light MITSUBISHI MONTERO 1987 1.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 30 of 284

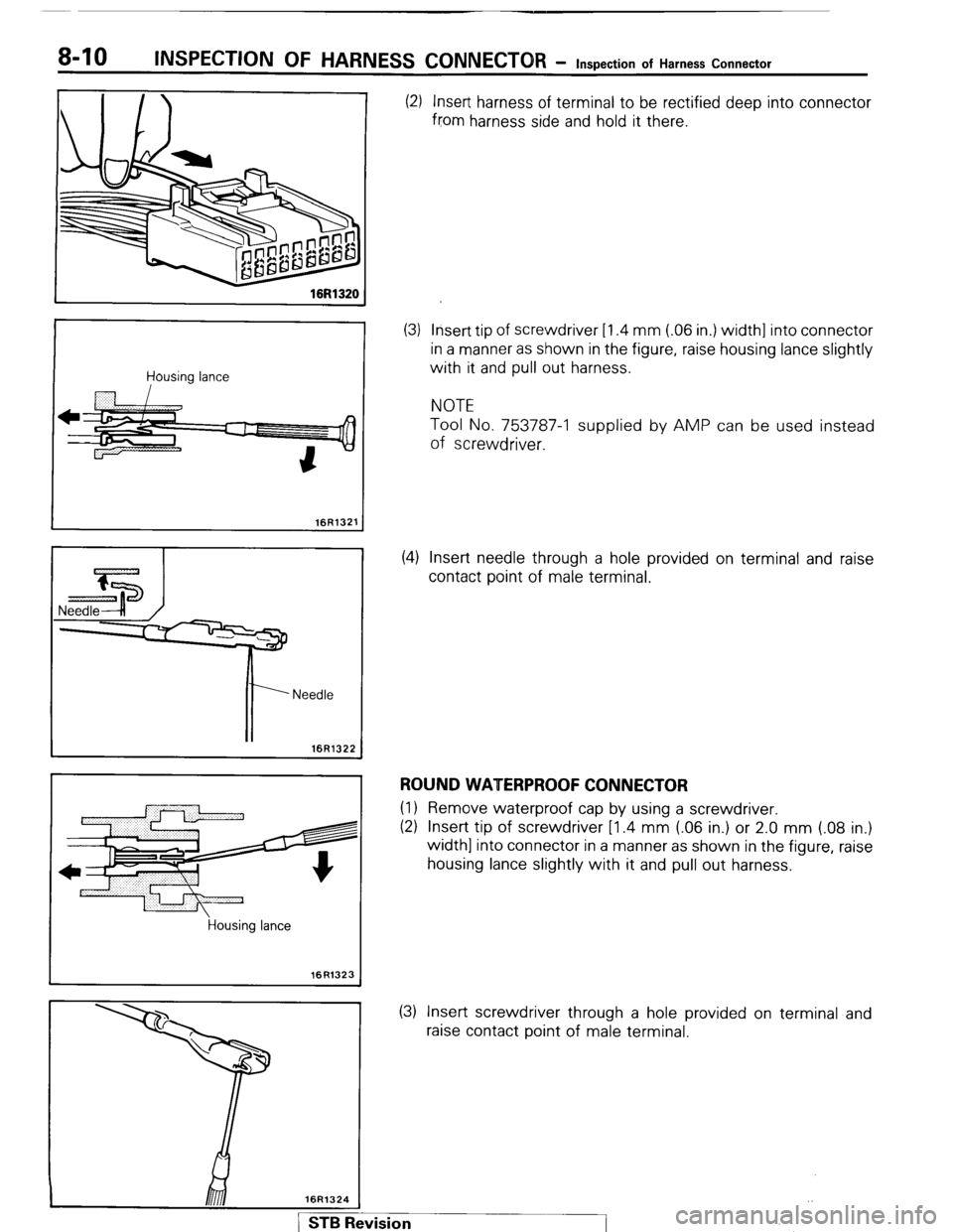

8-10 INSPECTION OF HARNESS CONNECTOR - Inspection of Harness Connector

Housing lance

-5

1 16R1321

’ Needle

16Ffi322

Housing lance

16R1323 (2) Insert harness of terminal to be rectified deep into connector

from harness side and hold it there.

(3) Insert tip of screwdriver [1.4 mm (.06 in.) width] into connector

in a manner as shown in the figure, raise housing lance slightly

with it and pull out harness.

NOTE

Tool No. 753787-l supplied by AMP can be used instead

of screwdriver.

(4) Insert needle through a hole provided on terminal and raise

contact point of male terminal.

ROUND WATERPROOF CONNECTOR (1) Remove waterproof cap by using a screwdriver.

(2) Insert tip of screwdriver [1.4 mm (.06 in.) or 2.0 mm (.08 in.)

width] into connector in a manner as shown in the figure, raise

housing lance slightly with it and pull out harness.

(3) Insert screwdriver through a hole provided on terminal and

raise contact point of male terminal.

Page 31 of 284

INSPECTION OF HARNESS CONNECTOR - Inspection of Harness Connector 8-71

RECTANGULAR WATERPROOF CONNECTOR

(1) Disengage front holder by using a screwdriver and remove it.

(2) Insert tip of screwdriver [*0.8 mm (03 in.) width] into connec-

tor in a manner as shown in the figure, push it lightly to raise

housing lancer and pull out harness.

*If right size screwdriver is not available, convert a conven-

tional driver to suit the size.

Housing lance

16R13 26

16R1329

L 16R1326)

(2)

Terminal lance

16Rl330

1 STB Revision (3) Press contact point of male terminal down by holding a screw-

driver [1.4 mm (.06 in.) width] in a manner as shown in the

figure.

INJECTOR CONNECTOR

(1) Remove waterproof cap.

