Coil MITSUBISHI MONTERO 1987 1.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 112 of 284

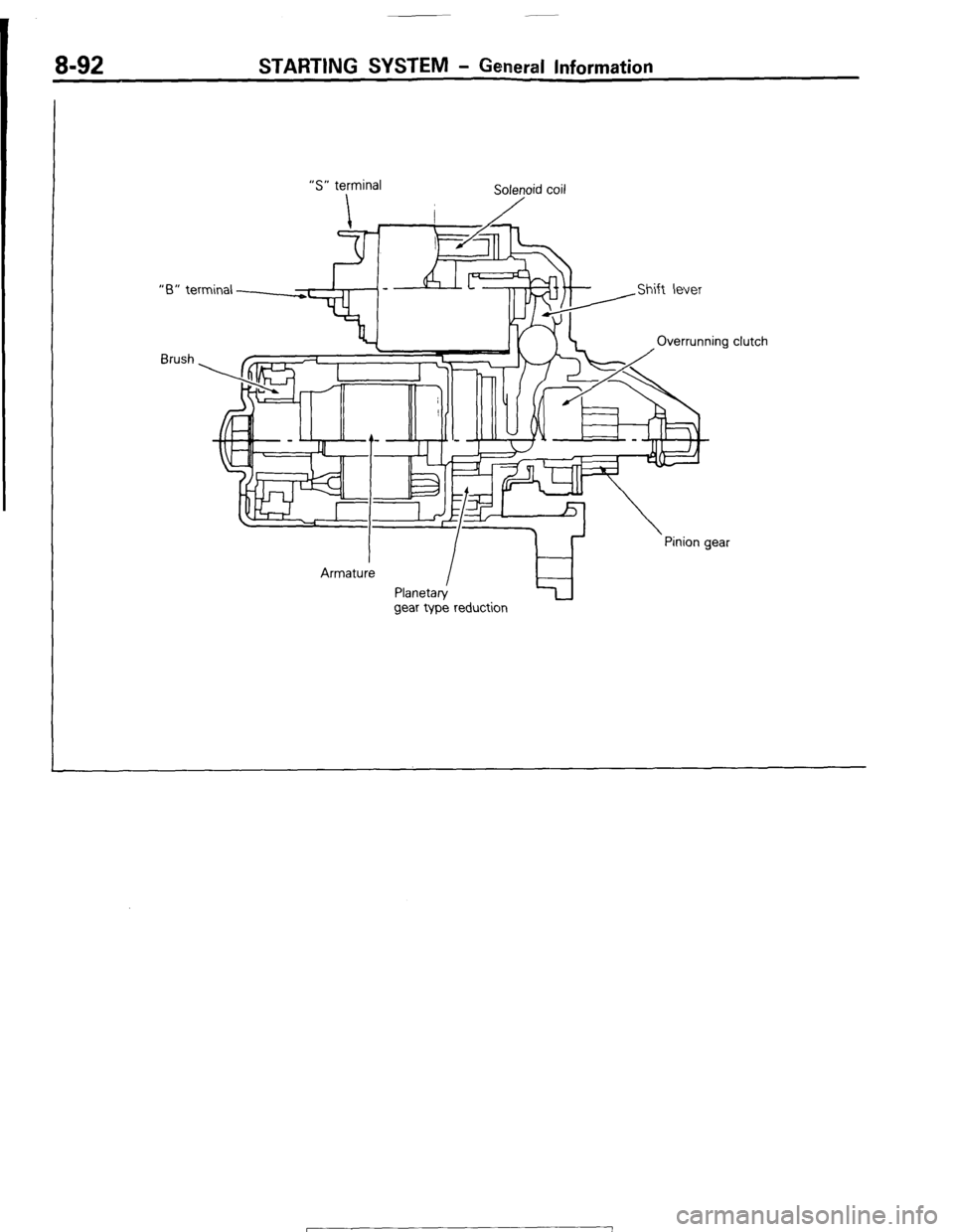

8-92 STARTING SYSTEM - General Information

“S” terminal

Sole;oid coil

“6” terminal -

clutch

Brush

gear type reduction

1 ST6 Revision

Page 117 of 284

STARTING WSTEM - Starter Motor 8-97

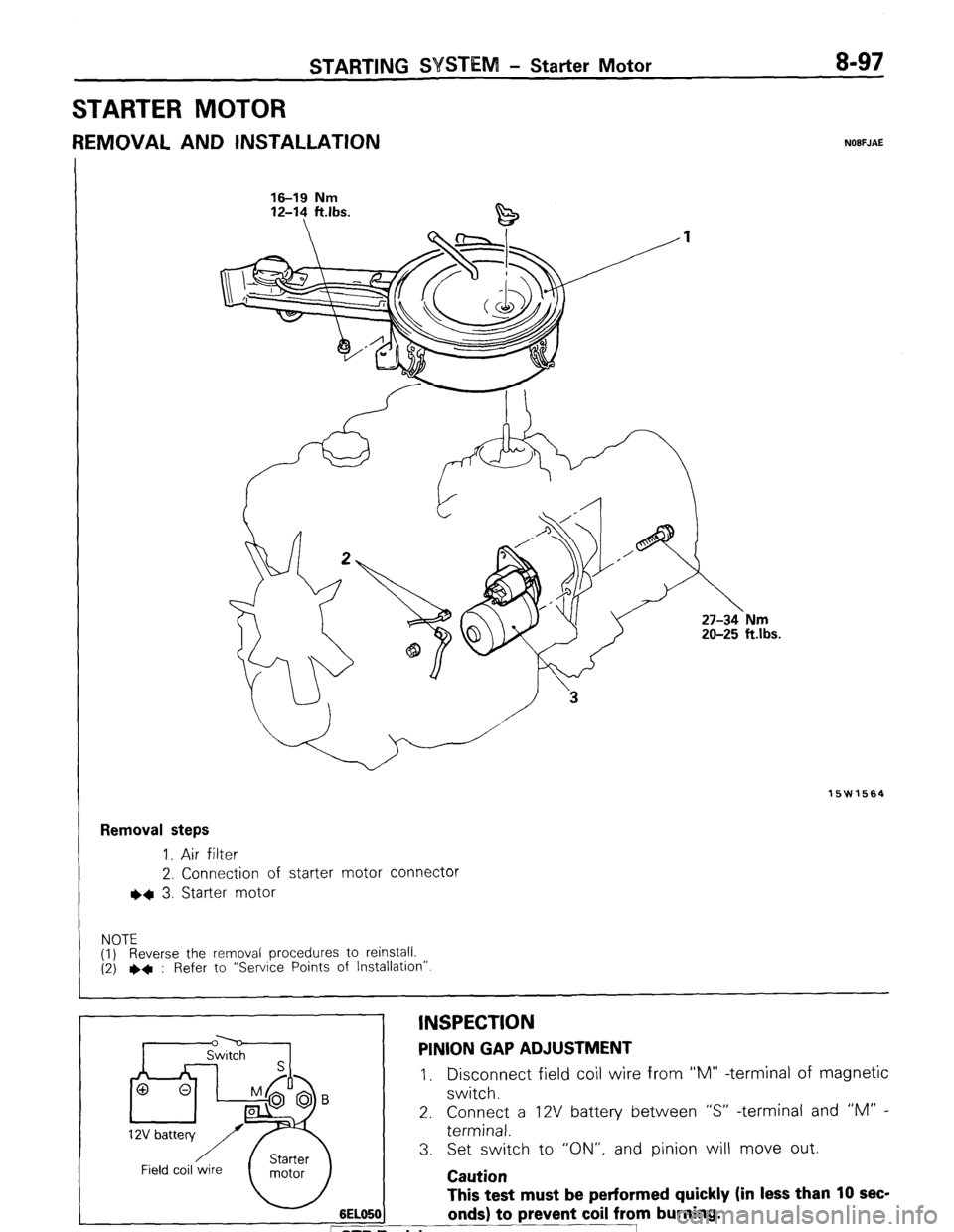

STARTER MOTOR

REMOVAL AND INSTALLATION NOBFJAE

16-19 Nm 16-19 Nm

12-l? ft.lbs. 12-14 ft.lbs.

