MITSUBISHI MONTERO 2000 Service Repair Manual

MONTERO 2000

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57331/w960_57331-0.png

MITSUBISHI MONTERO 2000 Service Repair Manual

Trending: alternator, reverse lamp, run flat, ABS, fuel pump, service reset, jacking

Page 1101 of 1839

M

B990947 M

B990847

M B990981

A

B L

.H ., R .H . - Fro nt R

ear M

B991318 M

B9911 83 M

B990843

D C

Page 1102 of 1839

REAR AXLE

Click on the applicable bookmark to selected the required model year.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1103 of 1839

27-1

REAR AXLE

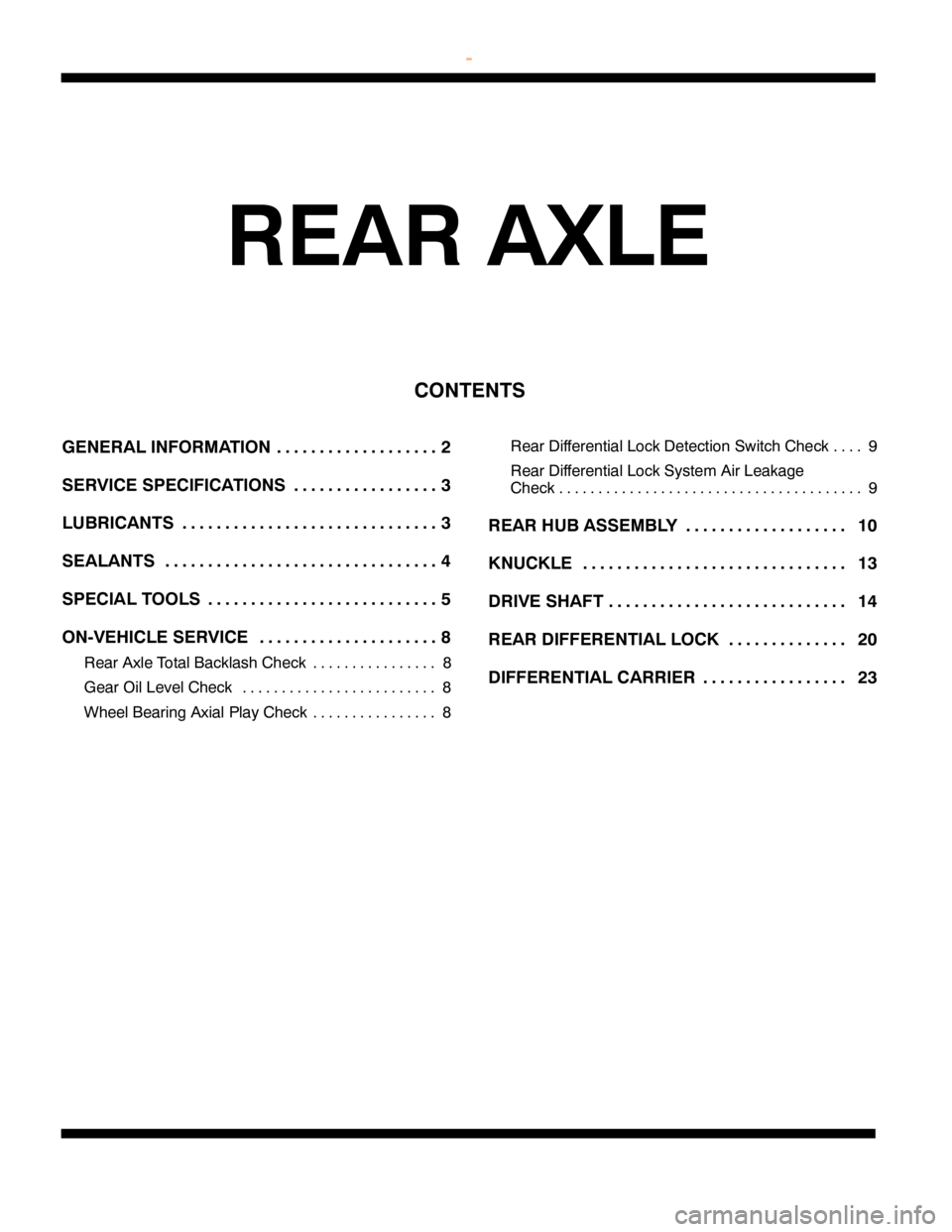

CONTENTS

GENERAL INFORMATION 2...................

SERVICE SPECIFICATIONS 3.................

LUBRICANTS 3..............................

SEALANTS 4................................

SPECIAL TOOLS 5...........................

ON-VEHICLE SERVICE 8.....................

Rear Axle Total Backlash Check 8................

Gear Oil Level Check 8.........................

Wheel Bearing Axial Play Check 8................Rear Differential Lock Detection Switch Check 9....

Rear Differential Lock System Air Leakage

Check 9.......................................

REAR HUB ASSEMBLY 10...................

KNUCKLE 13...............................

DRIVE SHAFT 14............................

REAR DIFFERENTIAL LOCK 20..............

