steering MITSUBISHI MONTERO 2000 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

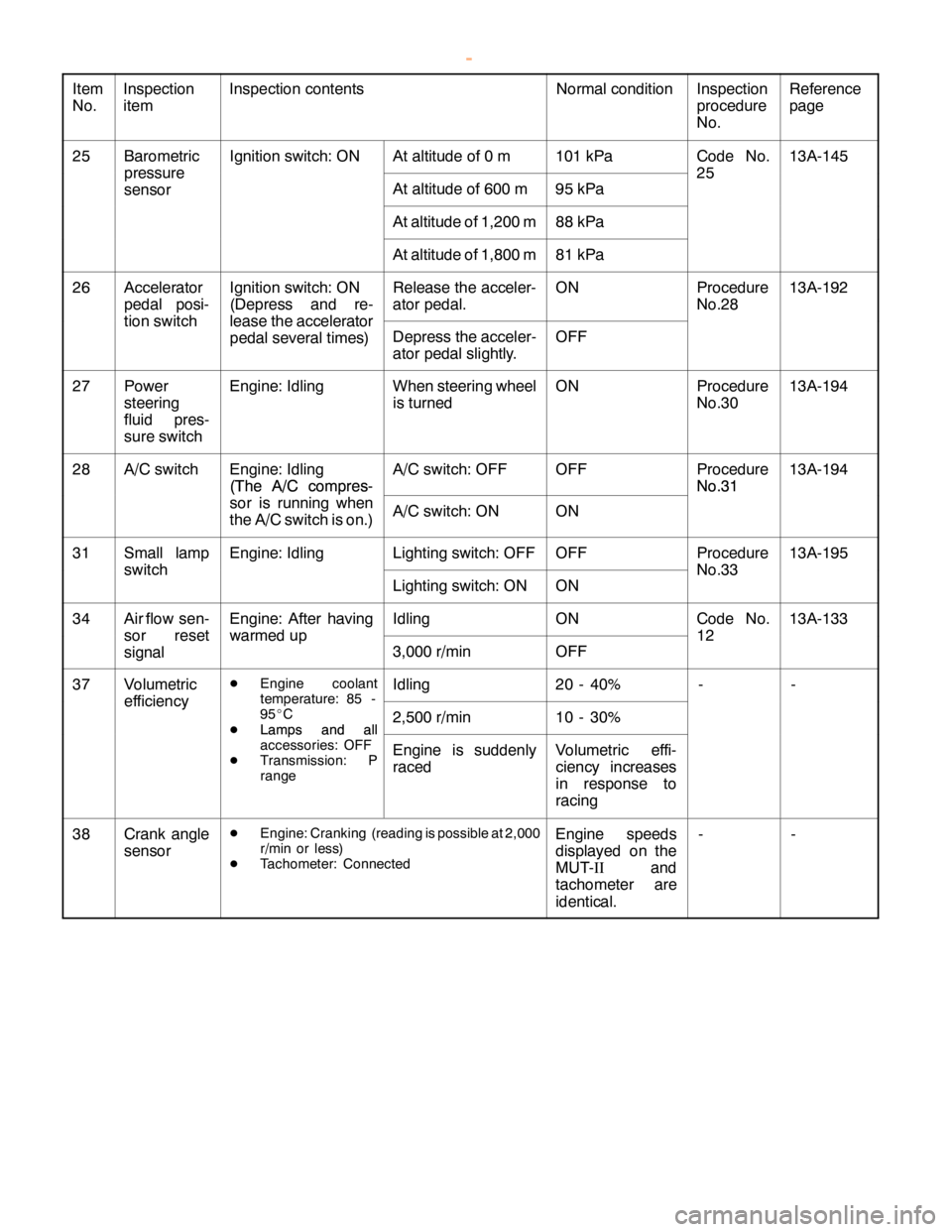

Page 414 of 1839

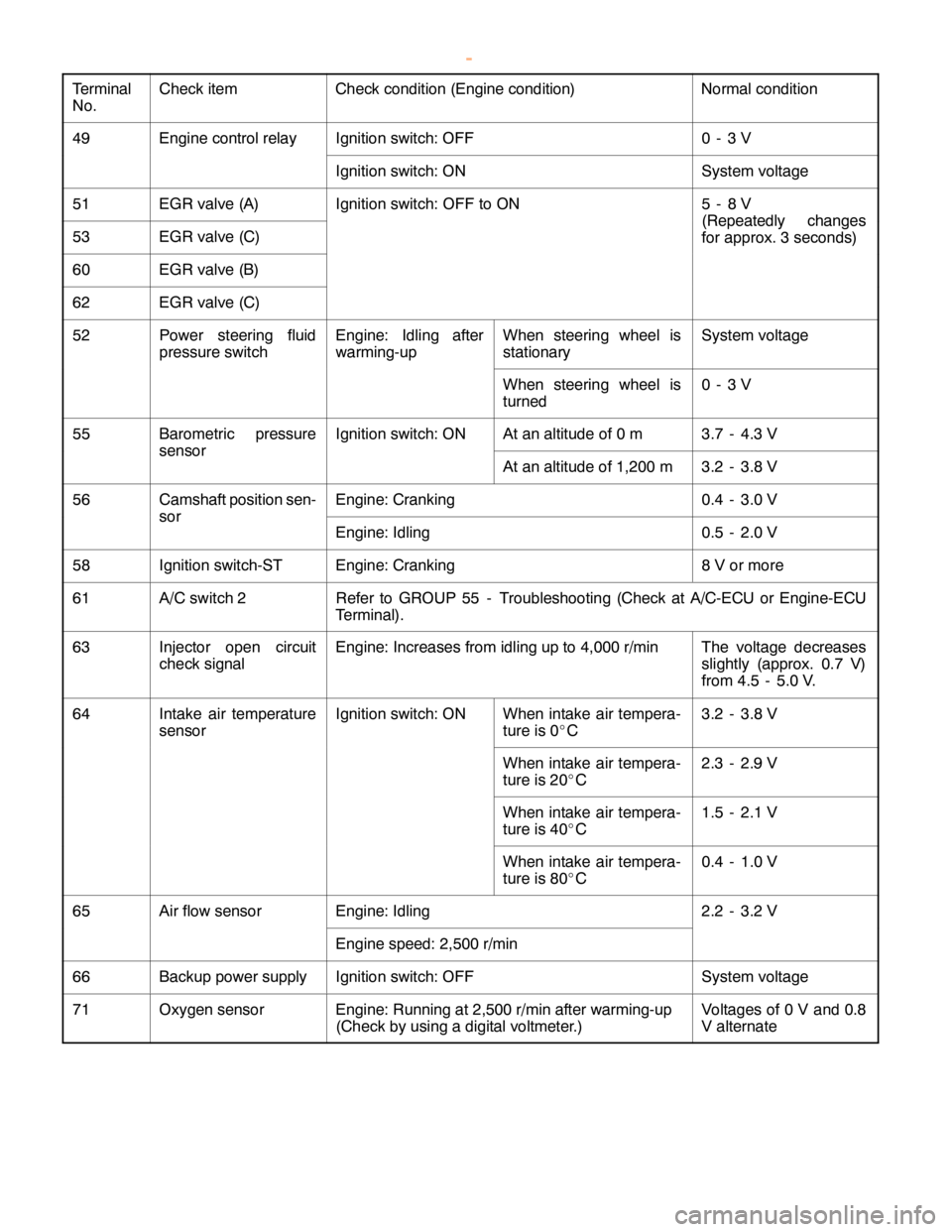

Page 420 of 1839

Page 464 of 1839

15

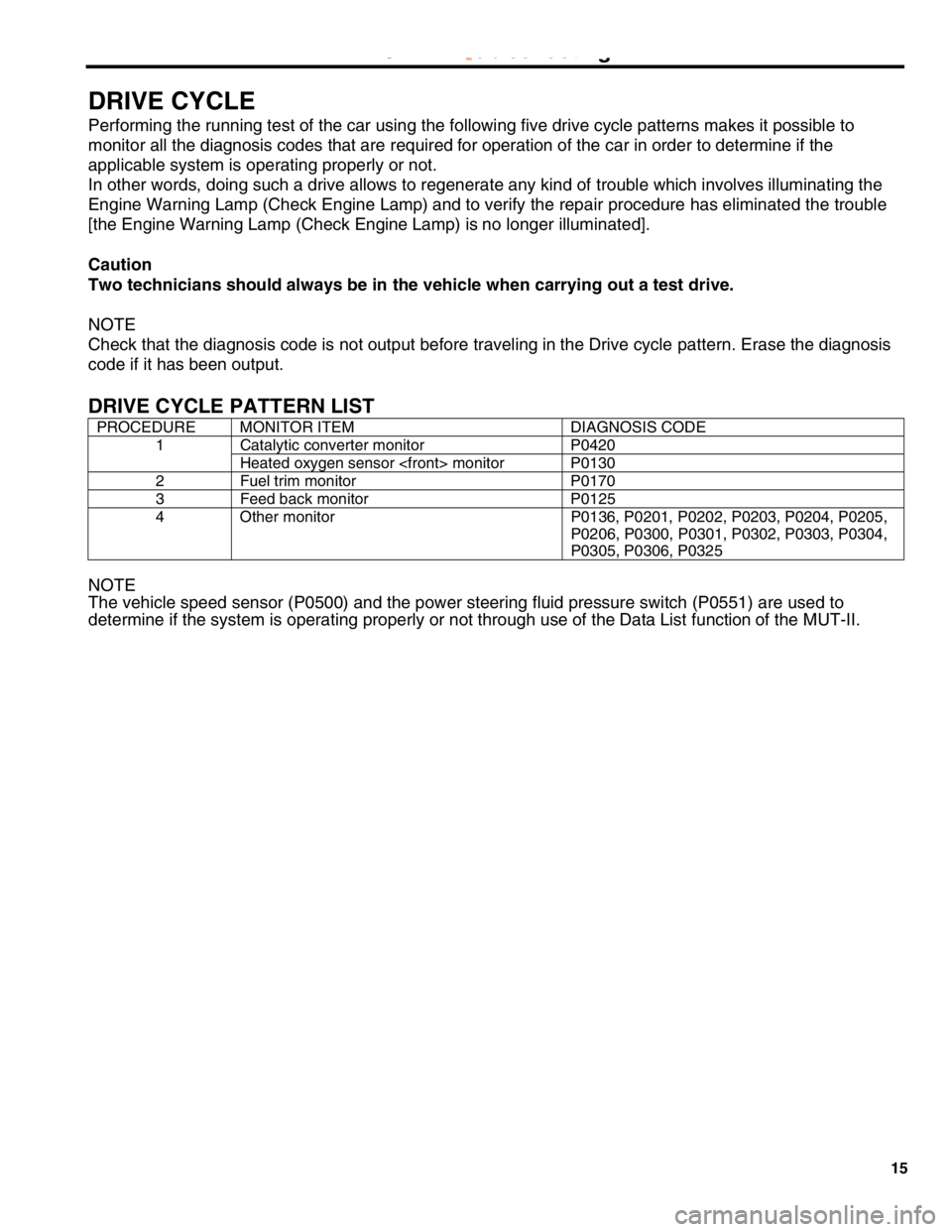

DRIVE CYCLE

Performing the running test of the car using the following five drive cycle patterns makes it possible to

monitor all the diagnosis codes that are required for operation of the car in order to determine if the

applicable system is operating properly or not.

In other words, doing such a drive allows to regenerate any kind of trouble which involves illuminating the

Engine Warning Lamp (Check Engine Lamp) and to verify the repair procedure has eliminated the trouble

[the Engine Warning Lamp (Check Engine Lamp) is no longer illuminated].

Caution

Two technicians should always be in the vehicle when carrying out a test drive.

NOTE

Check that the diagnosis code is not output before traveling in the Drive cycle pattern. Erase the diagnosis

code if it has been output.

DRIVE CYCLE PATTERN LIST

PROCEDURE MONITOR ITEM DIAGNOSIS CODE

Catalytic converter monitor P04201

Heated oxygen sensor

2 Fuel trim monitor P0170

3 Feed back monitor P0125

4 Other monitor P0136, P0201, P0202, P0203, P0204, P0205,

P0206, P0300, P0301, P0302, P0303, P0304,

P0305, P0306, P0325

NOTE

The vehicle speed sensor (P0500) and the power steering fluid pressure switch (P0551) are used to

determine if the system is operating properly or not through use of the Data List function of the MUT-II.

