adding oil MITSUBISHI MONTERO 1998 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1998, Model line: MONTERO, Model: MITSUBISHI MONTERO 1998Pages: 1501, PDF Size: 25.81 MB

Page 104 of 1501

Other Means Of Identification

Refrigerant R-134a, when viewed through a sight glass, may

have a "milky" appearance due to the mixture of refrigerant and

lubricating oil. As the refrigerant and oil DO NOT exhibit a "clear"

sight glass on a properly charged A/C system, most R-134a systems have

no sight glass.

REFRIGERANT OILS

NOTE: Use ONLY the specified oil for the appropriate system or A/C

compressor. Always check vehicle underhood A/C specification

label or A/C compressor label before adding refrigerant oil

to A/C compressor/system. See Figs. 2 and 3. Always use

refrigerant oil specified on vehicle underhood A/C

specification label if different from the following list.

Refrigerant R-12 based systems use mineral oil, while R-134a

systems use Polyalkylene Glycol (PAG) oils. Using a mineral oil based

lubricant with R-134a will result in A/C compressor failure due to

lack of proper lubrication. The following R-134a refrigerant oils are

currently specified:

Use DENSO/ND-Oil 8 refrigerant oil on Nippondenso

compressors. Use SUN PAG 56 refrigerant oil on Sanden compressors.

NOTE: PAG oils absorb moisture very rapidly, 2.3-5.6 percent by

weight, as compared to a mineral oil absorption rate of

0.005 percent by weight.

SERVICE EQUIPMENT

A/C systems using R-134a refrigerant and PAG lubricants

cannot use R-12 refrigerant or mineral oil lubricants. R-134a

refrigerant is NOT compatible or interchangeable with R-12

refrigerant. Separate sets of hoses, manifold gauge sets and

recovery/recycling equipment are required to service the different

systems. This is necessary to avoid cross-contaminating and damaging

A/C system. A single set of A/C service equipment cannot be cleaned

thoroughly enough to be used with both types of refrigerant.

All equipment used to service A/C systems using R-134a must

be U.L. listed and certified to meet SAE standard J2210. The service

hoses on the manifold gauge set must have manual (turn wheel) or

automatic back-flow valves at the service port connector ends. This

will prevent refrigerant from being released into the atmosphere.

For identification purposes, R-134a service hoses must have a

Black stripe along its length and be clearly labeled SAE J2196/R-134a.

The low pressure test hose is Blue with a Black stripe. The high

pressure test hose is Red with a Black stripe, and the center test

hose is Yellow with a Black stripe.

R-134a manifold gauge sets can be identified by one or all of

the following: Labeled FOR USE WITH R-134a on set, labeled HFC-134a or

R-134a on gauge face, or by a Light Blue color on gauge face. In

addition, pressure/temperature scales on R-134a gauge sets are

different from R-12 manifold gauge sets.

SYSTEM SERVICE VALVES

SCHRADER-TYPE VALVES

NOTE: Although similar in construction and operation to a tire

valve, NEVER replace a Schrader-type valve with a tire valve.

Page 968 of 1501

allowing metal objects to contact the battery posts and the

vehicle at the same time.

CAUTION: Never disconnect the battery while the engine is running;

doing so could damage the car's electrical components.

REPLACING BLOWN FUSES

Before replacing a blown fuse, remove ignition key, turn off

all lights and accessories to avoid damaging the electrical system. Be

sure to use fuse with the correct indicated amperage rating. The use

of an incorrect amperage rating fuse may result in a dangerous

electrical system overload.

BRAKE PAD WEAR INDICATOR

Indicator will cause a squealing or scraping noise, warning

that brake pads need replacement.

BRAKE FLUID

WARNING: DO NOT use reclaimed fluid or fluid that has been stored

in old or open containers. It is essential that foreign

particles and other liquids are kept out of the brake fluid

reservoir.

CATALYTIC CONVERTER

Continued operation of vehicle with a severe malfunction

could cause converter to overheat, resulting in possible damage to

converter and vehicle.

ENGINE COOLANT SERVICE

WARNING: To avoid the danger of being scalded never change the coolant

when the engine is hot.

WARNING: Never remove the radiator cap when the engine is hot Serious

burns could be caused by high pressure fluid escaping from

the radiator.

CAUTION: When adding or replacing engine coolant, use a high quality

ethylene glycol antifreeze diluted with 50% distilled water.

When putting the cap on the reserve tank, line up the arrow

on the cap and the arrow on the tank, or coolant can leak out

ENGINE DRIVE BELT SERVICE

WARNING: Be sure the ignition key is OFF. The engine could rotate

unexpectedly.

ENGINE OIL

WARNING: The engine oil may be high enough to burn your fingers

when the drain plug is loosened. Wait until the drain plug

is cool enough to touch with you bare hands.

