MITSUBISHI MONTERO 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: MONTERO, Model: MITSUBISHI MONTERO 1991Pages: 1333, PDF Size: 24.61 MB

Page 241 of 1333

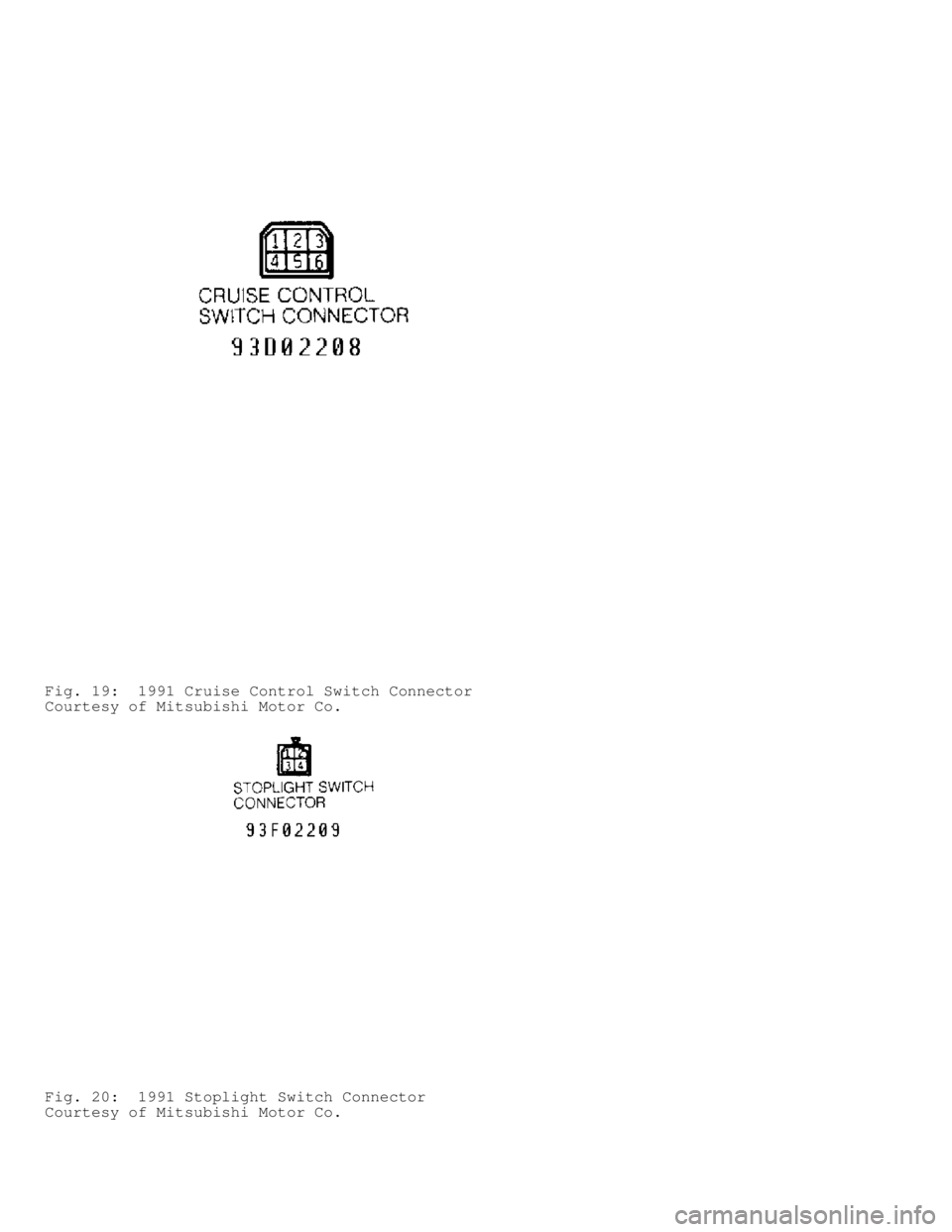

Fig. 19: 1991 Cruise Control Switch Connector

Courtesy of Mitsubishi Motor Co.

Fig. 20: 1991 Stoplight Switch Connector

Courtesy of Mitsubishi Motor Co.

