lock MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 6 of 284

6 INTRODUCTION - Vehicle Identification

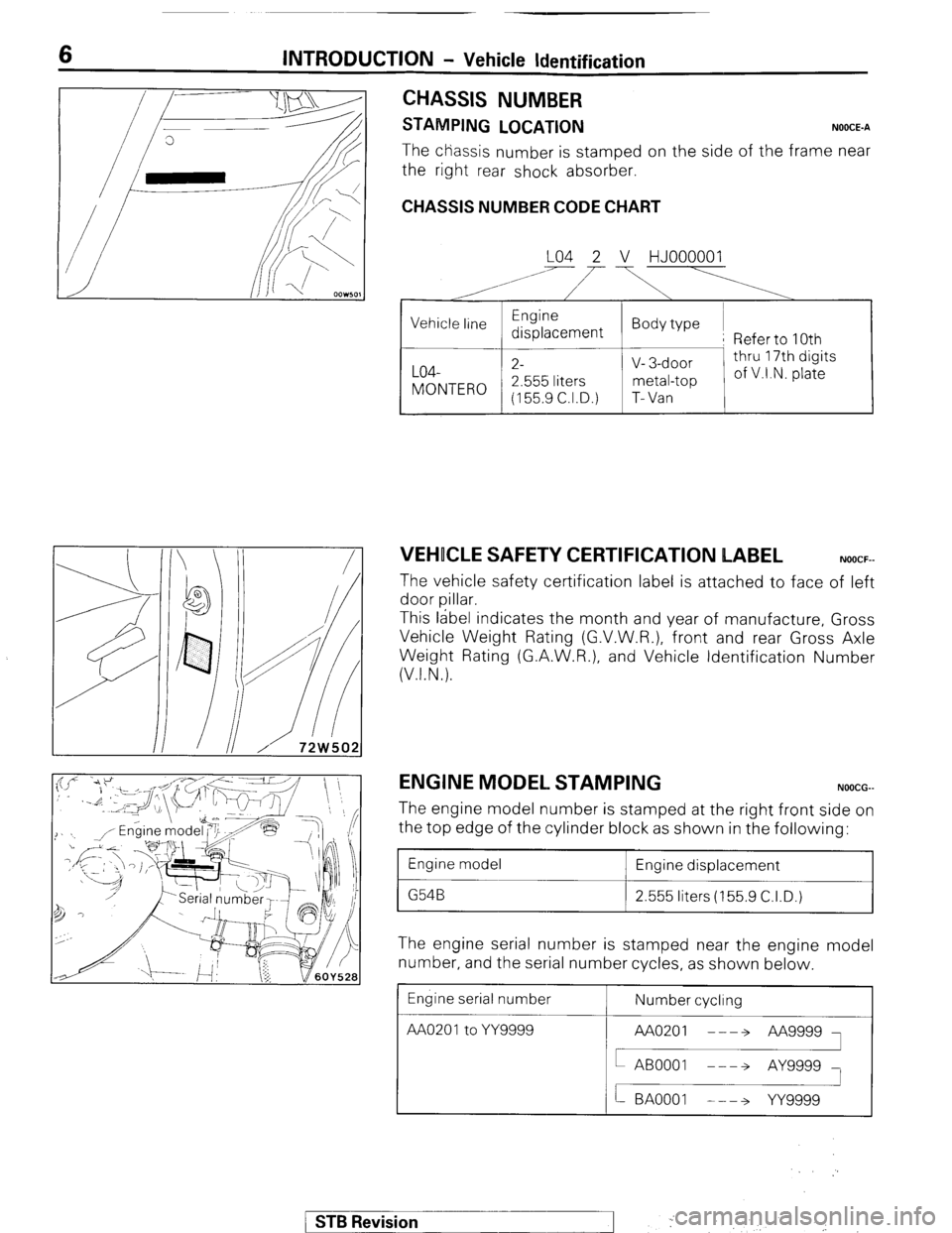

CHASSIS NUMBER

STAMPING LOCATION NOOCE-A

The chassis number is stamped on the side of the frame near

the right rear shock absorber.

CHASSIS NUMBER CODE CHART

LO4 2 V HJOOOOOl

A’ i’

,

VEHICLE SAFETY CERTIFICATION LABEL NOOCF-

The vehicle safety certification label is attached to face of left

door pillar.

This label indicates the month and year of manufacture, Gross

Vehicle Weight Rating (G.V.W.R.), front and rear Gross Axle

Weight Rating (G.A.W.R.), and Vehicle Identification Number

(V.I.N.).

ENGINE MODEL STAMPING NOOCG-

The engine model number is stamped at the right front side on

the top edge of the cylinder block as shown in the following:

1 Engine model

1 Engine displacement

1 2.555 liters (155.9 C.I.D.)

The engine serial number is stamped near the engine model

number, and the serial number cycles, as shown below

Engine serial number

AA020’toYY= Number cycling

/ STB Revision

--I f ,. ..-.

j ‘. .,

Page 8 of 284

8 INTRODUCTION - Precautions Before Service

r oorn,

FOOOl;

FOOOl8

PRECAUTIONS BEFORE SERVICE

PROTECTIN” THE VEHICLE NOODAAC

If theIre is a likelihood of damaging painted or interior parts

during service operations, protect them with suitable covers

(such as seat covers. fender covers, etc.).

REMOVAL AND DISASSEMBLY

When checking a malfunction, find the cause of the problem.

If it is determined that removal and/or disassembly is neces-

sary, perform the work by following the procedures contained

in this, Workshop Manual.

If punch marks or mating marks are made to avoid error in

assembly and facilitate the assembly work, be sure to make

them in locations which will have no detrimental effect on

performance and/or appearances.

