light MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 188 of 284

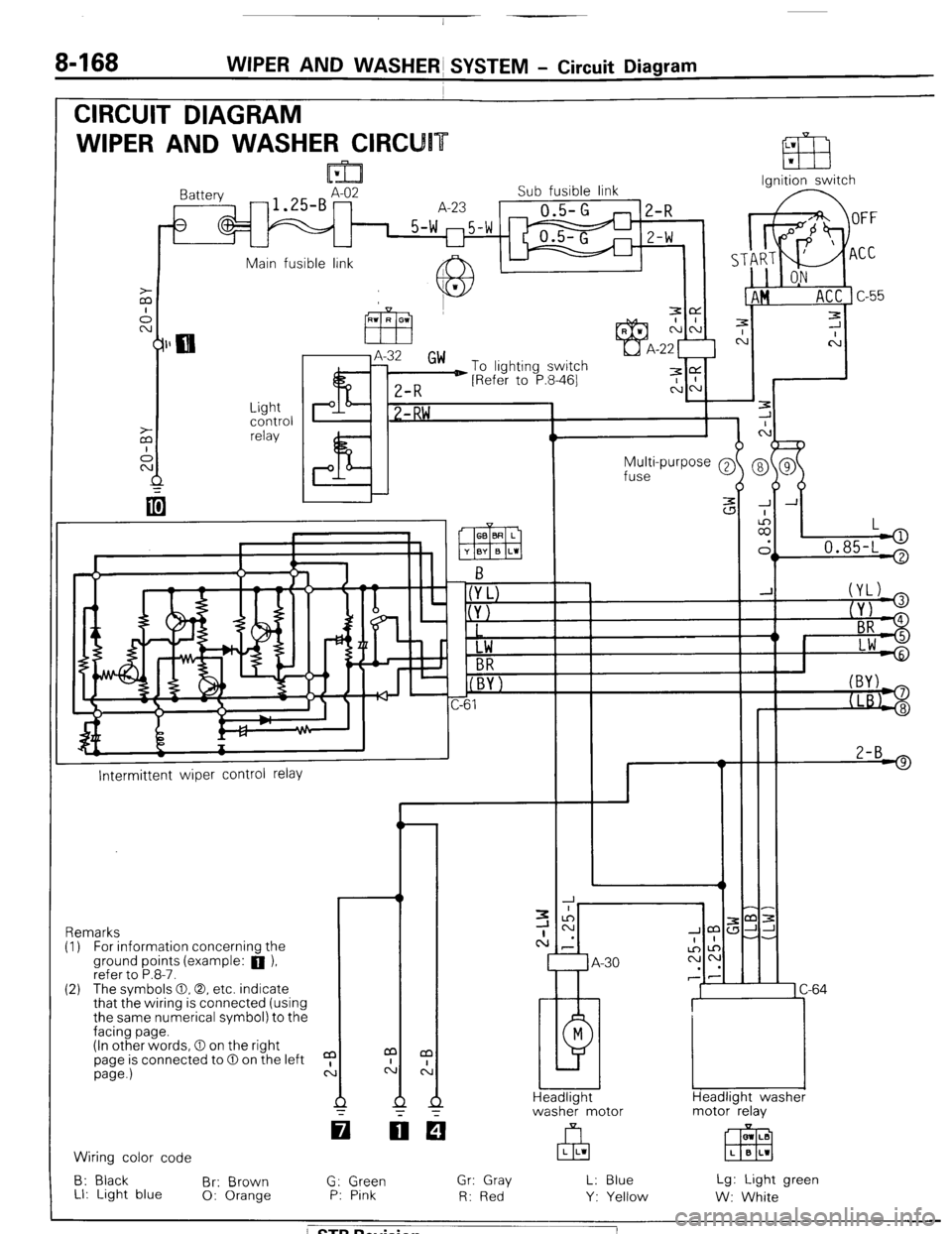

8468 WIPER AND WASHERS SYSTEM - Circuit Diagram

CIRCUIT DIAGRAM

WIPER AND WASHER CIRCU

Ignition switch

lattery

-1.SBAz2 Sub fusible link

A-23

0.5-G

1 5-w m5-w

U

2-R

Z-W

Main fusible link A IL

J.

c

7

C

-

-

-

-

-

-

J A

:

II,

L

.

> 0.85-L '

Light

control

relay P I? 1 -RW ,

Multi-purpose @

fuse

2-B 9

I--

Intermittent wiper control relay

-r ,m:

JJ-

-.

1 C-64

Headlight washer

motor relay Remarks

(I) For information concernina the

ground points (example: a ),

refer to P.8-7.

(2) The svmbols 0.0. etc. indicate

that the wiring is connected (using

the same numerical symbol) to the

facing page.

(In other words, 0 on the right

page is connected to 0 on the left

page.)