DIFFERENTIAL CARRIER 23.................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1104 of 1839

REAR AXLE -General Information27-2

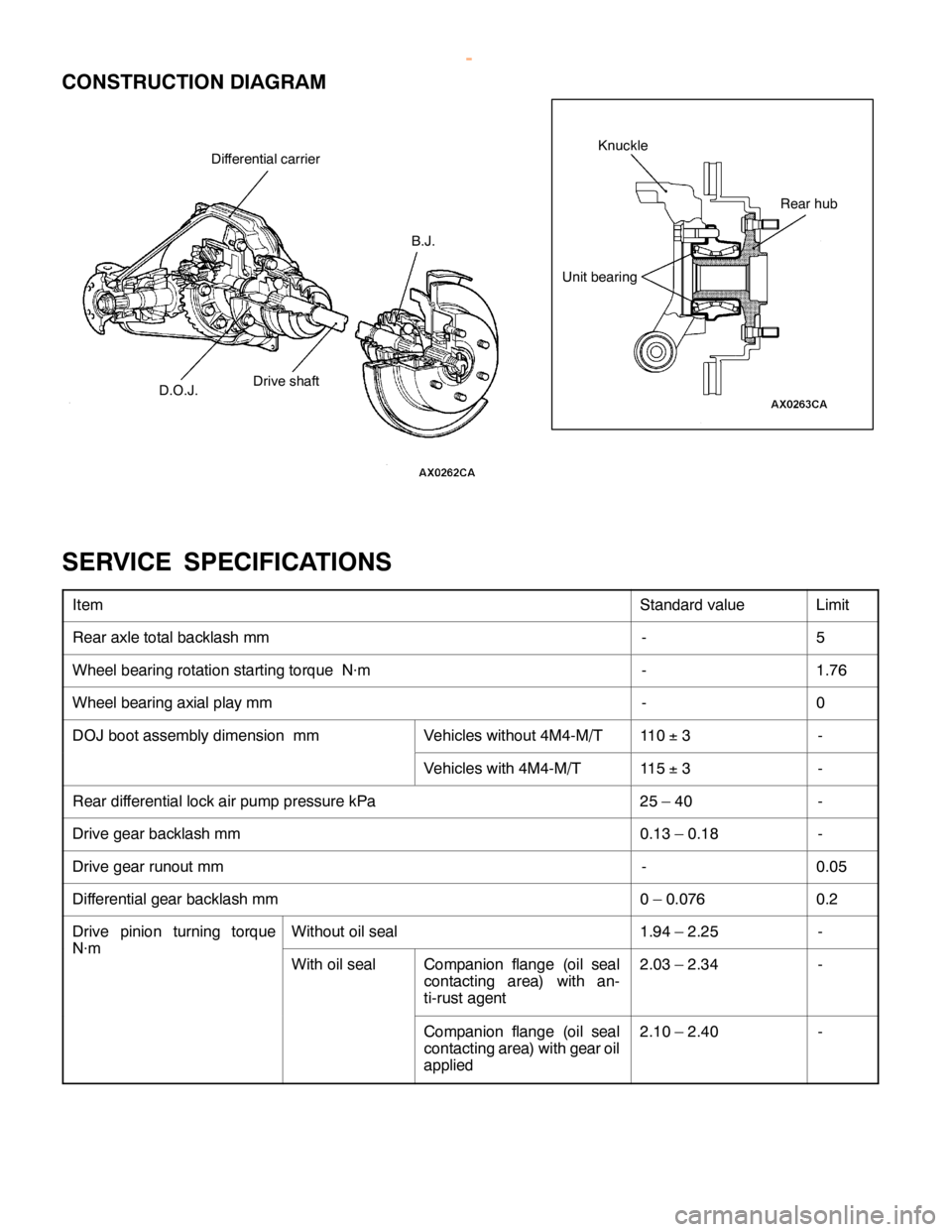

GENERAL INFORMATION

The rear axle has the following features.

DD.O.J.-type on the differential side and B.J.-type on the hub side constant velocity joints are featured

in the drive shaft.

DLarge capacity and high rigidity taper-roller type unit bearing in the wheel bearing is featured.

DThe hybrid LSD and differential lock with LSD which benefit driving on muddy and rough roads are

featured as an option.

DABS rotor to detect wheel speed is press-fitted in the drive shaft.

NOTE

The structure of normal differential and hybrid LSD is basically the same as featured in existing models.

