relay MITSUBISHI MONTERO 1987 1.G Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 98 of 284

8-78 CHARGING SYSTEM - Service Adiustment Procedures

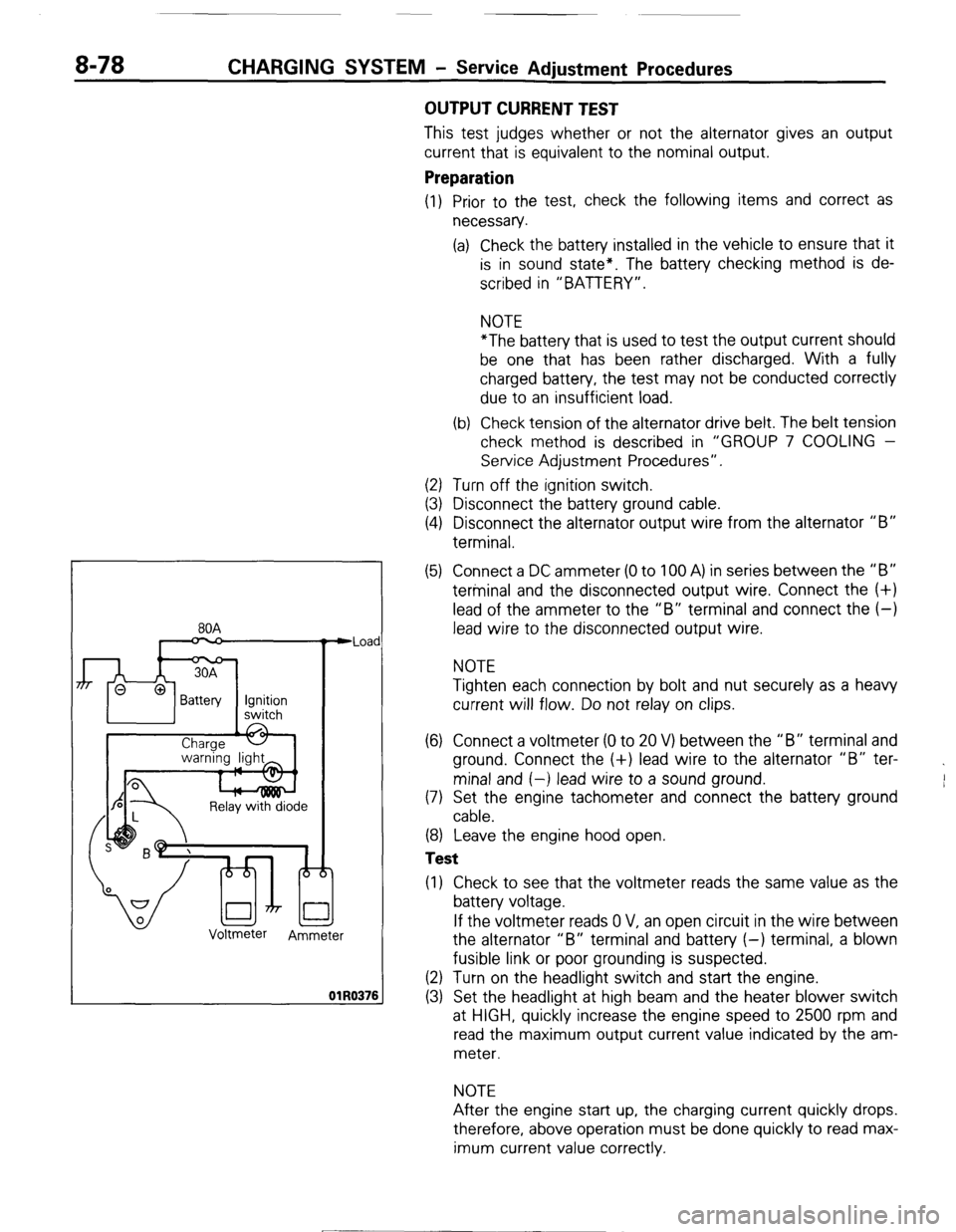

80A

n

Relay with diode

Voltmeter

Ammeter Iad

176

OUTPUT CURRENT TEST

This test judges whether or not the alternator gives an output

current that is equivalent to the nominal output.

Preparation

(1) Prior to the test, check the following items and correct as

necessary.

(a) Check the battery installed in the vehicle to ensure that it

is in sound state*. The battery checking method is de-

scribed in “BATTERY”.

NOTE

*The battery that is used to test the output current should

be one that has been rather discharged. With a fully

charged battery, the test may not be conducted correctly

due to an insufficient load.

(b) Check tension of the alternator drive belt. The belt tension

check method is described in “GROUP 7 COOLING -

Service Adjustment Procedures”.

(2) Turn off the ignition switch.

(3) Disconnect the battery ground cable.

(4) Disconnect the alternator output wire from the alternator “B”

terminal.

(5) Connect a DC ammeter (0 to 100 A) in series between the “B”

terminal and the disconnected output wire. Connect the (+)

lead of the ammeter to the “B” terminal and connect the (-)

lead wire to the disconnected output wire.

NOTE

Tighten each connection by bolt and nut securely as a heavy

current will flow. Do not relay on clips.

(6) Connect a voltmeter (0 to 20 V) between the “B” terminal and

ground. Connect the (+) lead wire to the alternator “B” ter-

minal and (-) lead wire to a sound ground.

(7) Set the engine tachometer and connect the battery ground

cable.

(8) Leave the engine hood open.

Test

(1) Check to see that the voltmeter reads the same value as the

battery voltage.

If the voltmeter reads 0 V, an open circuit in the wire between

the alternator “B” terminal and battery (-) terminal, a blown

fusible link or poor grounding is suspected.

(2) Turn on the headlight switch and start the engine.

(3) Set the headlight at high beam and the heater blower switch

at HIGH, quickly increase the engine speed to 2500 rpm and

read the maximum output current value indicated by the am-

meter.

NOTE

After the engine start up, the charging current quickly drops.

therefore, above operation must be done quickly to read max-

imum current value correctly.

