wheelbase MITSUBISHI MONTERO 2000 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 52 of 1839

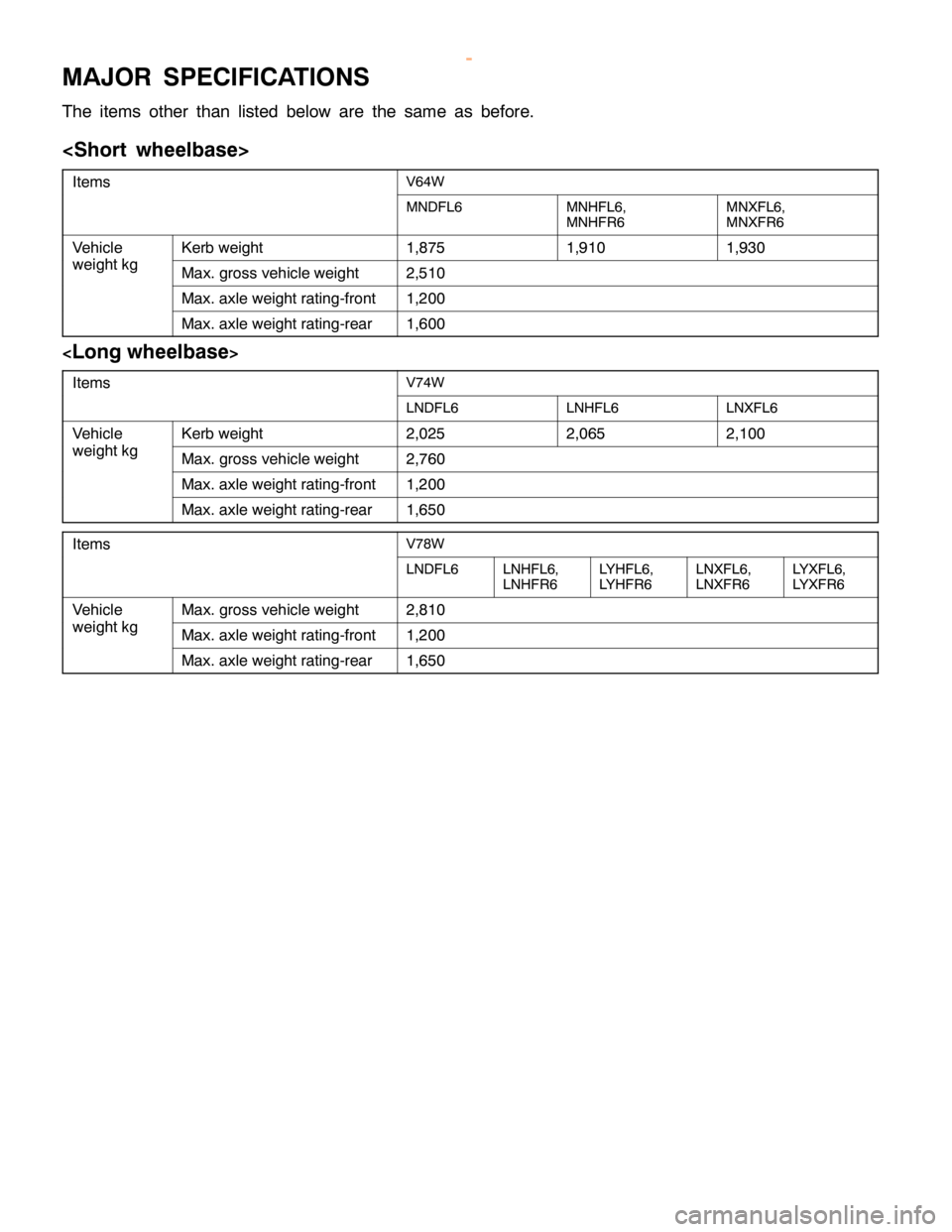

GENERAL -Major Specifications00-4

MAJOR SPECIFICATIONS

The items other than listed below are the same as before.

