clock MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 21 of 284

8-1

ELECTRICAL

CONTENTS

NOBAA-

ACCESSORY ......................................................

188

Cigarette Lighter ............................................

,190

Clock ...............................................................

,191

AUDIO SYSTEM ................................................

.192

AUTOMATIC FREE-WHEELING HUB

INDICATOR SYSTEM ........................................

208

Automatic Free-wheeling Hub

Indicator Control Unit

..................................... ,216

Pulse Generator ..............................................

215

BACK DOOR WINDOW DEFOGGER

................ .203

Defogger switch ............................................

,206

Printed Heater Lines

...................................... ,207

CHARGING SYSTEM .........................................

71

Alternator ........................................................

83

Service Adjustment Procedures

..................... 77

Battery Charging ........................................

82

Inspection of Battery ..................................

81

Output Current Test ...................................

78

Regulated Voltage Test ..............................

79

Voltage Drop Test of Alternator Output

Wire ............................................................

77

ELECTRICAL SYSTEM PARTS LOCATION

...... 2

Diode ...............................................................

5

Fusible Link and Fuse

..................................... 6

Grounding .......................................................

7

Relay and Control Unit ....................................

2

Sensor .............................................................

4

HORN ..................................................................

184

Horn Switch

.................................................... 187

IGNITION SYSTEM ............................................

105

Ignition Switch

................................................ 122

Ignition System ...............................................

1 14

Service Adjustment Procedures

.................... .l 1 1

Checking Ignition System

..........................

11 1

Checking Ignition Timing

...........................

11 1

Spark Plug Cable Test

................................

1 12

Spark Plug Test

.......................................... 1 12 INSPECTION OF HARNESS CONNECTOR ...... 9

Check for Improper Engagement of

Terminal .......................................................... 9

Continuity and Voltage Test for Connector .... 9

Engaging and Disengaging of Connector

Terminal ..........................................................

9

LIGHTING SYSTEM ........................................... 143

Column Switch

................................ .

.............. .I59

Dimmer Control Switch

................................. .I62

Hazard Warning Switch

................................. .I61

Headlight ........................................................ ,158

Service Adjustment Procedures

.................... .I57

Headlight Aiming .......................................

