ECU MITSUBISHI MONTERO 1987 1.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 155 of 284

METERS AND GAUGES - Combination Meter 8-135

.3

16WQ25

16W925

10W926

16F554

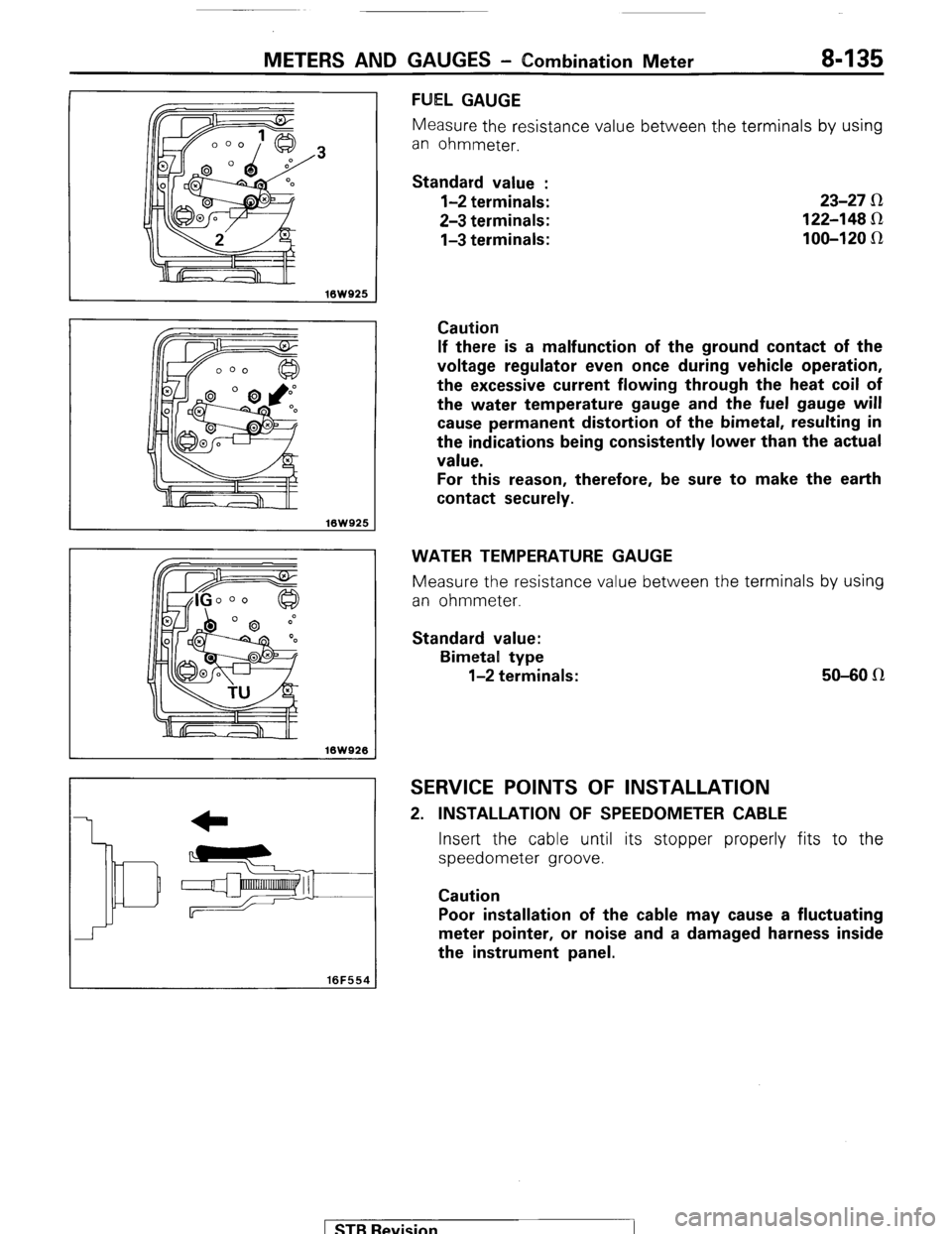

FUEL GAUGE

Measure the resistance value between t.he terminals by using

an ohmmeter.

Standard value :

l-2 terminals:

2-3 terminals:

l-3 terminals: 23-27 R

122-148 Sz

100-120 IR

Caution

If there is a malfunction of the ground contact of the

voltage regulator even once during vehicle operation,

the excessive current flowing through the heat coil of

the water temperature gauge and the fuel gauge will

cause permanent distortion of the bimetal, resulting in

the indications being consistently lower than the actual

value.

