ECU MITSUBISHI MONTERO 1989 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: MONTERO, Model: MITSUBISHI MONTERO 1989 1.GPages: 30, PDF Size: 1.61 MB

Page 2 of 30

~~~~ -~-L -.._i._--

--em._. -

2

~!

INTRODUCTION AND MASTER TROUBLESHOOTING - How To Use This Manual

E-m+

HOW TO USE THIS MANUAL

gg$I!

NWS&Wl g-

LIMIT g&i-

s : CONTENTS

Shows the standard for judging the quality of a part

or assembly on inspection and means the maxi- g ’

mum or minimum value within which the part or

ar-=

assembly must be-kept functionally or in strength. s

m.

It is a value established outside the range of

E-

standard value. z The preceding page contains the GROUP INDEX

which lists the group title and group number.

PAGE NUMBERS

All page numbers consist of two sets of digits

separated by a dash. The digits preceding the dash

identify the number of the group. The digits follow-

ing the dash represent the consecutive page

number within the group. The page numbers can

be found on the top left or right of each page.

TEXT

Unless otherwise specified, each service procedure

covers all models. Procedures covering specific

models are identified by the model codes, or similar

designation (engine type, transmission type, etc.).

A description of these designations is covered in

this unit under “VEHICLE IDENTIFICATION”.

TROUBLESHOOTING

Troubleshootings are classified into master trouble-

shooting and group troubleshooting and located as

follows:

The master troubleshooting is prepared when the

trouble symptom relates to two or more groups and

given in MASTER TROUBLESHOOTING.

The group troubleshooting guide is prepared for

causes of problems related to that individual group

only; a troubleshooting guide is prepared for each