157

METERS AND GAUGES .................................... 123

Service Adjustment Procedures

.................... .I30

Fuel Gauge Simple Test ................................. .I31

Fuel Gauge Unit Inspection ........................... .I31

Oil Pressure Gauge Simple Test

.................... .I32

Oil Pressure Gauge Unit Simple Test

............ ,132

Speedometer Inspection

............................... .I30

Tachometer Inspection .................................. ,130

Voltage Meter Simple Test

............................ .I33

Water Temperature Gauge Simple Test

....... ..I3 1

Water Temperature Gauge Unit Inspection

. ..I3 2

STARTING SYSTEM .......................................... 91

Starter Motor ............ ....................................... 97

WIPER AND WASHER SYSTEM

....................... .163

WIRING HARNESS ............................................ 13

Centralized Junction ....................................... 69

Circuit Diagram ............................................... 34

Configuration Diagram .................................... 27

How to Read Wiring Diagrams ....................... 20

Troubleshooting .............................................. 13

Page 52 of 284

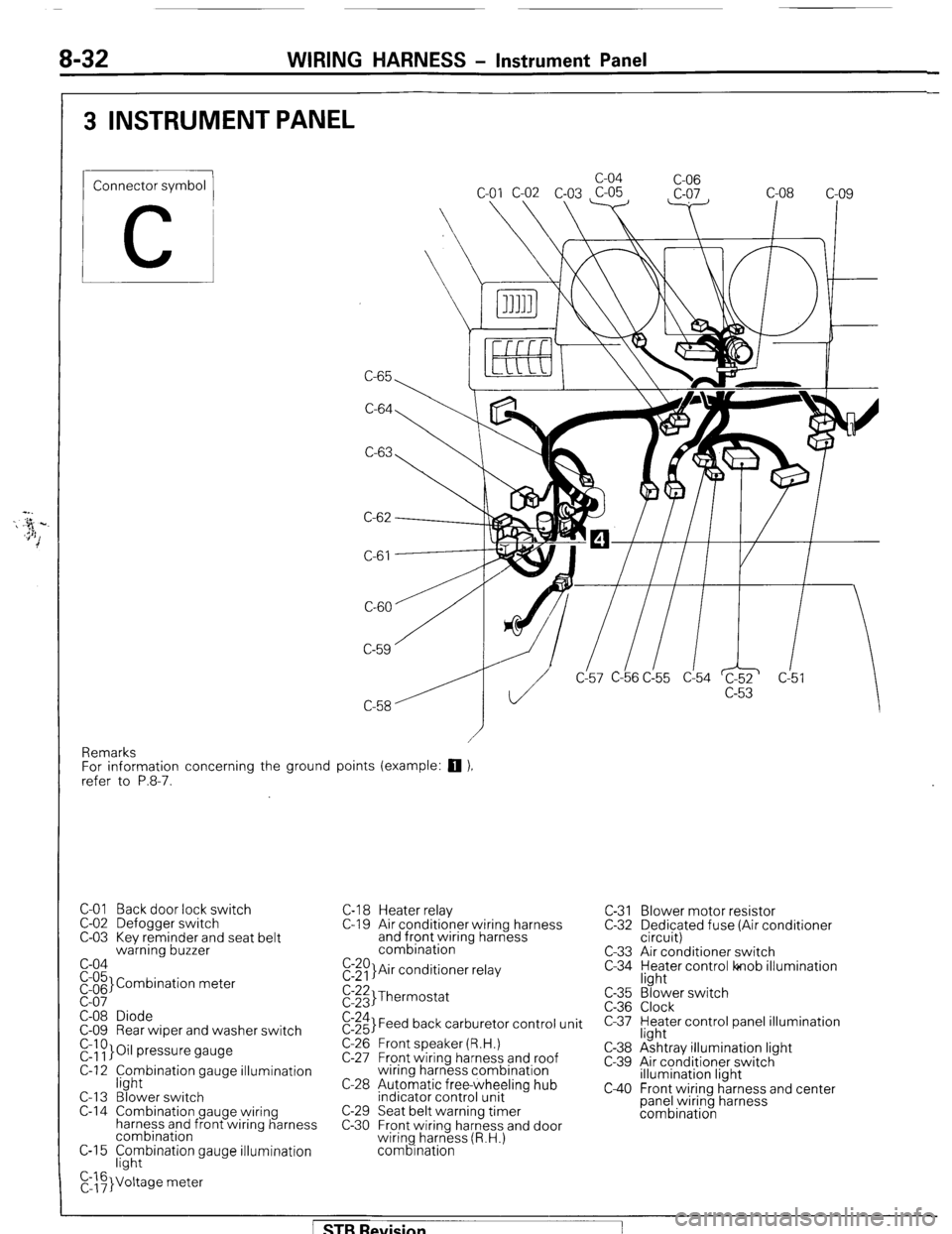

8-32 WIRING HARNESS - Instrument Panel

3 INSTRUMENT PANEL

Connector symbol

C

C-65 c-04

C-06

C-64

C-63

C-61

CL57 C-b6 C!55 d54 c!5

Remarks

For information concerning the ground points (example:

q ),

refer to P.8-7.

C-01 Back door lock switch

C-02 Defogger switch

C-03 Kev reminder and seat belt

warning buzzer

c-04

pi;’ Combination meter

C-08 Diode

C-09 Rear wiper and washer switch

r&~}Oil pressure gauge

C-12 f;hybination gauge illumination

C-l 3 Blower switch

C-14 Combination gauge wiring

harness and front wiring harness

combination

C-15 F;hybination gauge illumination

C,::F}Voltage meter C-l 8 Heater relay

C-l 9 Air conditioner wiring harness

and front wiring harness

combination

E:$)}Air conditioner relay C-31 Blower motor resistor

C-32 Dedicated fuse (Air conditioner

circuit)

C-33 Air conditioner switch

C-34 yl;Jer control lonob illumination

$:;;I Thermostat

$:;;I Feed back carburetor control unit

C-26 Front speaker (R.H.)

C-27 Front wiring harness and roof

wiring harness combination

C-28 Automatic free-wheeling hub

indicator control unit

C-29 Seat belt warning timer

C-30 Front wiring harness and door

wiring harness (R.H.)

