key MITSUBISHI MONTERO 1987 1.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 213 of 284

AUDIO SYSTEM - Specifications 8-193

NOISE SOURCES

Source of Electrical System Noise

Ignition system

(1) Spark plug

(2) High tension cable

(3) Distributor Power generation system

(1) Ripple at contact between alternator

armature and carbon brush

(2) Spark from voltage regulator contact

!

Other electrical device

(1) Armature of wiper, blower and other

motors.

(2) Starter and switch when starting engine

(3) Spark from changeover switch

(4) Horn

(5) Contact of turn signal

(6) Loose contact of wiring harness

(7) Static electricity generated by tire or

generator drive-belt

(8) Voltage stability unit for instrument

Noise Sourse of Vehicle Equipment

Kind of noise

Whistling sound Equipment

Alternator Symptom of noise generation

Noise increases when accelerator pedal is

depressed and it subsides soon after engine

is stopped.

Scratching sound

Water temperature gauge unit Noise is produced while engine is running

and it persists for a while after engine

shutdown.

Fuel gauge unit Noise is produced at sudden acceleration,

driving on rough road or when ignition key is

placed to ON.

Jarring

Wish-wash,

wish-wash

Buzz, click Oil pressure switch

Flasher relay

Horn

Wiper motor

Washer motor Noise is produced with engine operation

and no noise is made when engine is idling.

Noise is produced with operation of turn

signal light

Noise is made when horn button is pressed

or released.

Whinning Noise is generated with the wiper speed.

Noise is made when washer is operated.

STB Revision

Page 216 of 284

8-196 AUDIO SYSTEM - Service Adjustment Procedures

SERVICE ADJUSTMENT PROCEDURES

ANTkNNA TRUMMER NOBNIAA

70R0351

1.

2.

3.

1.

2.

3.

4.