15W1564

Removal steps

1. Air filter

2. Connection of starter motor connector

l * 3. Starter motor

NOTE

(1) Reverse the removal procedures to reinstall.

(2) ++ : Refer to “Service Points of Installation”

6EL05( This test must be performed quickly (in less than 10 sec-

onds) to prevent coil from burning. D Revision

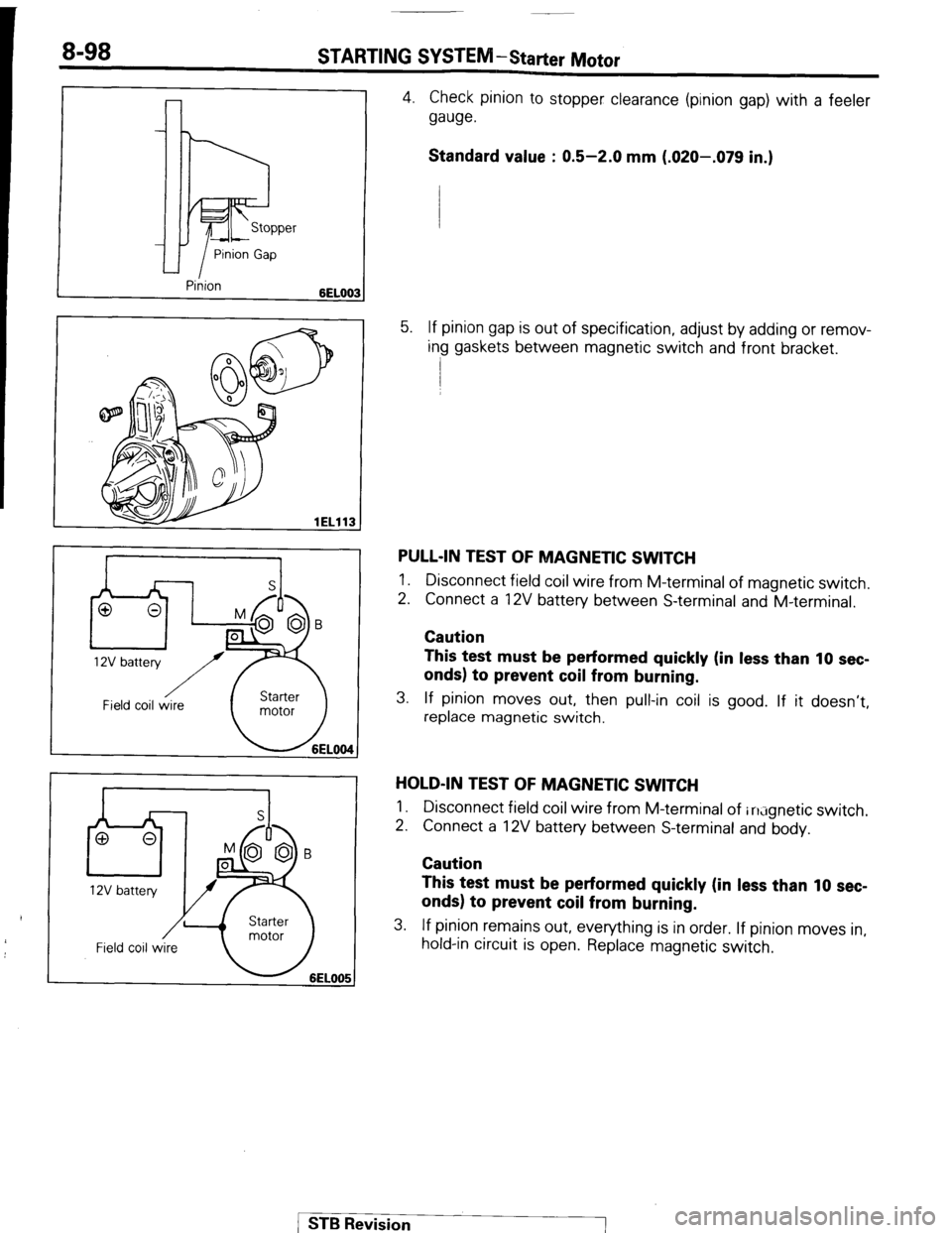

INSPECTION PINION GAP ADJUSTMENT

I, Disconnect field coil wire from “M” -terminal of magnetic

switch.