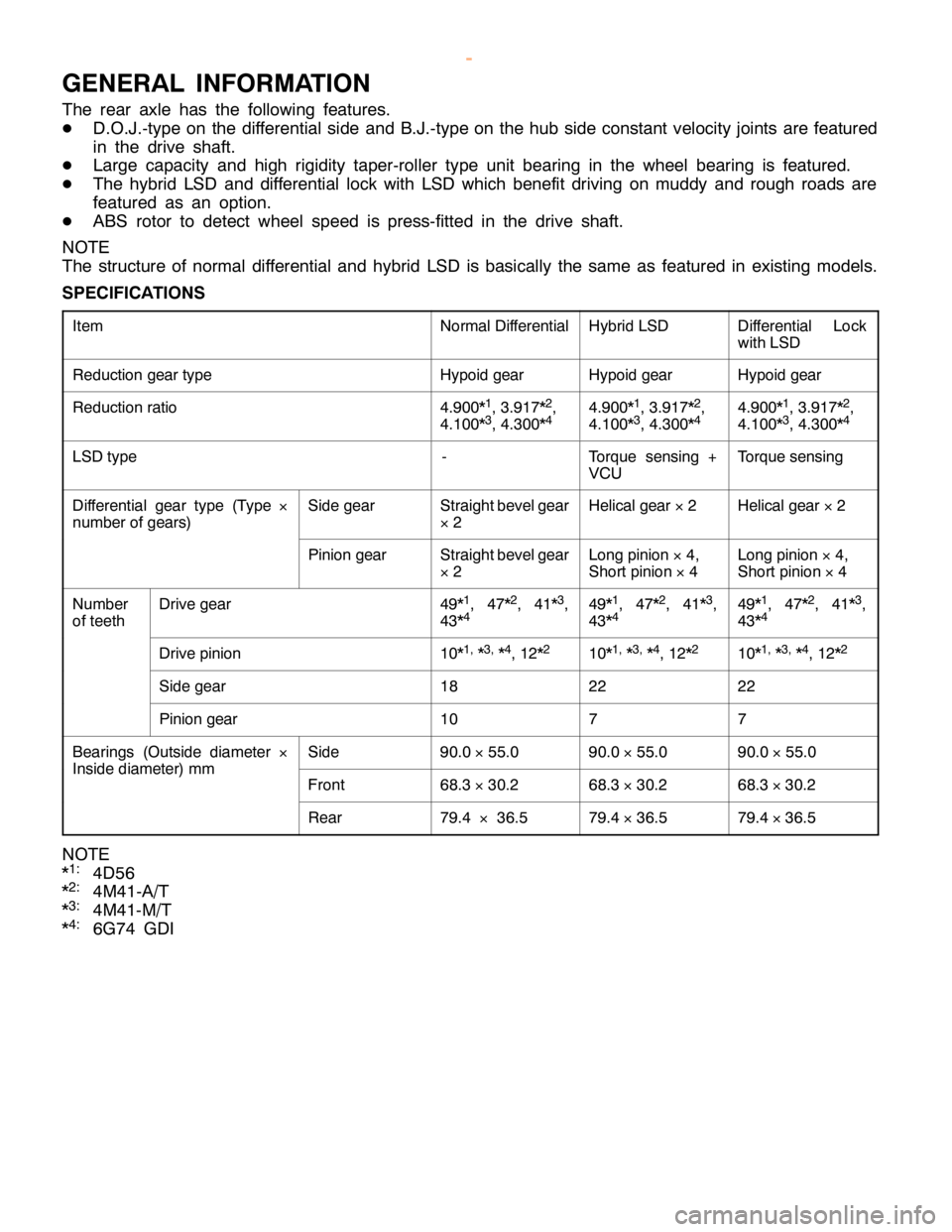

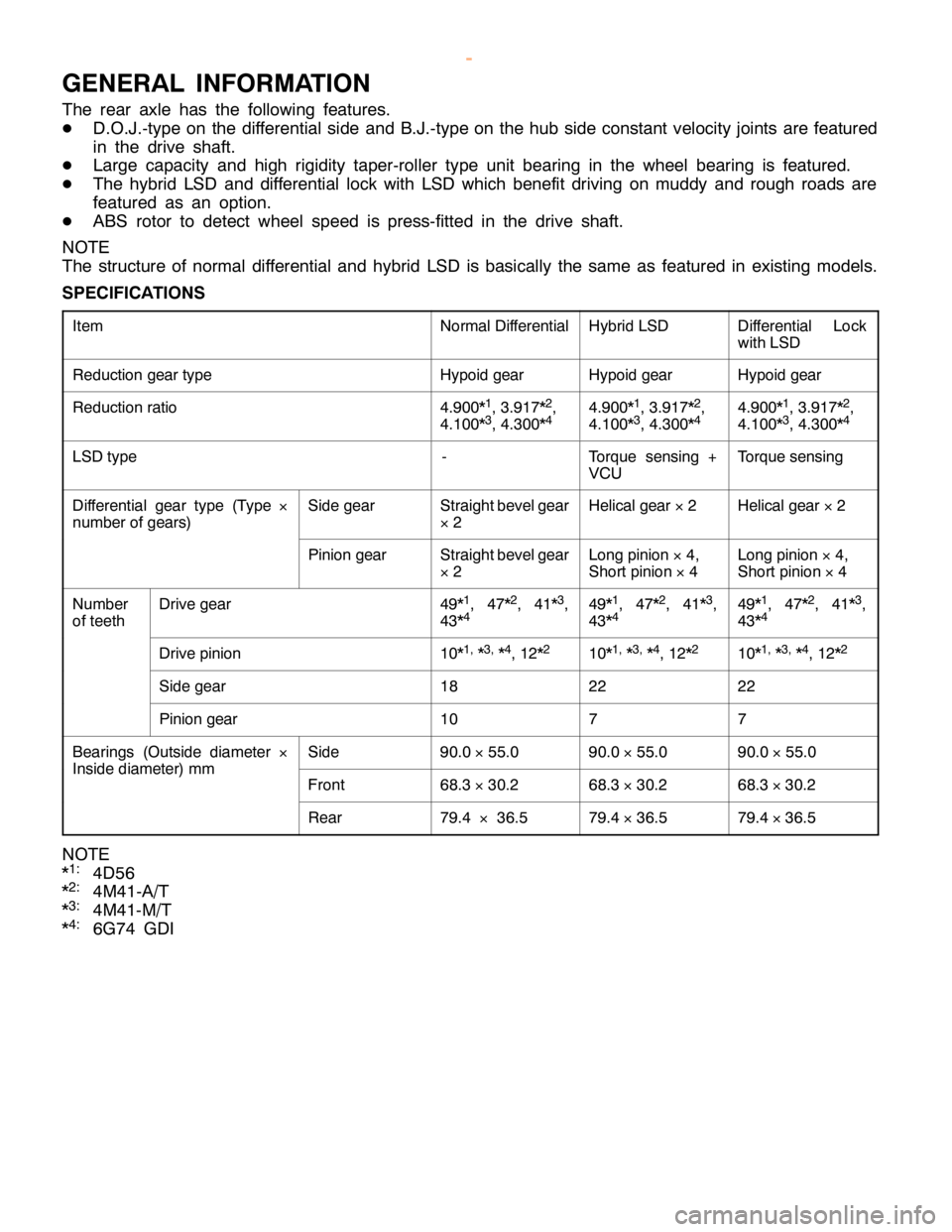

SPECIFICATIONS

ItemNormal DifferentialHybrid LSDDifferential Lock

with LSD

Reduction gear typeHypoid gearHypoid gearHypoid gear

Reduction ratio4.900*1, 3.917*2,

4.100*3, 4.300*44.900*1, 3.917*2,

4.100*3, 4.300*44.900*1, 3.917*2,

4.100*3, 4.300*4

LSD type-Torque sensing +

VCUTorque sensing

Differential gear type (Type´

number of gears)Side gearStraight bevel gear

´2Helical gear´2Helical gear´2

Pinion gearStraight bevel gear

´2Long pinion´4,

Short pinion´4Long pinion´4,

Short pinion´4

Number

of teethDrive gear49*1, 47*2, 41*3,

43*449*1, 47*2, 41*3,

43*449*1, 47*2, 41*3,

43*4

Drive pinion10*1,*3,*4, 12*210*1,*3,*4, 12*210*1,*3,*4, 12*2

Side gear182222

Pinion gear1077

Bearings (Outside diameter´Side90.0´55.090.0´55.090.0´55.0

Inside diameter) mm