appropriate group.

SERVICE PROCEDURES

The sewice steps are arranged in numerical order

and attentions to be paid in performing vehicle ser-

vice are described in detail in SERVICE POINTS.

DEFINITION OF TERMS

STANDARD VALUE

indicates the value used as the standard for judging

the quality of a part or assembly on inspection or the

value to which the part or assembly is corrected and

adjusted. It is given by tolerance.

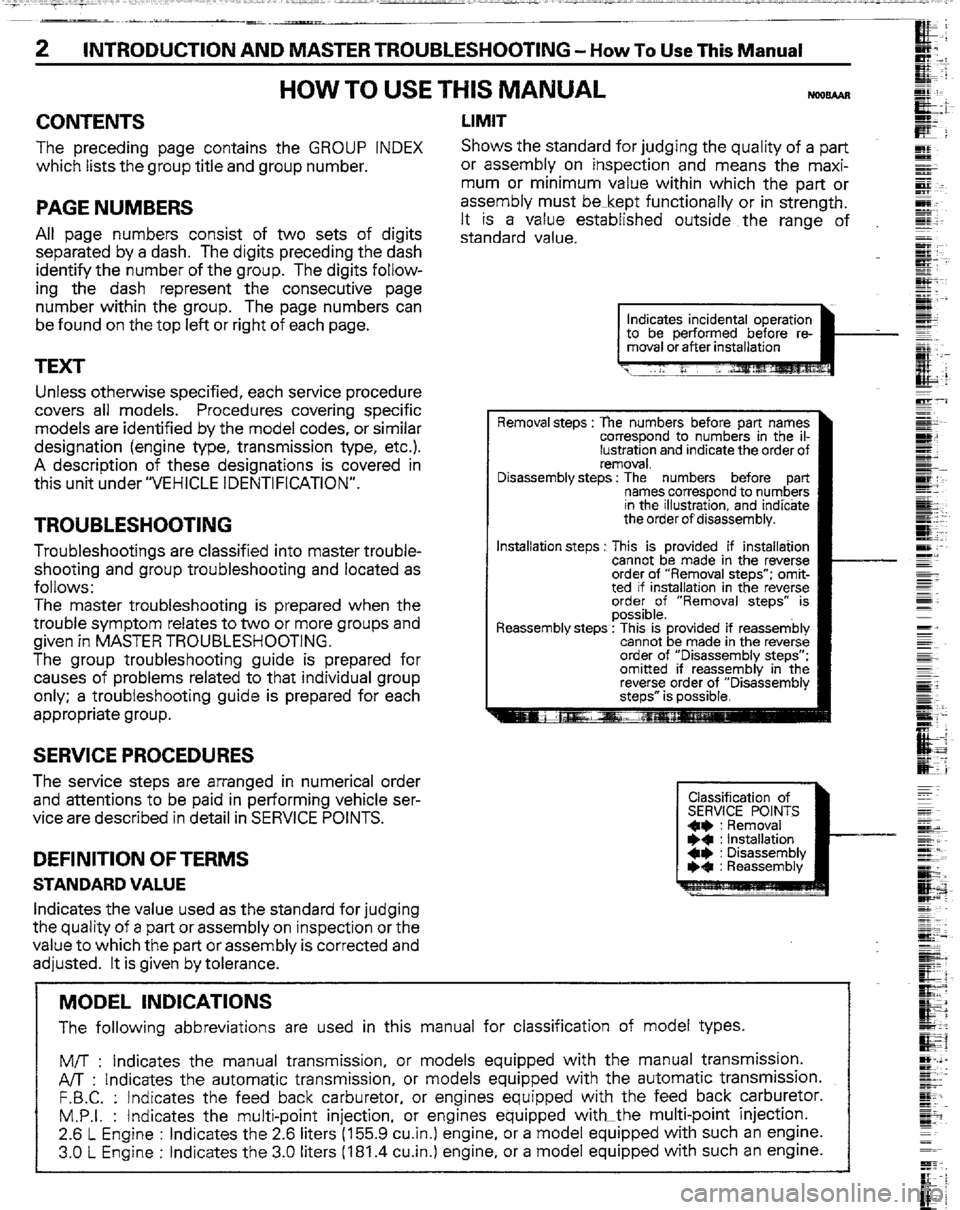

incidental operation

rformed before re-

Removal steps : The numbers before part names b

correspond to numbers in the il-

lustration and indicate the order of

removal.

Disassemblv steos : The numbers before oat-t

I ---I-- names co&pond to num6&

in the illustration, and indicate

the order of’disassembly.

Installation steps : This is provided if installation

cannot be made in the reverse

order of “Removal steps”; omit-

ted if installation in the reverse

order of “Removal steps” is

possible.

Reassembly steps : This is provided if reassembly

cannot be made in the reverse

order of “Disassembly steps”:

omitted if reassembly in the

reverse order

The following abbreviations are used in this manual for classification of model types.

M/T : Indicates the manual transmission, or models equipped with the manual transmission.

A/T : Indicates the automatic transmission, or models equipped with the automatic transmission.

F.B.C. : Indicates the feed back carburetor, or engines equipped with the feed back carburetor.

M.P.I. : Indicates the multi-point injection, or engines equipped witkthe multi-point injection.

2.6 L Engine : Indicates the 2.6 liters (155.9 cuin.) engine, or a model equipped with such an engine.