2. Connect a 12V battery between “S” -terminal and “M” -

terminal.

3. Set switch to “ON”, and pinion will move out.

Caution

Page 118 of 284

8-98 STARTING SYSTEM -Starter Motor

Pinion

6EL003

lEL113

/ Field coil wire

Field coil wire

4. Check pinion to stopper clearance (pinion gap) with a feeler

gauge.

Standard value : 0.5-2.0 mm (.020-.079 in.)

5. If pinion gap is out of specification, adjust by adding or remov-

ing gaskets between magnetic switch and front bracket.

PULL-IN TEST OF MAGNETIC SWITCH

1. Disconnect field coil wire from M-terminal of magnetic switch.

2. Connect a 12V battery between S-terminal and M-terminal.

Caution

This test must be performed quickly (in less than 10 sec-

onds) to prevent coil from burning.

3. If pinion moves out, then pull-in coil is good. If it doesn’t,

replace magnetic switch.

HOLD-IN TEST OF MAGNETIC SWITCH

1.

2. Disconnect field coil wire from M-terminal of in;ignetic switch.

Connect a 12V battery between S-terminal and body.

Caution

This test must be performed quickly (in less than 10 sec-

onds) to prevent coil from burning.

3. If pinion remains out, everything is in order. If pinion moves in,

hold-in circuit is open. Replace magnetic switch.

1 ST6 Revision

Page 119 of 284

WEEM -Starter Motor 8-99

I-

Carbon-pile rheostat

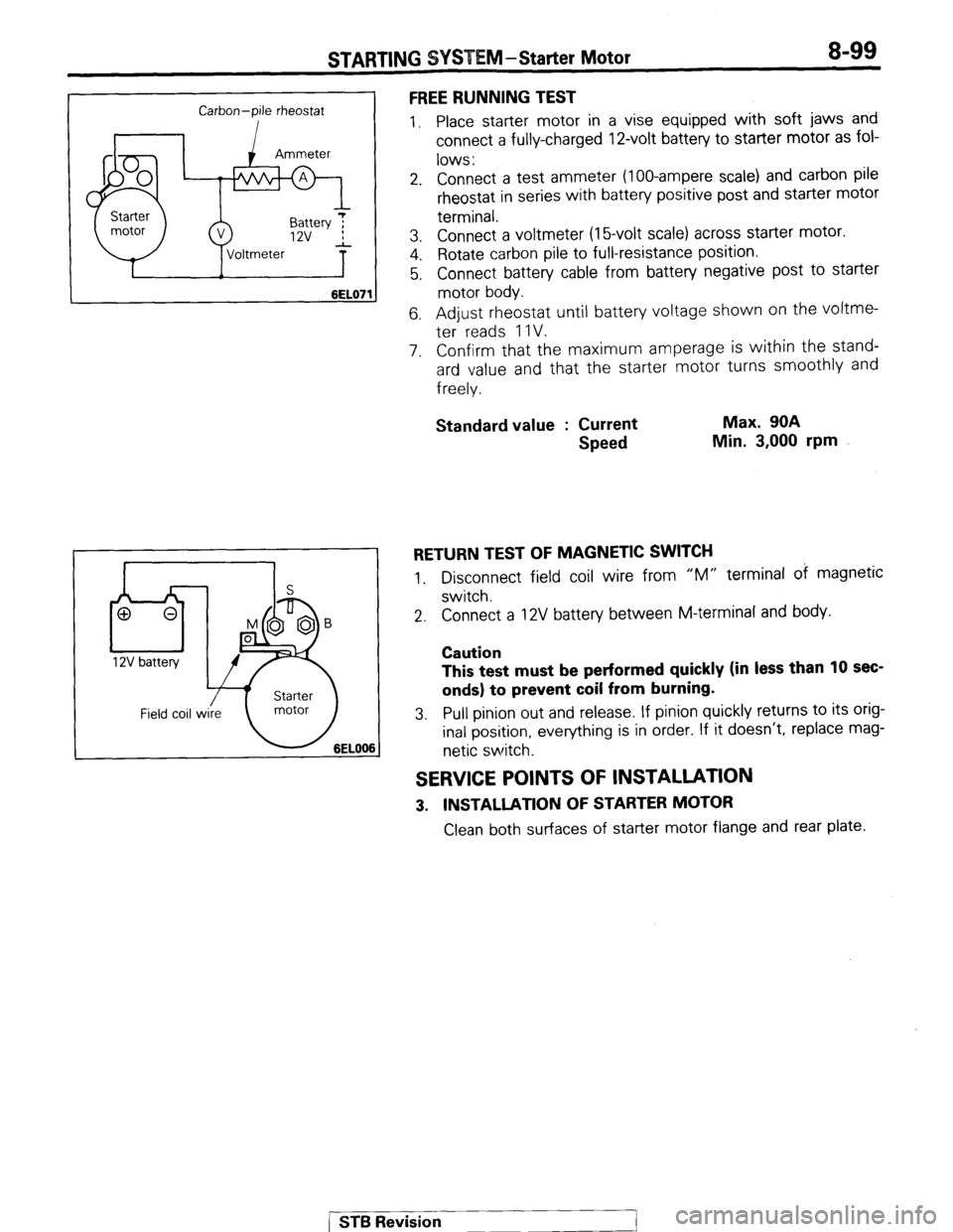

6EL07’ FREE RUNNING TEST

1. Place starter motor in a vise equipped with soft jaws and

connect a fully-charged 12-volt battery to starter motor as fol-

lows :

2. Connect a test ammeter (loo-ampere scale) and carbon pile

rheostat in series with battery positive post and starter motor

terminal.

3. Connect a voltmeter (16volt scale) across starter motor.

4. Rotate carbon pile to full-resistance position.

5. Connect battery cable from battery negative post to starter

motor body.

6. Adjust rheostat until battery voltage shown on the voltme-

ter reads 1 IV.

7. Confirm that the maximum amperage is within the stand-

ard value and that the starter motor turns smoothly and

freely.

Standard value : Current

Speed Max. 90A

Min. 3,000 rpm

RETURN TEST OF MAGNETIC SWITCH

1. Disconnect field coil wire from “M” terminal of magnetic

switch.

2. Connect a 12V battery between M-terminal and body.

Caution

This test must be performed quickly (in less than 10 sec-

onds) to prevent coil from burning.

3. Pull pinion out and release. If pinion quickly returns to its orig-

inal position, everything is in order. If it doesn’t, replace mag-

netic switch.

SERVICE POINTS OF INSTALLATION

3. INSTALLATlON OF STARTER MOTOR

Clean both surfaces of starter motor flange and rear plate.

[ ST6 Revision

1

Page 121 of 284

STARTING SYSTEM-Starter Motor 8-101

Snap

L Armature

1ELlO

pi-

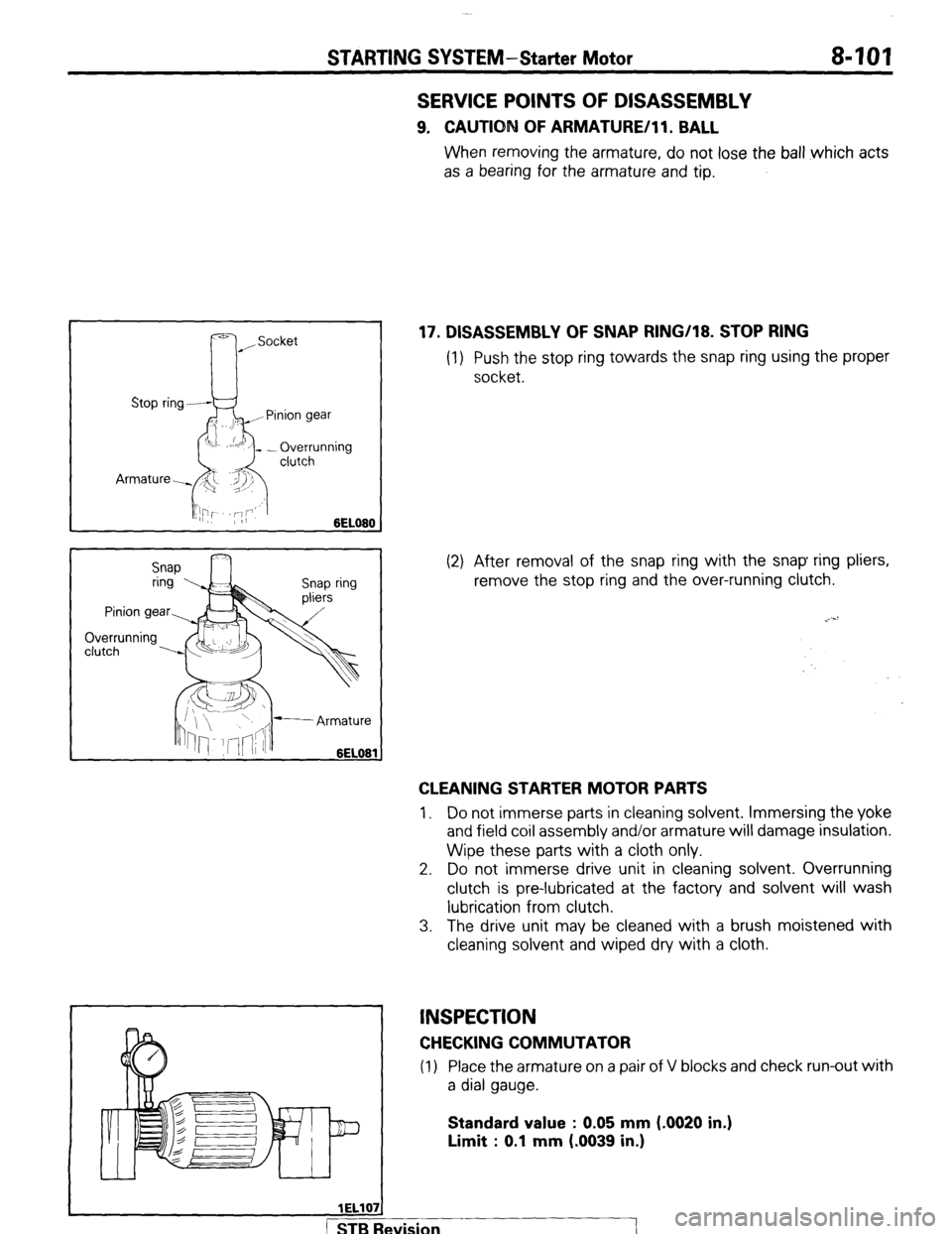

SERVICE POINTS OF DISASSEMBLY

9. CAUTION OF ARMATURE/ll. BALL

When removing the armature, do not lose the ball which acts

as a bearing for the armature and tip.

17. DISASSEMBLY OF SNAP RING/18. STOP RING

(1) Push the stop ring towards the snap ring using the proper

socket.

(2) After removal of the snap ring with the snap ring pliers,

remove the stop ring and the over-running clutch.

CLEANING STARTER MOTOR PARTS

1, Do not immerse parts in cleaning solvent. Immersing the yoke

and field coil assembly and/or armature will damage insulation.

Wipe these parts with a cloth only.

2. Do not immerse drive unit in cleaning solvent. Overrunning

clutch is pre-lubricated at the factory and solvent will wash

lubrication from clutch.

3. The drive unit may be cleaned with a brush moistened with

cleaning solvent and wiped dry with a cloth.

INSPECTION

CHECKING COMMUTATOR

(1) Place the armature on a pair of V blocks and check run-out with

a dial gauge.

Standard value : 0.05 mm (-0020 in.)

Limit : 0.1 mm (.0039 in.)

wision

I

Page 123 of 284

STARTING SYSTEM -Starter Motor 8-103

E i&l

-Limit line

1ELOlI

New brush

Soidered

(Make sure that

there is no excess

solder on brush

surface)

Surface marked If

1ELM

6EL082

1FL 108

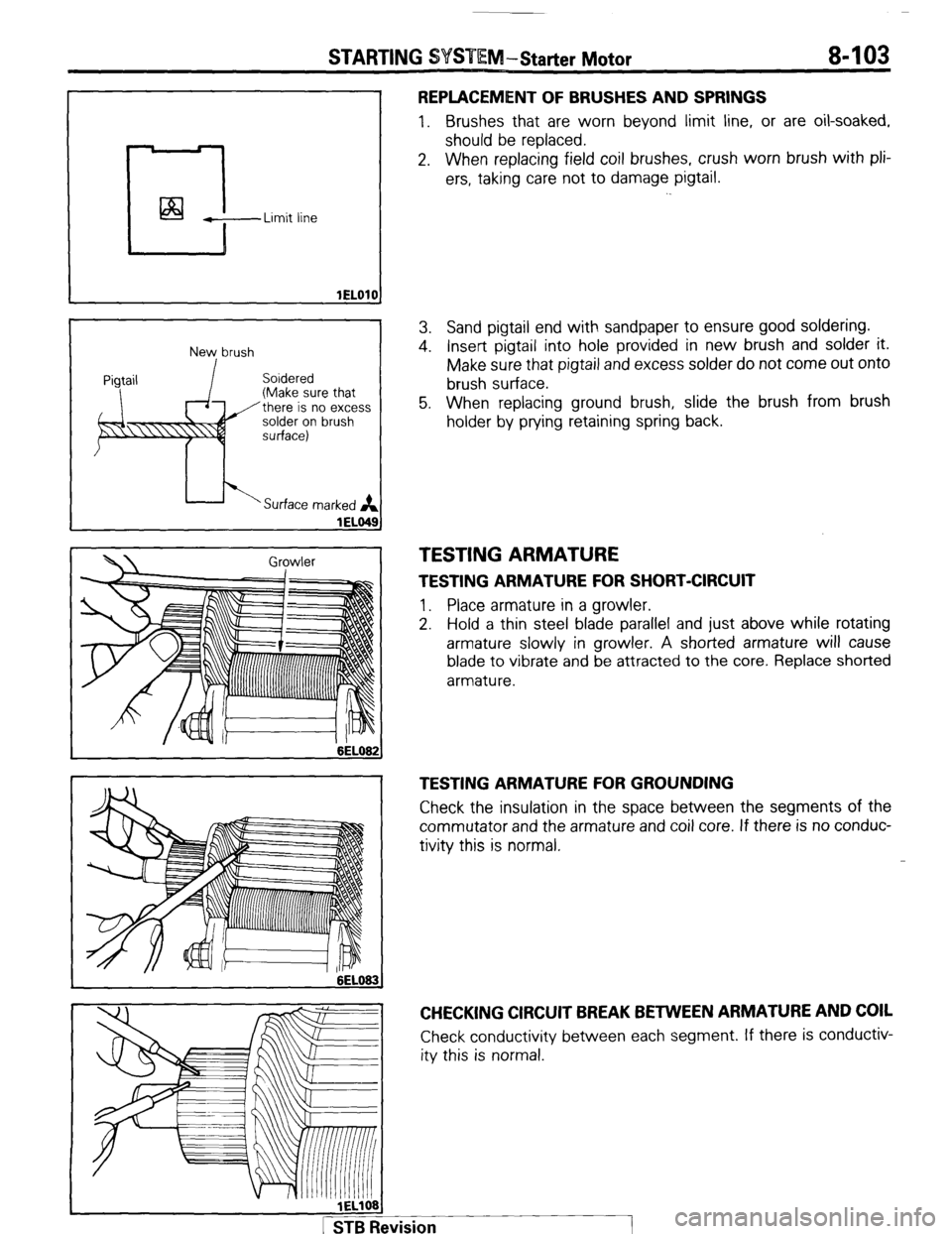

REPLACEMENT OF BRUSHES AND SPRINGS

1. Brushes that are worn beyond limit line, or are oil-soaked,

should be replaced.

2. When replacing field coil brushes, crush worn brush with pli-

ers, taking care not to damage pigtail.

3. Sand pigtail end with sandpaper to ensure good soldering.

4. Insert pigtail into hole provided in new brush and solder it.

Make sure that pigtail and excess solder do not come out onto

brush surface.

5. When replacing ground brush, slide the brush from brush

holder by prying retaining spring back.

TESTING ARMATURE

TESTING ARMATURE FOR SHORT-CIRCUIT

1. Place armature in a growler.

2. Hold a thin steel blade parallel and just above while rotating

armature slowly in growler. A shorted armature will cause

blade to vibrate and be attracted to the core. Replace shorted

armature.

TESTING ARMATURE FOR GROUNDING

Check the insulation in the space between the segments of the

commutator and the armature and coil core. If there is no conduc-

tivity this is normal.

CHECKING CIRCUIT BREAK BETWEEN ARMATURE AND COIL

Check conductivity between each segment. If there is conductiv-

ity this is normal.

1 STB Revision

Page 125 of 284

IGNITION SYSTEM -General Information 8-105

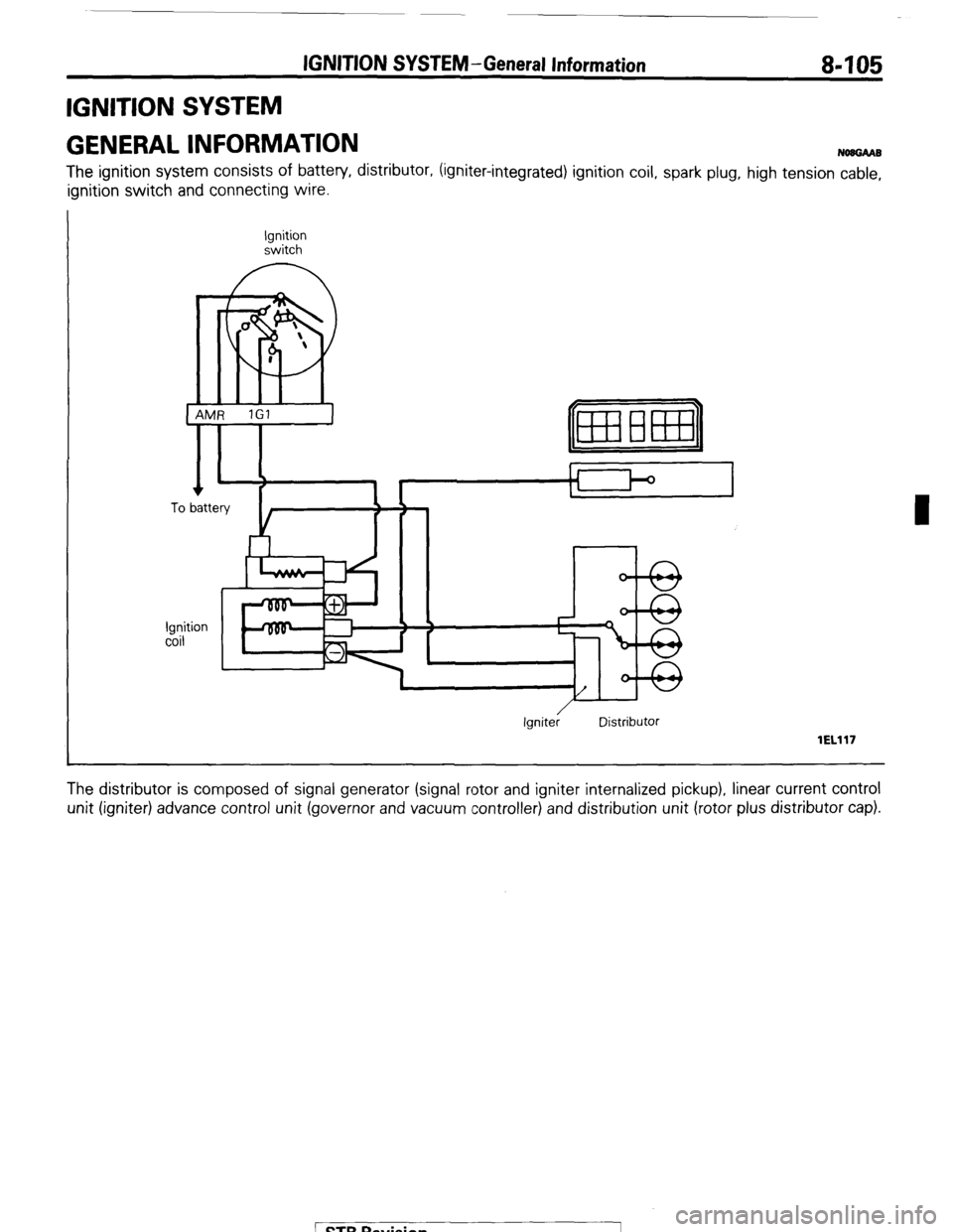

IGNITION SYSTEM

GENERAL INFORMATION

NOUGAAB

The ignition system consists of battery, distributor, (igniter-integrated) ignition coil, spark plug, high tension cable,

ignition switch and connecting wire.

Ignition

switch

0

m

I

1 AMR 1Gl

I

Ignition

coil

r

Ignite; Distributor

lEL117

The distributor is composed of signal generator (signal rotor and igniter internalized pickup), linear current control

unit (igniter) advance control unit (governor and vacuum controller) and distribution unit (rotor plus distributor cap).

Page 126 of 284

IGNITION SYSTEM-General Information

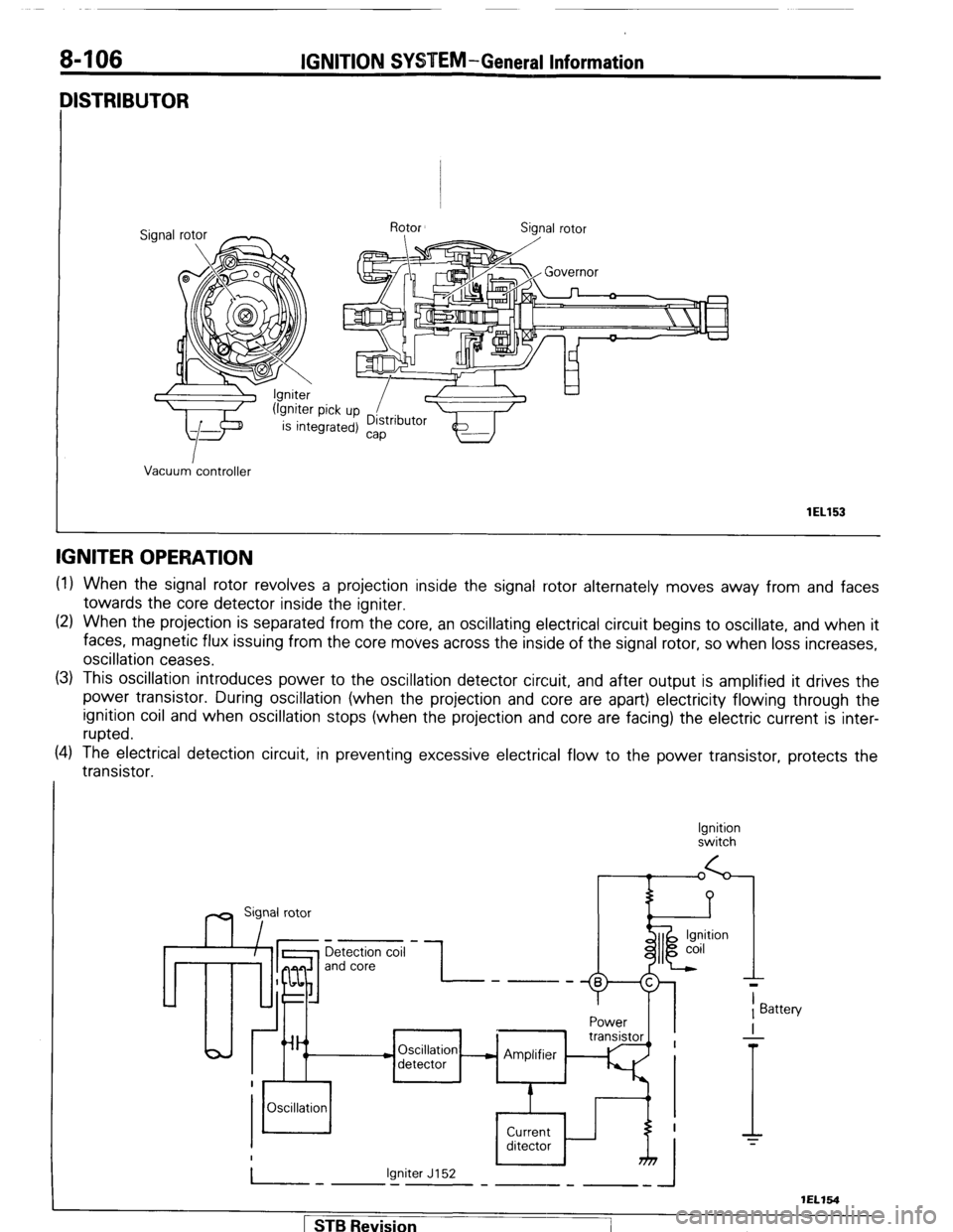

IISTRIBUTOR

Vacuum controller

lEL153

IGNITER OPERATION

(1) When the signal rotor revolves a projection inside the signal rotor alternately moves away from and faces

towards the core detector inside the igniter.

(2) When the projection is separated from the core, an oscillating electrical circuit begins to oscillate, and when it

faces, magnetic flux issuing from the core moves across the inside of the signal rotor, so when loss increases,

oscillation ceases.

(3) This oscillation introduces power to the oscillation detector circuit, and after output is amplified it drives the

power transistor. During oscillation (when the projection and core are apart) electricity flowing through the

ignition coil and when oscillation stops (when the projection and core are facing) the electric current is inter-

rupted.

(4) The electrical detection circuit, in preventing excessive electrical flow to the power transistor, protects the

transistor.

Ignition

switch

m Sig,nal rotor

Detection coil

and core -I- ----

Power

Oscillation - Amplifier

detector

Oscillation

Current

ditector

Igniter J152

-.I-

T

1 Battery

I

-

T

1 STB Revision

-7

Page 127 of 284

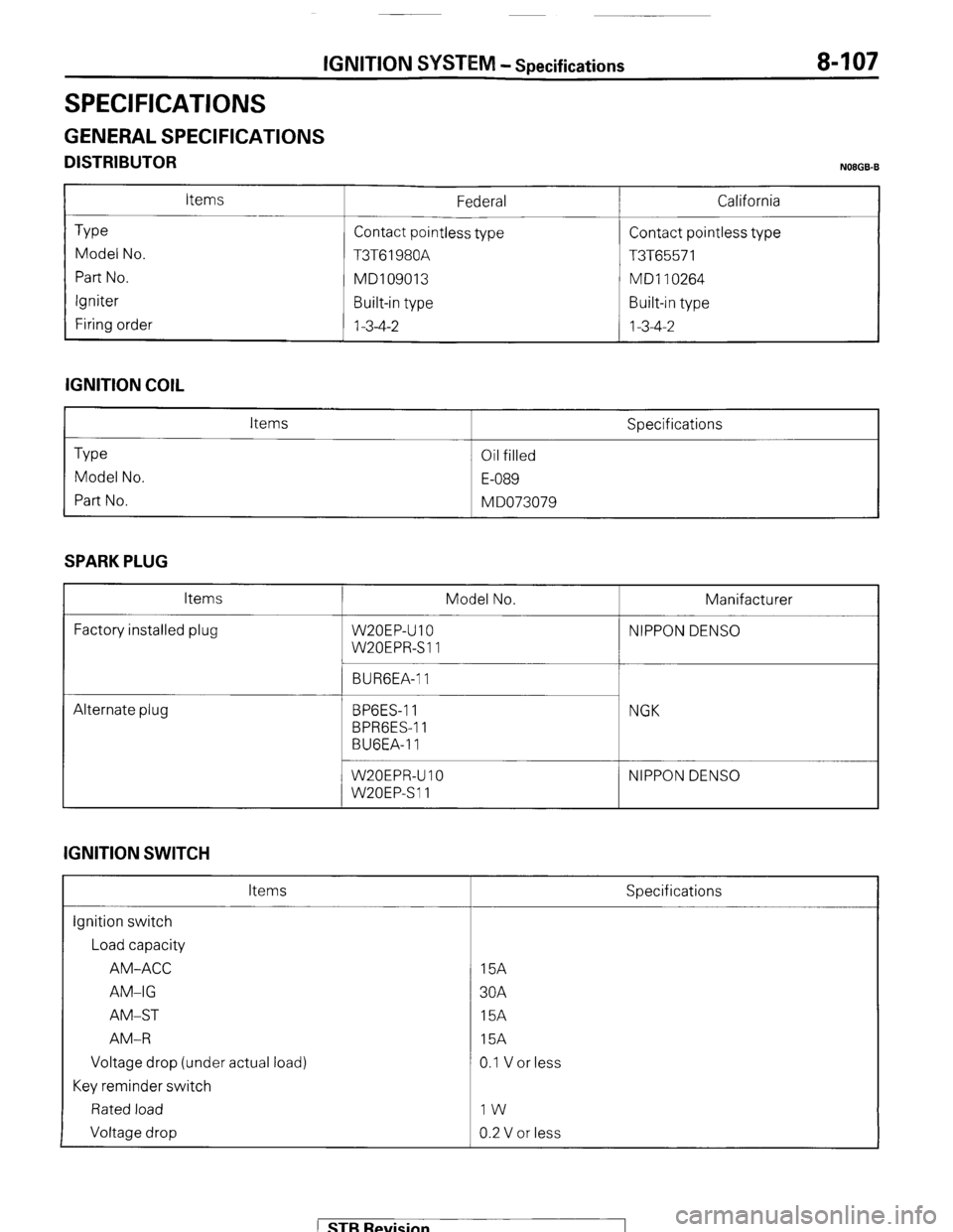

IGNITION SYSTEM - Specifications 8-107

SPECIFICATIONS

GENERAL SPECIFICATIONS

DISTRIBUTOR N08GB.B

Type

Model No.

Part No.

Igniter

Firing order Items Federal

Contact pointless type

T3T61980A

MD109013

Built-in type

1-3-4-2 California

Contact pointless type

T3T65571

MD1 10264

Built-in type

1-3-4-2

IGNITION COIL

Type

Model No.

Part No. Items

Oil filled

E-089

M DO73079 Specifications

SPARK PLUG

Items

Factory installed plug Model No. Manifacturer

W20EP-U 10 NIPPON DENS0

W20EPR-Sll

BURGEA-1 1

Alternate plug BPGES-1 1

BPRGES-1 1

BUGEA-11 NGK

W20EPR-U IO

W20EPSll NIPPON DENS0

IGNITION SWITCH

Items

ignition switch

Load capacity

AM-ACC

AM-IG

AM-ST

AM-R

Voltage drop (under actual load)

Key reminder switch

Rated load

Voltage drop Specifications

15A

30A

15A

15A

0.1 V or less

IW

0.2 V or less

) STB Revision

Page 128 of 284

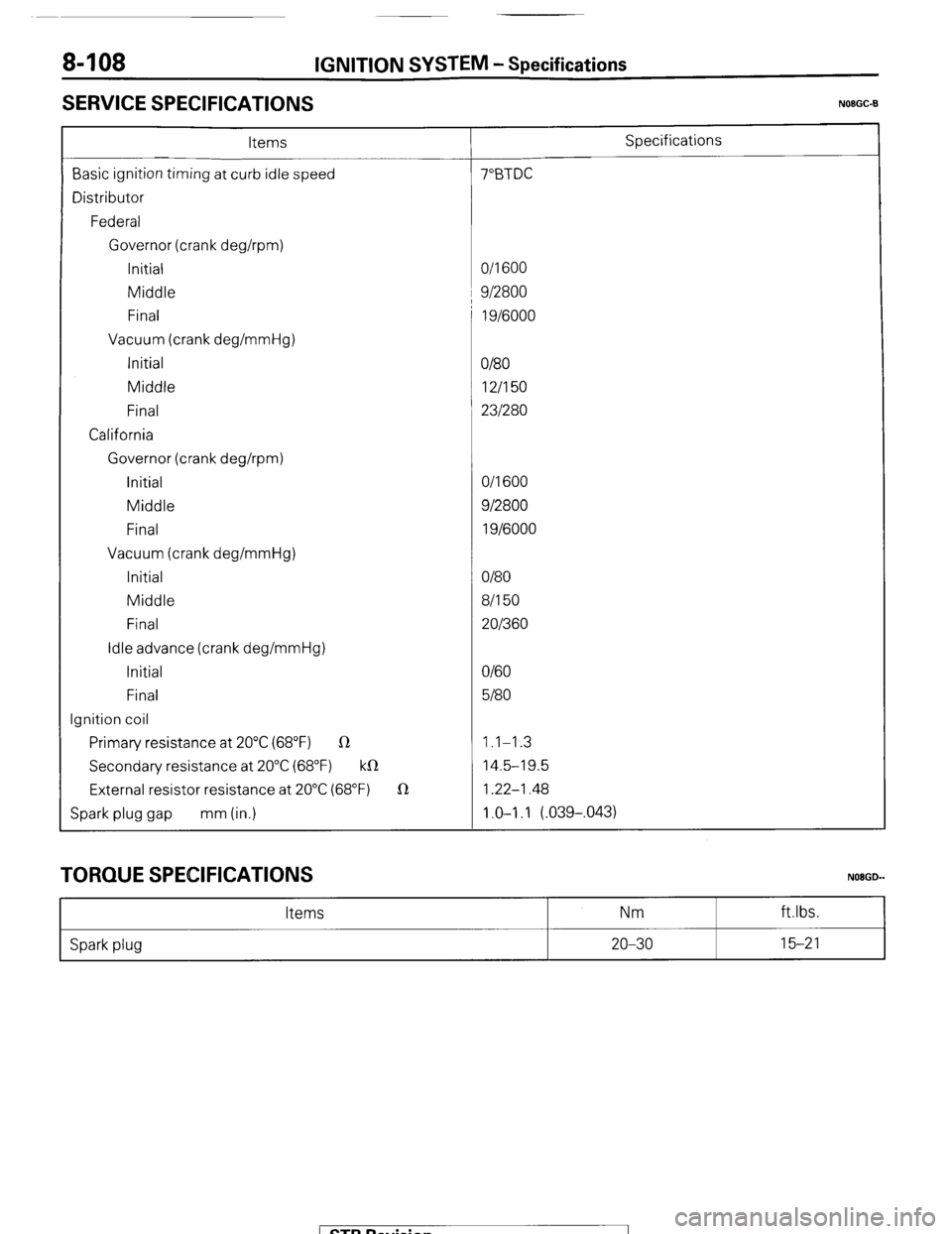

8408 IGNITION SYSTEM - Specifications

SERVICE SPECIFICATIONS

N08GC-B

Items Specifications

Basic ignition timing at curb idle speed 7”BTDC

Distributor

Federal

Governor (crank deghpm)

Initial O/l 600

Middle 1 9/2800

Final 1 g/6000

Vacuum (crank deg/mmHg)

Initial

O/80

Middle 12/I 50

Final 231280

California

Governor (crank deghpm)

initial O/l 600

Middle 912800

Final 1 g/6000

Vacuum (crank deg/mmHg)

Initial O/80

Middle 8/l 50

Final 201360

Idle advance (crank deg/mmHg)

Initial O/60

Final 5180

Ignition coil

Primary resistance at 20°C (68°F) R 1.1-1.3

Secondary resistance at 20°C (68°F) k0 14.5-19.5

External resistor resistance at 20°C (68°F) 1R 1.22-1.48

Spark plug gap mm (in.) 1.0-I .I (.039-,043)

TORQUE SPECIFICATIONS

Items Nm

NOBGD-

ft.lbs.

Spark plug 20-30 15-21

1 STB Revision