WARNING: Continuous contact with used engine oil has been found to

cause skin cancer in laboratory animals. Brief contact with

used engine oil may irritate skin. To minimize your exposure

to used oil, wear a long sleeve shirt and moisture-proof

gloves when changing oil. If oil contacts your skin, wash

Page 1085 of 1501

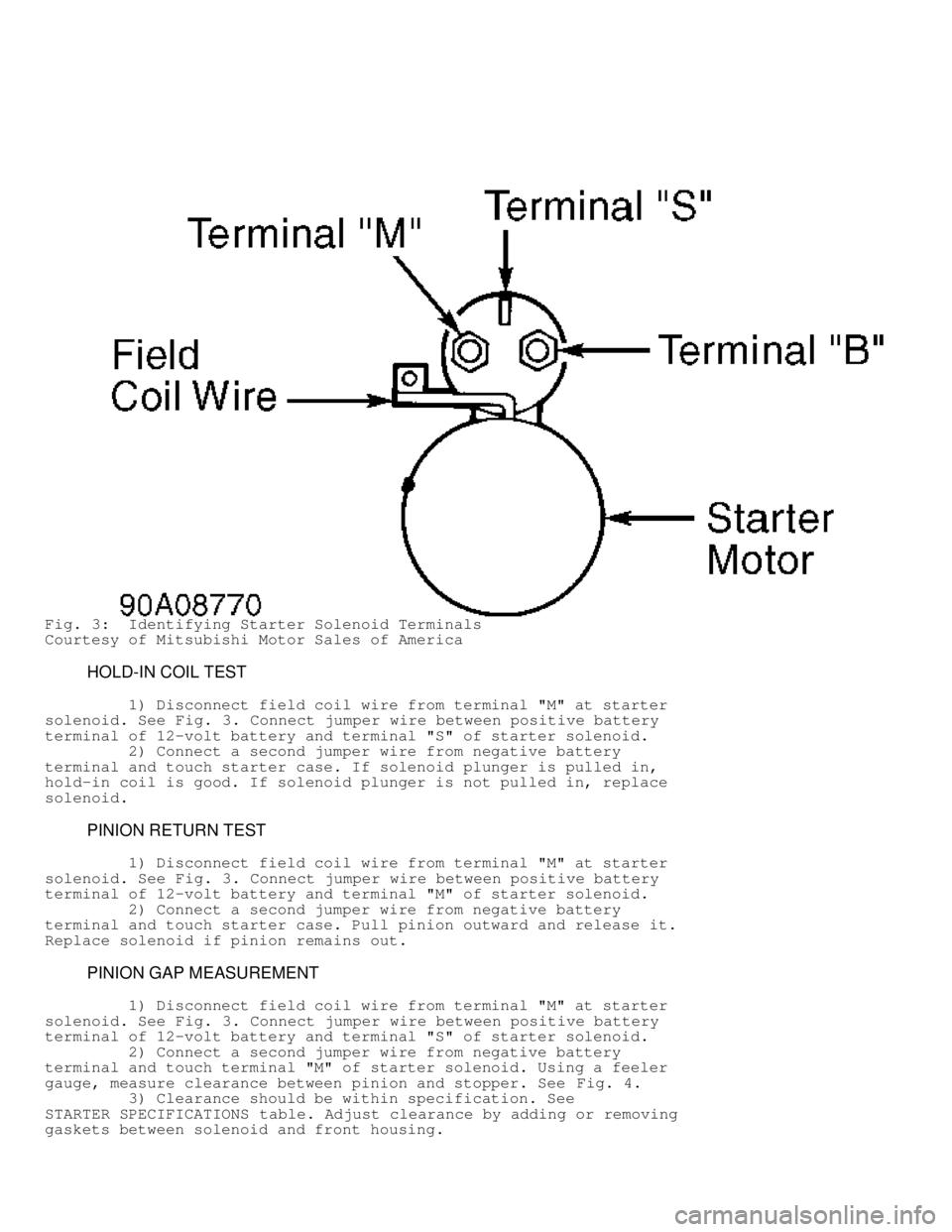

Fig. 3: Identifying Starter Solenoid Terminals

Courtesy of Mitsubishi Motor Sales of America

HOLD-IN COIL TEST

1) Disconnect field coil wire from terminal "M" at starter

solenoid. See Fig. 3. Connect jumper wire between positive battery

terminal of 12-volt battery and terminal "S" of starter solenoid.

2) Connect a second jumper wire from negative battery

terminal and touch starter case. If solenoid plunger is pulled in,

hold-in coil is good. If solenoid plunger is not pulled in, replace

solenoid.

PINION RETURN TEST

1) Disconnect field coil wire from terminal "M" at starter

solenoid. See Fig. 3. Connect jumper wire between positive battery

terminal of 12-volt battery and terminal "M" of starter solenoid.

2) Connect a second jumper wire from negative battery

terminal and touch starter case. Pull pinion outward and release it.

Replace solenoid if pinion remains out.

PINION GAP MEASUREMENT

1) Disconnect field coil wire from terminal "M" at starter

solenoid. See Fig. 3. Connect jumper wire between positive battery

terminal of 12-volt battery and terminal "S" of starter solenoid.

2) Connect a second jumper wire from negative battery

terminal and touch terminal "M" of starter solenoid. Using a feeler

gauge, measure clearance between pinion and stopper. See Fig. 4.

3) Clearance should be within specification. See

STARTER SPECIFICATIONS table. Adjust clearance by adding or removing

gaskets between solenoid and front housing.