a

c: m LB

EEEI L B L1 Wiring color code

B: Black

Br: Brown

LI: Light blue 0: Orange G: Green

P: Pink Gr: Gray

R: Red L: Blue

Y: Yellow Lg: Light green

W: White

/ STB Revision

Page 189 of 284

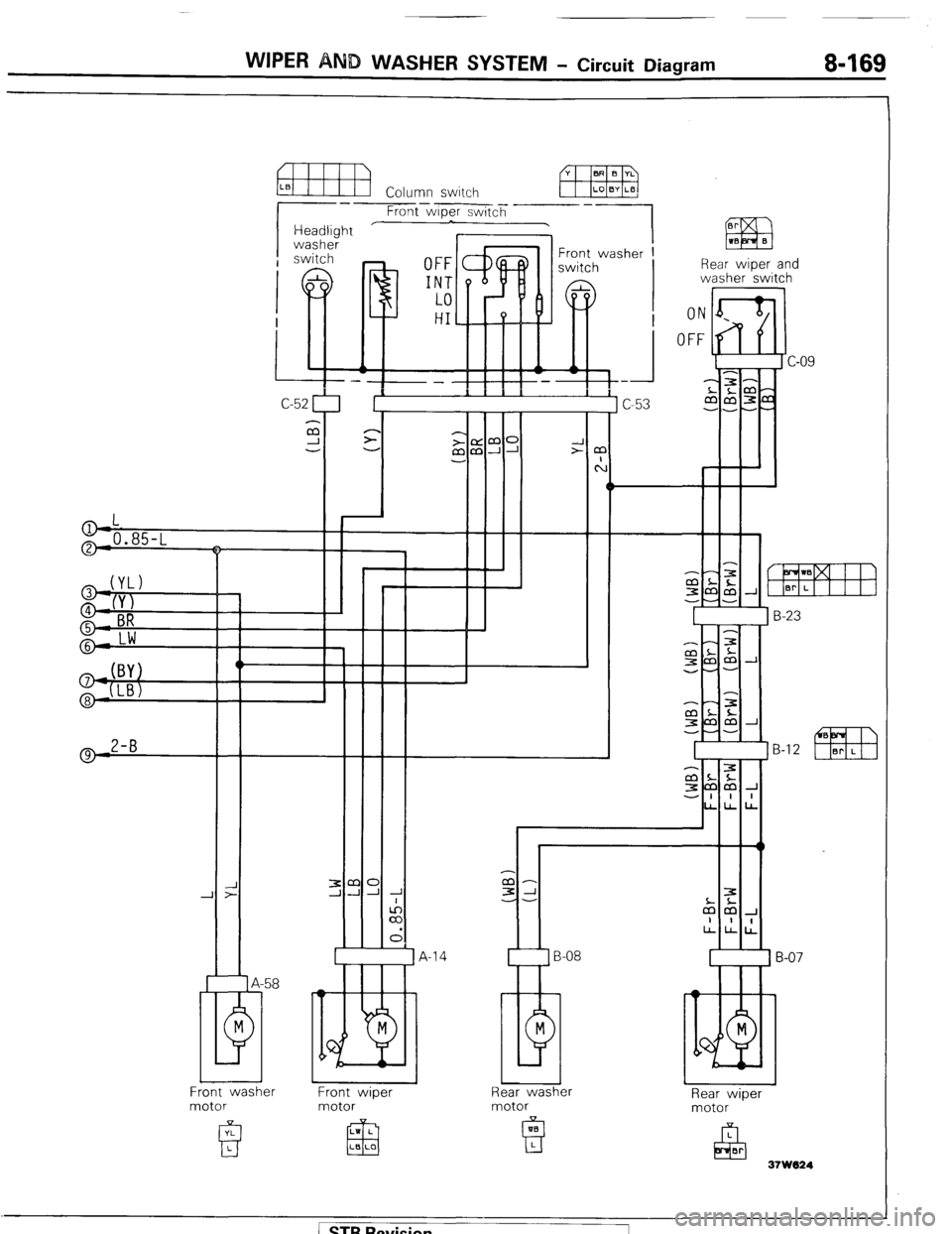

WIPER AND WASHER SYSTEM - Circuit Diagram 8469

m Column switch -- Front-koer switch -1

Rear wiper and

washer switch

r I Headlight

washer

switch

o-(YL)

@JYJ

(+ BR

@- Lw

L B-l 2

w2-B

! )

