light MITSUBISHI MONTERO 1987 1.G Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 99 of 284

CHARGING SYSTEM - Service Adjustment Procedures 8-79

Result

(1) The ammeter reading must be higher than the limit value. If it

is lower but the alternator output wire is normal, remove the

alternator from the vehicle and check it.

Limit value : 31 A min.

Caution

1. The nominal output current value is shown on the

nameplate affixed to the alternator body.

2. The output current value changes with the electrical

load and the temperature of the alternator itself.

Therefore, the nominal output current may not be ob-

tained if the vehicle electrical load at the time of test is

small. In such a case, keep the headlights on to cause

discharge of the battery or use lights of another vehi-

cle as a load to increase the electrical load. The nom-

inal output current may not be obtained if the temper-

ature of the alternator itself or abmient temperature is

too high. In such a case, reduce the temperature be-

fore testing again.

(2) Upon completion of the output current test, lower the engine

speed to the idle speed and turn off the ignition switch.

(3) Disconnect the battery ground cable.

(4) Remove the test ammeter and voltmeter and the engine ta-

chometer.

(5) connect the alternator output wire to the alternator “B” ter-

minal.

(6) Connect the battery ground cable.

REGULATED VOLTAGE TEST

The purpose of this test is to check that the electronic voltage

regulator controls the voltage correctly.

Preparation

(1) Prior to the test, check the following items and correct if nec-

essary.

(a) Check the battery installed on the vehicle to see that it is

fully charged. For battery checking method, see “BAT-

TERY”.

(b) Check the alternator drive belt tension. For belt tension

check, see “GROUP 7 COOLING - Service Adjustment

Procedures”.

(2) Turn the ignition switch to “OFF”.

(3) Disconnect the battery ground cable.

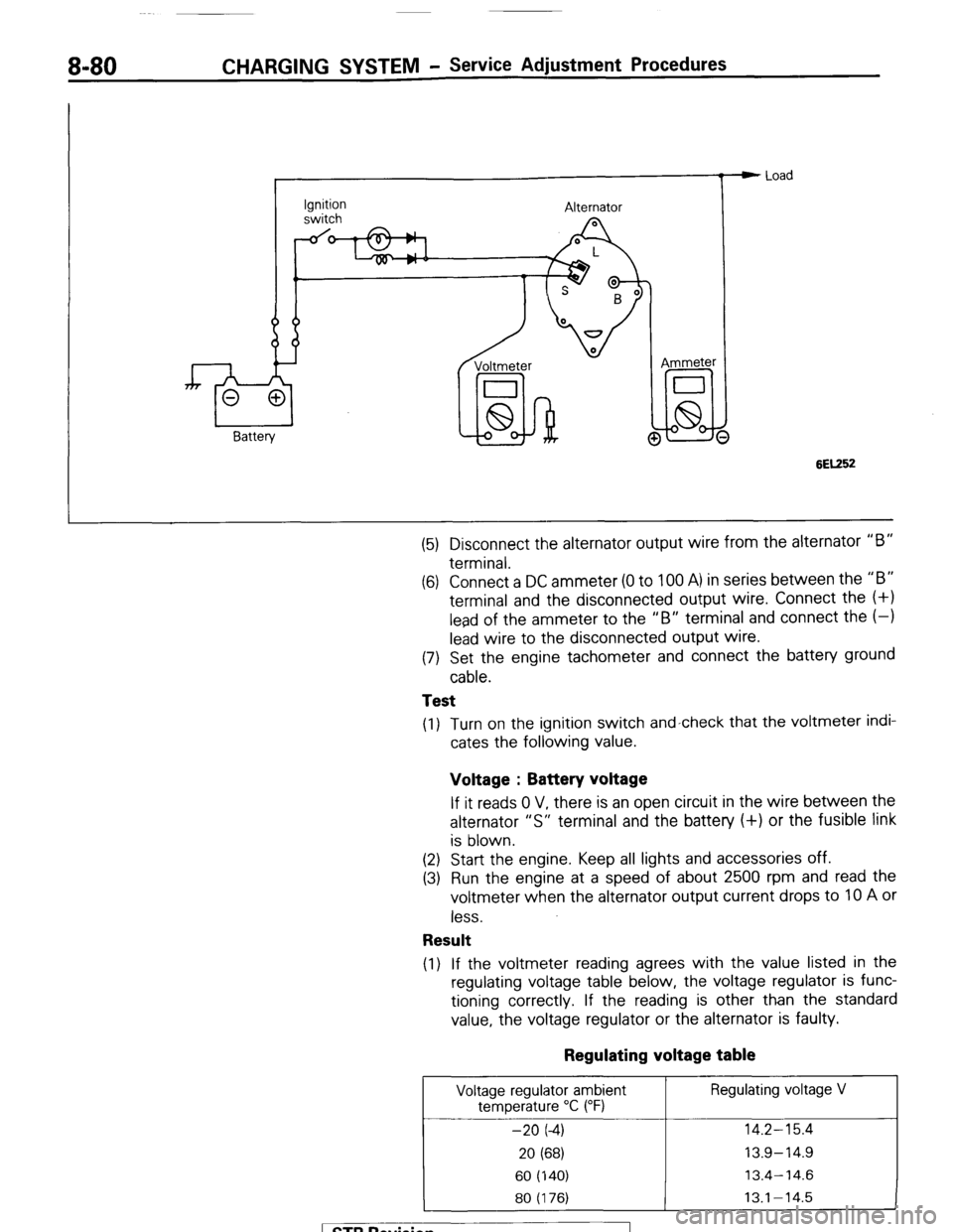

(4) Connect a digital voltmeter between the “S” terminal of the

alternator and ground. Connect the (+) lead of the voltmeter to

the “S” terminal of the alternator, inserting from the wire side

of the 2-way connector and connect the (-1 lead to sound

ground or battery (-) terminal.