If an area having many parts, similar parts, and/or parts which

are’ symmetrical right and left is disassembled, be sure to

arrange the parts so that they do not become mixed during the

assembly process.

1. Arrange the parts removed in the proper order.

2. Determine which parts are to be reused and which are to

be replaced.

3. If bolts, nuts, etc., are to be replaced, be sure to use only

the exact size specified.,

SPECIAL TOOLS

If other tools are substituted for the special tools to do service

or repair work, there is the danger that vehicle parts might be

damaged, or the mechanic might be injured; therefore, be

sure to use the special tool whenever doing any work for

which the use of one is specified.

PARTS TO IBE REPLACED

If any of the following parts are removed, they must be

replaced with new parts.

1. Oil seals

2. Gaskets (except rocker cover gasket)

3. Packings

4. O-rings

5. Lock washers

6. Cotter pins

7. Self-locking nuts

DO05111

STB Revision ,j .’

Page 15 of 284

INTRODUCTION - Towing and Hoisting

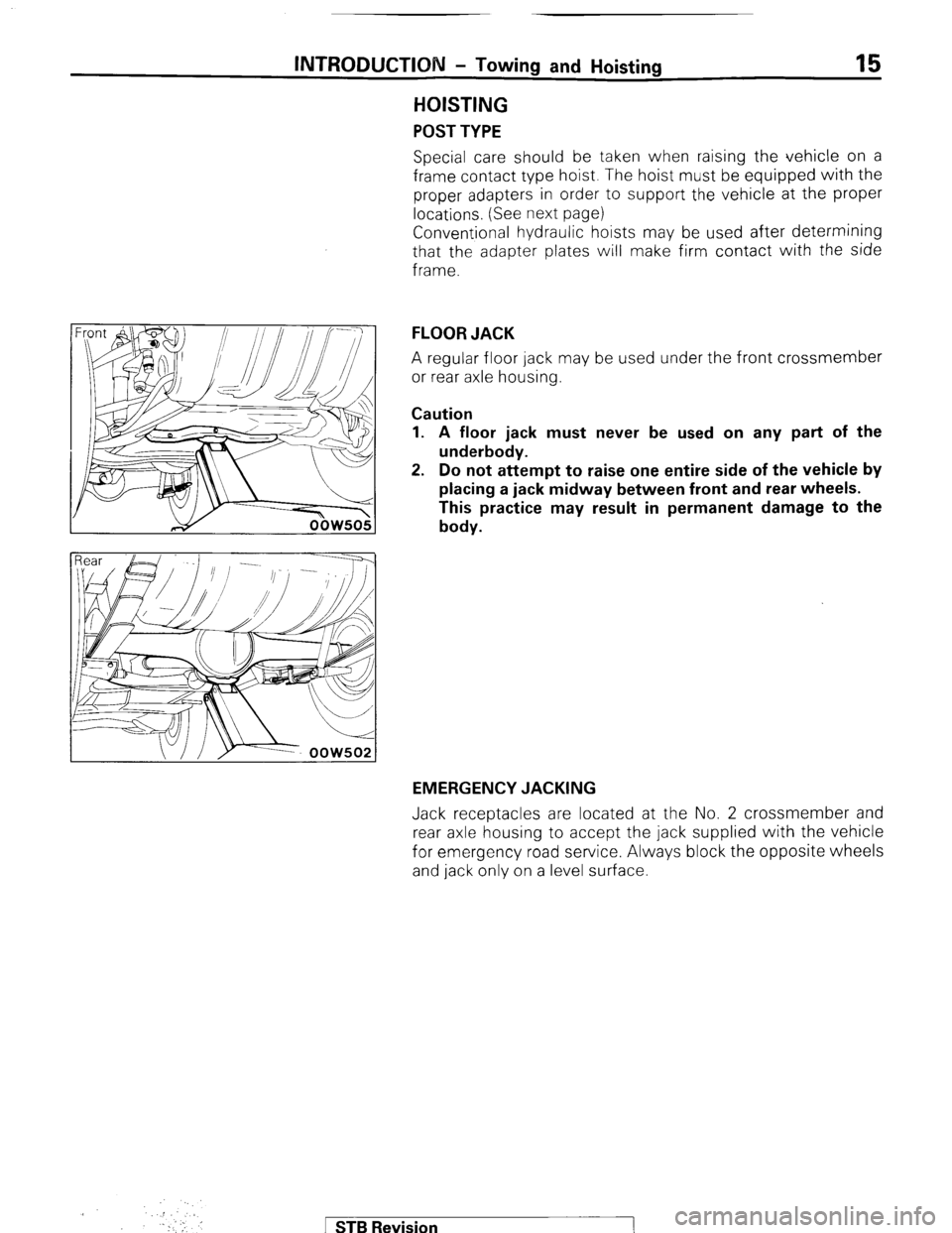

HOISTING

POST TYPE

15

Special care should be taken when raising the vehicle on a

frame contact type hoist. The hoist must be equipped with the

proper adapters in order to support the vehicle at the proper

locations. (See next page)

Conventional hydraulic hoists may be used after determining

that the adapter plates will make firm contact with the side

frame.

FLOOR JACK

A regular floor jack may be used under the front crossmember

or rear axle housing.

Caution

1. A floor jack must never be used on any part of the

underbody.

2. Do not attempt to raise one entire side of the vehicle by

placing a jack midway between front and rear wheels.

This practice may result in permanent damage to the

body.

EMERGENCY JACKING

Jack receptacles are located at the No. 2 crossmember and

rear axle housing to accept the jack supplied with the vehicle

for emergency road service. Always block the opposite wheels

and jack only on a level surface.

.::

. Y!’ ,,. I

.I

‘.

1 STB Revision

Page 21 of 284

8-1

ELECTRICAL

CONTENTS

NOBAA-

ACCESSORY ......................................................