1

L

(

7 A-14

1 B-07

81

M

A-58

>

1

GE&washer I

Rear wiper Front washer

motor Front wiper

motor motor

motor

37W124

/ STB Revision

Page 191 of 284

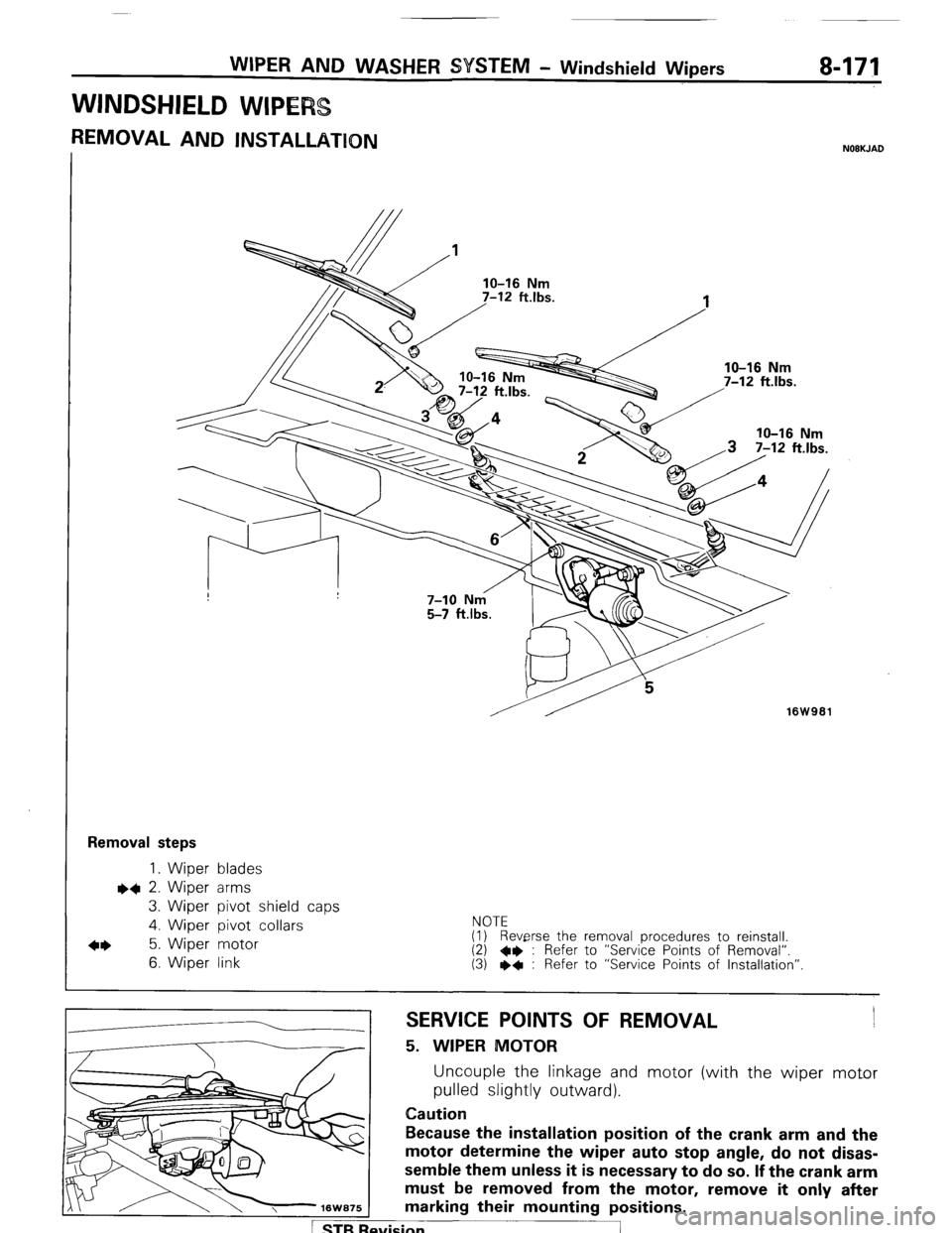

WIPER AND WASHER SYSTEM - Windshield Wipers 8-171

WINDSHIELD WIPE

REMOVAL AND INSTALLATION NOBKJAD

16W961

Removal steps

1. Wiper blades l

+ 2. Wiper arms

3. Wiper pivot shield caps

4. Wiber pivot collars NOTE

4* 5. Wiper motor (1) Reverse the removal procedures to reinstall.

6. Wiper link (2) 4* : Refer to “Service Points of Removal”.

(3) I)* : Refer to “Service Points of Installation”

SERVICE POINTS OF REMOVAL

5. WIPER MOTOR

Uncouple the linkage and motor (with the wiper motor

pulled slightly outward).

Caution

Because the installation position of the crank arm and the

motor determine the wiper auto stop angle, do not disas-

semble them unless it is necessary to do so. If the crank arm

must be removed from the motor, remove it only after

marking their mounting positions.

svision

I

Page 194 of 284

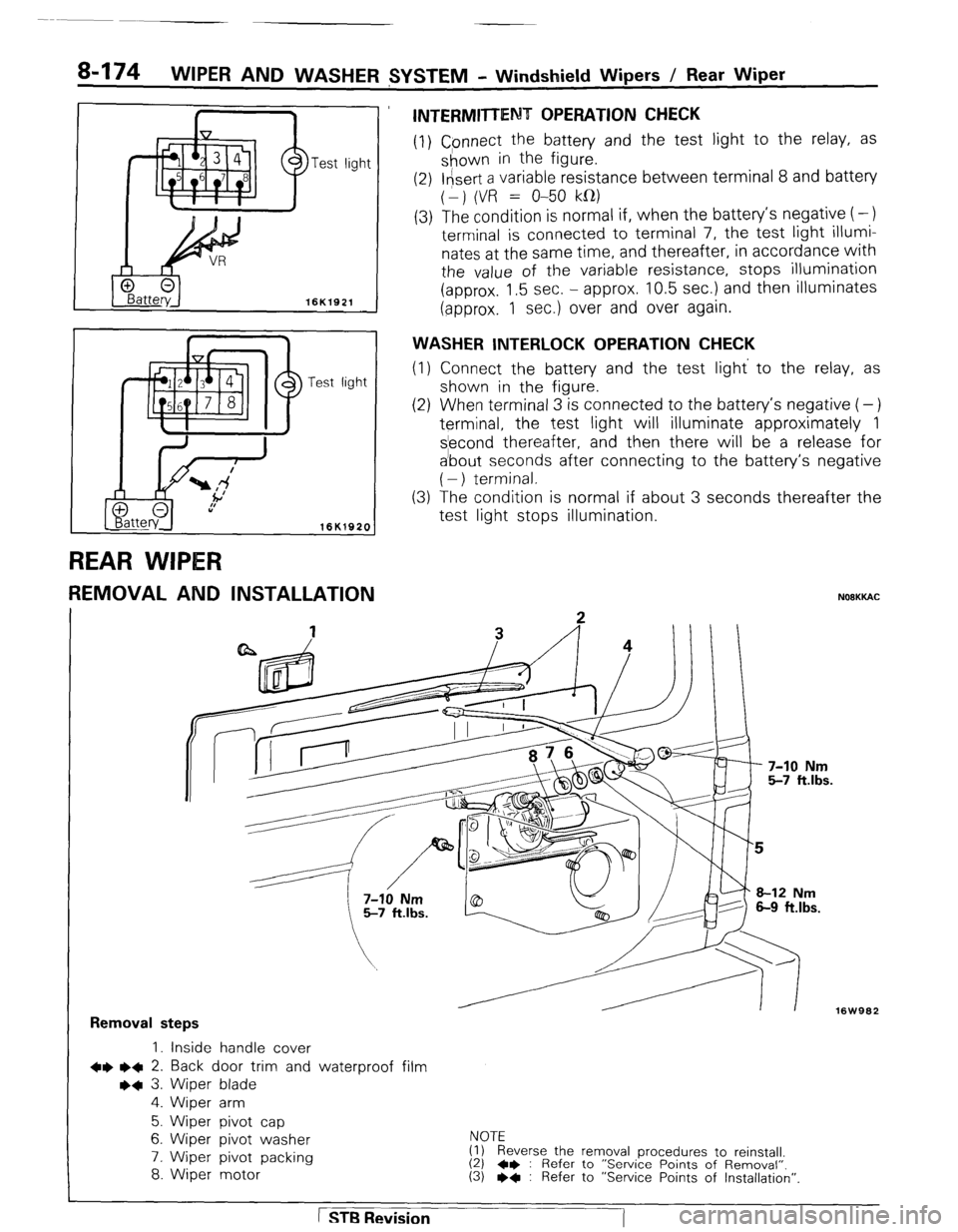

a-174 WIPER AND WASHER $YSTEM - Windshield Wipers / Rear Wiper

REAR WIPtER

7

-est light

16K1920

t

REMOVAL AND INSTALLATION

INTERMITTENT OPERATION CHECK

(1) Cpnnect the battery and the test light to the relay, as

shown in the figure.