[ STB Revision

--I

Page 143 of 284

METERS AND GAUGES-Specifications

METERS AND GAUGES

8-123

SPECIFICATIONS

GENERAL SPECIFICATIONS

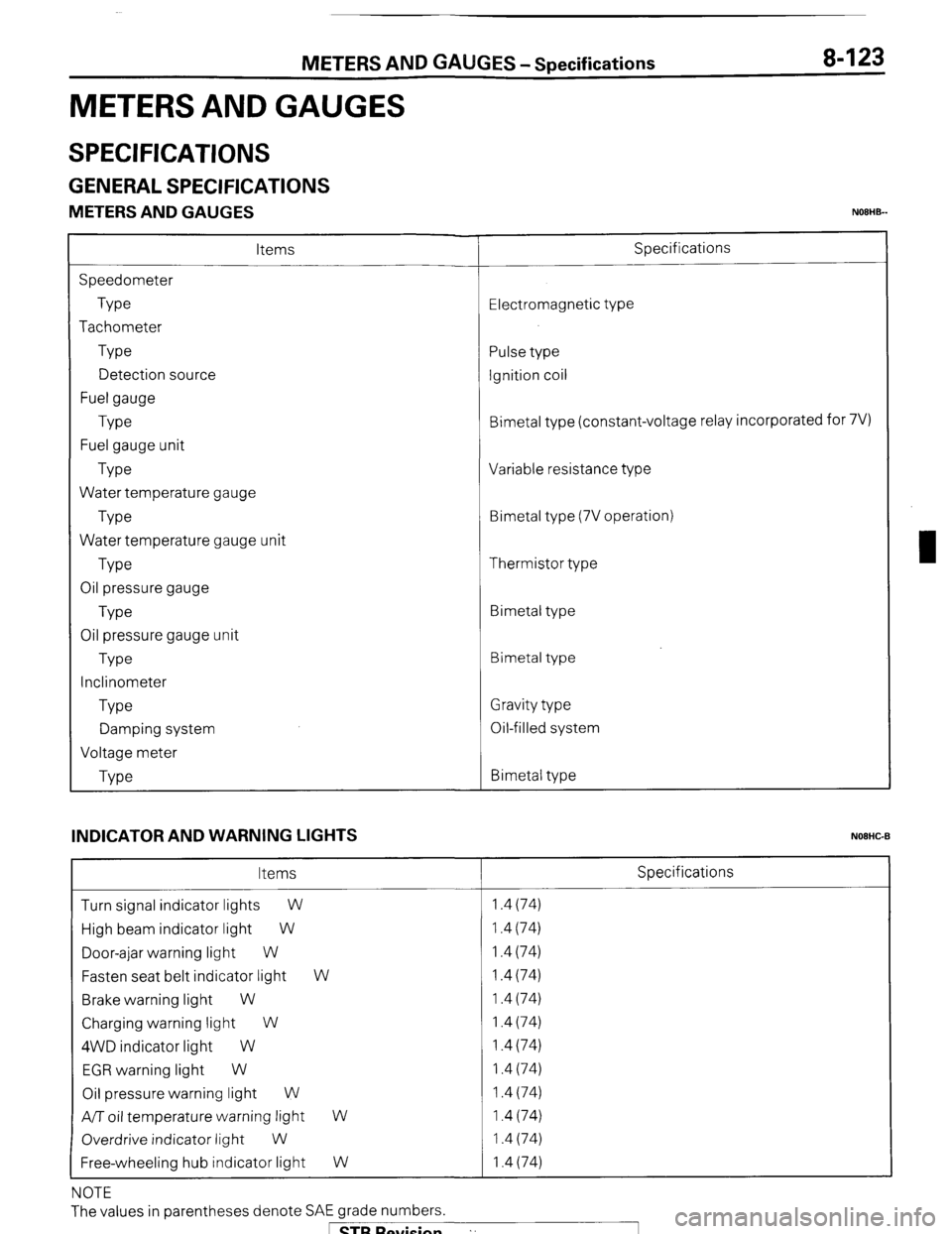

METERS AND GAUGES NOEHB-

Items

Speedometer

Type

Tachometer

Type

Detection source

Fuel gauge

Type

Fuel gauge unit

Type

Water temperature gauge

Type

Water temperature gauge unit

Type

Oil pressure gauge

Type

Oil pressure gauge unit

Type

Inclinometer

Type

Damping system

Voltage meter

Type Specifications

Electromagnetic type

Pulse type

Ignition coil

Bimetal type (constant-voltage relay incorporated for 7V)

Variable resistance type

Bimetal type (7V operation)

Thermistor type

Bimetal type

Bimetal type

Gravity type

Oil-filled system

Bimetal type

INDICATOR AND WARNING LIGHTS

NOEHC-B

Items Specifications

Turn signal indicator lights

W 1.4 (74)

High beam indicator light W 1.4 (74)

Door-ajar warning light W 1.4 (74)

Fasten seat belt indicator light W 1.4 (74)

Brake warning light W 1.4 (74)

Charging warning light W 1.4 (74)

4WD indicator light W 1.4 (74)

EGR warning light W 1.4 (74)

Oil pressure warning light W 1.4 (74)

A/T oil temperature warning light

W 1.4 (74)

Overdrive indicator light

W 1.4 (74)

Free-wheeling hub indicator light W 1.4 (74)

NOTE

The values in parentheses denote SAE grade numbers.

1 STB Revision ”

Page 163 of 284

LIGHTING SYSTEM - Specifications 8-143

LIGHTING SYSTEM

SPECIFICATIONS

GENERAL SPECIFICATIONS

EXTERIOR AND INTERIOR LIGHTS NOEIB-

Items

Exterior lights

Head lights W

Front combination lights cp

Turn-signal lights

Front side marker and position lights

Rear combination lights cp

Turn-signal light

Stop and tail lights

Back-up lights

Rear side marker lights W

Licence plate lights W

Interior lights

Dome light W

Heater panel illumination light W

Combination meter and gauge illumination light

Cigarette lighter illumination light

W

Ashtray illumination light

W

Shift illumination light (automatic transmission) W

W

NOTE

The values in parentheses denote SAE grade numbers.