188

Cigarette Lighter ............................................

,190

Clock ...............................................................

,191

AUDIO SYSTEM ................................................

.192

AUTOMATIC FREE-WHEELING HUB

INDICATOR SYSTEM ........................................

208

Automatic Free-wheeling Hub

Indicator Control Unit

..................................... ,216

Pulse Generator ..............................................

215

BACK DOOR WINDOW DEFOGGER

................ .203

Defogger switch ............................................

,206

Printed Heater Lines

...................................... ,207

CHARGING SYSTEM .........................................

71

Alternator ........................................................

83

Service Adjustment Procedures

..................... 77

Battery Charging ........................................

82

Inspection of Battery ..................................

81

Output Current Test ...................................

78

Regulated Voltage Test ..............................

79

Voltage Drop Test of Alternator Output

Wire ............................................................

77

ELECTRICAL SYSTEM PARTS LOCATION

...... 2

Diode ...............................................................

5

Fusible Link and Fuse

..................................... 6

Grounding .......................................................

7

Relay and Control Unit ....................................

2

Sensor .............................................................

4

HORN ..................................................................

184

Horn Switch

.................................................... 187

IGNITION SYSTEM ............................................

105

Ignition Switch

................................................ 122

Ignition System ...............................................

1 14

Service Adjustment Procedures

.................... .l 1 1

Checking Ignition System

..........................

11 1

Checking Ignition Timing

...........................

11 1

Spark Plug Cable Test

................................

1 12

Spark Plug Test

.......................................... 1 12 INSPECTION OF HARNESS CONNECTOR ...... 9

Check for Improper Engagement of

Terminal .......................................................... 9

Continuity and Voltage Test for Connector .... 9

Engaging and Disengaging of Connector

Terminal ..........................................................

9

LIGHTING SYSTEM ........................................... 143

Column Switch

................................ .

.............. .I59

Dimmer Control Switch

................................. .I62

Hazard Warning Switch

................................. .I61

Headlight ........................................................ ,158

Service Adjustment Procedures

.................... .I57

Headlight Aiming .......................................