Page 242 of 1333

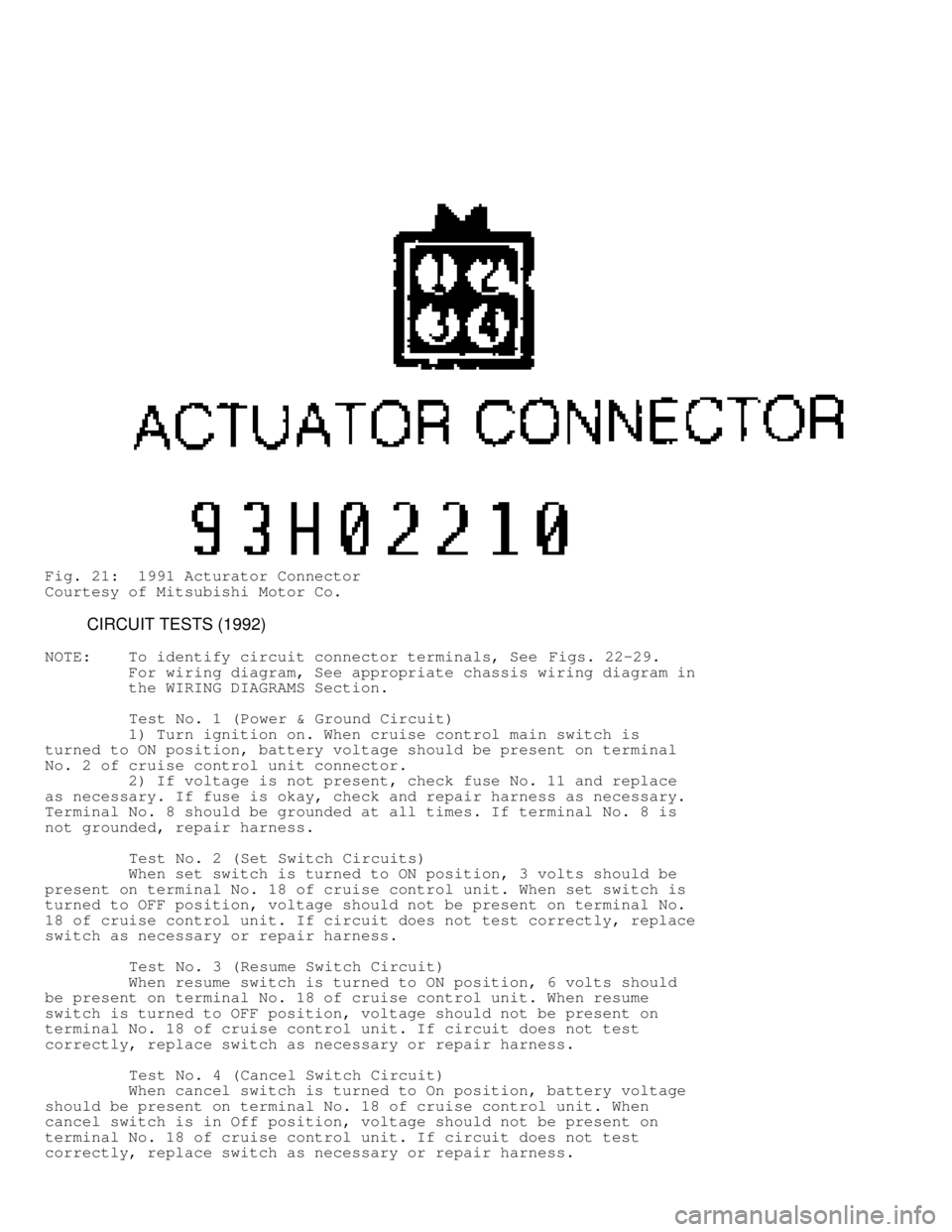

Fig. 21: 1991 Acturator Connector

Courtesy of Mitsubishi Motor Co.

CIRCUIT TESTS (1992)