2001 PAJERO/MONTERO WAGON Workshop Manual 6G74

GDI - Troubleshooting

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

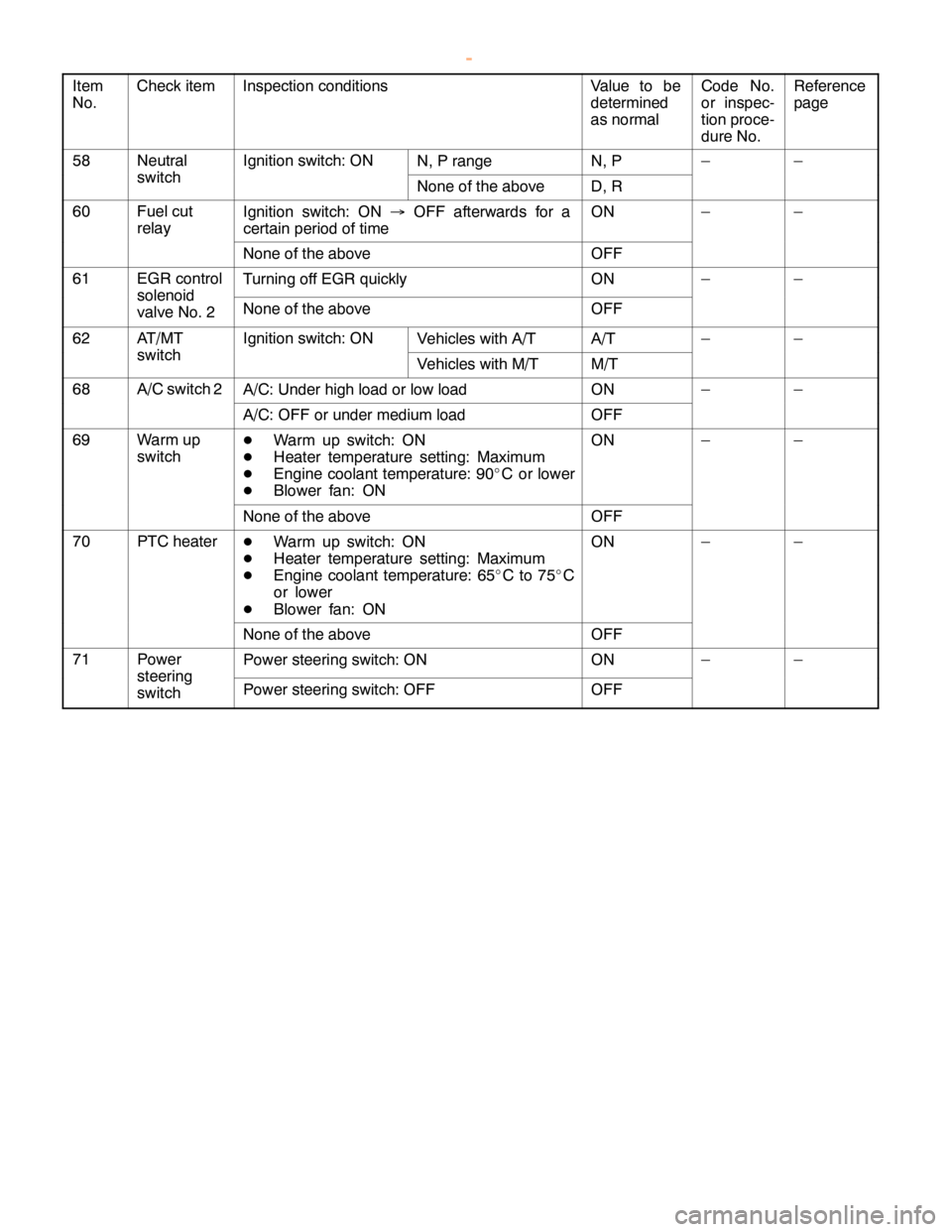

Page 527 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-36

Item

No.Reference

page Code No.

or inspec-

tion proce-

dure No. Value to be

determined

as normal Inspection conditions Check item

58NeutralIgnition switch: ONN, P rangeN, P––

switchNone of the aboveD, R

60Fuel cut

relayIgnition switch: ON®OFF afterwards for a

certain period of timeON––

None of the aboveOFF

61EGR controlTurning off EGR quicklyON––

solenoid

valve No. 2None of the aboveOFF

62AT/MTIgnition switch: ONVehicles with A/TA/T––

switchVehicles with M/TM/T

68A/C switch 2A/C: Under high load or low loadON––

A/C: OFF or under medium loadOFF

69Warm up

switchDWarm up switch: ON

DHeater temperature setting: Maximum

DEngine coolant temperature: 90_C or lower

DBlower fan: ONON––

None of the aboveOFF

70PTC heaterDWarm up switch: ON

DHeater temperature setting: Maximum

DEngine coolant temperature: 65_Cto75_C

or lower

DBlower fan: ONON––

None of the aboveOFF

71PowerPower steering switch: ONON––

steering

switchPower steering switch: OFFOFF

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1165 of 1839

POWER PLANT MOUNT - No.1 Crossmember32-7

No.1 CROSSMEMBER

REMOVAL AND INSTALLATION

Caution

1. Before removing the steering wheel and airbag module assembly, always refer to GROUP 52B

- Service Precautions, Airbag Module and Clock Spring. Also, set the front wheels so that

they are facing straight forward, and remove the ignition key. If you fail to do this, the SRS

clock spring will be damaged, causing the SRS airbag to be inoperative and serious injury.

2. *: Indicates parts which should be initially tightened, and then fully tightened after placing

the vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

DUnder Cover Removal

DDrive Shaft Removal

(Refer to GROUP 26.)

DDifferential Carrier and No.2 Crossmember

Assembly Removal (Refer to GROUP 26 -

Freewheel Assembly and Differential Carrier.)

DUpper Arm Removal

(Refer to GROUP 33A.)

DLower Arm Removal

(Refer to GROUP 33A.)

DStabilizer Bar Removal

(Refer to GROUP 33A.)

DEngine Oil Cooler Removal<6G7>

(Refer to GROUP 12.)

DAir Cleaner Removal<4M4>

(Refer to GROUP 15.)

DIntercooler Removal<4M4>

(Refer to GROUP 15.)

DEngine Cover Removal

(Refer to GROUP 11A - Timing Belt.)

DRadiator Removal

(Refer to GROUP 14.)

DPower Steering Fluid Draining

(Refer to GROUP 37A - On - vehicle Service.)Post - installation Operations

DDifferential Carrier and No.2 Crossmember

Assembly Installation (Refer to GROUP 26 -

Freewheel Assembly and Differential Carrier.)

DDrive Shaft Installation

(Refer to GROUP 26.)