3.0 L Engine : Indicates the 3.0 liters (181.4 cu.in.) engine, or a model equipped with such an engine.

Page 10 of 30

10 INTRODUCTION AND MASTER TROUBLESHOOTiNG - Precautions Before Service

F1617

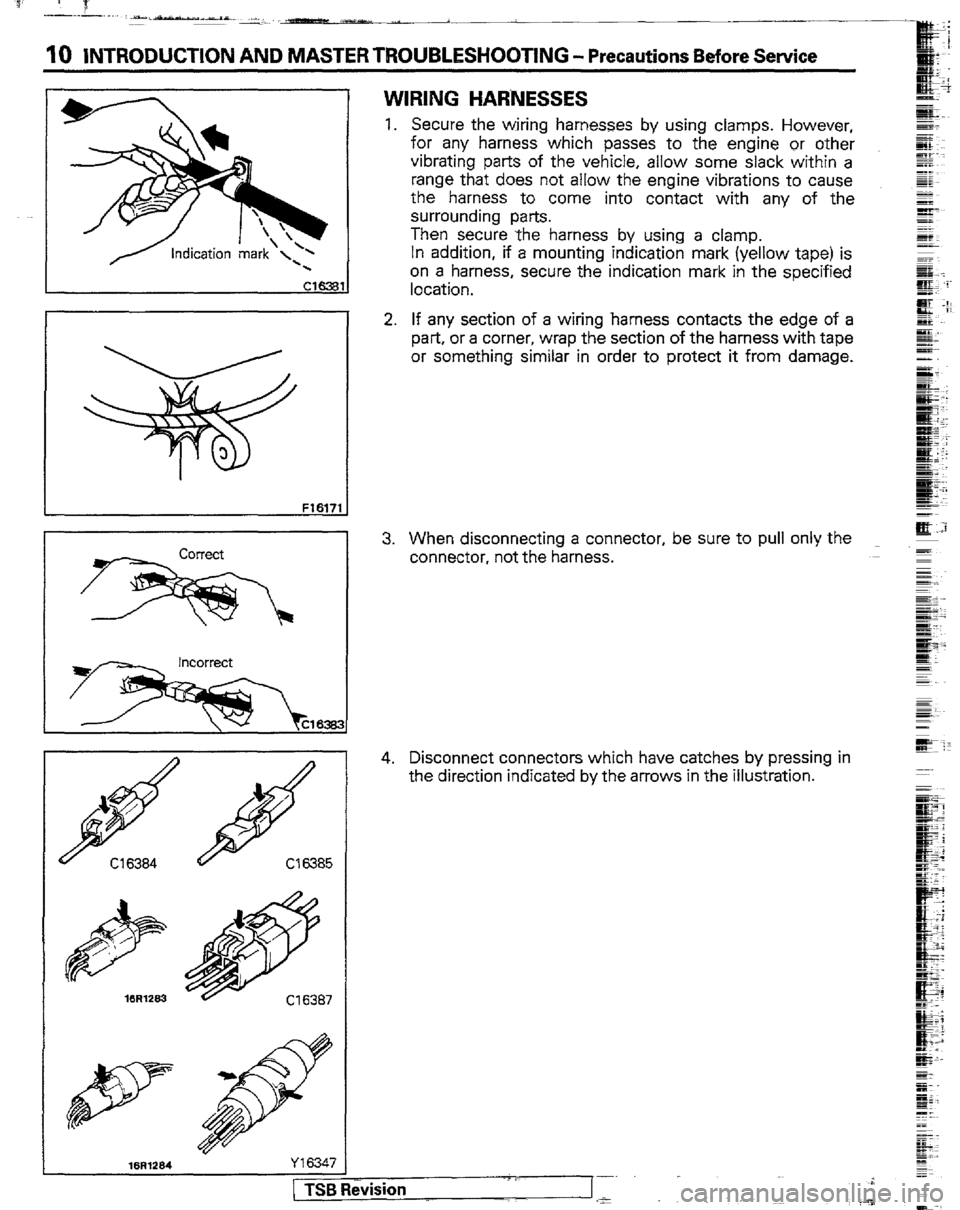

WIRING HARNESSES

1. Secure the wiring harnesses by using clamps. However,

for any harness which passes to the engine or other

vibrating parts of the vehicle, allow some slack within a

range that does not allow the engine vibrations to cause

the harness to come into contact with any of the

surrounding parts.

Then secure the harness by using a clamp.

In addition, if a mounting indication mark (yellow tape) is

on a harness, secure the indication mark in the specified

location.

2. If any section of a wiring harness contacts the edge of a

part, or a corner, wrap the section of the harness with tape

or something similar in order to protect it from damage.

3. When disconnecting a connector, be sure to pull only the

connector, not the harness.

4. Disconnect connectors which have catches by pressing in

the direction

indicated by the arrows in the illustration.