ItemsV64W

MNDFL6MNHFL6,

MNHFR6MNXFL6,

MNXFR6

Vehicle

ihtk

Kerb weight1,8751,9101,930

weight kgMax. gross vehicle weight2,510

Max. axle weight rating-front1,200

Max. axle weight rating-rear1,600

ItemsV74W

LNDFL6LNHFL6LNXFL6

Vehicle

ihtk

Kerb weight2,0252,0652,100

weight kgMax. gross vehicle weight2,760

Max. axle weight rating-front1,200

Max. axle weight rating-rear1,650

ItemsV78W

LNDFL6LNHFL6,

LNHFR6LYHFL6,

LYHFR6LNXFL6,

LNXFR6LYXFL6,

LYXFR6

Vehicle

ihtk

Max. gross vehicle weight2,810

weight kgMax. axle weight rating-front1,200

Max. axle weight rating-rear1,650

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 730 of 1839

INTAKE AND EXHAUST -Exhaust Pipe and Main Muffler <4D5>15-24

Exhaust main muffler and rear

floor heat protector removal steps

1. Exhaust main muffler

6. Hanger

7. Hanger bracket

8. Hanger bracket

11. Rear floor heat protector

Tail exhaust pipe and rear floor

heat protector removal steps

2. Tail exhaust pipe

7. Hanger

9. Hanger bracket

10. Hanger bracket

12. Rear floor heat protector

Center exhaust pipe removal steps

3. Center exhaust pipe

13. Hanger

14. Hanger bracketExhaust main muffler removal steps

4. Exhaust main muffler

13. Hanger

14. Hanger bracket

Front exhaust pipe and dash heat

protector removal steps

DUnder cover

5. Front exhaust pipe

15. Exhaust support bracket

16. Dash heat protector

Pre-muffler and front floor heat

protector removal steps

17. Pre-muffler

18. Front floor heat protector

19. Seal ring

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 732 of 1839

INTAKE AND EXHAUST -Exhaust Pipe and Main Muffler<4M4>15-26

Exhaust main muffler and rear

floor heat protector removal steps

1. Exhaust main muffler

6. Hanger

7. Hanger bracket

8. Hanger bracket

11. Rear floor heat protector

Tail exhaust pipe and rear floor

heat protector removal steps