DLower Arm Installation

(Refer to GROUP 33A.)

DUpper Arm Installation

(Refer to GROUP 33A.)

DStabilizer Bar Installation

(Refer to GROUP 33A.)

DAir Cleaner Installation<4M4>

(Refer to GROUP 15.)

DIntercooler Installation<4M4>

(Refer to GROUP 15.)

DRadiator Installation

(Refer to GROUP 14.)

DEngine Oil Cooler Installation

(Refer to GROUP 12.)

DPower Steering Fluid Supplying

(Refer to GROUP 37A - On - vehicle Service.)

DPower Steering Fluid Line Bleeding

(Refer to GROUP 37A - On - vehicle Service.)

DPress the dust cover with a finger tocheck whether

the dust cover is cracked or damaged.

DChecking Steering Wheel Position with Wheels

StraightAhead

DFront Wheel AlignmentCheck and Adjustment

(Refer to GROUP 37A - On - vehicle Service.)

DUnder Cover Installation

DEngine Cover Installation

(Refer to GROUP 11A - Timing Belt.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1265 of 1839

ABS <4WD> -General Information35B-2

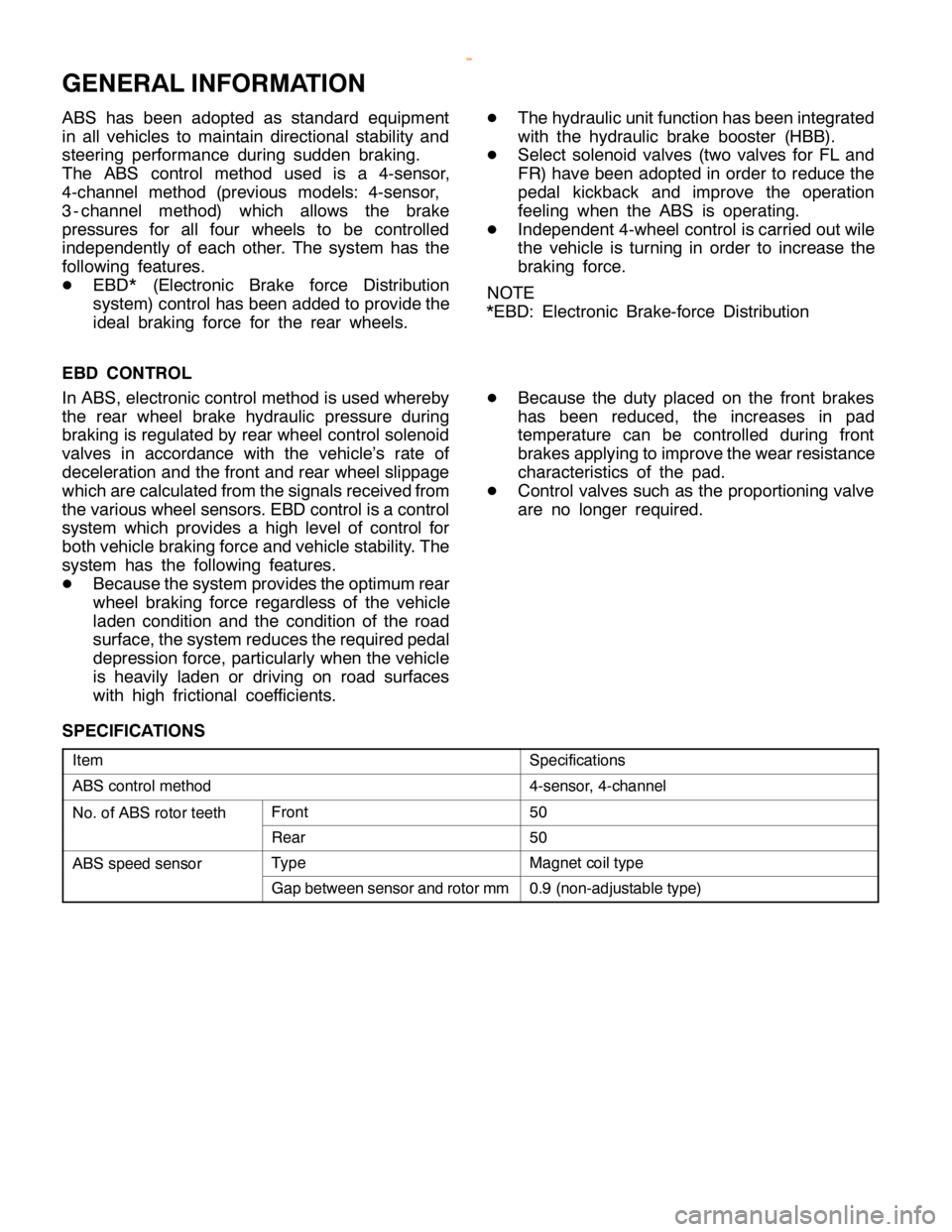

GENERAL INFORMATION

ABS has been adopted as standard equipment

in all vehicles to maintain directional stability and

steering performance during sudden braking.

