ECU MITSUBISHI LANCER IX 2006 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 141 of 800

Page 142 of 800

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-10

<

AC100128

MB990241

MB990767

AG

AC303949

MB990244

(Three)

MB990767

MB990242

MB991354

AF

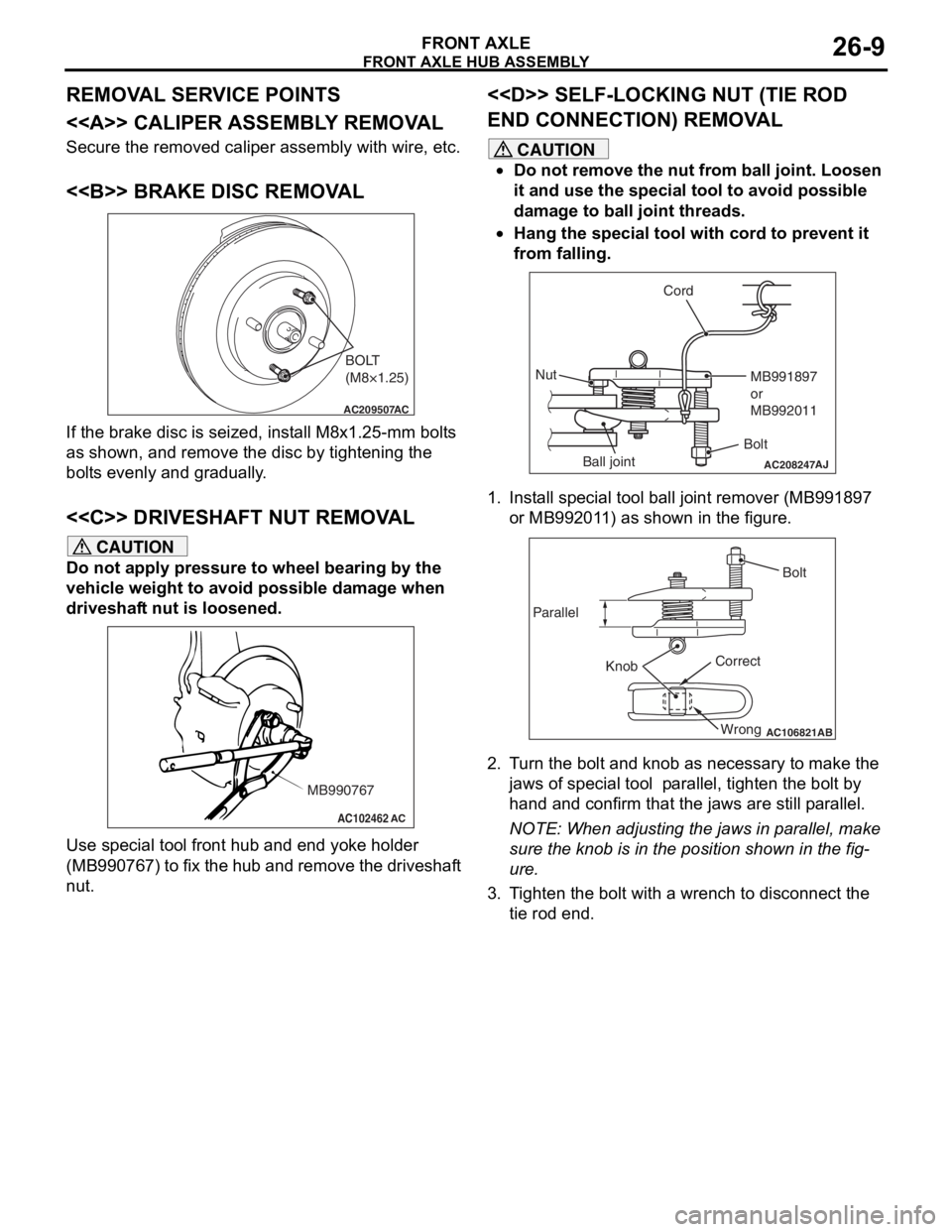

1.

Use the fo llo wing special to ols to pu sh ou t the

driveshaf t from the hub an d kn uckle.

•Axle shaf t puller (MB9 90241 )

•Puller shaft (MB990 242)

•Puller bar (MB990 244)

•Puller body (MB99135 4)

•

AC102551

AC

Driveshaft

Front hub a nd end yoke holder (MB99076 7)

2.Withdraw th e driveshaf t from the hu b by pulling

th e botto m of the hub and knuckle towards you .

3.Hang the dr ive s haf t on the vehicle b ody with a

rope.

INST ALLA T ION SER VICE POINT

>>A<< STABILIZER RUB-

BER/SELF-LOCKING NUT (ST A BILIZER

BAR CONNECTION) INST

ALLA TION

AC210393AC

A

I

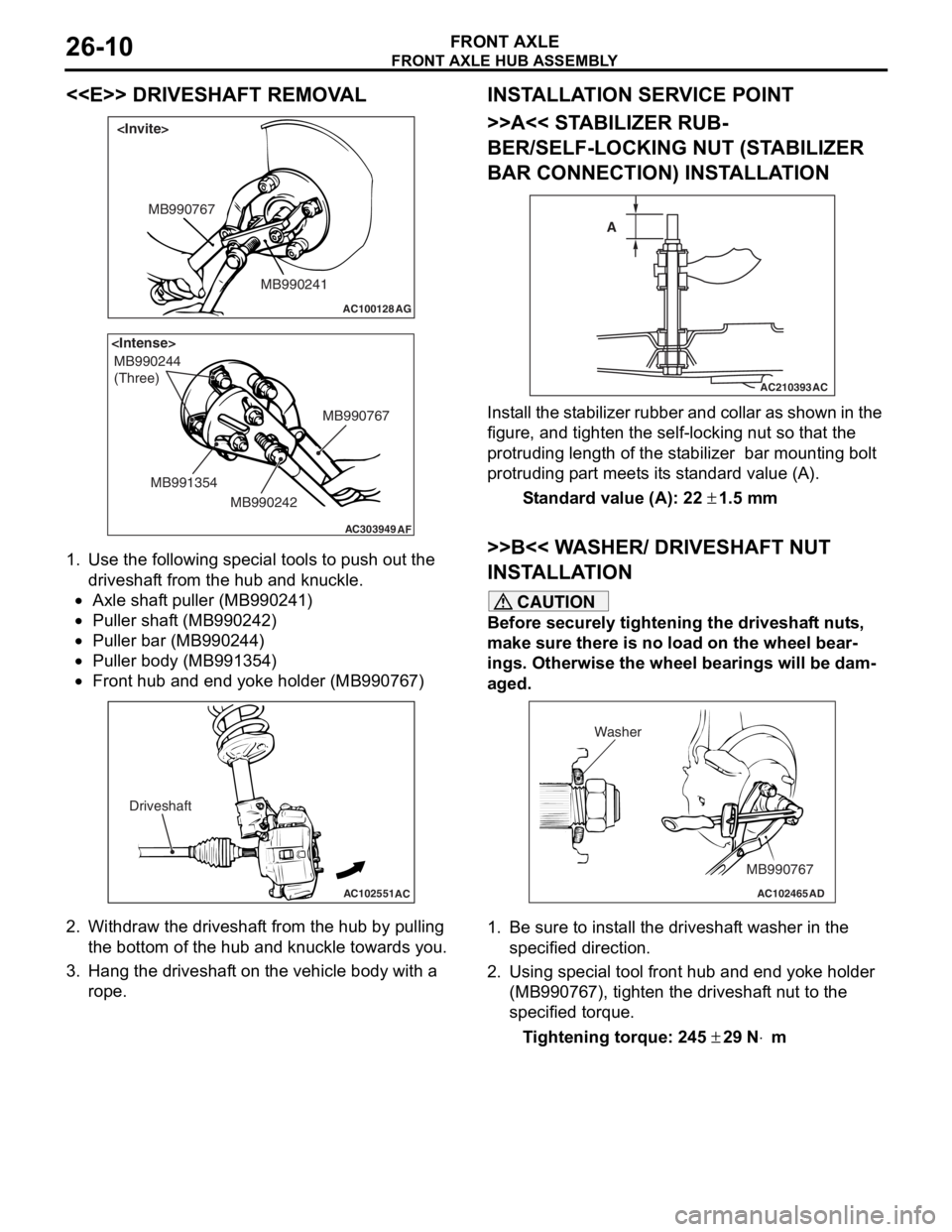

n st a ll the st a b ili zer rubb er an d coll ar as sho w n in t he

figure

, and t i ghte n the self-locking nut so tha t the

protruding length

of the st abilize r bar mount ing b o lt

protruding p

a rt meet s it s st and ard value (A).

St andard va lue (A): 22 ± 1.5 m m

>>B<< W A SHER/ DRIVESHAFT NUT

INST

ALLA TION

CAUTION

Before securely tightening the driveshaft nuts,

make sure there is no load on the wheel bear

-

ings. Otherwise the wheel bearings will be dam-

aged.

AC102465AD

MB990767

Washer

1. Be sure to install the driveshaft washer in the

specified direction.

2. Using special tool front hub and end yoke holder (MB990767), tighten the driveshaft nut to the

specified torque.

Tightening torque: 245 ± 29 N⋅m

Page 143 of 800

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-11

INSPECTION

M1261001800242

•Check the hub for cracks and spline for wear.

•Check the knuckle for cracks.

•Check for defective bearing.

NOTE: If the meshing of the wheel bearing outer

race and the knuckle, or of the wheel bearing

inner race and the hub, is loose, replace the

bearing or damaged parts.