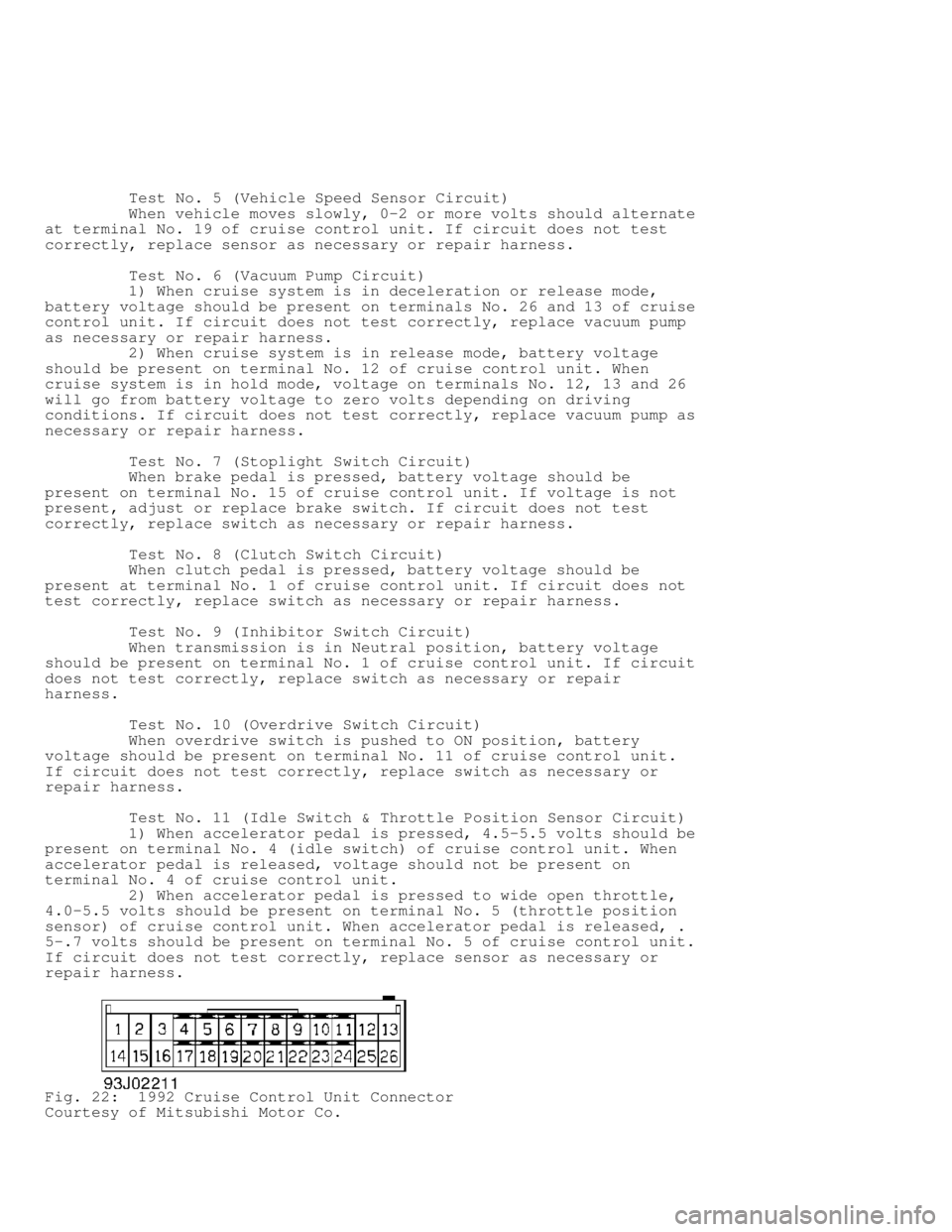

NOTE: To identify circuit connector terminals, See Figs. 22-29.

For wiring diagram, See appropriate chassis wiring diagram in

the WIRING DIAGRAMS Section.

Test No. 1 (Power & Ground Circuit)

1) Turn ignition on. When cruise control main switch is

turned to ON position, battery voltage should be present on terminal

No. 2 of cruise control unit connector.

2) If voltage is not present, check fuse No. 11 and replace

as necessary. If fuse is okay, check and repair harness as necessary.

Terminal No. 8 should be grounded at all times. If terminal No. 8 is

not grounded, repair harness.

Test No. 2 (Set Switch Circuits)

When set switch is turned to ON position, 3 volts should be

present on terminal No. 18 of cruise control unit. When set switch is

turned to OFF position, voltage should not be present on terminal No.

18 of cruise control unit. If circuit does not test correctly, replace

switch as necessary or repair harness.

Test No. 3 (Resume Switch Circuit)

When resume switch is turned to ON position, 6 volts should

be present on terminal No. 18 of cruise control unit. When resume

switch is turned to OFF position, voltage should not be present on

terminal No. 18 of cruise control unit. If circuit does not test

correctly, replace switch as necessary or repair harness.

Test No. 4 (Cancel Switch Circuit)

When cancel switch is turned to On position, battery voltage

should be present on terminal No. 18 of cruise control unit. When

cancel switch is in Off position, voltage should not be present on

terminal No. 18 of cruise control unit. If circuit does not test

correctly, replace switch as necessary or repair harness.

Page 243 of 1333

Test No. 5 (Vehicle Speed Sensor Circuit)

When vehicle moves slowly, 0-2 or more volts should alternate

at terminal No. 19 of cruise control unit. If circuit does not test

correctly, replace sensor as necessary or repair harness.

Test No. 6 (Vacuum Pump Circuit)

1) When cruise system is in deceleration or release mode,

battery voltage should be present on terminals No. 26 and 13 of cruise

control unit. If circuit does not test correctly, replace vacuum pump

as necessary or repair harness.

2) When cruise system is in release mode, battery voltage

should be present on terminal No. 12 of cruise control unit. When

cruise system is in hold mode, voltage on terminals No. 12, 13 and 26

will go from battery voltage to zero volts depending on driving

conditions. If circuit does not test correctly, replace vacuum pump as

necessary or repair harness.

Test No. 7 (Stoplight Switch Circuit)

When brake pedal is pressed, battery voltage should be

present on terminal No. 15 of cruise control unit. If voltage is not

present, adjust or replace brake switch. If circuit does not test

correctly, replace switch as necessary or repair harness.

Test No. 8 (Clutch Switch Circuit)

When clutch pedal is pressed, battery voltage should be

present at terminal No. 1 of cruise control unit. If circuit does not

test correctly, replace switch as necessary or repair harness.

Test No. 9 (Inhibitor Switch Circuit)

When transmission is in Neutral position, battery voltage

should be present on terminal No. 1 of cruise control unit. If circuit

does not test correctly, replace switch as necessary or repair

harness.

Test No. 10 (Overdrive Switch Circuit)

When overdrive switch is pushed to ON position, battery

voltage should be present on terminal No. 11 of cruise control unit.

If circuit does not test correctly, replace switch as necessary or

repair harness.

Test No. 11 (Idle Switch & Throttle Position Sensor Circuit)

1) When accelerator pedal is pressed, 4.5-5.5 volts should be

present on terminal No. 4 (idle switch) of cruise control unit. When

accelerator pedal is released, voltage should not be present on

terminal No. 4 of cruise control unit.

2) When accelerator pedal is pressed to wide open throttle,

4.0-5.5 volts should be present on terminal No. 5 (throttle position

sensor) of cruise control unit. When accelerator pedal is released, .

5-.7 volts should be present on terminal No. 5 of cruise control unit.

If circuit does not test correctly, replace sensor as necessary or

repair harness.

Fig. 22: 1992 Cruise Control Unit Connector

Courtesy of Mitsubishi Motor Co.

Page 244 of 1333

Fig. 23: 1992 Main Cruise Control Switch Connector

Courtesy of Mitsubishi Motor Co.

Fig. 24: 1992 Stoplight Switch Connector

Courtesy of Mitsubishi Motor Co.

Page 245 of 1333

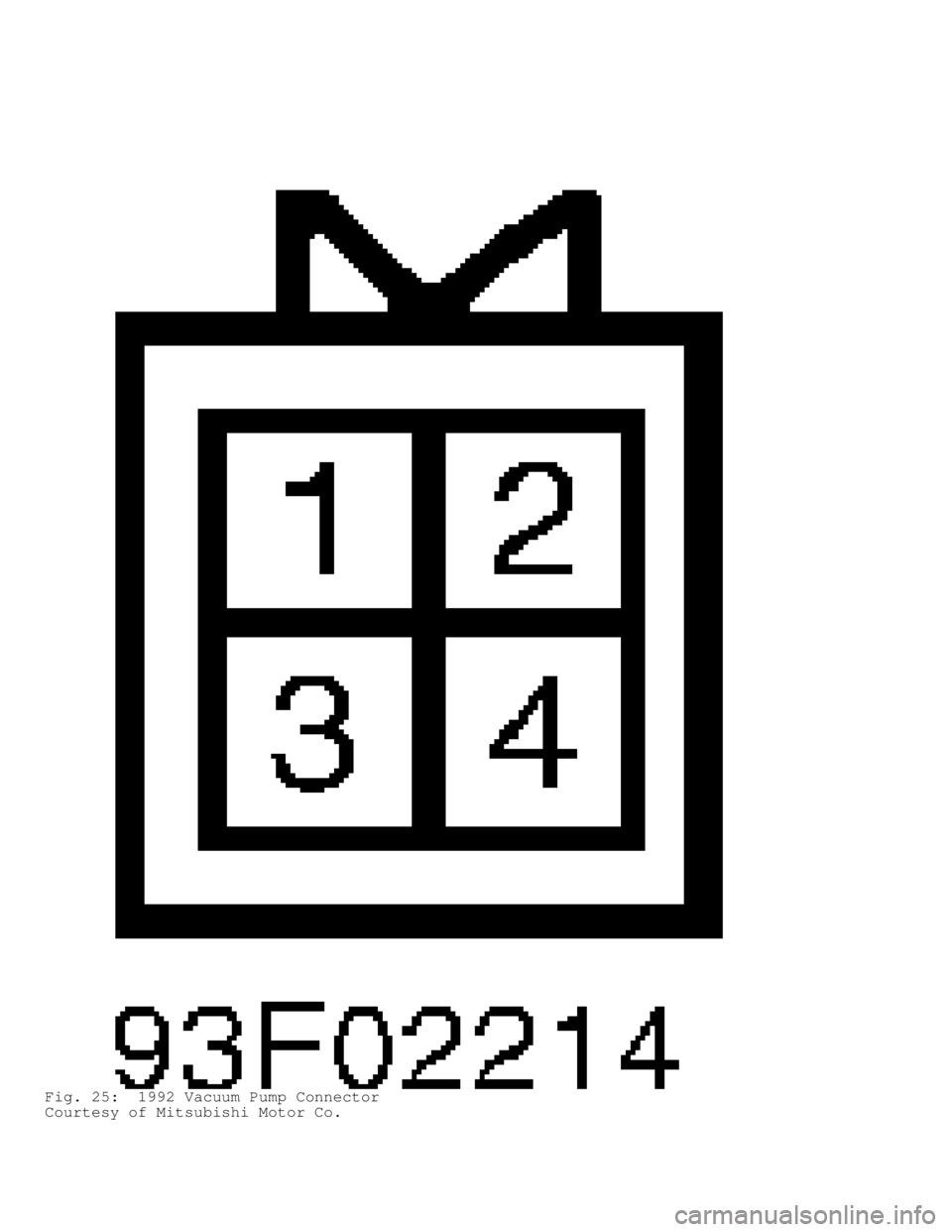

Fig. 25: 1992 Vacuum Pump Connector

Courtesy of Mitsubishi Motor Co.

Page 246 of 1333

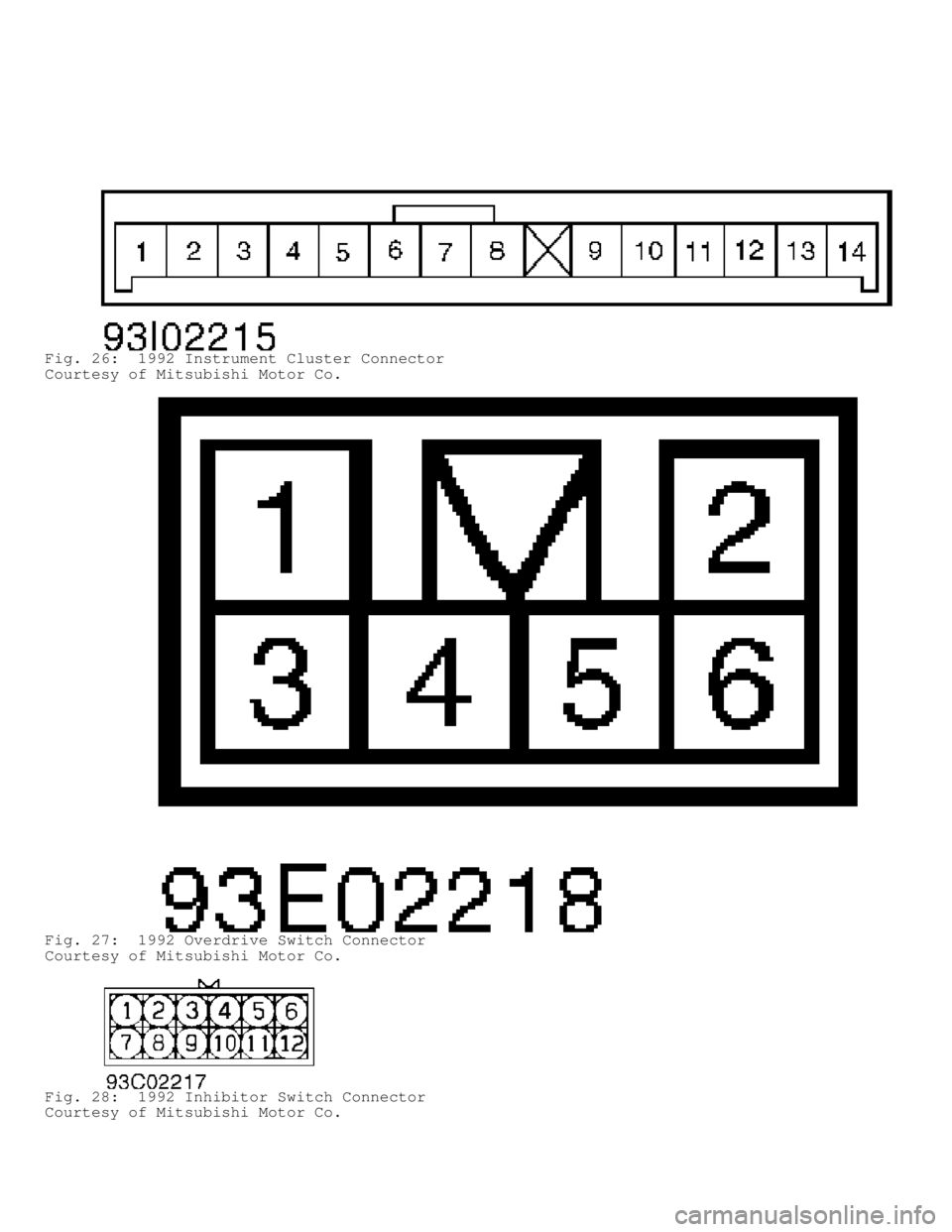

Fig. 26: 1992 Instrument Cluster Connector

Courtesy of Mitsubishi Motor Co.

Fig. 27: 1992 Overdrive Switch Connector

Courtesy of Mitsubishi Motor Co.

Fig. 28: 1992 Inhibitor Switch Connector

Courtesy of Mitsubishi Motor Co.

Page 247 of 1333

Fig. 29: 1992 Throttle Position Sensor & Idle Switch Connector

Courtesy of Mitsubishi Motor Co.

CRUISE CONTROL SWITCH TESTS

Main, Set & Resume Switches (1991)

1) Disconnect 6-pin cruise control switch connector. See

Figs. 17 -21. With main switch in ON position, continuity should be

present between terminals No. 3 and 6 of cruise control switch

connector. With set switch in ON position, continuity should be

present between terminals No. 1 and 2.

2) With resume switch in On position, continuity should be

present between terminals No. 2 and 4, and 3 and 6. If continuity is

not present, replace cruise control switch.

Set & Resume Switches (1992)

1) Remove lower steering column cover. Disconnect 2-pin

switch connector. Operate and test switch. When cancel switch is

operated, continuity should be present between terminals No. 1 and 2.

Zero ohms resistance should be indicated.

2) When resume switch is operated, 820 ohms resistance should

be present between terminals No. 1 and 2. When set switch is operated,

2700 ohms resistance should be present between terminals No. 1 and 2.

Page 248 of 1333

Replace cruise control switch if it does not test correctly.

Main Switch (1992)

1) In each switch position, continuity should be present

between terminals No. 2 and 7 for switch illumination. See Figs. 22-

29. When switch is moved to Neutral position, continuity should be

present between terminals No. 1 and 4.

2) When switch is moved to ON position, continuity should be

present between terminals No. 1, 4 and 5. Connect battery voltage to

terminal No. 5 and ground terminal No. 4.

3) Battery voltage should then be present on terminal No. 1

when main switch is moved to On position. Replace switch if it does

not test correctly.

BRAKELIGHT/STOPLIGHT SWITCH TEST

Disconnect switch connector. When brake pedal is pressed,

continuity should be present between terminals No. 2 and 3. See

Figs. 22 -29. When brake pedal is released, continuity should be

present between terminals No. 1 and 4. Replace switch if it does not

test correctly.

IDLE SWITCH & THROTTLE POSITION SENSOR TESTS

Throttle Position Sensor (1992)

1) Disconnect sensor connector. Resistance between terminals

No. 1 and 4 should be 3500-6500 ohms. Use an analog ohmmeter to

measure resistance between terminals No. 1 and 3. See Figs. 22-29.

2) Slowly open throttle valve to wide open throttle.

Resistance should change smoothly as throttle is opened. Replace

throttle position sensor if it does not test correctly.

Idle Switch (1992)

1) Disconnect throttle position sensor connector. Continuity

should be present between terminals No. 1 and 2 with accelerator pedal

released. See Figs. 22-29. Continuity should not be present with

accelerator pedal pressed.

2) If continuity is not present with accelerator released,

loosen throttle position sensor mounting screw. Turn throttle position

sensor completely clockwise. Recheck continuity. Replace throttle

position sensor if idle switch does not test correctly.

INHIBITOR SWITCH TEST

Disconnect switch connector. Shift transaxle into Neutral and

Park positions. On 1991 models, continuity should be present between

Black/Yellow wire terminals No. 3 and 4. On 1992 models, continuity

should be present between terminals No. 7 and 12. See Figs. 22-29. On

all models, if continuity is not present, adjust inhibitor switch. If

switch is adjusted properly, replace switch.

VACUUM PUMP TEST

1992

1) Remove vacuum pump connector. Resistance should be 50-60

ohms between terminal No. 1 and terminals No. 2 and 3. See Figs. 22-

29. Ensure solenoid valve makes operating noise when battery voltage

is applied between terminal No. 1 and terminals No. 2 and 3.

2) If solenoid valve does not make noise, replace vacuum pump

assembly. Apply battery voltage to terminals No. 1 and 4, motor should

operate. Replace vacuum pump if motor does not operate.

Page 249 of 1333

ACTUATOR TESTS

Resistance Test (1991)

Disconnect actuator connector. Resistance between terminals

No. 1 and 2 should be 20 ohms. See Figs. 17-21. If resistance is not

correct, replace actuator assembly.

Operational Test (1991)

1) With connector disconnected, connect battery voltage to

terminal No. 1. See Figs. 17-21. Ground terminal No. 2. Connect

ammeter between positive side of battery and terminal No. 1 of

actuator connector.

2) Solenoid should make a click sound. Ammeter should read .

5-.7 amps. Connect positive side of battery to terminal No. 4 and

ground terminal No. 3. Actuator should pull in and stop.

3) While actuator is moving in, ammeter should read less than

.5 amps. When actuator travel reaches midpoint, disconnect terminal

No. 1 from positive side of battery. Actuator should return to

original position. If actuator does not test correctly, replace

actuator.

4) Reverse connections of terminals No. 4 and 3 in step 2).

Connect battery voltage to terminal No. 3 and ground terminal No. 4.

Actuator should move out then stop. While actuator is moving, ammeter

should read less than .5 amps.

1992

Remove actuator. Apply vacuum to actuator. Actuator linkage

holder should move more than 1.38" (35 mm). Actuator diaphragm should

hold vacuum. Replace actuator if actuator does not test correctly.

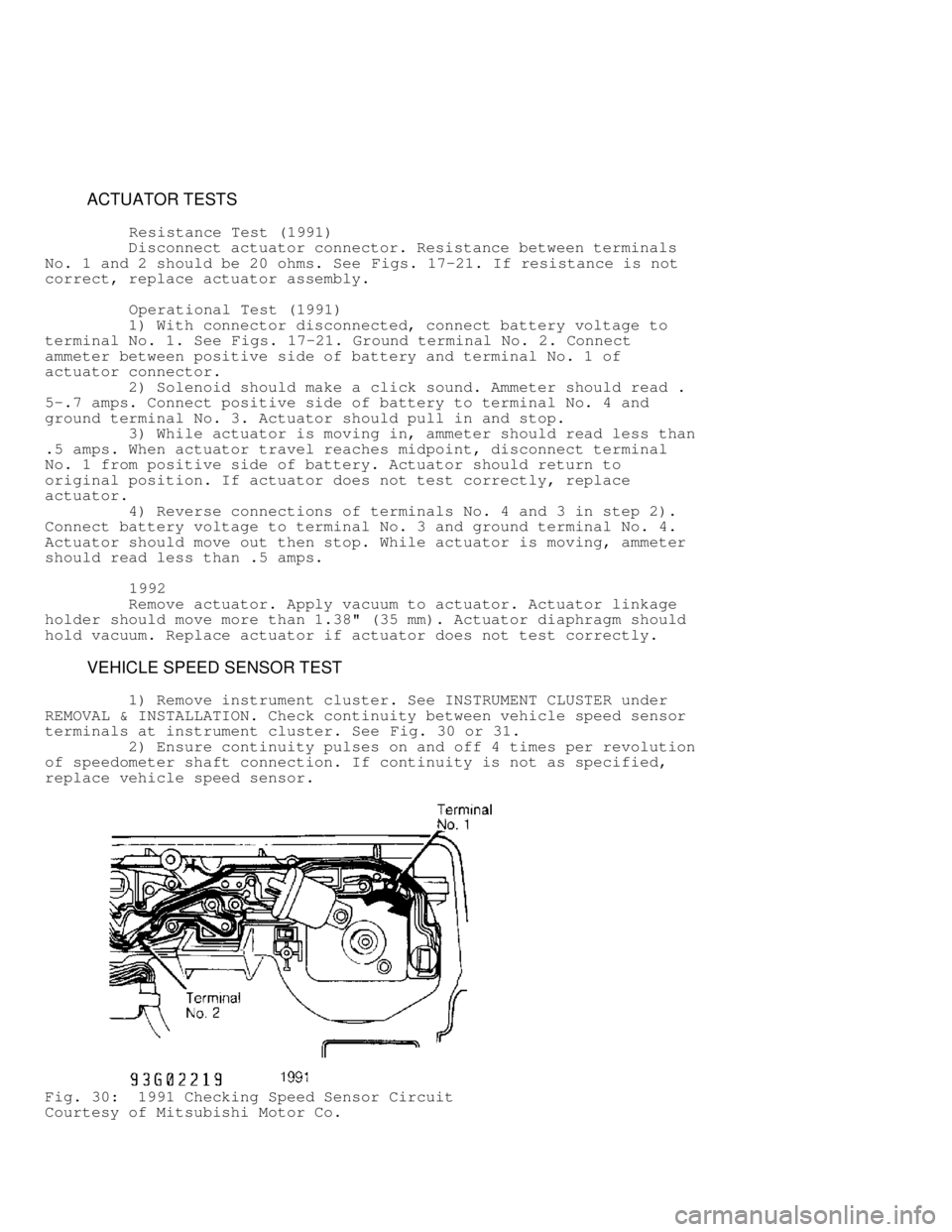

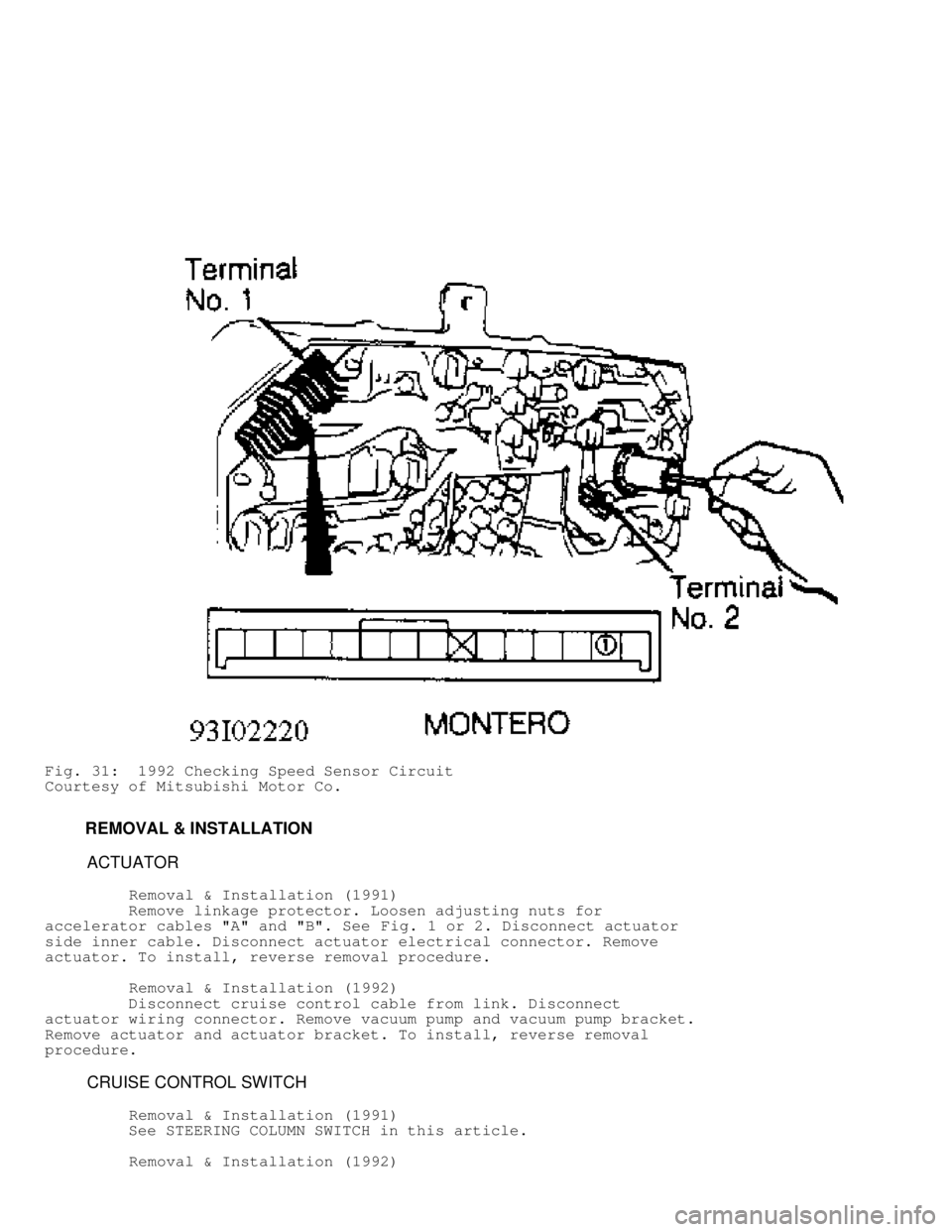

VEHICLE SPEED SENSOR TEST

1) Remove instrument cluster. See INSTRUMENT CLUSTER under

REMOVAL & INSTALLATION. Check continuity between vehicle speed sensor

terminals at instrument cluster. See Fig. 30 or 31.

2) Ensure continuity pulses on and off 4 times per revolution

of speedometer shaft connection. If continuity is not as specified,

replace vehicle speed sensor.

Fig. 30: 1991 Checking Speed Sensor Circuit

Courtesy of Mitsubishi Motor Co.

Page 250 of 1333

Fig. 31: 1992 Checking Speed Sensor Circuit

Courtesy of Mitsubishi Motor Co.

REMOVAL & INSTALLATION

ACTUATOR

Removal & Installation (1991)

Remove linkage protector. Loosen adjusting nuts for

accelerator cables "A" and "B". See Fig. 1 or 2. Disconnect actuator

side inner cable. Disconnect actuator electrical connector. Remove

actuator. To install, reverse removal procedure.

Removal & Installation (1992)

Disconnect cruise control cable from link. Disconnect

actuator wiring connector. Remove vacuum pump and vacuum pump bracket.

Remove actuator and actuator bracket. To install, reverse removal

procedure.

CRUISE CONTROL SWITCH

Removal & Installation (1991)

See STEERING COLUMN SWITCH in this article.

Removal & Installation (1992)