The ABS control method used is a 4-sensor,

4-channel method (previous models: 4-sensor,

3- channel method

)which allows the brake

pressures for all four wheels to be controlled

independently of each other. The system has the

following features.

DEBD

*(Electronic Brake force Distribution

system) control has been added to provide the

ideal braking force for the rear wheels.DThe hydraulic unit function has been integrated

with the hydraulic brake booster (HBB).

DSelect solenoid valves (two valves for FL and

FR) have been adopted in order to reduce the

pedal kickback and improve the operation

feeling when the ABS is operating.

DIndependent 4-wheel control is carried out wile

the vehicle is turning in order to increase the

braking force.

NOTE

*EBD: Electronic Brake-force Distribution

EBD CONTROL

In ABS, electronic control method is used whereby

the rear wheel brake hydraulic pressure during

braking is regulated by rear wheel control solenoid

valves in accordance with the vehicle’s rate of

deceleration and the front and rear wheel slippage

which are calculated from the signals received from

the various wheel sensors. EBD control is a control

system which provides a high level of control for

both vehicle braking force and vehicle stability. The

system has the following features.

DBecause the system provides the optimum rear

wheel braking force regardless of the vehicle

laden condition and the condition of the road

surface, the system reduces the required pedal

depression force, particularly when the vehicle

is heavily laden or driving on road surfaces

with high frictional coefficients.DBecause the duty placed on the front brakes

has been reduced, the increases in pad

temperature can be controlled during front

brakes applying to improve the wear resistance

characteristics of the pad.

DControl valves such as the proportioning valve

are no longer required.

SPECIFICATIONS

ItemSpecifications

ABS control method4-sensor, 4-channel

No. of ABS rotor teethFront50

Rear50

ABS speed sensorTypeMagnet coil type

Gap between sensor and rotor mm0.9 (non-adjustable type)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1309 of 1839

STEERING

Click on the applicable bookmark to selected the required model year.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1310 of 1839

37A-1

STEERING

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 5.................

LUBRICANTS 5..............................

SEALANT AND ADHESIVE 5.................

SPECIAL TOOLS 6..........................

ON-VEHICLE SERVICE 8.....................

Steering Wheel Free Play Check 8..............

Steering Angle Check 8........................

Tie Rod End Ball Joint Starting Torque Check 8..

Stationary Steering Effort Check 9...............

Steering Wheel Returnability Check 9............

Oil Pump Belt Tension Check <6G7,4D5> 9......Power Steering Fluid Level Check 10............

Power Steering Fluid Replacement 10...........

Power Steering System Bleeding 10.............

Oil Pump Pressure Test 11.....................

Power Steering Oil Pressure Switch Check

<6G7,4M4> 12.................................

Ball Joint Dust Cover Check 12.................

STEERING WHEEL AND SHAFT* 13.........

POWER STEERING GEAR BOX AND

LINKAGE 16................................

POWER STEERING OIL PUMP 30...........

POWER STEERING OIL HOSES 35..........

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring and interconnecting

wiring. Other SRS-related components (that mayhave to be removed/installed in connectionwith SRS service or maintenance) are

indicated in the table of contents by an asterisk(*).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1314 of 1839