157

METERS AND GAUGES .................................... 123

Service Adjustment Procedures

.................... .I30

Fuel Gauge Simple Test ................................. .I31

Fuel Gauge Unit Inspection ........................... .I31

Oil Pressure Gauge Simple Test

.................... .I32

Oil Pressure Gauge Unit Simple Test

............ ,132

Speedometer Inspection

............................... .I30

Tachometer Inspection .................................. ,130

Voltage Meter Simple Test

............................ .I33

Water Temperature Gauge Simple Test

....... ..I3 1

Water Temperature Gauge Unit Inspection

. ..I3 2

STARTING SYSTEM .......................................... 91

Starter Motor ............ ....................................... 97

WIPER AND WASHER SYSTEM

....................... .163

WIRING HARNESS ............................................ 13

Centralized Junction ....................................... 69

Circuit Diagram ............................................... 34

Configuration Diagram .................................... 27

How to Read Wiring Diagrams ....................... 20

Troubleshooting .............................................. 13

Page 37 of 284

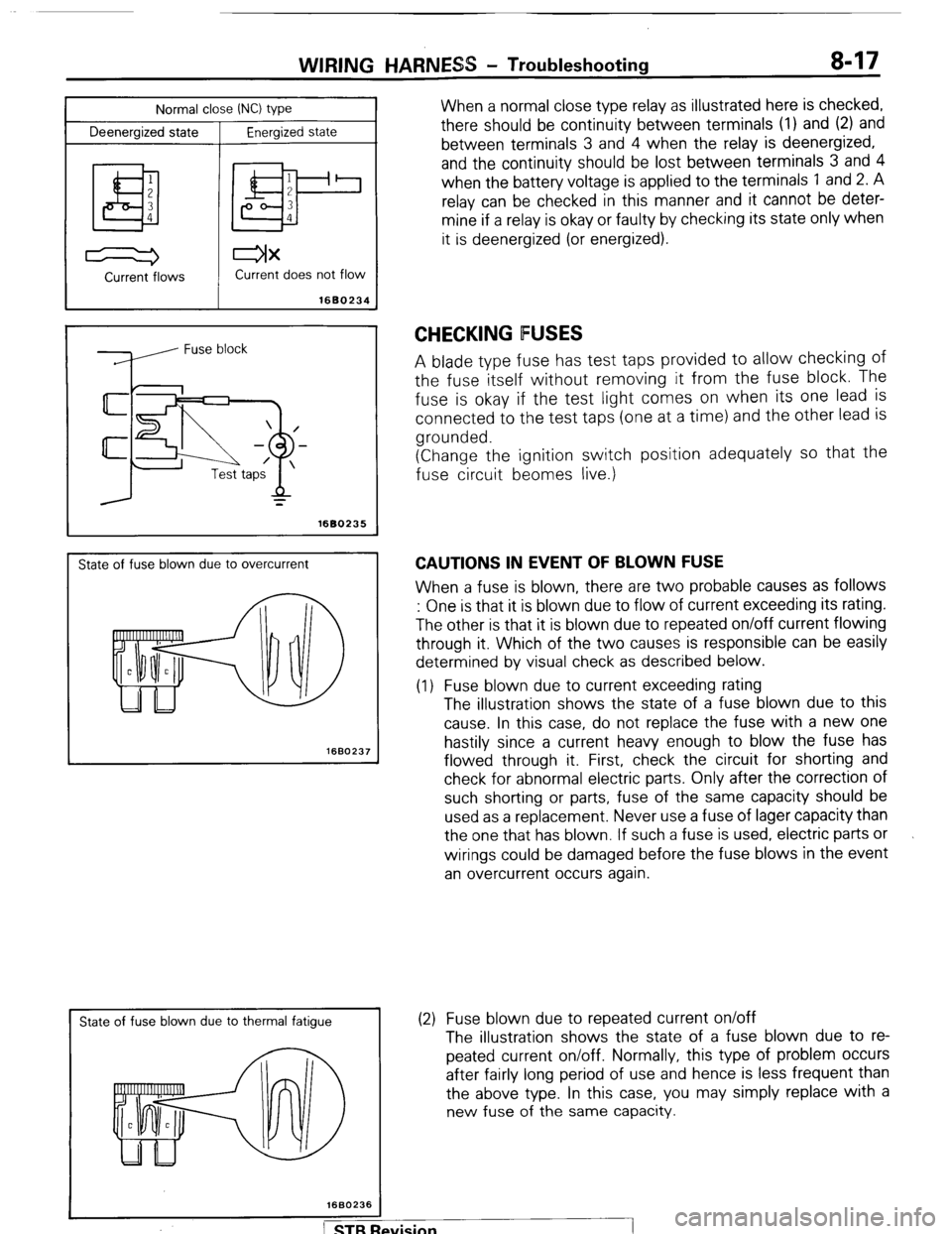

Normal close INC) type

Deenergized state

Energized state

I

WIRING HARNESS - Troubleshooting 8-17

When a normal close type relay as illustrated here is checked,

there should be continuity between terminals (1) and (2) and

between terminals 3 and 4 when the relay is deenergized,

and the continuity should be lost between terminals 3 and 4

when the battery voltage is applied to the terminals 1 and 2. A

relay can be checked in this manner and it cannot be deter-

mine if a relay is okay or faulty by checking its state only when

it is deenergized (or energized).

Current -flows Current does not flow

1680234

=

1680235

State of fuse blown due to overcurrent

1660237

I

State of fuse blown due to thermal fatigue

CHECKING FUSES

A blade type fuse has test taps provided to allow checking of

the fuse itself without removing it from the fuse block. The

fuse is okay if the test light comes on when its one lead is

connected to the test taps (one at a time) and the other lead is

grounded.

(Change the ignition switch position adequately so that the

fuse circuit beomes live.)

CAUTIONS IN EVENT OF BLOWN FUSE

When a fuse is blown, there are two probable causes as follows

: One is that it is blown due to flow of current exceeding its rating.

The other is that it is blown due to repeated on/off current flowing

through it. Which of the two causes is responsible can be easily

determined by visual check as described below.

(1) Fuse blown due to current exceeding rating

The illustration shows the state of a fuse blown due to this

cause. In this case, do not replace the fuse with a new one

hastily since a current heavy enough to blow the fuse has

flowed through it. First, check the circuit for shorting and

check for abnormal electric parts. Only after the correction of

such shorting or parts, fuse of the same capacity should be

used as a replacement. Never use a fuse of lager capacity than

the one that has blown. If such a fuse is used, electric parts or

wirings could be damaged before the fuse blows in the event

an overcurrent occurs again.

(2) Fuse blown due to repeated current on/off

The illustration shows the state of a fuse blown due to re-

peated current on/off. Normally, this type of problem occurs

after fairly long period of use and hence is less frequent than

the above type. In this case, you may simply replace with a

new fuse of the same capacity.

Page 39 of 284

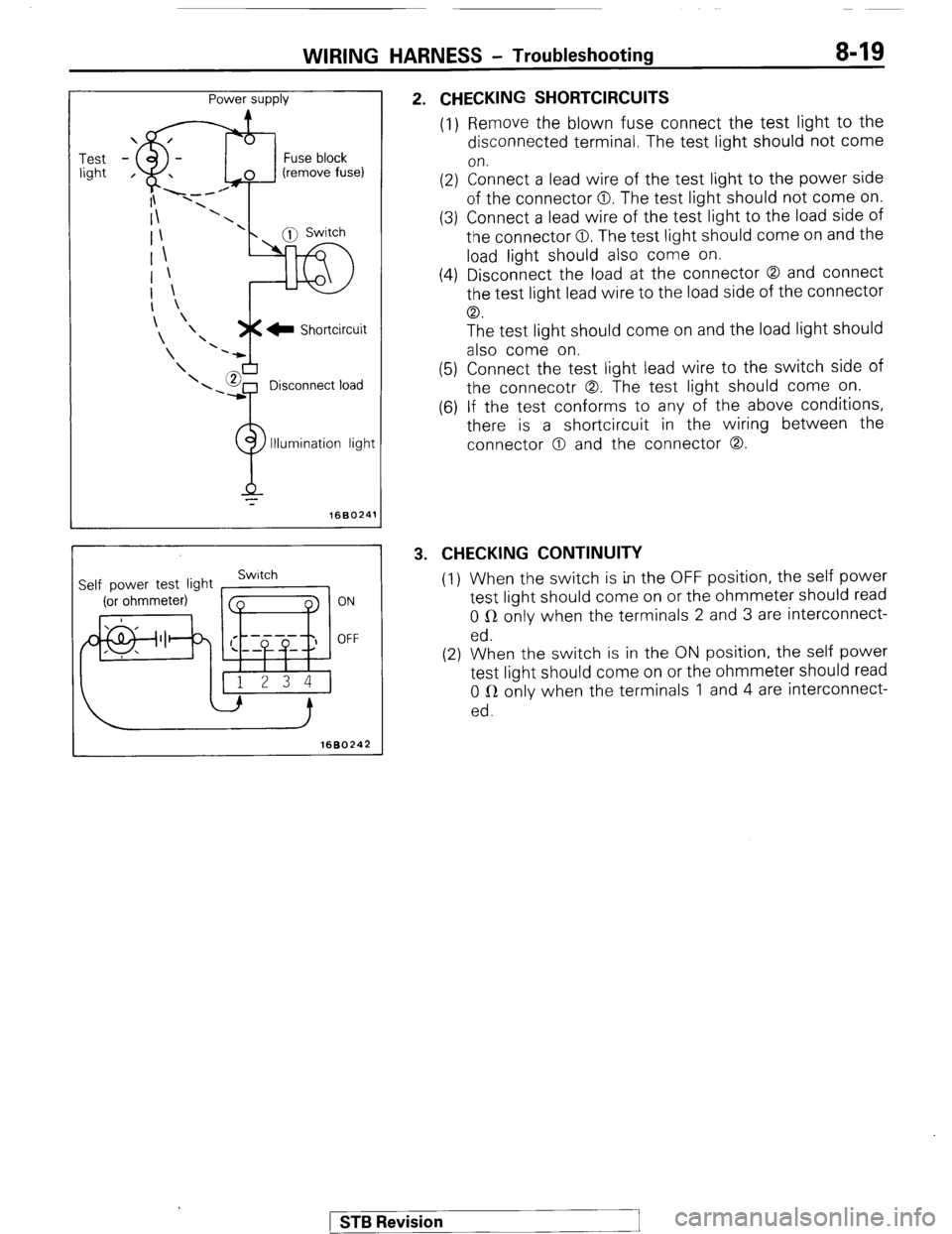

WIRING HARNESS - Troubleshooting 8-19

Test

light Power supply

Fuse block

(remove fuse)

r’TJ Switch

?

Illumination light

4, 1680241

Self power test light Switch

ON

OFF

1680242

2. CHECKING SHORTCIRCUITS

(1) Remove the blown fuse connect the test light to the

disconnected terminal. The test light should not come

on.

(2) Connect a lead wire of the test light to the power side

of the connector 0. The test light should not come on.

(3) Connect a lead wire of the test light to the load side of

the connector 0. The test light should come on and the

load light should also come on.

(4) Disconnect the load at the connector 0 and connect

the test light lead wire to the load side of the connector

CD.

The test light should come on and the load light should

also come on.

(5) Connect the test light lead wire to the switch side of

the connecotr 0. The test light should come on.

(6) If the test conforms to any of the above conditions,

there is a shortcircuit in the wiring between the

connector 0 and the connector 0.

3. CHECKING CONTINUITY

(I) When the switch is in the OFF position, the self power

test light should come on or the ohmmeter should read

0 R only when the terminals 2 and 3 are interconnect-

ed.

(2) When the switch is in the ON position, the self power

test light should come on or the ohmmeter should read

0 LR only when the terminals 1 and 4 are interconnect-

ed.