1 ST6 Revision

Page 100 of 284

8-80 CHARGING SYSTEM - Service Adjustment Procedures

Ignition

switch Alternator

Voltmeter

I

lid-hi! @ Ammeter e Load

6EK52

(5) Disconnect the alternator output wire from the alternator “B”

terminal.

(6) Connect a DC ammeter (0 to 100 A) in series between the “B”

terminal and the disconnected output wire. Connect the (+I

lead of the ammeter to the “B” terminal and connect the (-1

lead wire to the disconnected output wire.

(7) Set the engine tachometer and connect the battery ground

cable.

Test

(1) Turn on the ignition switch and-check that the voltmeter indi-

cates the following value.

Voltage : Battery voltage

If it reads 0 V, there is an open circuit in the wire between the

alternator “S” terminal and the battery (+) or the fusible link

is blown.

(2) Start the engine. Keep all lights and accessories off.

(3) Run the engine at a speed of about 2500 rpm and read the

voltmeter when the alternator output current drops to 10 A or

less.

Result

(1) If the voltmeter reading agrees with the value listed in the

regulating voltage table below, the voltage regulator is func-

tioning correctly. If the reading is other than the standard

value, the voltage regulator or the alternator is faulty.

Regulating voltage table

Voltage regulator ambient Regulating voltage V

temperature “C (“F)

-20 (-4) 14.2-15.4

20 (68) 13.9-14.9

60 (140) 13.4-14.6

80 (176) 13.1-14.5

1 STB Revision

Page 111 of 284

STARTING SYSTEM-General Information 8-91

STARTING SYSTEM

GENERAL INFORMATION

NOBFAAJ

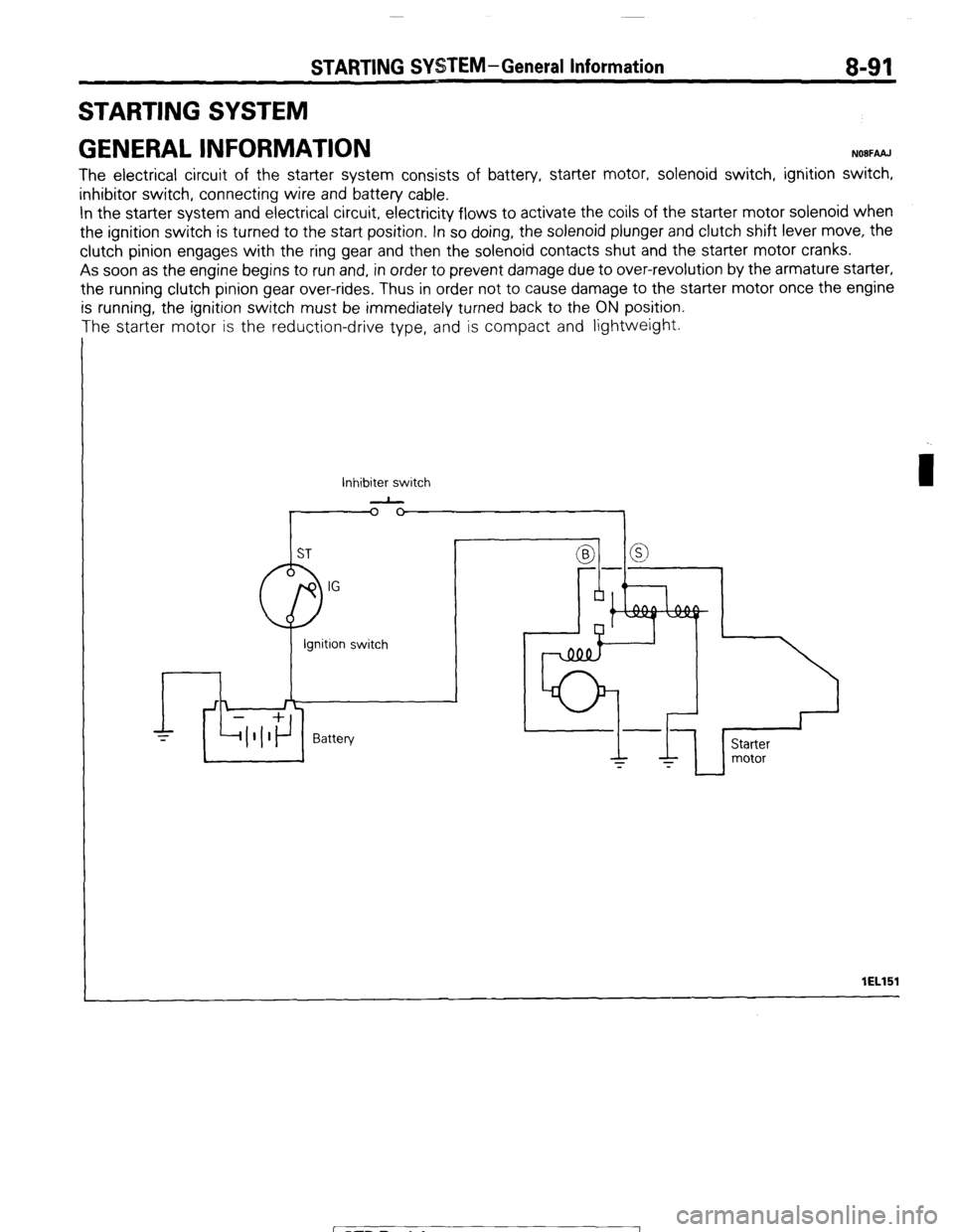

The electrical circuit of the starter system consists of battery, starter motor, solenoid switch, ignition switch,

inhibitor switch, connecting wire and battery cable.

In the starter system and electrical circuit, electricity flows to activate the coils of the starter motor solenoid when

the ignition switch is turned to the start position. In so doing, the solenoid plunger and clutch shift lever move, the

clutch pinion engages with the ring gear and then the solenoid contacts shut and the starter motor cranks.

As soon as the engine begins to run and, in order to prevent damage due to over-revolution by the armature starter,

the running clutch pinion gear over-rides, Thus in order not to cause damage to the starter motor once the engine

is running, the ignition switch must be immediately turned back to the ON position.