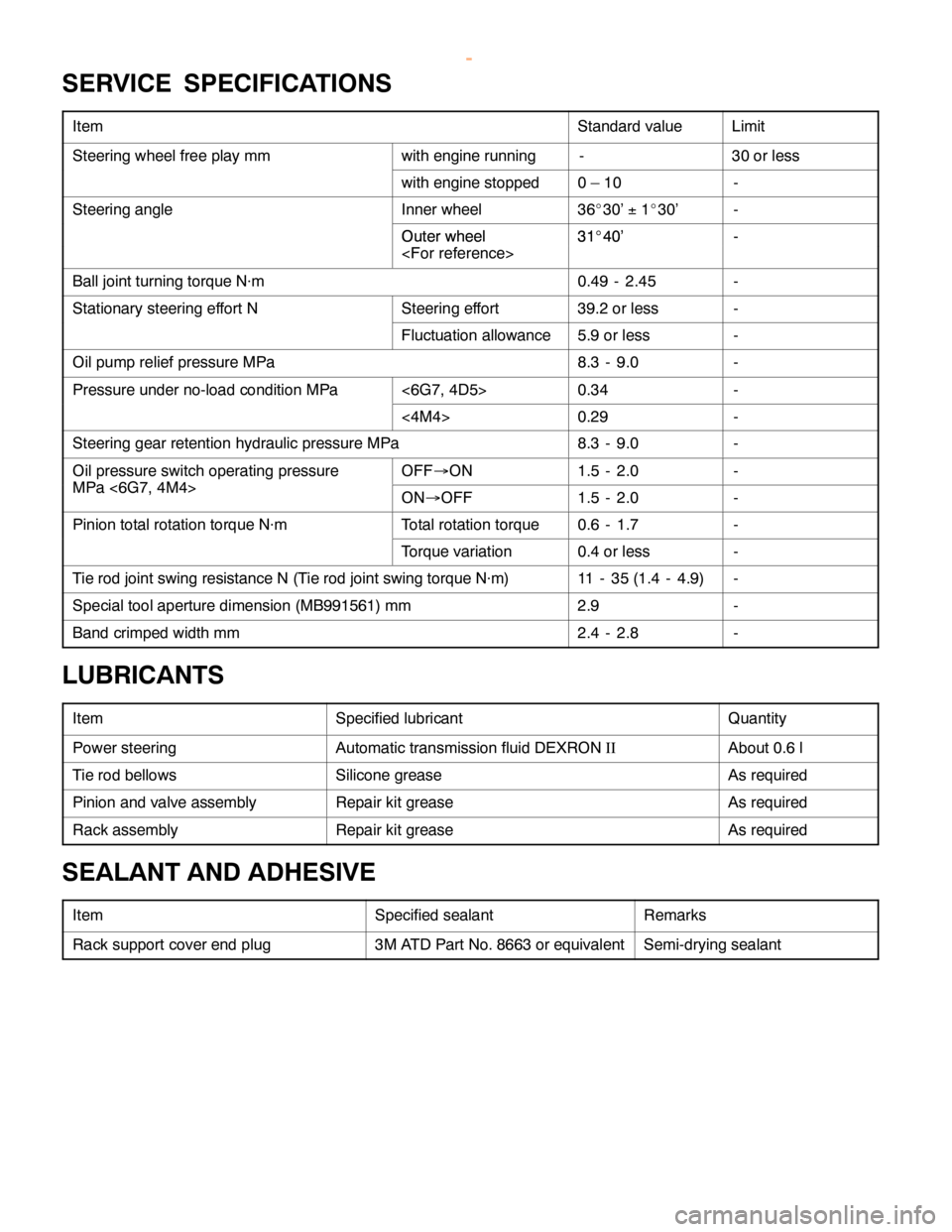

STEERING -Service Specifications/Lubricants/Sealant and Adhesive37A-5

SERVICE SPECIFICATIONS

ItemStandard valueLimit

Steering wheel free play mmwith engine running-30 or less

with engine stopped0–10-

Steering angleInner wheel36_30’±1_30’-

Outer wheel31_40’-Outer wheel

Ball joint turning torque N×m0.49 - 2.45-

Stationary steering effort NSteering effort39.2 or less-

Fluctuation allowance5.9 or less-

Oil pump relief pressure MPa8.3 - 9.0-

Pressure under no-load condition MPa<6G7, 4D5>0.34-

<4M4>0.29-

Steering gear retention hydraulic pressure MPa8.3 - 9.0-

Oil pressure switch operating pressureOFF®ON1.5 - 2.0-

MPa <6G7, 4M4>ON®OFF1.5 - 2.0-

Pinion total rotation torque N×mTotal rotation torque0.6 - 1.7-

Torque variation0.4 or less-

Tie rod joint swing resistance N (Tie rod joint swing torque N×m)11 - 35 (1.4 - 4.9)-

Special tool aperture dimension (MB991561) mm2.9-

Band crimped width mm2.4 - 2.8-

LUBRICANTS

ItemSpecified lubricantQuantity

Power steeringAutomatic transmission fluid DEXRONIIAbout 0.6 l

Tie rod bellowsSilicone greaseAs required

Pinion and valve assemblyRepair kit greaseAs required

Rack assemblyRepair kit greaseAs required

SEALANT AND ADHESIVE

ItemSpecified sealantRemarks

Rack support cover end plug3M ATD Part No. 8663 or equivalentSemi-drying sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1523 of 1839