RELAY AND FLASHER UNIT

Items

Light control relay

Rated load W

Range of voltage used V

Voltage drop between terminals V

Turn-signal flasher unit

Type

Rated load W

Blinking frequency [I 2.8 V, 20°C (68”F)l

Hazard flasher unit

Type cycle/min

Rated load W

Blinking frequency [ 12.8 V, 20°C (68”F)l cycle/min Specifications

60/50

32

2

32

32/3

32

3.8(194)

6

10 1.4 (74)

3.4 (158)

1.4 (74)

1.4 (74)

1.4 (74)

Specifications

Max. 200

IO-16

0.2 or less

Condenser type

84.4

85210

Heat band type

49.4-168.8

902 10

1 STB Revision

Page 169 of 284

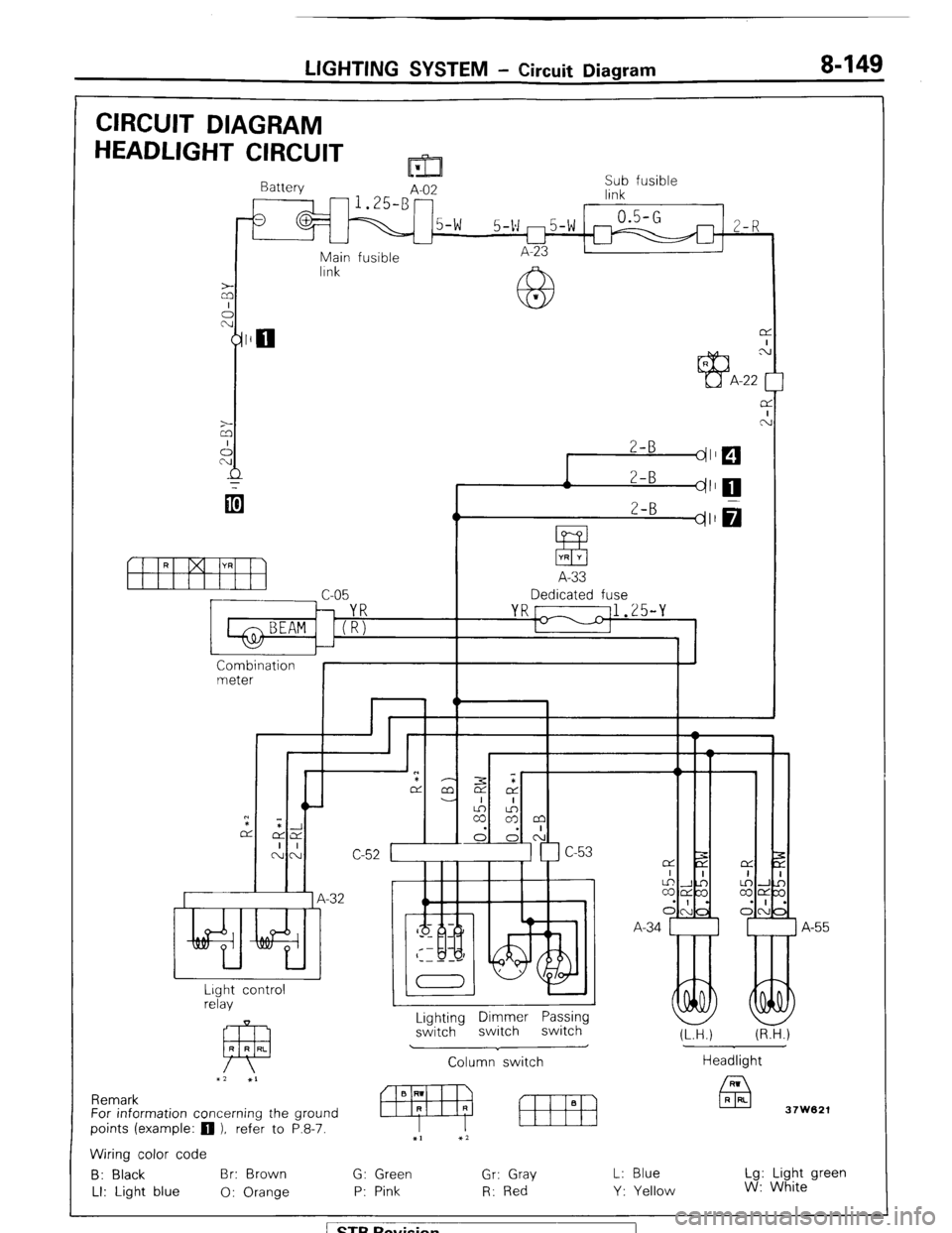

LIGHTING SYSTEM - Circuit Diagram 8-149

CIRCUIT DIAGRAM

HEADLIGHT CIRCUIT m

Battery

A-02 Sub fusible

link

0.5-G

5-v m5-w m 2-R

L-l

Main fusible A-23

lrnk

z

A

2-B

dl

r 2-B

I dl

ItfYH

A-33

c-05 Dedicated fuse

YR[ 11.25-Y

1-1

I

Combination

meter

I I

Wlir,L n

*

7

.-32 A

I

A-55

I

Lighting Dimmer Passing

switch switch switch

Column switch Lrght control

relay

FP R R RL

x2 XI

J

(LTH.) (R.H.)

Headlight

37W621 Remark

For information concerning the ground

points (example:

q ), refer to P.8-7.