The starter motor is the reduction-drive type, and is compact and lightweight.

Inhibiter switch

-

I lEL151

1 STB Revision

Page 116 of 284

8-96 STARTING SYSTEM - Circuit Diagram

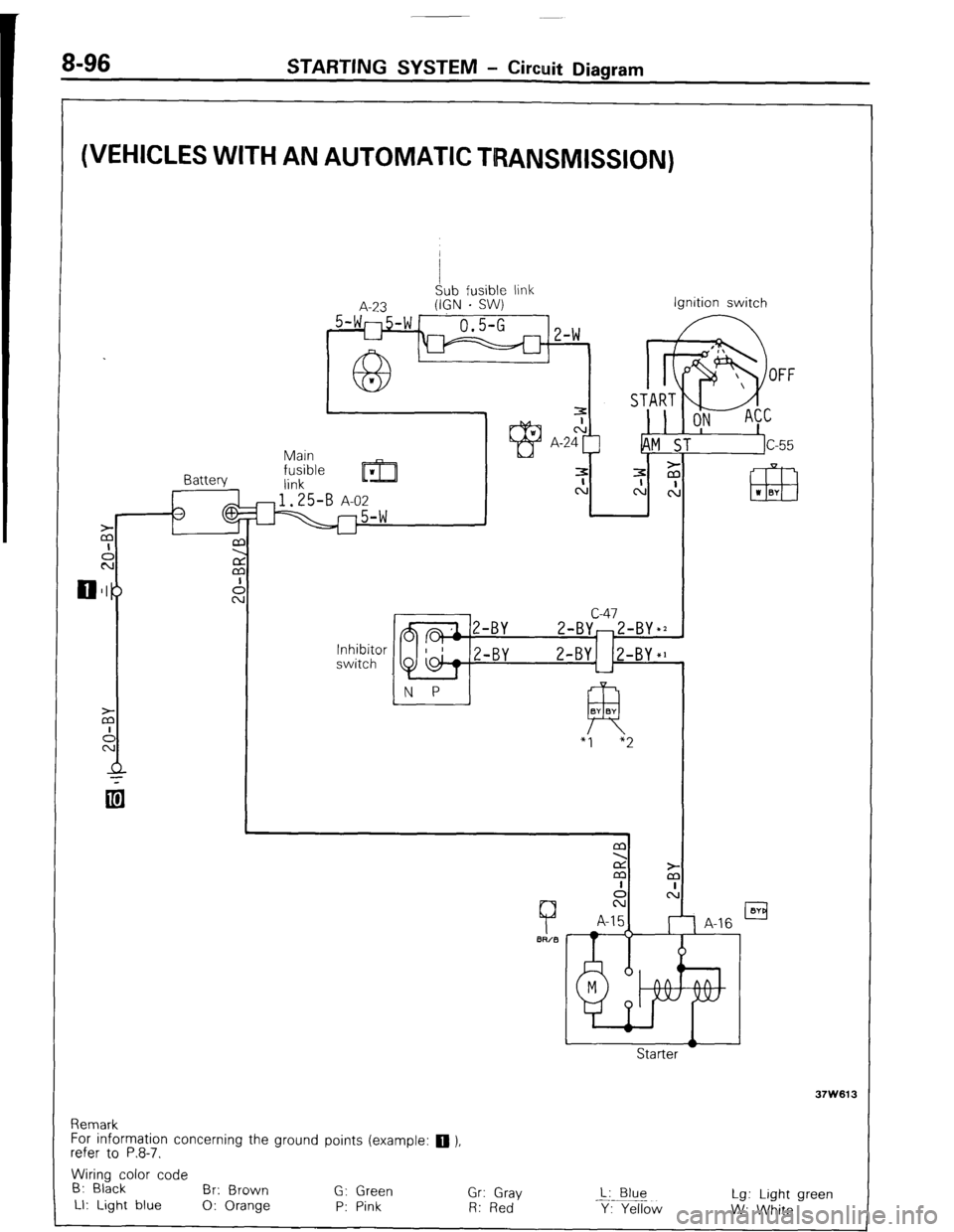

(VEHICLES WITH AN AUTOMATIC TRANSMISSION)

I

Sub fusible link

A-23 (IGN . SW)

_ 5-WI-754 1

0.5-G 1, 1,

L-l m 1 L-W

Battery Ignition switch

c-47

2-BY-Z-BY*2

N P

!-BY Z-BY1 (Z-BY*]

L-l

R BY BY

“I “2

Remark

For information concerning the ground points (example:

q ),

refer to P.8-7.