2. Tail exhaust pipe

7. Hanger

9. Hanger bracket

10. Hanger bracket

12. Rear floor heat protector

Center exhaust pipe removal steps

3. Center exhaust pipe

13. Hanger

14. Hanger bracketExhaust main muffler removal steps

4. Exhaust main muffler

13. Hanger

14. Hanger bracket

Front exhaust pipe and dash heat

protector removal steps

DUnder cover

5. Front exhaust pipe

15. Exhaust support bracket

16. Dash heat protector

Front floor heat protector removal

steps

17. Catalytic converter

18. Front floor heat protector

19. Seal ring

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 747 of 1839

INTAKE AND EXHAUST -Exhaust Pipe and Main Muffler <4D5>15-15

Exhaust main muffler and rear

floor heat protector removal steps

1. Exhaust main muffler

6. Hanger

7. Hanger bracket

8. Hanger bracket

11. Rear floor heat protector

Tail exhaust pipe and rear floor

heat protector removal steps

2. Tail exhaust pipe

6. Hanger

9. Hanger bracket

10. Hanger bracket

12. Rear floor heat protector

Center exhaust pipe removal steps

3. Center exhaust pipe

13. Hanger

14. Hanger bracketExhaust main muffler removal steps

4. Exhaust main muffler

13. Hanger

14. Hanger bracket

Front exhaust pipe and dash heat

protector removal steps

DUnder cover

5. Front exhaust pipe

15. Exhaust support bracket

16. Dash heat protector

Front floor heat protector removal

steps

17. Catalytic converter

18. Front floor heat protector

19. Seal ring

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1213 of 1839

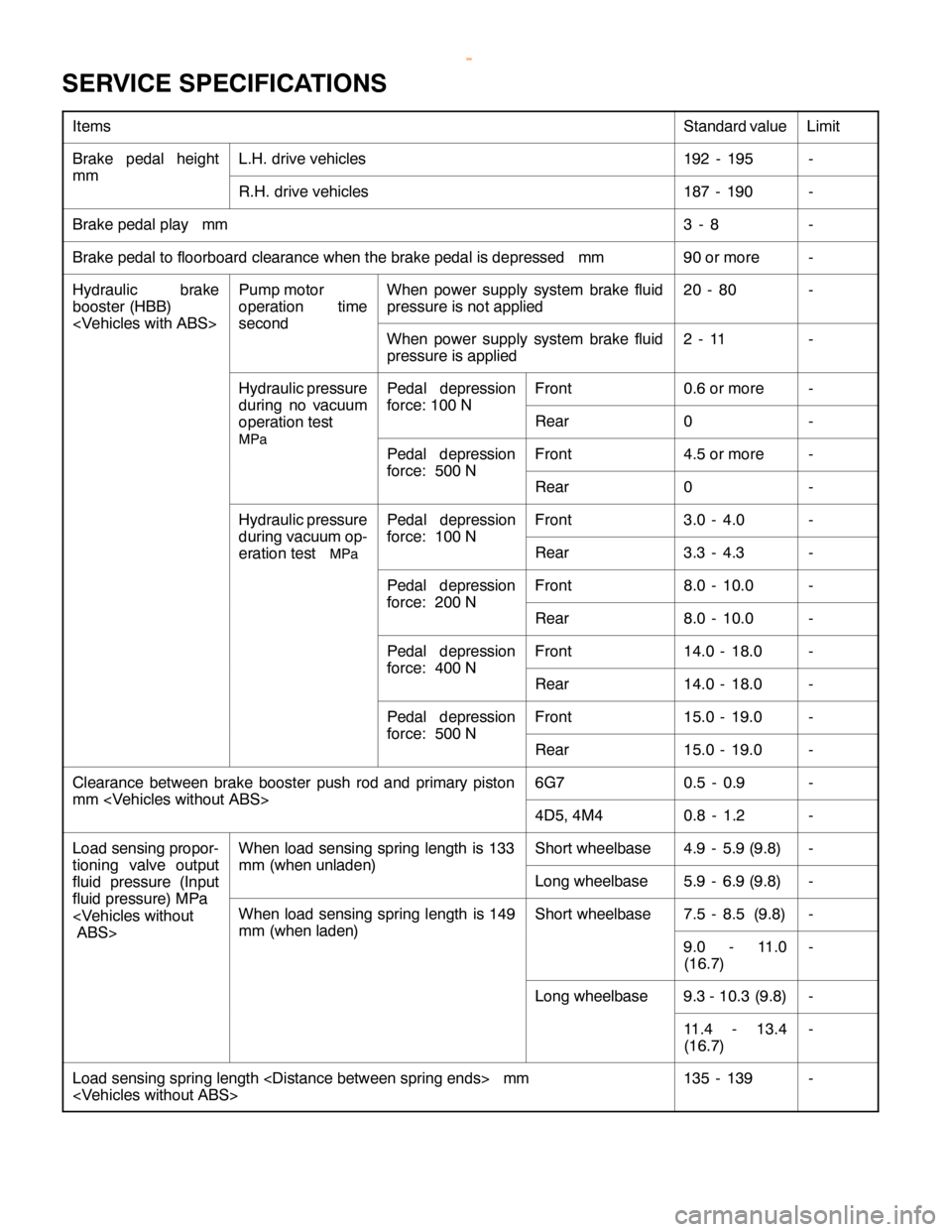

BASIC BRAKE SYSTEM -Service Specifications35A-5

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Brake pedal heightL.H. drive vehicles192 - 195-

mm

R.H. drive vehicles187 - 190-

Brake pedal play mm3-8-

Brake pedal to floorboard clearance when the brake pedal is depressed mm90 or more-