combination c-35

C-36

c-37

C-38

c-39

c40

“3’ ‘. Blower switch

Clock

Heater control panel illumination

light

Ashtray illumination light

Air conditioner switch

illumination light

Front wiring harness and center

panel wiring harness

combination

[ STB Revision

Page 71 of 284

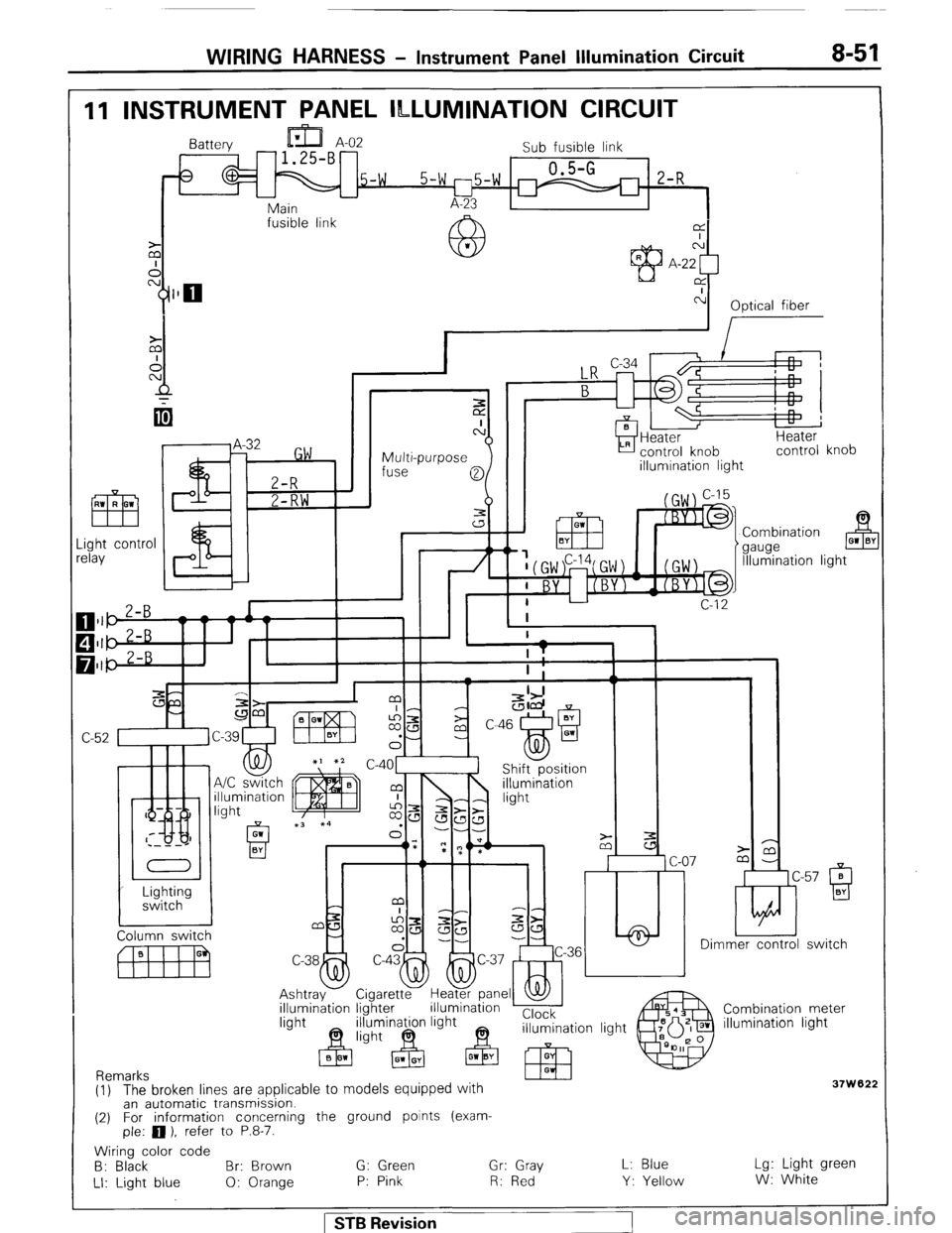

WIRING HARNESS - Instrument Panel Wumination Circuit 8-51

11 INSTRUMENT PANEL ILLUMINATION CIRCUIT

Battery

Sub fusible link

5-w 0.5-G

5-w l-75-W m 2-R - L-

Main A-23

fusible link

@L

M’ CA

A A-22

Y$lO rx

c-l

Optical fiber

I

I

Multi-purpose

fuse

0

3

a control knob

illumination light

.ight contr

clay

& 01 BY

7t Combination

gauge

Illumination ligl

c-4o1l Shift-position

lmer control switch

C-38

4

Ashtray

illumination Cigaretty Hegpane _

lighter illumination ’ I

minagn light Clock

n+ 63 illumination light Combination meter

illumination light

37w '62; (1) The broken lines are applicable to models equipped with

an automatic transmission.

(2) For information concerning the ground points (exam-

ple: 0 ), refer to P.8-7.

Wiring color code

B: Black Br: Brown G: Green Gr: Gray

LI: Light blue 0: Orange P: Pink R: Red L: Blue

Y: Yellow Lg: Light green

W: White

1 STB Revision

Page 82 of 284

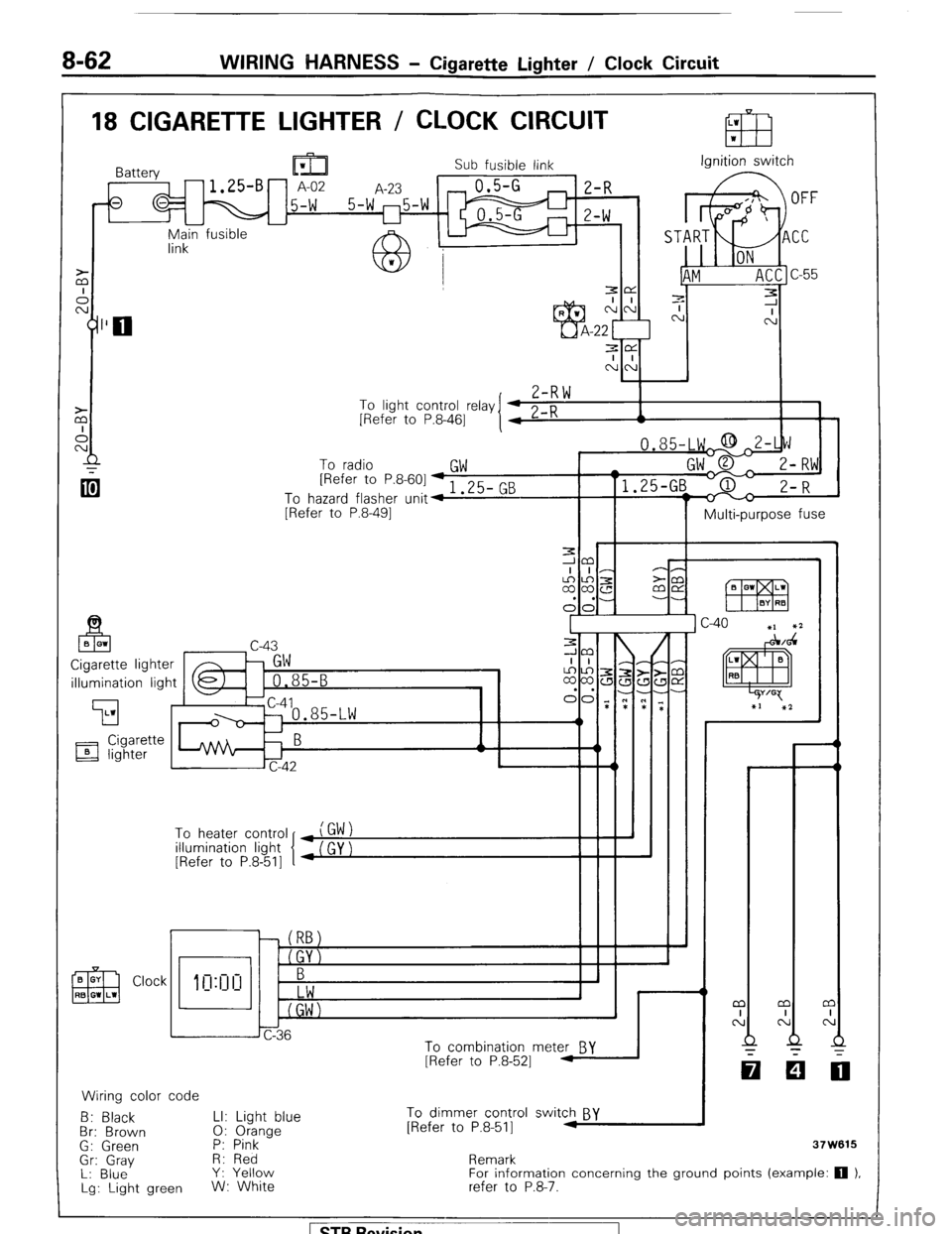

8-62 WIRING HARNESS - Cigarette Lighter / Clock Circuit

18 CIGARETTE LIGHTER / CLOCK CIRCUIT

Sub fusible link Ignition switch

r-l E-f? ‘) n

-u yn;in fusible

7-R \*I

To light control relay

[Refer to P.8-461

To radio

GW [Refer to P&601-, 3F- Pm

To hazard flasher unit4 I .LJ- G

[Refer to P.8-491

II I Multi-purpose fuse

illumination light

To heater control

illumination light

[Refer to P.8-511

Clock

CT

0: 1

h J

6

Jc-36

To combination mete& BY

[Refer to P.8-521 1

Wiring color code

B: Black LI: Light blue To dimmer control switch BY

Br: Brown 0: Orange [Refer to P.8-511 M

G: Green P: Pink

-

Gr: Gray H: Red

L: Blue Y: Yellow

Lg: Light green W: White Remark

For information concerning the ground points (example: 0 1,

refer to P.8-‘7.

Page 90 of 284

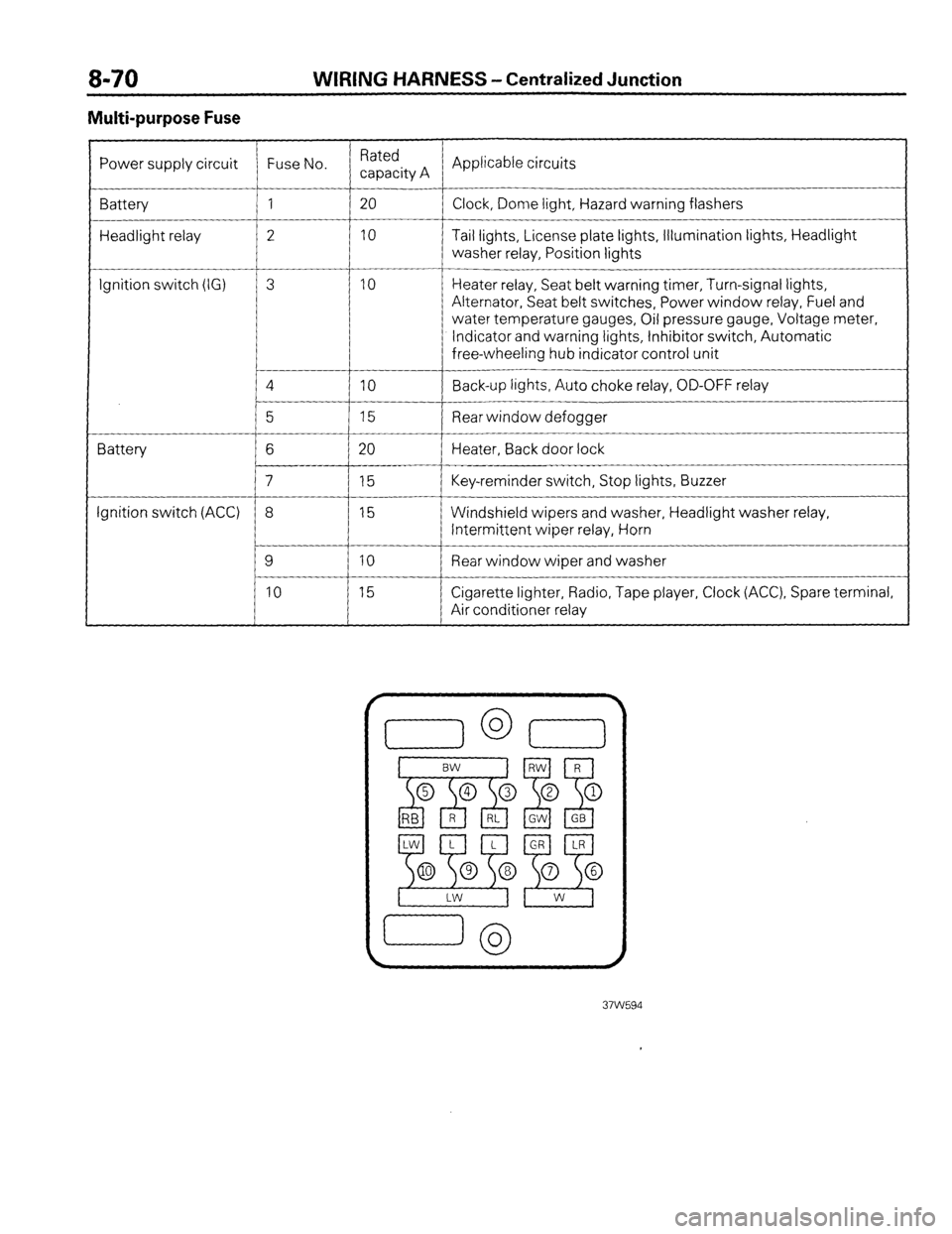

WIRING HARNESS - Centralized Junction

Multi-purpose Fuse

Power supply circuit Fuse No. Rated

capacity A Applicable circuits

Battery 1 20

Clock, Dome light, Hazard warning flashers

Headlight relay 2 10 Tail lights, License plate lights, Illumination lights, Headlight

washer relay, Position lights

__-

Ignition switch (IG) 3 10 Heater relay, Seat belt warning timer, Turn-signal lights,