Insert tip of screwdriver [1.4

in a manner as shown in the

pull out harness. mm (06 in.) width] into connector

figure, press in terminal lance and

Page 34 of 284

8-14 WIRING HARNESS - Troubleshooting

1680222

Changeover knob 1680224

1680225 1

1680226

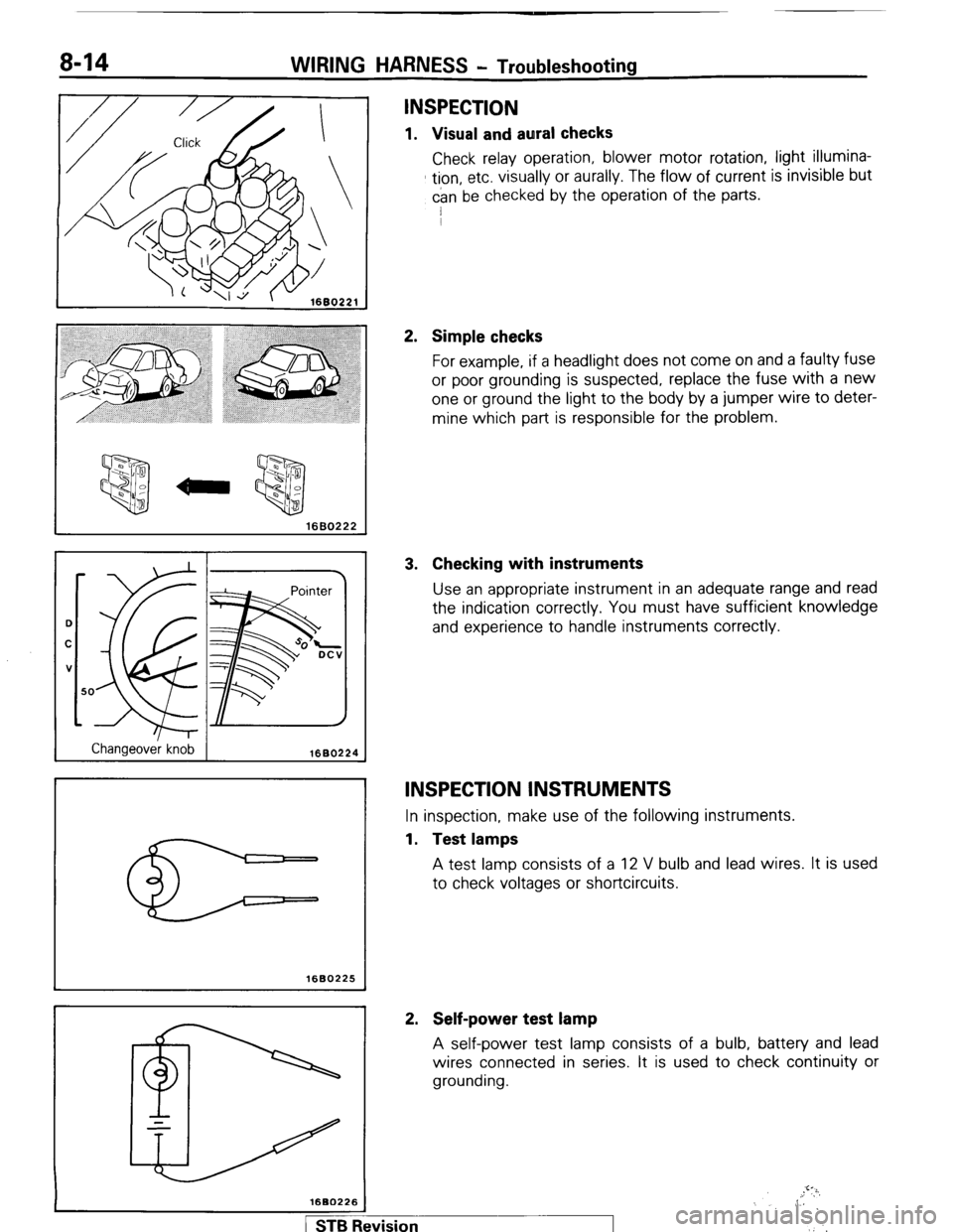

INSPECTION

1. Visual and aural checks

Check relay operation, blower motor rotation, light illumina-

tion, etc. visually or aurally. The flow of current is invisible but

can be checked by the operation of the parts.

I

2. Simple checks

For example, if a headlight does not come on and a faulty fuse

or poor grounding is suspected, replace the fuse with a new

one or ground the light to the body by a jumper wire to deter-

mine which part is responsible for the problem.

3. Checking with instruments

Use an appropriate instrument in an adequate range and read

the indication correctly. You must have sufficient knowledge

and experience to handle instruments correctly.

INSPECTION INSTRUMENTS

In inspection, make use of the following instruments.

1. Test lamps

A test lamp consists of a 12 V bulb and lead wires. It is used

to check voltages or shortcircuits.

2. Self-power test lamp

A self-power test lamp consists of a bulb, battery and lead

wires connected in series. It is used to check continuity or

grounding.

,.!‘?i,

,, 6

,‘.’

1 STB Revision

Page 36 of 284

8-16 WIRING HARNESS - Troubleshooting

OFF

1st stage

2nd stage

3rd stage

1

--_

4th stage

1660230

16W896

Cover

Coil

Iron

piece Spring

Iron

core

Contact

1660231

I

l-

Battery:

I

-

d

T Relav

T I

I 1660232 1

Normal ooen (NO) tvoe

Deenergized state Energized state

I

1

2

ED

3

4

1 2

BP

3

4

1 YZZZw;6B0233 CurreZ! not flow

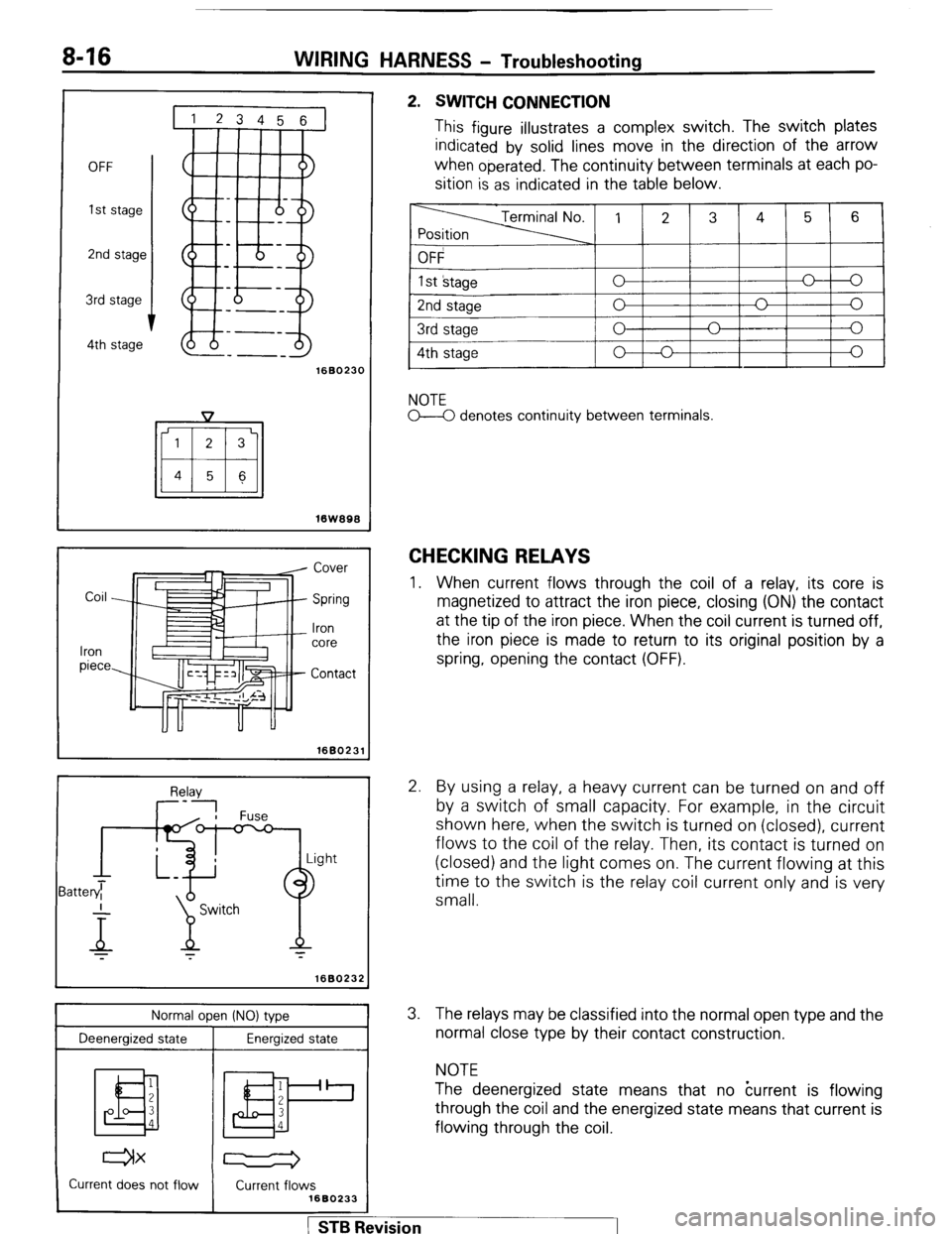

2. SWITCH CONNECTION

This figure illustrates a complex switch. The switch plates

indicated by solid lines move in the direction of the arrow

when

operated. The continuity between terminals at each po-

sition is as indicated in the table below.

NOTE

M denotes continuity between terminals.

CHECKING RELAYS

1. When current flows through the coil of a relay, its core is

magnetized to attract the iron piece, closing (ON) the contact

at the tip of the iron piece. When the coil current is turned off,

the iron piece is made to return to its original position by a

spring, opening the contact (OFF).

2. By using a relay, a heavy current can be turned on and off

by a switch of small capacity. For example, in the circuit

shown here, when the switch is turned on (closed), current

flows to the coil of the relay. Then, its contact is turned on

(closed) and the light comes on. The current flowing at this

time to the switch is the relay coil current only and is very

small.

3. The relays may be classified into the normal open type and the

normal close type by their contact construction.

NOTE

The deenergized state means that no kurrent is flowing

through the coil and the energized state means that current is

flowing through the coil.

J . . . I 1 STB Revmon

Page 37 of 284

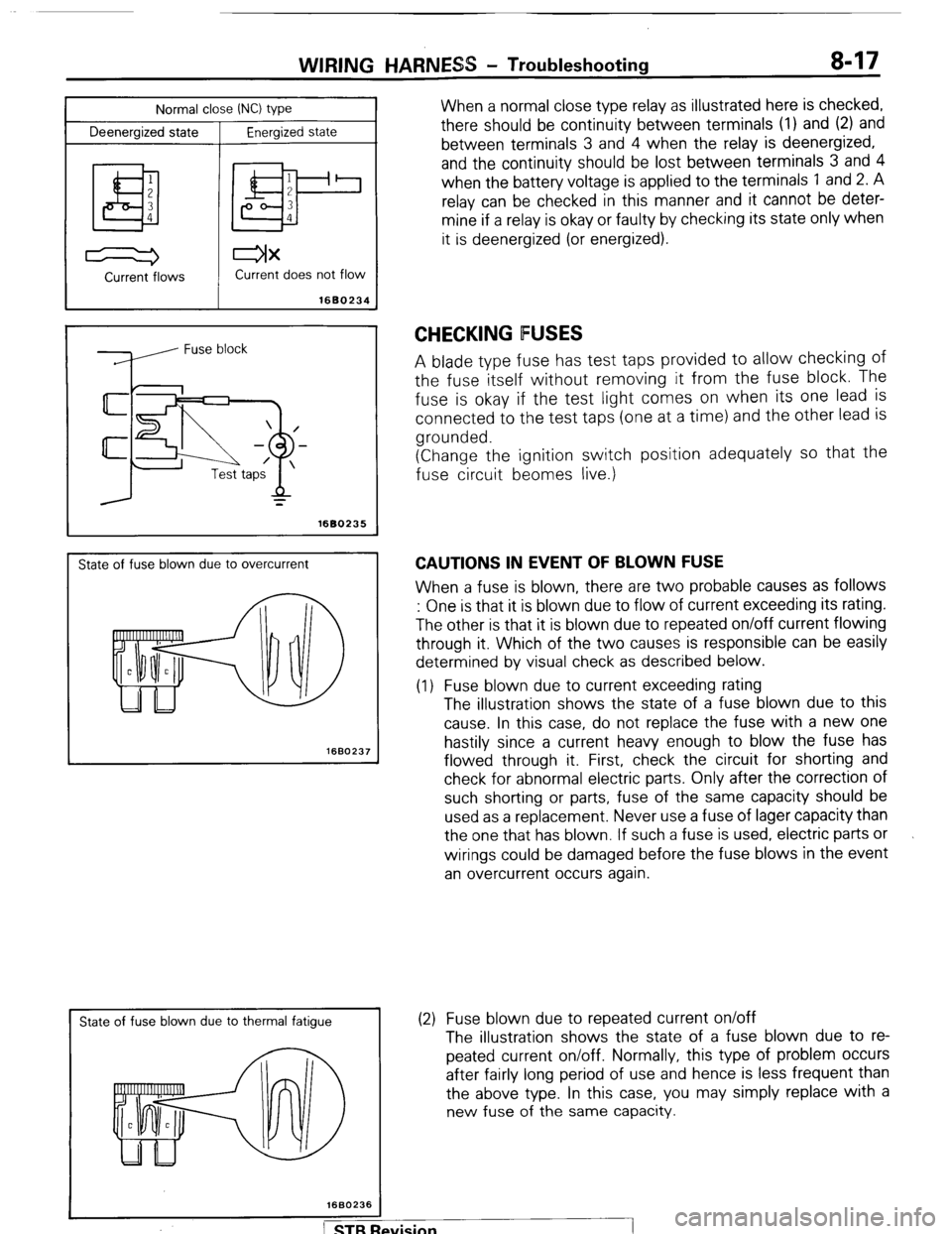

Normal close INC) type

Deenergized state

Energized state

I

WIRING HARNESS - Troubleshooting 8-17

When a normal close type relay as illustrated here is checked,

there should be continuity between terminals (1) and (2) and

between terminals 3 and 4 when the relay is deenergized,

and the continuity should be lost between terminals 3 and 4

when the battery voltage is applied to the terminals 1 and 2. A

relay can be checked in this manner and it cannot be deter-

mine if a relay is okay or faulty by checking its state only when

it is deenergized (or energized).

Current -flows Current does not flow

1680234

=

1680235

State of fuse blown due to overcurrent

1660237

I

State of fuse blown due to thermal fatigue

CHECKING FUSES

A blade type fuse has test taps provided to allow checking of

the fuse itself without removing it from the fuse block. The

fuse is okay if the test light comes on when its one lead is

connected to the test taps (one at a time) and the other lead is

grounded.

(Change the ignition switch position adequately so that the

fuse circuit beomes live.)

CAUTIONS IN EVENT OF BLOWN FUSE

When a fuse is blown, there are two probable causes as follows

: One is that it is blown due to flow of current exceeding its rating.

The other is that it is blown due to repeated on/off current flowing

through it. Which of the two causes is responsible can be easily

determined by visual check as described below.

(1) Fuse blown due to current exceeding rating

The illustration shows the state of a fuse blown due to this

cause. In this case, do not replace the fuse with a new one

hastily since a current heavy enough to blow the fuse has

flowed through it. First, check the circuit for shorting and

check for abnormal electric parts. Only after the correction of

such shorting or parts, fuse of the same capacity should be

used as a replacement. Never use a fuse of lager capacity than

the one that has blown. If such a fuse is used, electric parts or

wirings could be damaged before the fuse blows in the event

an overcurrent occurs again.

(2) Fuse blown due to repeated current on/off

The illustration shows the state of a fuse blown due to re-

peated current on/off. Normally, this type of problem occurs

after fairly long period of use and hence is less frequent than

the above type. In this case, you may simply replace with a

new fuse of the same capacity.

Page 38 of 284

WIRING HARNESS - Troubleshooting

1660236

Power

supply

h

Fuse

ON

/----

/

/

Motor

1660239

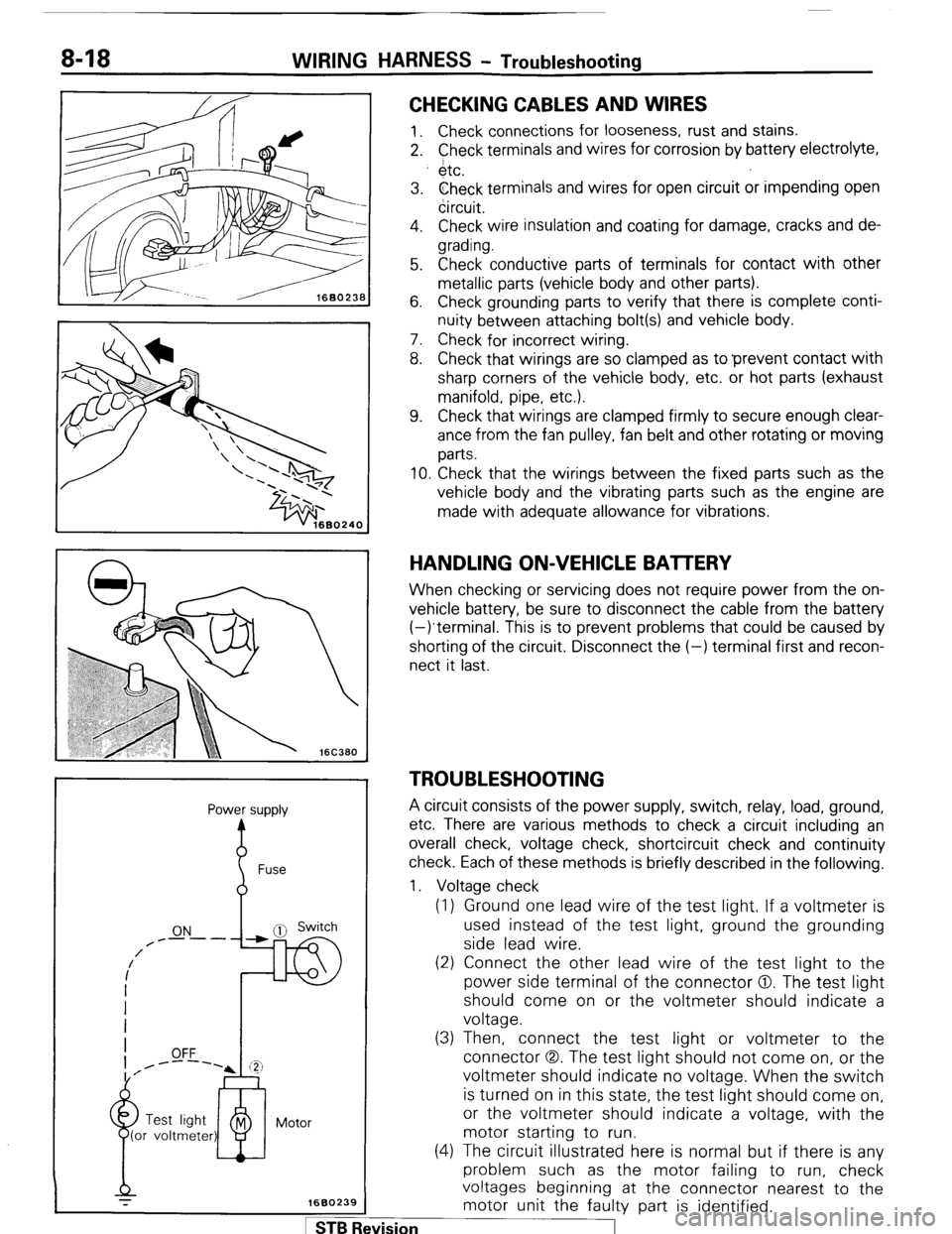

CHECKING CABLES AND WIRES

1. Check connections for looseness, rust and stains.

2. Check terminals and wires for corrosion by battery electrolyte,

$tc.

3. Check terminals and wires for open circuit or impending open

circuit.

4. Check wire insulation and coating for damage, cracks and de-

grading.

5. Check conductive parts of terminals for contact with other

metallic parts (vehicle body and other parts).

6. Check grounding parts to verify that there is complete conti-

nuity between attaching bolt(s) and vehicle body.

7. Check for incorrect wiring.

8. Check that wirings are so clamped as to ‘prevent contact with

sharp corners of the vehicle body, etc. or hot parts (exhaust

manifold, pipe, etc.).

9. Check that wirings are clamped firmly to secure enough clear-

ance from the fan pulley, fan belt and other rotating or moving

parts.

10. Check that the wirings between the fixed parts such as the

vehicle body and the vibrating parts such as the engine are

made with adequate allowance for vibrations.

HANDLING ON-VEHICLE BAlTERY

When checking or servicing does not require power from the on-

vehicle battery, be sure to disconnect the cable from the battery

(-)terminal. This is to prevent problems that could be caused by

shorting of the circuit. Disconnect the (-) terminal first and recon-

nect it last.

TROUBLESHOOTING

A circuit consists of the power supply, switch, relay, load, ground,

etc. There are various methods to check a circuit including an

overall check, voltage check, shortcircuit check and continuity

check. Each of these methods is briefly described in the following.

1. Voltage check

(1) Ground one lead wire of the test light. If a voltmeter is

used instead of the test light, ground the grounding

side lead wire.

(2) Connect the other lead wire of the test light to the

power side terminal of the connector 0. The test light

should come on or the voltmeter should indicate a

voltage.

(3) Then, connect the test light or voltmeter to the

connector (3,. The test light should not come on, or the

voltmeter should indicate no voltage. When the switch

is turned on in this state, the test light should come on,

or the voltmeter should indicate a voltage, with the

motor starting to run.

(4) The circuit illustrated here is normal but if there is any

problem such as the motor failing to run, check

voltages beginning at the connector nearest to the

motor unit the faulty part is identified. 1 ST6 Revision

Page 39 of 284

WIRING HARNESS - Troubleshooting 8-19

Test

light Power supply

Fuse block

(remove fuse)

r’TJ Switch

?

