motor MITSUBISHI LANCER IX 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 32 of 800

TROUBLESHOOTING

ENGINE COOLING14-18

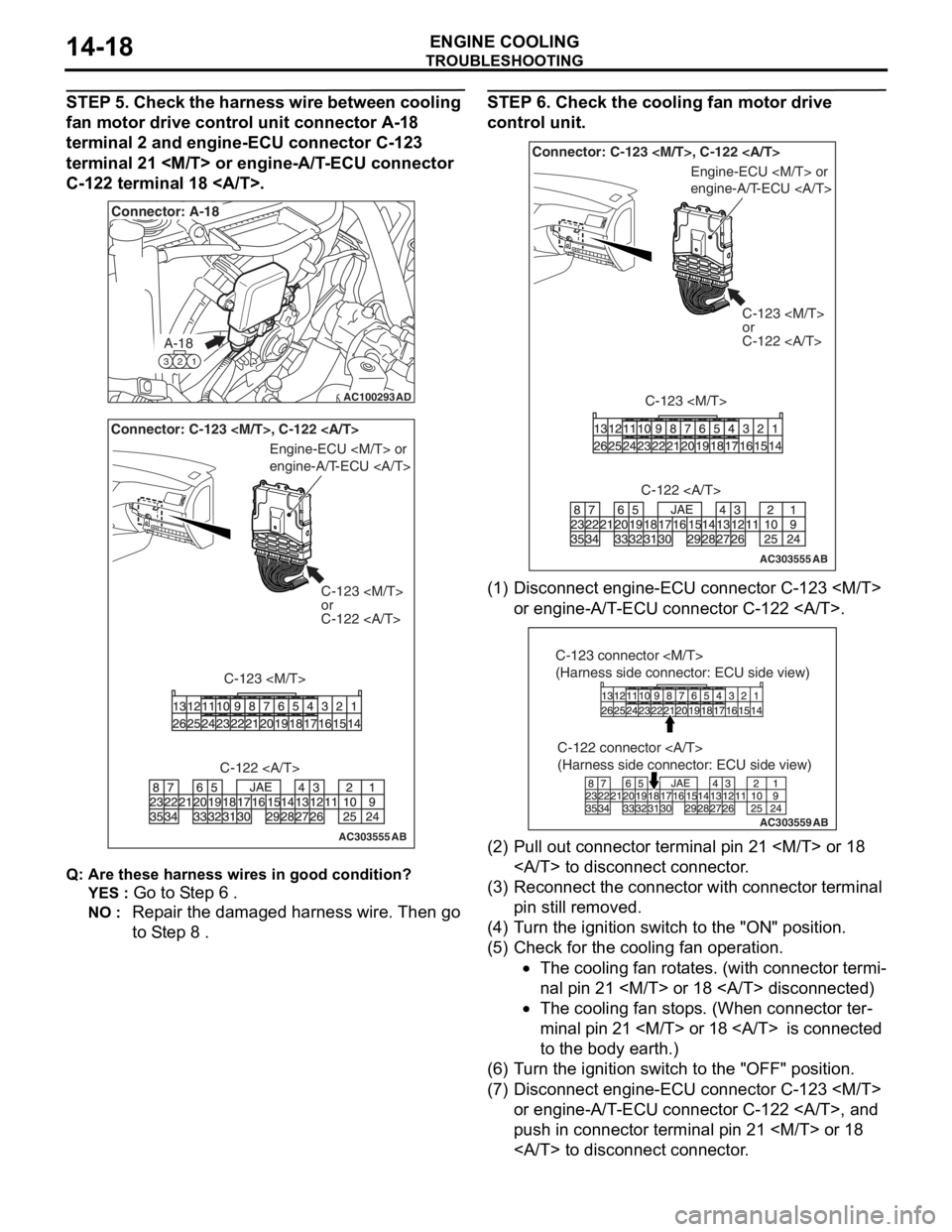

STEP 5. Check the harness wire between cooling

fan motor drive control unit connector A-18

terminal 2 and engine-ECU connector C-123

terminal 21

C-122 terminal 18 .

AC100293

A-18

321

Connector: A-18

AD

AC303555AB

Connector: C-123

or

C-122

C-123

Engine-ECU

engine-A/T-ECU

C-122

Q: Are t h es e har n es s wires in goo d cond it ion?

YES : Go to S t ep 6 .

NO : Repa ir the dama ged harness wire. Then go

to S

t ep 8

.

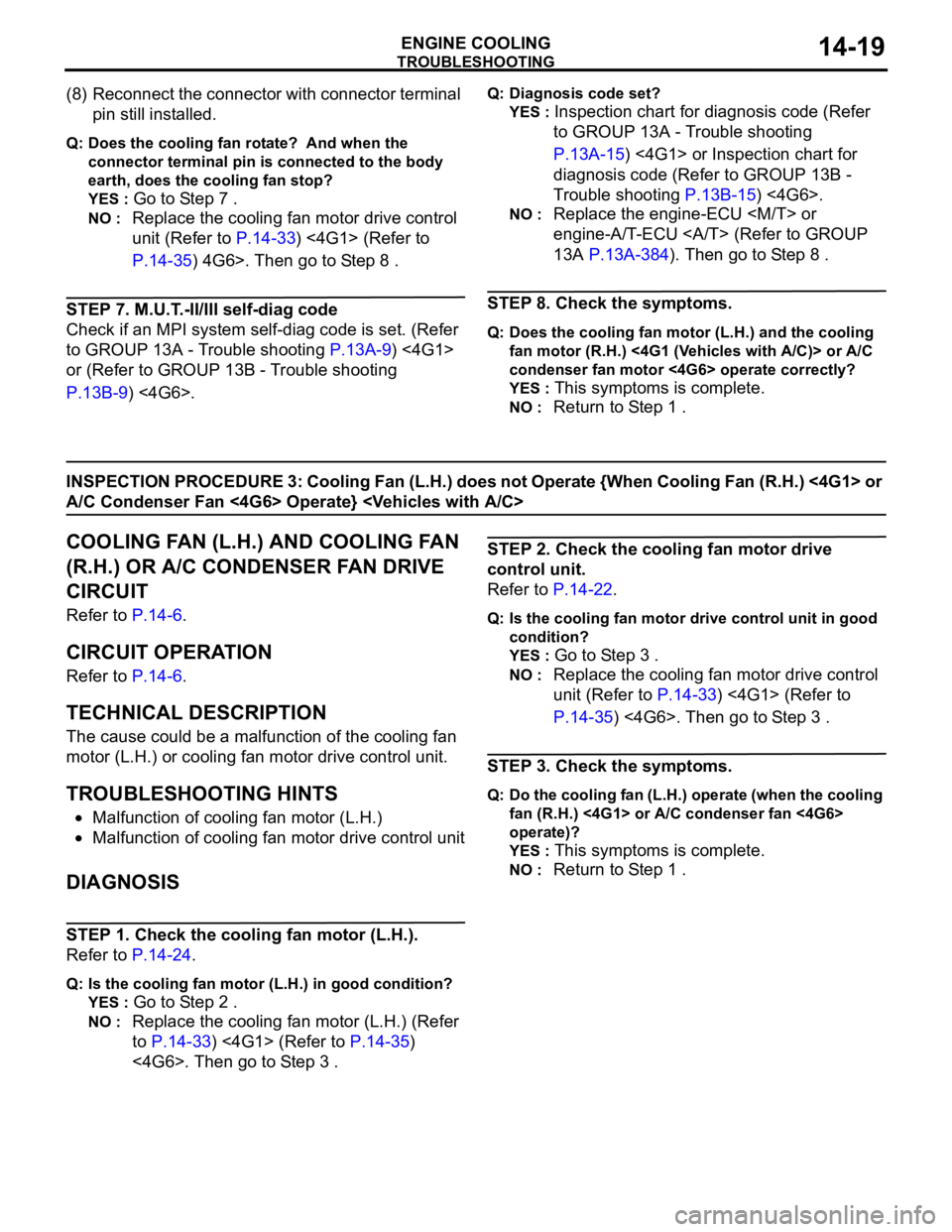

STEP 6 . Check the cooling fan moto r d r iv e

control unit.

AC303555AB

Connector: C-123

C-123

or

C-122

C-123

Engine-ECU

engine-A/T-ECU

C-122

(1) D isconn ect e ngin e -ECU conne ctor C-12 3

or e ngine -A/T -ECU conne ctor C-12 2 .

AC303559

C-122 connector

(Harness side connector: ECU side view)

AB

C-123 connector

(Harness side connector: ECU side view)

(2)P ull out conne ctor terminal p i n 21

to discon nect conn ector .

(3)R econnect the con necto r with conn ector te rmin al

pin still removed.

(4)T urn t he ig nition switch t o the "ON" positio n.

(5)C heck fo r the cooling fan opera t ion.

•The cooling fan ro t a t e s. (with conne ctor termi-

nal pi n 21

•The cooling fan stop s. (When con necto r ter-

minal pi n 21

to the

body earth.)

(6)T urn t he ig nition switch t o the "OFF" po sit i on.

(7)D isconn ect e ngin e -ECU conne ctor C-12 3

or e ngine -A/T -ECU conne ctor C-12 2 , a nd

push in con nect o r terminal pin 21

to discon nect conn ector .

Page 33 of 800

TROUBLESHOOTING

ENGINE COOLING14-19

(8) Reconnect the connector with connector terminal

pin still installed.

Q: Does the cooling fan rotate? And when the

connector terminal pin is connected to the body

earth, does the cooling fan stop?

YES : Go to Step 7 .

NO : Replace the cooling fan motor drive control

unit (Refer to

P.14-33) <4G1> (Refer to

P.14-35) 4G6>. Then go to Step 8 .

STEP 7. M.U.T.-II/III self-diag code

Check if an MPI system self-diag code is set. (Refer

to GROUP 13A - Trouble shooting

P.13A-9) <4G1>

or (Refer to GROUP 13B - Trouble shooting

P.13B-9) <4G6>.

Q: Diagnosis code set?

YES : Inspection chart for diagnosis code (Refer

to GROUP 13A - Trouble shooting

P.13A-15) <4G1> or Inspection chart for

diagnosis code (Refer to GROUP 13B -

Trouble shooting

P.13B-15) <4G6>.

NO : Replace the engine-ECU

engine-A/T-ECU (Refer to GROUP

13A

P.13A-384). Then go to Step 8 .

STEP 8. Check the symptoms.

Q: Does the cooling fan motor (L.H.) and the cooling

fan motor (R.H.) <4G1 (Vehicles with A/C)> or A/C

condenser fan motor <4G6> operate correctly?

YES : This symptoms is complete.

NO : Return to Step 1 .

INSPECTION PROCEDURE 3: Cooling Fan (L.H.) does not Operate {When Cooling Fan (R.H.) <4G1> or

A/C Condenser Fan <4G6> Operate}

COOLING FAN (L.H.) AND COOLING FAN

(R.H.) OR A/C CONDENSER FAN DRIVE

CIRCUIT

Refer to P.14-6.

CIRCUIT OPERATION

Refer to P.14-6.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the cooling fan

motor (L.H.) or cooling fan motor drive control unit.

TROUBLESHOOTING HINTS

•Malfunction of cooling fan motor (L.H.)

•Malfunction of cooling fan motor drive control unit

DIAGNOSIS

STEP 1. Check the cooling fan motor (L.H.).

Refer to P.14-24.

Q: Is the cooling fan motor (L.H.) in good condition?

YES : Go to Step 2 .

NO : Replace the cooling fan motor (L.H.) (Refer

to

P.14-33) <4G1> (Refer to P.14-35)

<4G6>. Then go to Step 3 .

STEP 2. Check the cooling fan motor drive

control unit.

Refer to P.14-22.

Q: Is the cooling fan motor drive control unit in good

condition?

YES : Go to Step 3 .

NO : Replace the cooling fan motor drive control

unit (Refer to

P.14-33) <4G1> (Refer to

P.14-35) <4G6>. Then go to Step 3 .

STEP 3. Check the symptoms.

Q: Do the cooling fan (L.H.) operate (when the cooling

fan (R.H.) <4G1> or A/C condenser fan <4G6>

operate)?

YES : This symptoms is complete.

NO : Return to Step 1 .

Page 34 of 800

TROUBLESHOOTING

ENGINE COOLING14-20

INSPECTION PROCEDURE 4: Cooling Fan (R.H.) <4G1> or A/C Condenser Fan <4G6> does not

Operate {When Cooling Fan (L.H.) Operate}

COOLING FAN (L.H.) AND COOLING FAN

(R.H.) OR A/C CONDENSER FAN DRIVE

CIRCUIT

Refer to P.14-6.

CIRCUIT OPERATION

Refer to P.14-6.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the cooling fan

motor (R.H.) <4G1> or A/C condenser fan motor

<4G6> or cooling fan motor drive control unit.

TROUBLESHOOTING HINTS

•Malfunction of cooling fan motor (R.H.) <4G1> or

A/C condenser fan motor <4G6>

•Malfunction of cooling fan motor drive control unit

DIAGNOSIS

STEP 1. Check the cooling fan motor (R.H.)