Wiring color code

B: Black

Br: Brown

G: Green

Gr: Gray L: Blue

LI: Light blue

0: Orange P: Pink Lg: Light green

R: Red

Y: Yellow

W: White

STB Revision

Page 130 of 284

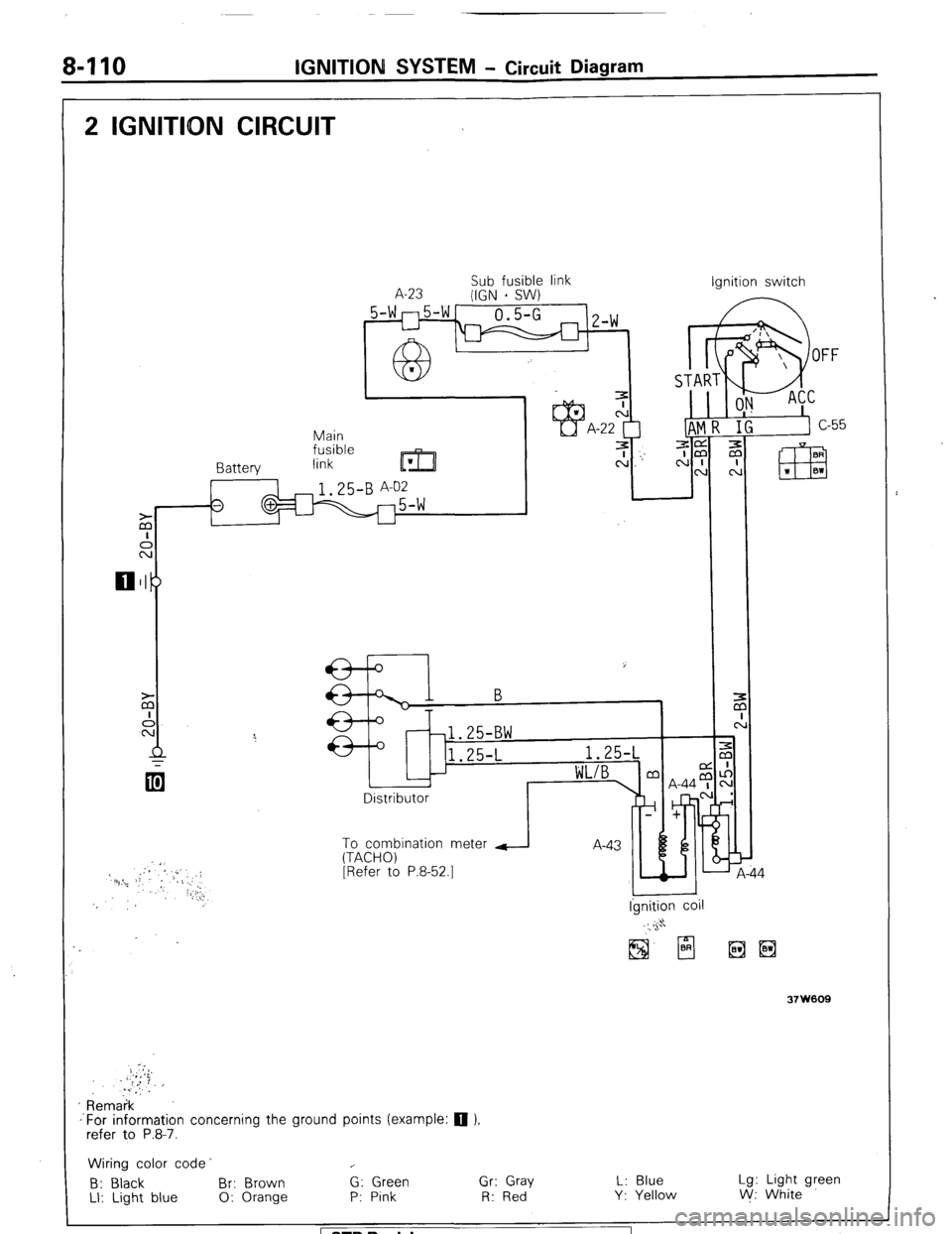

8-110 IGNITION SYSTEM - Circuit Diagram

2 IGNITDN CIRCUIT

Sub fusible link

A-23

(IGN - SW) Ignition switch

5-wn5-w-

0.5-G 1

u

63- Z-W

I

IAT

Main 1

fusible

Rnttprv link

m

ze 3 cj _-’ A:“p m

N CL

I 64-b I I I m

I

Ei

I

L Disi

To combination meter d A-an b

(TACHO)

[Refer to P.8-52.1

I I Ignition coil

37 w009

Remaik

-‘For information concerning the ground points (example: q ),

refer to P.8-7.

Wiring color code’ c

B: Black Br: Brown G: Green Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red Y: Yellow V/: White