Page 12 of 30

12 INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions Before Service

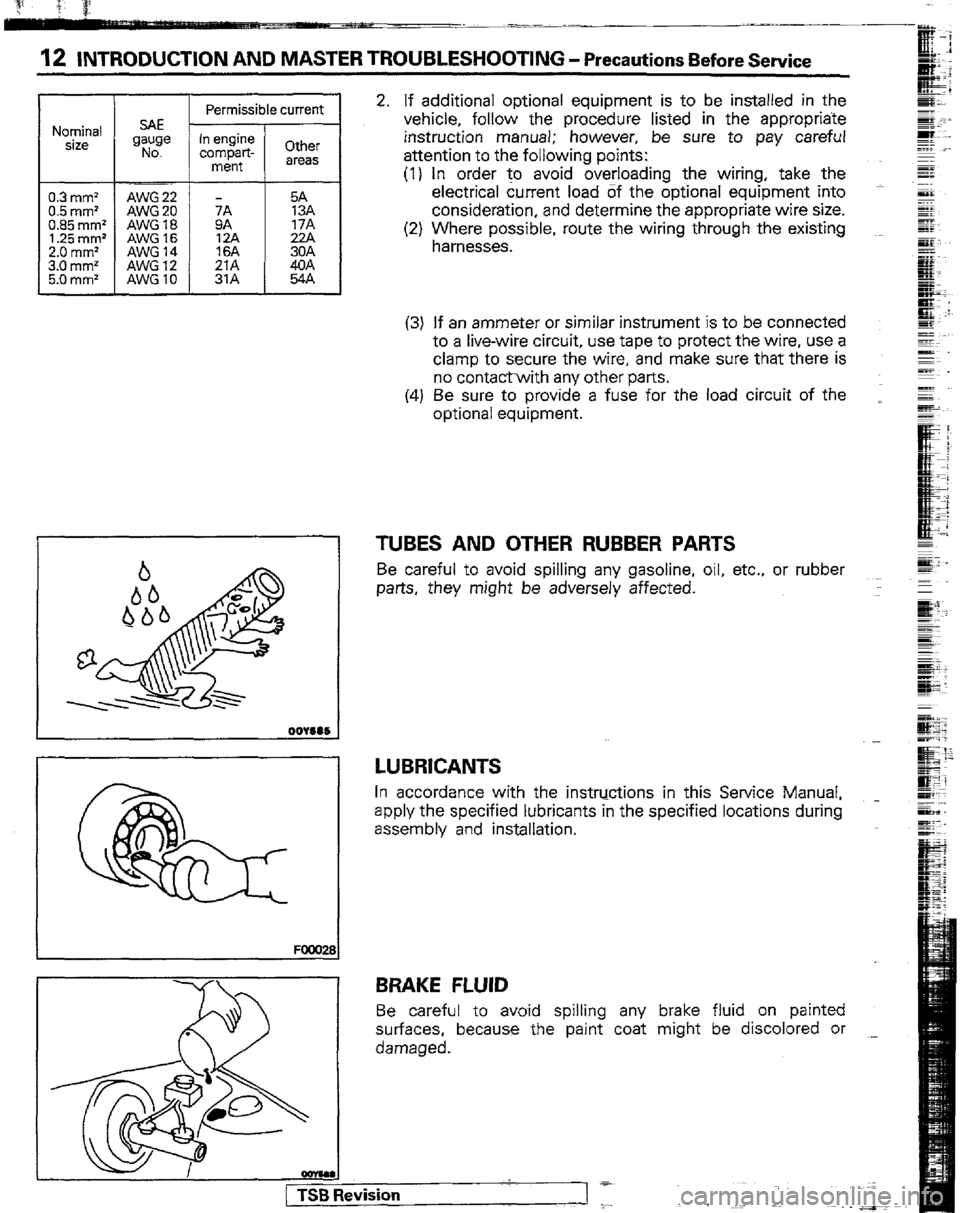

Nominal

size

0.3 mm2

0.5 mm2

0.85 mm*

1.25 mm2

2.0 mm*

3.0 mm2

5.0 mm2 Permissible current

SAE

I

Other

areas

2. If additional optional equipment is to be installed in the

vehicle, follow the procedure listed in the appropriate

instruction manual; however, be sure to pay careful

attention to the following points:

(1) In order to avoid overloading the wiring, take the

electrical current load of the optional equipment into

consideration, and determine the appropriate wire size.