Front68.3´30.268.3´30.268.3´30.2

Rear79.4´36.579.4´36.579.4´36.5

NOTE

*1:4D56

*2:4M41-A/T

*3:4M41-M/T

*4:6G74 GDI

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1105 of 1839

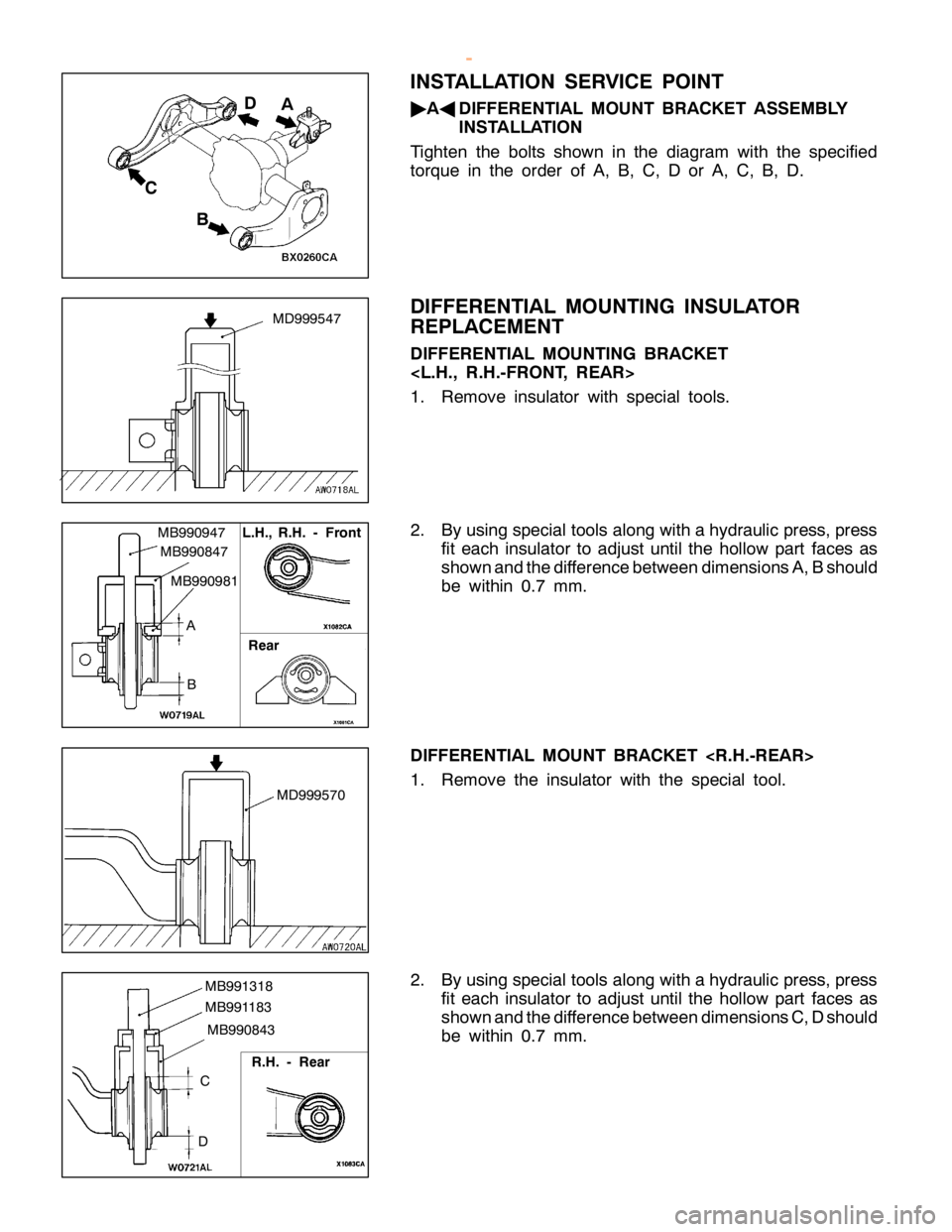

D

if f e re ntia lca rrie r

D riv e sh aft U

nit b earin g R

ear hub

K

nuckle

S ER VIC E SPEC IF IC ATIO NS

I te m S

ta ndard va lu e L

im it R

ear axle to ta lb ackla sh mm - 5

W

heelb earin g ro ta tio n sta rtin g to rq ue N×m - 1

.7 6 W

heelb earin g axia lp la y m m - 0

D

O J boota sse m bly dim ensio n mm V

ehic le s wit h out 4M 4-M /T 1

1 0 ± 3 -

V

ehic le s wit h 4M 4-M /T 1

1 5 ± 3 -

R

ear dif f e re ntia llo ck air pum p pre ssu re kP a 2

5 – 40 -

D

riv e gear backla sh mm 0

.1 3 – 0.1 8 -

D

riv e gear ru nout m m - 0

.0 5 D

if f e re ntia lg ear backla sh mm 0

–0.0 76 0

.2 D

riv e pin io n tu rn in g to rq ue W