1 STB Revision 1

Page 131 of 284

IGNITION SYSTEM - Service Adjustment Procedures 8-111

SERVICE ADJUSTMENT PROCEDURES

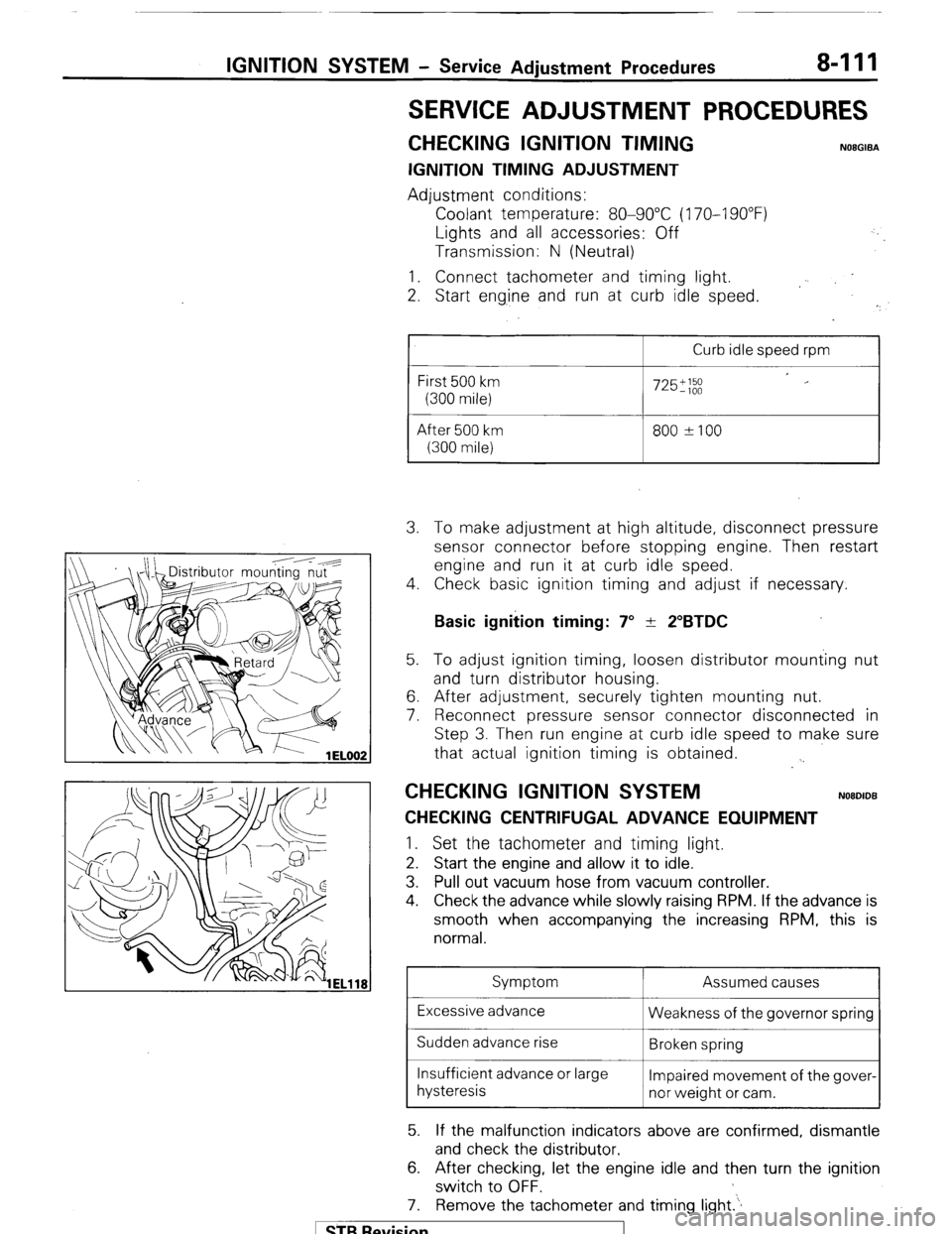

CHECKING IGNITION TIMING NOEGIBA

IGNITION TIMING ADJUSTMENT

Adjustment conditions:

Coolant temperature: 80-90°C (170-I 90°F)

Lights and all accessories: Off

Transmission: N (Neutral)

1. Connect tachometer and timing light.

2. Start eng.ine and run at curb idle speed.

I

Curb idle speed rpm

First 500 km

(300 mile)

After 500 km

(300 mile)

725';;;

800 ?I00 3. To make adjustment at high altitude, disconnect pressure

sensor connector before stopping engine. Then restart

engine and run it at curb idle speed.

4. Check basic ignition timing and adjust if necessary.

Basic ignition timing: 7” + 2”BTDC 5. To adjust ignition timing, loosen distributor mounting nut

and turn distributor housing.

6. After adjustment, securely tighten mounting nut.

7. Reconnect pressure sensor connector disconnected in

Step 3. Then run engine at curb idle speed to make sure

that actual ignition timing is obtained.

. .

CHECKING IGNITION SYSTEM NOBDIDB

CHECKING CENTRIFUGAL ADVANCE EQUIPMENT 1.

Set the tachometer and timing light.

2. Start the engine and allow it to idle.

3. Pull out vacuum hose from vacuum controller.

4. Check the advance while slowly raising RPM. If the advance is

smooth when accompanying the increasing RPM, this is

normal.

Symptom Assumed causes

Excessive advance

Weakness of the governor spring

Sudden advance rise

Broken spring

Insufficient advance or large

Impaired movement of the gover-

hysteresis

nor weight or cam.

5. If the malfunction indicators above are confirmed, dismantle

and check the distributor.

6. After checking, let the engine idle and then turn the ignition

switch to OFF.

7. Remove the tachometer and timing light.‘.

1 STB Revision

Page 132 of 284

8-112 IGNITION SYSTEM - Service Adjustment Procedures

CHECKING NEGATIVE PRESSURE ADVANCE EQUIPMENT

1. Set the timing light.

2. Start the engine and allow it to idle.

3. Pull out the vacuum hose from vacuum controller and attach

vacuum pump to nipple.

4. Check the advance while slowly applying negative pressure to

the vacuum pump. If the advance is smooth when accompa-

nying the increase in negative pressure, this is normal.