Wiring color code

B: Black Br: Brown G: Green Gr: Gray

LI: Light blue 0: Orange P: Pink R: Red L: Blue

Y: Yellow Lg: Light green

W: White

/ STB Revision

Page 171 of 284

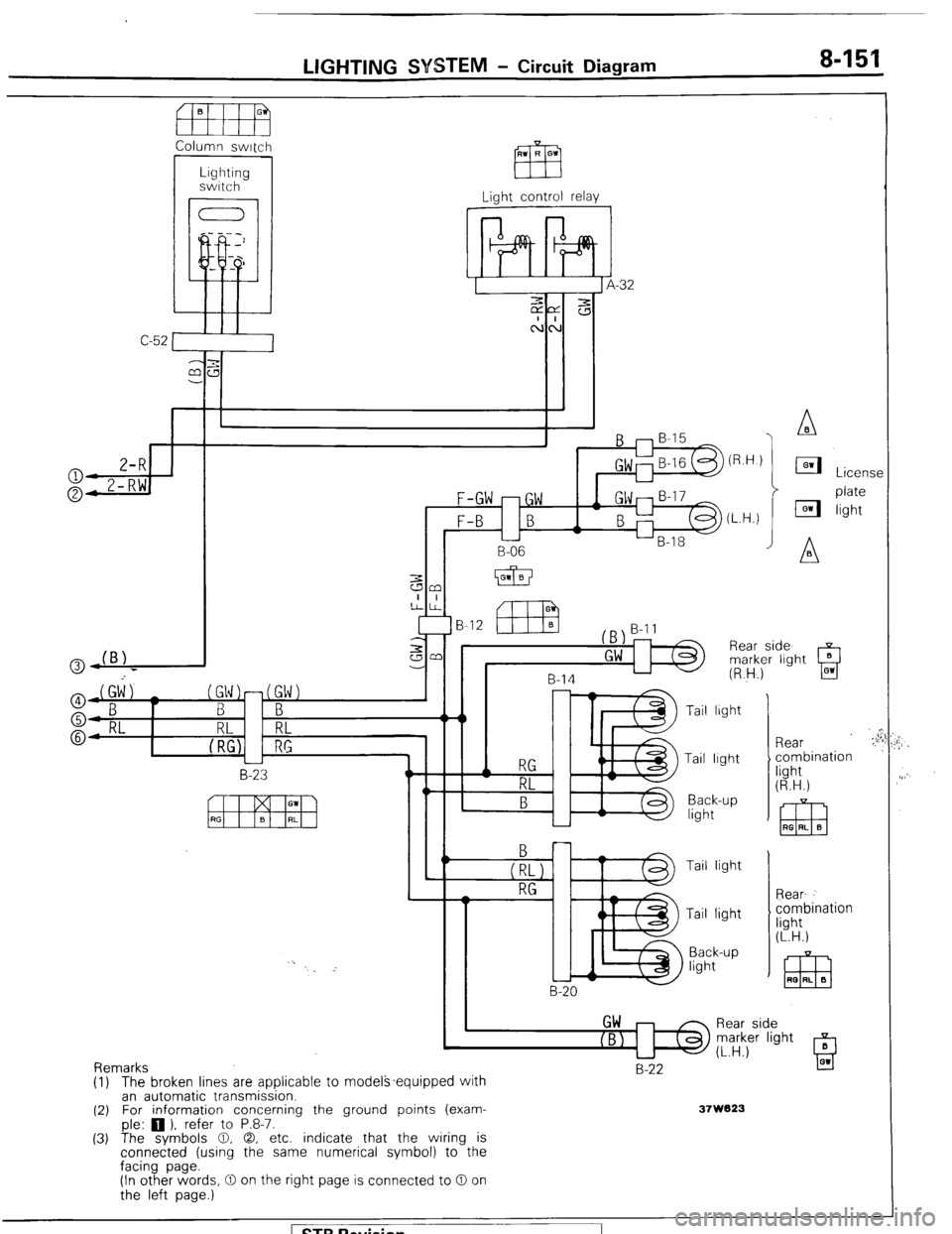

LIGHTING SYSTEM - Circuit Diagram 8-154

Column switch

C-52 Light control relay

1

-32

J

F-GW -GW

F-B B

L

B-06

B-12

B-14

L-l5 B-20 Tail light

Tail lrght

Back-up

light

Tail light

Tail light

Back-up

light Rear

combination

light

(R.H.)

Rear

combination

light

(L.H.)

Rear side

marker light

(L.H.)

Remarks

(1) (2)

(3) The broken lines are applicable to models~equipped with

an automatic transmission.

For information concerning the ground points (exam-

ple: 0 ). refer to P.8-7. B-22

37W823

The symbols 0, 0, etc. indicate that the wiring is

connected (using the same numerical symbol) to the

facing page.

(In other words, 0 on the right page is connected to 0 on

the left page.)