) STB Revision

Page 51 of 284

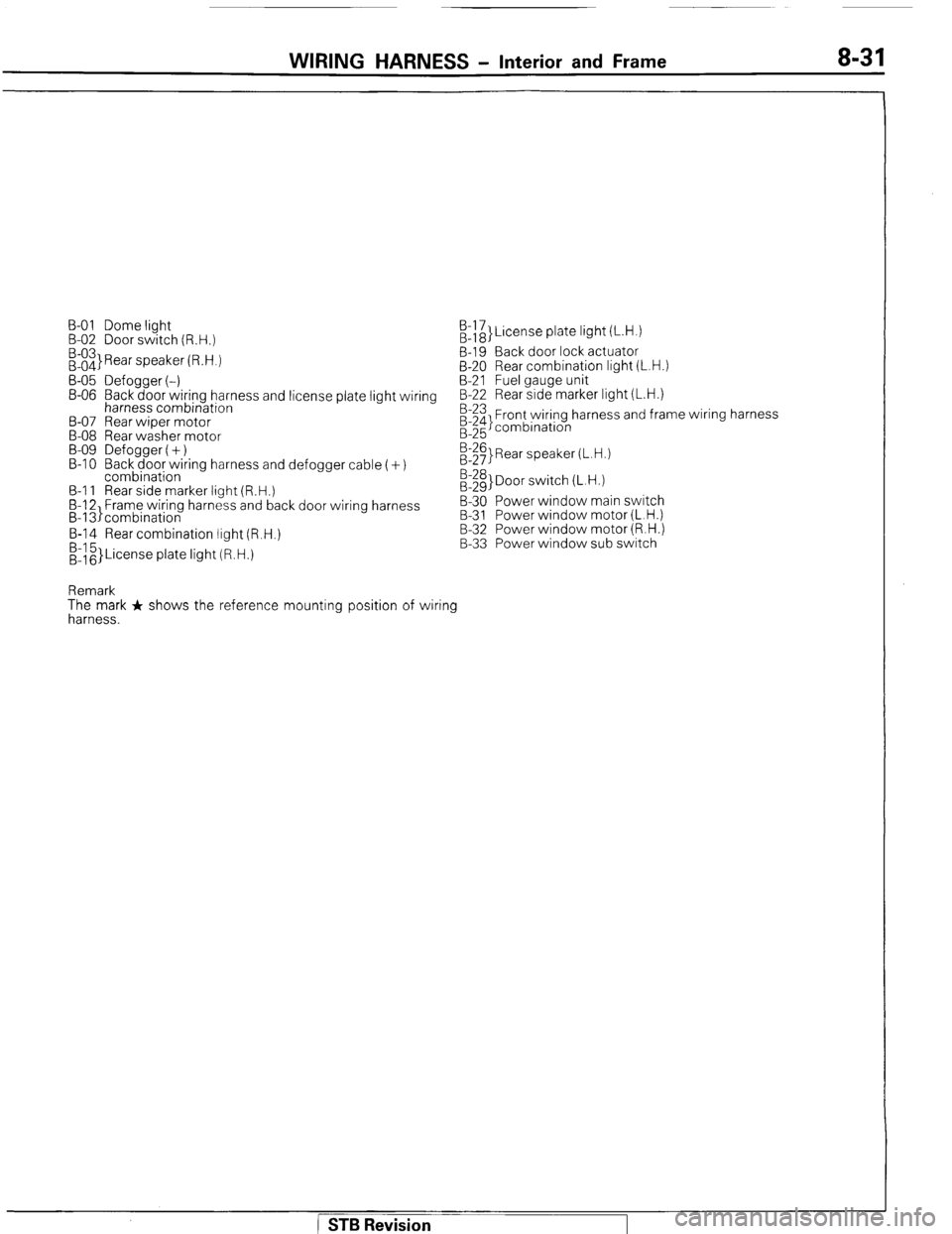

WIRING HARNESS - Interior and Frame 8-31

B-01 Dome light

B-02 Door switch (R.H.)

:::3 Rear speaker (R.H.) /&}License plate light (L.H.)

B-19 Back door lock actuator

B-20 Rear combination light (L.H.)

B-05 Defogger (-) B-21 Fuel gauge unit

B-06 Back door wiring harness and license plate light wiring B-22 Rear side marker light (L.H.)

harness combination

B-07 Rear wiper motor

B-08 Rear washer motor

B-09 Defogger (+)

B-l 0 Back door wiring harness and defogger cable (+)

combination

B-l 1 Rear side marker light (R.H.)

B-12 Frame wiring harness and back door wiring harness

B-13)combination B-23 Front wiring harness and frame wiring harness

;:g combination

E$ Rear speaker (L.H.)

:::g> Door switch (L.H.)

B-30 Power window main switch

B-31 Power window motor (L.H.)

B-14 Rear combination light (R.H.)

&z}License plate light (R.H.) B-32 Power window motor (R.H.)

B-33 Power window sub switch

Remark

The mark + shows the reference mounting position of wiring

harness.

STB Revision

Page 52 of 284

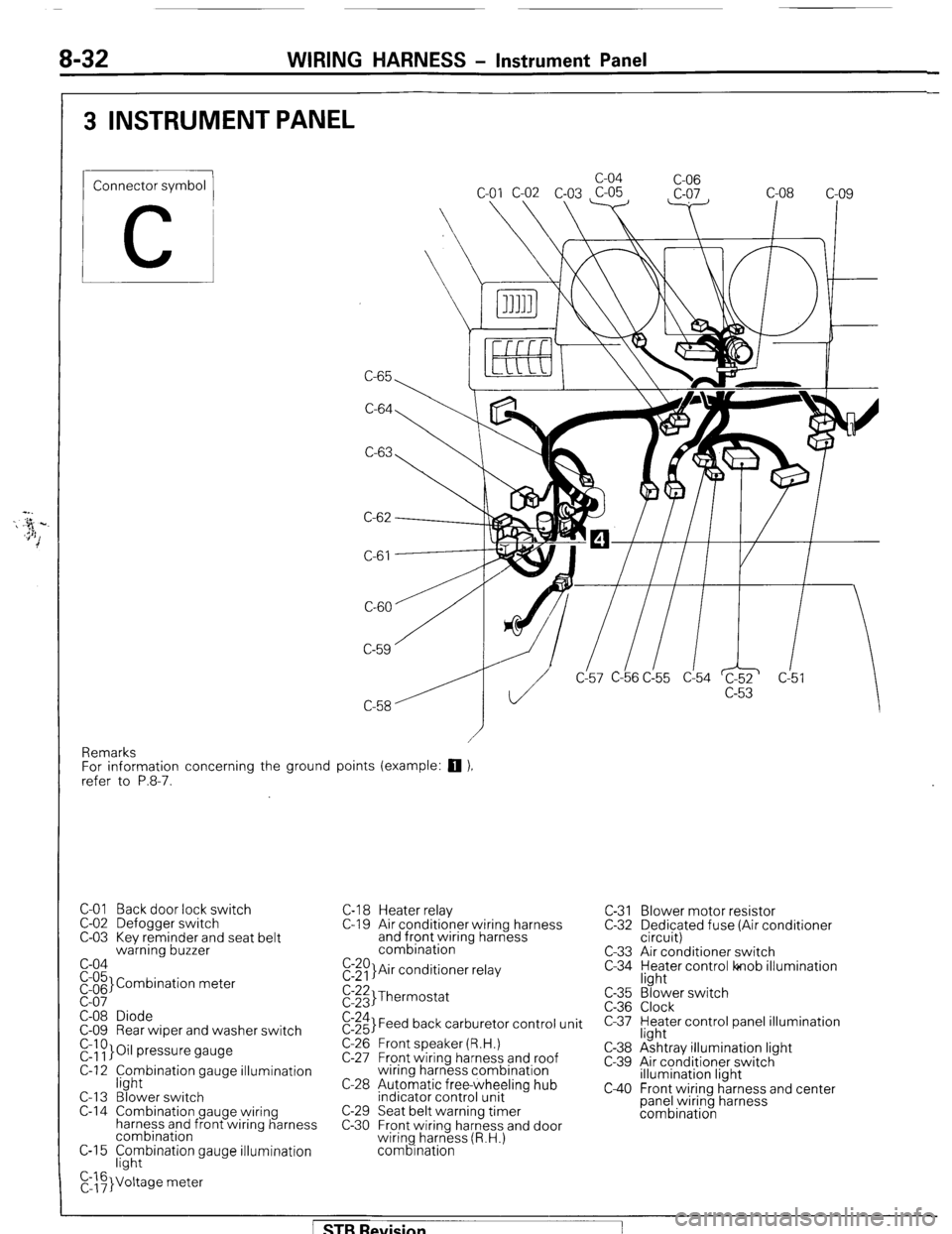

8-32 WIRING HARNESS - Instrument Panel

3 INSTRUMENT PANEL

Connector symbol

C

C-65 c-04

C-06

C-64

C-63

C-61

CL57 C-b6 C!55 d54 c!5

Remarks

For information concerning the ground points (example:

q ),

refer to P.8-7.