Hydraulic brake

booster (HBB)Pump motor

operation timeWhen power supply system brake fluid

pressure is not applied20 - 80-

When power supply system brake fluid

pressure is applied2-11-

Hydraulic pressurePedal depressionFront0.6 or more-

during no vacuum

operation testforce: 100 N

Rear0-

MPa

Pedal depressionFront4.5 or more-

force: 500 N

Rear0-

Hydraulic pressurePedal depressionFront3.0 - 4.0-

during vacuum op-

eration test

MPa

force: 100 N

Rear3.3 - 4.3-

Pedal depressionFront8.0 - 10.0-

force: 200 N

Rear8.0 - 10.0-

Pedal depressionFront14.0 - 18.0-

force: 400 N

Rear14.0 - 18.0-

Pedal depressionFront15.0 - 19.0-

force: 500 N

Rear15.0 - 19.0-

Clearance between brake booster push rod and primary piston6G70.5 - 0.9-

mm

4D5, 4M40.8 - 1.2-

Load sensing propor-When load sensing spring length is 133Short wheelbase4.9 - 5.9 (9.8)-

tioning valve output

fluid pressure (Inputmm (when unladen)

Long wheelbase5.9 - 6.9 (9.8)-

fluid pressure) MPa

9.0 - 11.0

(16.7)-

Long wheelbase9.3 - 10.3 (9.8)-

11.4 - 13.4

(16.7)-

Load sensing spring length

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1457 of 1839

52A-2

INTERIOR

CONTENTS

SERVICE SPECIFICATIONS 3.................

SPECIAL TOOL 3............................

INSTRUMENT PANEL

INSTRUMENT PANEL

FLOOR CONSOLE 12........................

TRIMS 13...................................

SUNVISOR HOLDER 17......................FRONT SEAT 18............................

REAR/SECOND SEAT 25....................

THIRD SEAT 35.............................

FRONT SEAT BELT 38.......................

REAR SEAT BELT

SECOND/THIRD SEAT BELT

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from rendering the SRS

inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: front impact sensors, SRS-ECU, SRS warning lamp, air bag module, clock spring and

interconnecting wiring. Other SRS-related components (that mayhave to be removed/installed in connectionwith SRS service or

maintenance) are indicated in the table of contents by an asterisk(*).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1737 of 1839