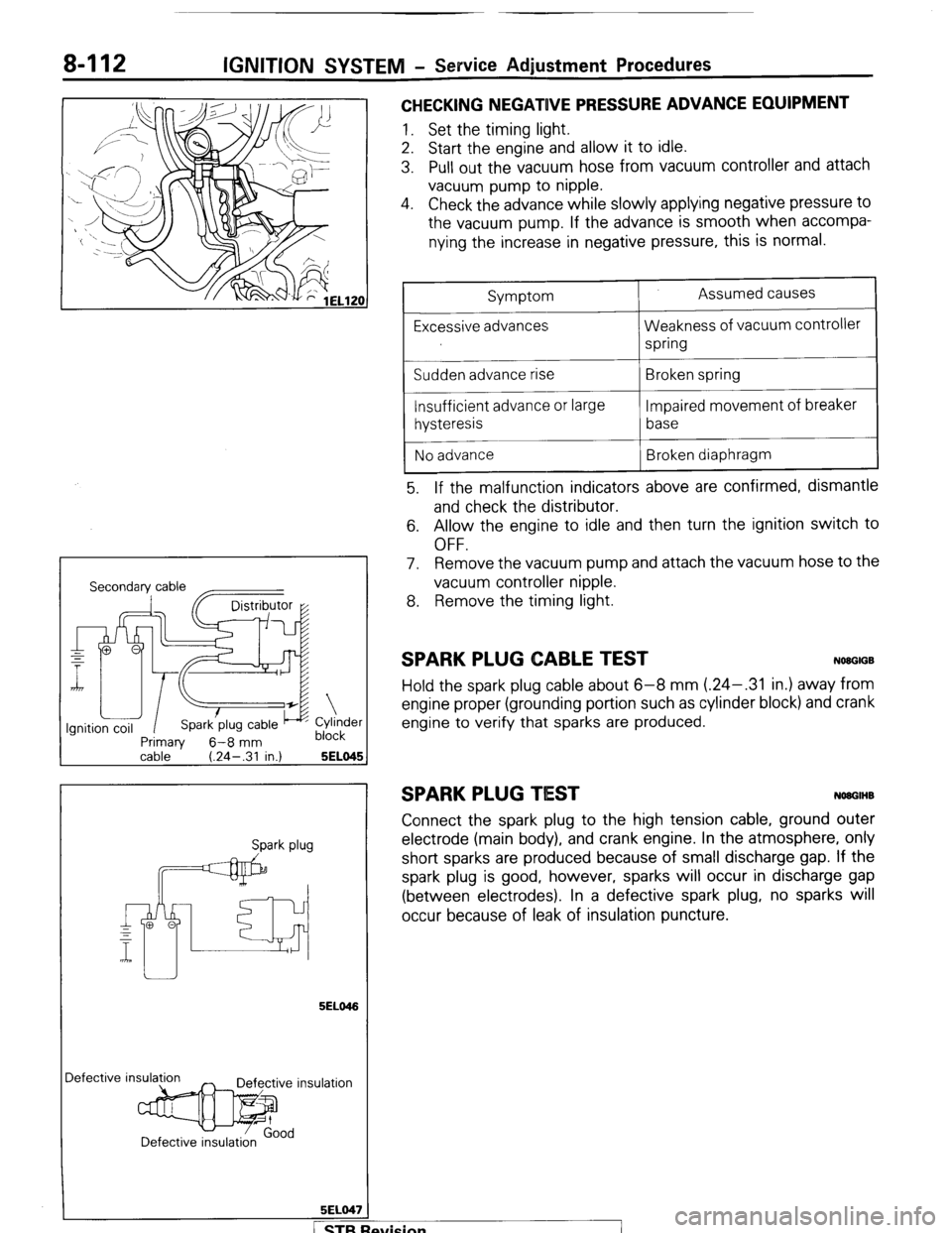

Secondary cable

~~

Primaw 6-8 mm

Cylinder

block

cable ’ (.24-.31 in.) 5ELO45 1

Spark plug

5ELO46

Iefective insula

5ELO47

/

Symptom

Excessive advances

Sudden advance rise

Insufficient advance or large

hysteresis

No advance Assumed causes

Weakness of vacuum controller

spring

Broken spring

Impaired movement of breaker

base

Broken diaphragm

5. If the malfunction indicators above are confirmed, dismantle

and check the distributor.

6. Allow the engine to idle and then turn the ignition switch to

OFF.

7. Remove the vacuum pump and attach the vacuum hose to the

vacuum controller nipple.

8. Remove the timing light.

SPARK PLUG CABLE TEST NWGIGB

Hold the spark plug cable about 6-8 mm (.24-.31 in.) away from

engine proper (grounding portion such as cylinder block) and crank

engine to verify that sparks are produced.

SPARK PLUG TIEST NOUGIHB

Connect the spark plug to the high tension cable, ground outer

electrode (main body), and crank engine. In the atmosphere, only

short sparks are produced because of small discharge gap. If the

spark plug is good, however, sparks will occur in discharge gap

(between electrodes). In a defective spark plug, no sparks will

occur because of leak of insulation puncture.

