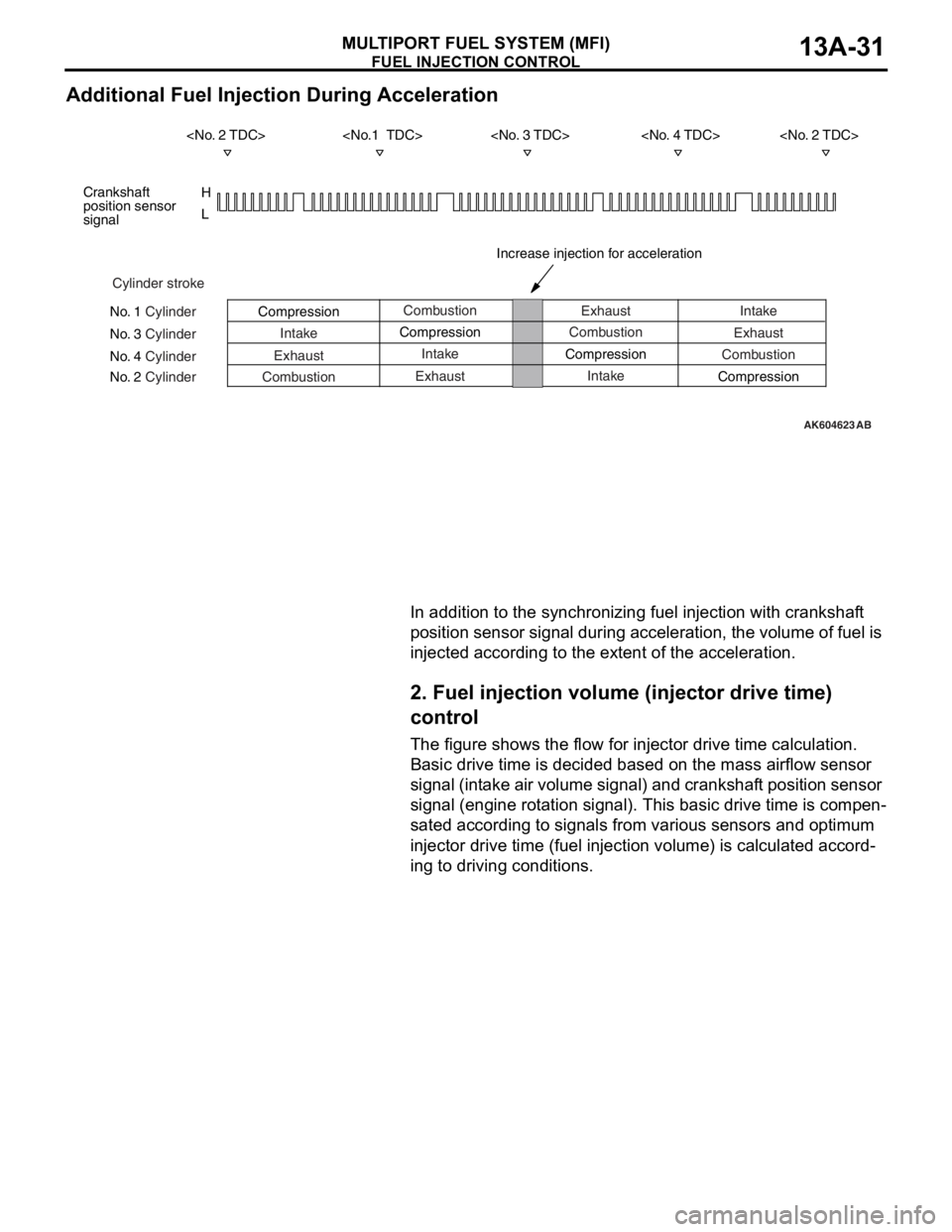

Additional Fuel Injection During Acceleration

In addition to the synchronizing fuel injection with crankshaft

position sensor signal during acceleration, the volume of fuel is

injected according to the extent of the acceleration.

2. Fuel injection volume (injector drive time)

control

The figure shows the flow for injector drive time calculation.

Basic drive time is decided based on the mass airflow sensor

signal (intake air volume signal) and crankshaft position sensor

signal (engine rotation signal). This basic drive time is compen

-

sated according to signals from various sensors and optimum

injector drive time (fuel injection volume) is calculated accord

-

ing to driving conditions.

AK604623

H

L

AB

Cylinder stroke

No. 1 Cylinder

No. 3 Cylinder

No. 4 Cylinder

No. 2 CylinderCombustion

Intake

Exhaust

CombustionExhaust

Compression

Intake

Exhaust CompressionCombustion

Intake CompressionIntake

Exhaust

Combustion

Compression Crankshaft

position sensor

signal

Increase injection for acceleration