For this reason, therefore, be sure to make the earth

contact securely.

WATER TEMPERATURE GAUGE

Measure the resistance value between the terminals by using

an ohmmeter.

Standard value:

Bimetal type

l-2 terminals: 50-80 n

SERVICE POINTS OF INSTALLATION

2. INSTALLATION OF SPEEDOMETER CABLE

Insert the cable until its stopper properly fits to the

speedometer groove.

Caution

Poor installation of the cable may cause a fluctuating

meter pointer, or noise and a damaged harness inside

the instrument panel.

) STB Revision

Page 190 of 284

8-170 WIPER AND WASHER SYSTEM - Service Adjustment Procedures

SERVICE ADJUSTMENT PROCEDURES

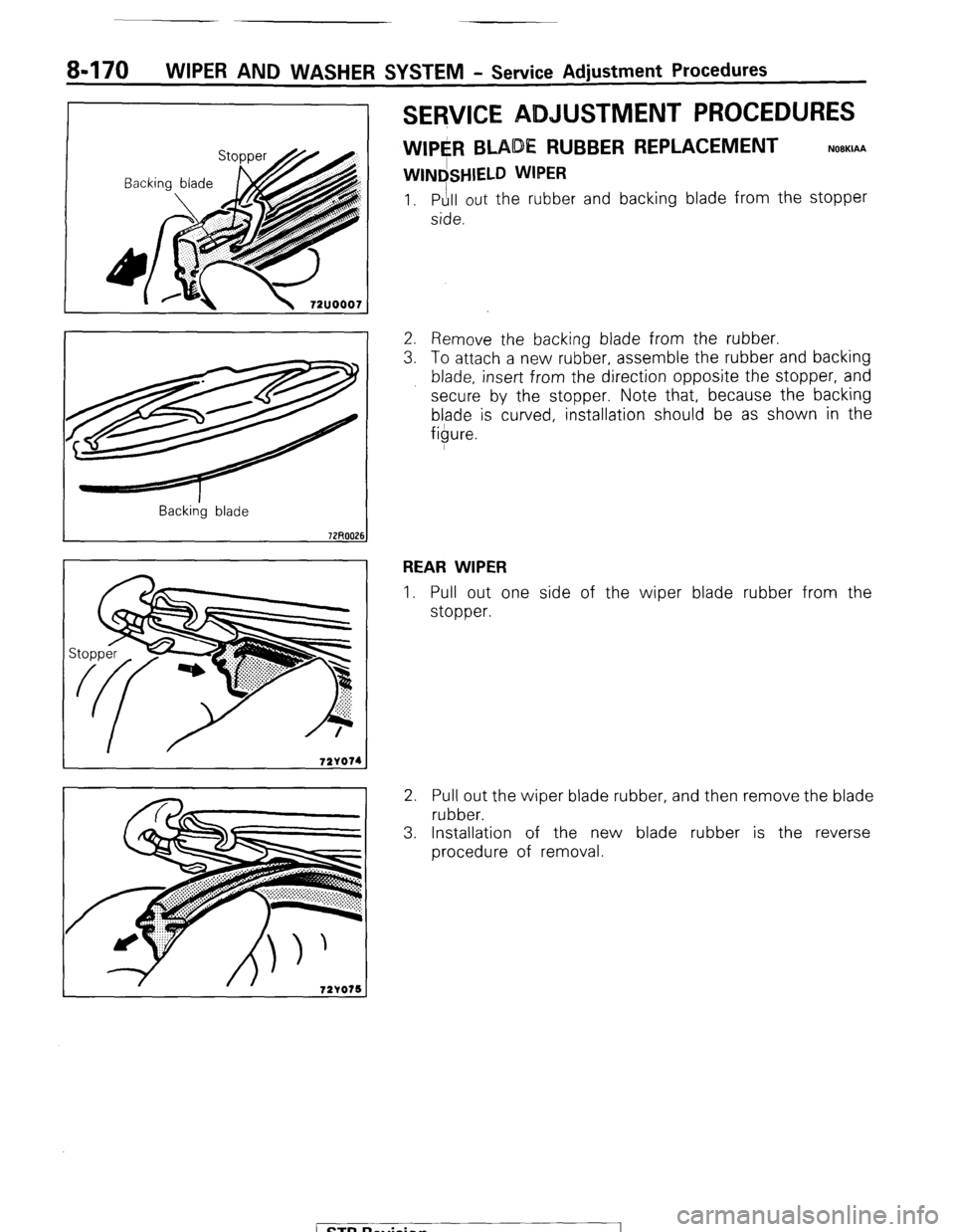

WIPE#l BLADE RUBBER REPLACEMENT

WINdSHIELD WIPER

NOBKIAA

1. Pull out the rubber and backing blade from the stopper

side.

Back&g blade

2. Remove the backing blade from the rubber.

3. To attach a new rubber, assemble the rubber and backing

blade, insert from the direction opposite the stopper, and

secure by the stopper. Note that, because the backing

blade is curved, installation should be as shown in the

figure.

REAR WIPER

1. Pull out one side of the wiper blade rubber from the

stopper.

2. Pull out the wiper blade rubber, and then remove the blade

rubber.

3. Installation of the new blade rubber is the reverse

procedure of removal.

( ST6 Revision

Page 206 of 284

8486 HORN - Horn

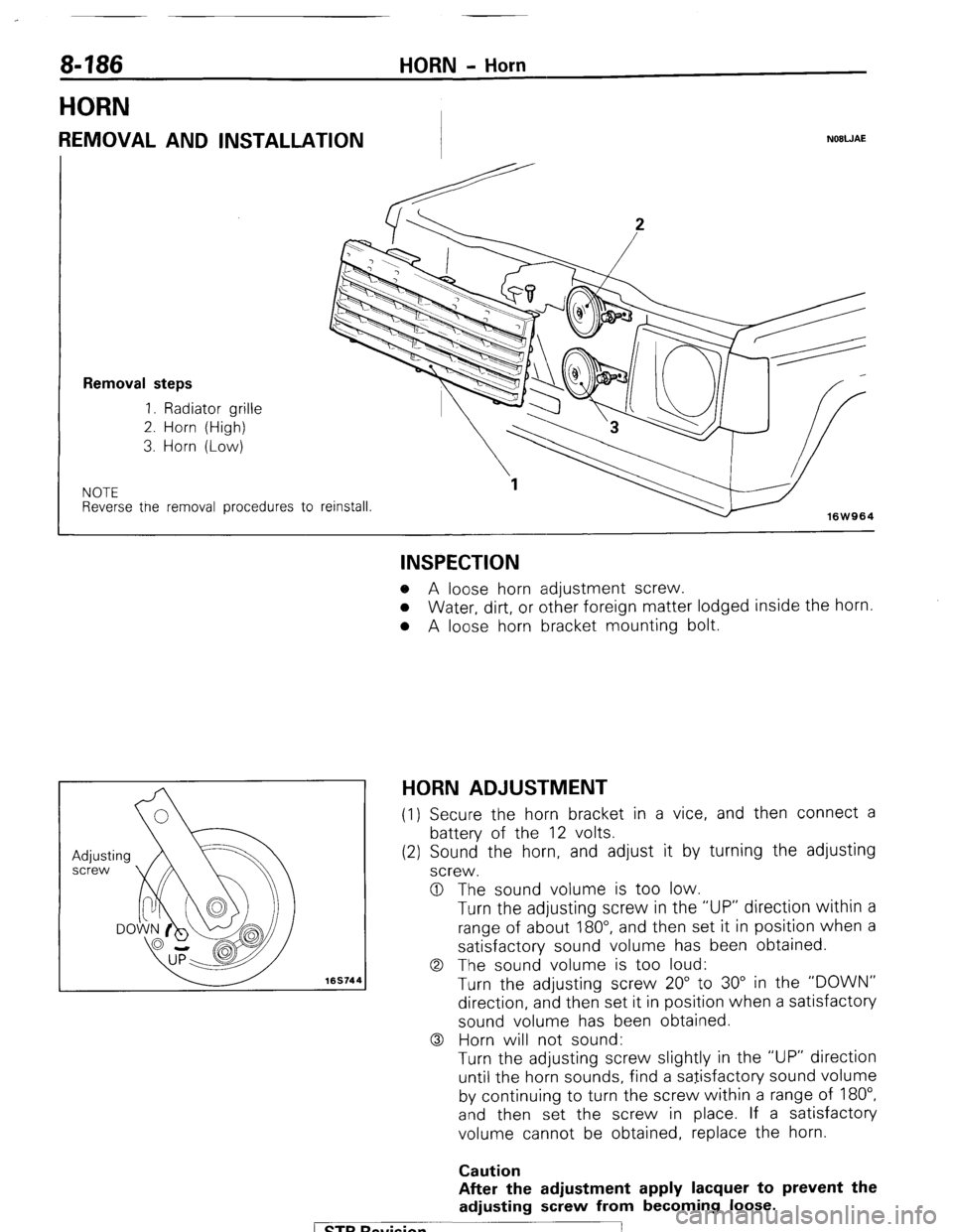

HORN

REMOVAL AND INSTALLATION NOBWAE

Removal steps

1. Radiator grille

2. Horn (High)

3. Horn (Low)

NOTE Reverse tne removal procedures to

reinstall.

16W964

169744

INSPECTION o A loose horn adjustment screw.

o Water, dirt, or other foreign matter lodged inside the horn.

l A loose horn bracket mounting bolt.

HORN ADJUSTMENT (1) Secure the horn bracket in a vice, and then connect a

battery of the 12 volts.

(2) Sound the horn, and adjust it by turning the adjusting

screw.

0 The sound volume is too low.

Turn the adjusting screw in the “UP” direction within a

range of about 180”, and then set it in position when a

satisfactory sound volume has been obtained.

0 The sound volume is too loud:

Turn the adjusting screw 20” to 30” in the “DOWN”

direction, and then set it in position when a satisfactory

sound volume has been obtained.

0 Horn will not sound:

Turn the adjusting screw slightly in the “UP” direction

until the horn sounds, find a satisfactory sound volume

by continuing to turn the screw within a range of 180”,

and then set the screw in place. If a satisfactory

volume cannot be obtained, replace the horn.

Caution

After the adjustment apply lacquer to prevent the

adjusting screw from becoming loose.

1 ST6 Revision

Page 221 of 284

AUDIO SYSTEM - Noise Suppression 8-201

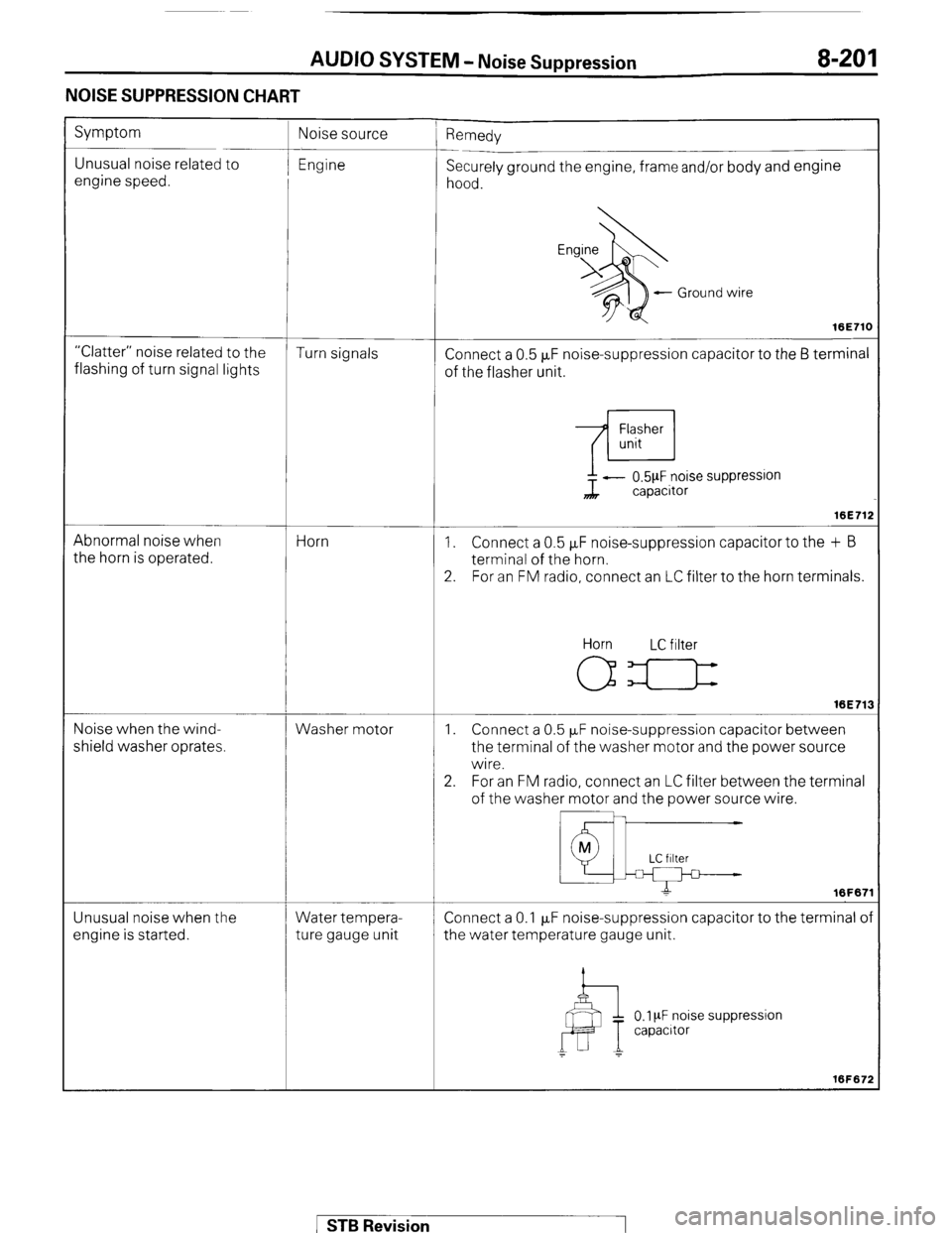

NOISE SUPPRESSION CHART

Symptom

Unusual noise related to

engine speed. ’ Remedy

Securely ground the engine, frame and/or body and engine

hood.

- Ground wire

16E71C

“Clatter” noise related to the

Turn signals

flashing of turn signal lights Connect a 0.5 FF noise-suppression capacitor to the 6 terminal

of the flasher unit.

Abnormal noise when

the horn is operated. Horn ?L - 0.5pF noise suppression

capacitor

16E71:

1. Connect a 0.5 FF noise-suppression capacitor to the + B

terminal of the horn.

2. For an FM radio, connect an LC filter to the horn terminals.

Noise when the wind-

shield washer oprates. Washer motor Horn LC filter

16E71:

1. Connect a 0.5 PF noise-suppression capacitor between

the terminal of the washer motor and the power source

wire.

2. For an FM radio, connect an LC filter between the terminal

of the washer motor and the power source wire.

Unusual noise when the

engine is started. Water tempera-

ture gauge unit Connect a 0.1 p,F noise-suppression capacitor to the terminal o

the water temperature gauge unit.

0.1 PF noise suppression

capacrtor

1 STB Revision

Page 247 of 284

HEATERS - Heater Control 24-11

Top view

Bottom view

I

2OW553

2OW534

2OW750

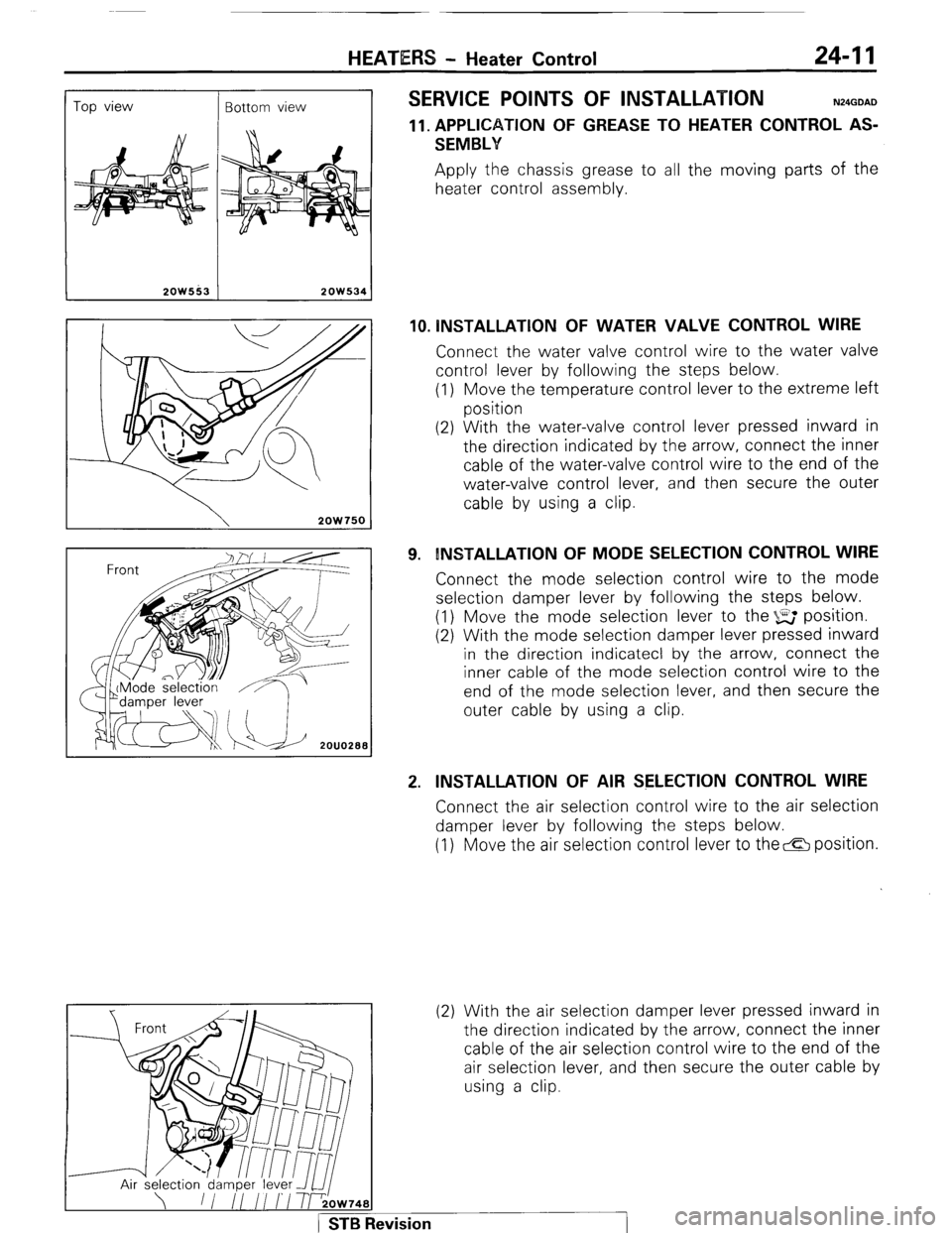

SERVICE POINTS OF INSTALLATION N24GDAD

11. APPLICATION OF GREASE TO HEATER CONTROL AS-

SEMBLY Apply the chassis grease to all the moving parts of the

heater control assembly.

10. lNSTALLATlON OF WATER VALVE CONTROL WIRE Connect the water valve control wire to the water valve

control lever by following the steps below.

(1) Move the temperature control lever to the extreme left

position

(2) With the water-valve control lever pressed inward in

the direction indicated by the arrow, connect the inner

cable of the water-valve control wire to the end of the

water-valve control lever, and then secure the outer

cable by using a clip.

9. INSTALLATION OF MODE SELECTION CONTROL WIRE Connect the mode selection control wire to the mode

selection damper lever by following the steps below.

(1) Move the mode selection lever to the %E position.

(2) With the mode selection damper lever pressed inward

in the direction indicatecl by the arrow, connect the

inner cable of the mode selection control wire to the

end of the mode selection lever, and then secure the

outer cable by using a clip.

2. INSTALLATION OF AIR SELECTION CONTROL WIRE Connect the air selection control wire to the air selection

damper lever by following the steps below.

(1) Move the air selection control lever to the& position.

(2) With the air selection damper lever pressed inward in

the direction indicated by the arrow, connect the inner

cable of the air selection control wire to the end of the

air selection lever, and then secure the outer cable by

using a clip.

1 STB Revision

Page 251 of 284

HEATERS - Blower Assembly 24-15

--I

Front wirina harness

d

!

2OW537

2OW768

2OW779

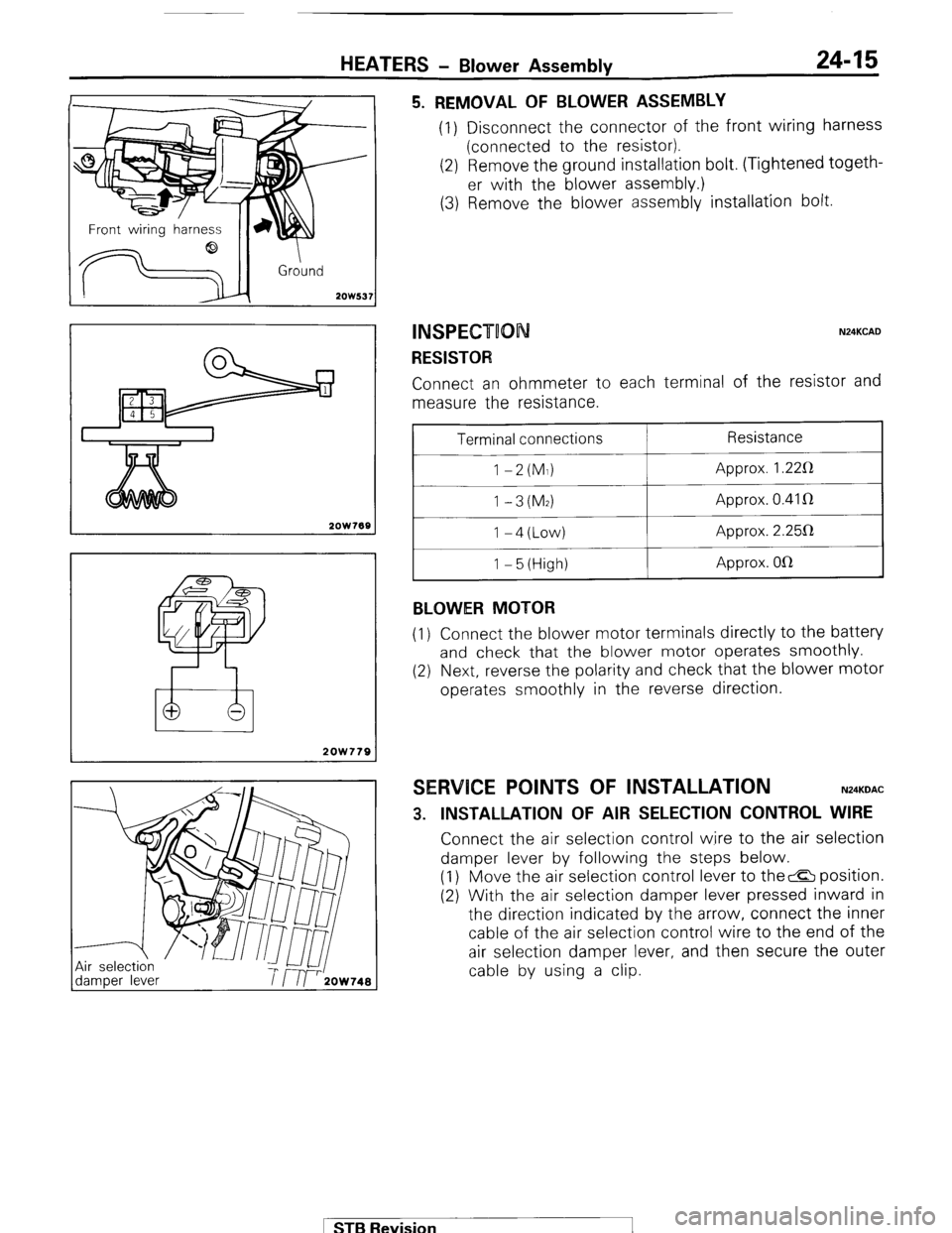

5. REMOVAL OF BLOWER ASSEMBLY (1) Disconnect the connector of the front wiring harness

(connected to the resistor).

(2) Remove the ground installation bolt. (Tightened togeth-

er with the blower assembly.)

(3) Remove the blower assembly installation bolt.

INSPECT00 N24KCAD

RESISTOR Connect an ohmmeter to each terminal of the resistor and

measure the resistance.

Terminal connections

1 -2(M1)

1 -3(M2) I-4(Low)

1 - 5 (High)

BLOWER MOTOR Resistance

Approx. 1.22R

Approx. 0.41 R

Approx. 2.25112

Approx. OlR

(1) Connect the blower motor terminals directly to the battery

and check that the blower motor operates smoothly.

(2) Next, reverse the polarity and check that the blower motor

operates smoothly in the reverse direction.

SERVICE POINTS OF INSTALLATION N24KDAC

3. INSTALLATION OF AIR SELECTION CONTROL WIRE Connect the air selection control wire to the air selection

damper lever by following the steps below.

(1) Move the air selection control lever to the& position.

(2) With the air selection damper lever pressed inward in

the direction indicated by the arrow, connect the inner

cable of the air selection control wire to the end of the

air selection damper lever, and then secure the outer

cable by using a clip.

1 STB Revision