<4G1> or A/C condenser fan motor <4G6>.

Cooling fan motor (R.H.) check. (Refer to P.14-24)

<4G1>.

A/C condenser fan motor check. (Refer to GROUP

55

P.55A-91) <4G6>.

Q: Is the cooling fan motor (R.H.) <4G1> or A/C

condenser fan motor <4G6> in good condition?

YES : Go to Step 2 .

NO : Replace the cooling fan motor (R.H.) (Refer

to

P.14-33) <4G1> or A/C condenser fan

motor (Refer to GROUP 55 P.55A-90)

<4G6>. Then go to Step 3 .

STEP 2. Check the cooling fan motor drive

control unit.

Refer to P.14-22.

Q: Is the cooling fan motor drive control unit in good

condition?

YES : Go to Step 3 .

NO : Replace the cooling fan motor drive control

unit (Refer to

P.14-33) <4G1> (Refer to

P.14-35) <4G6>. Then go to Step 3 .

STEP 3. Check the symptoms.

Q: Do the cooling fan (R.H.) <4G1> or A/C condenser

fan <4G6> operate (when the cooling fan (L.H.)

operate)?

YES : This symptoms is complete.

NO : Return to Step 1 .

Page 36 of 800

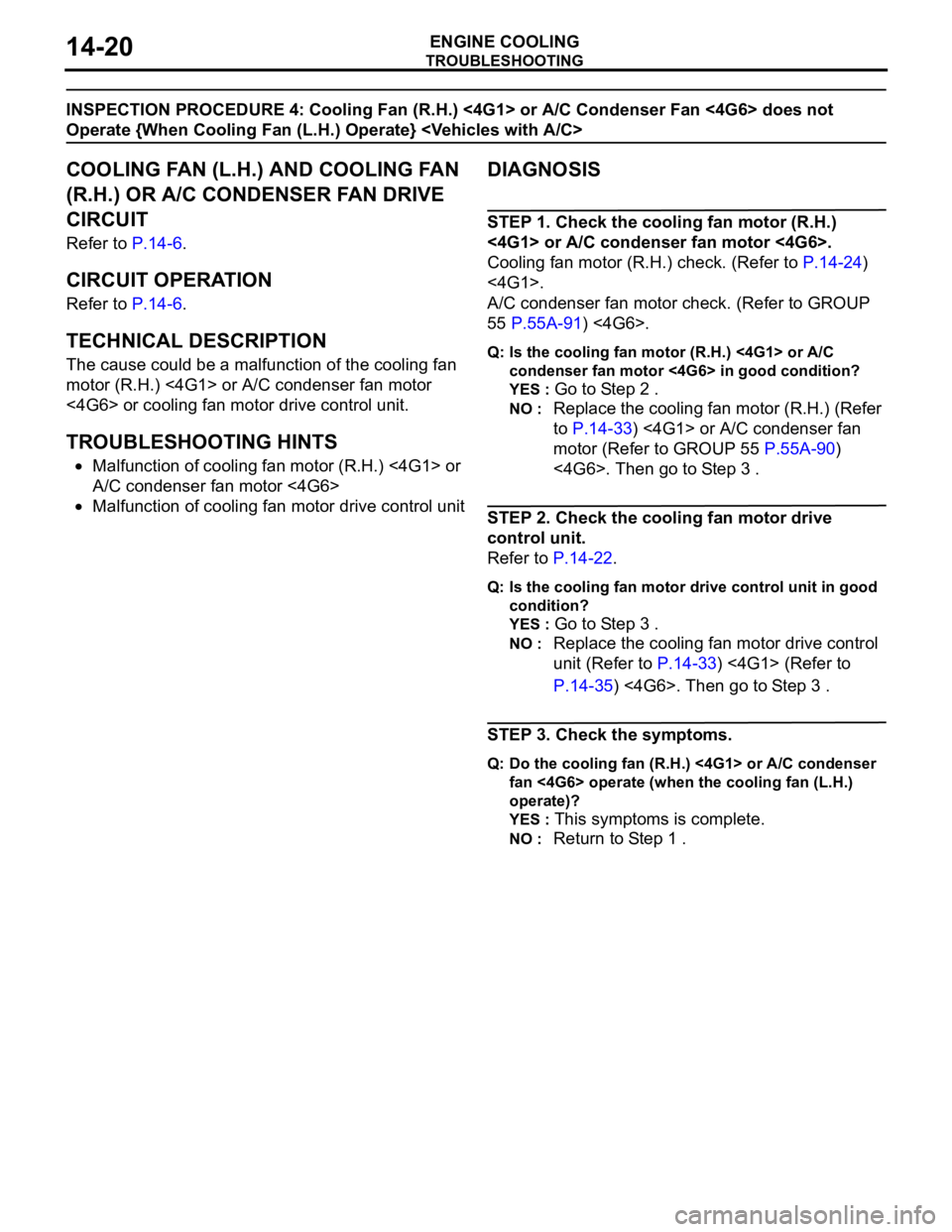

AC200625

Cylinder block

drain plug

AC

ON-VEHICLE SER VICE

ENGINE COOLING14-22

5.App l y the designa ted sealant to t he scre w area of

th e cylin der block drain plu g , and then tighten to

th e st and ard torq ue.

Sp e c ified s ealant: 3 M Nut Loc king Part

No. 4171 o r e quivale n t

Ti ghtenin g torque:

40 ± 5 N⋅m <4G1>

44 ± 5 N⋅m <4G6>

6.Securely tighten t he drain plug of t he radiator .

7.Reinst all the ra diato r con denser t ank.

CAUTION

Do not use alcohol or methanol anti-freeze or any

engine coolants mixed with alcohol or methanol

anti-freeze. The use of an improper anti-freeze

can cause corrosion of the aluminium compo

-

nents.

AC303612AB

MB991871

AIR HOSE

8. By referring to the section on coolant, select an

appropriate concentration for safe operating

temperature within the range of 30 to 60%. Use

special tool LLC changer (MB991871) to refill the

coolant. A convenient mixture is a 50% water and

50% antifreeze solution (freezing point:

−31°C).

Recommended antifreeze: DIAQUEEN SUPER LONG LIFE COOLANT or equivalent

Quantity:

5.0 L <4G1>

7.0 L <4G6>

NOTE: For how to use special tool MB991871,

refer to its manufacturer’s instructions.

9. Reinstall the radiator cap.

10.Start the engine and let it warm up until the thermostat opens.

11.After repeatedly revving the engine up to 3,000 r/min several times, then stop the engine.

12.Remove the radiator cap after the engine has become cold, and pour in coolant up to the brim.

Reinstall the cap.