Alternator, Seat belt switches, Power window relay, Fuel and

water temperature gauges, Oil pressure gauge, Voltage meter,

Indicator and warning lights, Inhibitor switch, Automatic

free-wheeling hub indicator control unit

4

IO Back-up lights, Auto choke relay, OD-OFF relay

__-

5 15 Rear window defogger

Battery 6 20 Heater, Back door lock

7 15 Key-reminder switch, Stop lights, Buzzer

Ignition switch (ACC) 8 15 Windshield wipers and washer, Headlight washer relay,

Intermittent wiper relay, Horn

9 10 Rear window wiper and washer

10 15 Cigarette lighter, Radio, Tape player, Clock (ACC), Spare terminal,

Air conditioner relay

Page 208 of 284

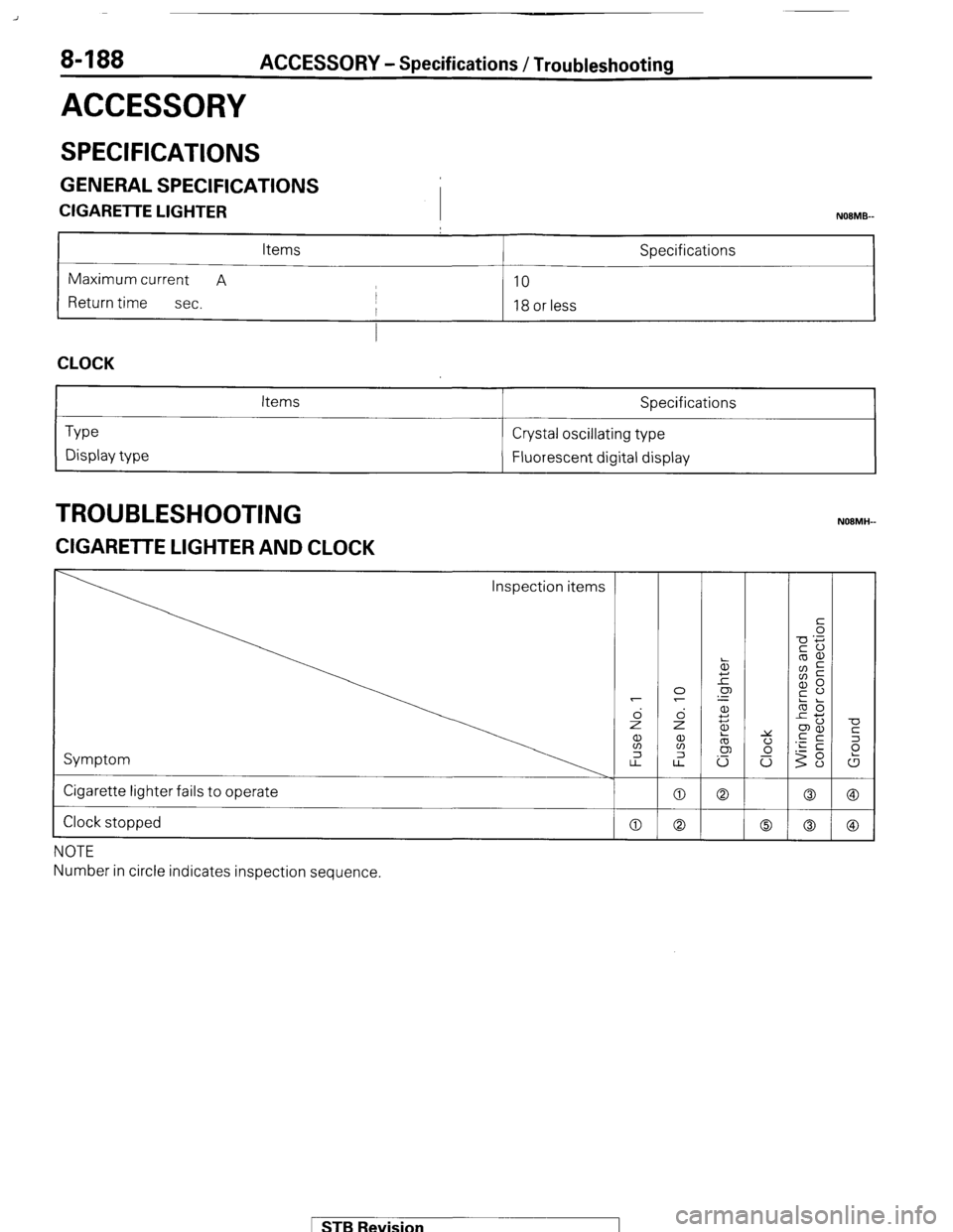

8-188 ACCESSORY - Specifications / Troubleshooting

ACCESSORY

SPECIFICATIONS

GENERAL SPECIFICATIONS

CIGARETTE LIGHTER

I NOBMB-

Items Specifications

Maximum current A

10

Return time

sec. I

I 18 or less

I

CLOCK

Type

Display type Items Specifications

Crystal oscillating type

Fluorescent digital display

TROUBLESHOOTING

ZIGARETTE LIGHTER AND CLOCK

Inspection items

Symptom

Cigarette lighter fails to operate

Clock stopped

NOTE

Number in circle indicates inspection sequence.

MB Revision

Page 209 of 284

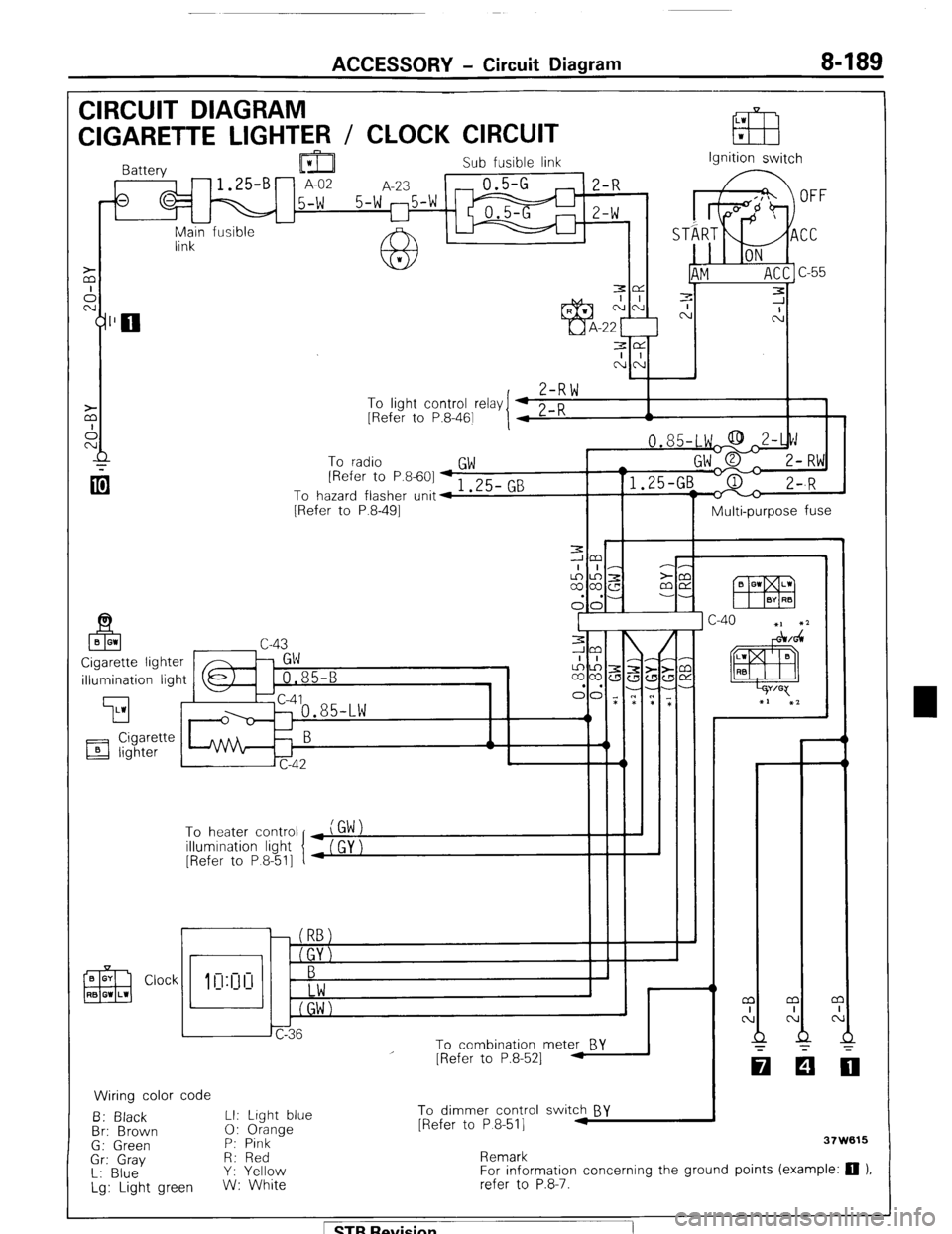

ACCESSORY - Circuit Diagram 8-189

CIRCUIT DIAGRAM

LW

CIGARETTE LIGHTER / CLOCK CIRCUIT EB w

Sub fusible link

,-fs q M 15-W 5-W 25-W m ;I;

I I

-

Main fusible -

link Ignition switch

3e

I I

NN

,

Z-RW To

linht cnntrnl r&v I 4 0 n

I 1 - .J . __._ - -., [Refer to P.8-461

I 4 L-K A

To radio

GW [Refer to P.8-601 + 1 .25- GB

To hazard flasher unit4

[Refer to P.8-491

Multi-purpose fuse

illumination light

’ To heater control

illumination light

[Refer to P 8-511

r

i I

To combination meter BY

Wiring color code

B: Black LI: Light blue

Br: Brown 0: Orange

G: Green P: Pink

Gr: Gray R: Red

L: Blue Y: Yellow

Lg: Light green W: White

I

I - - m

I

N

Q

-

[Refer to P.8-521 -

To dimmer control switch BY

[Refer to P 8-511 .I

Remark 37W615

For information concerning the ground points (example: 0 ).

refer to P.8-7.

1 STB Revision

Page 211 of 284

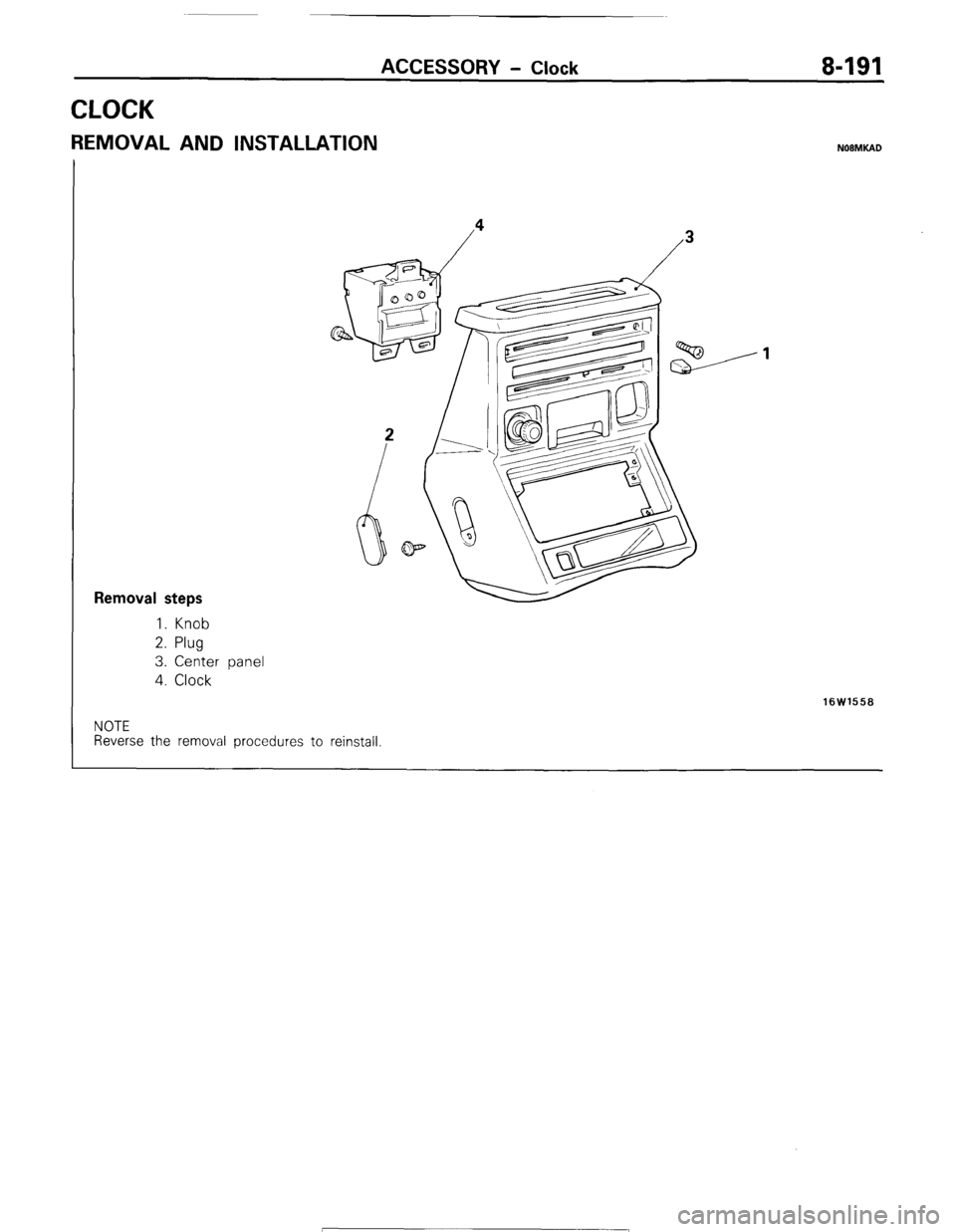

ACCESSORY - Clock 8-191

CLOCK

REMOVAL AND INSTALLATION NOBMKAD

Removal steps

1. Knob

2. Plug

3. Center panel

4. Clock

16W1558

NOTE

Reverse the removal procedures to reinstall 1 STB Revision

Page 216 of 284

8-196 AUDIO SYSTEM - Service Adjustment Procedures

SERVICE ADJUSTMENT PROCEDURES

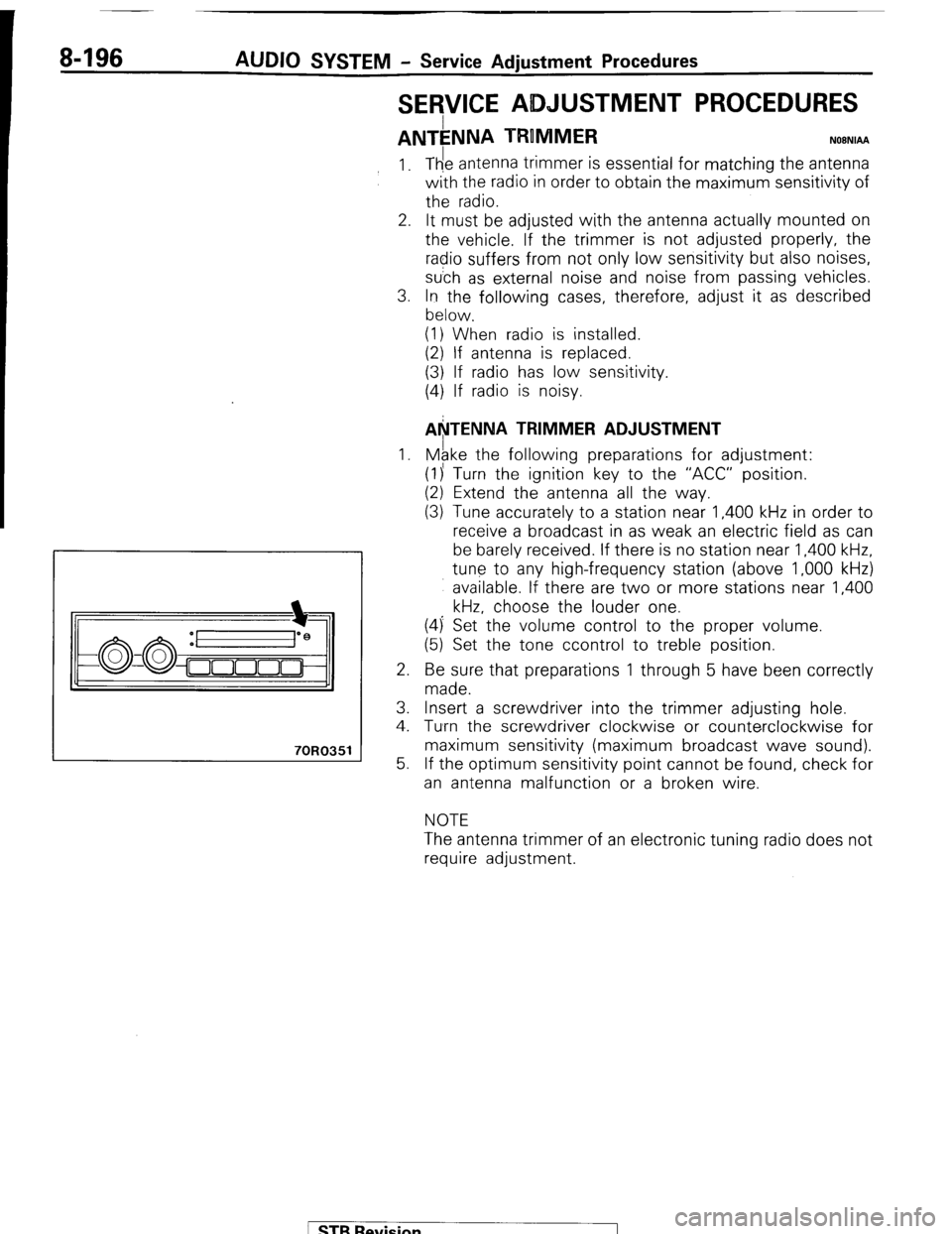

ANTkNNA TRUMMER NOBNIAA

70R0351

1.

2.

3.

1.

2.

3.

4.

5. The antenna trimmer is essential for matching the antenna

with the radio in order to obtain the maximum sensitivity of

the radio.

It must be adjusted with the antenna actually mounted on

the vehicle. If the trimmer is not adjusted properly, the

radio suffers from not only low sensitivity but also noises,

su’ch as external noise and noise from passing vehicles.

In the following cases, therefore, adjust it as described

below.

(1) When radio is installed.

(2) If antenna is replaced.

(3) If radio has low sensitivity.

(4) If radio is noisy.

AkTENNA TRIMMER ADJUSTMENT

Mgke the following preparations for adjustment:

(1)’ Turn the ignition key to the “ACC” position.

(2) Extend the antenna all the way.

(3) Tune accurately to a station near 1,400 kHz in order to

receive a broadcast in as weak an electric field as can

be barely received. If there is no station near 1,400 kHz,

tune to any high-frequency station (above 1,000 kHz)

available. If there are two or more stations near 1,400

kHz, choose the louder one.

(4) Set the volume control to the proper volume.

(5) Set the tone ccontrol to treble position.

Be sure that preparations 1 through 5 have been correctly

made.

Insert a screwdriver into the trimmer adjusting hole.

Tumrn the screwdriver clockwise or counterclockwise for

maximum sensitivity (maximum broadcast wave sound).

If the optimum sensitivity point cannot be found, check for

an antenna malfunction or a broken wire.

NOTE

The antenna trimmer of an electronic tuning radio does not

require adjustment.

/ STB Revision

Page 269 of 284

AIR-CONDITIONING-Service Adjustment Procedures 24-33

2080113

6

Refrigerant

Compressor

Cl”“” tester T-7

Leak

, tester

pick up

tube

b/

2OUO316

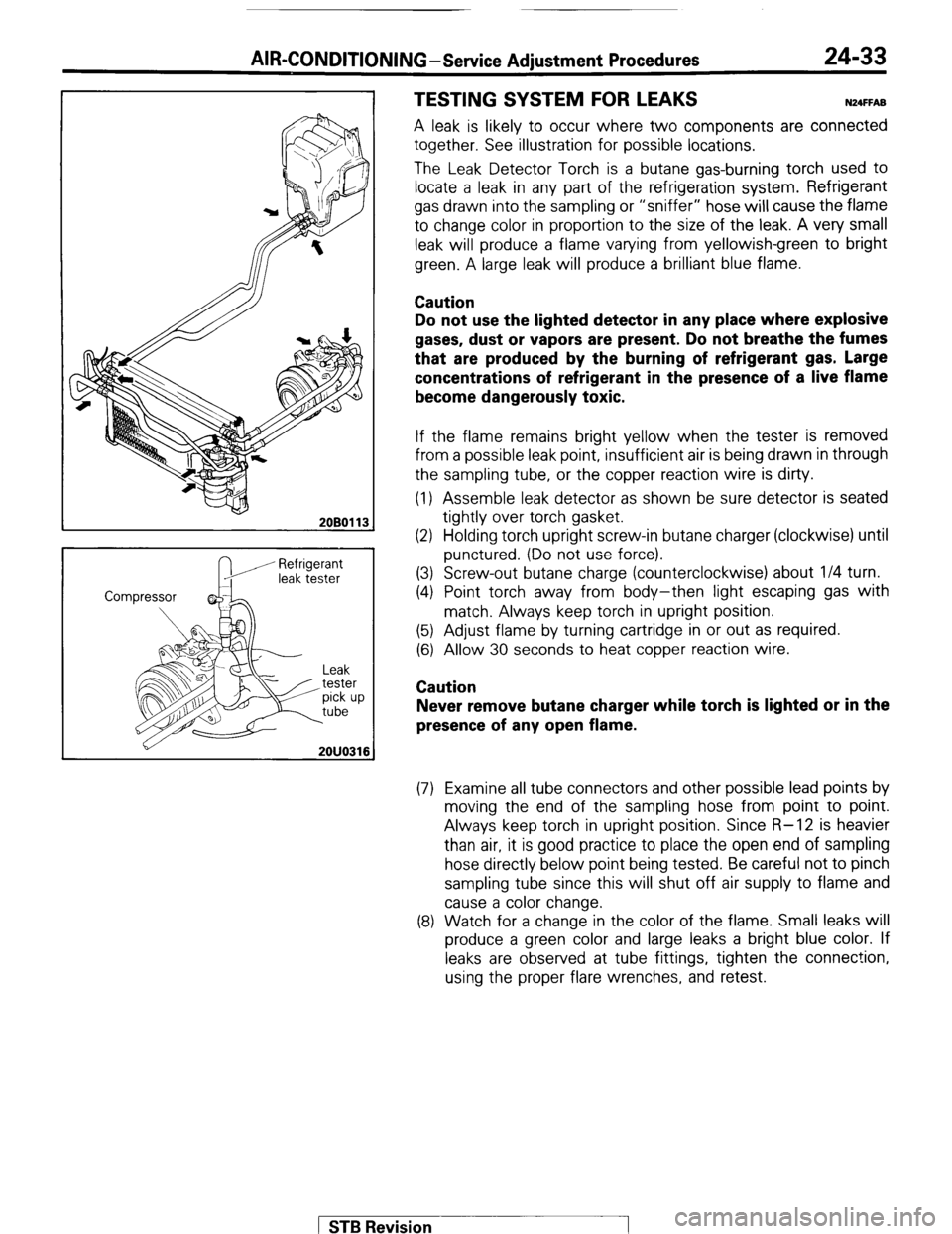

TESTING SYSTEM FOR LEAKS N24FFA8

A leak is likely to occur where two components are connected

together. See illustration for possible locations.

The Leak Detector Torch is a butane gas-burning torch used to

locate a leak in any part of the refrigeration system. Refrigerant

gas drawn into the sampling or “sniffer” hose will cause the flame

to change color in proportion to the size of the leak. A very small

leak will produce a flame varying from yellowish-green to bright

green. A large leak will produce a brilliant blue flame.

Caution

Do not use the lighted detector in any place where explosive

gases, dust or vapors are present. Do not breathe the

fumes

that are produced by the burning of refrigerant gas. Large

concentrations of refrigerant in the presence of a live flame

become dangerously toxic.

If the flame remains bright yellow when the tester is removed

from a possible leak point, insufficient air is being drawn in through

the sampling tube, or the copper reaction wire is dirty.

(1) Assemble leak detector as shown be sure detector is seated

tightly over torch gasket.

(2) Holding torch upright screw-in butane charger (clockwise) until

punctured. (Do not use force).

(3) Screw-out butane charge (counterclockwise) about l/4 turn.

(4) Point torch away from body-then light escaping gas with

match. Always keep torch in upright position.

(5) Adjust flame by turning cartridge in or out as required.

(6) Allow 30 seconds to heat copper reaction wire.

Caution

Never remove butane charger while torch is lighted or in the

presence of any open flame.

(7) Examine all tube connectors and other possible lead points by

moving the end of the sampling hose from point to point.

Always keep torch in upright position. Since R-12 is heavier

than air, it is good practice to place the open end of sampling

hose directly below point being tested. Be careful not to pinch

sampling tube since this will shut off air supply to flame and

cause a color change.

(8) Watch for a change in the color of the flame. Small leaks will

produce a green color and large leaks a bright blue color. If

leaks are observed at tube fittings, tighten the connection,

using the proper flare wrenches, and retest.

1 STB Revision