(2) Where possible, route the wiring through the existing

harnesses.

(3) If an ammeter or similar instrument is to be connected

to a live-wire circuit, use tape to protect the wire, use a

clamp to secure the wire, and make sure that there is

no contactwith any other parts.

(4) Be sure to provide a fuse for the load circuit of the

optional equipment.

TUBES AND OTHER RUBBER PARTS

Be careful to avoid spilling any gasoline, oil, etc., or rubber

parts, they might be adversely affected.

LUBRICANTS

In accordance with the instructions in this Service Manual,

apply the specified lubricants in the specified locations during

assembly and installation.

BRAKE FLUID

Be careful to avoid spilling any brake fluid on painted

surfaces, because the paint coat might be discolored or

damaged.

Page 17 of 30

INTRODUCTION AND MASTER TROUBLESHOOTING - Towing and Hoisting 17

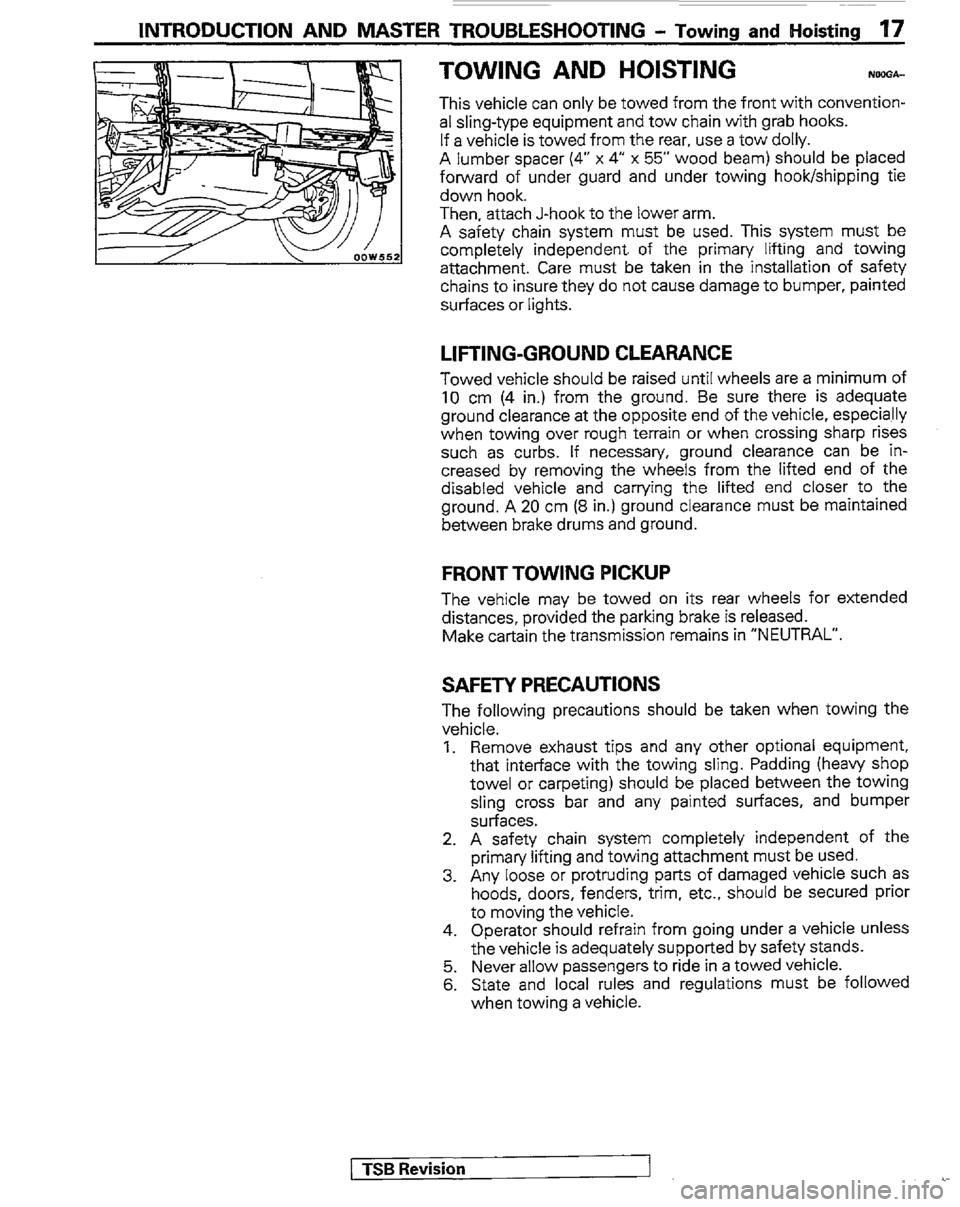

TOWING AND HOISTING

This vehicle can only be towed from the front with convention-

al sling-type equipment and tow chain with grab hooks.