it h out oil se al 1

.9 4 – 2.2 5 -

N

×m W

it h oil se al C

om panio n fla nge (o il se al

c o nta ctin g are a) wit h an-

t i- ru st agent 2

.0 3 – 2.3 4 -

C

om panio n fla nge (o il se al

c o nta ctin g are a) w it h gearo il

a pplie d 2

.1 0 – 2.4 0 -

Page 1106 of 1839

REAR AXLE -Lubricants/Sealants27-4

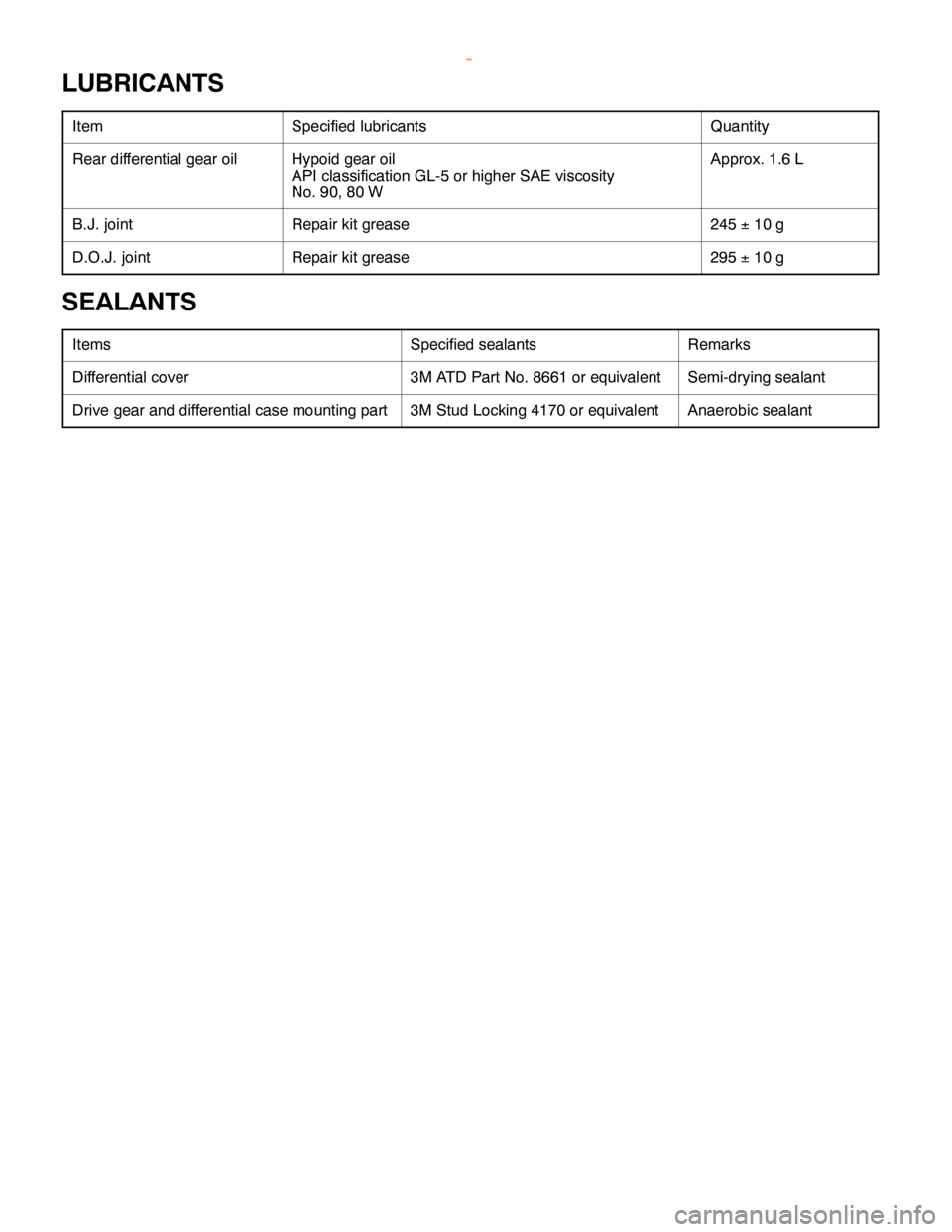

LUBRICANTS

ItemSpecified lubricantsQuantity

Rear differential gear oilHypoid gear oilApprox. 1.6 L

API classification GL-5 or higher SAE viscosity

No. 90, 80 W

B.J. jointRepair kit grease245±10 g

D.O.J. jointRepair kit grease295±10 g

SEALANTS

ItemsSpecified sealantsRemarks

Differential cover3M ATD Part No. 8661 or equivalentSemi-drying sealant

Drive gear and differential case mounting part3M Stud Locking 4170 or equivalentAnaerobic sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1107 of 1839