) STB Revision

Page 178 of 284

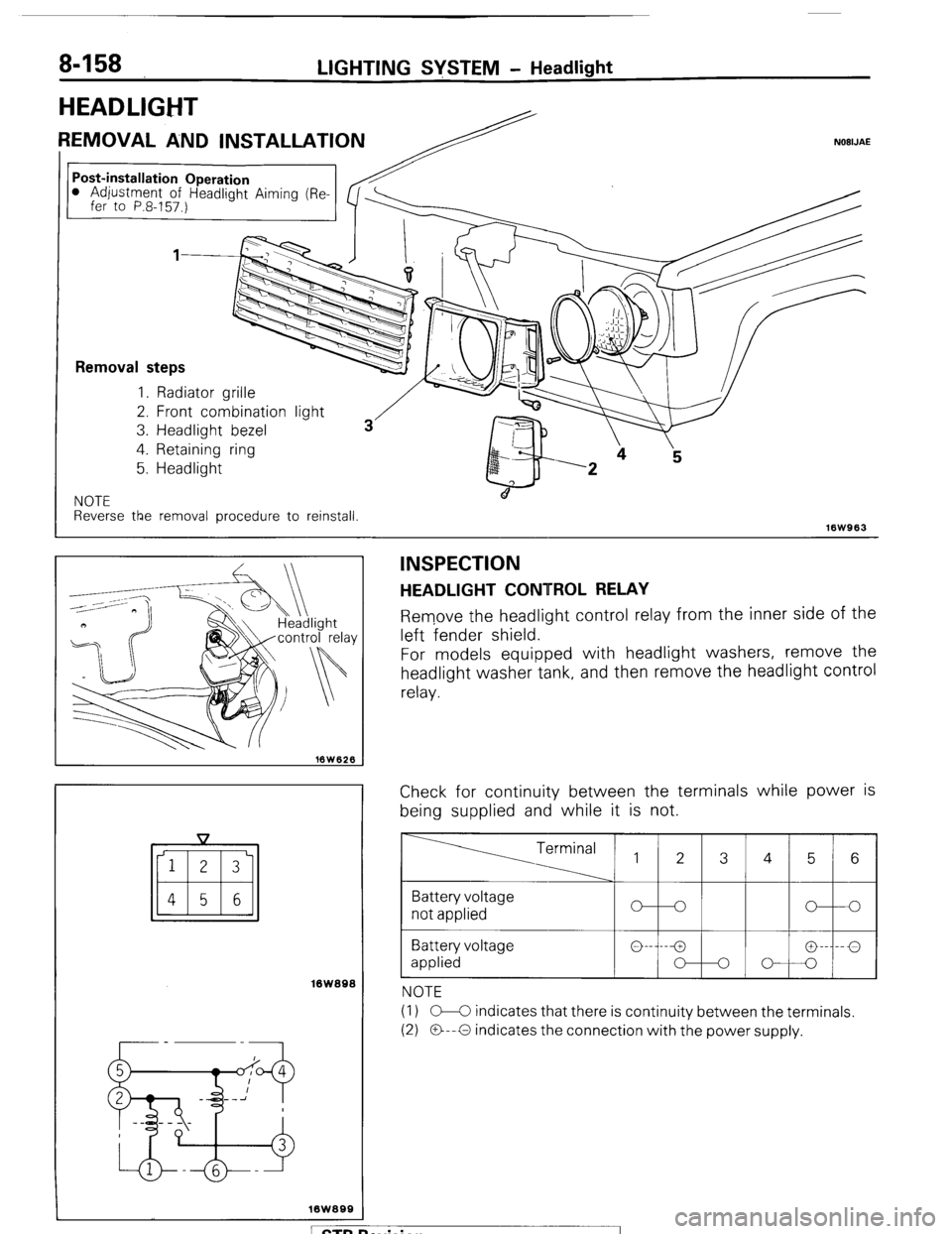

8-158 LIGHTING SYSTEM - Headlight

Post-installation Operation l Adjustment of Headliaht Aimina (

HEADLIGHT

REMOVAL AND INSTALLATION NOBIJAE

( fer to P.8-157.) Removal steps

1. Radiator grille

2. Front combinatior

3. Headlight bezel

4. Retaining ring

5. Headlight

I light

NOTE

Reverse the removal procedure to reinstall.

16W963

iswasa

INSPECTION

HEADLIGHT CONTROL RELAY

Remove the headlight control relay from the inner side of the

left fender shield.

For models equipped with headlight washers, remove the

headlight washer tank, and then remove the headlight control

relay.

Check for continuity between the terminals while power is

being supplied and while it is not. Terminal 1 2 3 4 5 6

Battery voltage

not applied

Battery voltage

applied

NOTE

(I 1 C-C indicates that there is continuity between the terminals.

(2) O--O indicates the connection with the power supply.

ewision I

Page 183 of 284

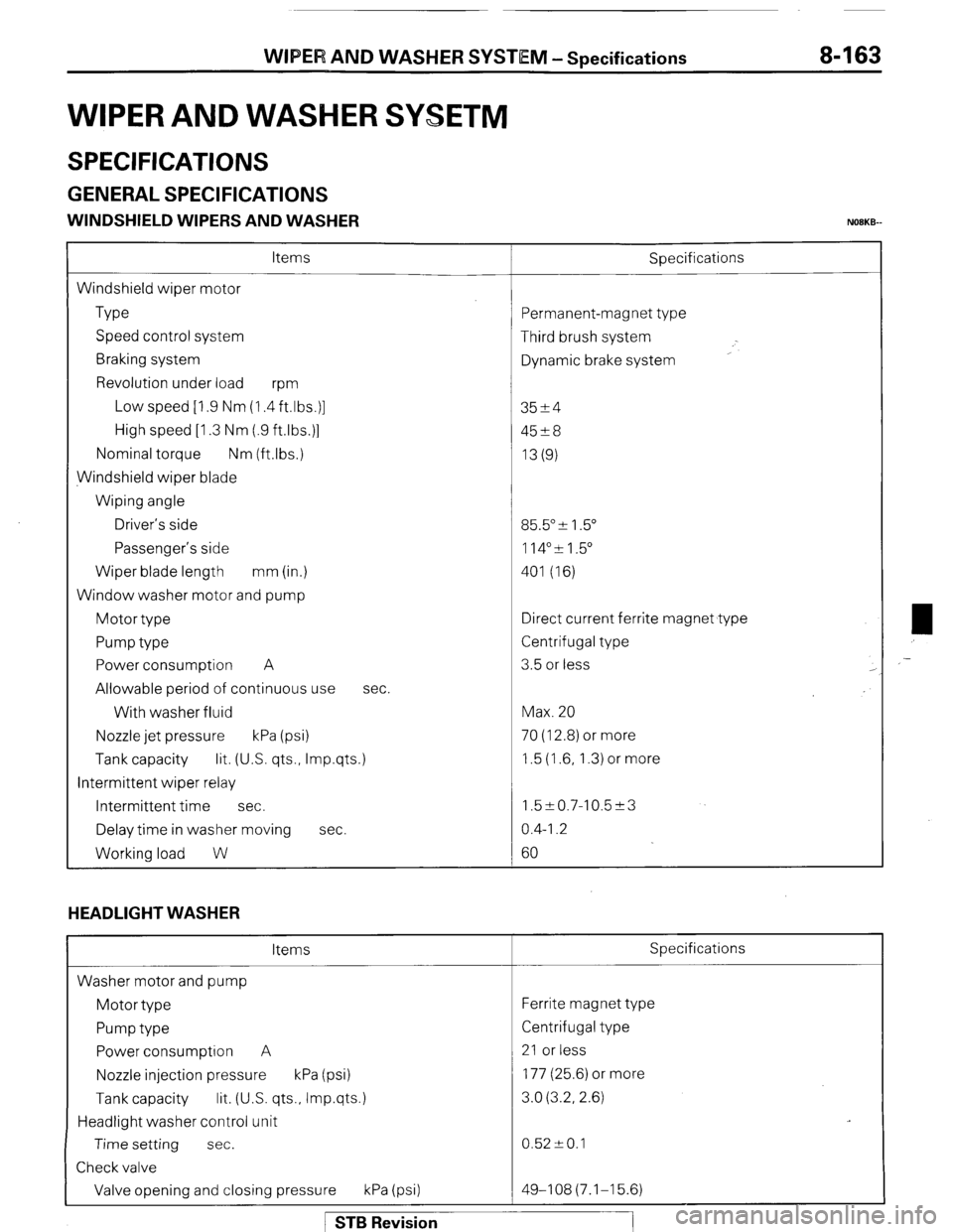

WIPER AND WASHER SYSTEM -Specifications 8-163

WIPER AND WASHER SYSETM

SPECIFICATIONS

GENERAL SPECIFICATIONS

WINDSHIELD WIPERS AND WASHER NOBKB-

Items

Windshield wiper motor

Type

Speed control system

Braking system

Revolution under load

wm

Low speed [I .9 Nm (1.4 ft.lbs.)]

High speed [I .3 Nm (.9 ftlbs.)]

Nominal torque Nm (ftlbs.)

Windshield wiper blade

Wiping angle

Driver’s side

Passenger’s side

Wiper blade length mm (in.)

Window washer motor and pump

Motor type

Pump type

Power consumption A

Allowable period of continuous use

With washer fluid

Nozzle jet pressure kPa (psi) Sbecifications

sec.

Tank capacity lit. (US. qts., Imp.qts.)

Intermittent wiper relay

Intermittent time sec.

Delay time in washer moving sec.

Working load W

HEADLIGHT WASHER

Items

Washer motor and pump

Motor type

Pump type

Power consumption A

Nozzle injection pressure kPa (psi)

Tank capacity lit. (U.S. qts., Imp.qts.)

Headlight washer control unit

Time setting sec.

Check valve

Valve opening and closing pressure kPa (psi) ‘ermanent-magnet type

Third brush system

Dynamic brake system

3524

45?8

13(g)

35.5” & 1.5”

114”51.5”

401 (16)

Iirect current ferrite magnet type

Zentrifugal type

3.5 or less

Max. 20

70 (12.8) or more

1.5 (1.6, 1.3) or more

1.5~0.7-10.5~3

0.4-I .2

60

Specifications

Ferrite magnet type

Centrifugal type

21 or less

177 (25.6) or more

3.0 (3.2, 2.6)