If a vehicle is towed from the rear, use a tow dolly.

A lumber spacer (4” x 4” x 55” wood beam) should be placed

forward of under guard and under towing hook/shipping tie

down hook.

Then, attach J-hook to the lower arm.

A safety chain system must be used. This system must be

completely independent. of the primary lifting and towing

attachment. Care must be taken in the installation of safety

chains to insure they do not cause damage to bumper, painted

surfaces or lights.

LIFTING-GROUND CLEARANCE

Towed vehicle should be raised until wheels are a minimum of

10 cm (4 in.) from the ground. Be sure there is adequate

ground clearance at the opposite end of the vehicle, especially

when towing over rough terrain or when crossing sharp rises

such as curbs. If necessary, ground clearance can be in-

creased by removing the wheels from the lifted end of the

disabled vehicle and carrying the lifted end closer to the

ground. A 20 cm (8 in.) ground clearance must be maintained

between brake drums and ground.

FRONT TOWING PICKUP

The vehicle may be towed on its rear wheels for extended

distances, provided the parking brake is released.

Make cartain the transmission remains in “NEUTRAL”.

SAFETY PRECAUTIONS

The following precautions should be taken when towing the

vehicle.

1. Remove exhaust tips and any other optional equipment,

that interface with the towing sling. Padding (heavy shop

towel or carpeting) should be placed between the towing

sling cross bar and any painted surfaces, and bumper

surfaces.

2. A safety chain system completely independent of the

primary lifting and towing attachment must be used.

3. Any loose or protruding parts of damaged vehicle such as