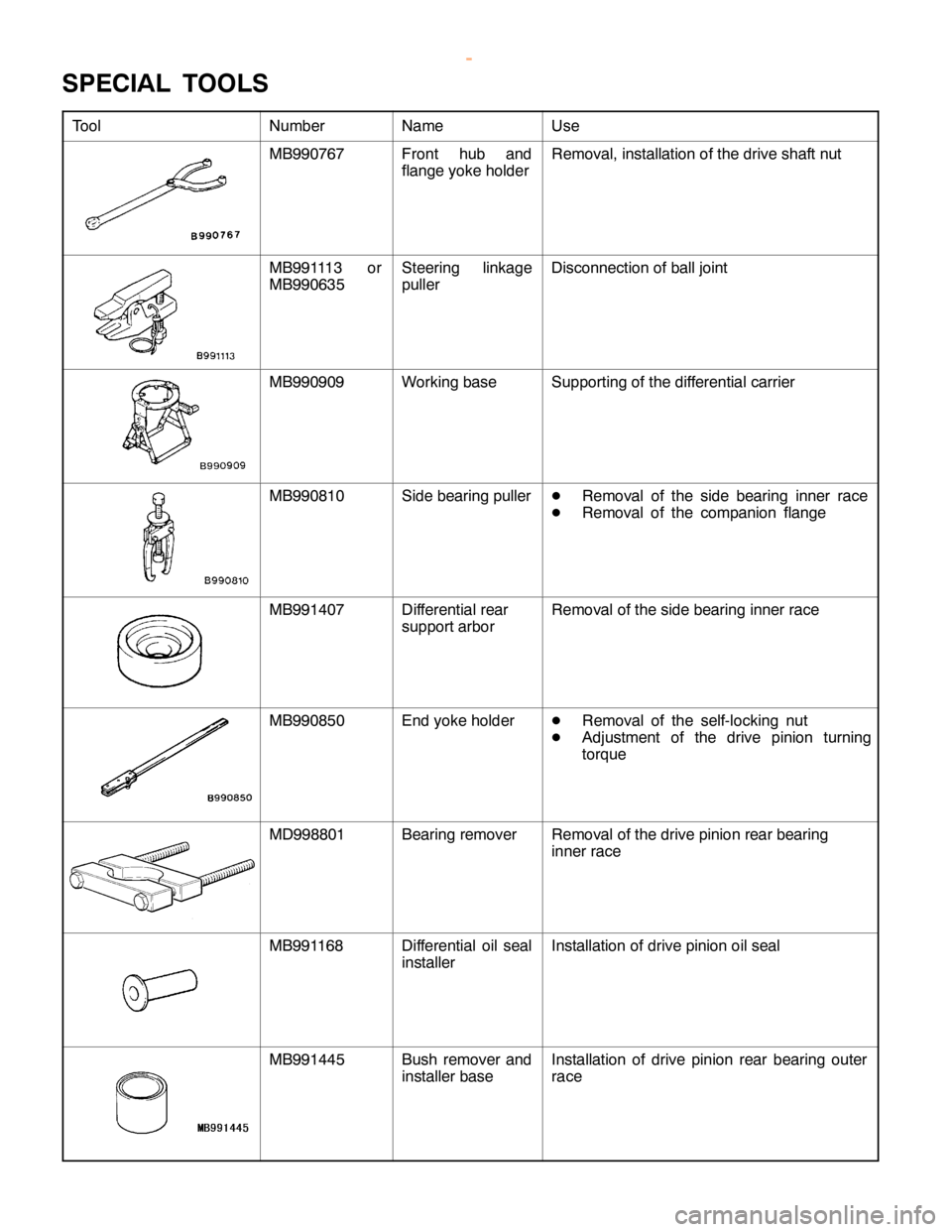

S

PEC IA L TO OLS

T o ol N

um ber N

am e U

se M

B990767 F

ro nt hub and

f la nge yo ke hold er R

em ova l, in sta lla tio n of th e driv e sh aft nut M

B99111 3 or

M B990635 S

te erin g lin ka ge

p ulle r D

is co nnectio n of ball jo in t M

B990909 W

ork in g base S

upportin g of th e dif f e re ntia lca rrie r M

B990810 S

id e bearin g pulle r M

B991407 D

if f e re ntia lre ar

s u pport arb or R

em ova lo f th e sid e bearin g in ner ra ce M

B990850 E

nd yo ke hold er M

D998801 B

earin g re m ove r R

em ova lo f th e driv e pin io n re ar bearin g

i n ner ra ce M

B9911 68 D

if f e re ntia l oil se al

i n sta lle r I

n sta lla tio n of driv e pin io n oil se al M

B991445 B

ush re m ove r and

i n sta lle r base I

n sta lla tio n of driv e pin io n re ar bearin g oute r

r a ce

Page 1108 of 1839

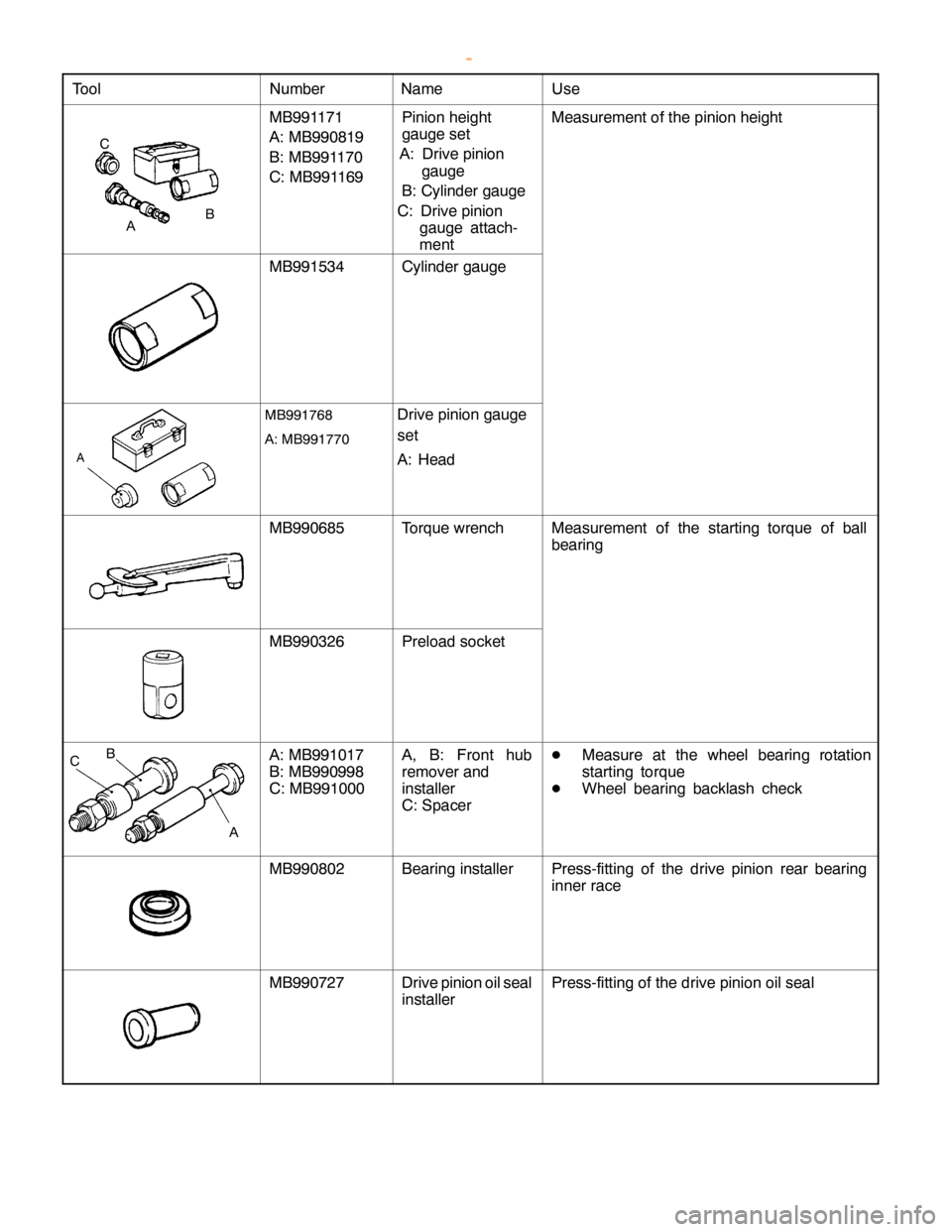

P

in io n heig ht

g auge se t

A : Driv e pin io n

