Oil pressure MITSUBISHI MONTERO 1987 1.G Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 266 of 284

24-30 AIR-CONDITIONING -Service Adjustunent Procedures

(4) If the sight glass shows foam or bubbles, the systpm could be low on charge. Occasional foam or bubbles are

normal when the ambient temperature is above 43”C(110”F) or below 21”C(7O”F).

Adjust the engine speed to 1,500 rpm. Block the airflow through the condenser to increase the compressor

discharge pressure to 1,422 to 1,520 kPa (20$ to 220 dsi). If sight glass still shows bubbles or foam, system charge

level is low.

The refrigerant system will not be low on charge unless there is a leak. Find and repair the leak. If the leak can be

repaired without discharging the system an oil level check is not necessary. Use the procedure for correcting low

refrigerant level found in the Refrigerant Sy$em Service Procedure Section.

FUSIBLE PLUG

When ambient temperature of the fusible plug reach& 105~221~F), the fusible plug melts and the refrigerant in

the system is released.

Once the fusible plug is operated, it cannot be used again.

SO, it is necessary to install new one and charge the refrigerant in the system.

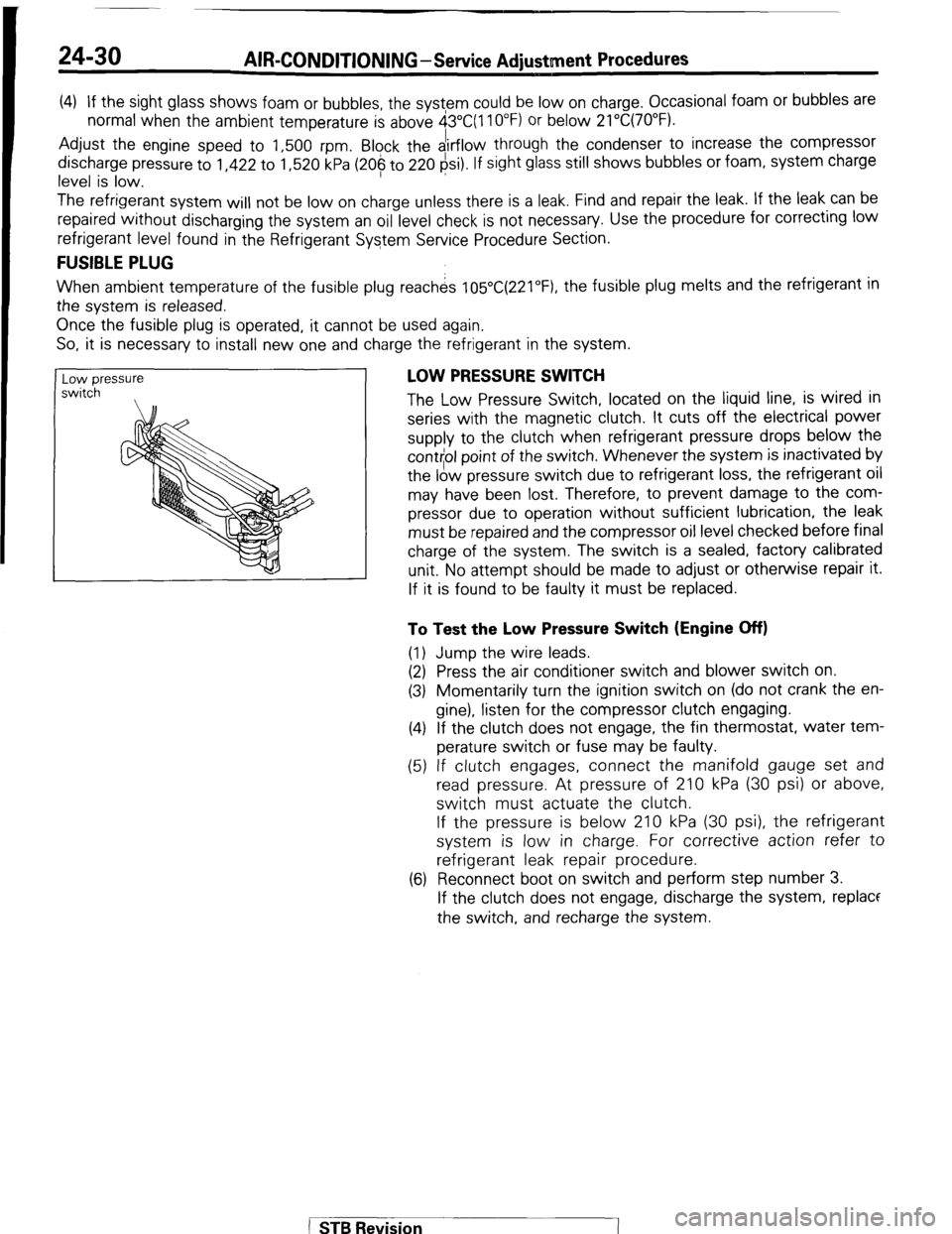

Low pressure

switch , LOW PRESSURE SWITCH

The Low Pressure Switch, located on the liquid line, is wired in

series with the magnetic clutch. It cuts off the electrical power

supply to the clutch when refrigerant pressure drops below the

cont$ol point of the switch. Whenever the system is inactivated by

the low pressure switch due to refrigerant loss, the refrigerant oil

may have been lost. Therefore, to prevent damage to the com-

pressor due to operation without sufficient lubrication, the leak

must be repaired and the compressor oil level checked before final

charge of the system. The switch is a sealed, factory calibrated

unit. No attempt should be made to adjust or otherwise repair it.

If it is found to be faulty it must be replaced.

To Test the Low Pressure Switch (Engine Off)

(1) Jump the wire leads.

(2) Press the air conditioner switch and blower switch on.

(3) Momentarily turn the ignition switch on (do not crank the en-

gine), listen for the compressor clutch engaging.

(4) If the clutch does not engage, the fin thermostat, water tem-

perature switch or fuse may be faulty.

(5) If clutch engages, connect the manifold gauge set and

read pressure. At pressure of 210 kPa (30 psi) or above,

switch must actuate the clutch.

If the pressure is below 210 kPa (30 psi), the refrigerant

system is low in charge. For corrective action refer to

refrigerant leak repair procedure.

(6) Reconnect boot on switch and perform step number 3.

If the clutch does not engage, discharge the system, replace

the switch, and recharge the system.

[

STB Revision

Page 272 of 284

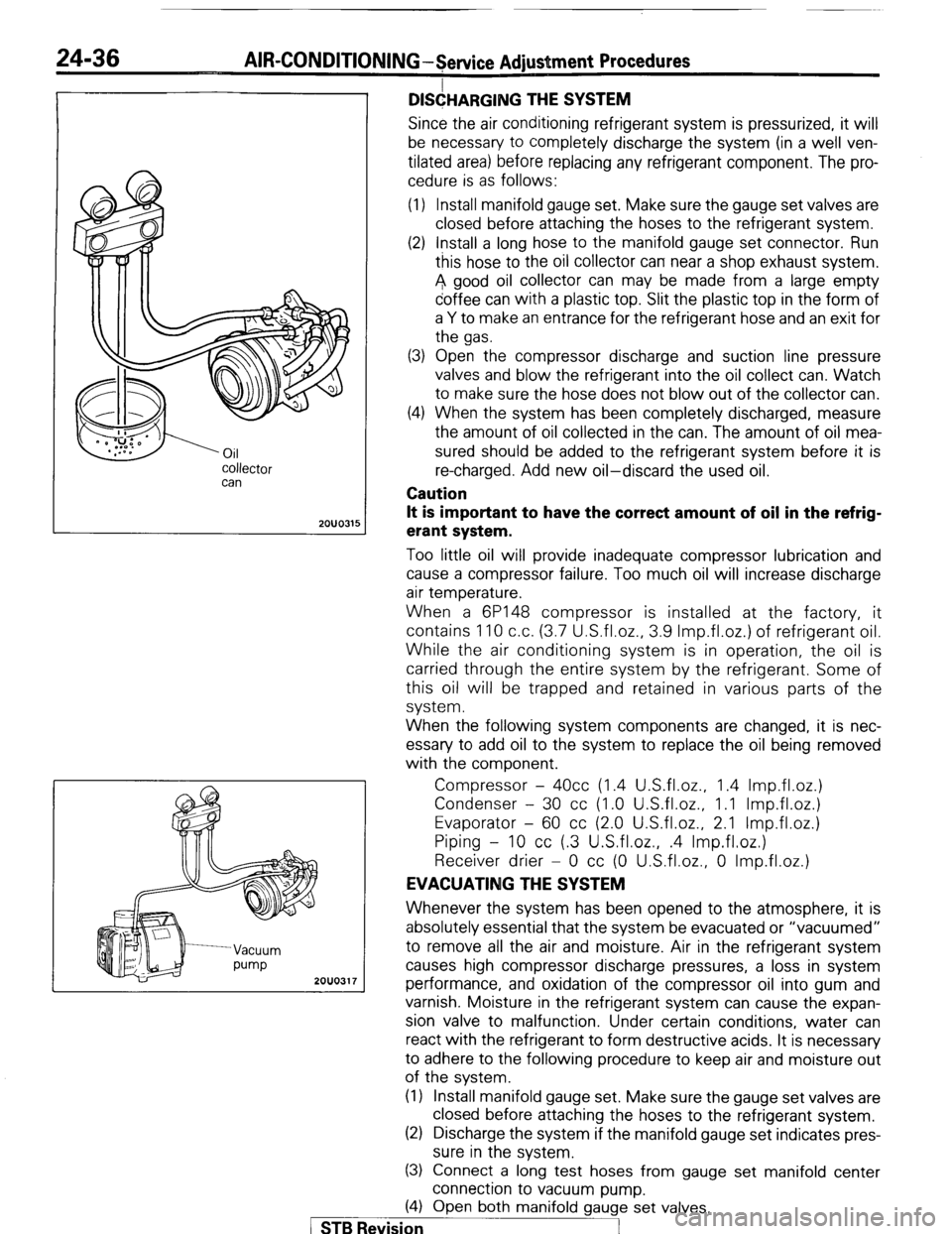

COllector

can

2OUO315

24-36 AIR-CONDITIONING-Service Adjustment Procedures

D&ARG,NG THE SYSTEM

Since the air conditioning refrigerant system is pressurized, it will

be necessary to completely discharge the system (in a well ven-

tilated area) before replacing any refrigerant component. The pro-

cedure is as follows:

(1) Install manifold gauge set. Make sure the gauge set valves are

closed before attaching the hoses to the refrigerant system.

(2) Install a long hose to the manifold gauge set connector. Run

this hose to the oil collector can near a shop exhaust system.

A good oil collector can may be made from a large empty

coffee can with a plastic top. Slit the plastic top in the form of

a Y to make an entrance for the refrigerant hose and an exit for

the gas.

(3) Open the compressor discharge and suction line pressure

valves and blow the refrigerant into the oil collect can. Watch

to make sure the hose does not blow out of the collector can.

(4) When the system has been completely discharged, measure

the amount of oil collected in the can. The amount of oil mea-

sured should be added to the refrigerant system before it is

re-charged. Add new oil-discard the used oil.

Caution

It is important to have the correct amount of oil in the refrig-

erant system.

Too little oil will provide inadequate compressor lubrication and

cause a compressor failure. Too much oil will increase discharge

air temperature.

When a 6P148 compressor is installed at the factory, it

contains 110 c.c. (3.7 U.S.fl.oz., 3.9 Imp.fl.oz.) of refrigerant oil.

While the air conditioning system is in operation, the oil is

carried through the entire system by the refrigerant. Some of

this oil will be trapped and retained in various parts of the

system.

When the following system components are changed, it is nec-

essary to add oil to the system to replace the oil being removed

with the component.

Compressor - 4Occ (1.4 U.S.fl.oz., 1.4 Imp.fl.oz.)

Condenser - 30 cc (1.0 U.S.fl.oz., 1.1 Imp.fl.oz.)

Evaporator - 60 cc (2.0 U.S.fl.oz., 2.1 Imp.fl.oz.)

Piping - 10 cc (.3 U.S.fl.oz., .4 Imp.fl.oz.)

Receiver drier - 0 cc (0 U.S.fl.oz., 0 Imp.fl.oz.)

EVACUATING THE SYSTEM

2OUO31

Whenever the system has been opened to the atmosphere, it is

absolutely essential that the system be evacuated or “vacuumed”

to remove all the air and moisture. Air in the refrigerant system

causes high compressor discharge pressures, a loss in system

performance, and oxidation of the compressor oil into gum and

varnish. Moisture in the refrigerant system can cause the expan-

sion valve to malfunction. Under certain conditions, water can

react with the refrigerant to form destructive acids. It is necessary

to adhere to the following procedure to keep air and moisture out

of the system.

(1) Install manifold gauge set. Make sure the gauge set valves are

closed before attaching the hoses to the refrigerant system.

(2) Discharge the system if the manifold gauge set indicates pres-

sure in the system.

(3) Connect a long test hoses from gauge set manifold center

connection to vacuum pump.

(4) Open both manifold gauge set valves.

/

/vision I

Page 277 of 284

AIR-CONDITIONING -Service Adjustment Procedures 24-41

COMPRESSOR NOISE NWLM

When investigating an air conditioning related noise, you must first know the conditions when the noise occurs.

These conditions are: weather, vehicle speed, in gear or neutral, engine temperature or any other special

conditions.

Noises that develop during air- conditioning operation can often be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be caused by loose bolts, nuts, mounting brackets, or a loose clutch

assembly. Verify accessory drive belt tension (power

steering, alternator or air pump). Improper accessory drive belt

tension can cause a misleading noise when the compressor is engaged and little or no noise when the compressor

is disengaged.

Drive belts are speed sensitive. That is, at different engine speeds, and depending upon belt tension, belts can

develop unusual noises that are often mistaken for mechanical problems within the compressor.

Adjustment Procedures

(1) Select a quiet area for testing. Duplicate conditions as much as possible. Switch compressor on and off several

times to clearly identify compressor noise.

To duplicate high ambient conditions (high head pressure), restrict air-flow through

condenser. Install

manifold gauge set to make sure discharge pressure does not exceed 2,070 kPa (300 psi).

(2) Tighten all compressor mounting bolts, clutch mounting bolt, and compressor drive belt. Check to assure clutch

coil is tight (no rotation or wobble).

(3) Check refrigerant hoses for rubbing or interference that can cause unusual noises.

(4) Check refrigerant charge (See “Charging the System”).

(5) Recheck compressor noise as in Step 1.

(6) If noise still exists, loosen compressor mounting bolts and retorque. Repeat Step 1.

(7) If noise continues, replace compressor and repeat Step 1.

1 STB Revision

Page 284 of 284

,: 24-48 AIR-CQNDITIONING - Compressor

I

2OY717

1 iOY718 l

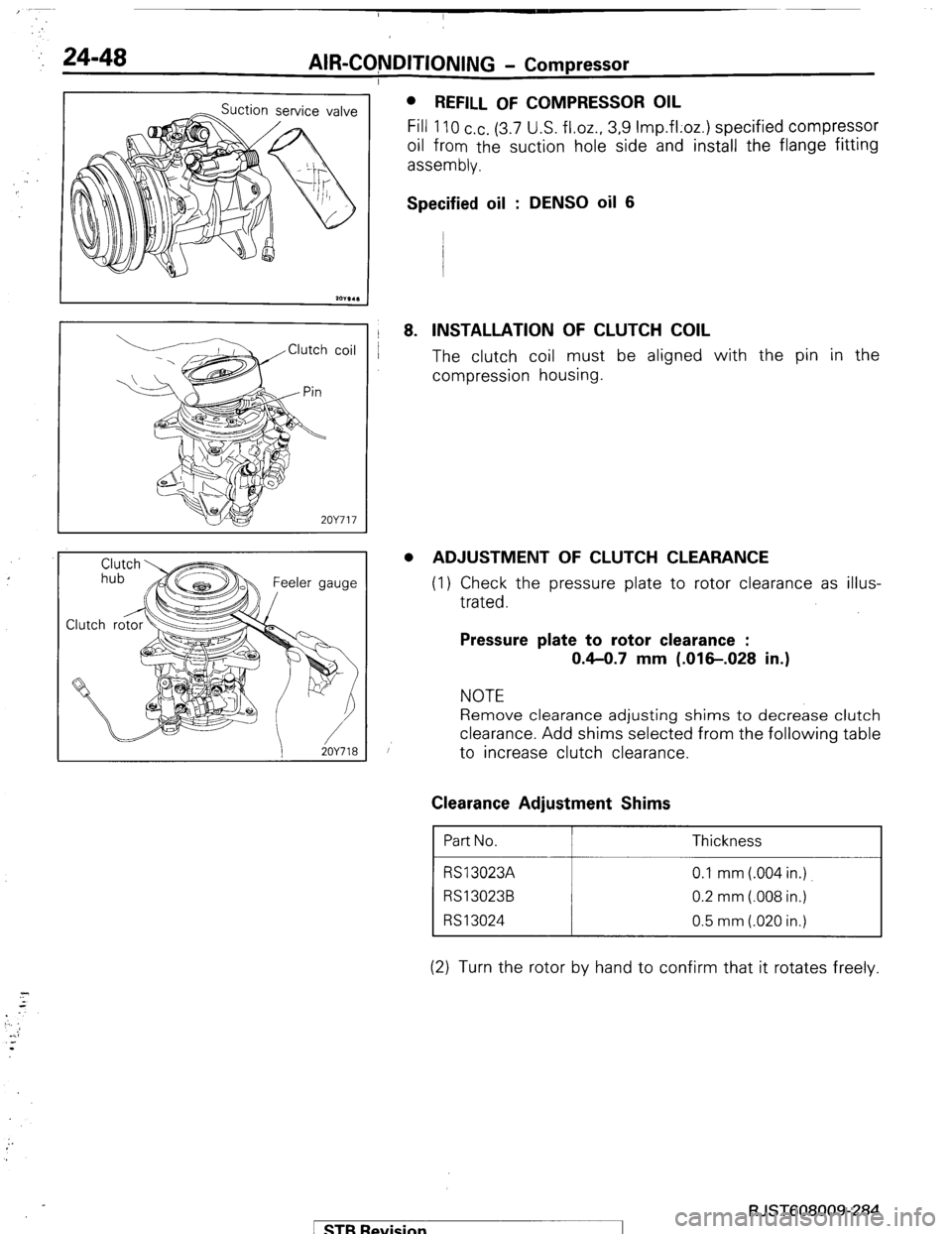

REFILL OF COMPRESSOR OIL

Fill 110 cc. (3.7 U.S. fl.oz., 3.9 Imp.fl;oz.) specified compressor

oil from the suction hole side and install the flange fitting

assembly.

Specified oil : DENS0 oil 6

8. INSTALLATION OF CLUTCH COIL

The clutch coil must be aligned with the pin in the

compression housing.

. ADJUSTMENT OF CLUTCH CLEARANCE

(1) Check the pressure plate to rotor clearance as illus-

trated.

Pressure plate to rotor clearance :

0.4-0.7 mm (.016-.028 in.)

NOTE

Remove clearance adjusting shims to decrease clutch

clearance. Add shims selected from the following table

to increase clutch clearance.

Clearance Adjustment Shims

Part No. Thickness

RSI 3023A 0.1 mm (.004 in.).

RSI 3023B 0.2 mm (.008 in.)

RSI 3024 0.5 mm (.020 in.)

(2) Turn the rotor by hand to confirm that it rotates freely.

:.

RJST608009-284

1 STB Revision

-1