hoods, doors, fenders, trim, etc., should be secured prior

to moving the vehicle.

4. Operator should refrain from going under a vehicle unless

the vehicle is adequately supported by safety stands.

5.

Never allow passengers to ride in a towed vehicle.

6. State and local rules and regulations must be followed

when towing a vehicle.

1 TSB Revision

Page 28 of 30

INTRODUCTION MASTER TROUBLESHOOTING - Master Troubleshootha

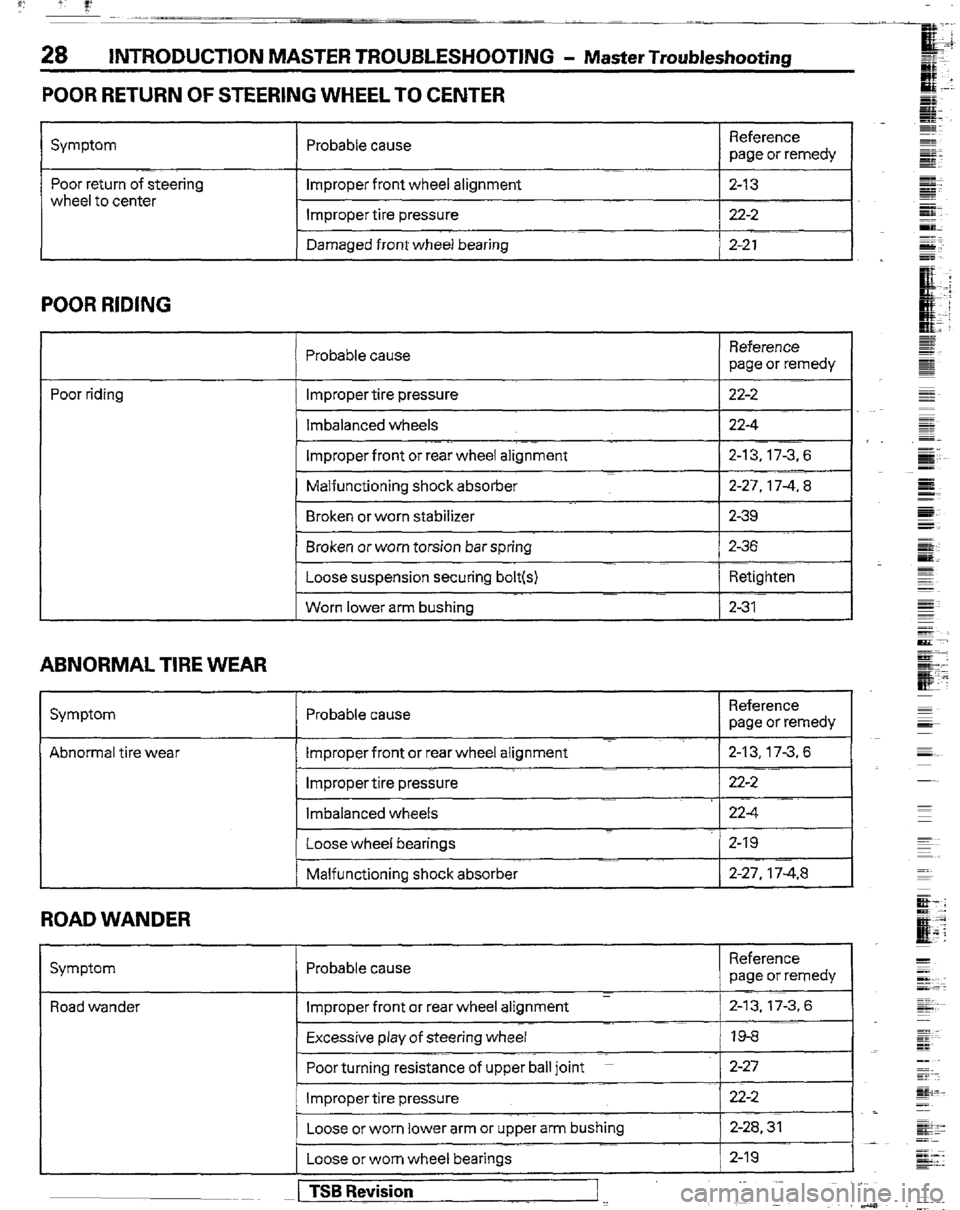

POOR RETURN OF STEERING WHEEL TO CENTER

Symptom Probable cause Reference

page or remedy

Poor return of steering

wheel to center improper front wheel alignment 2-13

Improper tire pressure 22-2

Damaged front wheel bearing 2-21

POOR RIDING

Probable cause Reference

page or remedy

Poor riding Impropertire pressure

lmbalanced wheels 22-2

22-4

1 Improper front or rear wheel alignment 1 2-13.17-3.6

1 Malfunctioning shock absorber 1 2-27,174.a

1 Broken or worn stabilizer

1 Broken or worn torsion bar spring j 2-36

I

Loose suspension securing bolt(s) Retighten

I

1 Worn lower arm bushing / 231

I

ABNORMAL TIRE WEAR

Symptom Probable cause Reference

page or remedy

Abnormal tire wear Improper front or rear wheel alignment 2-l 3,17-3.6

Improper tire pressure 22-2

lmbalanced wheels 22-4

Loose wheel bearings 2-19

Malfunctioning shock absorber 2-27. 174.8

ROAD WANDER

Symptom Probable cause Reference

page or remedy

Road wander z Improper front or rear wheel alignment 2-13. 17-3,6

Excessive play of steering wheel 19-6

Poor turning resistance of upper ball joint ~ 2-27

Improper tire pressure 22-2

/ Loose or worn lower arm or upper arm bushing 2-28.31

Loose or worn wheel bearinas

I

[ TSB Revision

I 2-19

1 ~- __

- rr.