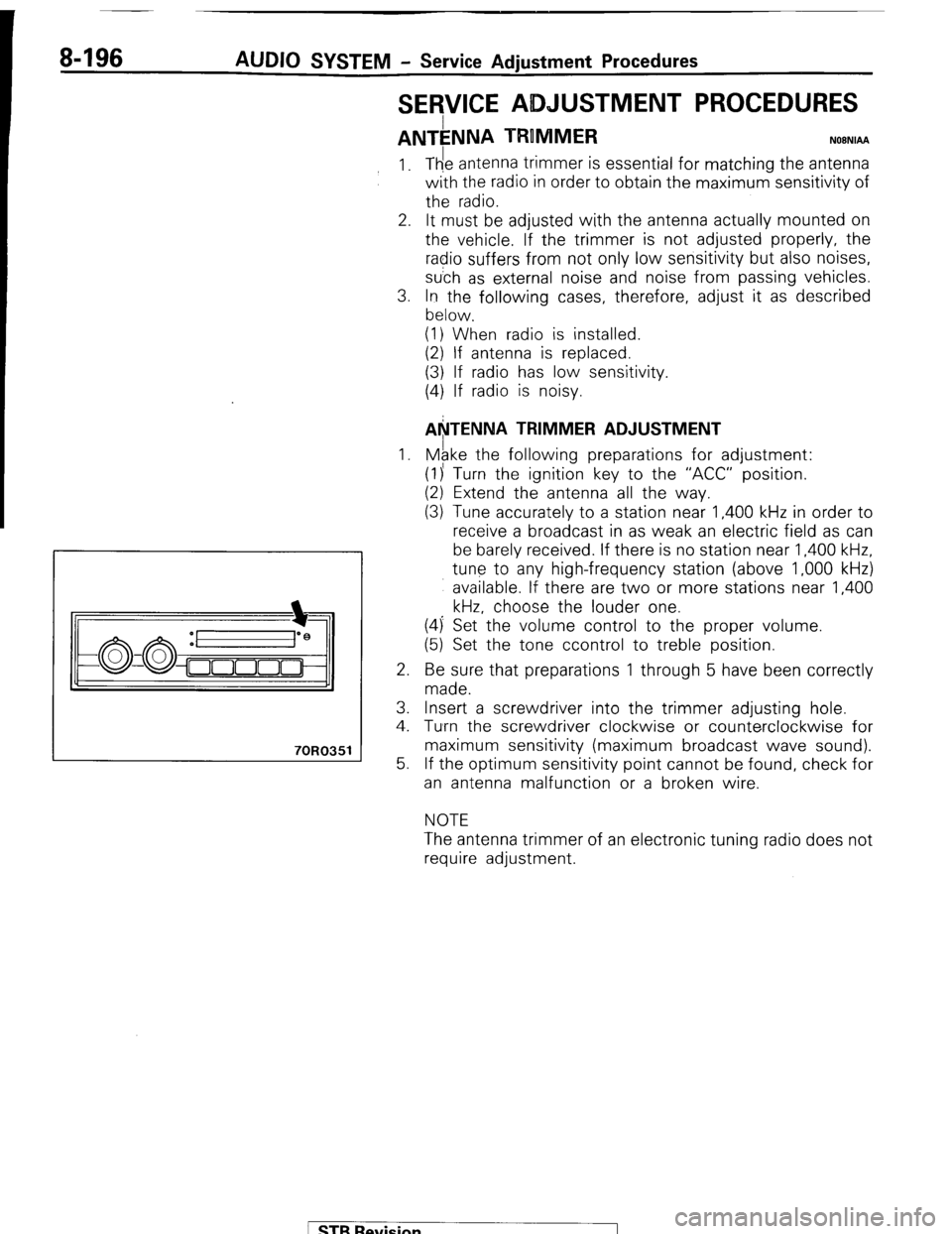

5. The antenna trimmer is essential for matching the antenna

with the radio in order to obtain the maximum sensitivity of

the radio.

It must be adjusted with the antenna actually mounted on

the vehicle. If the trimmer is not adjusted properly, the

radio suffers from not only low sensitivity but also noises,

su’ch as external noise and noise from passing vehicles.

In the following cases, therefore, adjust it as described

below.

(1) When radio is installed.

(2) If antenna is replaced.

(3) If radio has low sensitivity.

(4) If radio is noisy.

AkTENNA TRIMMER ADJUSTMENT

Mgke the following preparations for adjustment:

(1)’ Turn the ignition key to the “ACC” position.

(2) Extend the antenna all the way.

(3) Tune accurately to a station near 1,400 kHz in order to

receive a broadcast in as weak an electric field as can

be barely received. If there is no station near 1,400 kHz,

tune to any high-frequency station (above 1,000 kHz)

available. If there are two or more stations near 1,400

kHz, choose the louder one.

(4) Set the volume control to the proper volume.

(5) Set the tone ccontrol to treble position.

Be sure that preparations 1 through 5 have been correctly

made.

Insert a screwdriver into the trimmer adjusting hole.

Tumrn the screwdriver clockwise or counterclockwise for

maximum sensitivity (maximum broadcast wave sound).

If the optimum sensitivity point cannot be found, check for

an antenna malfunction or a broken wire.

NOTE

The antenna trimmer of an electronic tuning radio does not

require adjustment.

/ STB Revision

Page 229 of 284

AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM - General Information 8-209

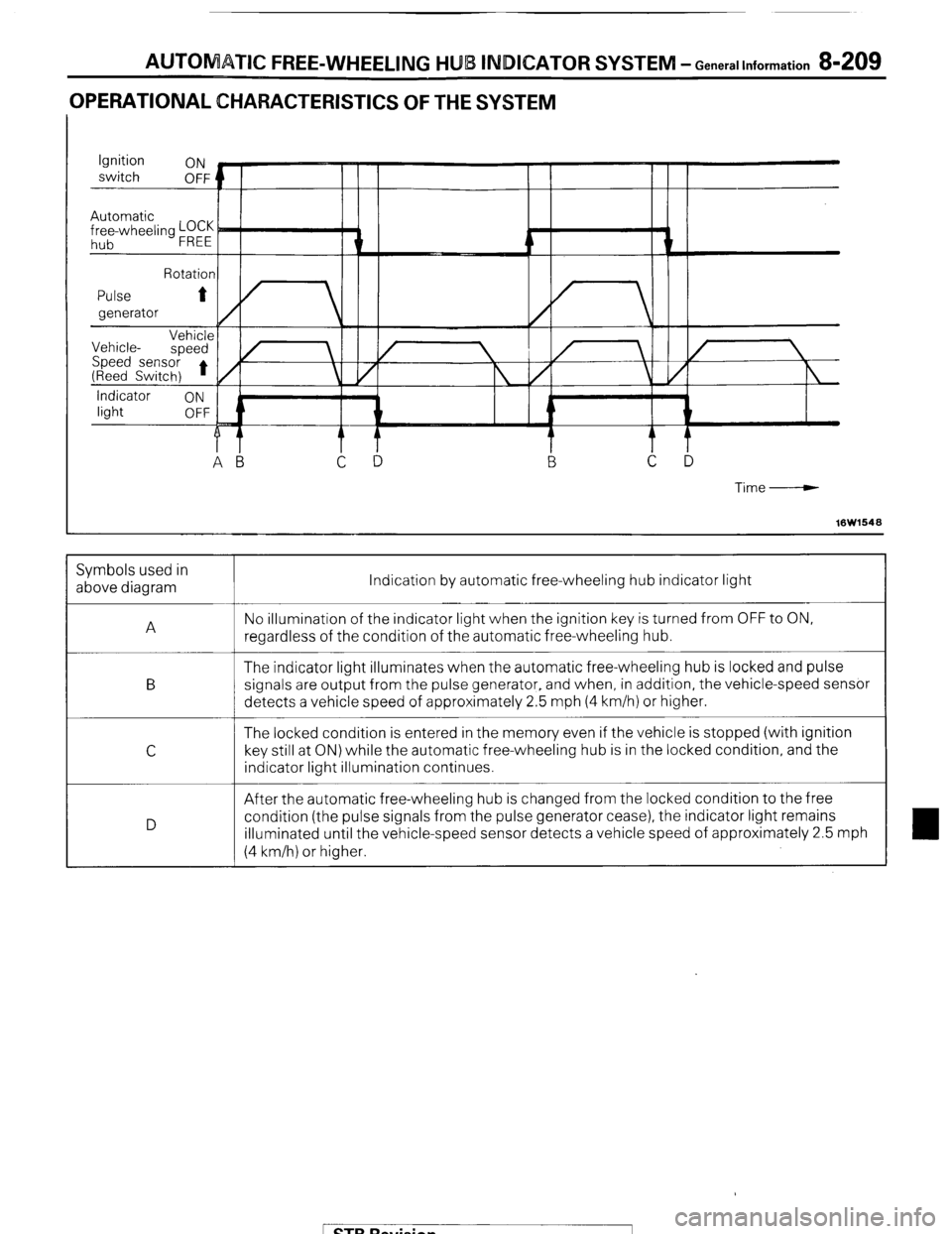

OPERATIONAL CHARACTERISTICS OF THE SYSTEM

Time-----w

16W1548 Indication by automatic free-wheeling hub indicator light

No illumination of the indicator light when the ignition key is turned from OFF to ON,

regardless of the condition of the automatic free-wheeling hub.

The indicator light illuminates when the automatic free-wheeling hub is locked and pulse

signals are output from the pulse generator, and when, in addition, the vehicle-speed sensor

detects a vehicle speed of approximately 2.5 mph (4 km/h) or higher.

The locked condition is entered in the memory even if the vehicle is stopped (with ignition

key still at ON) while the automatic free-wheeling hub is in the locked condition, and the

indicator light illumination continues.

After the automatic free-wheeling hub is changed from the locked condition to the free

condition (the pulse signals from the pulse generator cease), the indicator light remains

illuminated until the vehicle-speed sensor detects a vehicle speed of approximately 2.5 mph

(4 km/h) or higher. Symbols used in

above diagram

A

B

C

D

1 STB Revision

Page 230 of 284

8-210 AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM - General Information

EXPLANATION OF INDICATOR OPERATION

.

1.

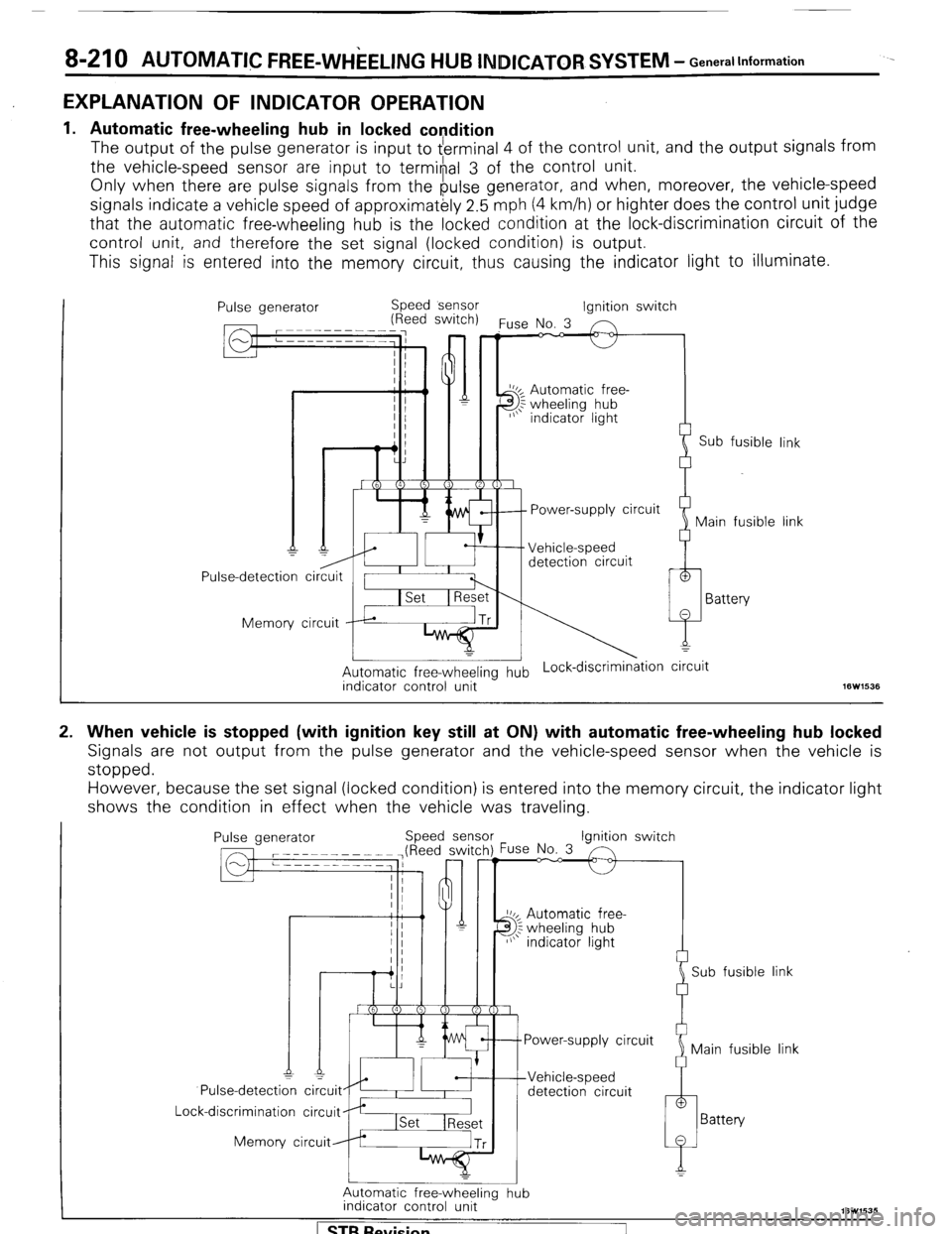

2. Automatic free-wheeling hub in locked condition

The

output of the pulse generator is input to $ertninal 4 of the control unit, and the output signals from

the vehicle-speed sensor are input

to termi#al 3 of the control unit.

Only when there are pulse signals from the pulse generator, and when, moreover, the vehicle-speed

signals indicate a vehicle speed of approximatkly 2.5 mph (4 km/h) or highter does the control unit judge

that the automatic free-wheeling hub is the locked condition at the lock-discrimination circuit of the

control unit, and therefore the set signal (locked condition) is output.

This signal is entered into the memory circuit, thus causing the indicator light to illuminate.

Pulse generator Speed sensor

(Reed switch)

Pulse-detection circuit / I I

Memory circuit rp*

I

Automatic free-wheeling hub Lock-discrimin&ion circuit

indicator control unit 16W1535 Ignition switch

‘use No. 3 n

J 2

I_

Power-supply circuit

Vehicle-speed

detection circuit 1

Sub fusible link 1

Main fusible link 1

)

1

Battery

When vehicle is stopped (with ignition key still at ON) with automatic free-wheeling hub locked

Signals are not output from the pulse generator and the vehicle-speed sensor when the vehicle is

stopped.

However, because the set signal (locked condition) is entered into the memory circuit, the indicator light

shows the condition in effect when the vehicle was traveling.

Pulse generator Speed sense

Pulse-detecti: ci~uit~~I~ #

Lock-discrimination circuit

Memory circuit ‘use No. 3 Ignition switch

10~ Automatic free-

3; wheeling hub

I/\’ indicator light

Sub fusible link

Power-supply circuit

Main fusible link

detection circuit

Automatic free-wheeling hub

indicator control unit

[ STB Revision

Page 233 of 284

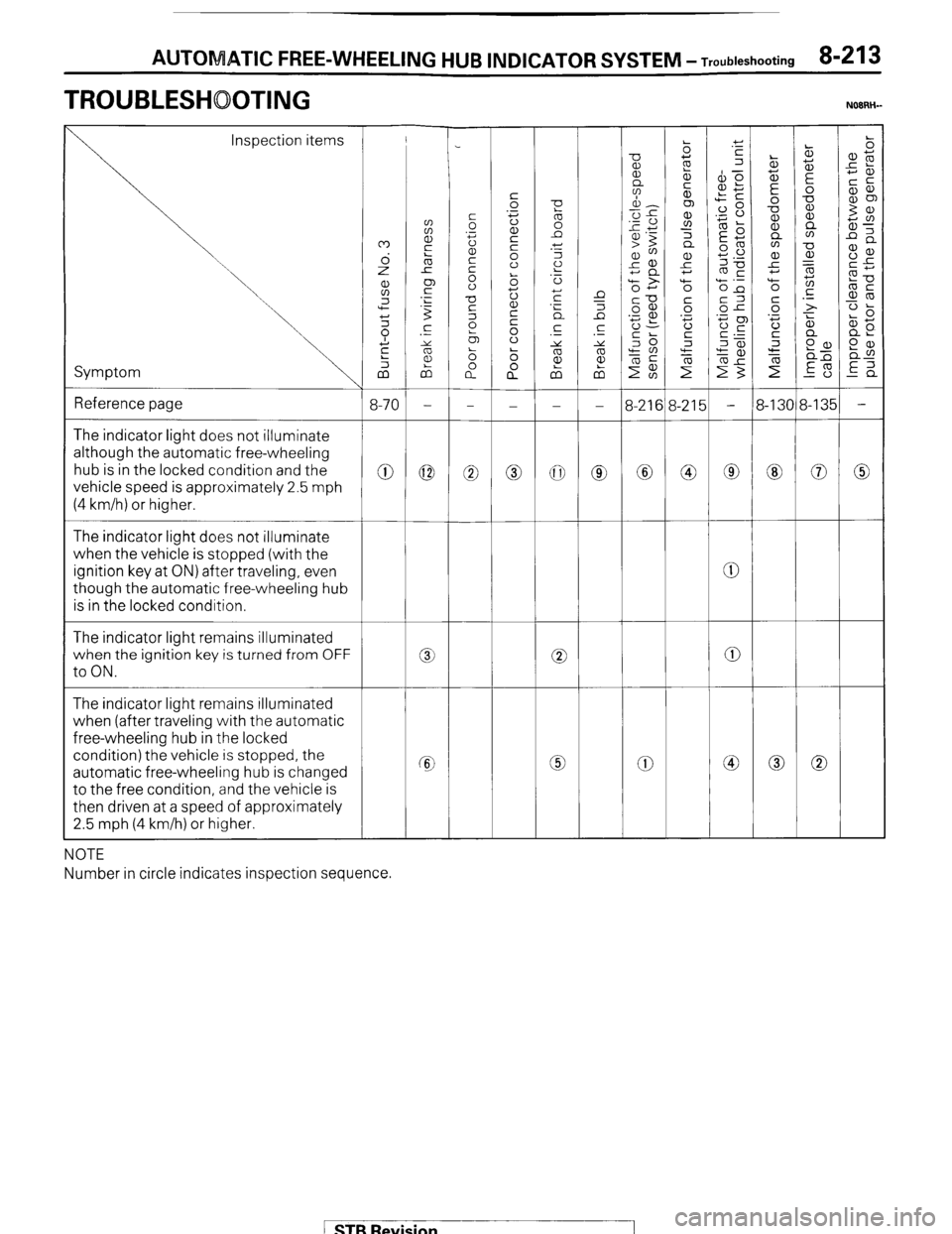

AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM -Troubleshooting 8-213

TROUBLESHOOTING NOIRH-

Inspection items

Symptom

Reference page

3-21E

0 The indicator light does not illuminate

although the automatic free-wheeling

hub is in the locked condition and the

vehicle speed is approximately 2.5 mph

(4 km/h) or higher.

0 0 0

0

The indicator light does not illuminate

when the vehicle is stopped (with the

ignition key at ON) after traveling, even

though the automatic free-wheeling hub

is in the locked condition.

The indicator light remains illuminated

when the ignition key is turned from OFF

to ON.

0

0 0 0

a 0

The indicator light remains illuminated

when (after traveling with the automatic

free-wheeling hub in the locked

condition) the vehicle is stopped, the

automatic free-wheeling hub is changed

to the free condition, and the vehicle is

then driven at a speed of approximately

2.5 mph (4 km/h) or higher.

0 Cc 0

NOTE

Number in circle indicates inspection sequence.

/ STB Revision

Page 236 of 284

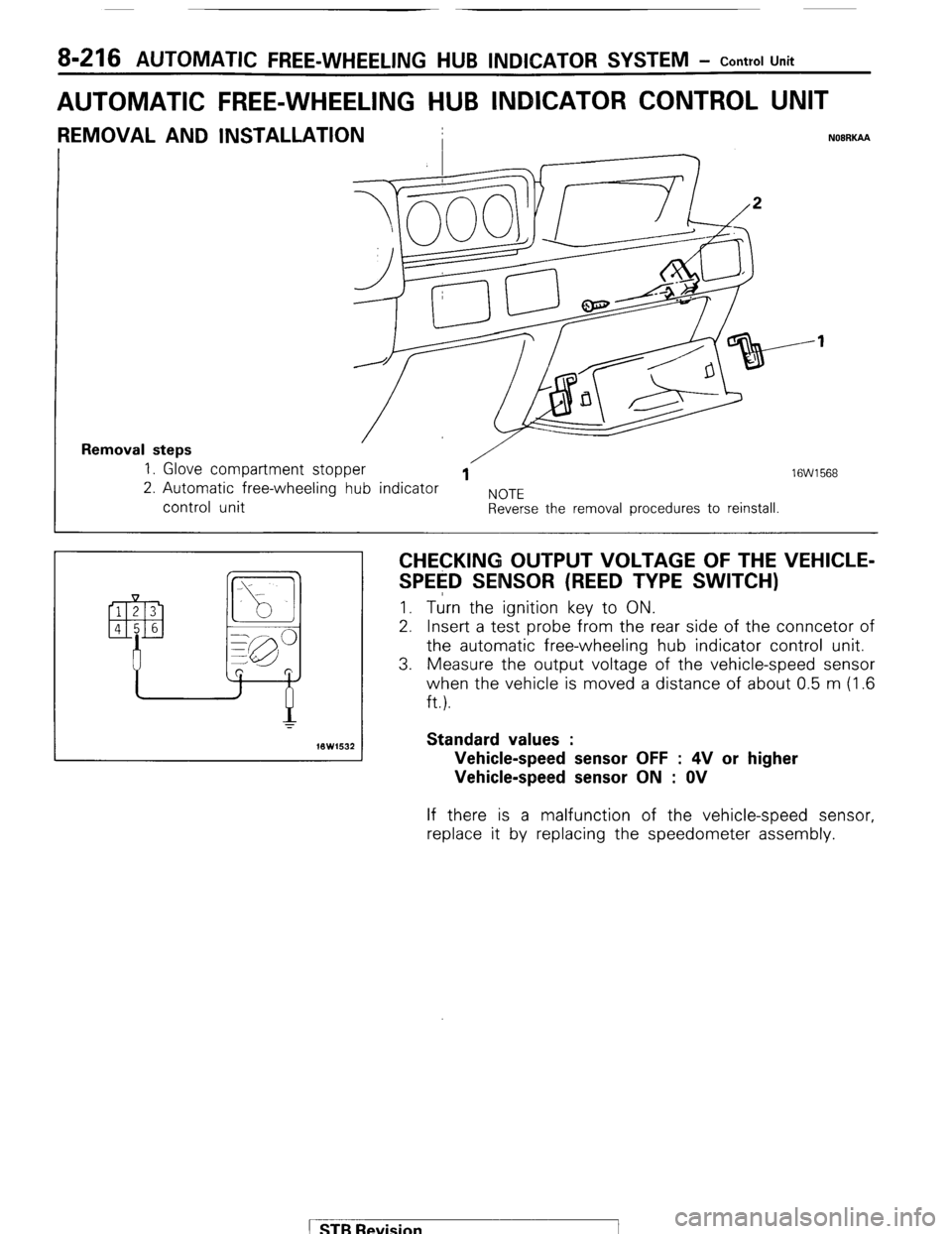

8-216 AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM - Control Unit

AUTOMATIC FREE-WHEELING HUB INDICATOR CONTROL UNIT

REMOVAL AND INSTALLATION

I NOBRKAA

Removal steps 1. Glove compartment stopper /

1 16W1568 2. Automatic free-wheeling hub indicator

NOTE control unit Reverse the removal procedures to reinstall.

CHECKING OUTPUT VOLTAGE OF THE VEHICLE-

SPE$D SENSOR (REED TYPE SWITCH) I. Turn the ignition key to ON.

2. Insert a test probe from the rear side of the conncetor of

the automatic free-wheeling hub indicator control unit.

3. Measure the output voltage of the vehicle-speed sensor

when the vehicle is moved a distance of about 0.5 m (1.6

ft.).

Standard values :

Vehicle-speed sensor OFF : 4V or higher

Vehicle-speed sensor ON : OV If there is a malfunction of the vehicle-speed sensor,

replace it by replacing the speedometer assembly.

( STB Revision

Page 282 of 284

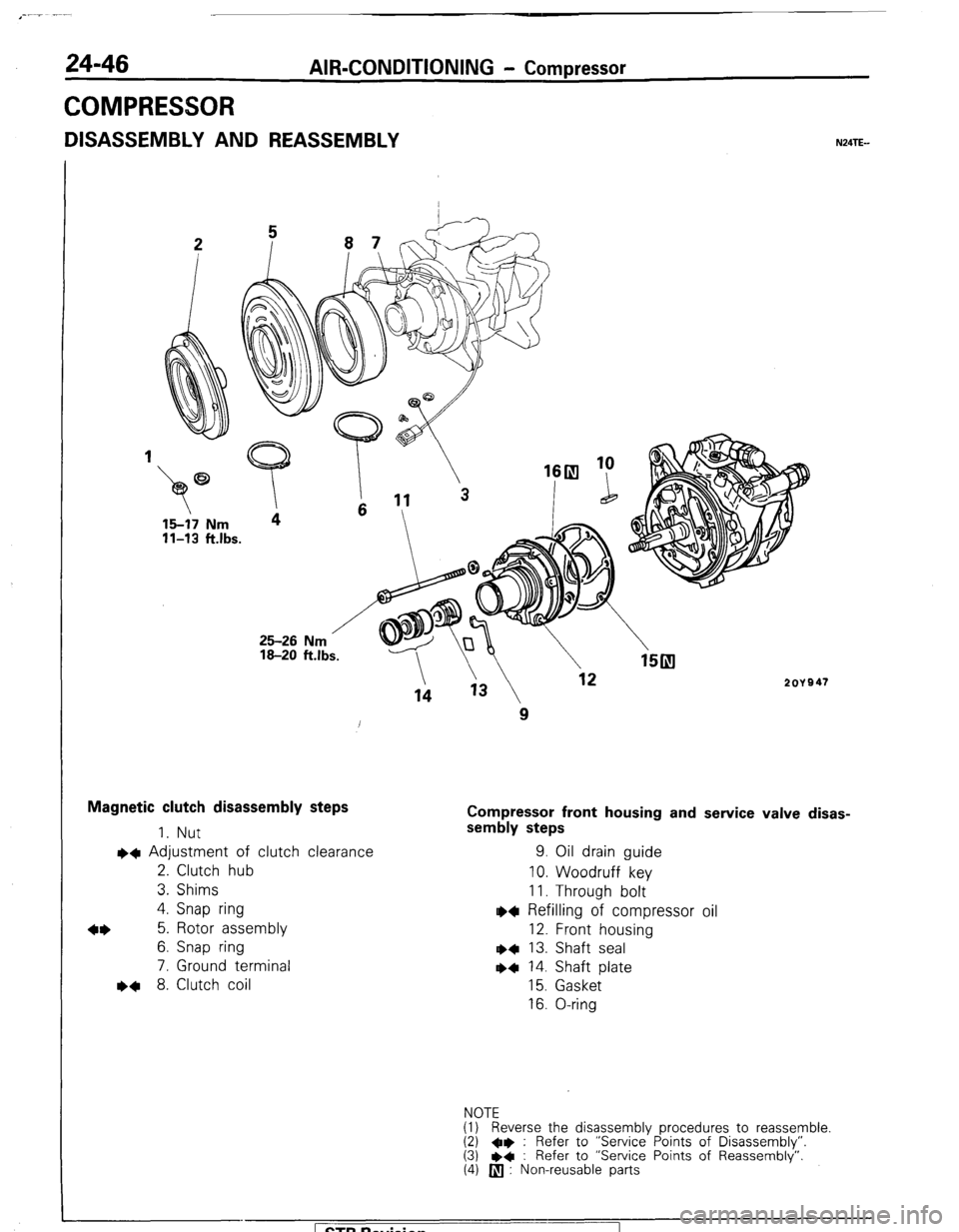

24-46

COMPRESSOR

AIR-CONDITIONING - Compressor

DISASSEMBLY AND REASSEMBLY N24TE-

15-h Nm

11-13 ftlbs 16

a 0

I

26-26 Nm

16-20 ftlbs. Magnetic clutch disassembly steps

1. Nut

~~ Adjustment of clutch clearance

2. Clutch hub

3. Shims

4.

Snap ring

4* 5. Rotor assembly

6.

Snap ring

7.

Ground terminal

l + 8. Clutch coil

l5Dl

2QY947 Compressor front housing and service valve disas-

sembly steps

9. Oil drain guide

10.

Woodruff key

Il. Through bolt

** Refilling of compressor oil

12. Front housing

o+

13. Shaft seal

04 14.

Shaft plate

15.

Gasket

16. O-ring

NOTE

(1) Reverse the disassembly procedures to reassemble.

(2) +e : Refer to “Service Points of Disassembly”.

(3) e+ : Refer to “Service Points of Reassembly”.

(4)

q : Non-reusable parts 1 STB Revision