(2) l&ert a variable resistance between terminal 8 and battery

(1) (VR = O-50 kfl)

(3) The condition is normal if, when the battery’s negative (-)

terminal is connected to terminal 7, the test light illumi-

nates at the same time, and thereafter, in accordance with

the value of the variable resistance, stops illumination

(approx. 1.5 sec. - approx. 10.5 sec.) and then illuminates

(approx. 1 sec.) over and over again.

WASHER INTERLOCK OPERATION CHECK

(1) Connect the battery and the test light’ to the relay, as

shown in the .figure.

(2) When terminal 3 is connected to the battery’s negative (-)

terminal, the test light will illuminate approximately 1

s’econd thereafter, and then there will be a release for

a’bout seconds after connecting to the battery’s negative

( - ) terminal.

The condition is normal if about 3 seconds thereafter the

test light stops illumination. (3

NOOKKAC

16W962

Removal steps

1. inside handle cover

+e l + 2. Back door trim and waterproof film

++ 3. Wiper blade

4. Wiper arm

5. Wiper pivot cap

6. Wiper pivot washer

7. Wiper pivot packing

8. Wiper motor NOTE

(1) Reverse the removal procedures to reinstall.

(2) 4* : Refer to “Service Points of Removal”. (3) l * : Refer to “Service Points of Installation”.

1 STB Revision

-7

Page 199 of 284

I 1

+ -

li.if 1

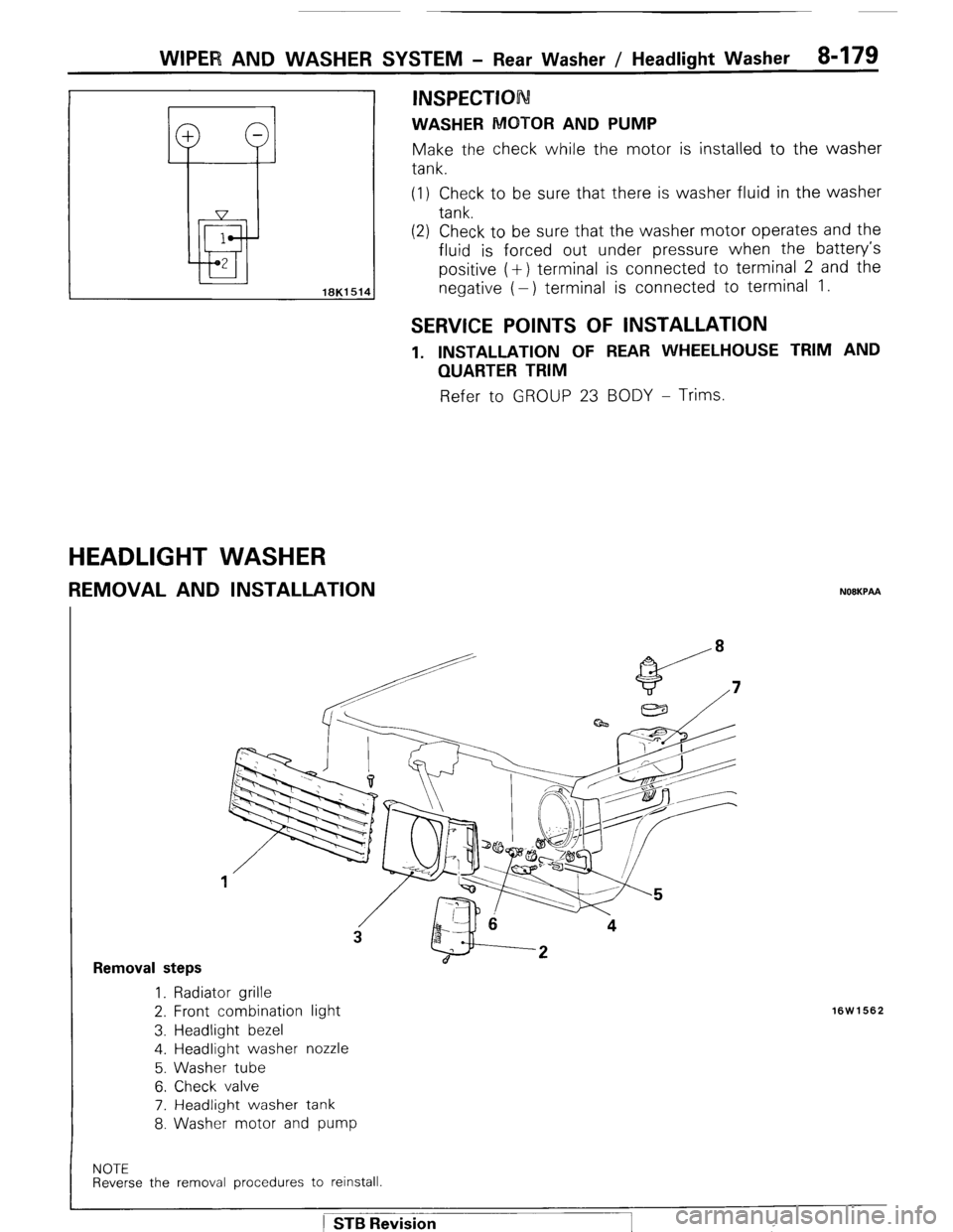

2

WIPER AND WASHER SYSTEM - Rear Washer / Headlight Washer 8-179 (1) Check to be sure that there is washer fluid in the washer

tank.

(2) Check to be sure that the washer motor operates and the

fluid is forced out under pressure when the battery’s

positive (+) terminal is connected to terminal 2 and the

negative (-) terminal is connected to terminal 1.

INSPECTION

WASHER MOTOR AND PUMP Make the check while the motor is installed to the washer

tank.

