light MITSUBISHI MONTERO 1987 1.G Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 86 of 284

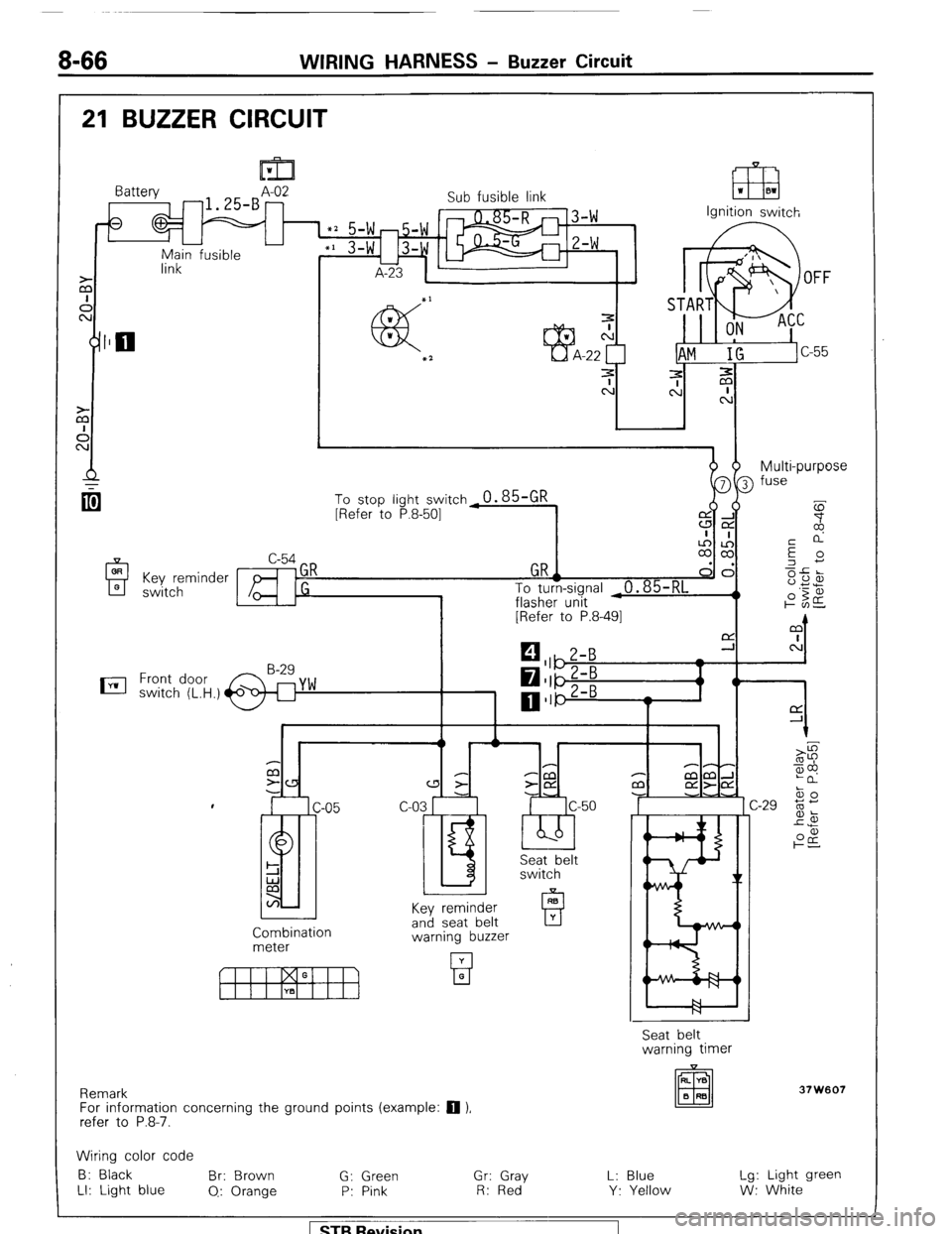

8-66 WIRING HARNESS - Buzzer Circuit

21 BUZZER CIRCUIT

OR

A 0 Key reminder

switch

nil 1

link Battery A-02

-1.25-B -

0

-

Main fusible Sub fusible link

IT8 ‘I 01

Ignition switch

dhm b- Multi-purpose

[Refer to P.8-491

0 1

C P-P

a 3

-CCl P mm-l

z- z-CY m aa-cd

c-03 r c-50 -J -.A

I.5 ‘bb’ IC ski&t

switch

Key reminder

Combination

meter and seat belt

warning buzzer

Remark

For information concerning the ground points (example:

q ),

refer to P.8-7. Seat belt

warning timer

37W607

Wiring color code

B: Black Br: Brown

G: Green Gr: Gray L: Blue Lg: Light green

LI: Light blue

0.: Orange P: Pink R: Red Y: Yellow W: White 1 ST9 Revision

Page 87 of 284

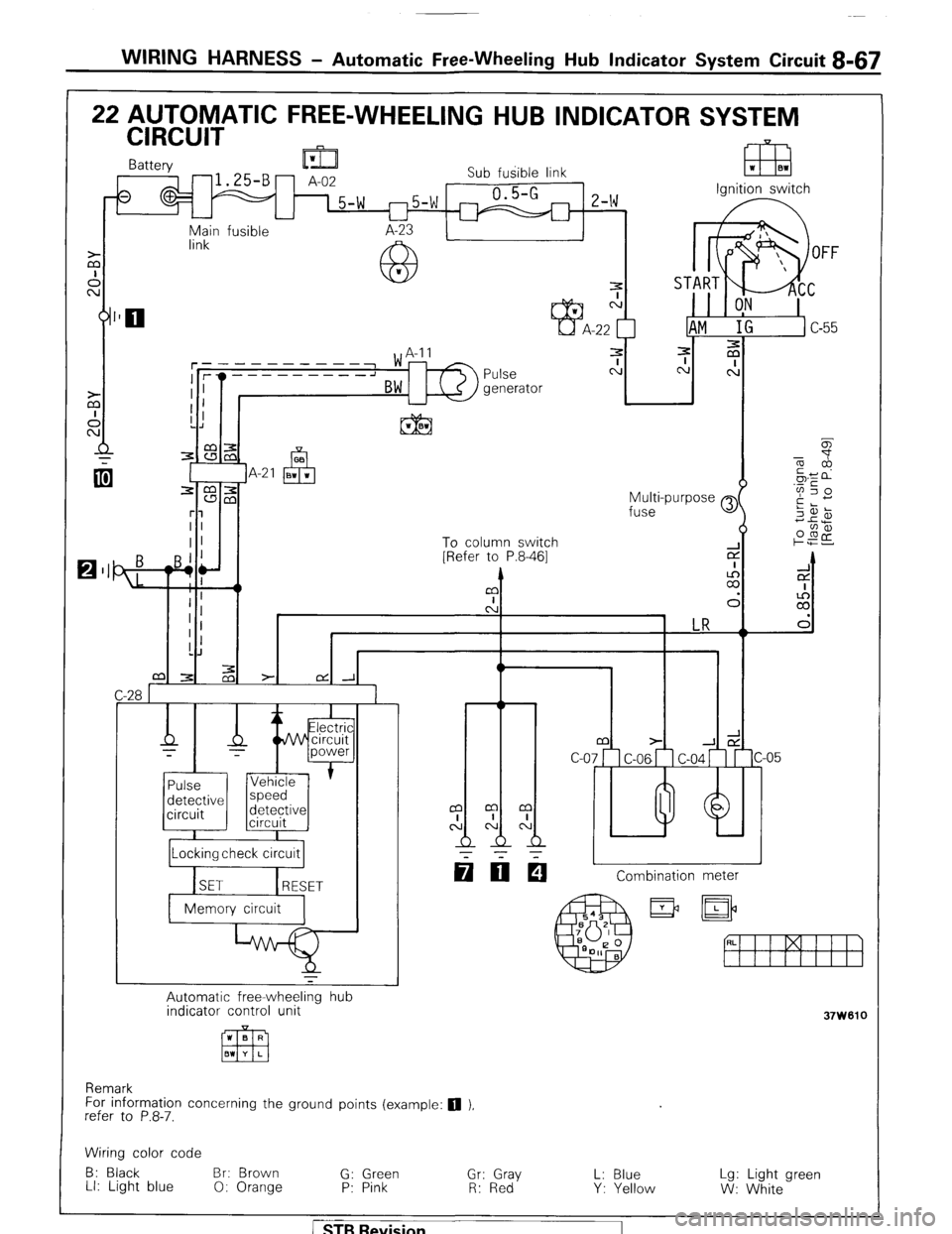

WIRING HARNESS - Automatic Free-Wheeling Hub Indicator System Circuit B-67

FREE-WHEELING HUB INDICATOR SYSTFM

Sub fusible link

-5-w 1 m2-G m Iz-w rgntrron swrtcn Battery n 171.

Main fusible

link

- _I

ON I

Pulse

generator

-

Multi-purpose e

fuse

To column switch

[Refer to P.8-461 z

1

m ::

0:

C

1 LR

I

1

I

0

2-

I I

!!I m m m

,:cAcJl

-

T-r- m z-

-.I;

c-07 C-06 c-04

I++-

q OE! L 1 Combination meter ’ EleAtrir

d&V+ circuit

- -

power

1

Pulse Vehicle

detective speed

circuit detective

circuit

r

Automatic free-wheeling hub

indicator control unit

37W610

For information concerning the ground points (example: 0 ).

refer to P.8-7.

Wiring color code

B: Black Br: Brown

G: Green

L: Blue

LI: Light blue

0: Orange “,;: ;;;Y Lg: Light green

P: Pink Y: Yellow

W: White

STB Revision

Page 88 of 284

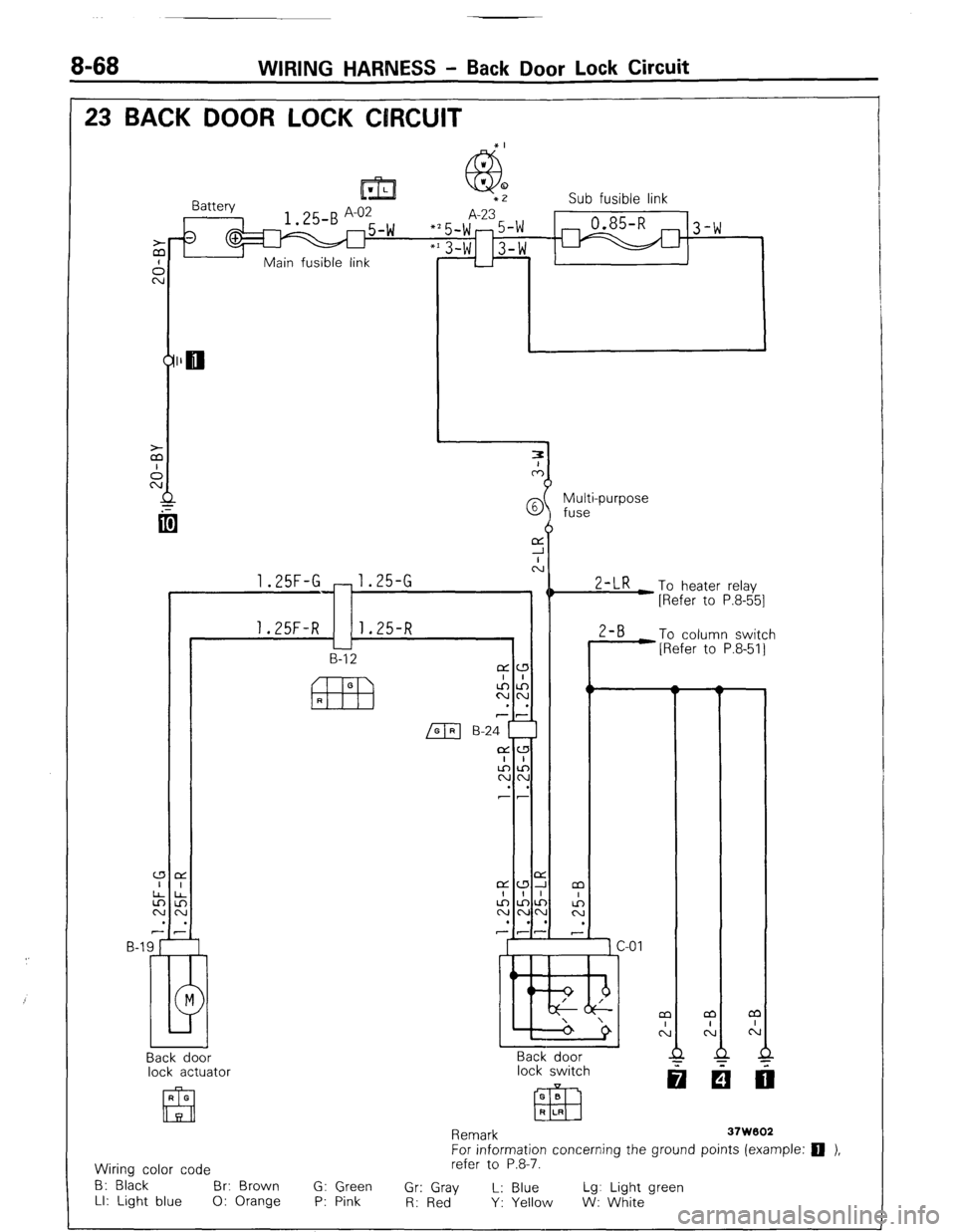

WIRING HARNESS - Back Door Lock Circuit

23 BACK DOOR LOCK CIRCUIT

Battery _ Sub fusible link

$’

m 5 Multi-purpose ’

fuse

)

A 1.25F-G -1.25-G

0 2-LR -To heater relay

[Refer to P.8-551

1.25F-R 1.25-R

2-B -To column switch

B-l 2 [Refer to P.8-511

cza

I I

xx 0

I

. .

77

m B-24 [

cLL3

ALA

CVN

. .

77

Back door

lock actuator

Remark

37W602

For information concerning the ground points (example: q ),

Wiring color code refer to P.8-7.

B: Black

Br: Brown G: Green

Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink

R: Red Y: Yellow W: White

/ STB Revision

Page 89 of 284

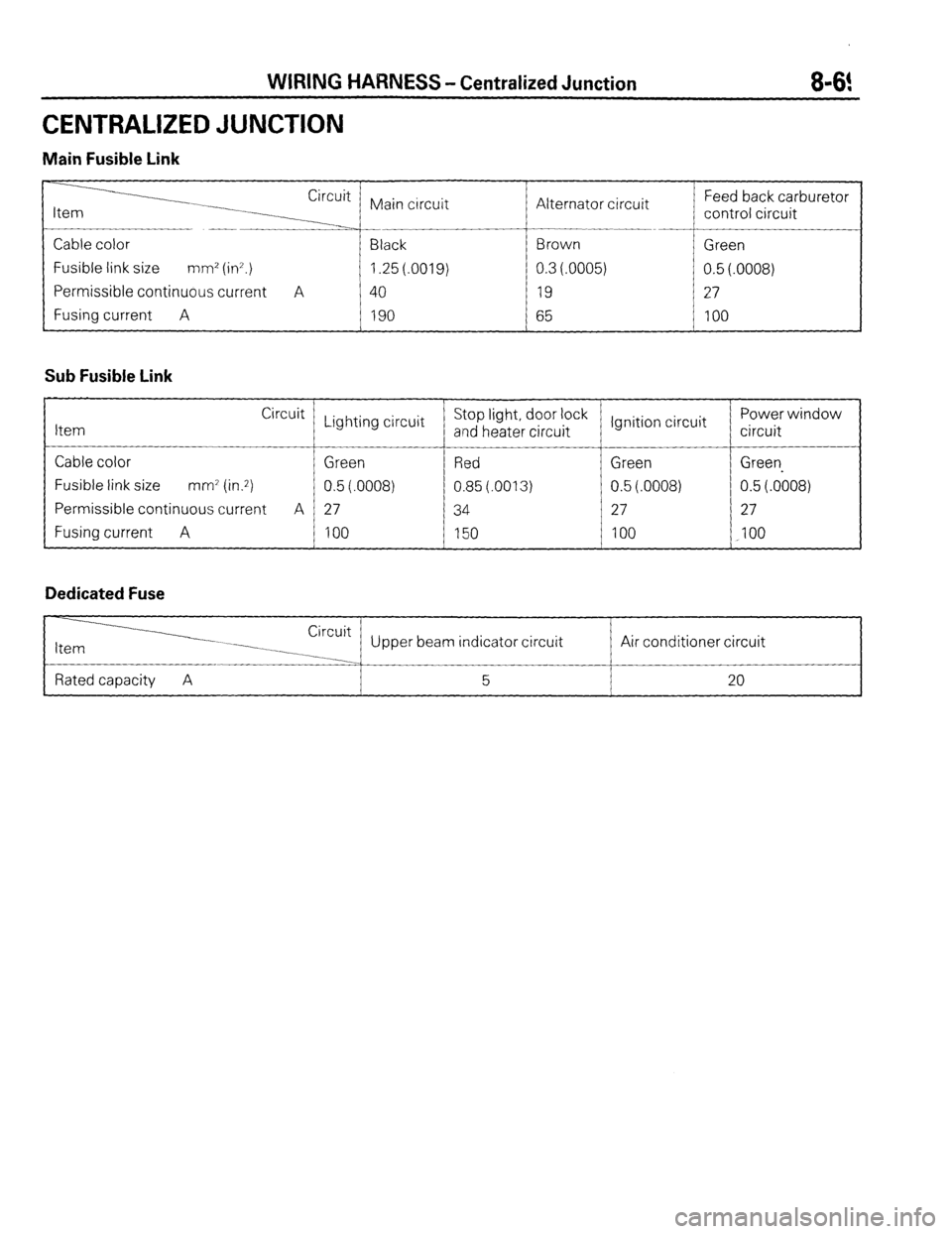

WIRING HARNESS - Centralized Junction

CENTRALIZED JUNCTION

Main Fusible Link

896!

Circuit

Main circuit

Cable color Black

Fusible link size mm’ (ir?.) 1.25 (.0019)

Permissible continuous current A 40

Fusing current A 190

Sub Fusible Link

Item Circuit

Cable color

Fusible link size mm7 (in.2)

Permissible continuous current A

Fusing current A

Dedicated Fuse Lighting circuit

Green

0.5(.0008)

27

100 Alternator circuit Feed back carburetor

control circuit

Stop light, door lock

and heater circuit

Red

0.85(.0013)

34

150 Ignition circuit Power window

circuit

Green Green-

0.5(.0008) 0.5(.0008)

27 27

100 100

Upper beam indicator circuit / Air conditioner cixit

Page 90 of 284

WIRING HARNESS - Centralized Junction

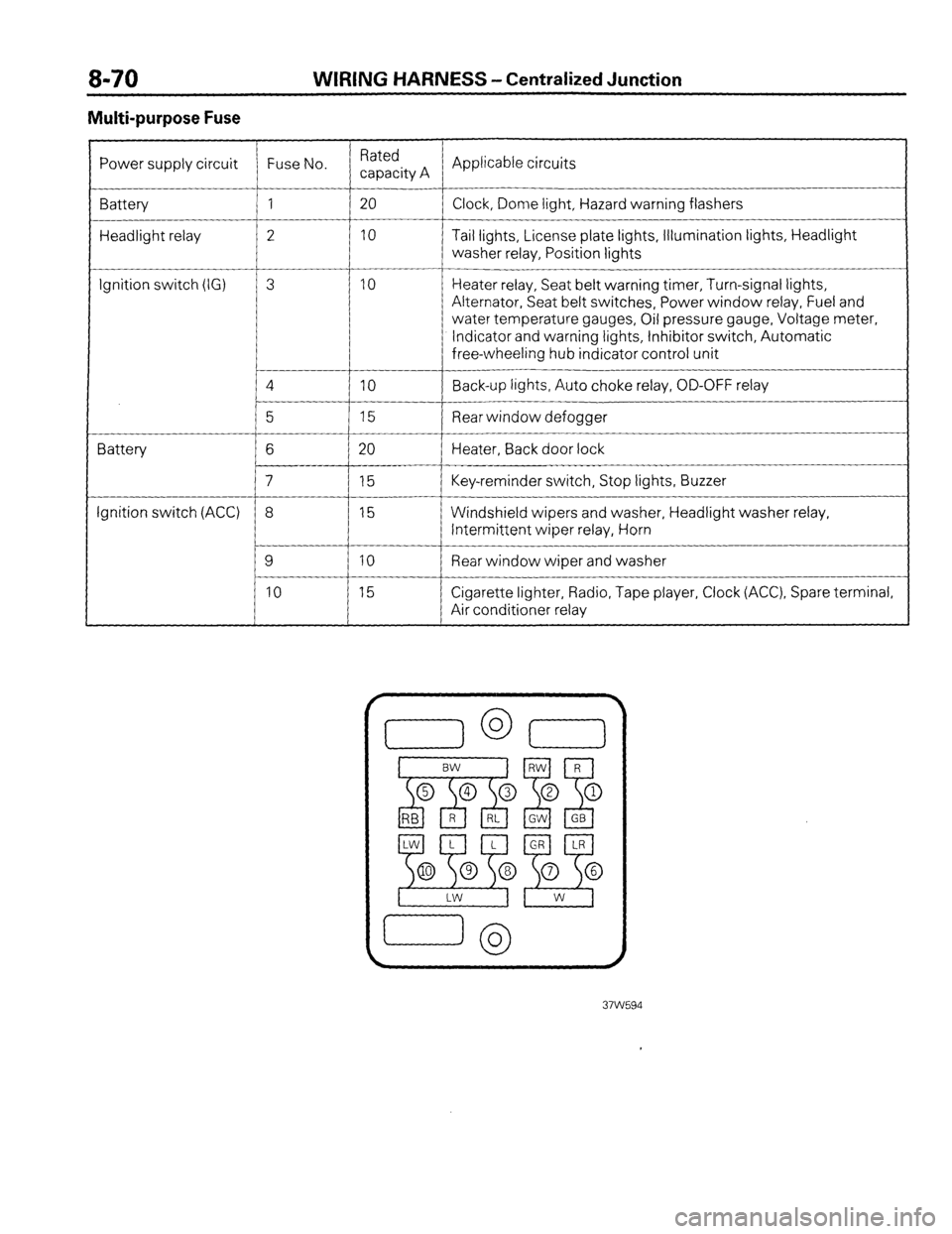

Multi-purpose Fuse

Power supply circuit Fuse No. Rated

capacity A Applicable circuits

Battery 1 20

Clock, Dome light, Hazard warning flashers

Headlight relay 2 10 Tail lights, License plate lights, Illumination lights, Headlight

washer relay, Position lights

__-

Ignition switch (IG) 3 10 Heater relay, Seat belt warning timer, Turn-signal lights,

Alternator, Seat belt switches, Power window relay, Fuel and

water temperature gauges, Oil pressure gauge, Voltage meter,

Indicator and warning lights, Inhibitor switch, Automatic

free-wheeling hub indicator control unit

4

IO Back-up lights, Auto choke relay, OD-OFF relay

__-

5 15 Rear window defogger

Battery 6 20 Heater, Back door lock

7 15 Key-reminder switch, Stop lights, Buzzer

Ignition switch (ACC) 8 15 Windshield wipers and washer, Headlight washer relay,

Intermittent wiper relay, Horn

9 10 Rear window wiper and washer

10 15 Cigarette lighter, Radio, Tape player, Clock (ACC), Spare terminal,

Air conditioner relay

Page 91 of 284

CHARGING SYSTEM - General Information 8-71

CHARGING SYSTEM

GENERAL INFORMATION

NOBEMD

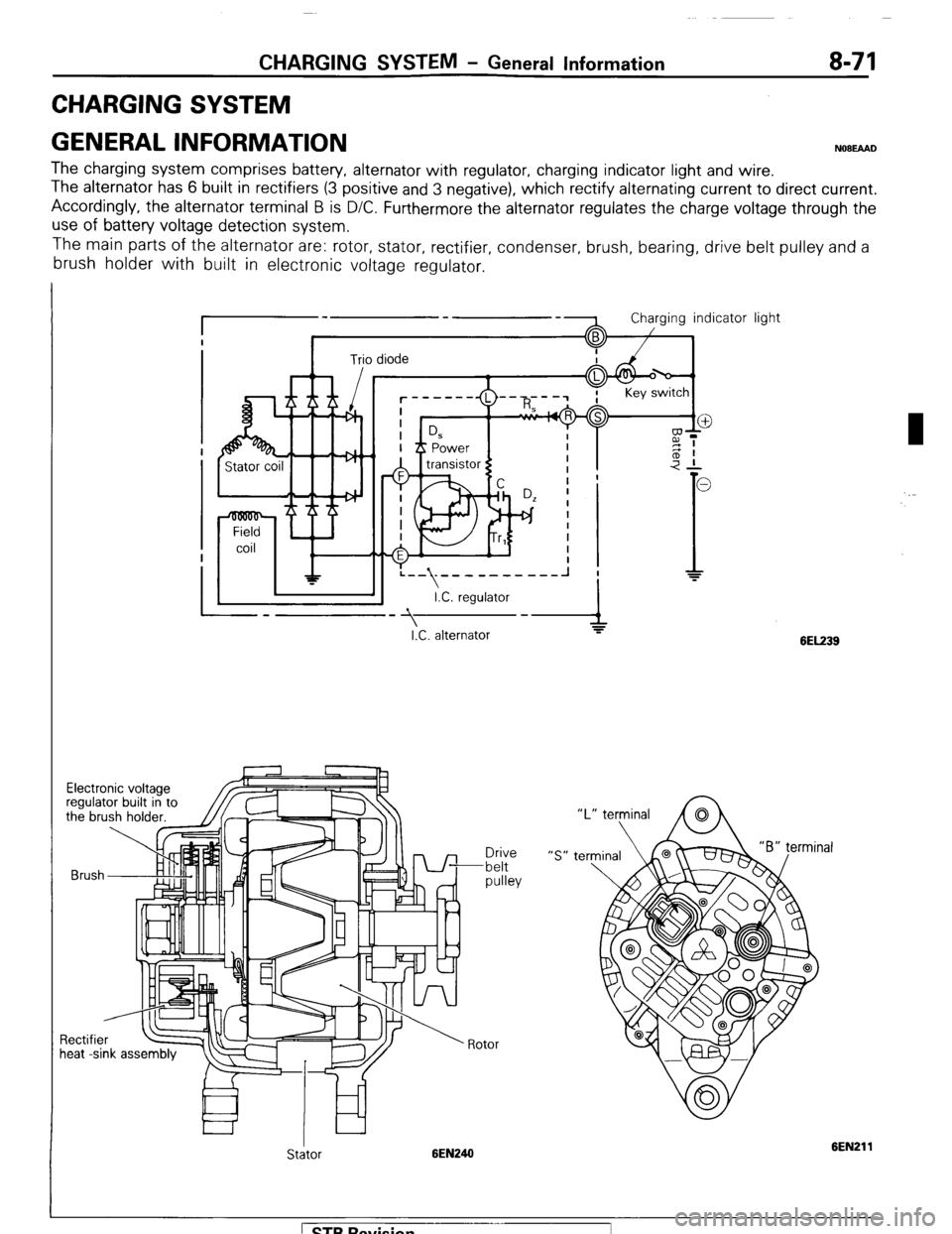

The charging system comprises battery, alternator with regulator, charging indicator light and wire.

The alternator has 6 built in rectifiers (3 positive and 3 negative), which rectify alternating current to direct current.

Accordingly, the alternator terminal B is D/C. Furthermore the alternator regulates the charge voltage through the

use of battery voltage detection system.

The main parts of the alternator are: rotor, stator, rectifier, condenser, brush, bearing, drive belt pulley and a

brush holder with built in electronic voltage regulator.

:--\;-----------I ;

I.C. regulator

I

-A I.C. alternator -y

Brush

heat -sink assembly Drive

-belt

pulley

Rotor light

6EL239

Stator 6EN246 6EN211

1 STB Revision

Page 95 of 284

CHARGING SYSTEM -Troubleshooting 8-75

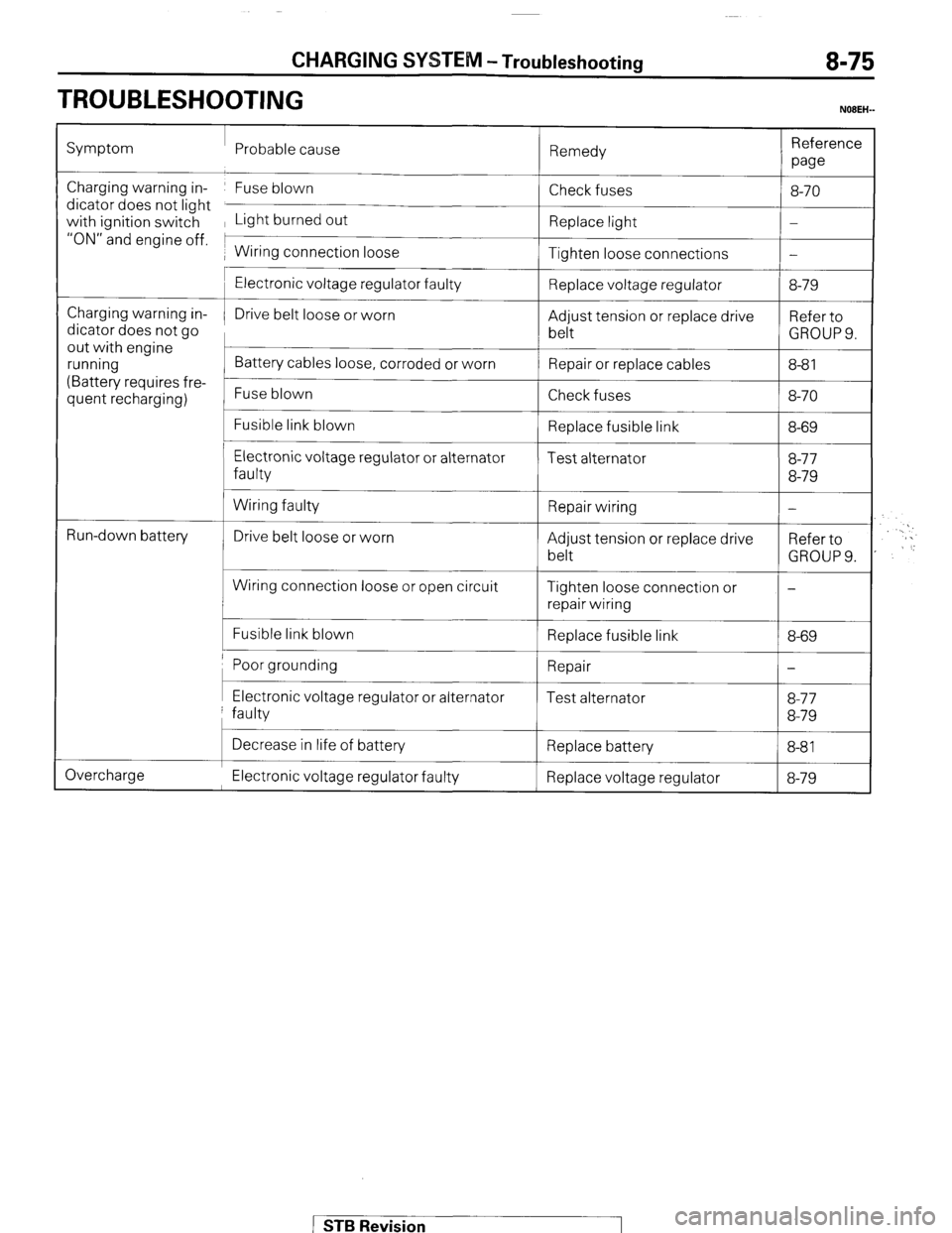

TROUBLESHOOTING

NOBEH-

Symptom Probable cause

Remedy Reference

we

Charging warning in- Fuse blown

dicator does not light

with ignition switch Light burned out

“ON” and engine off. 1

1 Wiring connection loose Check fuses

Replace light

Tighten loose connections 8-70

-

-

Charging warning in-

dicator does not go

out with engine

running

(Battery requires fre-

quent recharging)

L

t

Run-down battery

c

Electronic voltage regulator faulty

Drive belt loose or worn

Battery cables loose, corroded or worn

Fuse blown

Fusible link blown

Electronic voltage regulator or alternator

faulty

Wiring faulty

Drive belt loose or worn

Wiring connection loose or open circuit

Fusible link blown Replace voltage regulator

Adjust tension or replace drive

belt

Repair or replace cables

Check fuses

Replace fusible link

Test alternator

Repair wiring

Adjust tension or replace drive

belt

Tighten loose connection or

repair wiring

Replace fusible link 8-79

Refer to

GROUPS.

8-8 1

8-70

8-69

8-77

8-79

-

Refer to

GROUP 9.

-

8-69

Poor grounding 1 Repair

I-

I I I Electronic voltage regulator or alternator

faulty Test alternator 8-77

8-79

Overcharge Decrease in life of battery

Replace battery

8-81 I

Electronic voltage regulator faulty Replace voltage regulator 8-79

STB Revision

Page 96 of 284

![MITSUBISHI MONTERO 1987 1.G Repair Manual 8-76 CHARGING SYSTEM - Circuit Diagram

3 CHARGING CIRCUIT

Battery Ignition switch

OFF

Main

m fusible ’ L

link

A-02

fl.3-Br 1~5~~

, A-23 Sub fusible link

(IGN . SW)

IAM IG ] c-55

3

3

A MITSUBISHI MONTERO 1987 1.G Repair Manual 8-76 CHARGING SYSTEM - Circuit Diagram

3 CHARGING CIRCUIT

Battery Ignition switch

OFF

Main

m fusible ’ L

link

A-02

fl.3-Br 1~5~~

, A-23 Sub fusible link

(IGN . SW)

IAM IG ] c-55

3

3

A](/img/19/7559/w960_7559-95.png)

8-76 CHARGING SYSTEM - Circuit Diagram

3 CHARGING CIRCUIT

Battery Ignition switch

OFF

Main

m fusible ’ L

link

A-02

fl.3-Br 1~5~~

, A-23 Sub fusible link

(IGN . SW)

IAM IG ] c-55

3

3

A m

A

To turn signal flasher

unit [Refer to P.8-49.1 Multi-

n, Irnn4P

ComSeter

Remark

For information concerning the ground points (example:

q ),

refer to P.8-7. 37W605

Wiring color code

B: Black Br: Brown G: Green Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red Y: Yellow W: White

1 STB Revision

Page 97 of 284

CHARGING SYSTEM - Service Adjustment Procedures 8-77

SERVICE ADJUSTMENT PROCEDUREswmAB

lEL15I

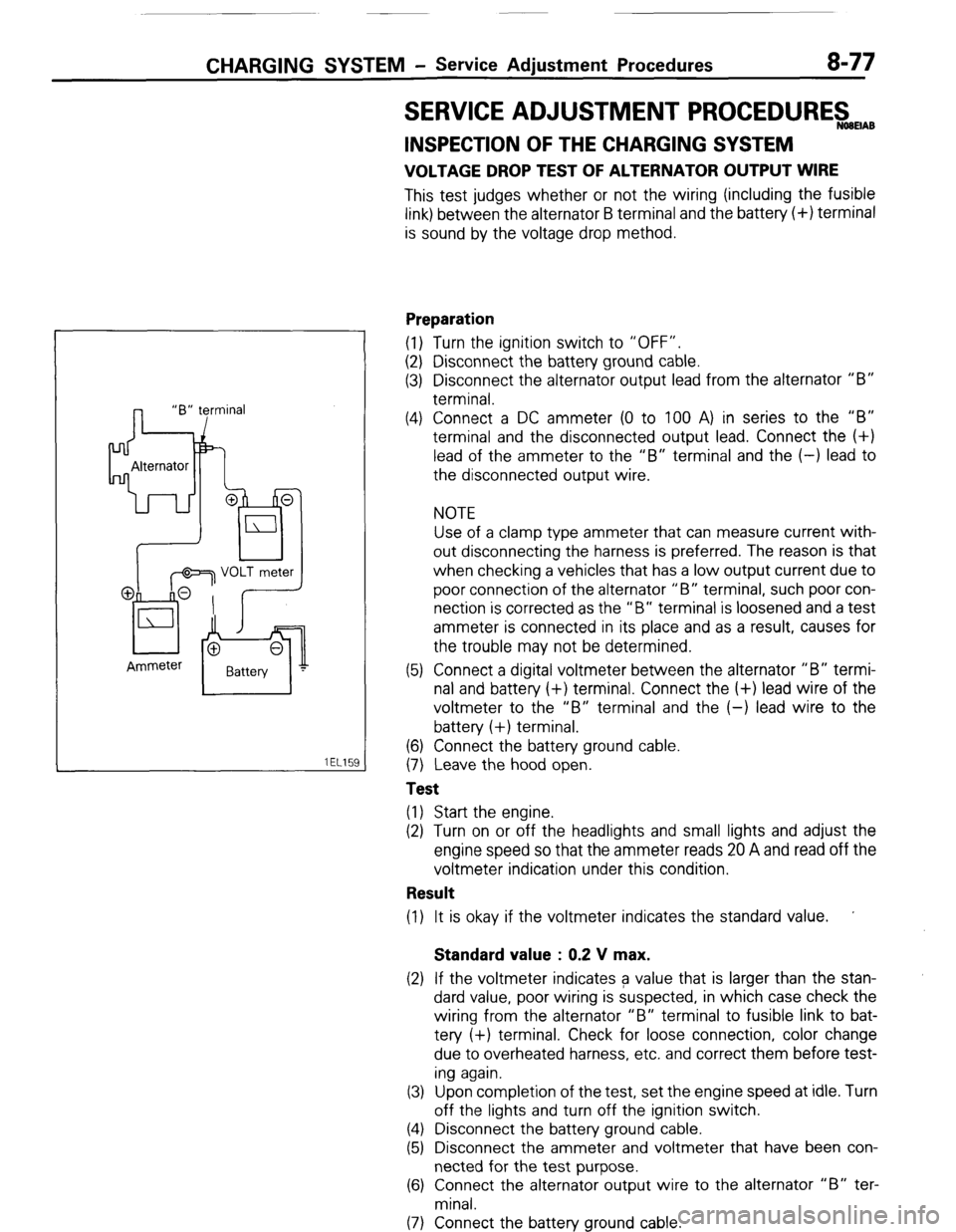

INSPECTION OF THE CHARGING SYSTEM

VOLTAGE DROP TEST OF ALTERNATOR OUTPUT WIRE

This test judges whether or not the wiring (including the fusible

link) between the alternator B terminal and the battery (+) terminal

is sound by the voltage drop method.

Preparation

(1) Turn the ignition switch to “OFF”.

(2) Disconnect the battery ground cable.

(3) Disconnect the alternator output lead from the alternator “B”

terminal.

(4) Connect a DC ammeter (0 to 100 A) in series to the “B”

terminal and the disconnected output lead. Connect the (+)

lead of the ammeter to the “B” terminal and the (-) lead to

the disconnected output wire.

NOTE

Use of a clamp type ammeter that can measure current with-

out disconnecting the harness is preferred. The reason is that

when checking a vehicles that has a low output current due to

poor connection of the alternator “B” terminal, such poor con-

nection is corrected as the “B” terminal is loosened and a test

ammeter is connected in its place and as a result, causes for

the trouble may not be determined.

(5) Connect a digital voltmeter between the alternator “B” termi-

nal and battery (+) terminal. Connect the (+) lead wire of the

voltmeter to the “B” terminal and the (-) lead wire to the

battery (+) terminal.

(6) Connect the battery ground cable.

(7) Leave the hood open.

Test

(1) Start the engine.

(2) Turn on or off the headlights and small lights and adjust the

engine speed so that the ammeter reads 20 A and read off the

voltmeter indication under this condition.

Result

(1) It is okay if the voltmeter indicates the standard value. ’

Standard value : 0.2 V max.

(2) If the voltmeter indicates a value that is larger than the stan-

dard value, poor wiring is suspected, in which case check the

wiring from the alternator “B” terminal to fusible link to bat-

tery (+) terminal. Check for loose connection, color change

due to overheated harness, etc. and correct them before test-

ing again.

(3) Upon completion of the test, set the engine speed at idle. Turn

off the lights and turn off the ignition switch.

(4) Disconnect the battery ground cable.

(5) Disconnect the ammeter and voltmeter that have been con-

nected for the test purpose.

(6) Connect the alternator output wire to the alternator “B” ter-

minal.

(7) Connect the battery ground cable.

( STB Revision

Page 98 of 284

8-78 CHARGING SYSTEM - Service Adiustment Procedures

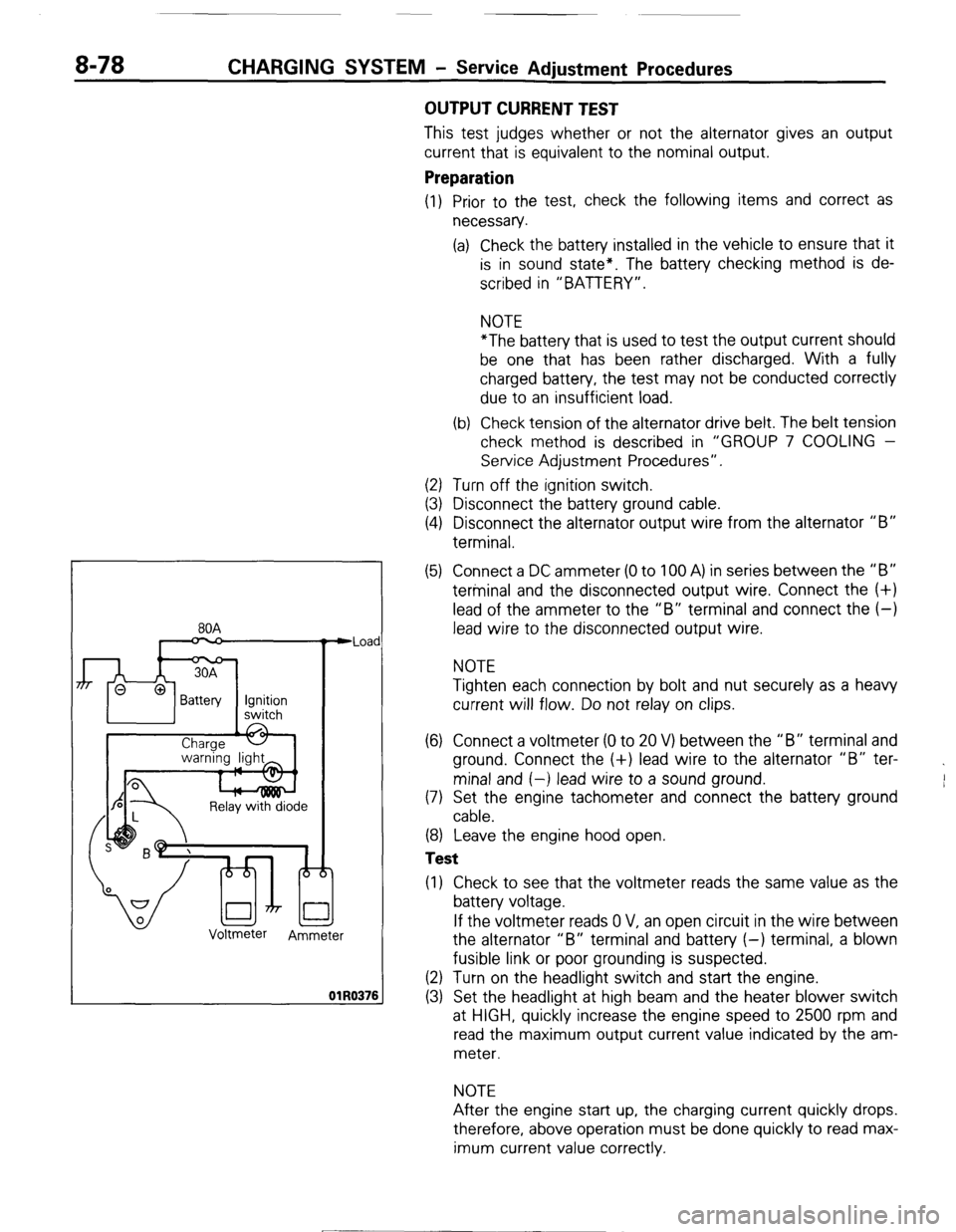

80A

n

Relay with diode

Voltmeter

Ammeter Iad

176

OUTPUT CURRENT TEST

This test judges whether or not the alternator gives an output

current that is equivalent to the nominal output.

Preparation

(1) Prior to the test, check the following items and correct as

necessary.

(a) Check the battery installed in the vehicle to ensure that it

is in sound state*. The battery checking method is de-

scribed in “BATTERY”.

NOTE

*The battery that is used to test the output current should

be one that has been rather discharged. With a fully

charged battery, the test may not be conducted correctly

due to an insufficient load.

(b) Check tension of the alternator drive belt. The belt tension

check method is described in “GROUP 7 COOLING -

Service Adjustment Procedures”.

(2) Turn off the ignition switch.

(3) Disconnect the battery ground cable.

(4) Disconnect the alternator output wire from the alternator “B”

terminal.

(5) Connect a DC ammeter (0 to 100 A) in series between the “B”

terminal and the disconnected output wire. Connect the (+)

lead of the ammeter to the “B” terminal and connect the (-)

lead wire to the disconnected output wire.

NOTE

Tighten each connection by bolt and nut securely as a heavy

current will flow. Do not relay on clips.

(6) Connect a voltmeter (0 to 20 V) between the “B” terminal and

ground. Connect the (+) lead wire to the alternator “B” ter-

minal and (-) lead wire to a sound ground.

(7) Set the engine tachometer and connect the battery ground

cable.

(8) Leave the engine hood open.

Test

(1) Check to see that the voltmeter reads the same value as the

battery voltage.

If the voltmeter reads 0 V, an open circuit in the wire between

the alternator “B” terminal and battery (-) terminal, a blown

fusible link or poor grounding is suspected.

(2) Turn on the headlight switch and start the engine.

(3) Set the headlight at high beam and the heater blower switch

at HIGH, quickly increase the engine speed to 2500 rpm and

read the maximum output current value indicated by the am-

meter.

NOTE

After the engine start up, the charging current quickly drops.

therefore, above operation must be done quickly to read max-

imum current value correctly.

[ STB Revision

--I