CAUTION

Do not overfill the radiator condenser tank.

13.Add coolant to the radiator condenser tank between the "F" and "L" mark if necessary.

CONCENTRATION MEASUREMENT

M1141001100352

Measure the temperature and specific gravity of the

engine coolant to check the antifreeze concentration.

Standard value: 30 − 60% (allowable concentra-

tion range)

Recommended antifreeze: DIAQUEEN SUPER

LONG LIFE COOLANT or equivalent

CAUTION

If the concentration of the anti-freeze is below

30%, the anti-corrosion property will be

adversely affected. In addition, if the concentra

-

tion is above 60%, both the anti-freezing and

engine cooling properties will decrease, affecting

the engine adversely. For these reasons, be sure

to maintain the concentration level within the

specified range.

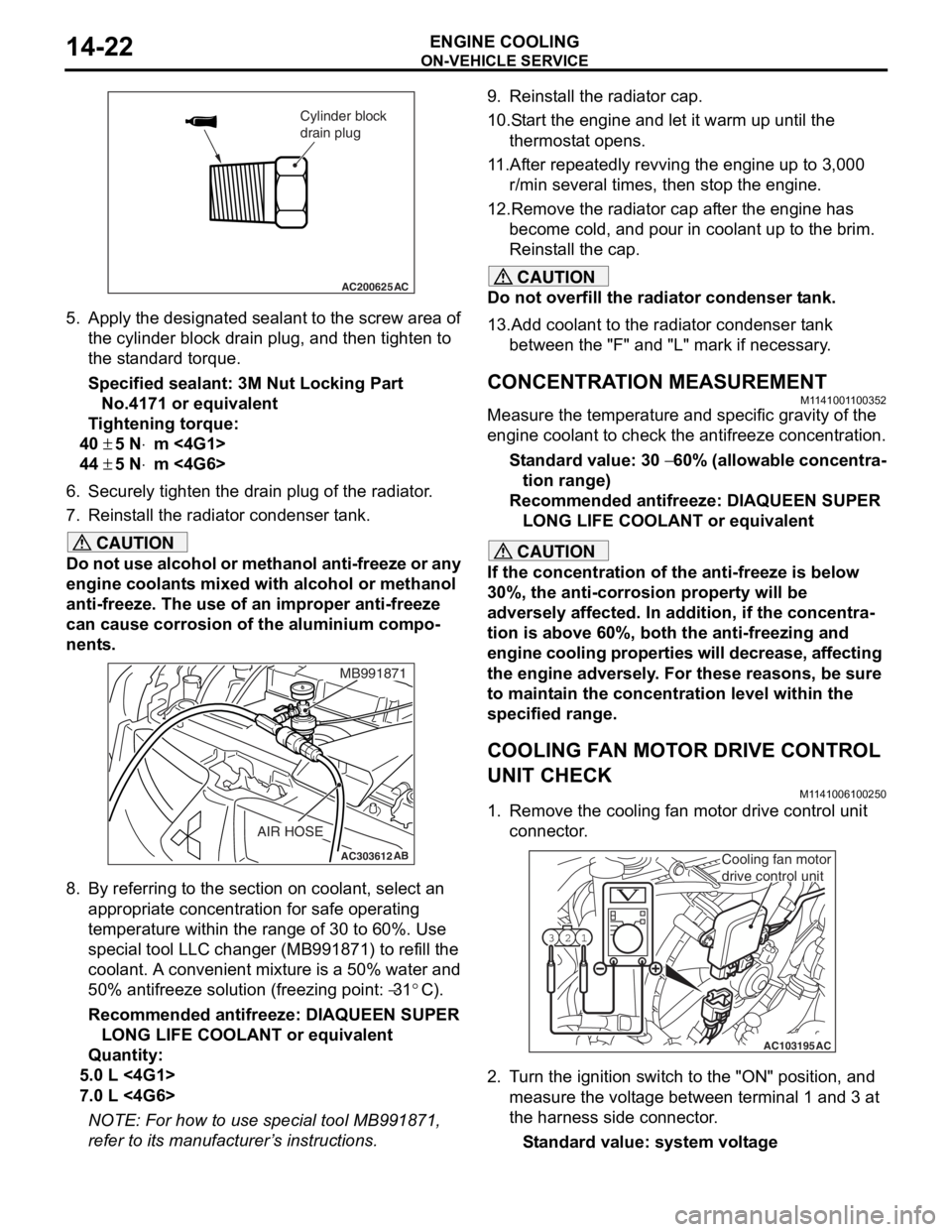

COOLING FAN MOTOR DRIVE CONTROL

UNIT CHECK

M1141006100250

1. Remove the cooling fan motor drive control unit connector.

AC103195

Y1716AU

1

23

AC

Cooling fan motor

drive control unit

2. Turn the ignition switch to the "ON" position, and

measure the voltage between terminal 1 and 3 at

the harness side connector.