0.52 -+ 0.1

49-108(7.1-15.6) ,-

1 STB Revision

Page 188 of 284

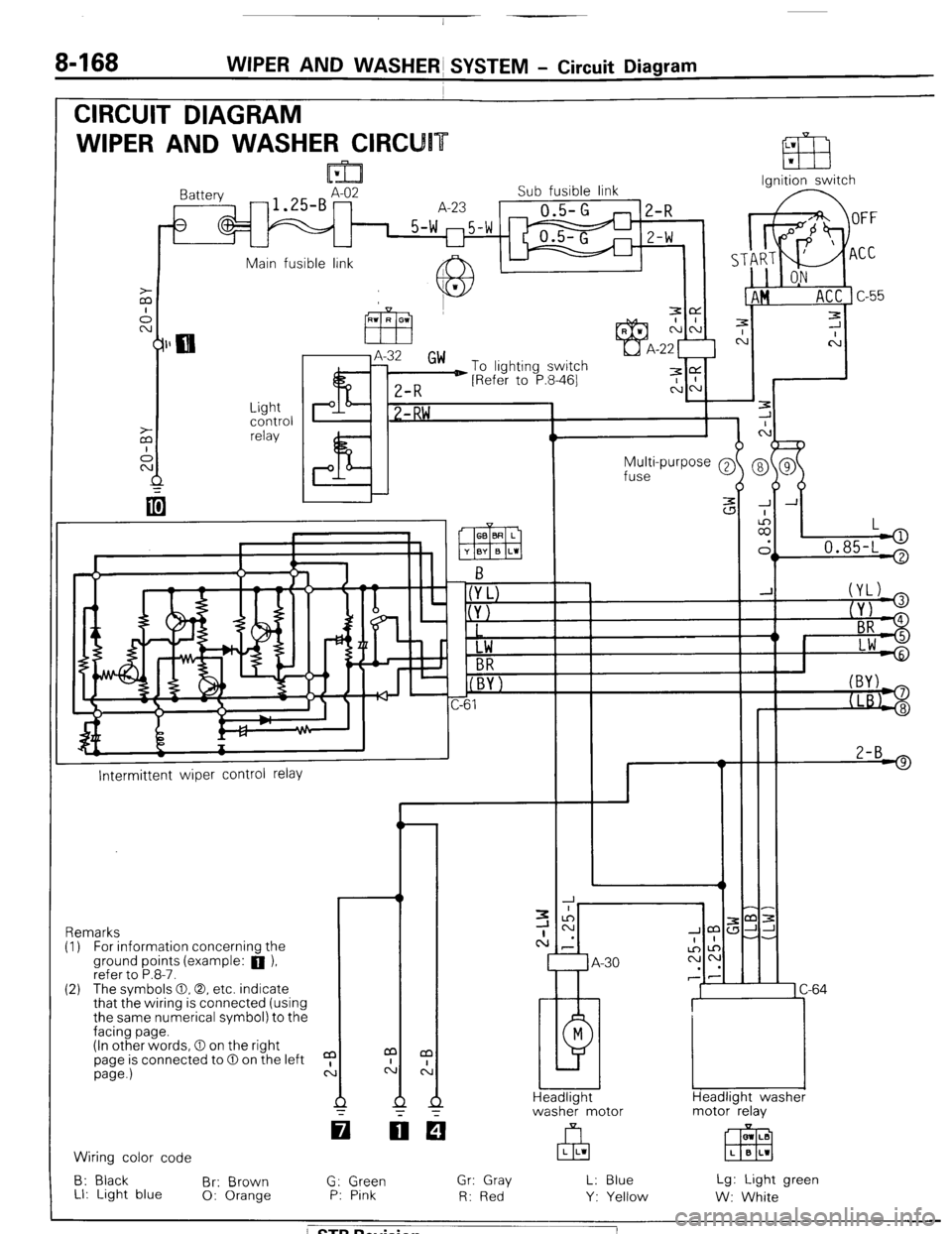

8468 WIPER AND WASHERS SYSTEM - Circuit Diagram

CIRCUIT DIAGRAM

WIPER AND WASHER CIRCU

Ignition switch

lattery

-1.SBAz2 Sub fusible link

A-23

0.5-G

1 5-w m5-w

U

2-R

Z-W

Main fusible link A IL

J.

c

7

C

-

-

-

-

-

-

J A

:

II,

L

.

> 0.85-L '

Light

control

relay P I? 1 -RW ,

Multi-purpose @

fuse

2-B 9

I--

Intermittent wiper control relay

-r ,m:

JJ-

-.

1 C-64

Headlight washer

motor relay Remarks

(I) For information concernina the

ground points (example: a ),

refer to P.8-7.

(2) The svmbols 0.0. etc. indicate

that the wiring is connected (using

the same numerical symbol) to the

facing page.

(In other words, 0 on the right

page is connected to 0 on the left

page.)

a

c: m LB

EEEI L B L1 Wiring color code

B: Black

Br: Brown

LI: Light blue 0: Orange G: Green

P: Pink Gr: Gray

R: Red L: Blue

Y: Yellow Lg: Light green

W: White

/ STB Revision

Page 193 of 284

WIPER AND WASHER SYSTEM - Windshield Wipers 8-173

I Battery

To wiper

motor bracket

16W1540

16W1524

16UO373

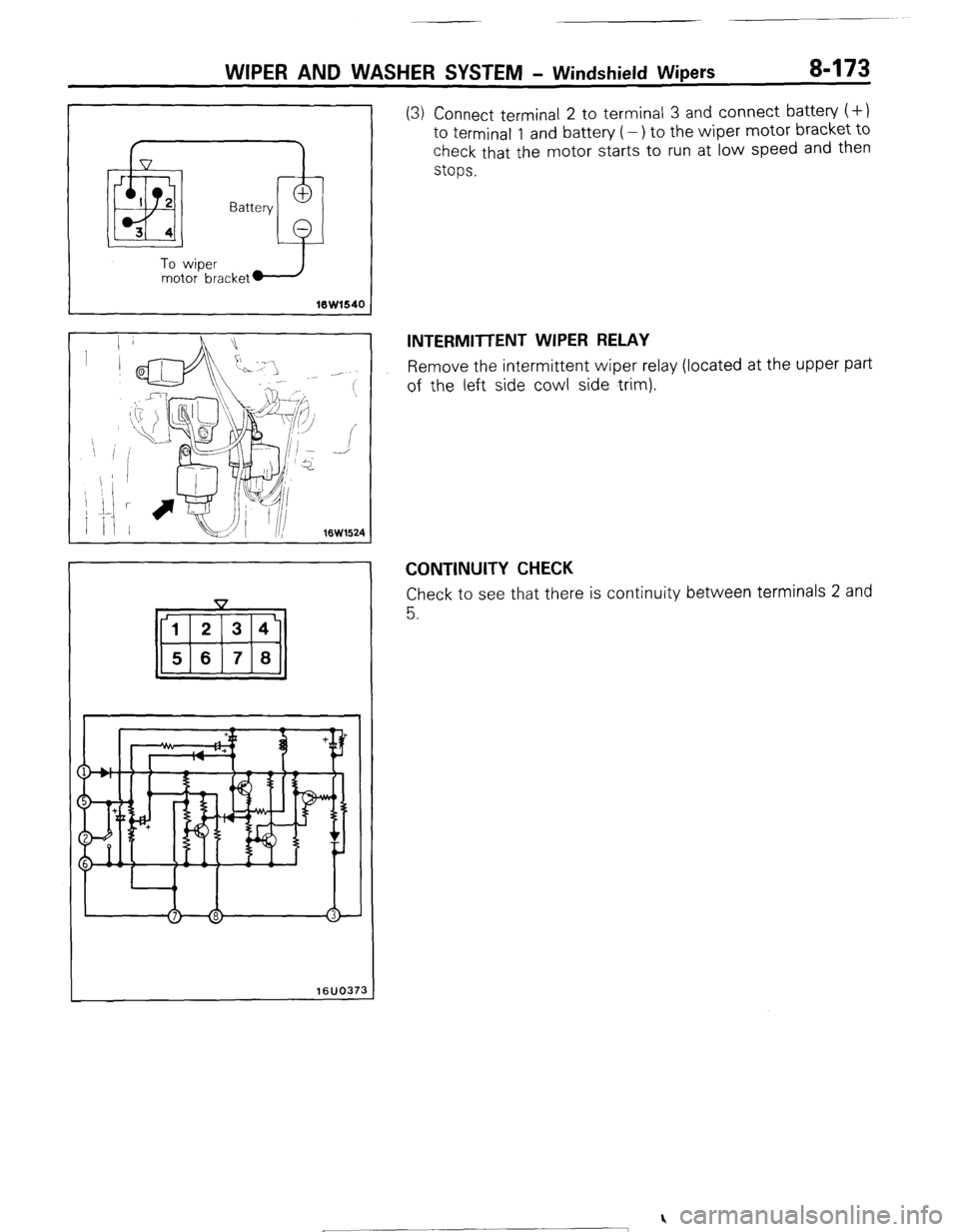

(3) Connect terminal 2 to terminal 3 and connect battery (+)

to terminal 1 and battery (-) to the wiper motor bracket to

check that the motor starts to run at low speed and then

stops.