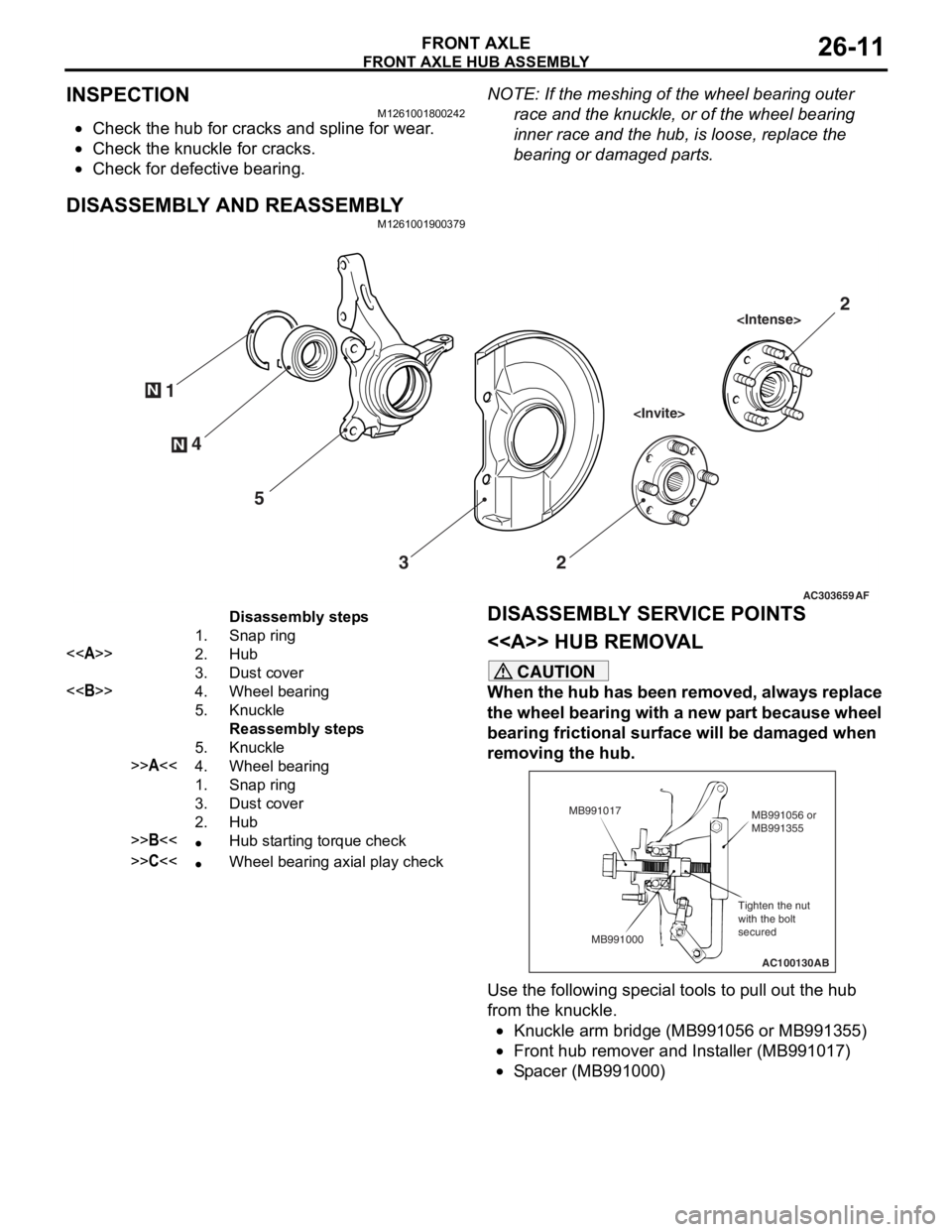

DISASSEMBLY AND REASSEMBLY

M1261001900379

AC303659

N

N4

1

5 3 2

AF

2

Disassembly steps

1.Snap ring

<>2.Hub

3.Dust cover

<>4.Wheel bearing

5.Knuckle

Reassembly steps

5.Knuckle

>>A<<4.Wheel bearing

1.Snap ring

3.Dust cover

2.Hub

>>B<<•Hub starting torque check

>>C<<•Wheel bearing axial play check

DISASSEMBL

Y SER V ICE POINTS

< > HUB REMOV A L

CAUTION

When the hub has been removed, always replace

the wheel bearing with a new part because wheel

bearing frictional surface will be damaged when

removing the hub.

AC100130

Tighten the nut

with the bolt

secured MB991056 or

MB991355

MB991017

MB991000 AB

Use the following special tools to pull out the hub

from the knuckle.

•Knuckle arm bridge (MB991056 or MB991355)

•Front hub remover and Installer (MB991017)

•Spacer (MB991000)

Page 144 of 800

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-12

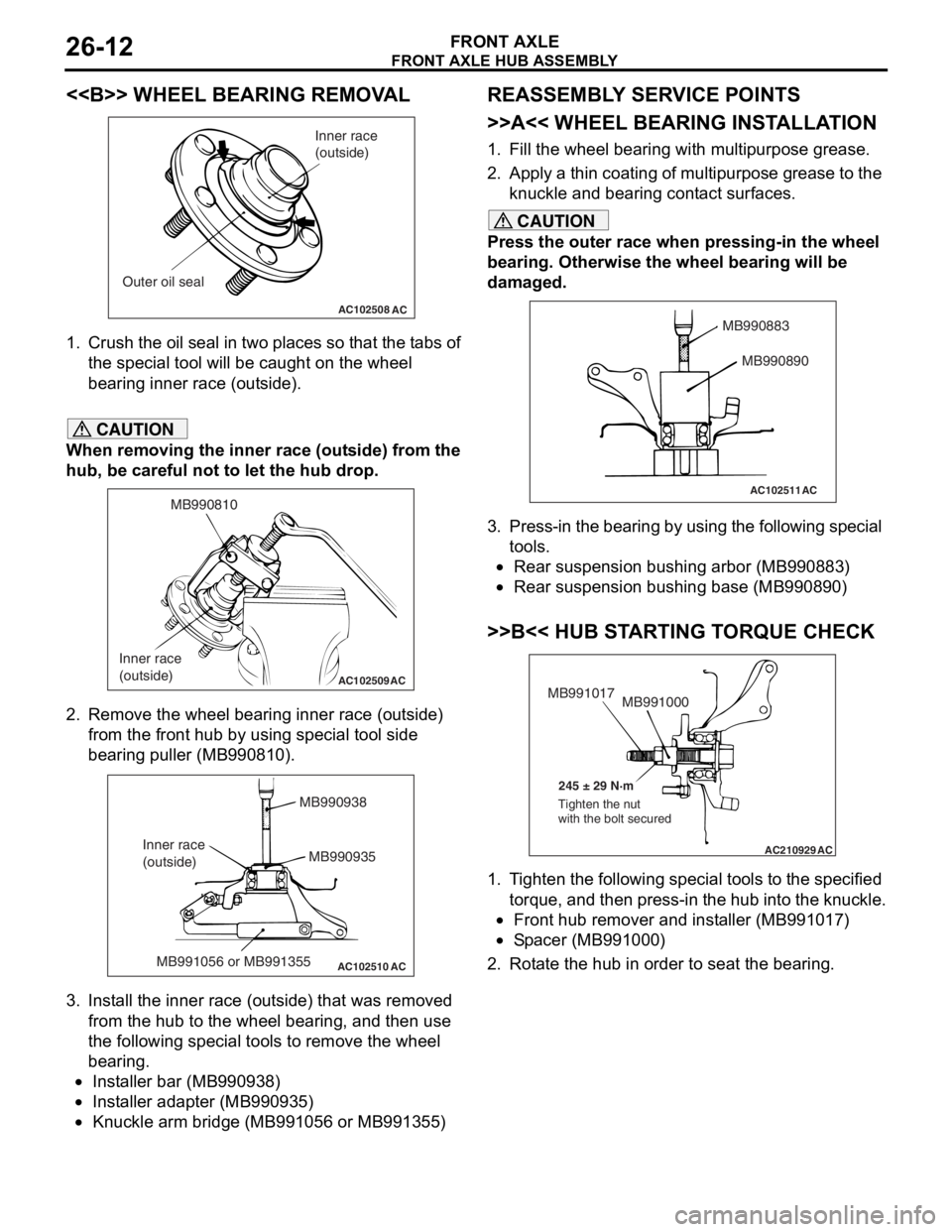

<> WHEEL BEARING REMOVAL

AC102508AC

Inner race

(outside)

Outer oil seal

1. Crush th e oil seal in two pl ace s so t hat t he t abs of

th e spe c ia l too l will be caugh t on th e wheel

be aring inne r race (out side).

CAUTION

When removing the inner race (outside) from the

hub, be careful not to let the hub drop.

AC102509

MB990810

Inner race

(outside)

AC

2. Remove the wheel bearing inner race (outside) from the front hub by using special tool side

bearing puller (MB990810).

AC102510 AC

MB990938

MB990935

MB991056 or MB991355

Inner race

(outside)

3. Install the inner race (outside) that was removed

from the hub to the wheel bearing, and then use

the following special tools to remove the wheel

bearing.

•Installer bar (MB990938)

•Installer adapter (MB990935)

•Knuckle arm bridge (MB991056 or MB991355)

REASSEMBLY SERVICE POINTS

>>A<< WHEEL BEARING INSTALLATION

1. Fill the wheel bearing with multipurpose grease.

2. Apply a thin coating of multipurpose grease to the knuckle and bearing contact surfaces.

CAUTION

Press the outer race when pressing-in the wheel

bearing. Otherwise the wheel bearing will be

damaged.

AC102511

MB990883

MB990890

AC

3. Press-in the bearing by using the following special tools.

•Rear suspension bushing arbor (MB990883)

•Rear suspension bushing base (MB990890)

>>B<< HUB STARTING TORQUE CHECK

AC210929AC

MB991000

MB991017

245 ± 29 N·m

Tighten the nut

with the bolt secured

1. Tighten the following special tools to the specified torque, and then press-in the hub into the knuckle.

•Front hub remover and installer (MB991017)

•Spacer (MB991000)

2. Rotate the hub in order to seat the bearing.

Page 145 of 800

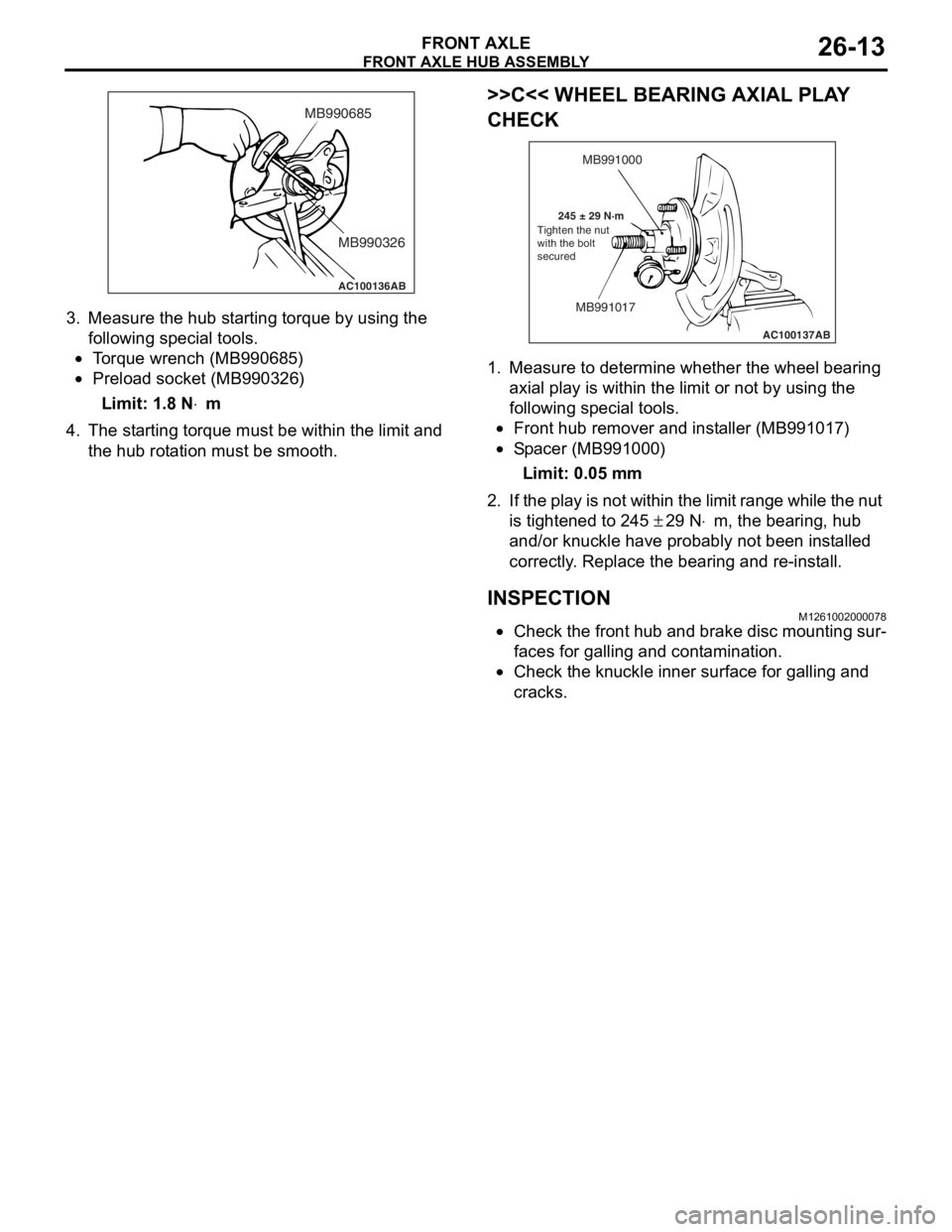

AC100136

MB990685MB990326

AB

FRONT AXLE HUB ASSEMBL Y

FRONT AXLE26-13

3.Measure the hub st a r ting torque b y using the

fo llowing special to ols.

•To rque wren ch (MB99068 5)

•Preload socket (MB9 90326 )

Limit: 1.8 N⋅m

4.Th e st arting torq ue must b e within the limit an d

th e hub rot a tion must be smoo th.

>>C<< WH EEL BEARING AXIAL PLA Y

CHECK

AC100137

MB991000

MB991017

245 ± 29 N·m AB

Tighten the nut

with the bolt

secured

1.

Measure to d e termine whe t her th e wheel bearing

a x ial pla y is with in the limit o r not by using t he

fo llowing special to ols.

•Front hub re mover and inst a ller (MB9910 17)

•Sp a c er (MB9910 00)

Limit: 0.05 mm

2. If the play is not wit h in the limit rang e while the nut

is tighten ed to 2 45

± 29 N⋅m, the bearing, hu b

a

nd/or knuckle

have

proba

bly not be en in st alled

correctly

. Replace

the be

aring and re -inst a ll.

INSPECTION

M12610020 0007 8

•Check the fro n t hu b and brake disc mo untin g sur-

faces for gallin g and cont amination.

•Check the knu c kle in ner surface for ga lling an d

crac

ks .

Page 148 of 800

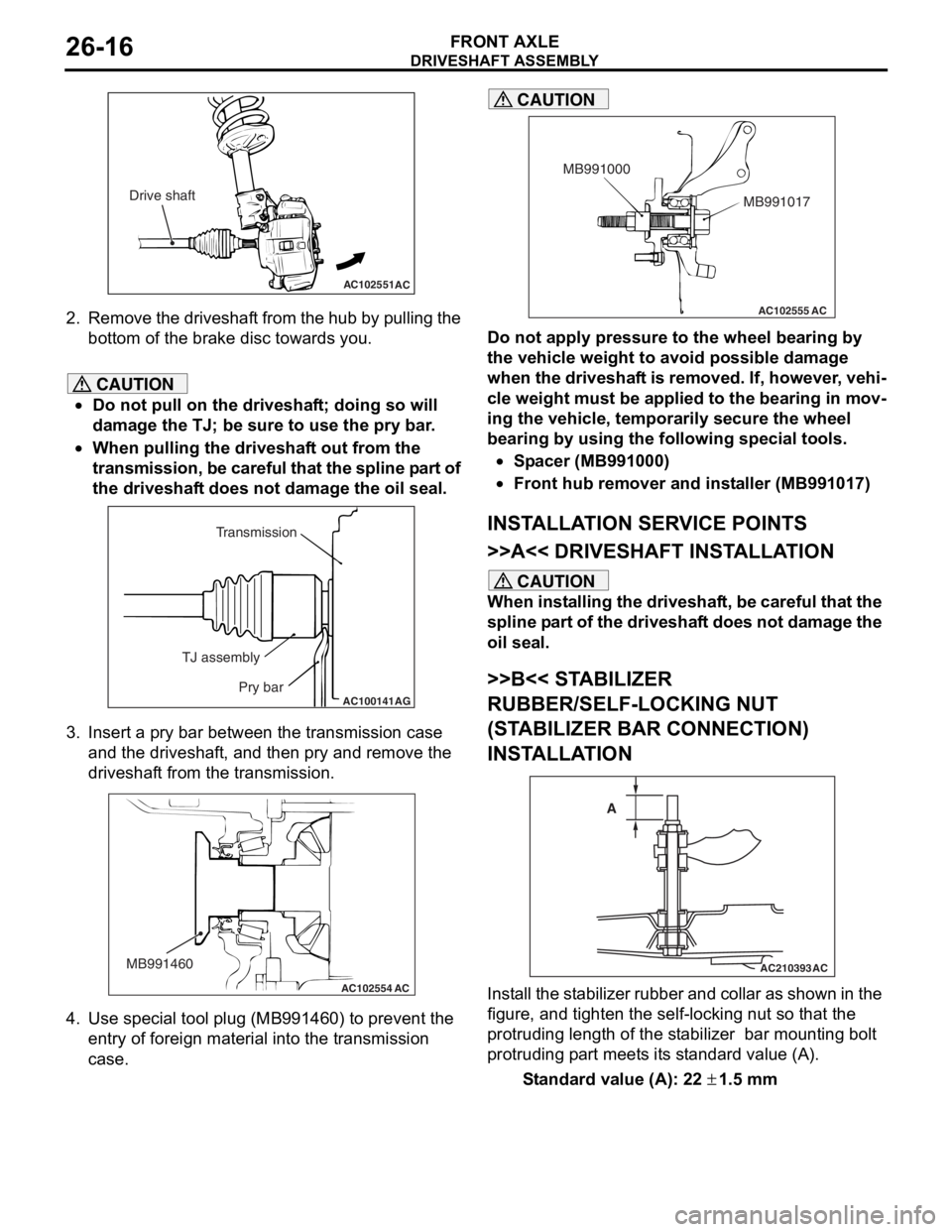

AC102551AC

Drive shaft

DRIVESHAFT ASSEMBL Y

FRONT AXLE26-16

2.Remove th e dr ivesh a f t from th e h ub b y p u lling the

bo ttom of the brake disc toward s you.

CAUTION

•Do not pull on the driveshaft; doing so will

damage the TJ; be sure to use the pry bar.

•

AC100141

Transmission

TJ assembly Pry bar

AG

When pulling the driveshaft out from the

transmission, be careful that the spline part of

the driveshaft does not damage the oil seal.

3. Insert a pry bar between the transmission case and the driveshaft, and then pry and remove the

driveshaft from the transmission.

AC102554

MB991460

AC

4. Use special tool plug (MB991460) to prevent the

entry of foreign material into the transmission

case.

AC102555 AC

MB991017

MB991000

CAUTION

Do not apply pressure to the wheel bearing by

the vehicle weight to avoid possible damage

when the driveshaft is removed. If, however, vehi

-

cle weight must be applied to the bearing in mov-

ing the vehicle, temporarily secure the wheel

bearing by using the following special tools.

•Spacer (MB991000)

•Front hub remover and installer (MB991017)

INSTALLATION SERVICE POINTS

>>A<< DRIVESHAFT INSTALLATION

CAUTION

When installing the driveshaft, be careful that the

spline part of the driveshaft does not damage the

oil seal.

>>B<< STABILIZER

RUBBER/SELF-LOCKING NUT

(STABILIZER BAR CONNECTION)

INSTALLATION

AC210393

AC

A

Install the stabilizer rubber and collar as shown in the

figure, and tighten the self-locking nut so that the

protruding length of the stabilizer bar mounting bolt

protruding part meets its standard value (A).

Standard value (A): 22 ± 1.5 mm

Page 149 of 800

DRIVESHAFT ASSEMBLY

FRONT AXLE26-17

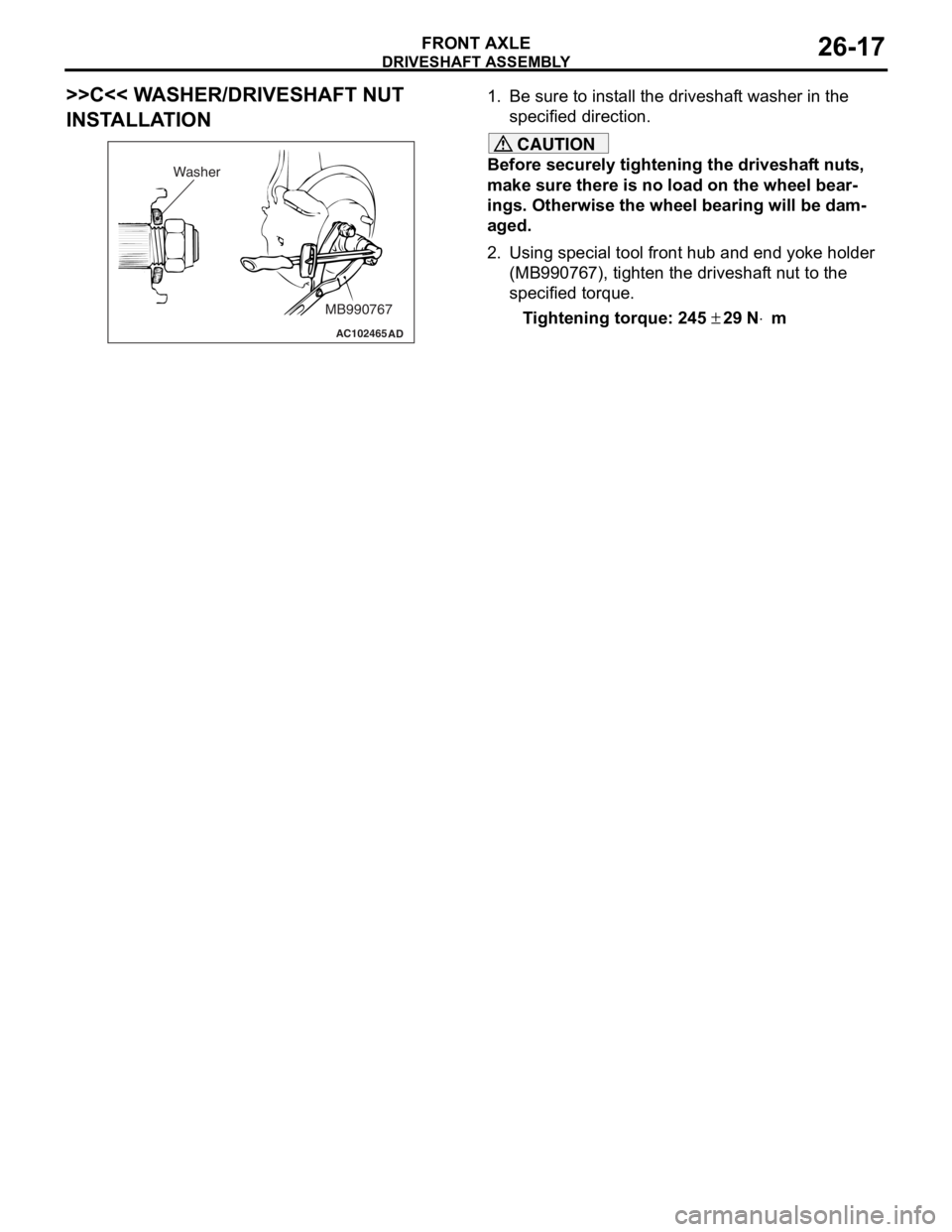

>>C<< WASHER/DRIVESHAFT NUT

INSTALLATION

AC102465AD

MB990767

Washer

1.

Be sure t o inst a ll t he driveshaf t washe r in th e

specifie d dire ctio n.

CAUTION

Before securely tightening the driveshaft nuts,

make sure there is no load on the wheel bear

-

ings. Otherwise the wheel bearing will be dam-

aged.

2. Using special tool front hub and end yoke holder (MB990767), tighten the driveshaft nut to the

specified torque.

Tightening torque: 245 ± 29 N⋅m

Page 152 of 800

DRIVESHAFT ASSEMBLY

FRONT AXLE26-20

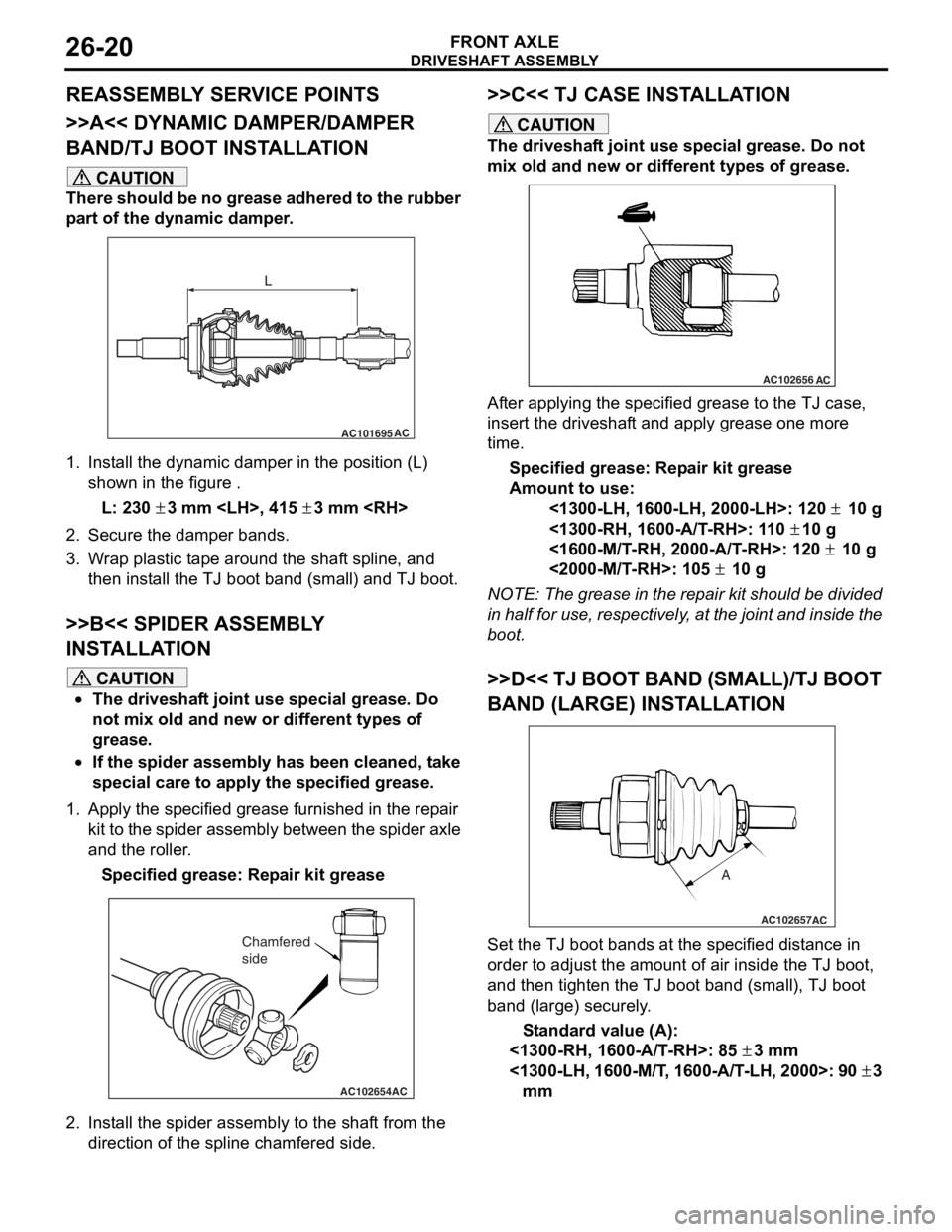

REASSEMBLY SERVICE POINTS

>>A<< DYNAMIC DAMPER/DAMPER

BAND/TJ BOOT INSTALLATION

CAUTION

There should be no grease adhered to the rubber

part of the dynamic damper.

AC101695AC

L

1. Install the dynamic damper in the position (L)

shown in the figure .

L: 230 ± 3 mm

2. Secure the damper bands.

3. Wrap plastic tape around the shaft spline, and then install the TJ boot band (small) and TJ boot.

>>B<< SPIDER ASSEMBLY

INSTALLATION

CAUTION

•The driveshaft joint use special grease. Do

not mix old and new or different types of

grease.

•If the spider assembly has been cleaned, take

special care to apply the specified grease.

1. Apply the specified grease furnished in the repair kit to the spider assembly between the spider axle

and the roller.

Specified grease: Repair kit grease

AC102654AC

Chamfered

side

2. Install the spider assembly to the shaft from the direction of the spline chamfered side.

>>C<< TJ CASE INSTALLATION

CAUTION

The driveshaft joint use special grease. Do not

mix old and new or different types of grease.

AC102656AC

After applying the specified grease to the TJ case,

insert the driveshaft and apply grease one more

time.

Specified grease: Repair kit grease

Amount to use:

<1300-LH, 1600-LH, 2000-LH>: 120 ± 10 g

<1300-RH, 1600-A/T-RH>: 110 ± 10 g

<1600-M/T-RH, 2000-A/T-RH>: 120 ± 10 g

<2000-M/T-RH>: 105 ± 10 g

NOTE: The grease in the repair kit should be divided

in half for use, respectively, at the joint and inside the

boot.

>>D<< TJ BOOT BAND (SMALL)/TJ BOOT

BAND (LARGE) INSTALLATION

AC102657

A

AC

Set the TJ boot bands at the specified distance in

order to adjust the amount of air inside the TJ boot,

and then tighten the TJ boot band (small), TJ boot

band (large) securely.

Standard value (A):

<1300-RH, 1600-A/T-RH>: 85 ± 3 mm

<1300-LH, 1600-M/T, 1600-A/T-LH, 2000>: 90 ± 3

mm

Page 153 of 800

DRIVESHAFT ASSEMBLY

FRONT AXLE26-21

INSPECTION

M1261003800130

•Check the driveshaft for damage, bending or cor-

rosion.

•Check the driveshaft spline part for wear or dam-

age.

•Check the spider assembly for roller rotation,

wear or corrosion.

•Check the groove inside TJ case for wear or cor-

rosion.

•Check the dynamic damper for damage or crack-

ing.

•Check the boots for deterioration, damage or

cracking.

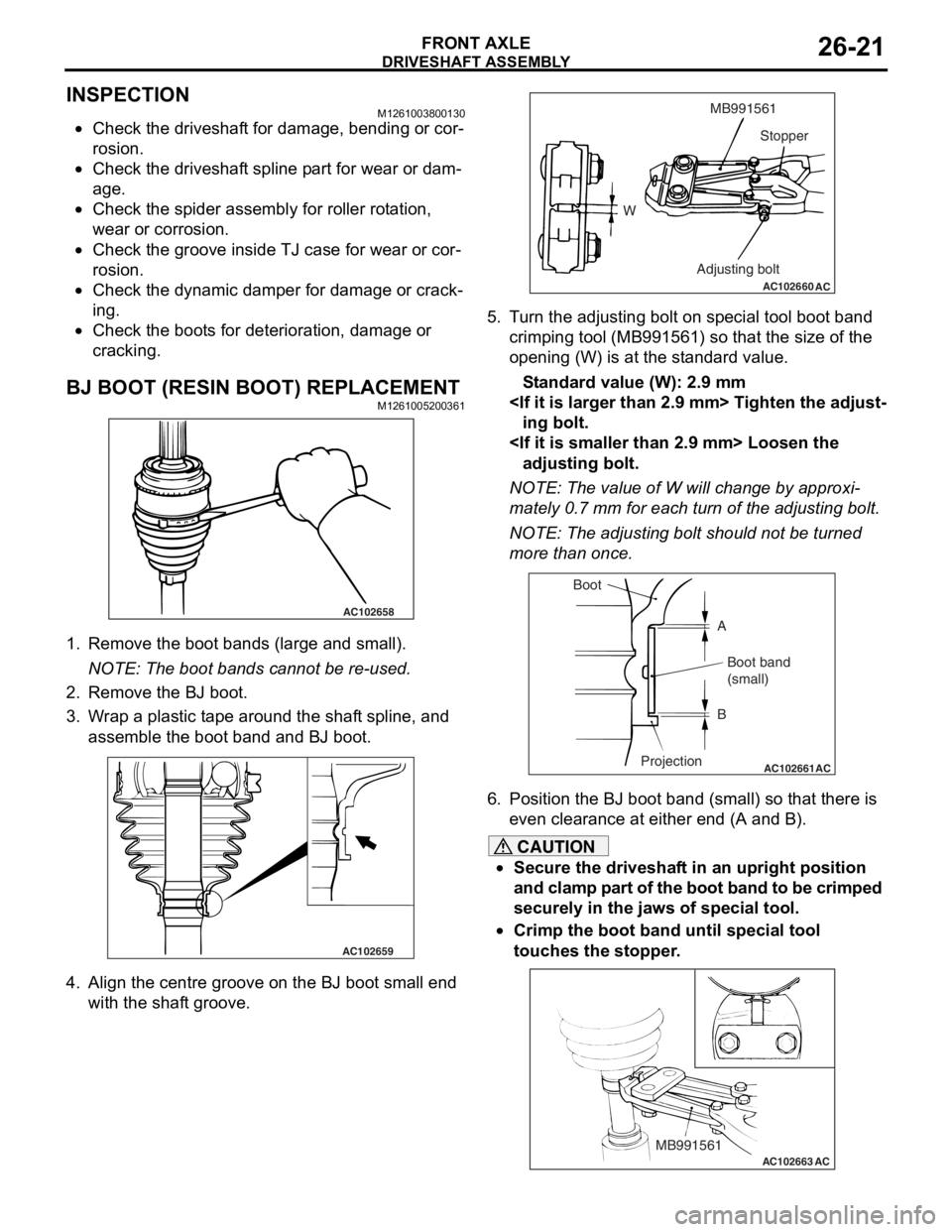

BJ BOOT (RESIN BOOT) REPLACEMENTM1261005200361

AC102658

1.Remove the bo ot ban ds (large a nd small).

