length MITSUBISHI LANCER IX 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 184 of 800

GENERAL INFORMATION

FRONT SUSPENSION33-2

GENERAL INFORMATION

M1332000100537

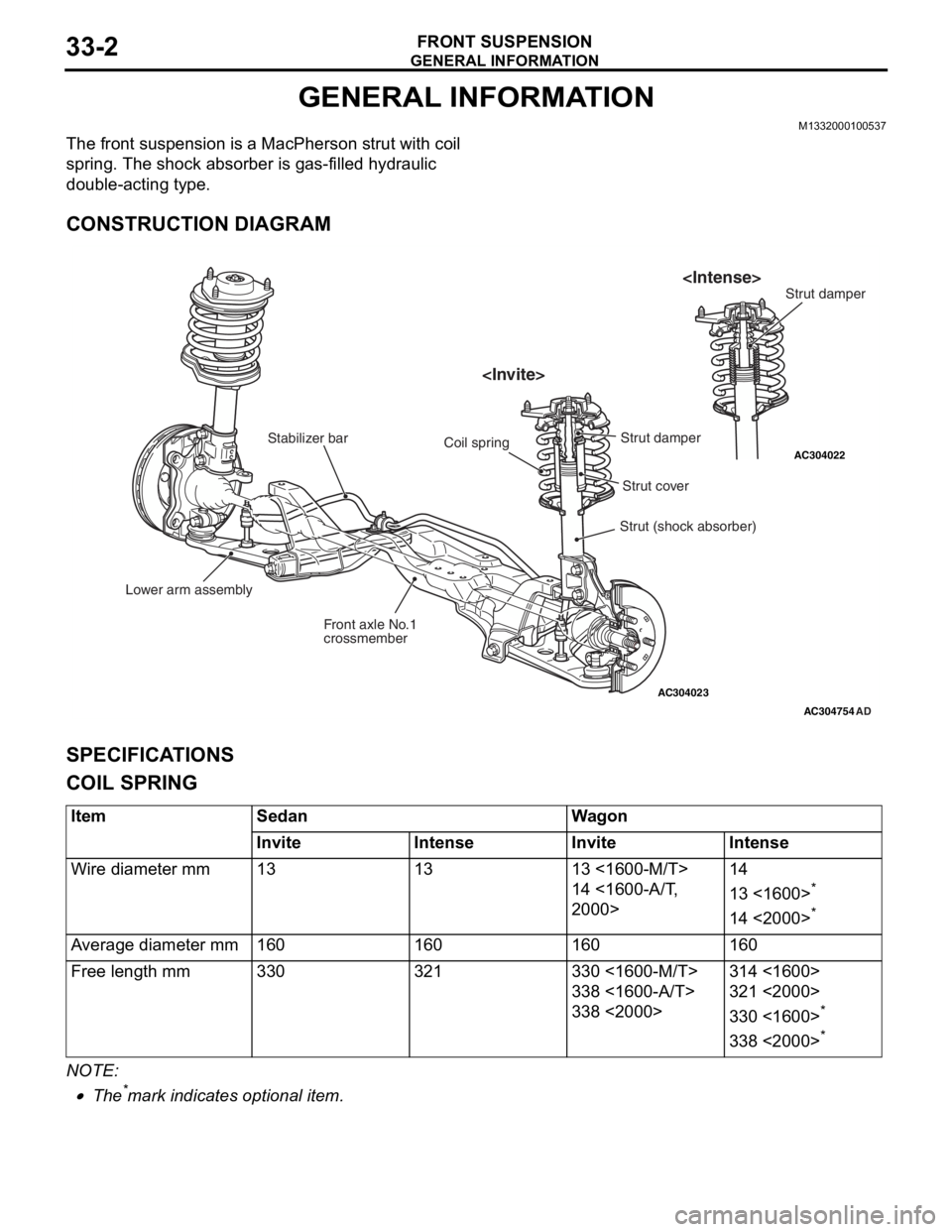

The front suspension is a MacPherson strut with coil

spring. The shock absorber is gas-filled hydraulic

double-acting type.

CONSTRUCTION DIAGRAM

AC304023

AC304022

AC304754

Lower arm assembly Front axle No.1

crossmember

Stabilizer bar

Strut (shock absorber)

Coil spring

AD

Strut cover

Strut damper

SPECIFICA

T IONS

COIL SPRING

ItemSedanWagon

InviteIntenseInviteIntense

Wire diameter mm131313 <1600-M/T>

14 <1600-A/T,

2000>

14

13 <1600>*

14 <2000>*

Average diameter mm160160160160

Free length mm330321330 <1600-M/T>

338 <1600-A/T>

338 <2000>

314 <1600>

321 <2000>

330 <1600>*

338 <2000>*

NOTE: .

•The*mark indicat e s op tiona l it em.

Page 185 of 800

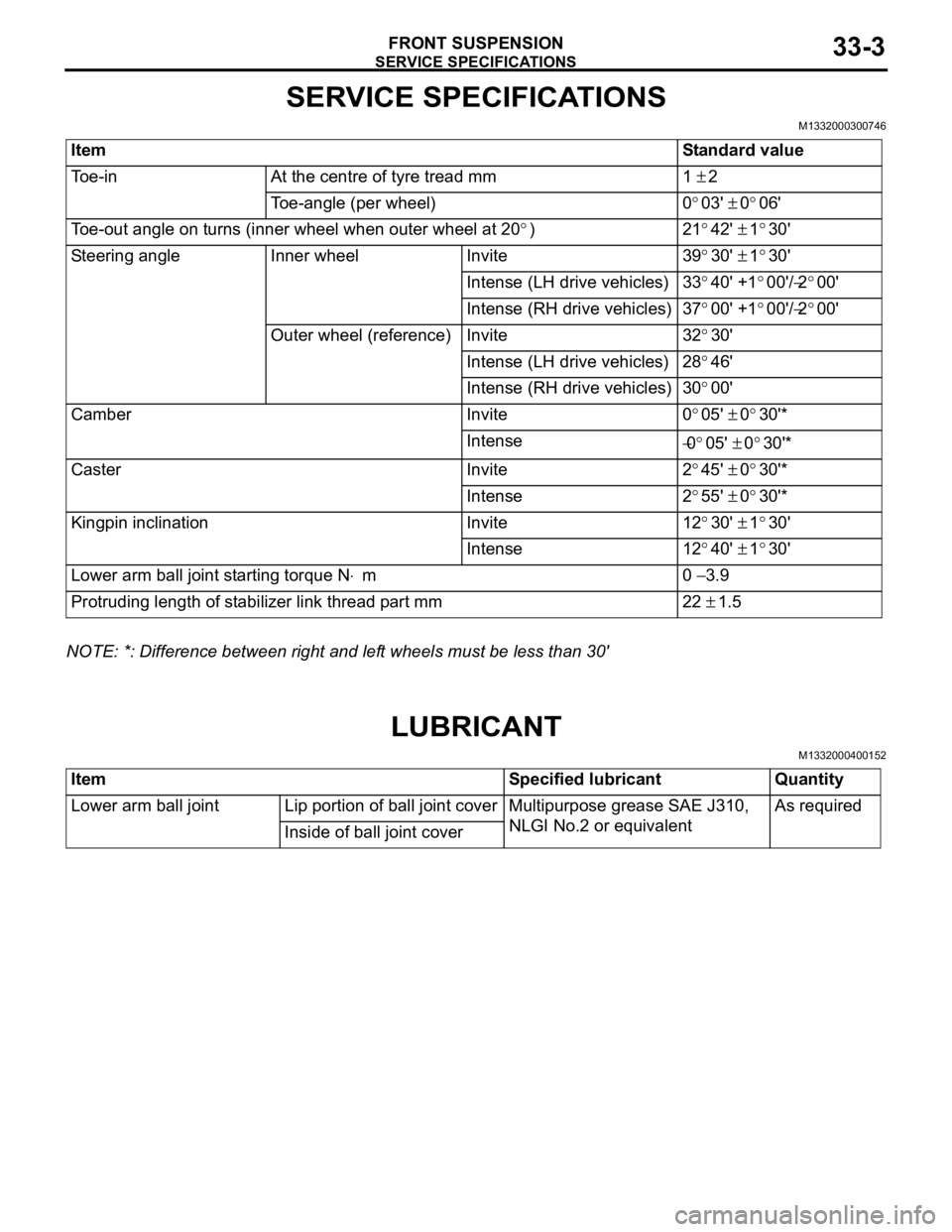

SERVICE SPECIFICATIONS

FRONT SUSPENSION33-3

SERVICE SPECIFICATIONS

M1332000300746

ItemStandard value

Toe-inAt the centre of tyre tread mm1 ± 2

Toe-angle (per wheel)0°03' ± 0°06'

Toe-out angle on turns (inner wheel when outer wheel at 20°)21°42' ± 1°30'

Steering angleInner wheelInvite39°30' ± 1°30'

Intense (LH drive vehicles)33°40' +1°00'/−2°00'

Intense (RH drive vehicles)37°00' +1°00'/−2°00'

Outer wheel (reference)Invite32°30'

Intense (LH drive vehicles)28°46'

Intense (RH drive vehicles)30°00'

CamberInvite0°05' ± 0°30'*

Intense−0°05' ± 0°30'*

CasterInvite2°45' ± 0°30'*

Intense2°55' ± 0°30'*

Kingpin inclinationInvite12°30' ± 1°30'

Intense12°40' ± 1°30'

Lower arm ball joint starting torque N⋅m0 − 3.9

Protruding length of stabilizer link thread part mm22 ± 1.5

NOTE: *: Difference between right and left wheels must be less than 30'

LUBRICANT

M1332000400152

ItemSpecified lubricantQuantity

Lower arm ball jointLip portion of ball joint coverMultipurpose grease SAE J310,

NLGI No.2 or equivalentAs required

Inside of ball joint cover

Page 191 of 800

Page 194 of 800

LOWER ARM

FRONT SUSPENSION33-12

As for the L.H. lower arm assembly, withdraw the

lower arm bolt (front) with the transmission lift up by

using a transmission jack.

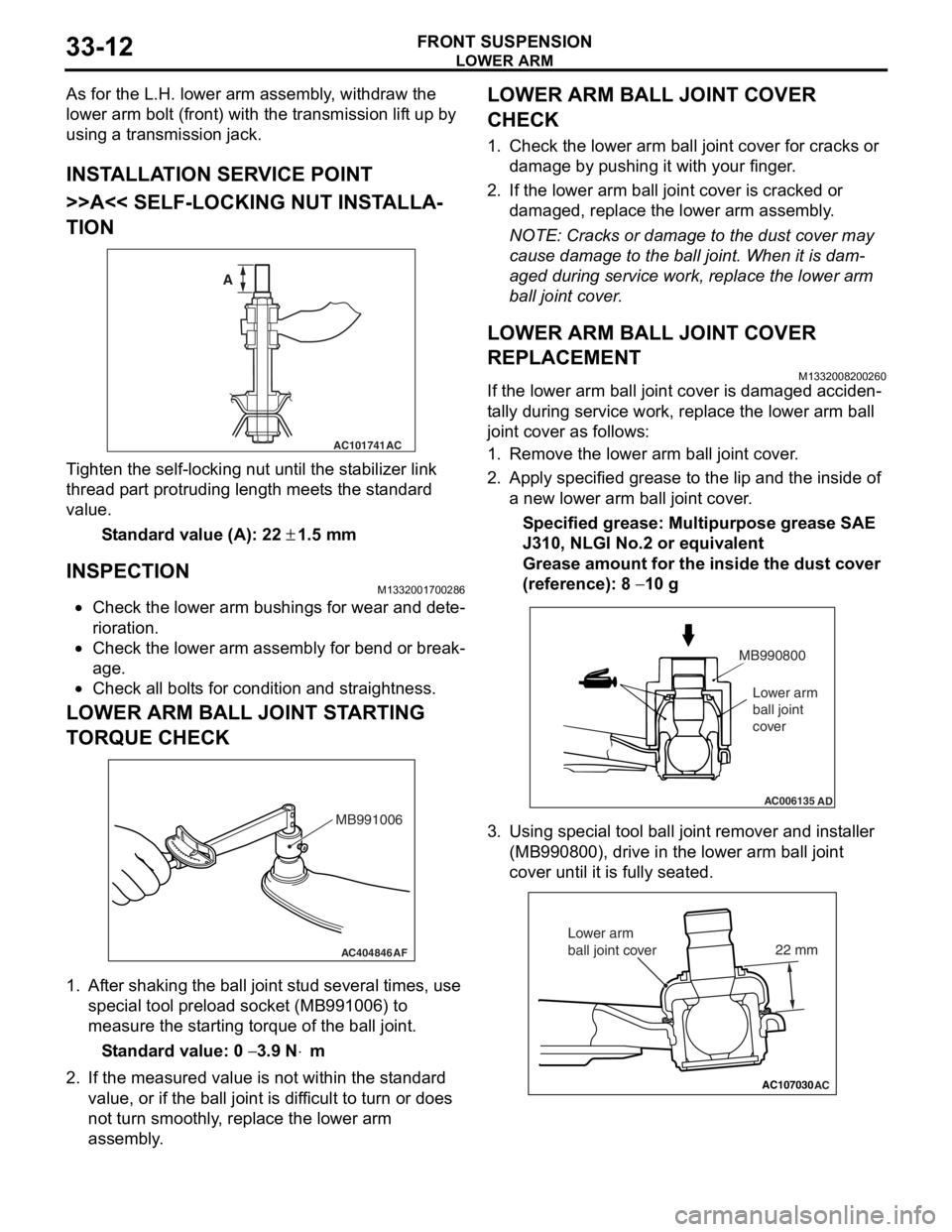

INSTALLATION SERVICE POINT

>>A<< SELF-LOCKING NUT INSTALLA-

TION

AC101741AC

A

T i ghten the self-locking nut un til t he st abilizer link

thread p

a rt protrud i ng length meet s the st a ndard

valu

e.

St andard va lue (A): 22 ± 1.5 m m

INSPECTION

M1332 0017 0028 6

•Check the lower arm bushing s for wear and det e-

riora t i o n.

•Check th e lo we r arm assemb ly for be nd or break-

age.

•Check all bo lt s for c ond ition and straightness.

LOWER ARM BALL JOINT ST ARTING

T

O RQUE CHECK

AC404846AF

MB991006

1.Af ter shaking the b a ll joint stud several times, use

special tool p r eloa d socke t (MB991 006) to

measure the st artin g torqu e of the ball joint.

St andard va lue: 0 − 3.9 N⋅m

2.If the measu r ed value is n o t within the st anda rd

value , or if the ba ll joint is dif f icu l t to t u rn or d oes

no t turn smo o thly , replace the lower a r m

asse mbly .

LOWER ARM BALL JOINT COVER

CHECK

1.Check t he lo we r arm b a ll joint co ver fo r cracks or

d a mag e by push i ng it with your finger .

2.If the lower arm ball joint co ver is cracked or

d a mag ed, rep l ace the lower arm assemb ly .

NOTE: Cracks or dama ge to t he dust co ver may

cause damage to the b a ll join t. When it is dam

-

aged du ring service wo rk, rep l ace the lower arm

b

a ll j o in t cover .

LOWER ARM BALL JOINT COVER

REPLACEMENT

M13320082 0026 0

If the lower arm ball jo int cove r is dama ged acciden-

ta lly durin g ser v ice work, repla c e th e lower arm b a ll

join

t cover as follows:

1.Remove the lower arm ball joint cover .

2.App l y specified grea se to the lip an d the inside of

a new lower arm ba ll join t cover .

Specified grease: Multipurpos e grease SAE

J310,

NLGI No.2 o r e quivale n t

Grease amount for the insi de the du st cove r

(re

f erence): 8

− 10 g

AC006135AD

MB990800

Lower arm

ball joint

cover

3. Using special tool ball joint remover and inst aller

(MB99080 0), drive in the lower arm ball jo int

cove r until it is fu lly se ated.

AC107030AC

22 mm

Lower arm

ball joint cover

Page 198 of 800

STABILIZER BAR

FRONT SUSPENSION33-16

>>B<< SELF-LOCKING NUT

INSTALLATION

AC101741AC

A

Ti ghten the self-locking nut un til t he st ab ilizer link

thread

p a rt protrud i ng length mee t s the st a ndard

value.

St andard va lue (A): 22 ± 1.5 m m

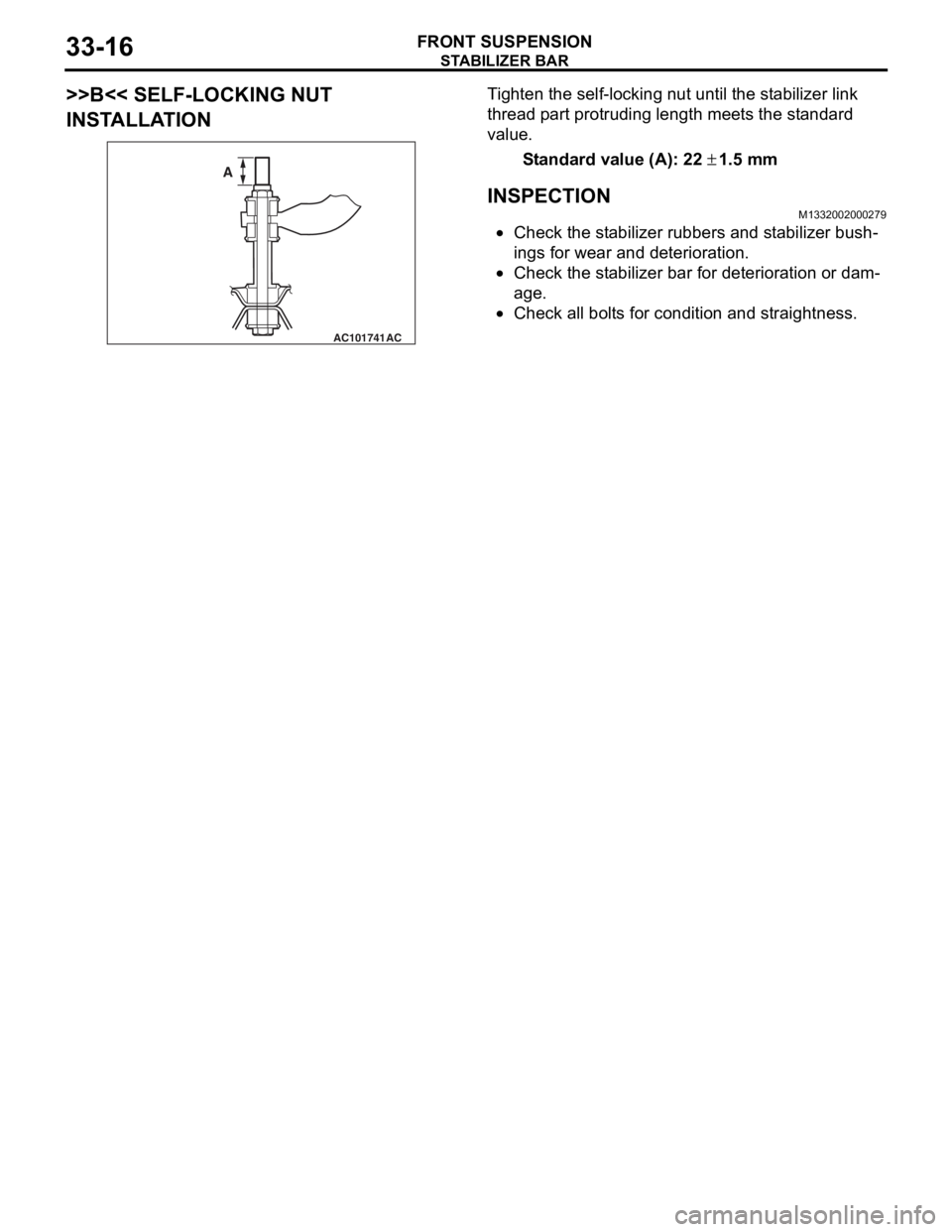

INSPECTION

M1332 0020 0027 9

•Check the st abilizer rubb ers a nd st ab ilizer b u sh-

ings fo r wear and deterioration.

•Check the st abilizer bar for dete r iorat i on o r dam-

age.

•Check all bo lt s for cond itio n and straightness.

Page 201 of 800

SERVICE SPECIFICATIONS

REAR SUSPENSION34-3

SPECIFICATION

COIL SPRING

ItemSedanWagon

InviteIntenseInviteIntense

Wire diameter mm10101010

Average diameter mm78 − 9078 − 9078 − 9078 − 90

Free length mm359331377368

SERVICE SPECIFICATIONS

M1341000300733

ItemStandard value

Camber (Difference between right and left within 30') −0°40' ± 0°30'

Toe-inAt the centre of tyre tread mm3 ± 2

Toe-angle (per wheel)0°08' ± 0°05'

Thrust angle0°00' ± 0°09'

Control link pillow ball bushing starting torque

Upper arm pillow ball bushing starting torque

Lower arm pillow ball bushing starting torque N⋅m0.5 − 3.0

Protruding length of stabilizer link bolt mm6 − 8

Stabilizer link ball joint continuous turning torque N⋅m0.5 − 1.5

LUBRICANT

M1341000400172

ItemSpecified lubricantQuantity

Stabilizer link ball joint (inside of dust cover)Multipurpose grease SAE J310, NLGI No.2

or equivalentAs required

Page 207 of 800

Page 211 of 800

Page 213 of 800

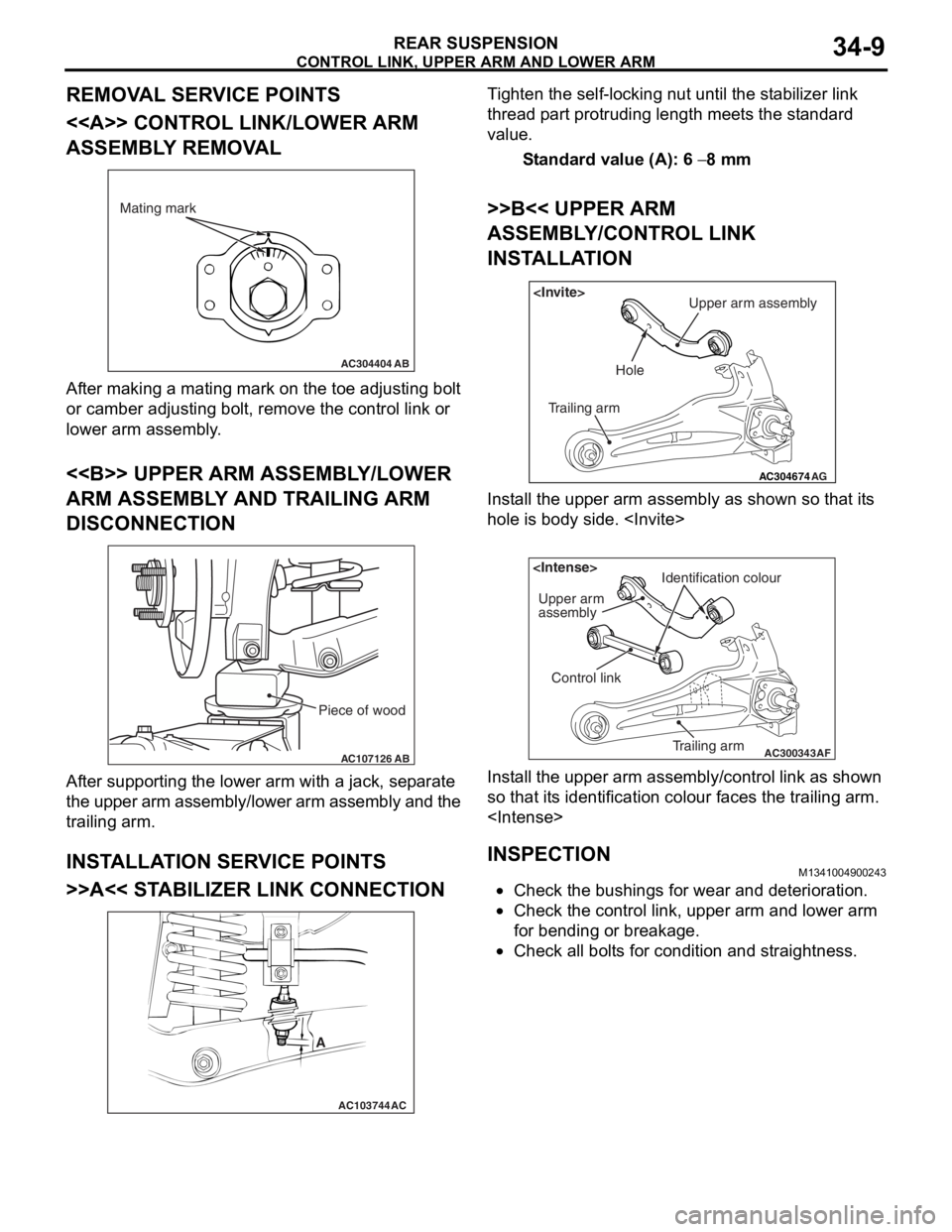

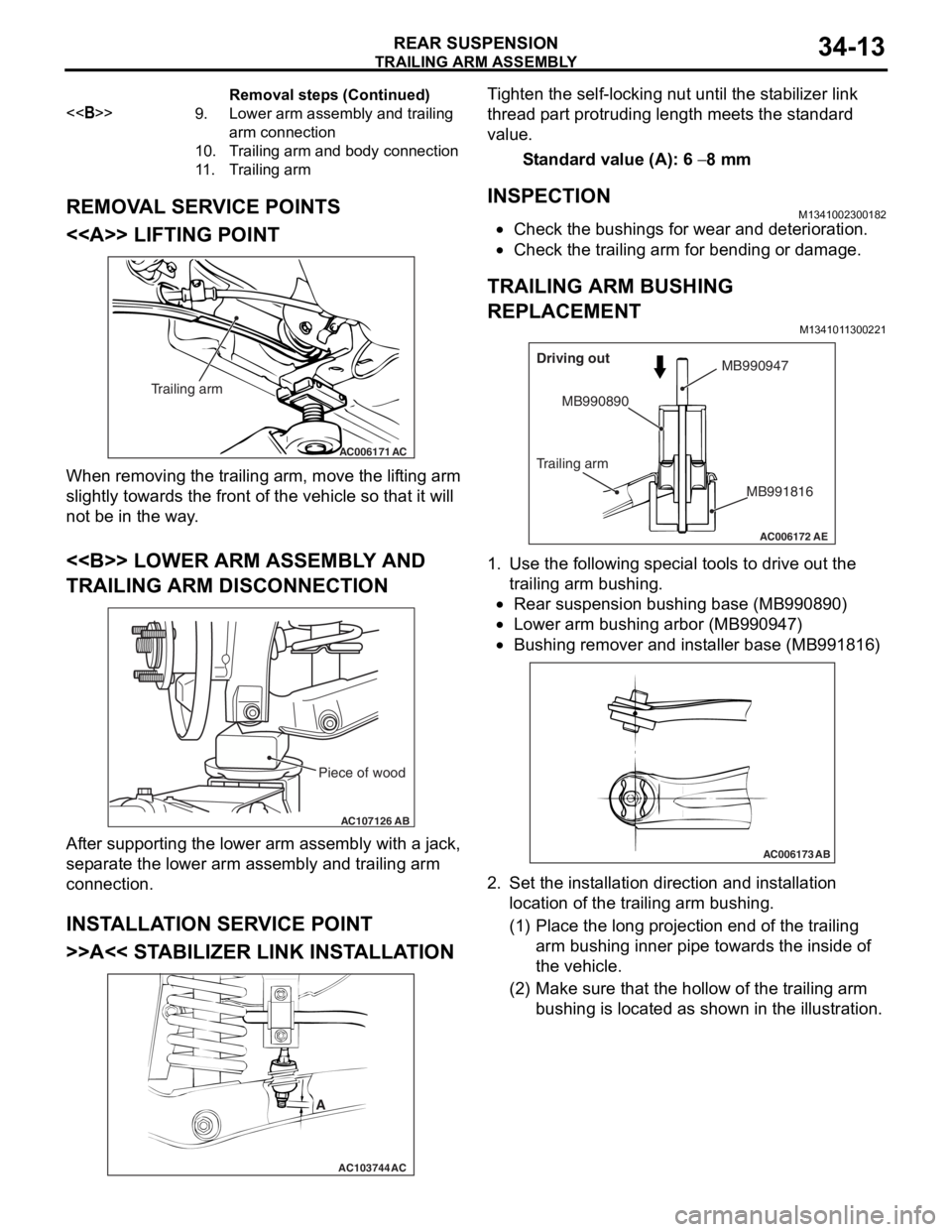

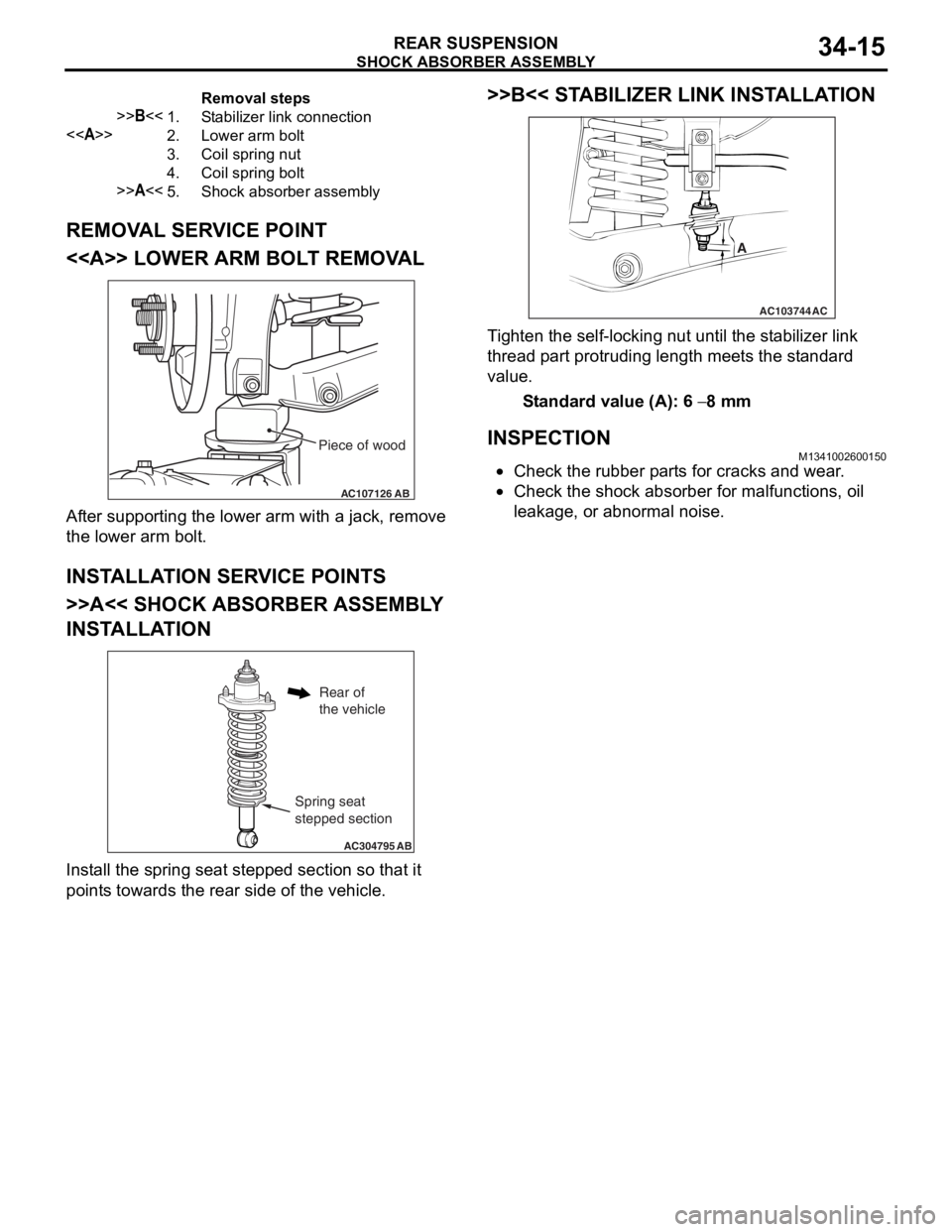

Removal steps

>>B<<1.Stabilizer link connection

<>2.Lower arm bolt

3.Coil spring nut

4.Coil spring bolt

>>A<<5.Shock absorber assembly

SHOCK ABSORBER ASSEMBLY

REAR SUSPENSION34-15

REMOVAL SERVICE POINT

<> LOWER ARM BOLT REMOVAL

AC107126AB

Piece of wood

After suppo rting the lo we r arm with a jack, remove

the lo

we r arm b o lt.

INSTALLA T ION SER VICE POINT S

>>A<< SHOCK ABSORBER ASSEMBL Y

INST

ALLA TION

AC304795 AB

Spring seat

stepped section

Rear of

the vehicle

Install the sprin g se at ste pped section so th at it

point

s towards the rea r side of th e ve hicle.

>>B<< STABILIZER LINK INST ALLA TION

AC103744

A

AC

Ti ghten the self-locking nut un til t he st ab ilizer link

thread

p a rt protrud i ng length mee t s the st a ndard

value.

St andard va lue (A): 6 − 8 mm

INSPECTIONM13410026 0015 0

•Check the rubbe r p a rt s for cracks a nd wear .

•Check the sho c k abso r ber for malfunct i ons, oil

le

akag e, or a bnormal no ise .

Page 217 of 800

STABILIZER BAR

REAR SUSPENSION34-19

STABILIZER BAR

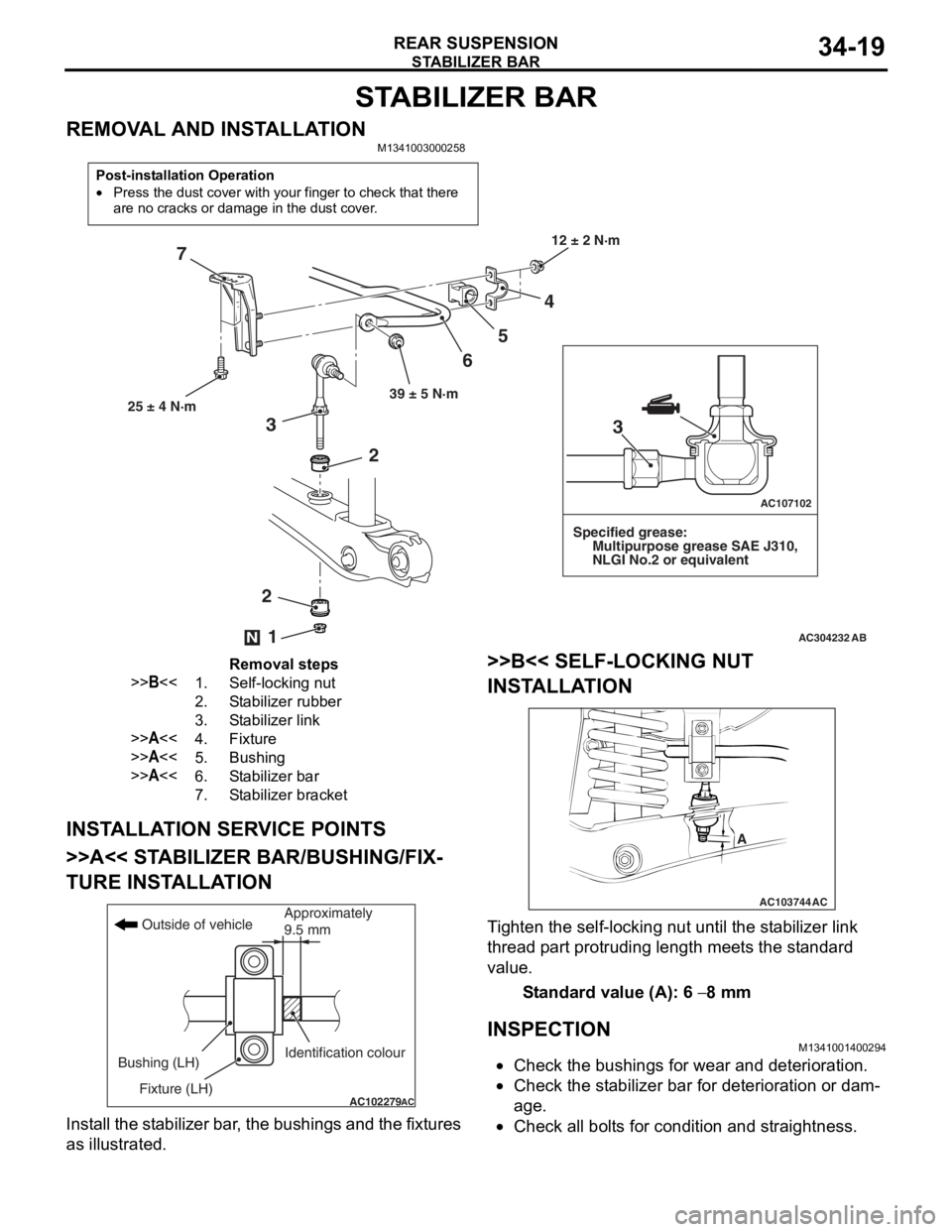

REMOVAL AND INSTALLATIONM1341003000258

Post-installation Operation

•Press the dust cover with your finger to check that there

are no cracks or damage in the dust cover.

AC304232

AC107102

AB

12 ± 2 N·m

39 ± 5 N·m

4

5

6

7

25 ± 4 N·m

Specified grease:

Multipurpose grease SAE J310,

NLGI No.2 or equivalent

2

2

3

1N

3

Removal steps

>>B<<1.Self-locking nut

2.Stabilizer rubber

3.Stabilizer link

>>A<<4.Fixture

>>A<<5.Bushing

>>A<<6.Stabilizer bar

7.Stabilizer bracket

INST ALLA T ION SER VICE POINT S

>>A<< STABILIZER BAR/BUSHING/FIX-

TURE INST ALLA TION

AC102279AC

Outside of vehicle

Bushing (LH) Fixture (LH) Identification colourApproximately

9.5 mm

Inst

all the st abilizer bar , th e bushings and the fixtures

as illustrate

d.

>>B<< SELF-LOCKING NUT

INST

ALLA TION

AC103744

A

AC

Ti ghten the self-locking nut un til t he st ab ilizer link

thread

p a rt protrud i ng length mee t s the st a ndard

value.

St andard va lue (A): 6 − 8 mm

INSPECTION

M13410014 0029 4

•Check the bushing s for wea r and d e terio r ation .

•Check the st abilizer bar for dete r iorat i on o r dam-

age.

•Check all bo lt s for cond itio n and straightness.