INTERMITTENT WIPER RELAY

Remove the intermittent wiper relay (located at the upper part

of the left side cowl side trim).

CONTINUITY CHECK

Check to see that there is continuity between terminals 2 and

5.

) STB Revision

Page 194 of 284

a-174 WIPER AND WASHER $YSTEM - Windshield Wipers / Rear Wiper

REAR WIPtER

7

-est light

16K1920

t

REMOVAL AND INSTALLATION

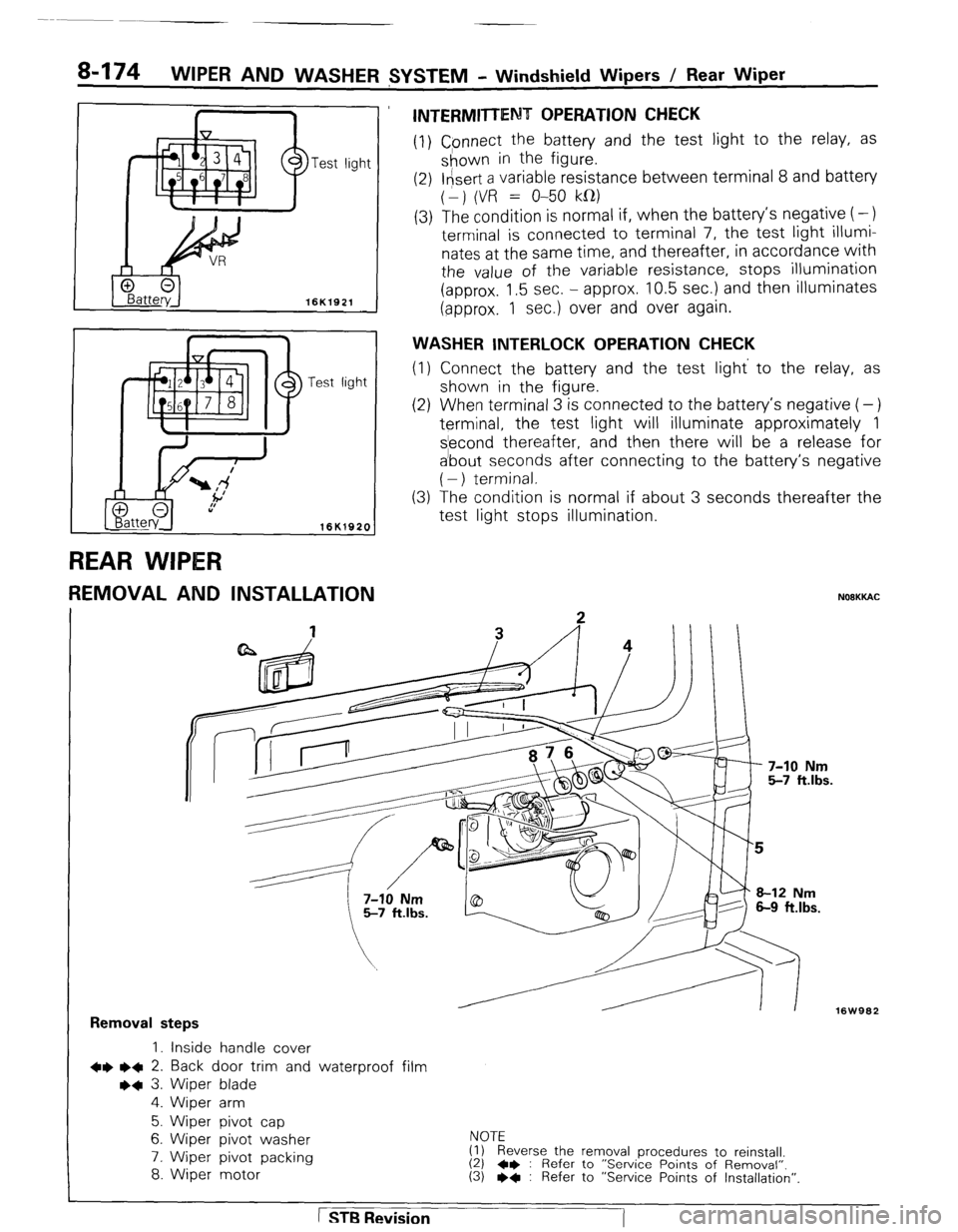

INTERMITTENT OPERATION CHECK

(1) Cpnnect the battery and the test light to the relay, as

shown in the figure.

(2) l&ert a variable resistance between terminal 8 and battery

(1) (VR = O-50 kfl)

(3) The condition is normal if, when the battery’s negative (-)

terminal is connected to terminal 7, the test light illumi-

nates at the same time, and thereafter, in accordance with

the value of the variable resistance, stops illumination

(approx. 1.5 sec. - approx. 10.5 sec.) and then illuminates

(approx. 1 sec.) over and over again.

WASHER INTERLOCK OPERATION CHECK

(1) Connect the battery and the test light’ to the relay, as

shown in the .figure.

(2) When terminal 3 is connected to the battery’s negative (-)

terminal, the test light will illuminate approximately 1

s’econd thereafter, and then there will be a release for

a’bout seconds after connecting to the battery’s negative

( - ) terminal.

The condition is normal if about 3 seconds thereafter the

test light stops illumination. (3

NOOKKAC

16W962

Removal steps

1. inside handle cover

+e l + 2. Back door trim and waterproof film

++ 3. Wiper blade

4. Wiper arm

5. Wiper pivot cap

6. Wiper pivot washer

7. Wiper pivot packing

8. Wiper motor NOTE

(1) Reverse the removal procedures to reinstall.

(2) 4* : Refer to “Service Points of Removal”. (3) l * : Refer to “Service Points of Installation”.

1 STB Revision

-7