NOTE: The boot ba nds canno t be re -used .

2.Remove the BJ boot.

3.W r ap a plastic t a pe arou nd the shaf t spline, an d

asse mble the b oot ba nd and BJ boo t.

AC102659

4.Align th e ce ntre gro o ve o n the BJ boot small end

wit h the shaf t groo ve.

AC102660

WMB991561

Stopper

Adjusting bolt

AC

5. T u rn the ad justing bolt o n sp ecial too l boo t band

crimping tool (MB9915 61) so that the size of the

o penin g (W) is at t he st and ard value .

St andard va lue (W): 2 . 9 mm

ing bolt.

adjustin g bolt.

NOTE: The value of W will chang e by approxi-

mately 0.7 mm for ea ch tu rn of th e adjusting bolt.

NOTE: The ad justing bolt shou ld no t be tu rned

more th an once.

AC102661AC

Boot

ABoot band

(small)

B

Projection

6. Position the BJ boo t band (small) so th at there is

e v en clea rance at either en d (A and B).

CAUTION

•Secure the driveshaft in an upright position

and clamp part of the boot band to be crimped

securely in the jaws of special tool.

•

AC102663 ACMB991561

Crimp the boot band until special tool

touches the stopper.

Page 161 of 800

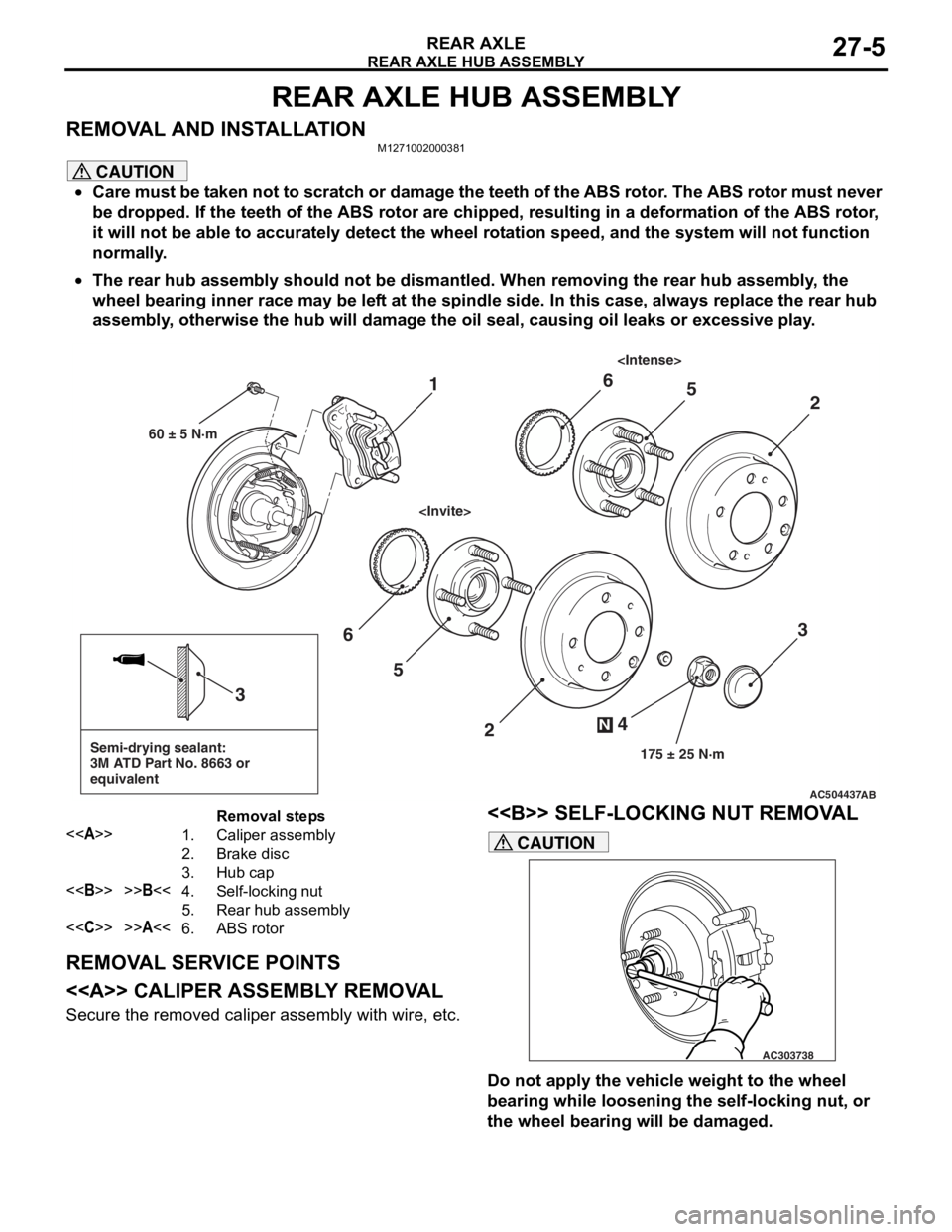

REAR AXLE HUB ASSEMBLY

REAR AXLE27-5

REAR AXLE HUB ASSEMBLY

REMOVAL AND INSTALLATIONM1271002000381

CAUTION

•Care must be taken not to scratch or damage the teeth of the ABS rotor. The ABS rotor must never

be dropped. If the teeth of the ABS rotor are chipped, resulting in a deformation of the ABS rotor,

it will not be able to accurately detect the wheel rotation speed, and the system will not function

normally.

•

AC504437

Semi-drying sealant:

3M ATD Part No. 8663 or

equivalent

2

3

5

6

4

N

175 ± 25 N·m

3

AB

1

60 ± 5 N·m

2

56

Removal steps

<>1.Caliper assembly

2.Brake disc

3.Hub cap

<>>>B<<4.Self-locking nut

5.Rear hub assembly

<

The rear hub assembly should not be dismantled. When removing the rear hub assembly, the

wheel bearing inner race may be left at the spindle side. In this case, always replace the rear hub

assembly, otherwise the hub will damage the oil seal, causing oil leaks or excessive play.

REMOVAL SERVICE POINTS

<> CALIPER ASSEMBLY REMOVAL

Secure the removed caliper assembly with wire, etc.

<> SELF-LOCKING NUT REMOVAL

AC303738

CAUTION

Do not apply the vehicle weight to the wheel

bearing while loosening the self-locking nut, or

the wheel bearing will be damaged.