SERVICE POINTS OF INSTALLATION

1. INSTALLATION OF REAR WHEELHOUSE TRIM AND

QUARTER TRIM Refer to GROUP 23 BODY - Trims.

HEADLIGHT WASHER

REMOVAL AND INSTALLATION NOEKPAA

Removal steps 1. Radiator grille

2. Front combination light

3. Headlight bezel

4. Headlight washer nozzle

5. Washer tube

6. Check valve

7. Headlight washer tank

8. Washer motor and pump

16W1562

NOTE Reverse the removal procedures to reinstall.

) STB Revision

Page 200 of 284

WIPER AND WASHER SYSTEM - Headlight Washer

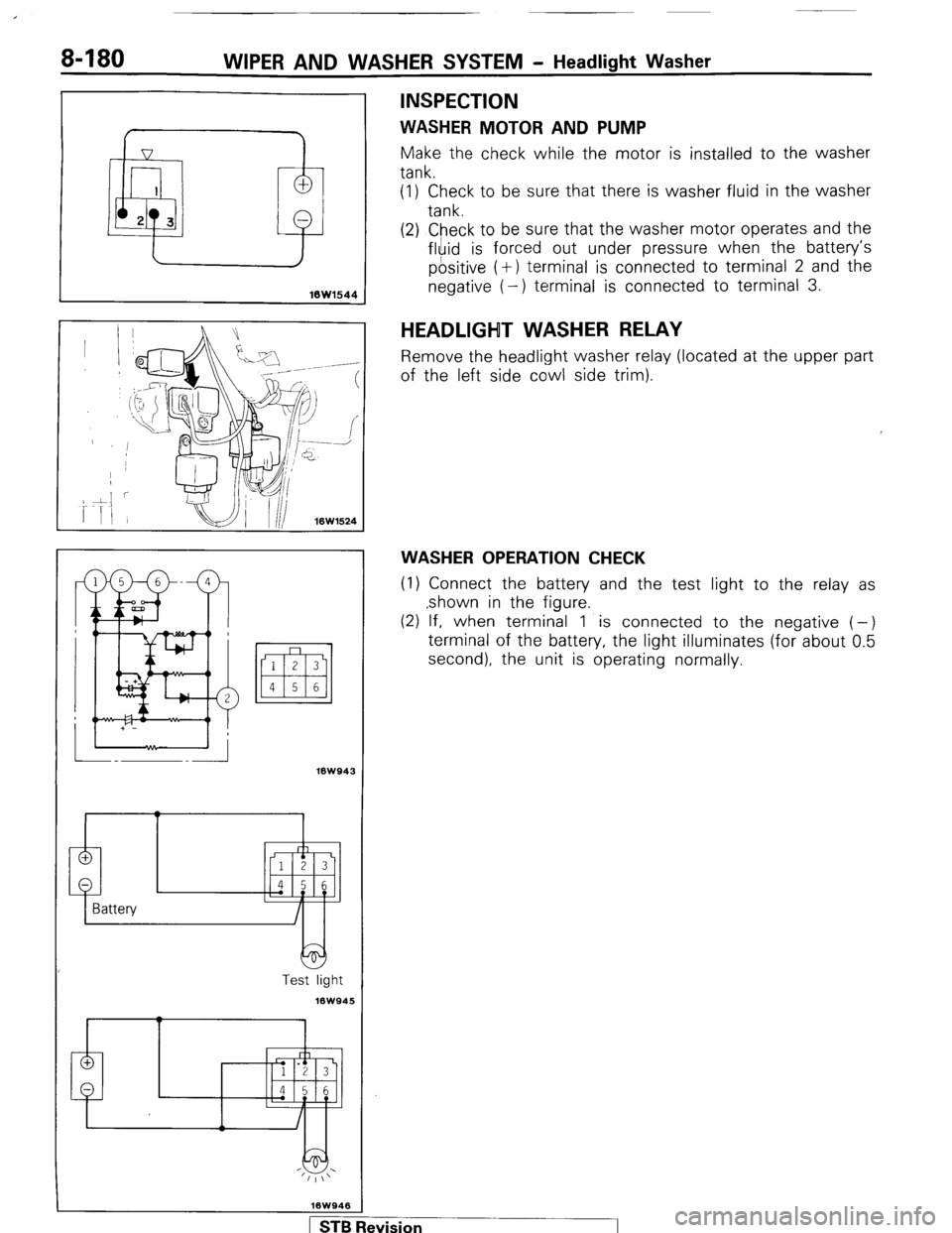

INSPECTION

WASHER MOTOR AND PUMP

Make the check while the motor is installed to the washer

tank.

(1) Check to be sure that there is washer fluid in the washer

tank.

16Wl544

(2) Check to be sure that the washer motor operates and the

fluid is forced out under pressure when the battery’s

positive (+) terminal is connected to terminal 2 and the

negative (-) terminal is connected to terminal 3.

18W943

Test light

16W945

HEADLIGHT WASHER RELAY

Remove the headlight washer relay (located a

of the left side cowl side trim). It the upper part

WASHER OPERATION CHECK

(1) Connect the battery and the test light to the relay as

,shown in the figure.

(2) If, when terminal 1 is connected to the negative (-)

terminal of the battery, the light illuminates (for about 0.5

second), the unit is operating normally.

1 STB Revision -1

Page 202 of 284

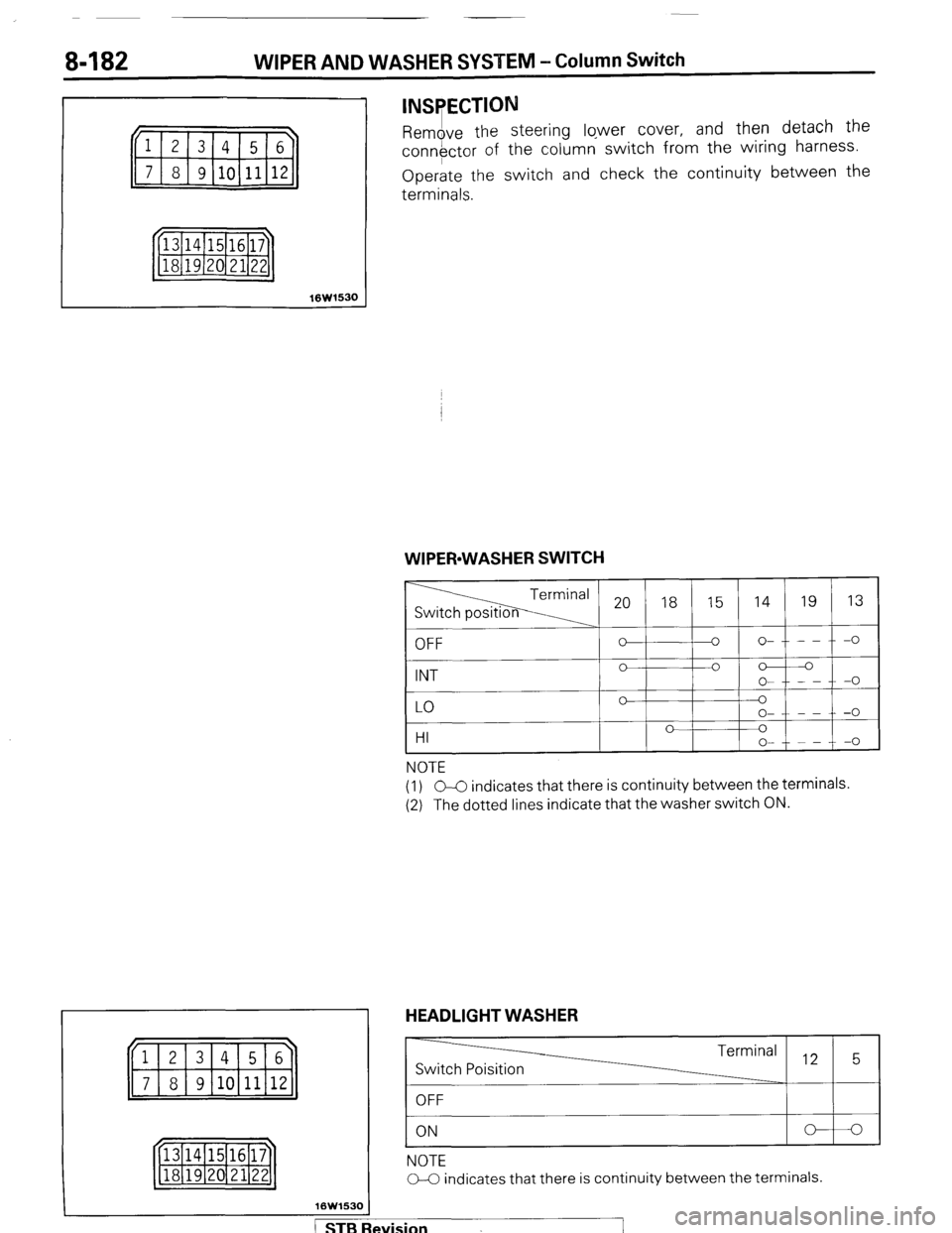

8482 WIPER AND WASHER SYSTEM - Column Switch

INSPECTION

Remove the steering lqwer cover, and the! detach the

conn#ctor of the c:olumn switch from the wlnng harness.

Operate the switch and check the continuity between the

terminals.

16W1530 WIPER-WASHER SWITCH

16W153C

20 18 15 14 19 13 1 OFF

I - I o-t--t-o I

Ip-I’

’ ’ -

HI v 1 v

o- - - -0

NOTE

(1) GC indicates that there is continuity between the terminals.

(2) The dotted lines indicate that the washer switch ON. HEADLIGHT WASHER

-

Switch Poisition Terminal .,2 5

OFF

ON

NOTE

C-C indicates that there is continuity between the terminals.

/ STB Revision

Page 205 of 284

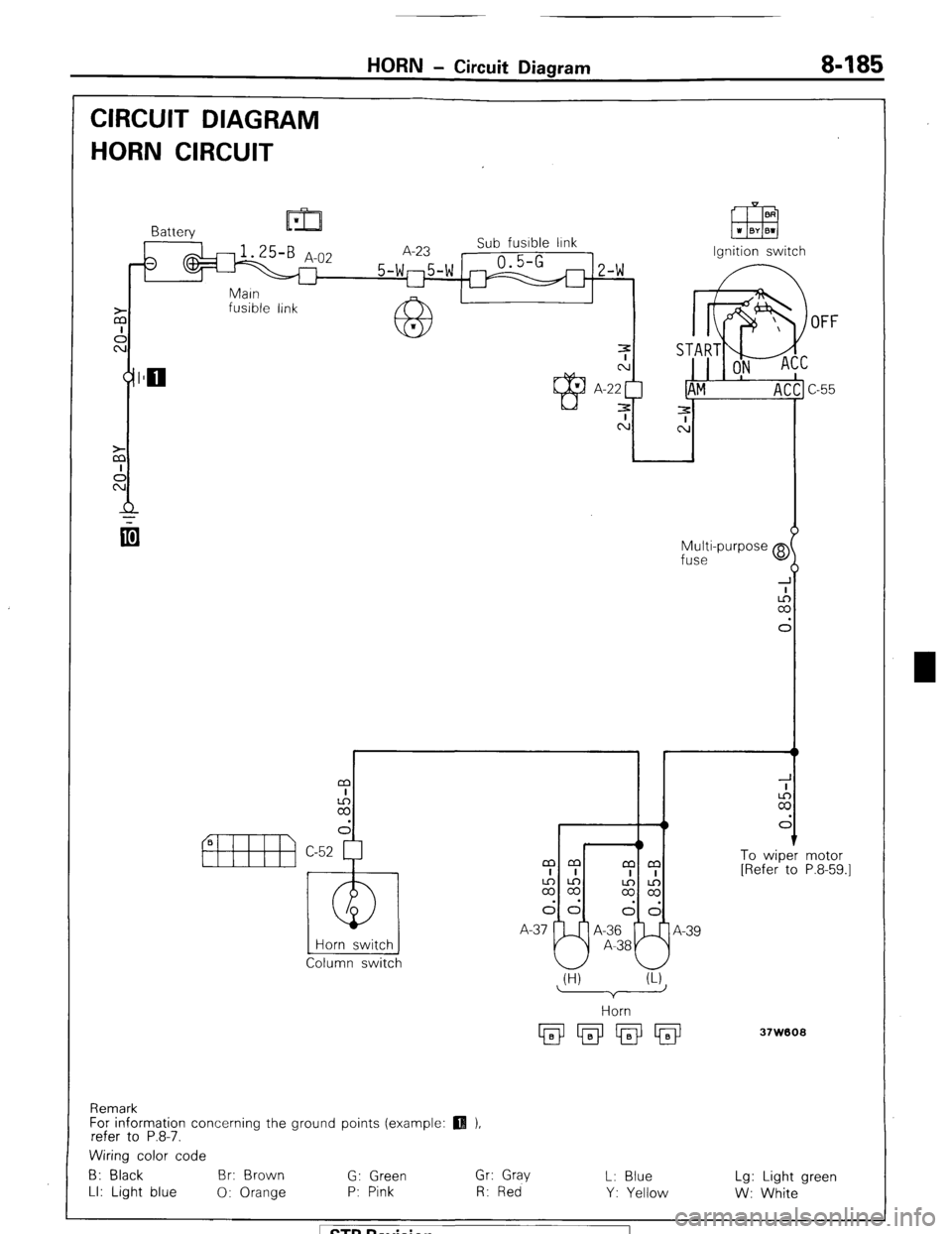

HORN - Circuit Diagram 8485

CIRCUIT DIAGRAM

HORN CIRCUIT

fusible link

OFF

Multi-purpose @

fuse

I r t

m

I

2

d

1 To wiper

[Refer to

Horn switch

Column switch mm

mm

I I

I I

2%

$2

dd

I--J!

dd

A-37 A-36

A-39

A-38 motor

P.8-59.1

(H) (U

37W608

Remark

For information concerning the ground points (example:

refer to P.8-7.

Wiring color code

B: Black Br: Brown

G: Green Gr: Gray

L: Blue Lg: Light green

LI: Light blue

0: Orange P: Pink R: Red

Y: Yellow

W: White 1 STB Revision

Page 206 of 284

8486 HORN - Horn

HORN

REMOVAL AND INSTALLATION NOBWAE

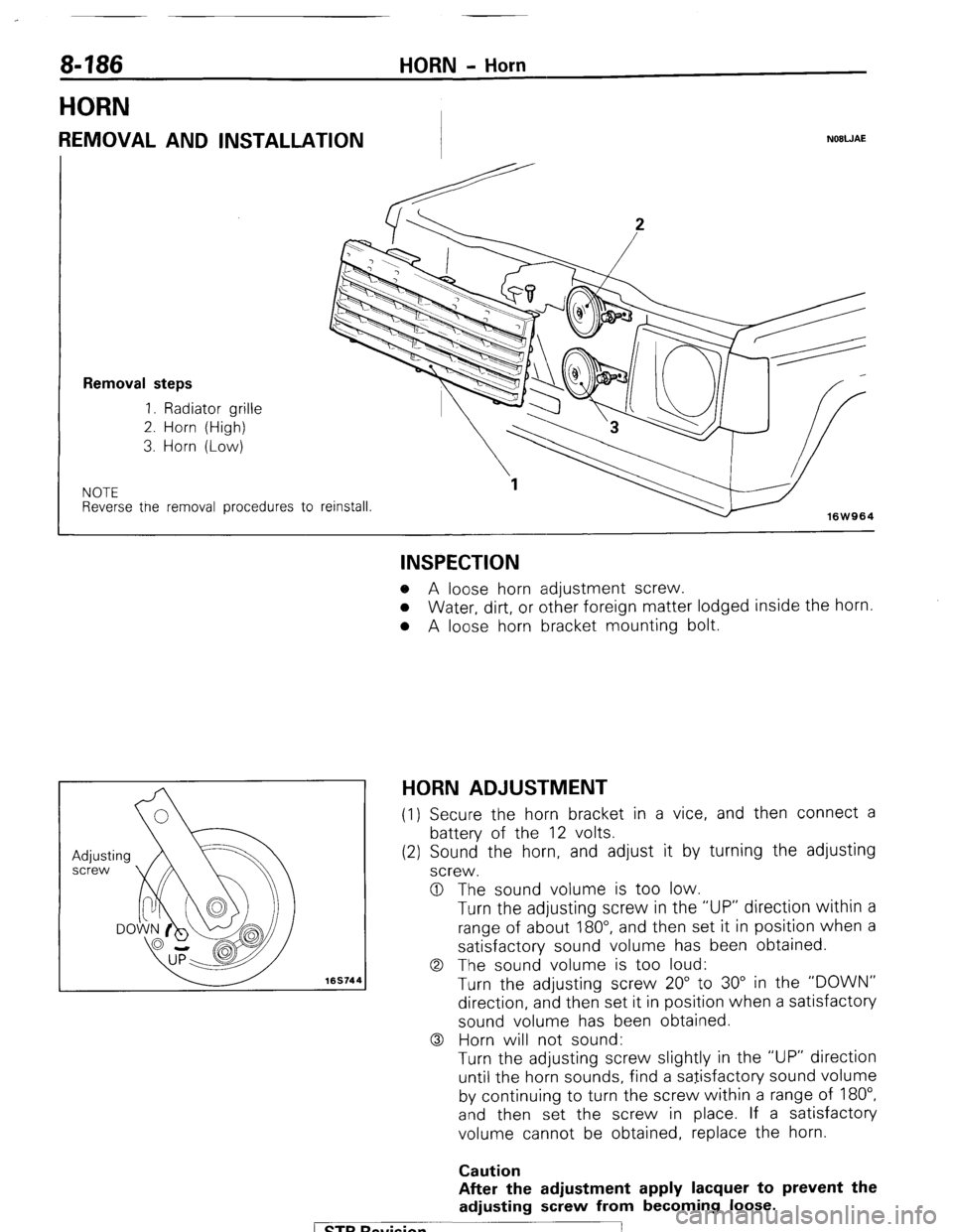

Removal steps

1. Radiator grille

2. Horn (High)

3. Horn (Low)

NOTE Reverse tne removal procedures to

reinstall.

16W964

169744

INSPECTION o A loose horn adjustment screw.

o Water, dirt, or other foreign matter lodged inside the horn.

l A loose horn bracket mounting bolt.

HORN ADJUSTMENT (1) Secure the horn bracket in a vice, and then connect a

battery of the 12 volts.

(2) Sound the horn, and adjust it by turning the adjusting

screw.

0 The sound volume is too low.

Turn the adjusting screw in the “UP” direction within a

range of about 180”, and then set it in position when a

satisfactory sound volume has been obtained.

0 The sound volume is too loud:

Turn the adjusting screw 20” to 30” in the “DOWN”

direction, and then set it in position when a satisfactory

sound volume has been obtained.

0 Horn will not sound:

Turn the adjusting screw slightly in the “UP” direction

until the horn sounds, find a satisfactory sound volume

by continuing to turn the screw within a range of 180”,

and then set the screw in place. If a satisfactory

volume cannot be obtained, replace the horn.

Caution

After the adjustment apply lacquer to prevent the

adjusting screw from becoming loose.

1 ST6 Revision

Page 208 of 284

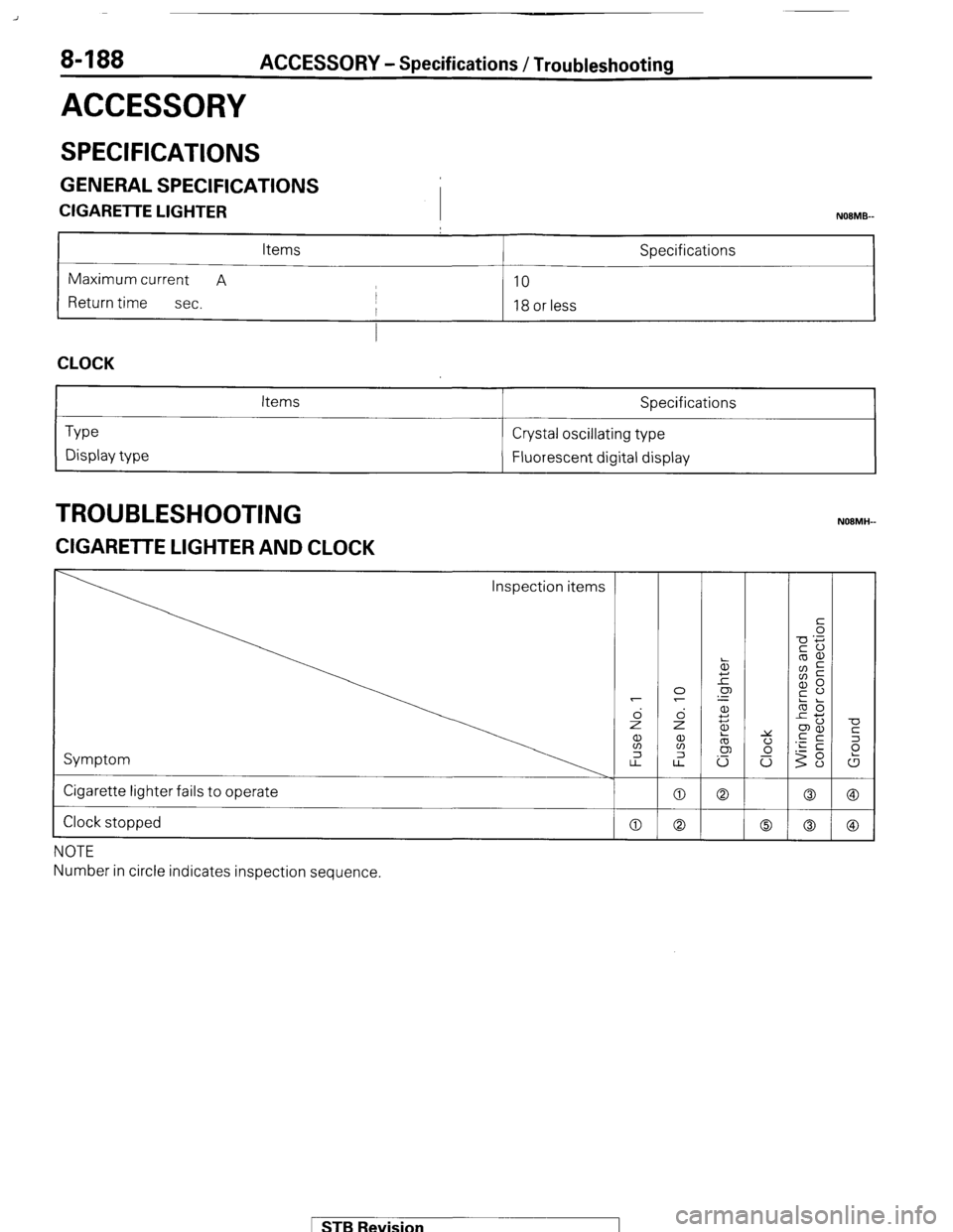

8-188 ACCESSORY - Specifications / Troubleshooting

ACCESSORY

SPECIFICATIONS

GENERAL SPECIFICATIONS

CIGARETTE LIGHTER

I NOBMB-

Items Specifications

Maximum current A

10

Return time

sec. I

I 18 or less

I

CLOCK

Type

Display type Items Specifications

Crystal oscillating type

Fluorescent digital display

TROUBLESHOOTING

ZIGARETTE LIGHTER AND CLOCK

Inspection items

Symptom

Cigarette lighter fails to operate

Clock stopped

NOTE

Number in circle indicates inspection sequence.

MB Revision