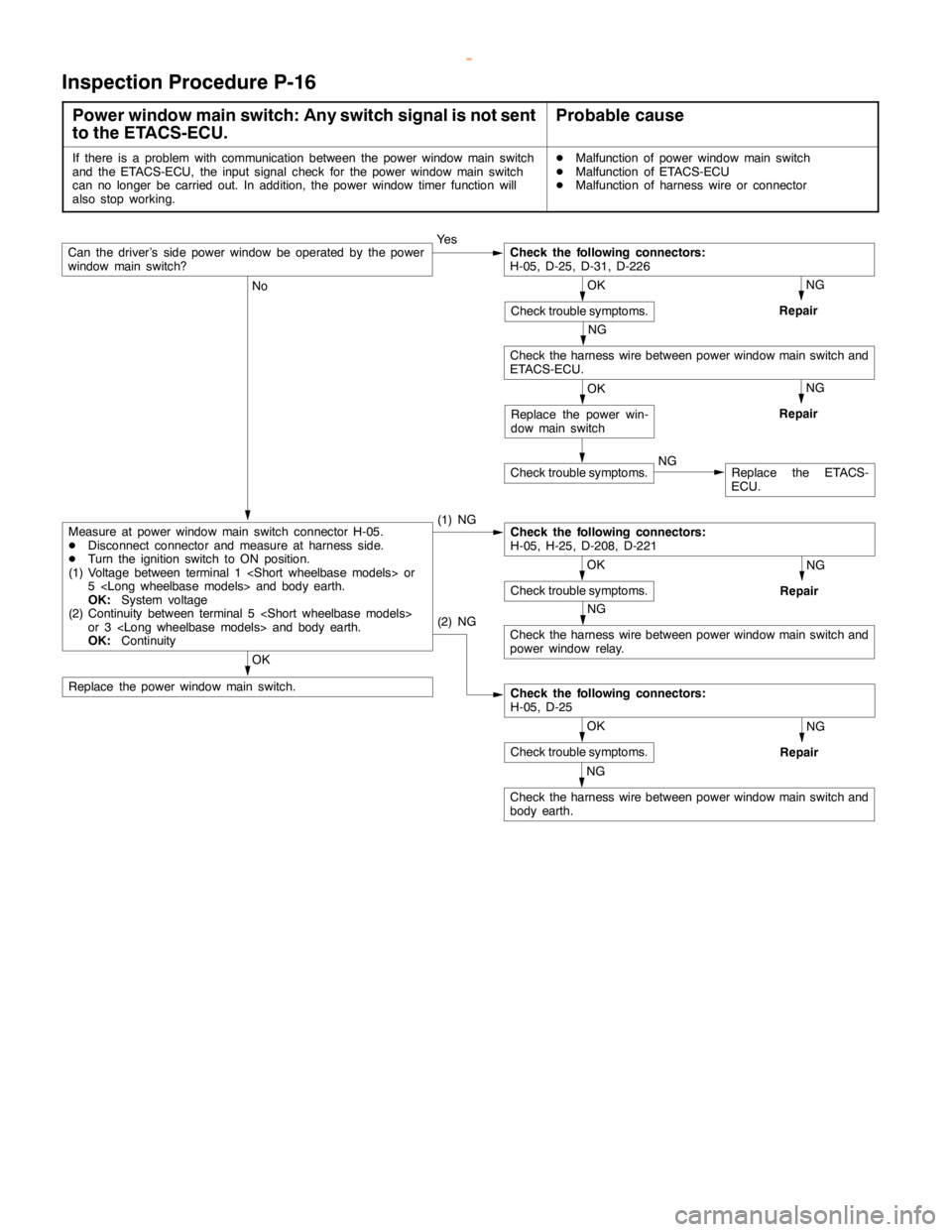

SWS -Troubleshooting54B-51

Inspection Procedure P-16

Power window main switch: Any switch signal is not sent

to the ETACS-ECU.Probable cause

If there is a problem with communication between the power windowmainswitch

and the ETACS-ECU, the input signal check for the power windowmainswitch

can no longer be carried out. In addition, the power window timer function will

also stop working.DMalfunction of power windowmainswitch

DMalfunction of ETACS-ECU

DMalfunction of harness wire or connector

Ye s

NG

Repair

NG

No

(1) NG

NG

Repair

NG

Check the harness wire between power windowmainswitch and

power window relay.

OK

Replace the power windowmainswitch.

NG

Repair

NG

Check the harness wire between power windowmainswitch and

body earth.

NG

Repair

Check trouble symptoms.NGReplace the ETACS-

ECU.

OK

Check trouble symptoms.

(2) NG

Check the following connectors:

H-05, D-25

OK

Check trouble symptoms.

Check the following connectors:

H-05, H-25, D-208, D-221Measure at power windowmainswitch connector H-05.

DDisconnect connector and measure at harness side.

DTurn the ignition switch to ON position.

(1) Voltage between terminal 1

5

OK:System voltage

(2) Continuity between terminal 5

or 3

OK:Continuity

OK

Replace the power win-

dow mainswitch

Check the harness wire between power windowmainswitch and

ETACS-ECU.

OK

Check trouble symptoms.

Check the following connectors:

H-05, D-25, D-31, D-226Can the driver’s side power window be operated by the power

window mainswitch?

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk