Coil MITSUBISHI MONTERO 1987 1.G Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 260 of 284

AIR-CONDITIONING-Service Adjustment Procedures

SERVICE ADJUSTMENT PROCQDURES 24-29 N24FDAD

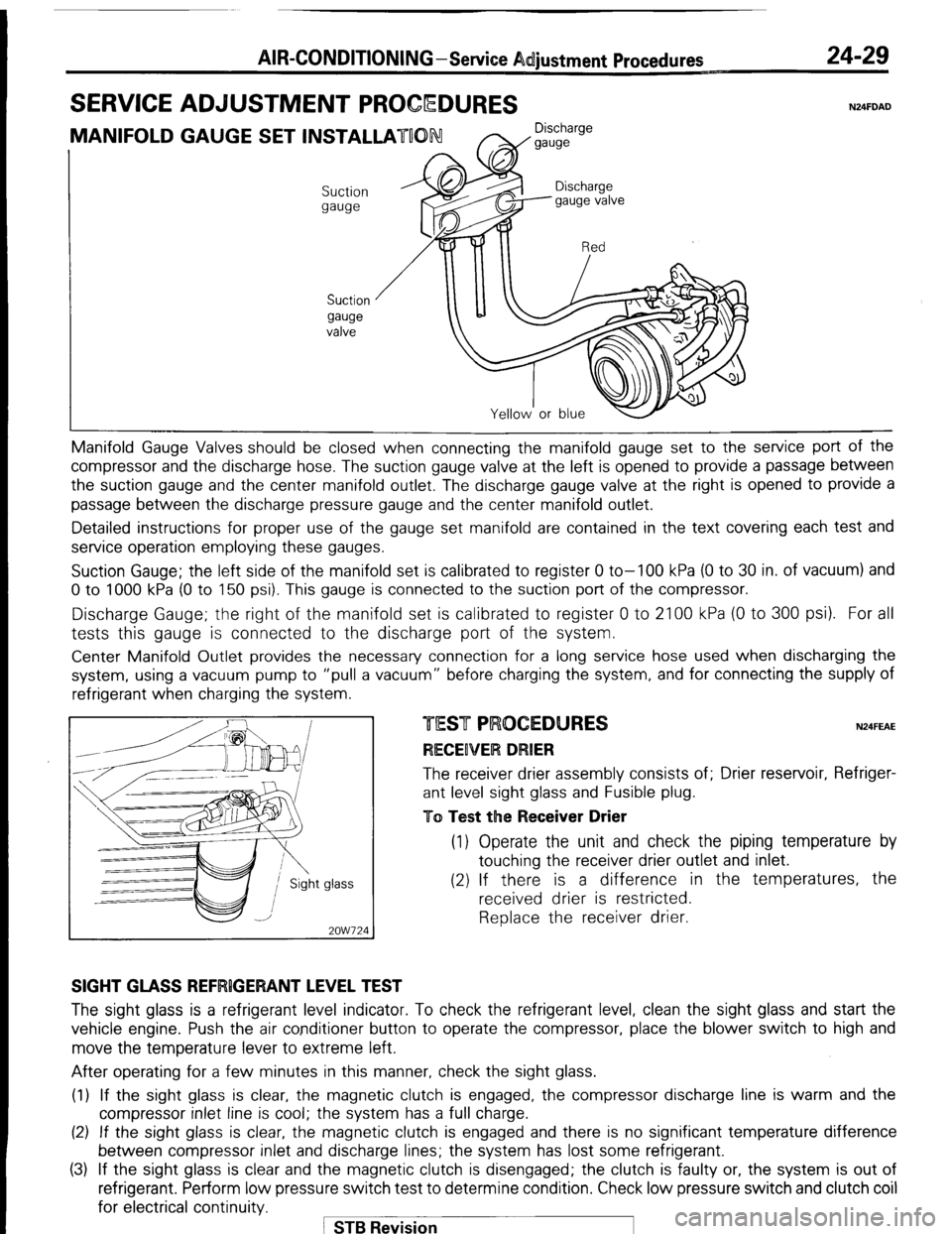

MANIFOLD GAUGE SET INSTALLATUON Discharge

W gauge

Suction

gauge

Suction

gauge

valve Manifold Gauge Valves should be closed

when connecting the manifold gauge set to the service port of the

compressor and the discharge hose. The suction gauge valve at the left is opened to provide a passage between

the suction gauge and the center manifold outlet. The discharge gauge valve at the right is opened to provide a

passage between the discharge pressure gauge and the center manifold outlet.

Detailed instructions for proper use of the gauge set manifold are contained in the text covering each test and

service operation employing these gauges.

Suction Gauge; the left side of the manifold set is calibrated to register 0 to-100 kPa (0 to 30 in. of vacuum) and

0 to 1000 kPa (0 to 150 psi). This gauge is connected to the suction port of the compressor.

Discharge Gauge; the right of the manifold set is calibrated to register 0 to 2100 kPa (0 to 300 psi). For all

tests this gauge is connected to the discharge port of the system.

Center Manifold Outlet provides the necessary connection for a long service hose used when discharging the

system, using a vacuum pump to “pull a vacuum” before charging the system, and for connecting the supply of

refrigerant when charging the system

glass -

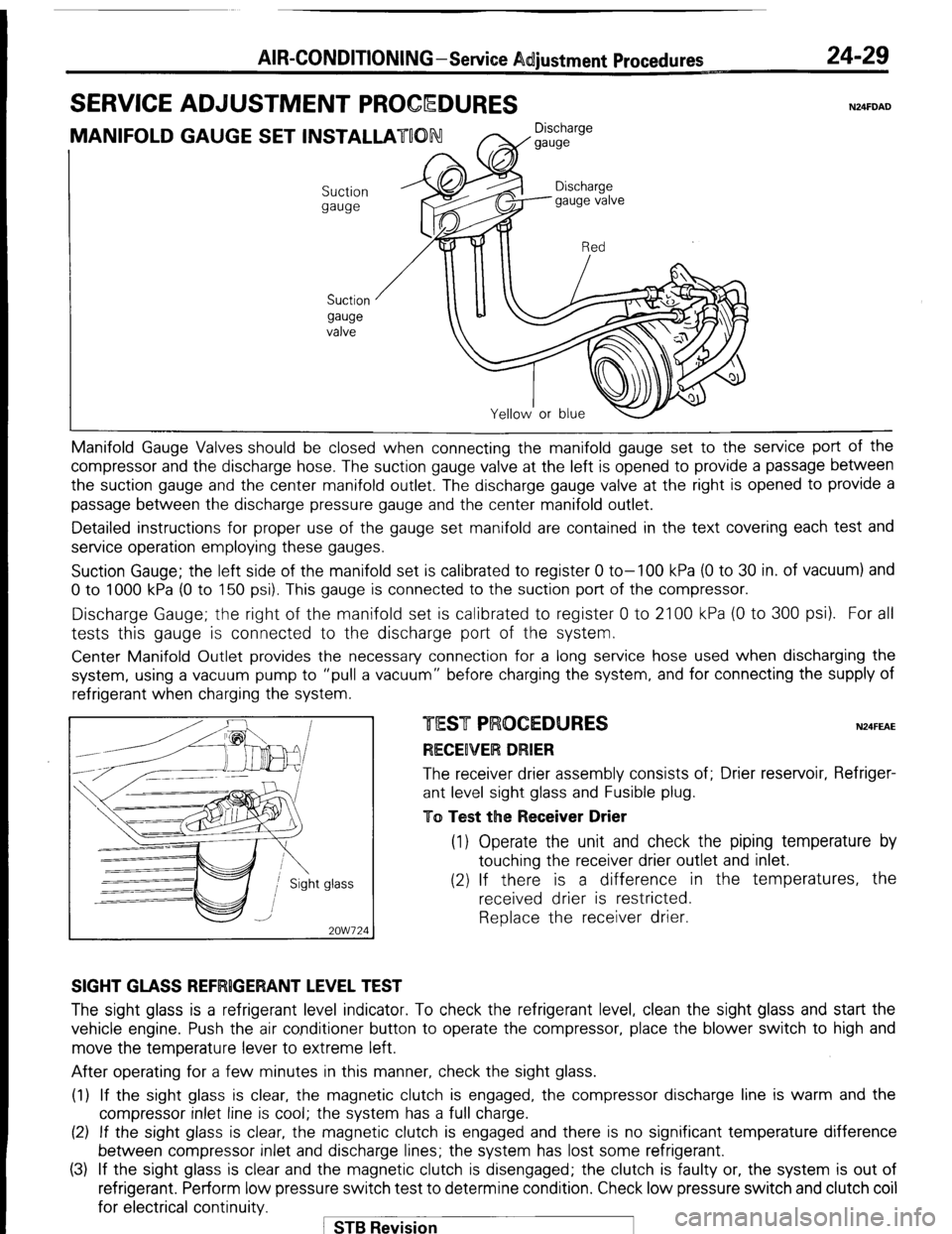

2OW724 N24FEAE The receiver drier assembly consists of; Drier reservoir, Refriger-

ant level sight glass and Fusible plug.

To Test the Receiver Drier (1) Operate the unit and check the piping temperature by

touching the receiver drier outlet and inlet.

(2) If there is a difference in the temperatures, the

received drier is restricted.

Replace the receiver drier.

SIGHT GLASS REFRlGERANT LEVEL TEST The sight glass is a refrigerant level indicator. To check the refrigerant level, clean the sight glass and start the

vehicle engine. Push the air conditioner button to operate the compressor, place the blower switch to high and

move the temperature lever to extreme left.

After operating for a few minutes in this manner, check the sight glass.

(1) If the sight glass is clear, the magnetic clutch is engaged, the compressor discharge line is warm and the

compressor inlet line is cool; the system has a full charge.

(2) If the sight glass is clear, the magnetic clutch is engaged and there is no significant temperature difference

between compressor inlet and discharge lines; the system has lost some refrigerant.

(3) If the sight glass is clear and the magnetic clutch is disengaged; the clutch is faulty or, the system is out of

refrigerant. Perform low pressure switch test to determine condition. Check low pressure switch and clutch coil

for electrical continuity.

1 STB Revision

Page 265 of 284

AIR-CONDITIONING-Service Adjustment Procedures

SERVICE ADJUSTMENT PROCQDURES 24-29 N24FDAD

MANIFOLD GAUGE SET INSTALLATUON Discharge

W gauge

Suction

gauge

Suction

gauge

valve Manifold Gauge Valves should be closed

when connecting the manifold gauge set to the service port of the

compressor and the discharge hose. The suction gauge valve at the left is opened to provide a passage between

the suction gauge and the center manifold outlet. The discharge gauge valve at the right is opened to provide a

passage between the discharge pressure gauge and the center manifold outlet.

Detailed instructions for proper use of the gauge set manifold are contained in the text covering each test and

service operation employing these gauges.

Suction Gauge; the left side of the manifold set is calibrated to register 0 to-100 kPa (0 to 30 in. of vacuum) and

0 to 1000 kPa (0 to 150 psi). This gauge is connected to the suction port of the compressor.

Discharge Gauge; the right of the manifold set is calibrated to register 0 to 2100 kPa (0 to 300 psi). For all

tests this gauge is connected to the discharge port of the system.

Center Manifold Outlet provides the necessary connection for a long service hose used when discharging the

system, using a vacuum pump to “pull a vacuum” before charging the system, and for connecting the supply of

refrigerant when charging the system

glass -

2OW724 N24FEAE The receiver drier assembly consists of; Drier reservoir, Refriger-

ant level sight glass and Fusible plug.

To Test the Receiver Drier (1) Operate the unit and check the piping temperature by

touching the receiver drier outlet and inlet.

(2) If there is a difference in the temperatures, the

received drier is restricted.

Replace the receiver drier.

SIGHT GLASS REFRlGERANT LEVEL TEST The sight glass is a refrigerant level indicator. To check the refrigerant level, clean the sight glass and start the

vehicle engine. Push the air conditioner button to operate the compressor, place the blower switch to high and

move the temperature lever to extreme left.

After operating for a few minutes in this manner, check the sight glass.

(1) If the sight glass is clear, the magnetic clutch is engaged, the compressor discharge line is warm and the

compressor inlet line is cool; the system has a full charge.

(2) If the sight glass is clear, the magnetic clutch is engaged and there is no significant temperature difference

between compressor inlet and discharge lines; the system has lost some refrigerant.

(3) If the sight glass is clear and the magnetic clutch is disengaged; the clutch is faulty or, the system is out of

refrigerant. Perform low pressure switch test to determine condition. Check low pressure switch and clutch coil

for electrical continuity.

1 STB Revision

Page 277 of 284

AIR-CONDITIONING -Service Adjustment Procedures 24-41

COMPRESSOR NOISE NWLM

When investigating an air conditioning related noise, you must first know the conditions when the noise occurs.

These conditions are: weather, vehicle speed, in gear or neutral, engine temperature or any other special

conditions.

Noises that develop during air- conditioning operation can often be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be caused by loose bolts, nuts, mounting brackets, or a loose clutch

assembly. Verify accessory drive belt tension (power

steering, alternator or air pump). Improper accessory drive belt

tension can cause a misleading noise when the compressor is engaged and little or no noise when the compressor

is disengaged.

Drive belts are speed sensitive. That is, at different engine speeds, and depending upon belt tension, belts can

develop unusual noises that are often mistaken for mechanical problems within the compressor.

Adjustment Procedures

(1) Select a quiet area for testing. Duplicate conditions as much as possible. Switch compressor on and off several

times to clearly identify compressor noise.

To duplicate high ambient conditions (high head pressure), restrict air-flow through

condenser. Install

manifold gauge set to make sure discharge pressure does not exceed 2,070 kPa (300 psi).

(2) Tighten all compressor mounting bolts, clutch mounting bolt, and compressor drive belt. Check to assure clutch

coil is tight (no rotation or wobble).

(3) Check refrigerant hoses for rubbing or interference that can cause unusual noises.

(4) Check refrigerant charge (See “Charging the System”).

(5) Recheck compressor noise as in Step 1.

(6) If noise still exists, loosen compressor mounting bolts and retorque. Repeat Step 1.

(7) If noise continues, replace compressor and repeat Step 1.

1 STB Revision

Page 282 of 284

24-46

COMPRESSOR

AIR-CONDITIONING - Compressor

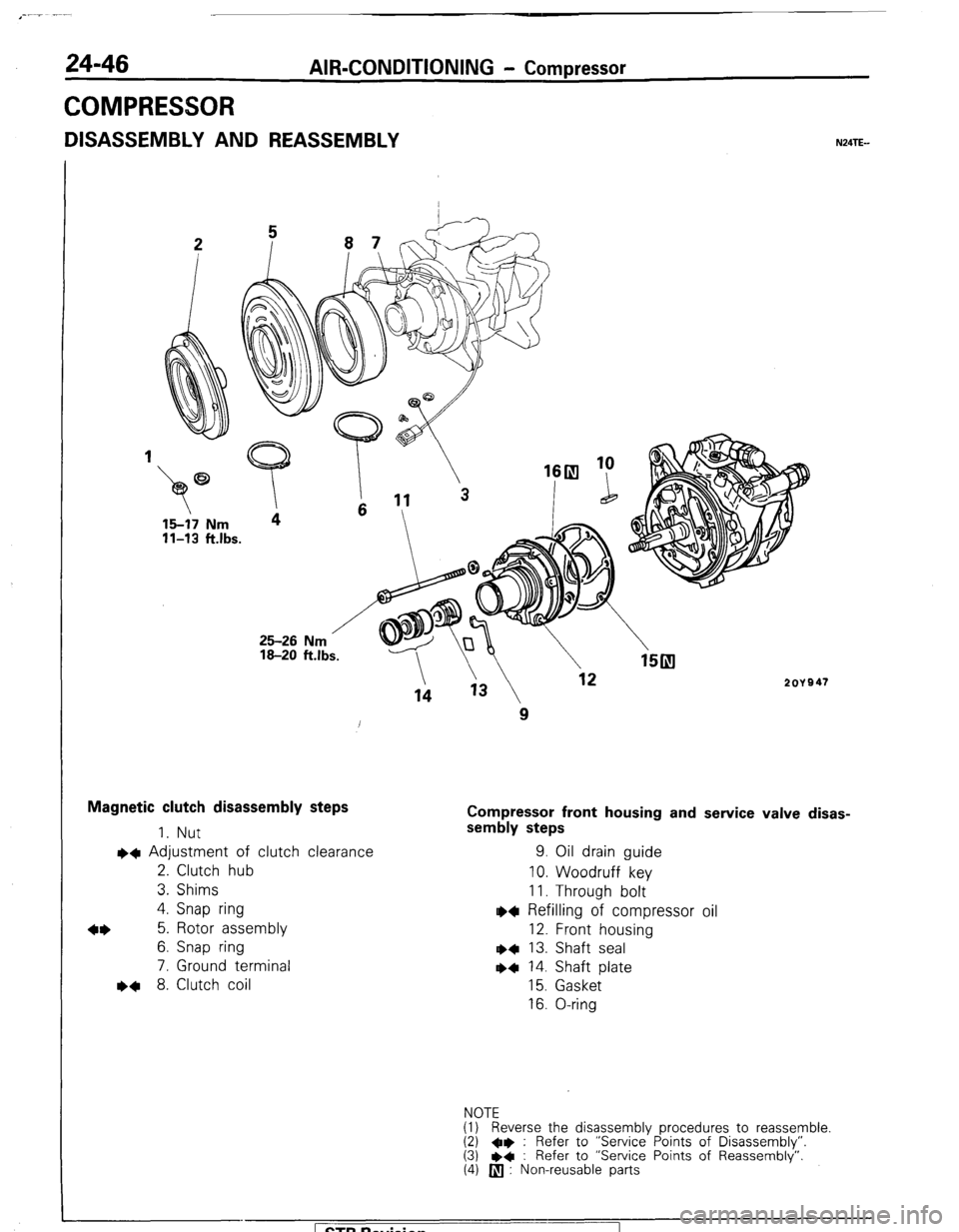

DISASSEMBLY AND REASSEMBLY N24TE-

15-h Nm

11-13 ftlbs 16

a 0

I

26-26 Nm

16-20 ftlbs. Magnetic clutch disassembly steps

1. Nut

~~ Adjustment of clutch clearance

2. Clutch hub

3. Shims

4.

Snap ring

4* 5. Rotor assembly

6.

Snap ring

7.

Ground terminal

l + 8. Clutch coil

l5Dl

2QY947 Compressor front housing and service valve disas-

sembly steps

9. Oil drain guide

10.

Woodruff key

Il. Through bolt

** Refilling of compressor oil

12. Front housing

o+

13. Shaft seal

04 14.

Shaft plate

15.

Gasket

16. O-ring

NOTE

(1) Reverse the disassembly procedures to reassemble.

(2) +e : Refer to “Service Points of Disassembly”.

(3) e+ : Refer to “Service Points of Reassembly”.

(4)

q : Non-reusable parts 1 STB Revision

Page 284 of 284

,: 24-48 AIR-CQNDITIONING - Compressor

I

2OY717

1 iOY718 l

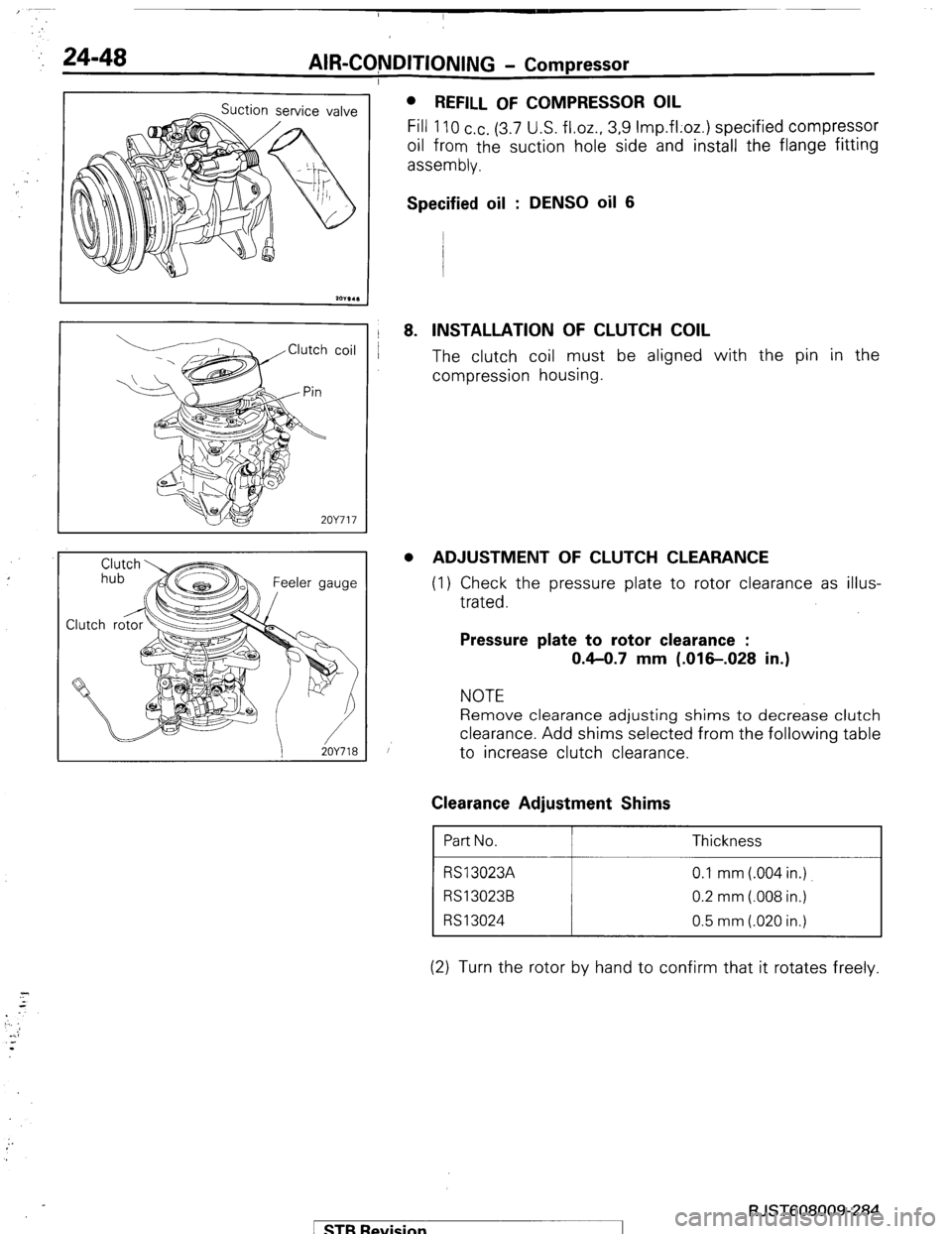

REFILL OF COMPRESSOR OIL

Fill 110 cc. (3.7 U.S. fl.oz., 3.9 Imp.fl;oz.) specified compressor

oil from the suction hole side and install the flange fitting

assembly.

Specified oil : DENS0 oil 6

8. INSTALLATION OF CLUTCH COIL

The clutch coil must be aligned with the pin in the

compression housing.

. ADJUSTMENT OF CLUTCH CLEARANCE

(1) Check the pressure plate to rotor clearance as illus-

trated.

Pressure plate to rotor clearance :

0.4-0.7 mm (.016-.028 in.)

NOTE

Remove clearance adjusting shims to decrease clutch

clearance. Add shims selected from the following table

to increase clutch clearance.

Clearance Adjustment Shims

Part No. Thickness

RSI 3023A 0.1 mm (.004 in.).

RSI 3023B 0.2 mm (.008 in.)

RSI 3024 0.5 mm (.020 in.)

(2) Turn the rotor by hand to confirm that it rotates freely.

:.

RJST608009-284

1 STB Revision

-1