g auge

B :C ylin der gauge

C : Driv e pin io n

g auge atta ch -

m ent M

easu re m ent of th e pin io n heig ht M

B991534 C

ylin der gauge M

B990685 T

o rq ue wre nch M

easu re m ent of th e sta rtin g to rq ue of ball

b earin g M

B990326 P

re lo ad so cke t B

C A

, B: Fro nt hub

r e m ove r and

i n sta lle r

C :S pace r M

B990802 B

earin g in sta lle r P

re ss-fit tin g of th e driv e pin io n re ar bearin g

i n ner ra ce M

B990727 D

riv e pin io n oil s e al

i n sta lle r P

re ss-fit tin g of th e driv e pin io n oil se al

Page 1109 of 1839

M

D998812 I

n sta lle r ca p P

re ss-fit tin g of th e sid e bearin g in ner ra ce M

D998829 I

n sta lle r adapto r A B

earin g and oil

s e alin sta lle r se t

A :In sta lle r adapto r

B :B ar

C :B ra ss bar

Page 1110 of 1839

O

N-V EH IC LE SER VIC E

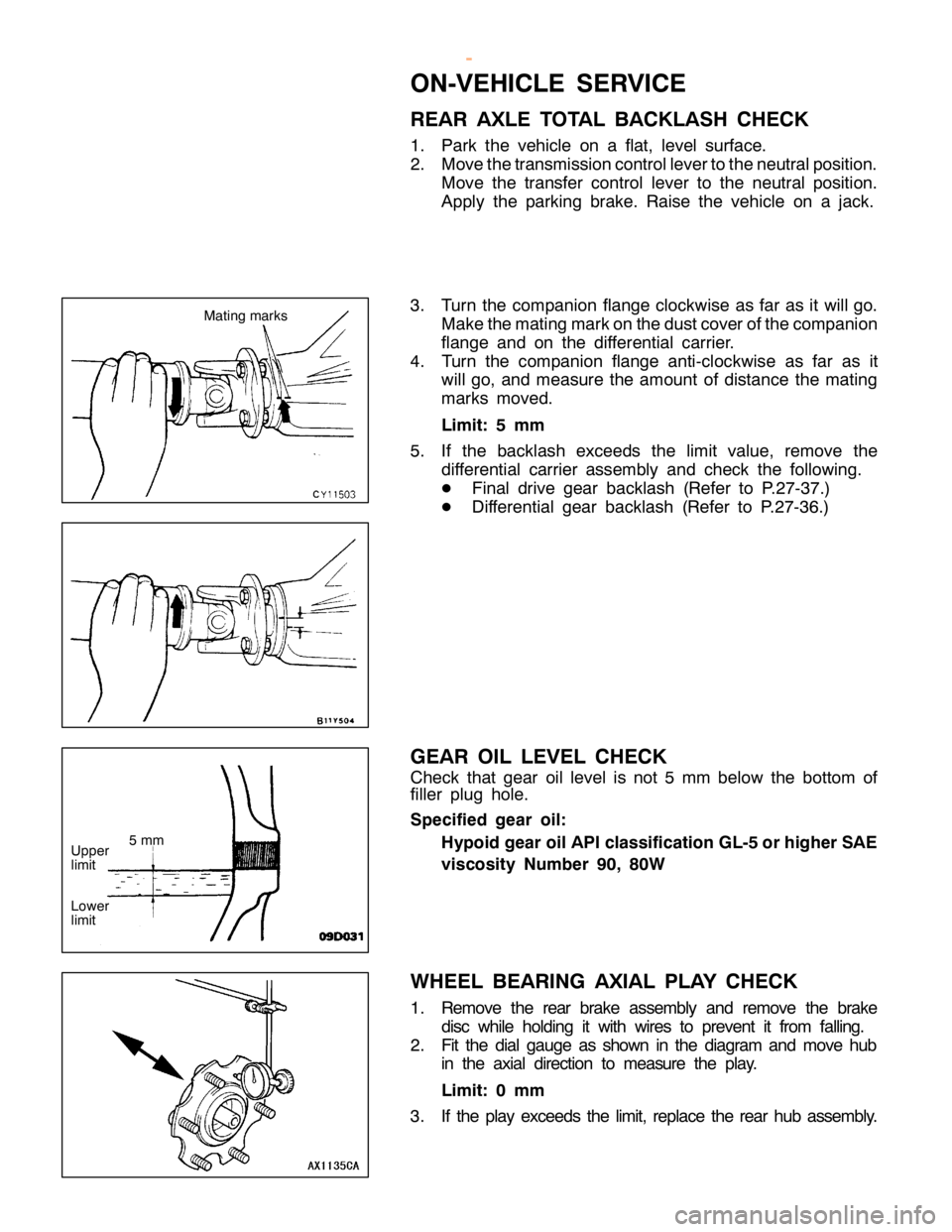

R EA R AXLE TO TA L BACKLA SH CHEC K

1 . Park th e ve hic le on afla t, le ve l su rfa ce .