Illumination light

4, 1680241

Self power test light Switch

ON

OFF

1680242

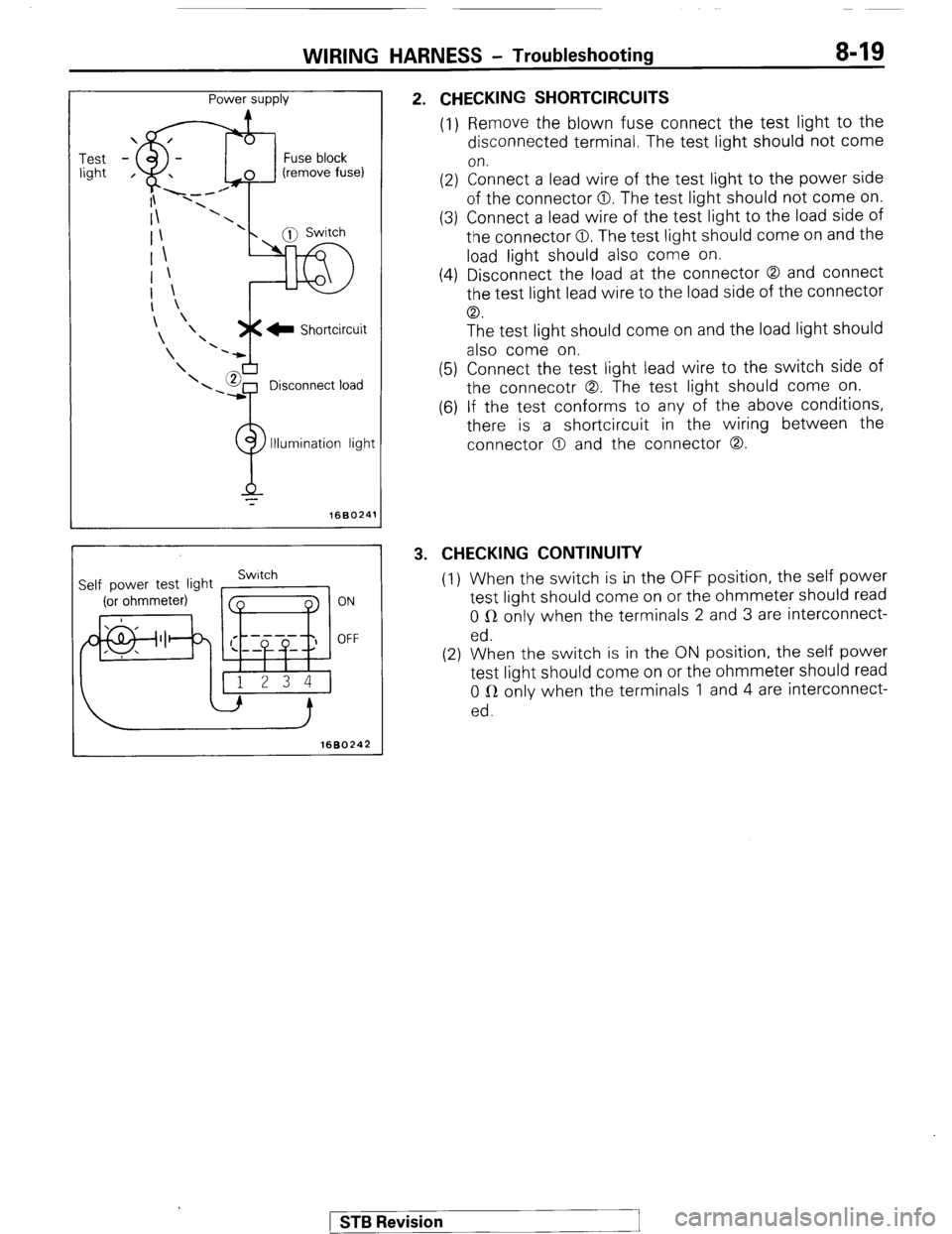

2. CHECKING SHORTCIRCUITS

(1) Remove the blown fuse connect the test light to the

disconnected terminal. The test light should not come

on.

(2) Connect a lead wire of the test light to the power side

of the connector 0. The test light should not come on.

(3) Connect a lead wire of the test light to the load side of

the connector 0. The test light should come on and the

load light should also come on.

(4) Disconnect the load at the connector 0 and connect

the test light lead wire to the load side of the connector

CD.

The test light should come on and the load light should

also come on.

(5) Connect the test light lead wire to the switch side of

the connecotr 0. The test light should come on.

(6) If the test conforms to any of the above conditions,

there is a shortcircuit in the wiring between the

connector 0 and the connector 0.

3. CHECKING CONTINUITY

(I) When the switch is in the OFF position, the self power

test light should come on or the ohmmeter should read

0 R only when the terminals 2 and 3 are interconnect-

ed.

(2) When the switch is in the ON position, the self power

test light should come on or the ohmmeter should read

0 LR only when the terminals 1 and 4 are interconnect-

ed.

) STB Revision

Page 42 of 284

8-22 WIRING HARNESS - How to Read Wiring Diagrams

HOW TO READ CIRCUIT DIAGRAMS

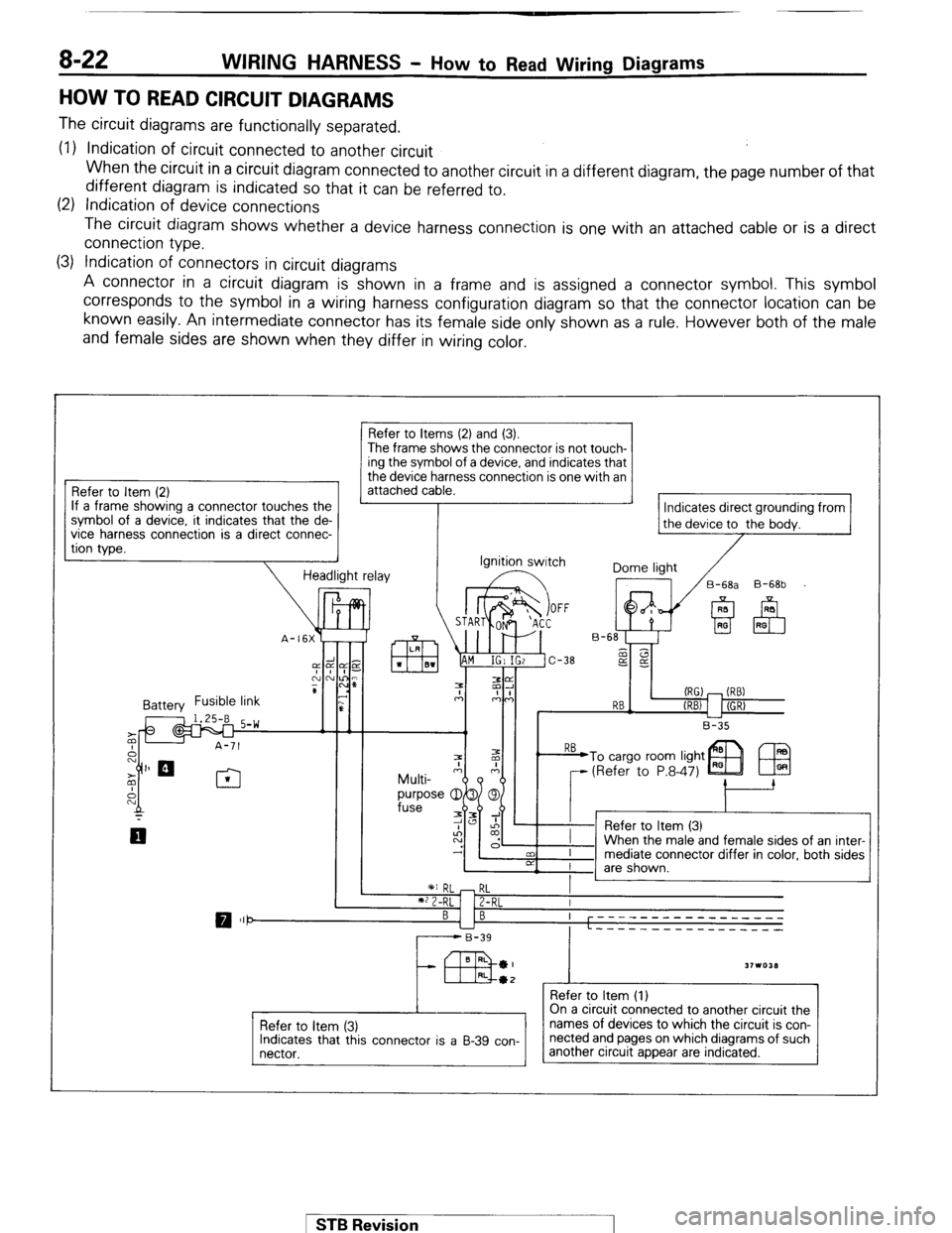

The circuit diagrams are functionally separated.

(1) Indication of circuit connected to another circuit

When the circuit in a circuit diagram connected to another circuit in a different diagram, the page number of that

different diagram is indicated so that it can be referred to.

(2) Indication of device connections

The circuit diagram shows whether a device harness connection is one with an attached cable or is a direct

connection type.

(3) Indication of connectors in circuit diagrams

A connector in a circuit diagram is shown in a frame and is assigned a connector symbol. This symbol

corresponds to the symbol in a wiring harness configuration diagram so that the connector location can be

known easily. An intermediate connector has its female side only shown as a rule. However both of the male

and female sides are shown when they differ in wiring color.

Refer to Item (2)

If a frame showing a connector touches the

?. it indicates that the de-

a direct connec- symbol of a device

vice

harness connectlon IS

tion type.

Refer to Items (2) and (3).

The frame shows the connector is not touch- ing the symbol of a device, and indicates that

the device harness connection is one with an

attached cable.

Indicates direct grounding from

the device to the bodv.

Ignition switch

Dome light

/

17 /B-6& B-68b

(RG) - (RB)

RB-

(REV 1 I (GR)

L-2

B-35

1 *I RL - RL

I

**2-RL 1 Z-RL I

BI B ----- ---- --------

L ----_ __---___----

r------B-39

43 BRL *I

31103LI RL*2 _

Refer to Item (1)

Refer to item (3)

Indicates that this connector is a B-39 con-

nectar. On a circuit connected to another circuit the

names of devices to which the circuit is con-

nected and pages on which diagrams of such

another circuit appear are indicated.

1 STB Revision 1

Page 43 of 284

WIRING HARNESS - HOW BO Read Wiring Diagrams 8-23

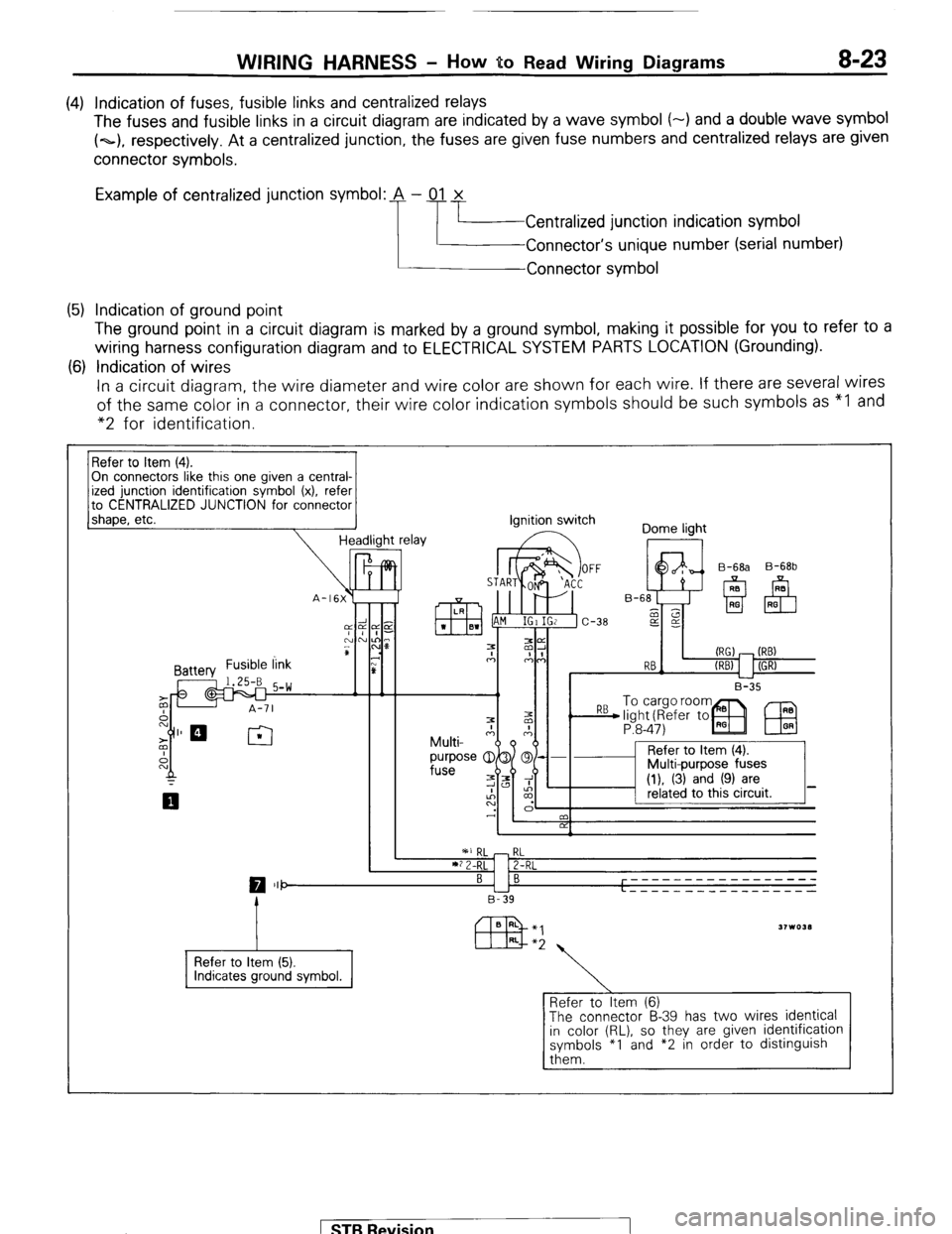

(4) Indication of fuses, fusible links and centralized relays

The fuses and fusible links in a circuit diagram are indicated by a wave symbol (-) and a double wave symbol

(~1, respectively. At a centralized junction, the fuses are given fuse numbers and centralized relays are given

connector symbols.

Example of centralized junction symbol: A - 01 x

Centralized junction indication symbol

Connector’s unique number (serial number)

Connector symbol

(5) Indication of ground point

The ground point in a circuit diagram is marked by a ground symbol, making it possible for you to refer to a

wiring harness configuration diagram and to ELECTRICAL SYSTEM PARTS LOCATION (Grounding).

(6) Indication of wires

In a circuit diagram, the wire diameter and wire color are shown for each wire. If there are several wires

of the same color in a connector, their wire color indication symbols should be such symbols as “I and

“2 for identification.

On connectors like this one given a central-

to CENTRALIZED JUNCTION for connector

1 shaoe. etc.

-I Headlight relay ignition switch

Dome light

I II I B-35 B-68b

P:8-47)

IEU

I ’ 2 I

RL

2-RL

0 III- BI B -----____________

L - - - - - _ _ _ _ _ __ _ _ _ _ _

B-39

Refer to Item (5).

Refer to Item (6)

The connector B-39 has two wires identical

in color (RL), so they are given identification

symbols *I and *2 in order to distinguish

them. 1 ST6 Revision

Page 44 of 284

8-24 WIRING HARNESS - How to Read Wiring Diagrams

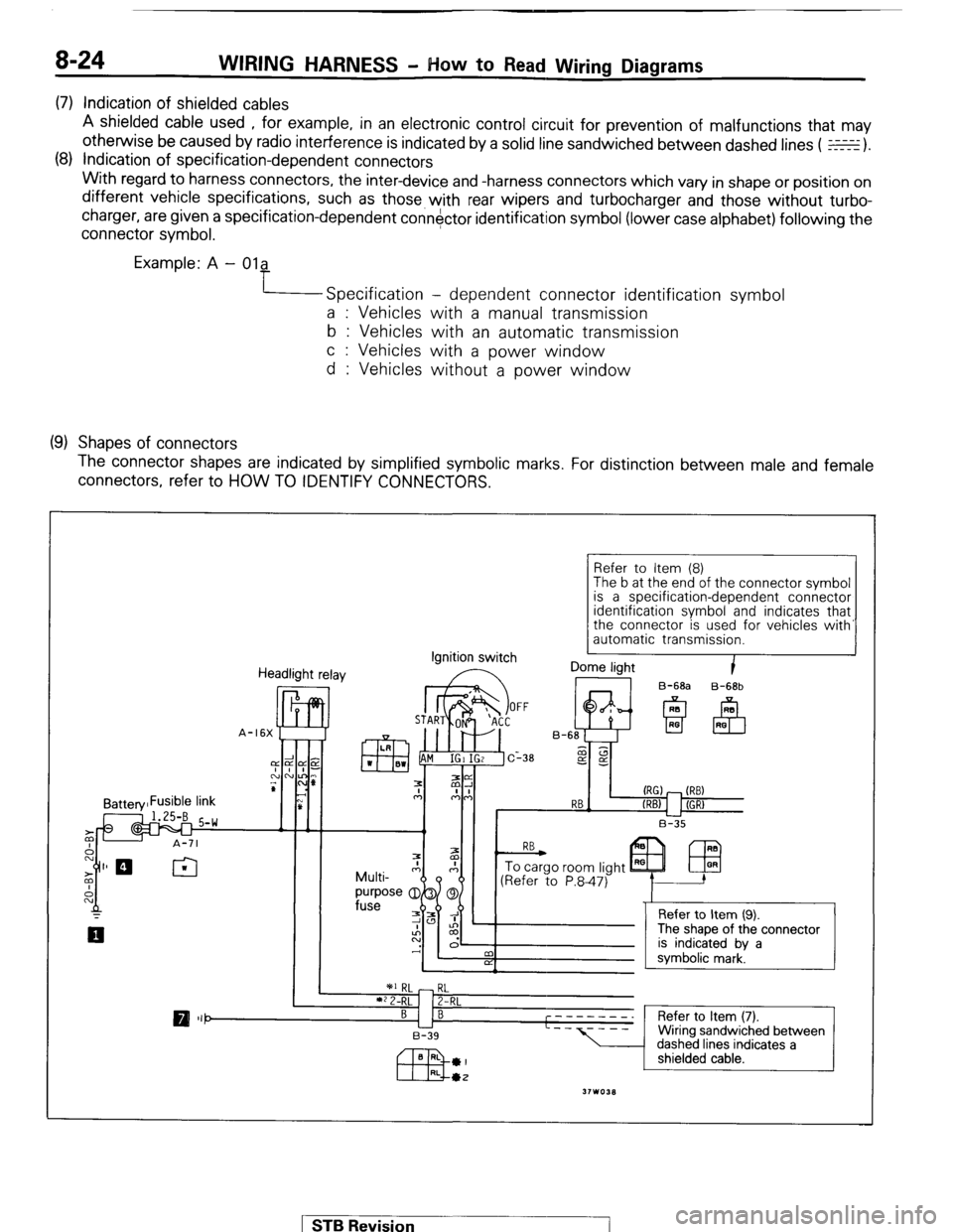

(7) Indication of shielded cables

A shielded cable used , for example, in an electronic control circuit for prevention of malfunctions that may

otherwise be caused by radio interference is indicated by a solid line sandwiched between dashed lines ( E).

(8) Indication of specification-dependent connectors

With regard to harness connectors, the inter-device and -harness connectors which vary in shape or position on

different vehicle specifications, such as those with rear wipers and turbocharger and those without turbo-

charger, are given a specification-dependent connector identification symbol (lower case alphabet) following the

connector symbol.

Example: A - Ola

Specification - dependent connector identification symbol

a : Vehicles with a manual transmission

b : Vehicles with an automatic transmission

c : Vehicles with a power window

d : Vehicles without a power window

(9) Shapes of connectors

The connector shapes are indicated by simplified symbolic marks. For distinction between male and female

connectors, refer to HOW TO IDENTIFY CONNECTORS.

Refer to Item (8)

The b at the end of the connector symbol

is a specification-dependent connector

identification

symbol and indicates that

the connector is used for vehicles with’

automatic transmission.

Headlight relay Ignition

switch I Dome light

B-68a B-68b STB Revision