fvision

I

Page 140 of 284

8-120 IGNITION SYSTEM - Distributor

6ELO6i

ti Pin punch

II

1ELlOi

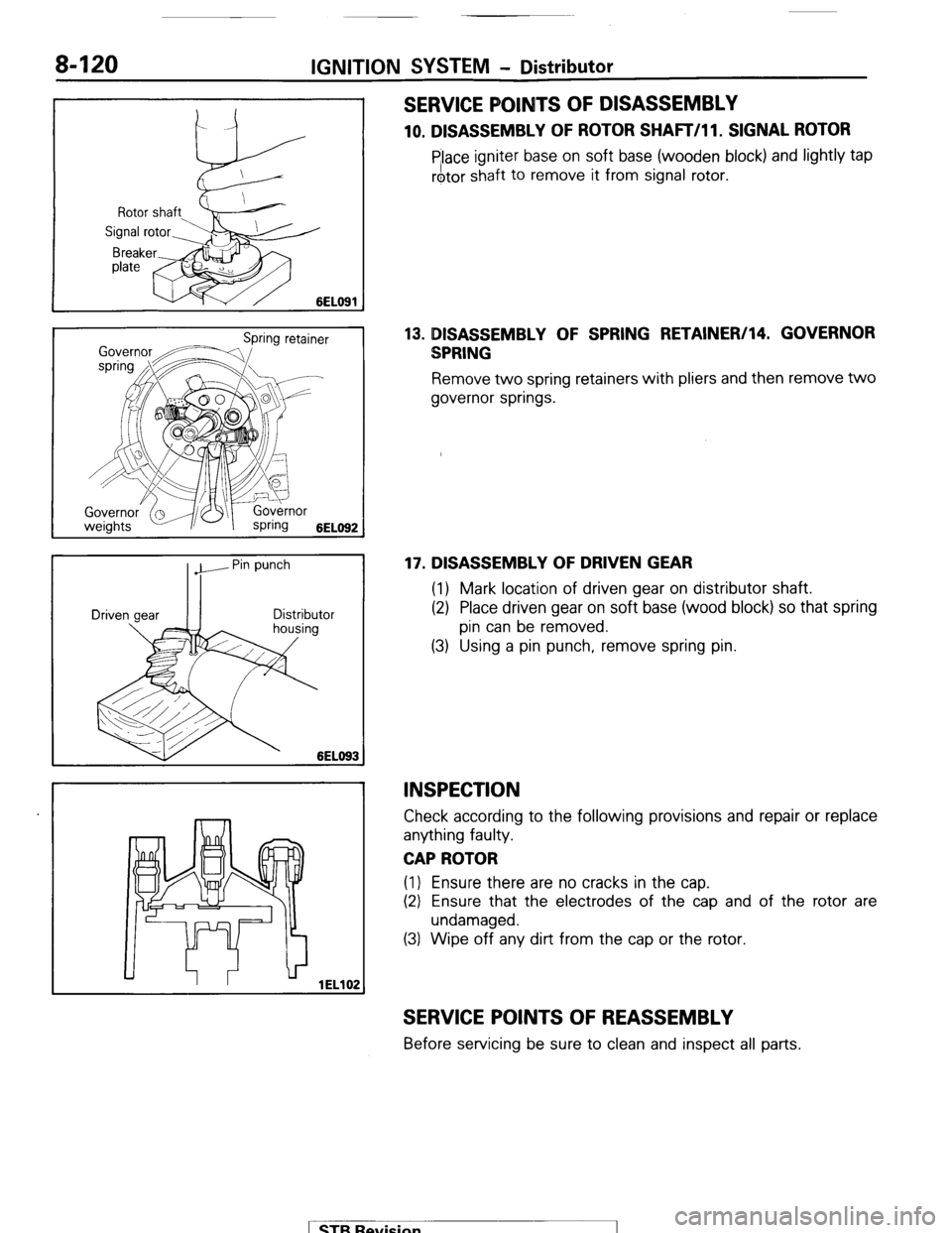

SERVICE POINTS OF DISASSEMBLY

10. DISASSEMBLY OF ROTOR SHAFT/l 1. SIGNAL ROTOR

Place igniter base on soft base (wooden block) and lightly tap

rotor shaft to remove it from signal rotor.

13. DISASSEMBLY OF SPRING RETAINERI14. GOVERNOR

SPRING

Remove two spring retainers with pliers and then remove two

governor springs.

17. DISASSEMBLY OF DRIVEN GEAR

(1) Mark location of driven gear on distributor shaft.

(2) Place driven gear on soft base (wood block) so that spring

pin can be removed.

(3) Using a pin punch, remove spring pin.

INSPECTION

Check according to the following provisions and repair or replace

anything faulty.

CAP ROTOR

(1) Ensure there are no cracks in the cap.

(2) Ensure that the electrodes of the cap and of the rotor are

undamaged.

(3) Wipe off any dirt from the cap or the rotor.

SERVICE POINTS OF REASSEMBLY

Before servicing be sure to clean and inspect all parts.

1 STB Revision

Page 143 of 284

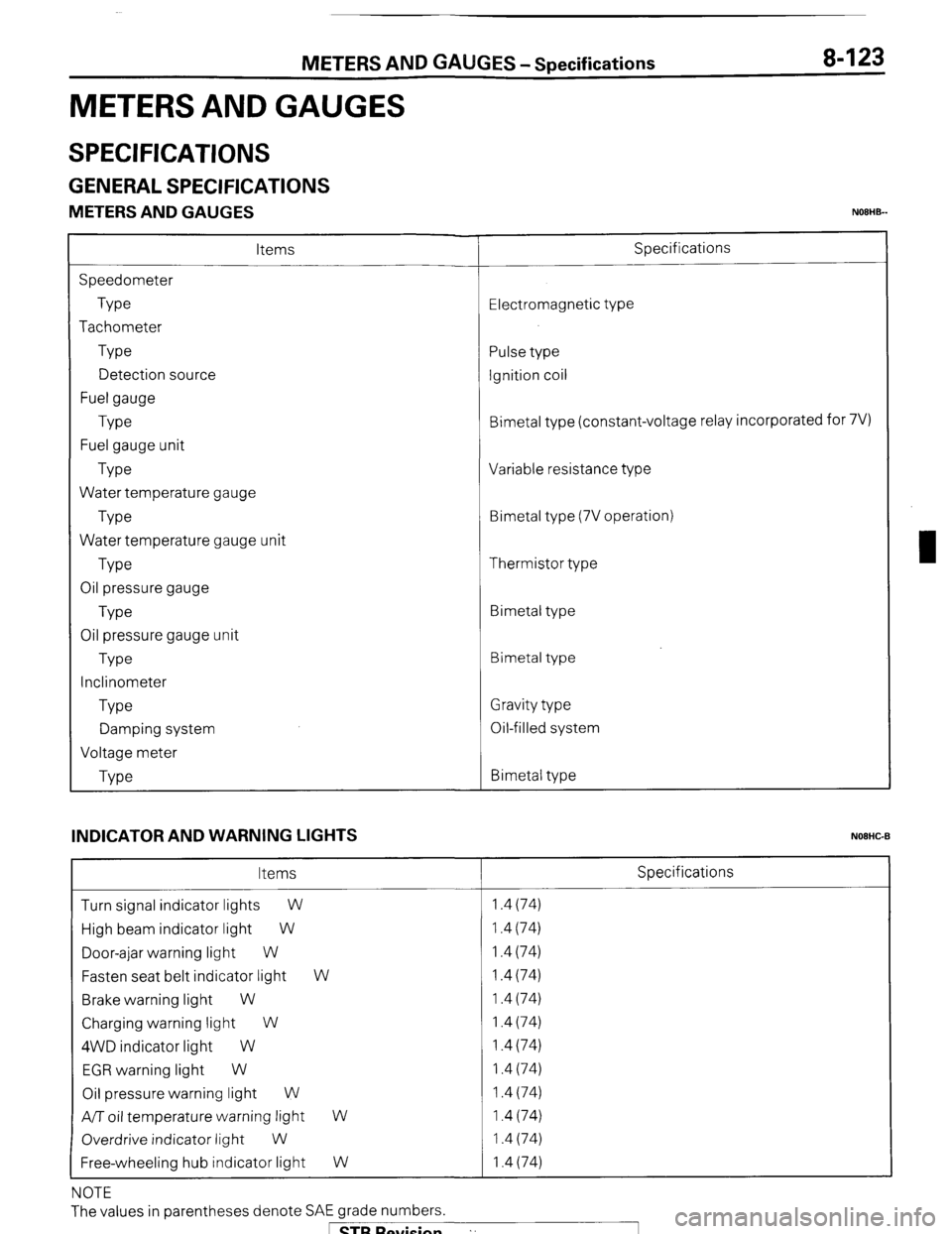

METERS AND GAUGES-Specifications

METERS AND GAUGES

8-123

SPECIFICATIONS

GENERAL SPECIFICATIONS

METERS AND GAUGES NOEHB-

Items

Speedometer

Type

Tachometer

Type

Detection source

Fuel gauge

Type

Fuel gauge unit

Type

Water temperature gauge

Type

Water temperature gauge unit

Type

Oil pressure gauge

Type

Oil pressure gauge unit

Type

Inclinometer

Type

Damping system

Voltage meter

Type Specifications

Electromagnetic type

Pulse type

Ignition coil

Bimetal type (constant-voltage relay incorporated for 7V)