Standard value: system voltage

Page 37 of 800

ON-VEHICLE SERVICE

ENGINE COOLING14-23

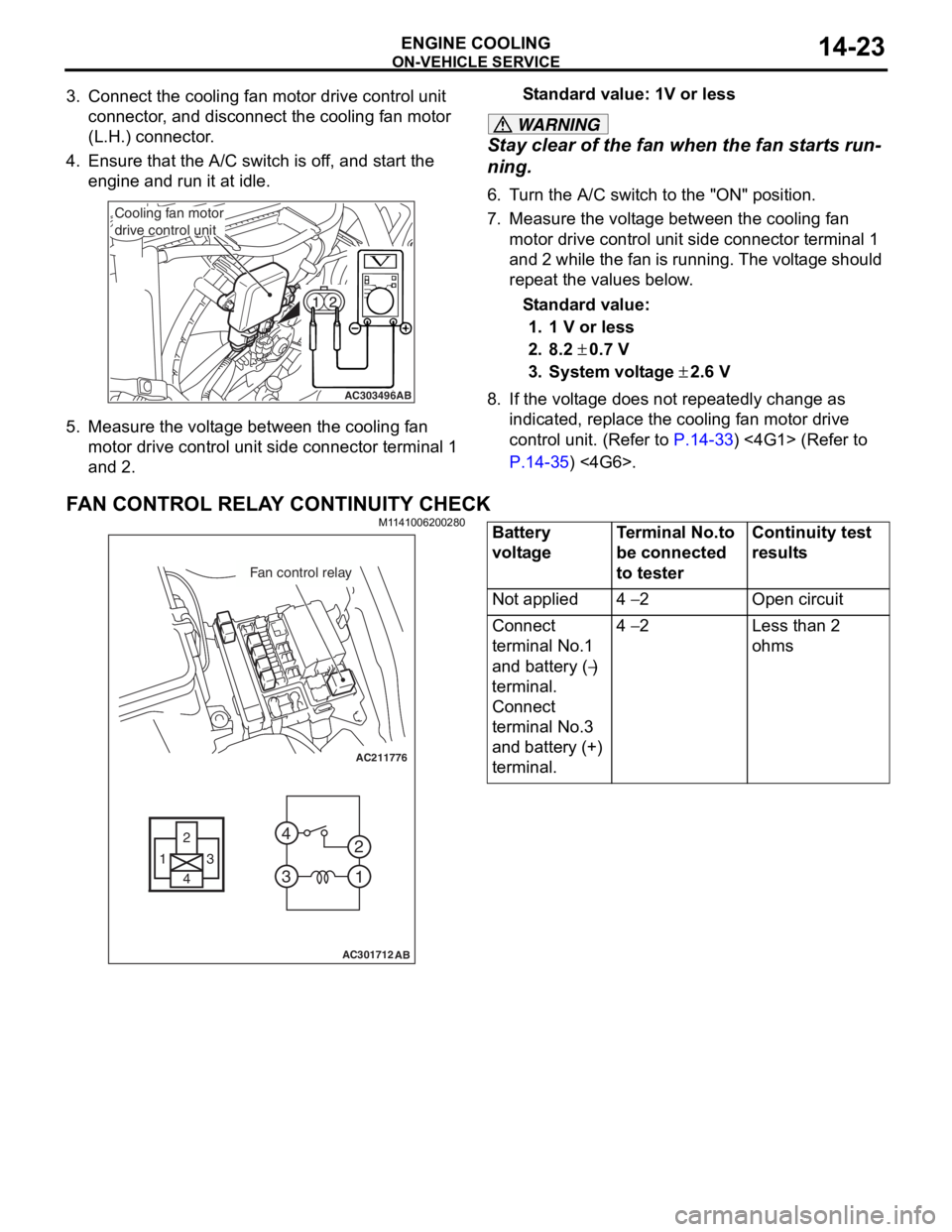

3. Connect the cooling fan motor drive control unit connector, and disconnect the cooling fan motor

(L.H.) connector.

4. Ensure that the A/C switch is off, and start the engine and run it at idle.

AC303496AB

Cooling fan motor

drive control unit

5.Measure the volt ag e betwee n the cooling f an

motor d r ive cont rol un it side conne ctor t e rminal 1

an d 2.

St andard va lue: 1V or le ss

WARNING

Stay clear of the fan when the fan starts run-

ning.

6. Turn the A/C switch to the "ON" position.

7. Measure the voltage between the cooling fan

motor drive control unit side connector terminal 1

and 2 while the fan is running. The voltage should

repeat the values below.

Standard value:

1. 1 V or less

2. 8.2 ± 0.7 V

3. System voltage ± 2.6 V

8. If the voltage does not repeatedly change as indicated, replace the cooling fan motor drive

control unit. (Refer to

P.14-33) <4G1> (Refer to

P.14-35) <4G6>.

FAN CONTROL RELAY CONTINUITY CHECK

M1141006200280

AC211776

13

4 2

3 4

1

2

AC301712

Fan control relay

AB

Battery

voltageTerminal No.to

be connected

to testerContinuity test

results

Not applied4 − 2Open circuit

Connect

terminal No.1

and battery (

−)

terminal.

Connect

terminal No.3

and battery (+)

terminal.

4 − 2Less than 2

ohms

Page 38 of 800

THERMOSTAT

ENGINE COOLING14-24

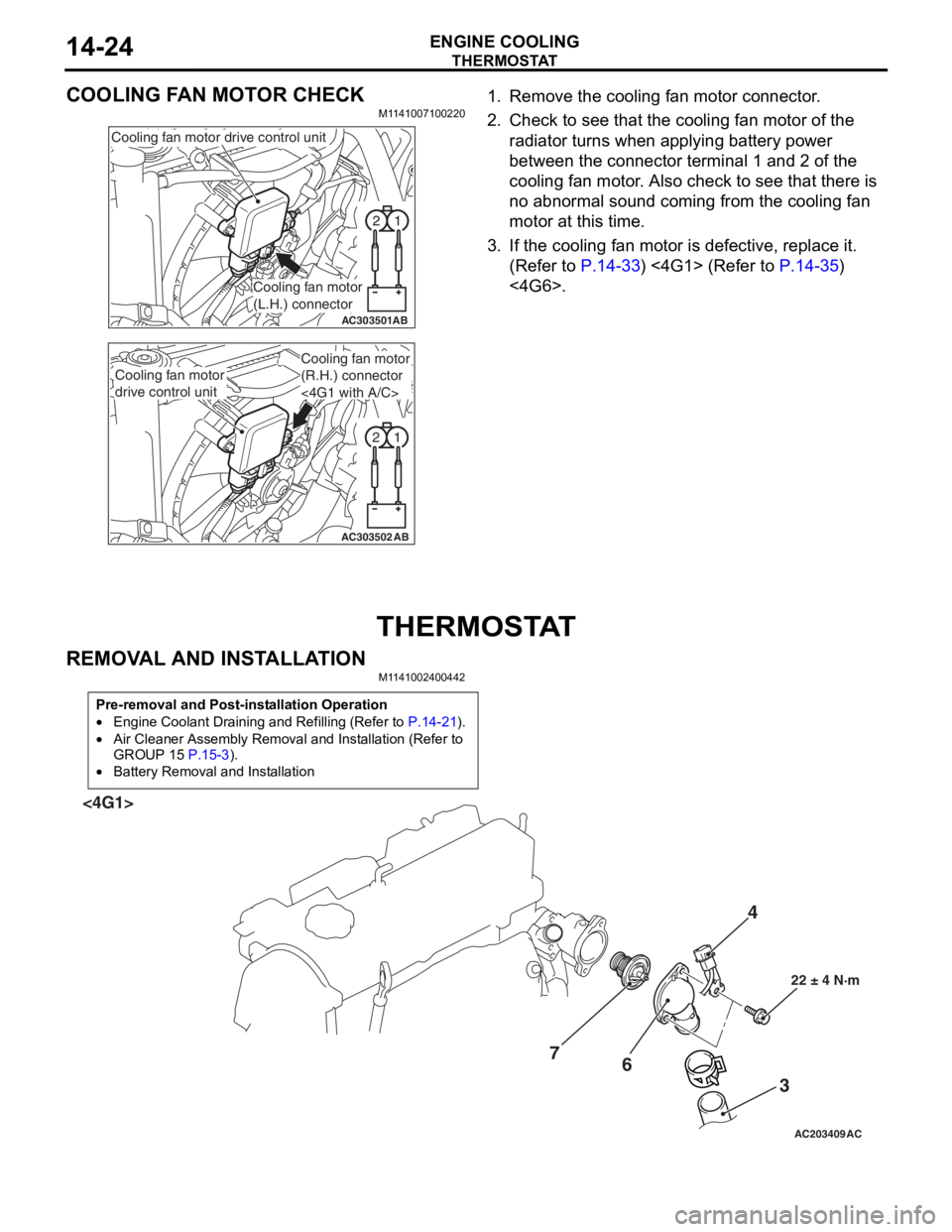

COOLING FAN MOTOR CHECK

M1141007100220

1

2

AC303501AB

Cooling fan motor drive control unit

Cooling fan motor

(L.H.) connector

1

2

AC303502AB

Cooling fan motor

drive control unit

Cooling fan motor

(R.H.) connector

<4G1 with A/C>

1. Remove the cooling fa n mot o r co nnector .

2.Check t o see that t he co oling fan motor of the

ra diato r turns wh en ap plying b a ttery power

b e tween th e con nect o r terminal 1 and 2 of t he

cooling fa n mo tor . Also ch eck to see tha t there is

n o abno rmal soun d co min g from the cooling fa n

motor a t this time.

3.If the cooling fan moto r is defective, replace it.

(Refe r to

P.14-33) <4G1> (Refer to P.14-35)

<4G6>.

THERMOSTA T

REMOVA L AND INST ALLA TION

M1141 0024 0044 2

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Refilling (Refer to P.14-21).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15

P.15-3).

•Battery Removal and Installation

AC203409AC

4

3

6

7

22 ± 4 N·m

<4G1>

Page 48 of 800

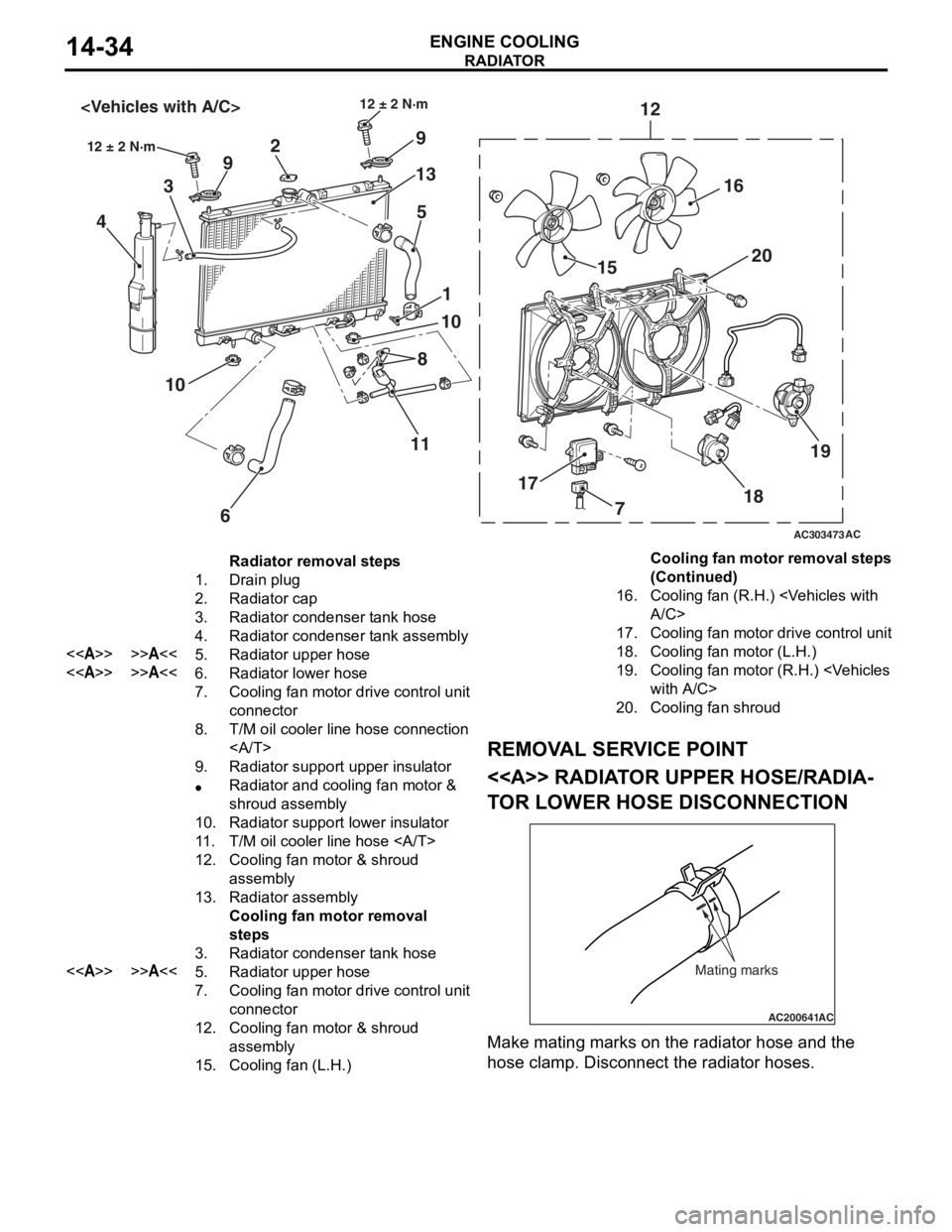

AC303473

18

17 15

20

12

9

13

5

2

9

3

4

1

10

6

10

12 ± 2 N·m

AC

12 ± 2 N·m

16

19

8

11

7

Radiator removal steps

1.Drain plug

2.Radiator cap

3.Radiator condenser tank hose

4.Radiator condenser tank assembly

<>>>A<<5.Radiator upper hose

<>>>A<<6.Radiator lower hose

7.Cooling fan motor drive control unit

connector

8.T/M oil cooler line hose connection

9.Radiator support upper insulator

•Radiator and cooling fan motor &

shroud assembly

10.Radiator support lower insulator

11 .T/M oil cooler line hose

12.Cooling fan motor & shroud

assembly

13.Radiator assembly

Cooling fan motor removal

steps

3.Radiator condenser tank hose

<>>>A<<5.Radiator upper hose

7.Cooling fan motor drive control unit

connector

12.Cooling fan motor & shroud

assembly

15.Cooling fan (L.H.)

16.Cooling fan (R.H.)

17.Cooling fan motor drive control unit

18.Cooling fan motor (L.H.)

19.Cooling fan motor (R.H.)

20.Cooling fan shroud

RADIA T OR

ENGINE COOLING14-34

REMOV A L SER VICE POINT

<> RADIAT OR UPPER HOSE/RADIA-

TO R LOW E R HOSE DISCONNECTION

AC200641AC

Mating marks

Make mating marks on the rad i ator hose and th e

hose

cla m p. Disconnect the ra diat or hoses.

Cooling fan motor removal steps

(Continued)

Page 49 of 800

RADIATOR

ENGINE COOLING14-35

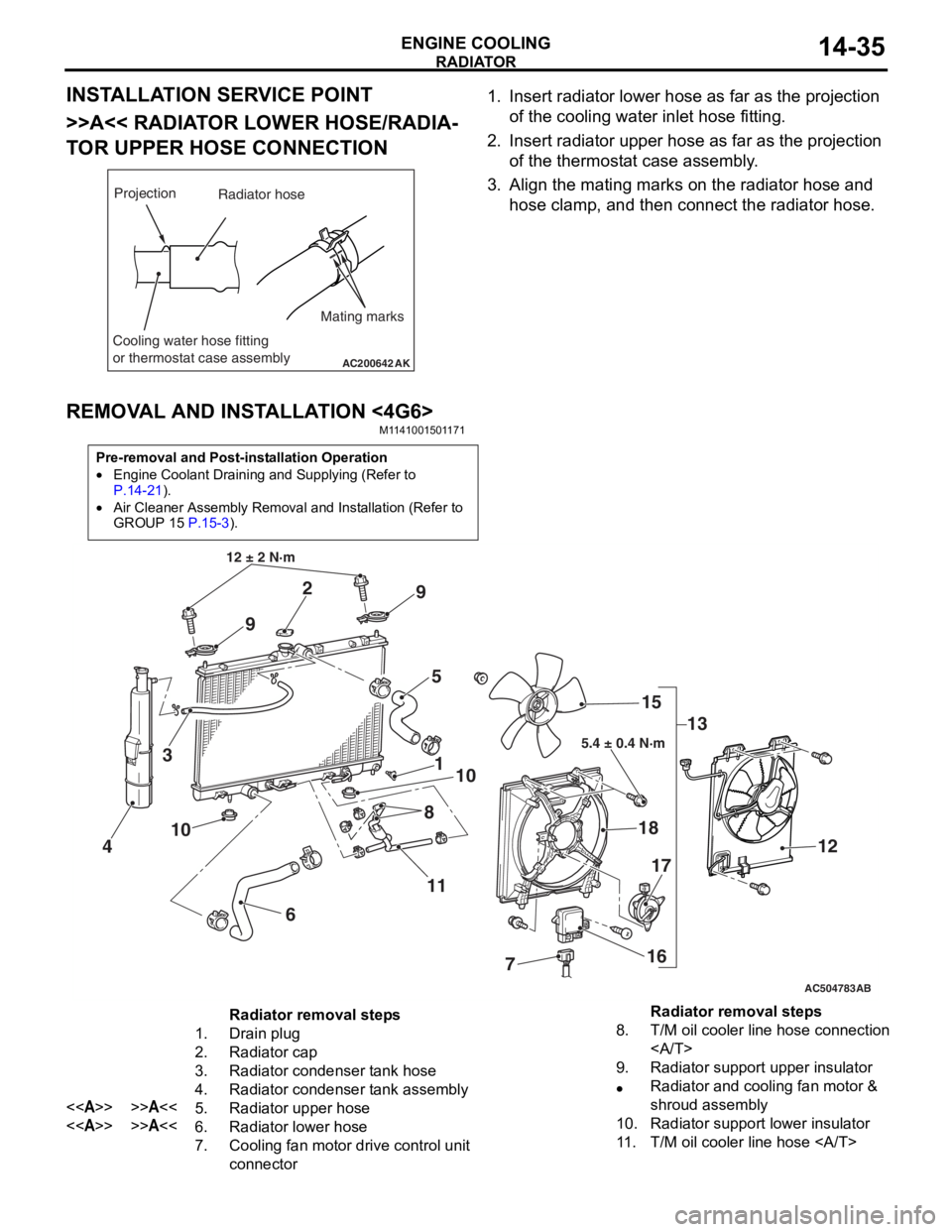

INSTALLATION SERVICE POINT

>>A<< RADIATOR LOWER HOSE/RADIA-

TOR UPPER HOSE CONNECTION

AC200642

Mating marks

Projection

Cooling water hose fitting

or thermostat case assembly

AK

Radiator hose

1.In sert ra diato r lower h o se as fa r as th e projection

o f the cooling wate r inlet hose fit t ing.

2.In sert radia t or up per h o se as far a s t he pro j ection

o f the th ermost at ca se asse mbly .

3.Align th e ma ting marks on the rad i ator hose and

h o se clamp, an d then conn ect the radiator h o se.

REMOVA L AND INST ALLA TION <4G6>

M11 4100 1501 17 1

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Supplying (Refer to

P.14-21).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15

P.15-3).

AC504783

1

12 ± 2 N·m

10

2

3

4

5

6

7

8

9

9

10

11 13

15

18

16

17

12

AB

5.4 ± 0.4 N·m

Radiator removal steps

1.Drain plug

2.Radiator cap

3.Radiator condenser tank hose

4.Radiator condenser tank assembly

<>>>A<<5.Radiator upper hose

<>>>A<<6.Radiator lower hose

7.Cooling fan motor drive control unit

connector

8.T/M oil cooler line hose connection

9.Radiator support upper insulator

•Radiator and cooling fan motor &

shroud assembly

10.Radiator support lower insulator

11 .T/M oil cooler line hose

Radiator removal steps

Page 63 of 800

16-1

GROUP 16

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM . . . . . . . .16-2

GENERAL INFORMATION . . . . . .16-2

SERVICE SPECIFICATIONS. . . . .16-3

SPECIAL TOOL . . . . . . . . . . . . . . .16-3

ON-VEHICLE SERVICE. . . . . . . . .16-3

ALTERNATOR OUTPUT LINE VOLTAGE

DROP TEST . . . . . . . . . . . . . . . . . . . . . 16-3

OUTPUT CURRENT TEST . . . . . . . . . . 16-5

REGULATED VOLTAGE TEST . . . . . . . 16-7

WAVEFORM CHECK USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . 16-9

ALTERNATOR ASSEMB LY . . . . .16-12

REMOVAL AND INSTALLATION

<4G1> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-12

REMOVAL AND INSTALLATION

<4G6> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-13

DISASSEMBLY AND REASSEMBLY . . 16-15

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-17

STARTING SYSTEM . . . . . . . . .16-19

GENERAL INFORMATION . . . . . .16-19

SERVICE SPECIFICATIONS. . . . .16-20

STARTER MOTOR ASSEMBLY . .16-21

REMOVAL AND INSTALLATION

<4G1> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-21

REMOVAL AND INSTALLATION

<4G6> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-22

STARTER MOTOR ASSEMBLY

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-23

DISASSEMBLY AND REASSEMBLY . . 16-26

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-27

IGNITION SYSTEM . . . . . . . . . 16-30

GENERAL INFORMATION . . . . . .16-30

SERVICE SPECIFICATIONS . . . . .16-31

SPECIAL TOOL . . . . . . . . . . . . . . .16-31

ON-VEHICLE SERVICE . . . . . . . . .16-32

IGNITION COIL (WITH BUILT-IN

POWER TRANSISTOR) CHECK . . . . . . 16-32

RESISTIVE CORD CHECK . . . . . . . . . . 16-32

SPARK PLUG CHECK AND CLEANING

<4G1>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-32

SPARK PLUG CHECK AND CLEANING

<4G6>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-33

CAMSHAFT POSITION SENSOR

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 16-33

CRANK ANGLE SENSOR CHECK . . . . 16-33

DETONATION SENSOR CHECK . . . . . 16-33

IGNITION SECONDARY VOLTAGE

WAVEFORM CHECK USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . 16-33

IGNITION COIL RELAY CHECK . . . . . . 16-37

IGNITION COIL . . . . . . . . . . . . . . . .16-38

REMOVAL AND INSTALLATION

<4G1>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-38

REMOVAL AND INSTALLATION

<4G6>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-39

CAMSHAFT POSITION SENSOR .16-40

REMOVAL AND INSTALLATION . . . . . . 16-40

CRANKSHAFT POSITION SENSOR16-41

REMOVAL AND INSTALLATION

<4G1>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-41

REMOVAL AND INSTALLATION

<4G6>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-42

DETONATION SENSOR . . . . . . . .16-43

REMOVAL AND INSTALLATION . . . . . . 16-43

Page 81 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-19

STARTING SYSTEM

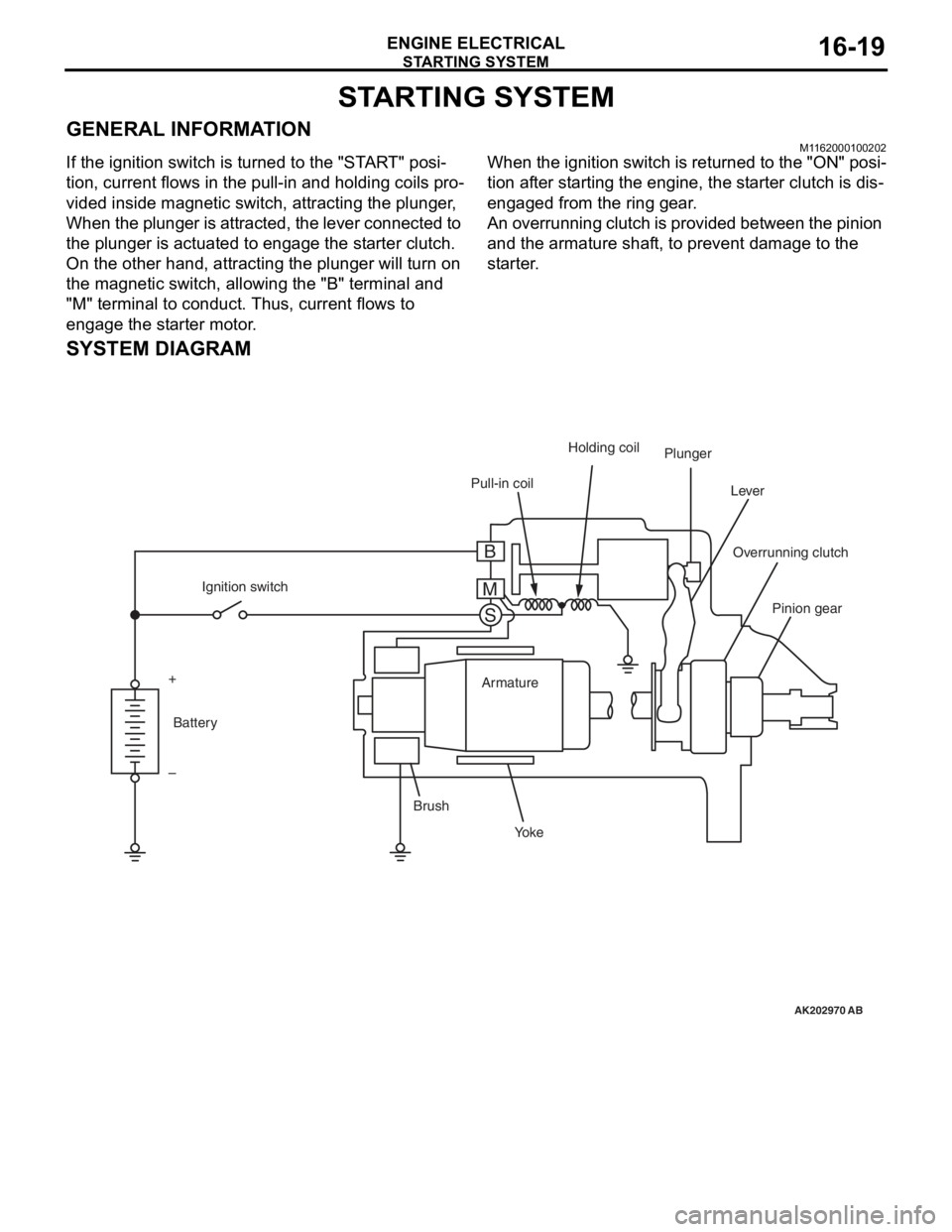

GENERAL INFORMATIONM1162000100202

If the ignition switch is turned to the "START" posi-

tion, current flows in the pull-in and holding coils pro-

vided inside magnetic switch, attracting the plunger,

When the plunger is attracted, the lever connected to

the plunger is actuated to engage the starter clutch.

On the other hand, attracting the plunger will turn on

the magnetic switch, allowing the "B" terminal and

"M" terminal to conduct. Thus, current flows to

engage the starter motor.

When the ignition switch is returned to the "ON" posi-

tion after starting the engine, the starter clutch is dis-

engaged from the ring gear.

An overrunning clutch is provided between the pinion

and the armature shaft, to prevent damage to the

starter.

SYSTEM DIAGRAM

AK202970

Pull-in coilHolding coil

Plunger

Lever

Pinion gear

Overrunning clutch

Yo k e

Brush Armature

Ignition switch

Battery

+

–

AB

B

M S