C-01 Back door lock switch

C-02 Defogger switch

C-03 Kev reminder and seat belt

warning buzzer

c-04

pi;’ Combination meter

C-08 Diode

C-09 Rear wiper and washer switch

r&~}Oil pressure gauge

C-12 f;hybination gauge illumination

C-l 3 Blower switch

C-14 Combination gauge wiring

harness and front wiring harness

combination

C-15 F;hybination gauge illumination

C,::F}Voltage meter C-l 8 Heater relay

C-l 9 Air conditioner wiring harness

and front wiring harness

combination

E:$)}Air conditioner relay C-31 Blower motor resistor

C-32 Dedicated fuse (Air conditioner

circuit)

C-33 Air conditioner switch

C-34 yl;Jer control lonob illumination

$:;;I Thermostat

$:;;I Feed back carburetor control unit

C-26 Front speaker (R.H.)

C-27 Front wiring harness and roof

wiring harness combination

C-28 Automatic free-wheeling hub

indicator control unit

C-29 Seat belt warning timer

C-30 Front wiring harness and door

wiring harness (R.H.)

combination c-35

C-36

c-37

C-38

c-39

c40

“3’ ‘. Blower switch

Clock

Heater control panel illumination

light

Ashtray illumination light

Air conditioner switch

illumination light

Front wiring harness and center

panel wiring harness

combination

[ STB Revision

Page 71 of 284

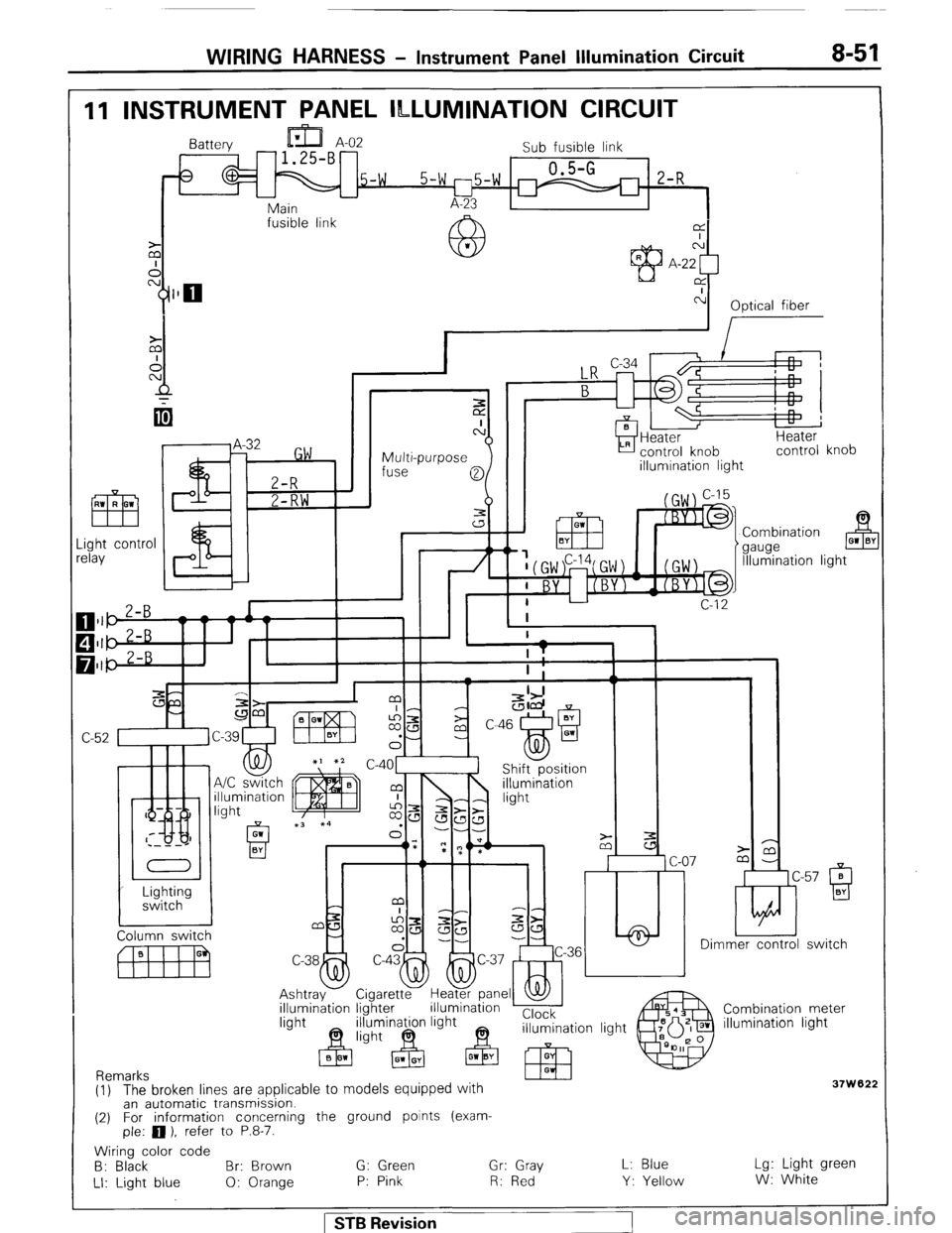

WIRING HARNESS - Instrument Panel Wumination Circuit 8-51

11 INSTRUMENT PANEL ILLUMINATION CIRCUIT

Battery

Sub fusible link

5-w 0.5-G

5-w l-75-W m 2-R - L-

Main A-23

fusible link

@L

M’ CA

A A-22

Y$lO rx

c-l

Optical fiber

I

I

Multi-purpose

fuse

0

3

a control knob

illumination light

.ight contr

clay

& 01 BY

7t Combination

gauge

Illumination ligl

c-4o1l Shift-position

lmer control switch

C-38

4

Ashtray

illumination Cigaretty Hegpane _

lighter illumination ’ I

minagn light Clock

n+ 63 illumination light Combination meter

illumination light

37w '62; (1) The broken lines are applicable to models equipped with

an automatic transmission.