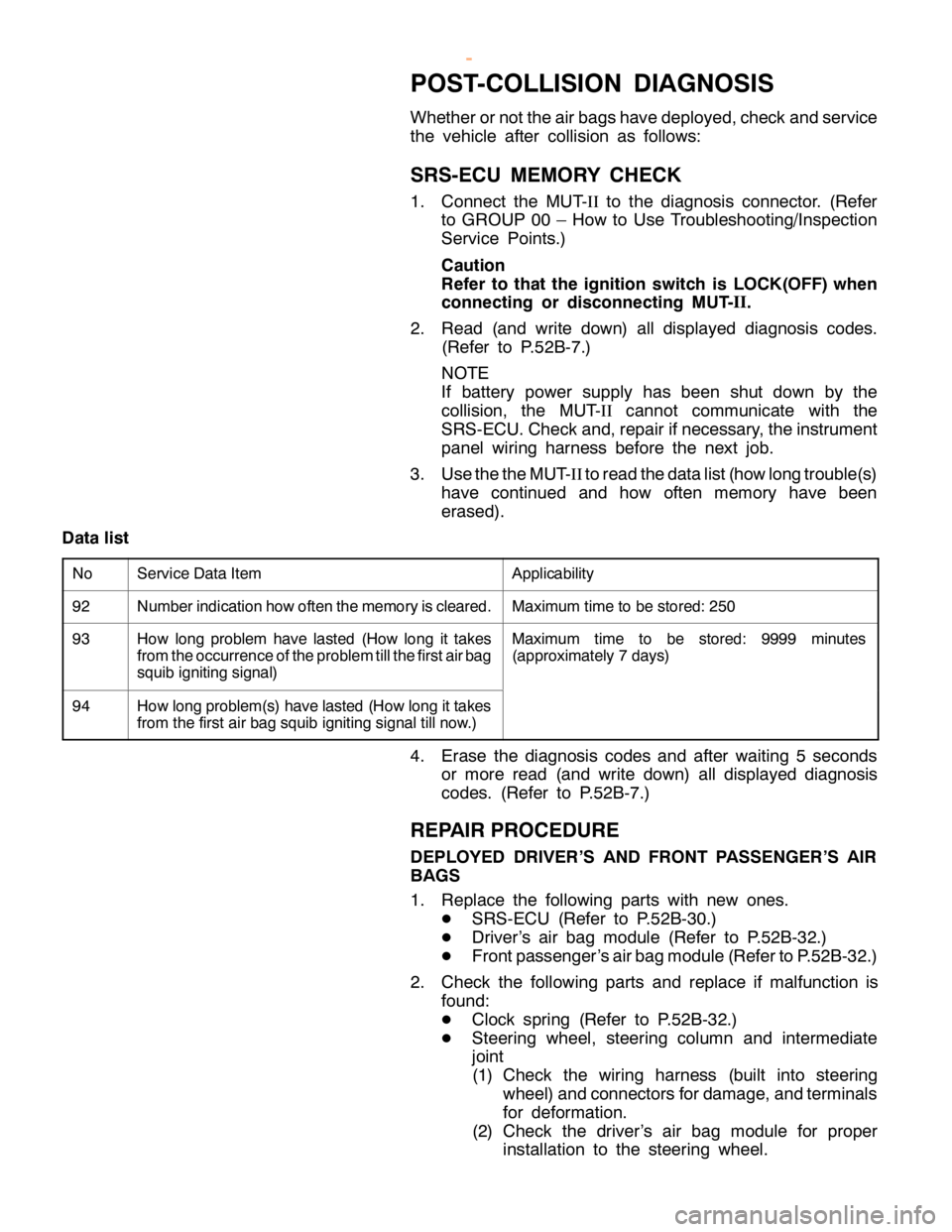

SRS -Post-collision Diagnosis52B-23

POST-COLLISION DIAGNOSIS

Whether or not the air bags have deployed, check and service

the vehicle after collision as follows:

SRS-ECU MEMORY CHECK

1. Connect the MUT-

IIto the diagnosis connector. (Refer

to GROUP 00 – How to Use Troubleshooting/Inspection

Service Points.)

Caution

Refer to that the ignition switch is LOCK(OFF) when

connecting or disconnecting MUT-II

.

2. Read (and write down) all displayed diagnosis codes.

(Refer to P.52B-7.)

NOTE

If battery power supply has been shut down by the

collision, the MUT-

IIcannot communicate with the

SRS-ECU. Check and, repair if necessary, the instrument

panel wiring harness before the next job.

3. Use the the MUT-

IIto read the data list (how long trouble(s)

have continued and how often memory have been

erased).

Data list

NoService Data ItemApplicability

92Number indication how often the memory is cleared.Maximum time to be stored: 250

93How long problem have lasted (How long it takes

from the occurrence of the problem till the first air bag

squib igniting signal)Maximum time to be stored: 9999 minutes

(approximately 7 days)

94How long problem(s) have lasted (How long it takes

from the first air bag squib igniting signal till now.)

4. Erase the diagnosis codes and after waiting 5 seconds

or more read (and write down) all displayed diagnosis

codes. (Refer to P.52B-7.)

REPAIR PROCEDURE

DEPLOYED DRIVER’S AND FRONT PASSENGER’S AIR

BAGS

1. Replace the following parts with new ones.

DSRS-ECU (Refer to P.52B-30.)

DDriver’s air bag module (Refer to P.52B-32.)

DFront passenger’s air bag module (Refer to P.52B-32.)

2. Check the following parts and replace if malfunction is

found:

DClock spring (Refer to P.52B-32.)

DSteering wheel, steering column and intermediate

joint

(1) Check the wiring harness (built into steering

wheel) and connectors for damage, and terminals

for deformation.

(2) Check the driver’s air bag module for proper

installation to the steering wheel.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk