Ignition MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 1 of 284

Service Manual

MONTERO

1987 : Volume 2

FOREWORD

This Service Manual has been prepared with the

latest service information available at the time of

publication. It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliability

designed into these outstanding vehicles.

WE SUPPORT

VOLUNTARY TECHNICIAN

CERTIFICATION THROUGH

MITSUBISHI MOTOR SALES OF AMERICA. Inc.

Mitsubishi Motors corporation reserves the right to make changes in

design or to make additions to or improvements in its products without

imposing any obligations upon itself to install them on its products

previously manufactured.

I

GROUP/SECTION INDEX ‘kme-.

INTRODUCTION ..............................

Electrical ...........................................

Electrical System Parts

Location .........................................

Relays, Control Units, Sensors,

Fuses, Groundings

Inspection of Harness

Connector ......................................

Wiring Harness .............................

Charging System ..........................

Starting System ............................

Ignition System .............................

Meters and Gauges ......................

Lighting System .............................

Wiper and Washer System ..........

Horn ...............................................

Accessory ......................................

Audio System ................................

Back Door Window Defogger ......

Automatic Free-wheeling Hub

Indicator System ..........................

Heaters and Air-conditioning .........

Heaters ..........................................

Air-conditioning ............................

**, For Engine Chassis & Body refer to

0 1986 Mitsubishi Motors Corporation Printed in Japan

Page 9 of 284

INTRODUCTION - Precautions Before Service 9

nm (in.)

so0059

PARTS

When replacing parts, use MITSUBISHI genuine parts.

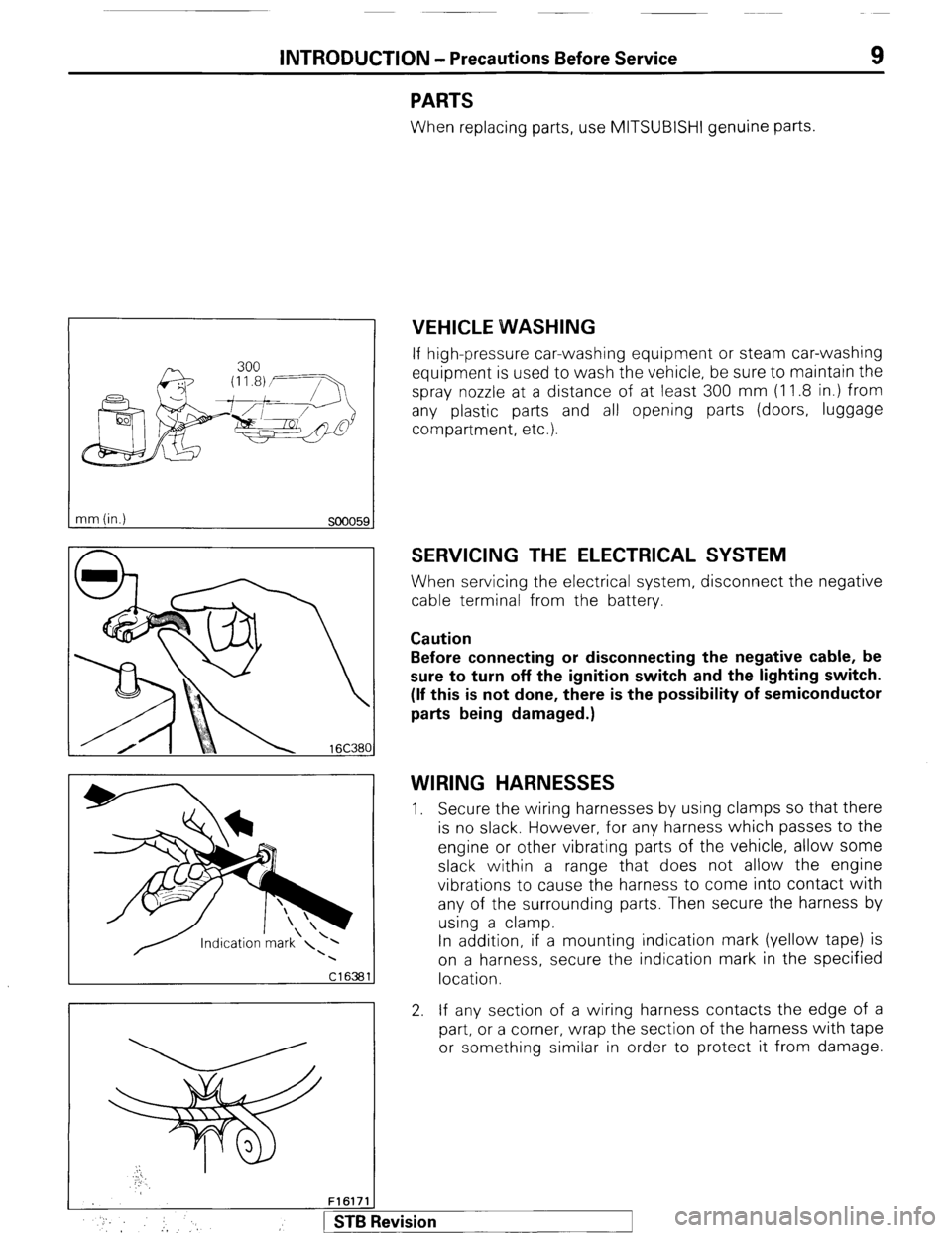

VEHICLE WVASHING

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least 300 mm (1 1.8 in.) from

any plastic parts and all opening parts (doors, luggage

compartment, etc.).

SERVICING THE ELECTRICAL SYSTEM

When servicing the electrical system, disconnect the negative

cable terminal from the battery.

Caution

Before connecting or disconnecting the negative cable, be

sure to turn off the ignition switch and the lighting switch.

(If this is not done, there is the possibility of semiconductor

parts being damaged.)

WIRING HARNESSES

1. Secure the wiring harnesses by using clamps so that there

is no slack. However, for any harness which passes to the

engine or other vibrating parts of the vehicle, allow some

slack within a range that does not allow the engine

vibrations to cause the harness to come into contact with

any of the surrounding parts. Then secure the harness by

using a clamp.

In addition, if a mounting indication mark (yellow tape) is

on a harness, secure the indication mark in the specified

location.

2. If any section of a wiring harness contacts the edge of a

part, or a corner, wrap the section of the harness with tape

or something similar in order to protect it from damage.

F161711

* :, :, 1 STB Revision

Page 21 of 284

8-1

ELECTRICAL

CONTENTS

NOBAA-

ACCESSORY ......................................................

188

Cigarette Lighter ............................................

,190

Clock ...............................................................

,191

AUDIO SYSTEM ................................................

.192

AUTOMATIC FREE-WHEELING HUB

INDICATOR SYSTEM ........................................

208

Automatic Free-wheeling Hub

Indicator Control Unit

..................................... ,216

Pulse Generator ..............................................

215

BACK DOOR WINDOW DEFOGGER

................ .203

Defogger switch ............................................

,206

Printed Heater Lines

...................................... ,207

CHARGING SYSTEM .........................................

71

Alternator ........................................................

83

Service Adjustment Procedures

..................... 77

Battery Charging ........................................

82

Inspection of Battery ..................................

81

Output Current Test ...................................

78

Regulated Voltage Test ..............................

79

Voltage Drop Test of Alternator Output

Wire ............................................................

77

ELECTRICAL SYSTEM PARTS LOCATION

...... 2

Diode ...............................................................

5

Fusible Link and Fuse

..................................... 6

Grounding .......................................................

7

Relay and Control Unit ....................................

2

Sensor .............................................................

4

HORN ..................................................................

184

Horn Switch

.................................................... 187

IGNITION SYSTEM ............................................

105

Ignition Switch

................................................ 122

Ignition System ...............................................

1 14

Service Adjustment Procedures

.................... .l 1 1

Checking Ignition System

..........................

11 1

Checking Ignition Timing

...........................

11 1

Spark Plug Cable Test

................................

1 12

Spark Plug Test

.......................................... 1 12 INSPECTION OF HARNESS CONNECTOR ...... 9

Check for Improper Engagement of

Terminal .......................................................... 9

Continuity and Voltage Test for Connector .... 9

Engaging and Disengaging of Connector

Terminal ..........................................................

9

LIGHTING SYSTEM ........................................... 143

Column Switch

................................ .

.............. .I59

Dimmer Control Switch

................................. .I62

Hazard Warning Switch

................................. .I61

Headlight ........................................................ ,158

Service Adjustment Procedures

.................... .I57

Headlight Aiming .......................................

157

METERS AND GAUGES .................................... 123

Service Adjustment Procedures

.................... .I30

Fuel Gauge Simple Test ................................. .I31

Fuel Gauge Unit Inspection ........................... .I31

Oil Pressure Gauge Simple Test

.................... .I32

Oil Pressure Gauge Unit Simple Test

............ ,132

Speedometer Inspection

............................... .I30

Tachometer Inspection .................................. ,130

Voltage Meter Simple Test

............................ .I33

Water Temperature Gauge Simple Test

....... ..I3 1

Water Temperature Gauge Unit Inspection

. ..I3 2

STARTING SYSTEM .......................................... 91

Starter Motor ............ ....................................... 97

WIPER AND WASHER SYSTEM

....................... .163

WIRING HARNESS ............................................ 13

Centralized Junction ....................................... 69

Circuit Diagram ............................................... 34

Configuration Diagram .................................... 27

How to Read Wiring Diagrams ....................... 20

Troubleshooting .............................................. 13

Page 37 of 284

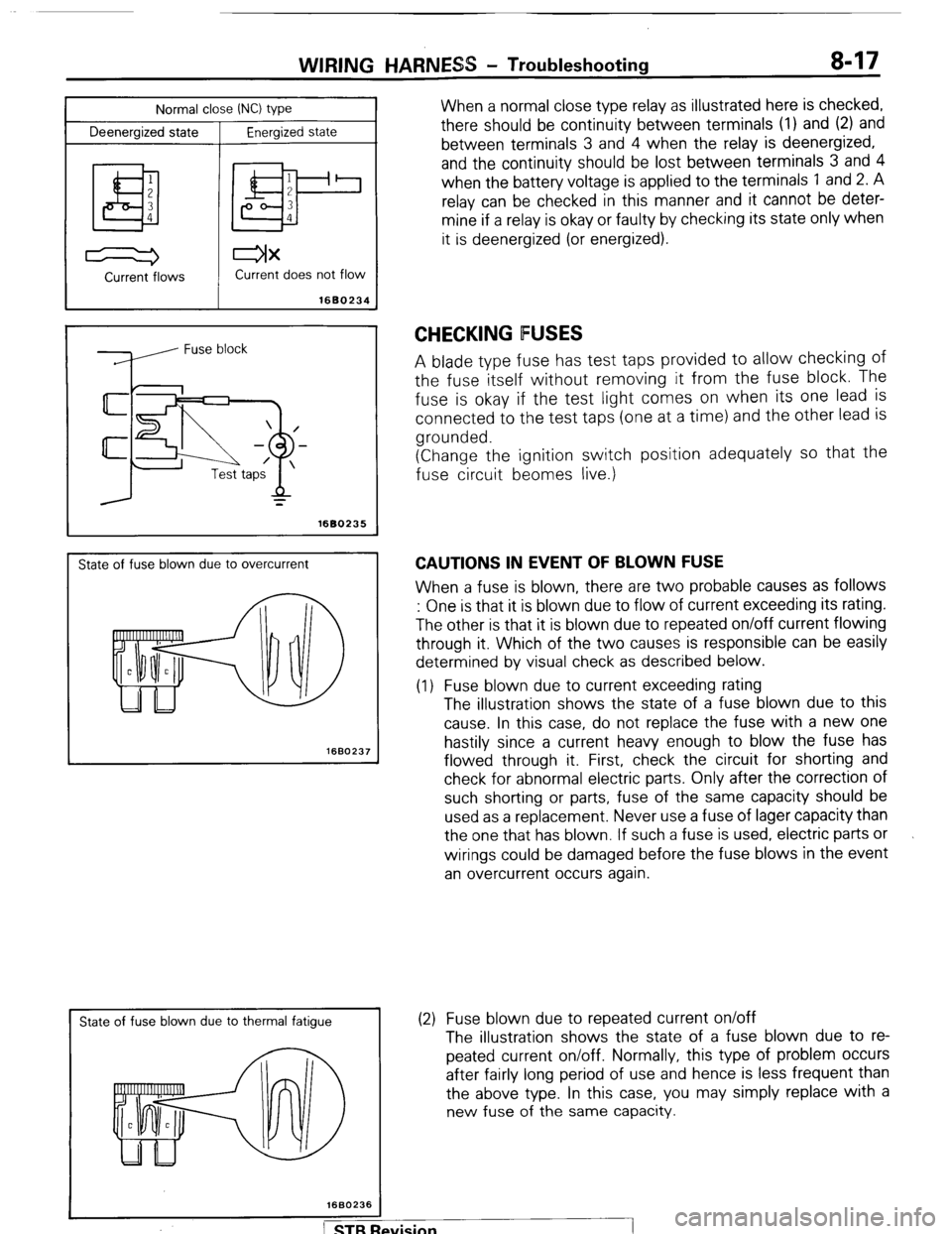

Normal close INC) type

Deenergized state

Energized state

I

WIRING HARNESS - Troubleshooting 8-17

When a normal close type relay as illustrated here is checked,

there should be continuity between terminals (1) and (2) and

between terminals 3 and 4 when the relay is deenergized,

and the continuity should be lost between terminals 3 and 4

when the battery voltage is applied to the terminals 1 and 2. A

relay can be checked in this manner and it cannot be deter-

mine if a relay is okay or faulty by checking its state only when

it is deenergized (or energized).

Current -flows Current does not flow

1680234

=

1680235

State of fuse blown due to overcurrent

1660237

I

State of fuse blown due to thermal fatigue

CHECKING FUSES

A blade type fuse has test taps provided to allow checking of

the fuse itself without removing it from the fuse block. The

fuse is okay if the test light comes on when its one lead is

connected to the test taps (one at a time) and the other lead is

grounded.

(Change the ignition switch position adequately so that the

fuse circuit beomes live.)

CAUTIONS IN EVENT OF BLOWN FUSE

When a fuse is blown, there are two probable causes as follows

: One is that it is blown due to flow of current exceeding its rating.

The other is that it is blown due to repeated on/off current flowing

through it. Which of the two causes is responsible can be easily

determined by visual check as described below.

(1) Fuse blown due to current exceeding rating

The illustration shows the state of a fuse blown due to this

cause. In this case, do not replace the fuse with a new one

hastily since a current heavy enough to blow the fuse has

flowed through it. First, check the circuit for shorting and

check for abnormal electric parts. Only after the correction of

such shorting or parts, fuse of the same capacity should be

used as a replacement. Never use a fuse of lager capacity than

the one that has blown. If such a fuse is used, electric parts or

wirings could be damaged before the fuse blows in the event

an overcurrent occurs again.

(2) Fuse blown due to repeated current on/off

The illustration shows the state of a fuse blown due to re-

peated current on/off. Normally, this type of problem occurs

after fairly long period of use and hence is less frequent than

the above type. In this case, you may simply replace with a

new fuse of the same capacity.

Page 42 of 284

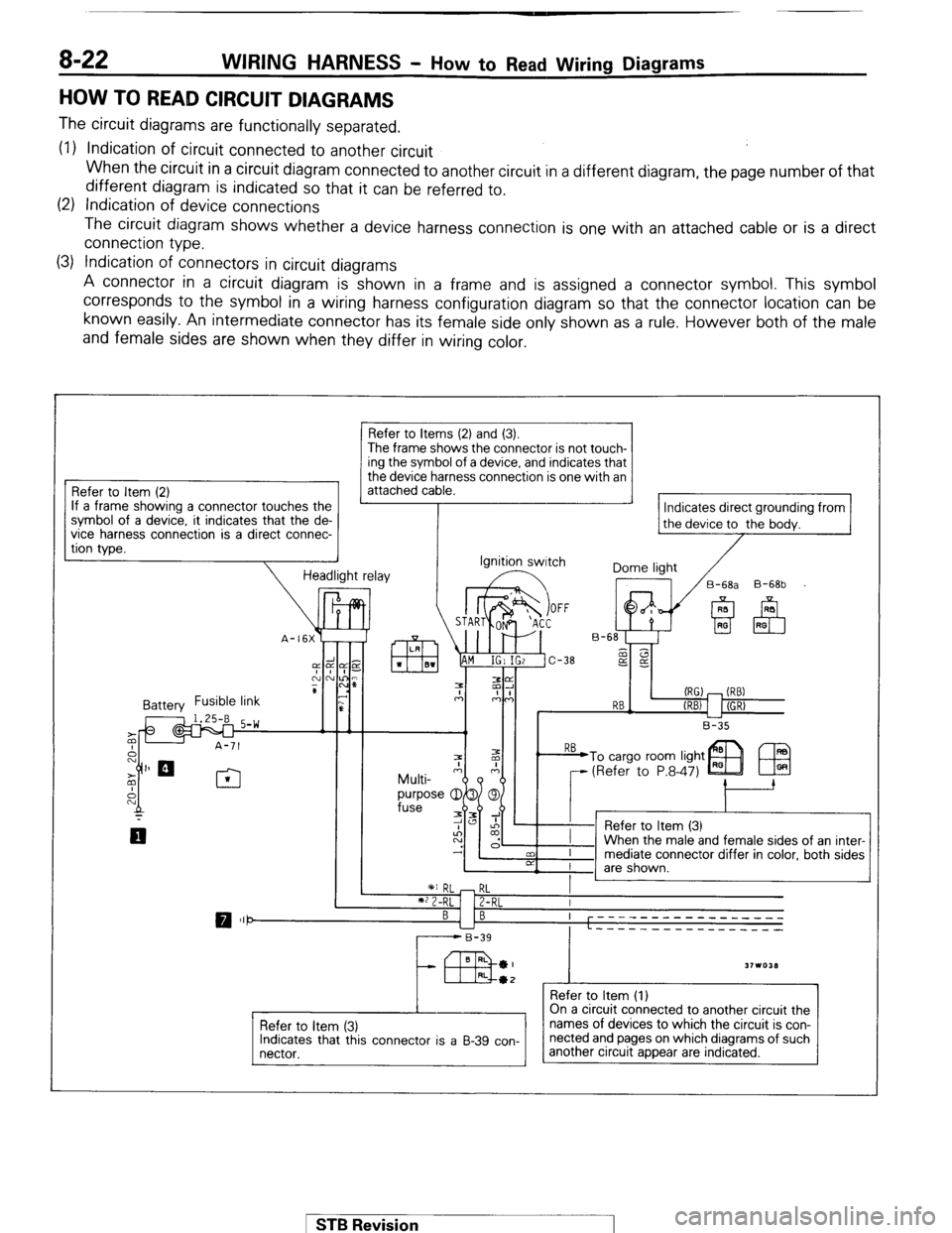

8-22 WIRING HARNESS - How to Read Wiring Diagrams

HOW TO READ CIRCUIT DIAGRAMS

The circuit diagrams are functionally separated.

(1) Indication of circuit connected to another circuit

When the circuit in a circuit diagram connected to another circuit in a different diagram, the page number of that

different diagram is indicated so that it can be referred to.

(2) Indication of device connections

The circuit diagram shows whether a device harness connection is one with an attached cable or is a direct

connection type.

(3) Indication of connectors in circuit diagrams

A connector in a circuit diagram is shown in a frame and is assigned a connector symbol. This symbol

corresponds to the symbol in a wiring harness configuration diagram so that the connector location can be

known easily. An intermediate connector has its female side only shown as a rule. However both of the male

and female sides are shown when they differ in wiring color.

Refer to Item (2)

If a frame showing a connector touches the

?. it indicates that the de-

a direct connec- symbol of a device

vice

harness connectlon IS

tion type.

Refer to Items (2) and (3).

The frame shows the connector is not touch- ing the symbol of a device, and indicates that

the device harness connection is one with an

attached cable.

Indicates direct grounding from

the device to the bodv.

Ignition switch

Dome light

/

17 /B-6& B-68b

(RG) - (RB)

RB-

(REV 1 I (GR)

L-2

B-35

1 *I RL - RL

I

**2-RL 1 Z-RL I

BI B ----- ---- --------

L ----_ __---___----

r------B-39

43 BRL *I

31103LI RL*2 _

Refer to Item (1)

Refer to item (3)

Indicates that this connector is a B-39 con-

nectar. On a circuit connected to another circuit the

names of devices to which the circuit is con-

nected and pages on which diagrams of such

another circuit appear are indicated.

1 STB Revision 1

Page 43 of 284

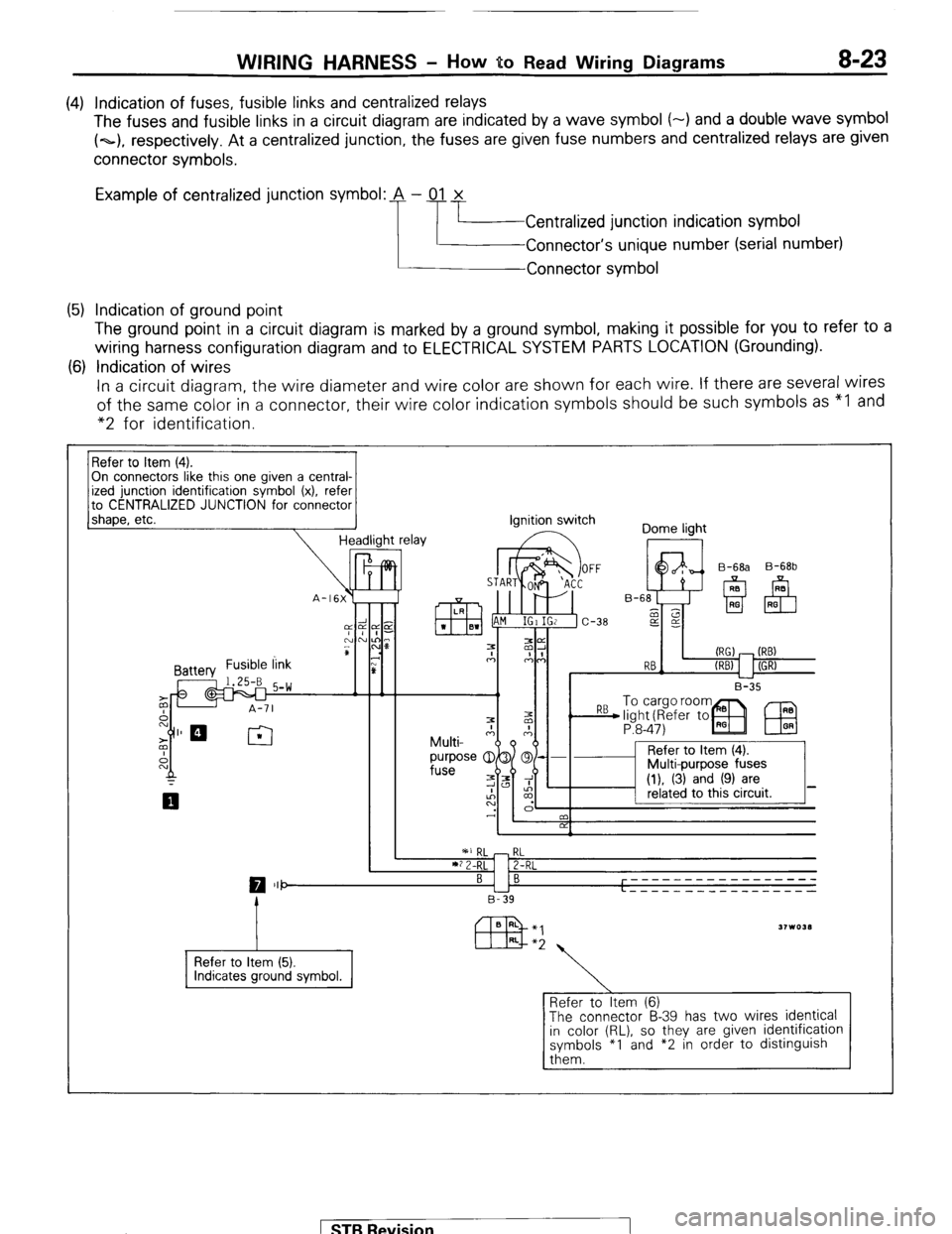

WIRING HARNESS - HOW BO Read Wiring Diagrams 8-23

(4) Indication of fuses, fusible links and centralized relays

The fuses and fusible links in a circuit diagram are indicated by a wave symbol (-) and a double wave symbol

(~1, respectively. At a centralized junction, the fuses are given fuse numbers and centralized relays are given

connector symbols.

Example of centralized junction symbol: A - 01 x

Centralized junction indication symbol

Connector’s unique number (serial number)

Connector symbol

(5) Indication of ground point

The ground point in a circuit diagram is marked by a ground symbol, making it possible for you to refer to a

wiring harness configuration diagram and to ELECTRICAL SYSTEM PARTS LOCATION (Grounding).

(6) Indication of wires

In a circuit diagram, the wire diameter and wire color are shown for each wire. If there are several wires

of the same color in a connector, their wire color indication symbols should be such symbols as “I and

“2 for identification.

On connectors like this one given a central-

to CENTRALIZED JUNCTION for connector

1 shaoe. etc.

-I Headlight relay ignition switch

Dome light

I II I B-35 B-68b

P:8-47)

IEU

I ’ 2 I

RL

2-RL

0 III- BI B -----____________

L - - - - - _ _ _ _ _ __ _ _ _ _ _

B-39

Refer to Item (5).

Refer to Item (6)

The connector B-39 has two wires identical

in color (RL), so they are given identification

symbols *I and *2 in order to distinguish

them. 1 ST6 Revision

Page 44 of 284

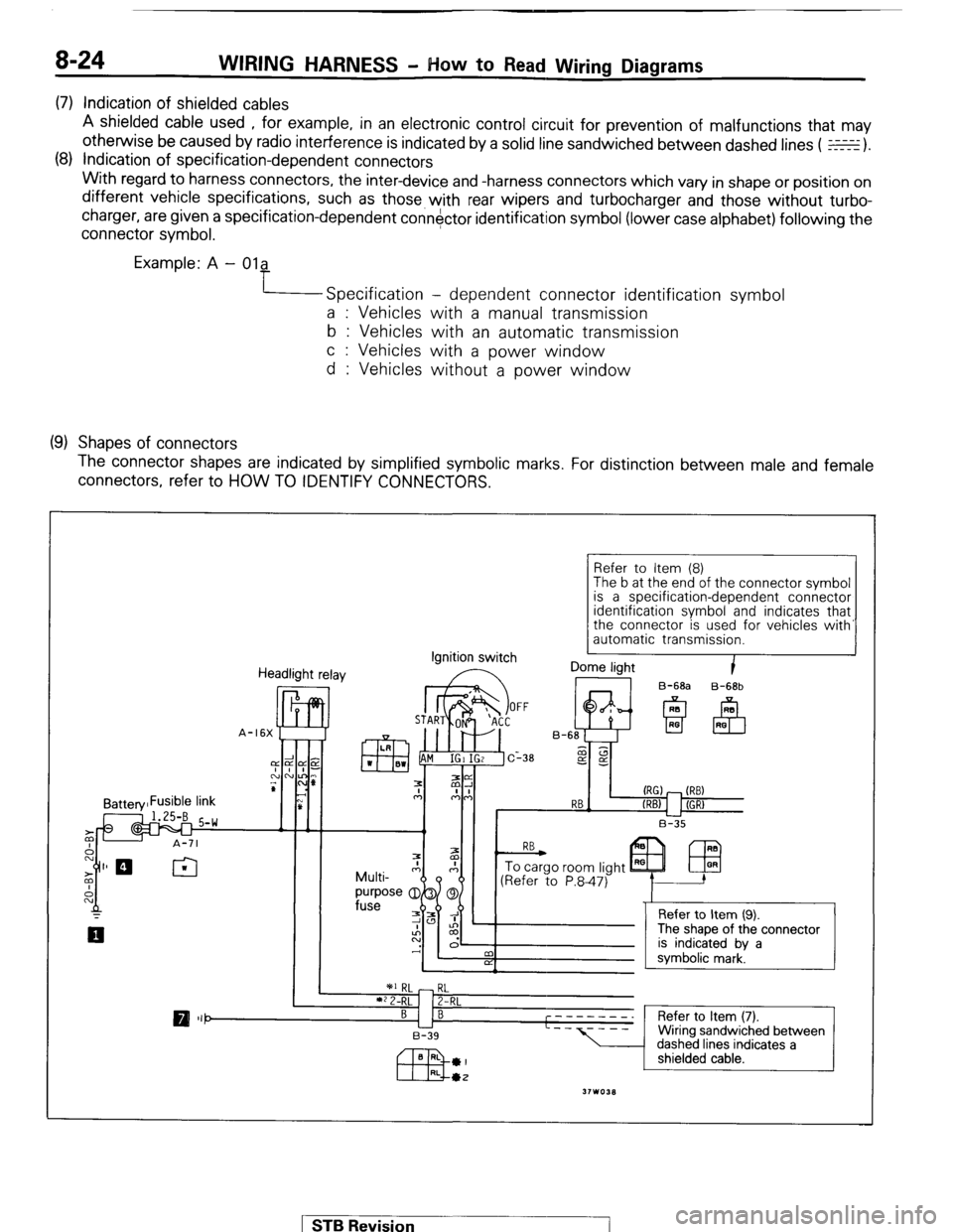

8-24 WIRING HARNESS - How to Read Wiring Diagrams

(7) Indication of shielded cables

A shielded cable used , for example, in an electronic control circuit for prevention of malfunctions that may

otherwise be caused by radio interference is indicated by a solid line sandwiched between dashed lines ( E).

(8) Indication of specification-dependent connectors

With regard to harness connectors, the inter-device and -harness connectors which vary in shape or position on

different vehicle specifications, such as those with rear wipers and turbocharger and those without turbo-

charger, are given a specification-dependent connector identification symbol (lower case alphabet) following the

connector symbol.

Example: A - Ola

Specification - dependent connector identification symbol

a : Vehicles with a manual transmission

b : Vehicles with an automatic transmission

c : Vehicles with a power window

d : Vehicles without a power window

(9) Shapes of connectors

The connector shapes are indicated by simplified symbolic marks. For distinction between male and female

connectors, refer to HOW TO IDENTIFY CONNECTORS.

Refer to Item (8)

The b at the end of the connector symbol

is a specification-dependent connector

identification

symbol and indicates that

the connector is used for vehicles with’

automatic transmission.

Headlight relay Ignition

switch I Dome light

B-68a B-68b STB Revision

Page 49 of 284

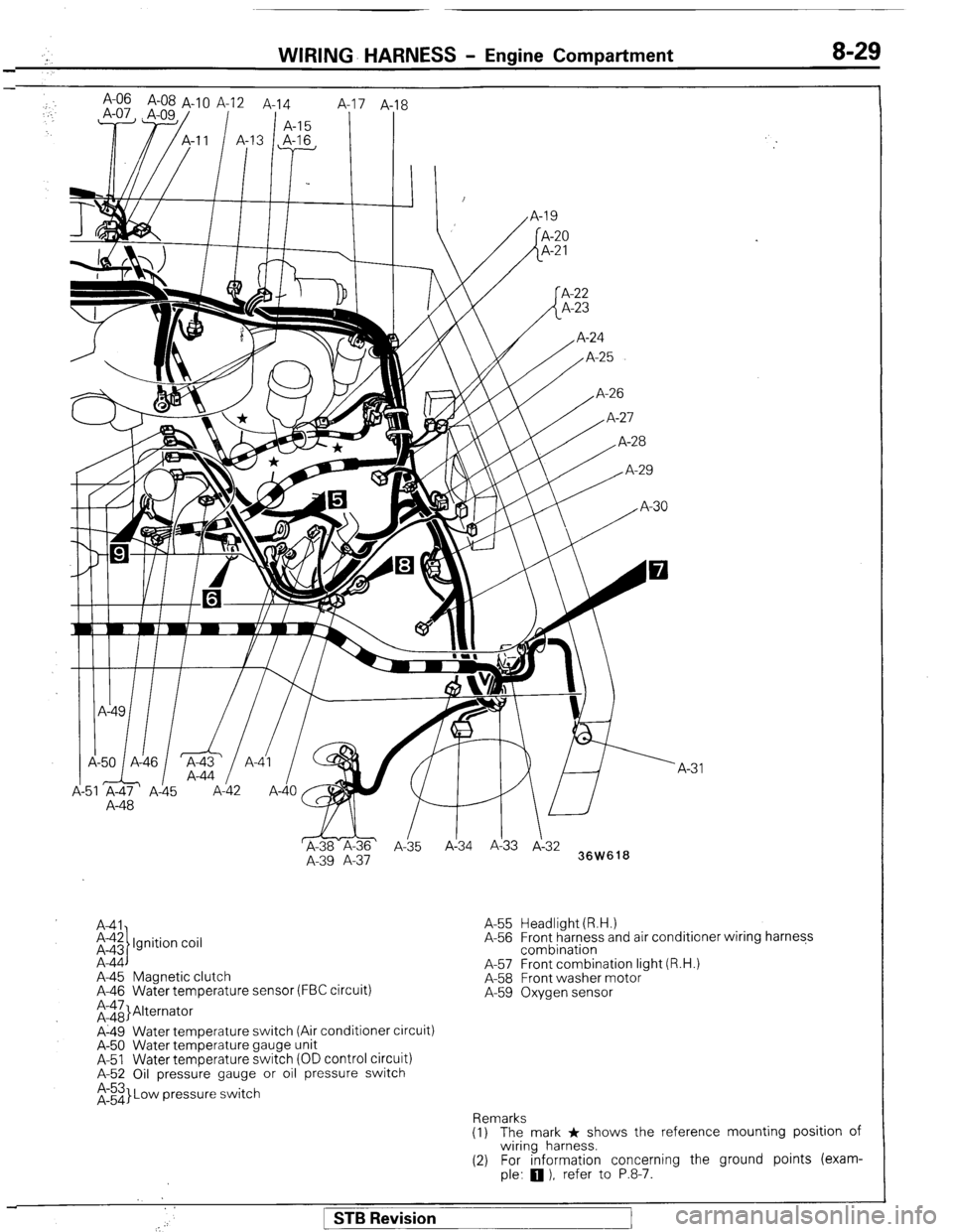

WIRING- HARNESS - Engine Compartment 8-29

; A-06 A-08 A-1 0 A-12 A-14

,.

1 A-15 8

I I

,I I I, I /

A-48

WI

&-ii& ’

A-35 Ai34 A!33 J-3:

A-39 A-37

36W618

A41

i-$ Ignition coil

A-44

A-45 Magnetic clutch

A-46 Water temperature sensor (FBC circuit)

;rii}Alternator

A-49 Water temperature switch (Air conditioner circuit)

A-50 Water temperature gauge unit

A-51 Water temperature switch (OD control circuit)

A-52 Oil pressure gauge or oil pressure switch

$3 Low pressure switch A-55 Headlight (R.H.)

A-56 Front harness and air conditioner wiring harness

combination

A-57 Front combination light (R.H.)

A-58 Front washer motor

A-59 Oxygen sensor

Remarks

(1) The mark * shows the reference mounting position of

wiring harness.

(2) For information concerning the ground points (exam-

ple:

q ), refer to P.8-7.

1 STB Revision

Page 53 of 284

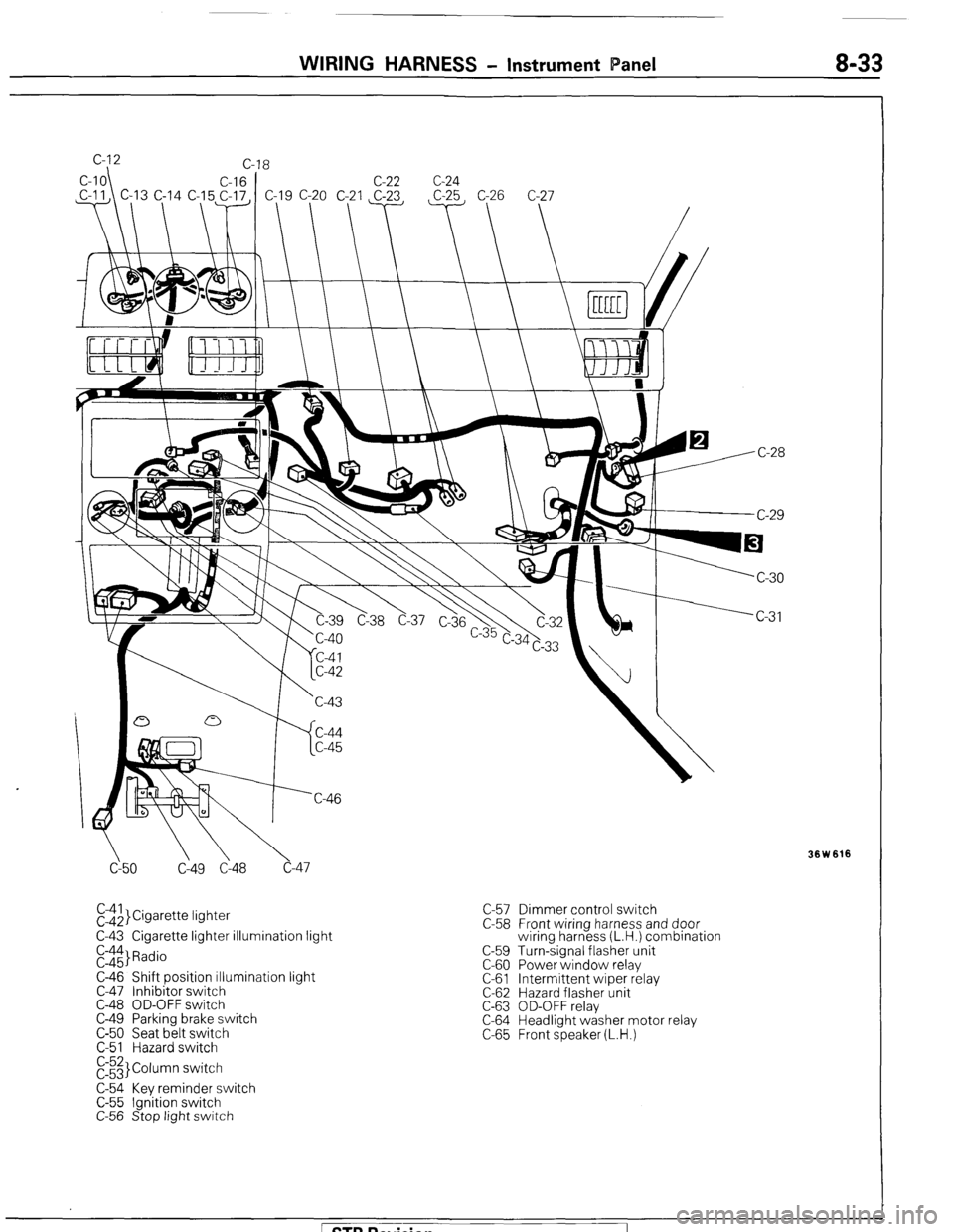

WIRING HARNESS - Instrument Panel 8-33

cy50 C149 Cl48 c-47

El$,}Cigarette lightet

C-43 Cigarette lighter illumination light

E::$ Radio

C-46 Shift position illumination light

C-47 Inhibitor switch

C-48 OD-OFF switch

C-49 Parking brake switch

C-50 Seat belt switch

C-51 Hazard switch

E3 Column switch

C-54 Key reminder switch

C-55 Ignition switch

C-56 Stop light switch C-57 Dimmer control switch

C-58 Front wiring harness and door

wiring harness (L.H.) combination

C-59 Turn-signal flasher unit

C-60 Power window relay

C-61 Intermittent wiper relay

C-62 Hazard flasher unit

C-63 OD-OFF relay

C-64 Headlight washer motor relay

C-65 Front speaker (L.H.)

Ision

Page 54 of 284

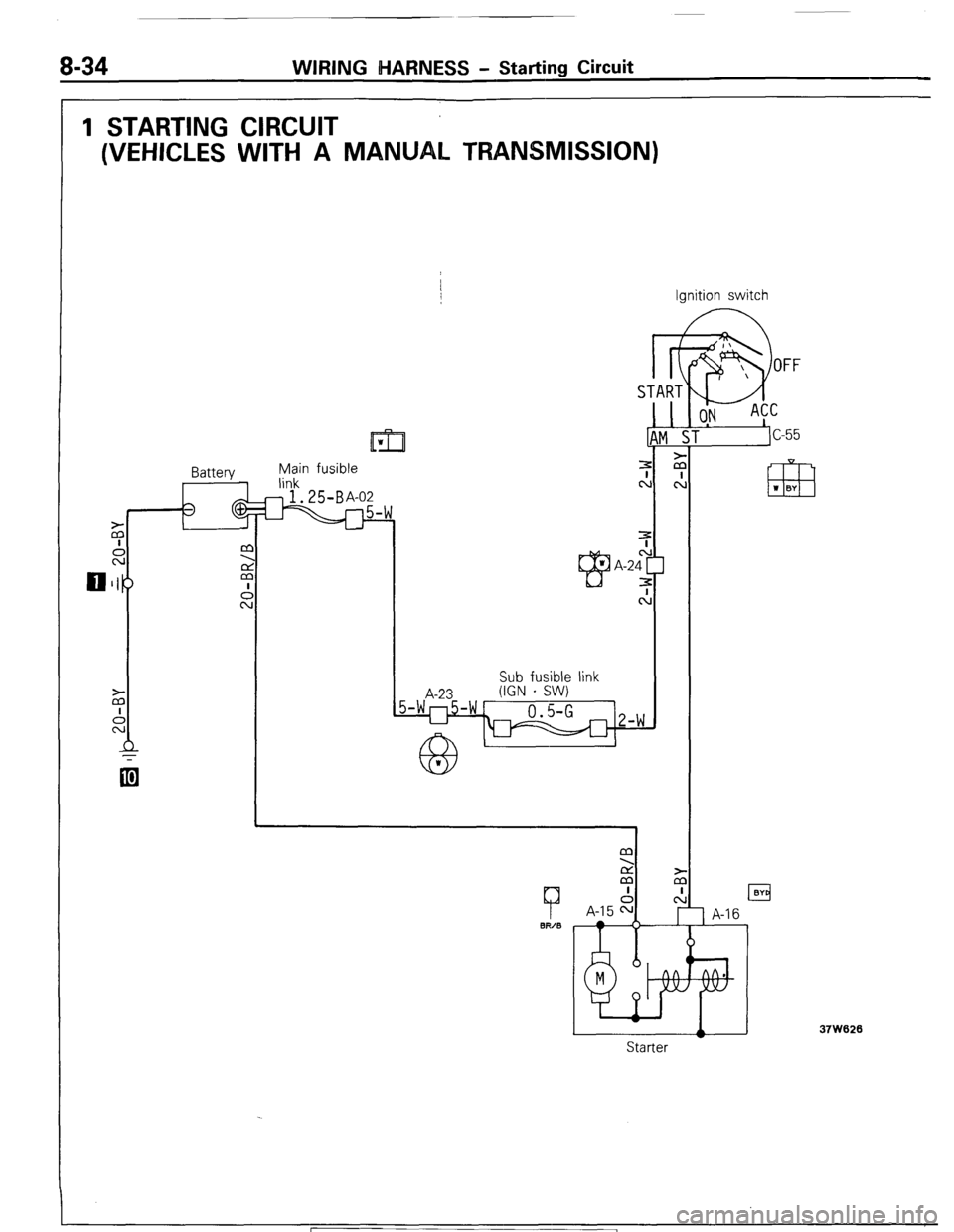

8-34 WIRING MARNESS - Starting Circuit

1 STARTING CIRCUIT

(VEHICLES WITH A MANUAL TRANSMISSION)

Ignition switch

Battery Main fusible

link

@.25B+

A-23 Sub fusible link

(IGN - SW)

7

BIT/B

M

2

M

I

A-15 F=

TA RT

L

1!

z

cl

m w BY

A

Starter

37W620

1 STB Revision