(2) For information concerning the ground points (exam-

ple: 0 ), refer to P.8-7.

Wiring color code

B: Black Br: Brown G: Green Gr: Gray

LI: Light blue 0: Orange P: Pink R: Red L: Blue

Y: Yellow Lg: Light green

W: White

1 STB Revision

Page 82 of 284

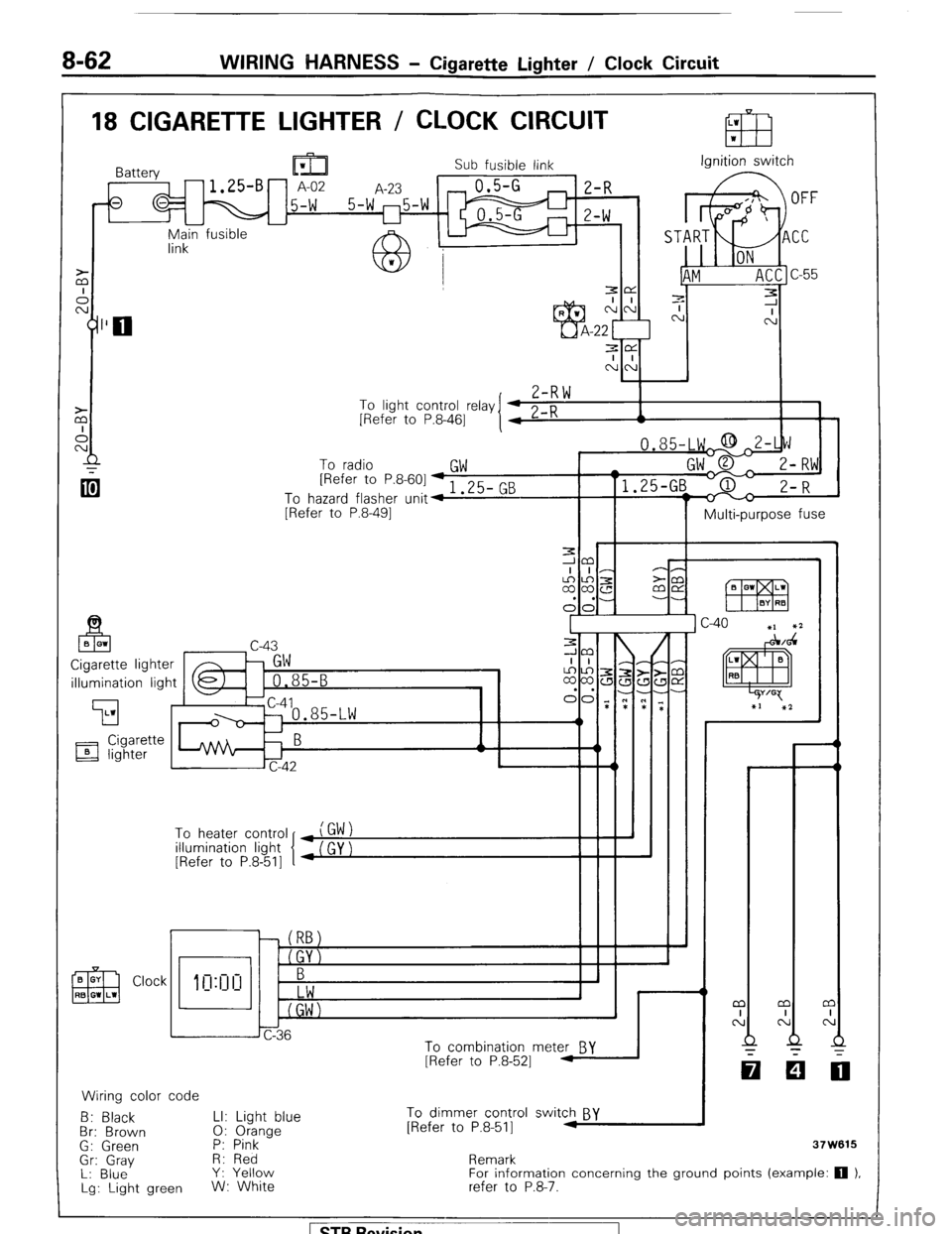

8-62 WIRING HARNESS - Cigarette Lighter / Clock Circuit

18 CIGARETTE LIGHTER / CLOCK CIRCUIT

Sub fusible link Ignition switch

r-l E-f? ‘) n

-u yn;in fusible

7-R \*I

To light control relay

[Refer to P.8-461

To radio

GW [Refer to P&601-, 3F- Pm

To hazard flasher unit4 I .LJ- G

[Refer to P.8-491

II I Multi-purpose fuse

illumination light

To heater control

illumination light

[Refer to P.8-511

Clock

CT

0: 1

h J

6

Jc-36

To combination mete& BY

[Refer to P.8-521 1

Wiring color code

B: Black LI: Light blue To dimmer control switch BY

Br: Brown 0: Orange [Refer to P.8-511 M

G: Green P: Pink

-

Gr: Gray H: Red

L: Blue Y: Yellow

Lg: Light green W: White Remark

For information concerning the ground points (example: 0 1,

refer to P.8-‘7.