Ignition coil MITSUBISHI MONTERO 1987 1.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 133 of 284

IGNITION SYSTEM-Service Adjustment Procedures 8-113

SPARK TEST - ENGINE CANNOT BE CRANKED

If spark test is performed by cranking while the catalyst is hot,

unburned gas will be supplied to the catalyst, and this is not de-

sirable to the catalyst.

For this reason, use the following methods which allow spark test

to be performed without cranking.

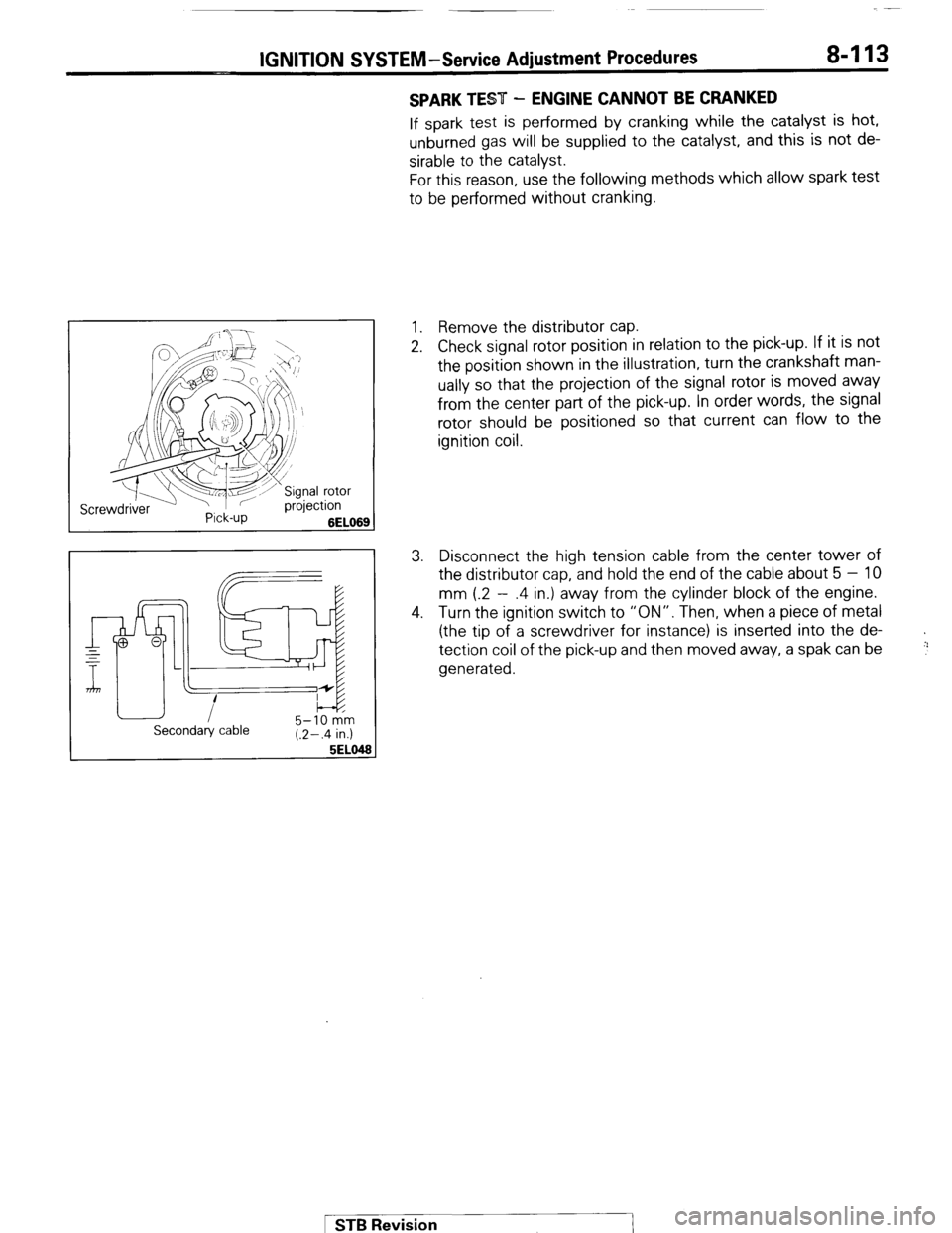

1. Remove the distributor cap.

2. Check signal rotor position in relation to the pick-up. If it is not

the position shown in the illustration, turn the crankshaft man-

ually so that the projection of the signal rotor is moved away

from the center part of the pick-up. In order words, the signal

rotor should be positioned so that current can flow to the

ignition coil.

3. Disconnect the high tension cable from the center tower of

the distributor cap, and hold the end of the cable about 5 - 10

mm (.2 - .4 in.) away from the cylinder block of the engine.

4. Turn the ignition switch to “ON”. Then, when a piece of metal

(the tip of a screwdriver for instance) is inserted into the de-

tection coil of the pick-up and then moved away, a spak can be

generated.

+

!:’

Secondary cable 5-10 km

(.2-.4 in.)

5EL0

1 STB Revision

Page 134 of 284

8-114 IGNITION SYSTEM - Ignition System

IGNITION SYSTEM

REMOVAL AND INSTALLATION NOEGJAE

20-30

Nm

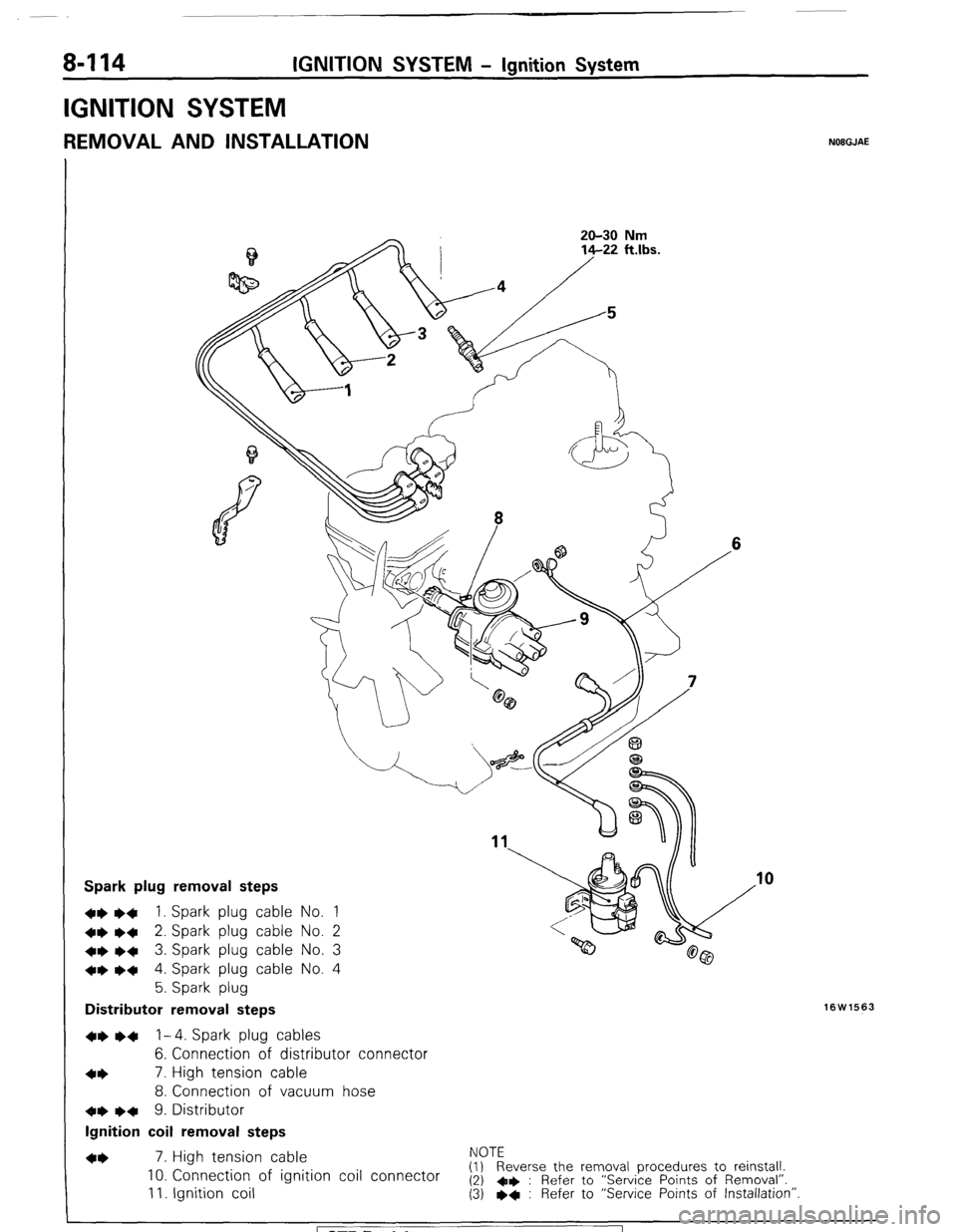

Spark plug removal steps

+e l

+ 1. Spark plug cable No. 1

~~ ~~ 2. Spark plug cable No. 2

+e e+ 3. Spark plug cable No. 3

*e e+ 4. Spark plug cable No. 4

5. Spark plug

Distributor removal steps

16W1563

~~ l + 1-4. Spark plug cables

6. Connection of distributor connector

+* 7. High tension cable

8. Connection of vacuum hose

de l

q 9. Distributor

Ignition coil removal steps

7. High tension cable NOTE

10. Connection of ignition coil connector (1) Reverse the removal procedures to reinstall.

(2) +e : Refer to “Service Points of Removal”. 11. Ignition coil (3) l + : Refer to “Service Points of Installation”

I

1 STB Revision

Page 136 of 284

8-116 IGNITION SYSTEM-Ignition System

Plug

cleaner

OlUOO89

Plug gap

gauge NIPPON

termine

rl

direction

High voltage

terminal

01R0234

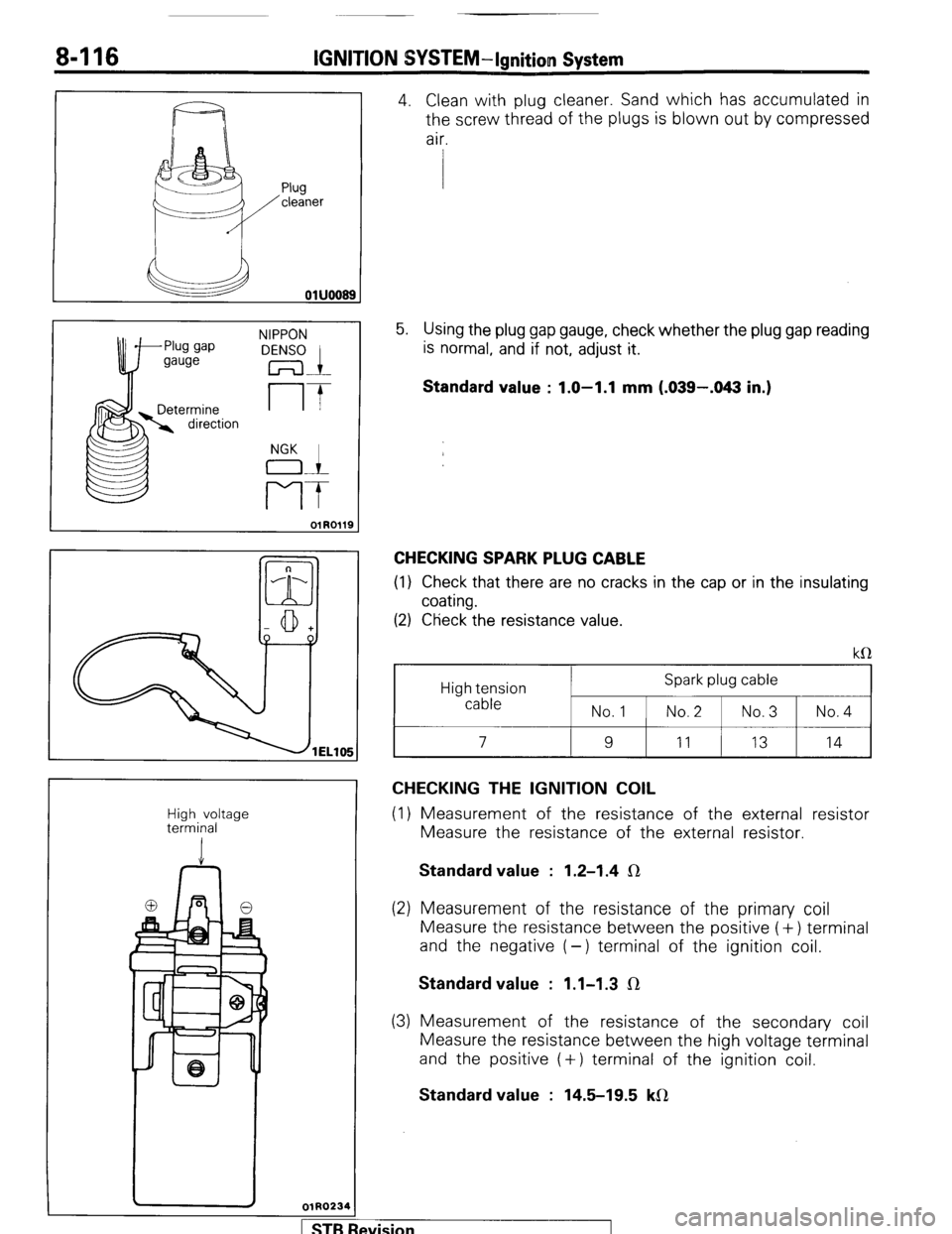

4. Clean with plug cleaner. Sand which has accumulated in

the screw thread of the plugs is blown out by compressed

air.

5. Using the plug gap gauge, check whether the plug gap reading

is normal, and if not, adjust it.

Standard value : 1.0-1.1 mm (.039-.043 in.)

CHECKING SPARK PLUG CABLE

(1) Check that there are no cracks in the cap or in the insulating

coating.

(2) Ctieck the resistance value.

High tension

cable Spark plug cable

No.1 1 No.2 1 No.3 1 No.4

I 9

I

11

I 13 I 14

CHECKING THE IGNITION COIL

(1) Measurement of the resistance of the external resistor

Measure the resistance of the external resistor. Standard value : 1.2-1.4 IR

(2) Measurement of the resistance of the primary coil

Measure the resistance between the positive (+) terminal

and the negative (-) terminal of the ignition coil. Standard value : 1.1-1.3 IR

(3) Measurement of the resistance of the secondary coil

Measure the resistance between the high voltage terminal

and the positive (+) terminal of the ignition coil. Standard value : 14.5-19.5 kfl

wision I

Page 143 of 284

METERS AND GAUGES-Specifications

METERS AND GAUGES

8-123

SPECIFICATIONS

GENERAL SPECIFICATIONS

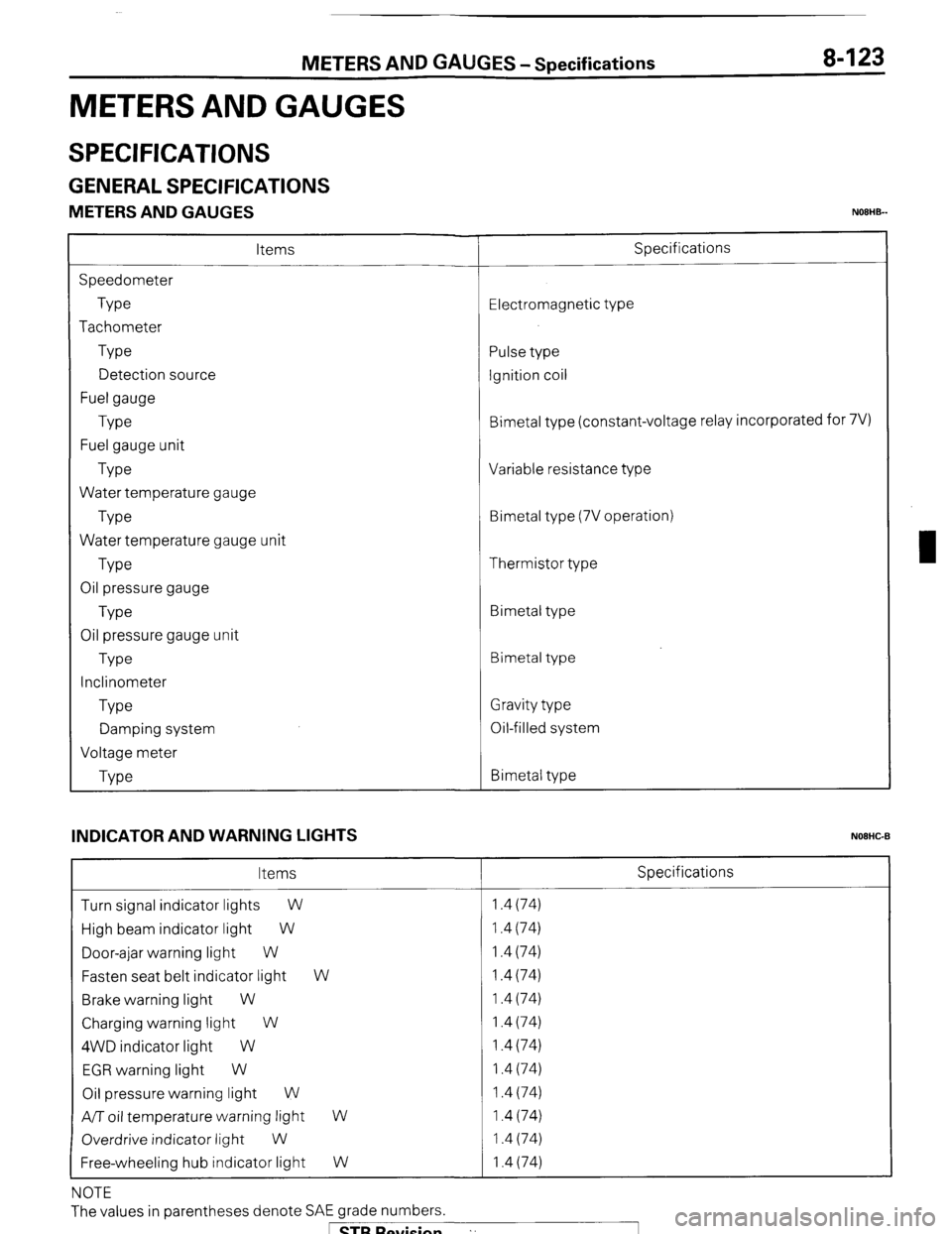

METERS AND GAUGES NOEHB-

Items

Speedometer

Type

Tachometer

Type

Detection source

Fuel gauge

Type

Fuel gauge unit

Type

Water temperature gauge

Type

Water temperature gauge unit

Type

Oil pressure gauge

Type

Oil pressure gauge unit

Type

Inclinometer

Type

Damping system

Voltage meter

Type Specifications

Electromagnetic type

Pulse type

Ignition coil

Bimetal type (constant-voltage relay incorporated for 7V)

Variable resistance type

Bimetal type (7V operation)

Thermistor type

Bimetal type

Bimetal type

Gravity type

Oil-filled system

Bimetal type

INDICATOR AND WARNING LIGHTS

NOEHC-B

Items Specifications

Turn signal indicator lights

W 1.4 (74)

High beam indicator light W 1.4 (74)

Door-ajar warning light W 1.4 (74)

Fasten seat belt indicator light W 1.4 (74)

Brake warning light W 1.4 (74)

Charging warning light W 1.4 (74)

4WD indicator light W 1.4 (74)

EGR warning light W 1.4 (74)

Oil pressure warning light W 1.4 (74)

A/T oil temperature warning light

W 1.4 (74)

Overdrive indicator light

W 1.4 (74)

Free-wheeling hub indicator light W 1.4 (74)

NOTE

The values in parentheses denote SAE grade numbers.

1 STB Revision ”

Page 231 of 284

AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM - Generallnformation 8-211

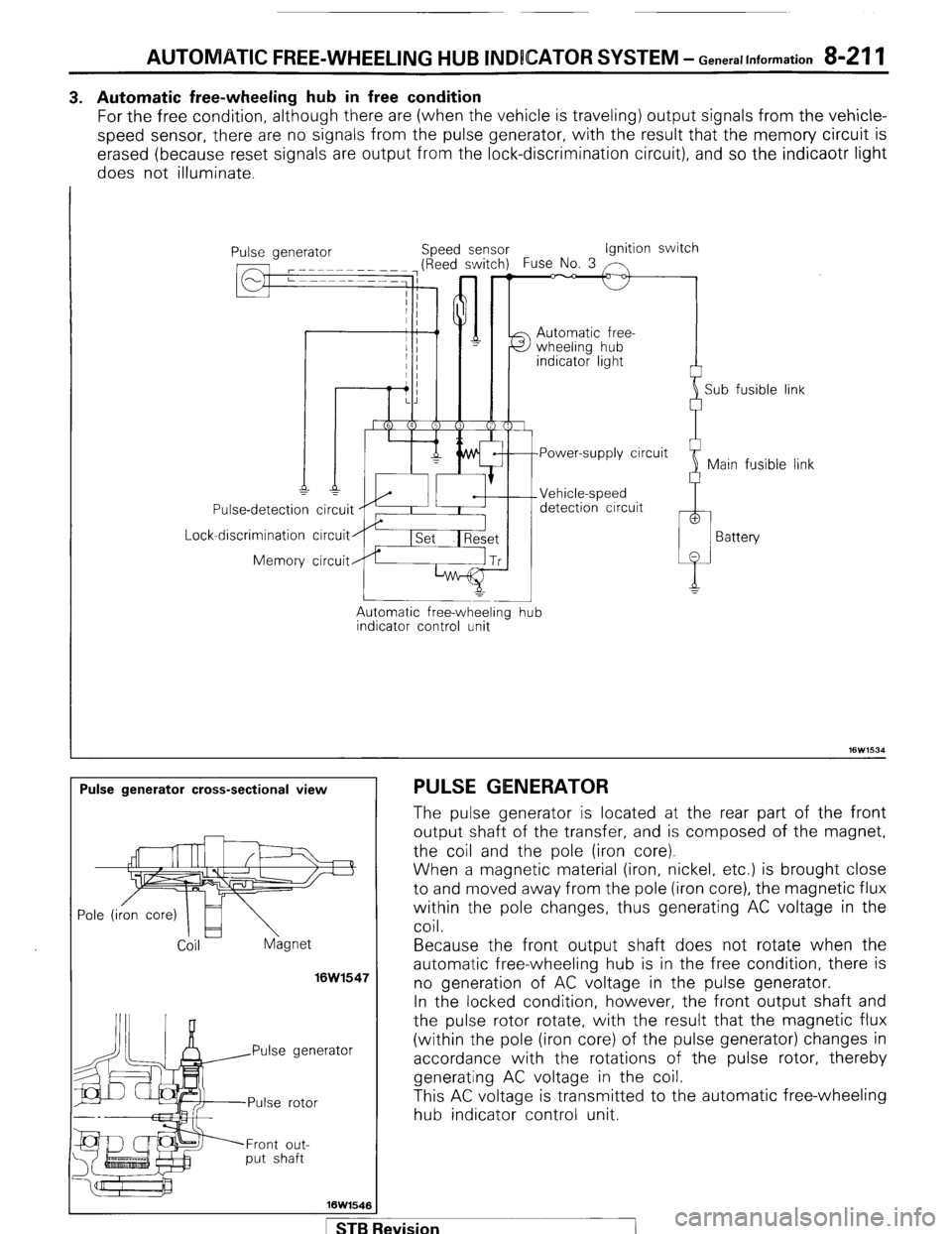

3. Automatic free-wheeling hub in free condition

For the free condition, although there are (when the vehicle is traveling) output signals from the vehicle-

speed sensor, there are no signals from the pulse generator, with the result that the memory circuit is

erased (because reset signals are output from the lock-discrimination circuit), and so the indicaotr light

does not illuminate.

I

Lock Use-detection

-discrimination

Memory ipeed sensor Ignition switch

Automatic free-

detection circuit

circuit

circuit

Automatic free-wheeling

indicator control unit -

hub i

Sub fusible link

link

Pulse generator cross-sectional view PULSE GENERATOR

Coil hgnet

16W1547

rator

Front out-

put shaft

16W1546 The pulse generator is located at the rear part of the front

output shaft of the transfer, and is composed of the magnet,

the coil and the pole (iron core).

When a magnetic material (iron, nickel, etc.) is brought close

to and moved away from the pole (iron core), the magnetic flux

within the pole changes, thus generating AC voltage in the

coil.

Because the front output shaft does not rotate when the

automatic free-wheeling hub is in the free condition, there is

no generation of AC voltage in the pulse generator.

In the locked condition, however, the front output shaft and

the pulse rotor rotate, with the result that the magnetic flux

(within the p o e I (’ Iron core) of the pulse generator) changes in

accordance with the rotations of the pulse rotor, thereby

generating AC voltage in the coil.

This AC voltage is transmitted to the automatic free-wheeling

hub indicator control unit.

STB Revision