Variable resistance type

Bimetal type (7V operation)

Thermistor type

Bimetal type

Bimetal type

Gravity type

Oil-filled system

Bimetal type

INDICATOR AND WARNING LIGHTS

NOEHC-B

Items Specifications

Turn signal indicator lights

W 1.4 (74)

High beam indicator light W 1.4 (74)

Door-ajar warning light W 1.4 (74)

Fasten seat belt indicator light W 1.4 (74)

Brake warning light W 1.4 (74)

Charging warning light W 1.4 (74)

4WD indicator light W 1.4 (74)

EGR warning light W 1.4 (74)

Oil pressure warning light W 1.4 (74)

A/T oil temperature warning light

W 1.4 (74)

Overdrive indicator light

W 1.4 (74)

Free-wheeling hub indicator light W 1.4 (74)

NOTE

The values in parentheses denote SAE grade numbers.

1 STB Revision ”

Page 147 of 284

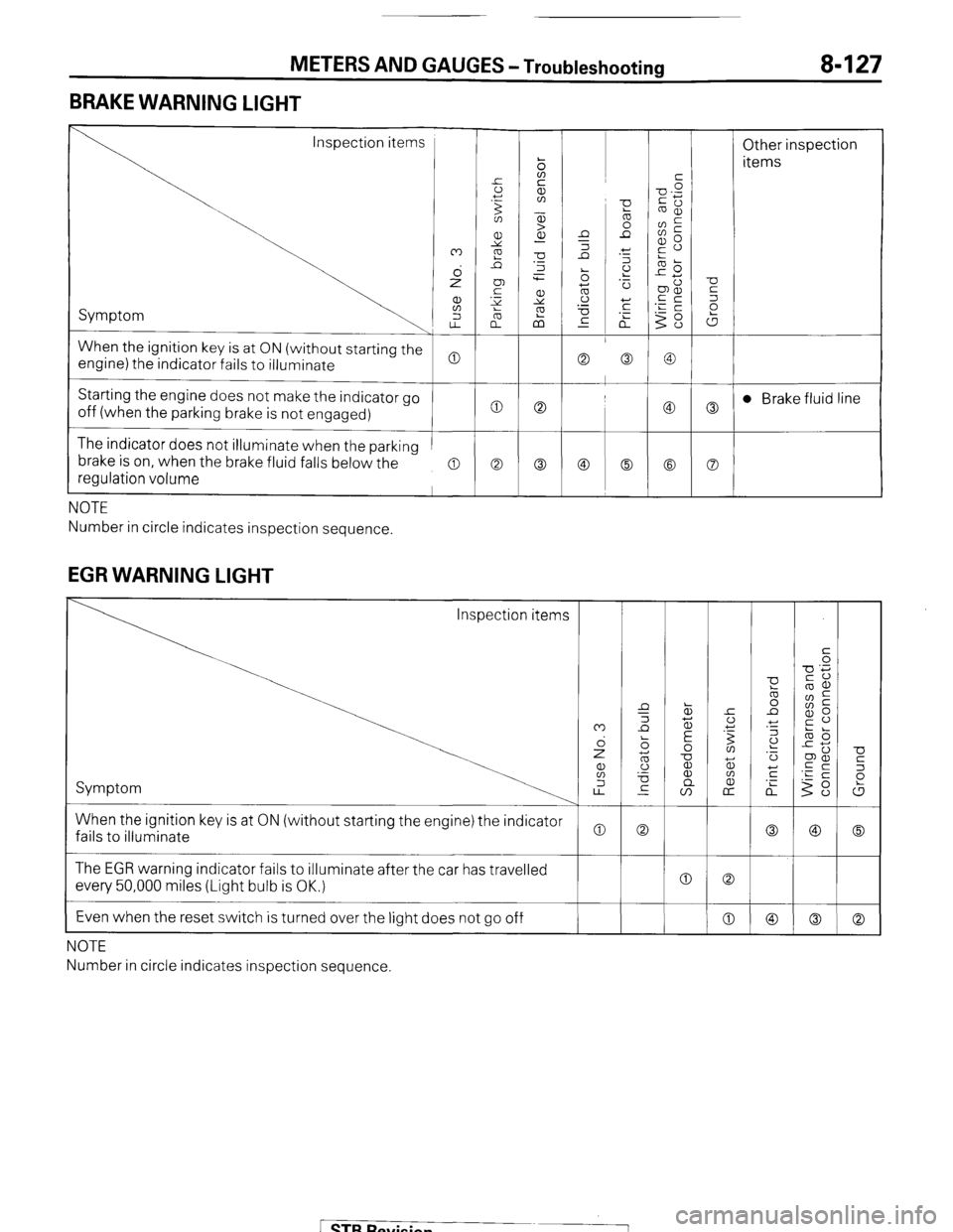

METERS AND GAUGES -Troubleshooting 8-127

BRAKE WARNING LIGHT

Inspection items

Other inspection

items

Symptom

When the ignition key is at ON (without starting the

engine) the indicator fails to illuminate

Starting the engine does not make the indicator go

off (when the parking brake is not engaged) t 0 0

c

The indicator does not illuminate when the parking

brake is on, when the brake fluid falls below the

regulation volume

a a Co

NOTE

Number in circle indicates inspection sequence.

EGR WARNING LIGHT

U

5

P

W

0

Co When the ignition key is at ON (without starting the engine) the indicator

fails to illuminate

0 The EGR warning indicator fails to illuminate after the car has travelled

every 50,000 miles (Light bulb is OK.)

Even when the reset switch is turned over the light does not go off 0 0

0

I

NOTE

Number in circle indicates inspection sequence.

[ STB Revision