2 . Move th e tr a nsm is sio n co ntr o lle ve rto th e neutr a lp osit io n.

M ove th e tr a nsfe r co ntr o l le ve r to th e neutr a l posit io n.

A pply th e park in g bra ke . Rais e th e ve hic le on aja ck.

3 . Turn th e co m panio n fla nge clo ckw is e as fa r as it w ill g o.

M ake th e m atin g m ark on th e dustc o ve r ofth e co m panio n

f la nge and on th e dif f e re ntia l ca rrie r.

4 . Turn th e co m panio n fla nge anti- c lo ckw is e as fa r as it

w ill g o, and measu re th e am ount of dis ta nce th e matin g

m ark s move d.

L im it : 5 mm

5 . If th e backla sh exce eds th e lim it va lu e, re m ove th e

d if f e re ntia l ca rrie r asse m bly and ch eck th e fo llo w in g.

D F

in al driv e gear backla sh (R efe r to P.2 7-3 7.)

D D

if f e re ntia l gear backla sh (R efe r to P.2 7-3 6.)

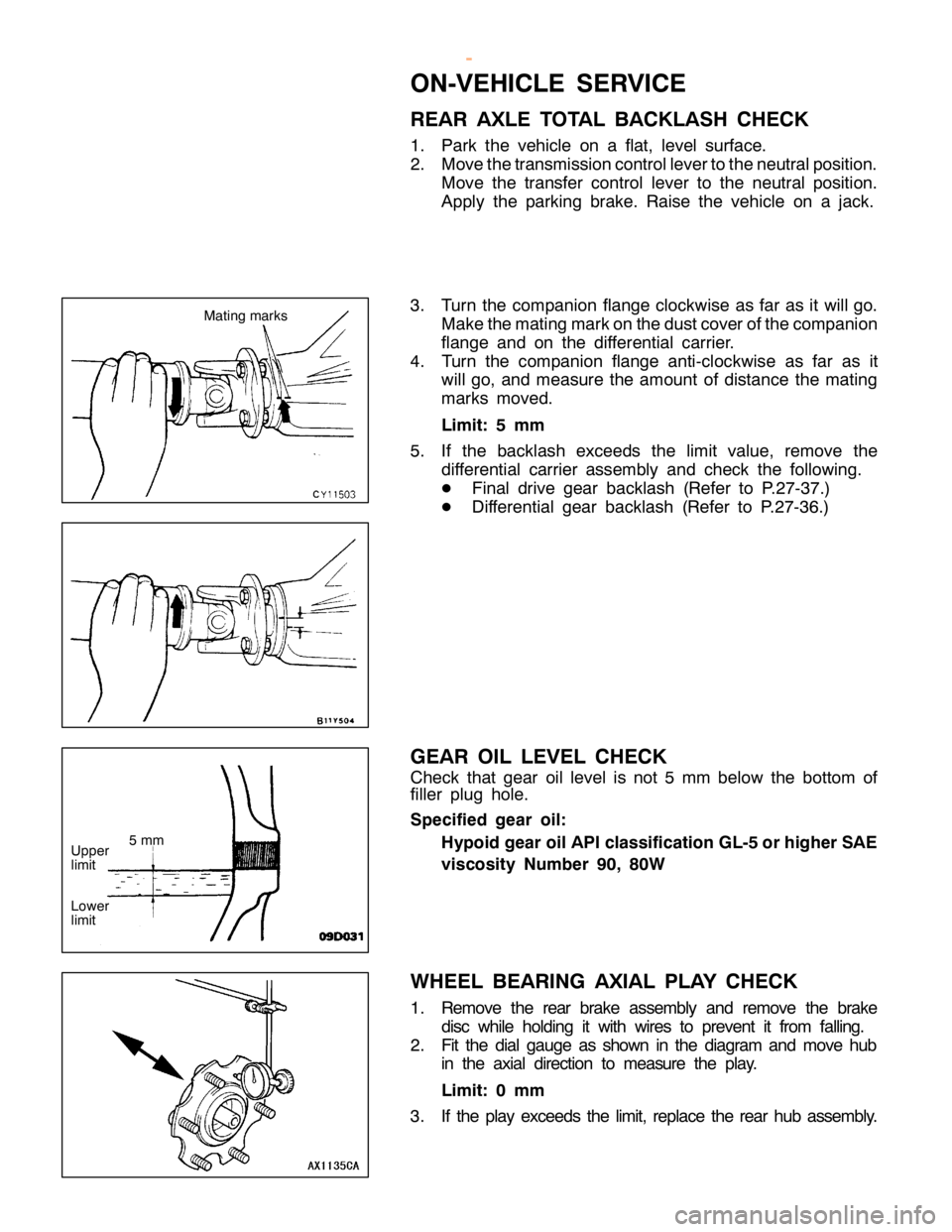

G EA R OIL LE VEL CHEC K

C heck th at gear oil le ve l is not 5 mm belo w th e botto m of

f ille r plu g hole .

S pecif ie d gear oil:

H yp oid gear oil A PIcla ssif ic atio n GL-5 or hig her S A E

v is co sit y Num ber 90, 80W

W HEEL BEA RIN G AXIA L PLA Y CHEC K

1 . Rem ove th e re ar bra ke asse m bly and re m ove th e bra ke

d is c while hold in g it wit h wir e s to pre ve nt it fr o m fa llin g.

2 . Fit th e dia l gauge as sh ow n in th e dia gra m and move hub

i n th e axia l dir e ctio n to measu re th e pla y.

L im it : 0 mm

3 . If th e pla y exce eds th e lim it , re pla ce th e re ar hub asse m bly . U

pper

l im it 5

mm

L ow er

l im it

Trending: trip computer, low oil pressure, reverse lamp, keyless, parking, ESP, parking brake