compressor MITSUBISHI MONTERO 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 719 of 1839

INTAKE AND EXHAUST -Intake and Exhaust Manifold,

Turbocharger <4D5>15-13

INSTALLATION SERVICE POINT

"

AA

TURBOCHARGER ASSEMBLY INSTALLATION

1. Check the internal surface, the eye bolt and the

mating surface of the oil pipe and water pipe for

clogging, and clean if necessary.

2. If deposits of carbon are accumulated on the

turbocharger oil passage, remove them and clean

using the compressed air.

Caution

Be careful not to allow foreign material to enter the

turbocharger.

3. Add clean engine oil through the oil feed pipe port

on the turbocharger.

INSPECTION

TURBOCHARGER ASSEMBLY CHECK

DVisually check the turbine wheel and the compressor

wheel for cracking or other damage.

DCheck whether the turbine wheel and the compressor

wheel can be easily turned by hand.

DCheck for oil leakage from the turbocharger assembly.

DCheck whether or not the waste gate valve remains open.

If any problem is found, replace the part after disassembly.

OIL PIPE AND OIL RETURN PIPE CHECK

Check the oil pipe and oil return pipe for clogging, bending,

or other damage. If there is clogging, clean it.

EXHAUST MANIFOLD CHECK

Damage or cracking of any part.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 721 of 1839

INTAKE AND EXHAUST -Turbocharger and Exhaust

Manifold <4M4>15-15

INSTALLATION SERVICE POINT

"

AA

TURBOCHARGER ASSEMBLY INSTALLATION

1. Check the internal surface, the eye bolt and the

mating surface of the oil pipe and water pipe for

clogging, and clean if necessary.

2. If deposits of carbon are accumulated on the

turbocharger oil passage, remove them and clean

using the compressed air.

Caution

Be careful not to allow foreign material to enter the

turbocharger.

3. Add clean engine oil through the oil feed pipe port

on the turbocharger.

INSPECTION

Check the following points; replace the part if a problem is

found.

EXHAUST MANIFOLD CHECK

1. Check for damage or cracking of any part.

2. Using a straight edge and a thickness gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

TURBOCHARGER ASSEMBLY CHECK

DVisually check the turbine wheel and the compressor

wheel for cracking or other damage.

DCheck whether the turbine wheel and the compressor

wheel can be easily turned by hand.

DCheck for oil leakage from the turbocharger assembly.

DCheck whether or not the waste gate valve remains open.

If any problem is found, replace the part after disassembly.

OIL PIPE AND OIL RETURN PIPE CHECK

Check the oil pipe and oil return pipe for clogging, bending,

or other damage. If there is clogging, clean it.

EXHAUST MANIFOLD CHECK

Damage or cracking of any part.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 968 of 1839

Page 1748 of 1839

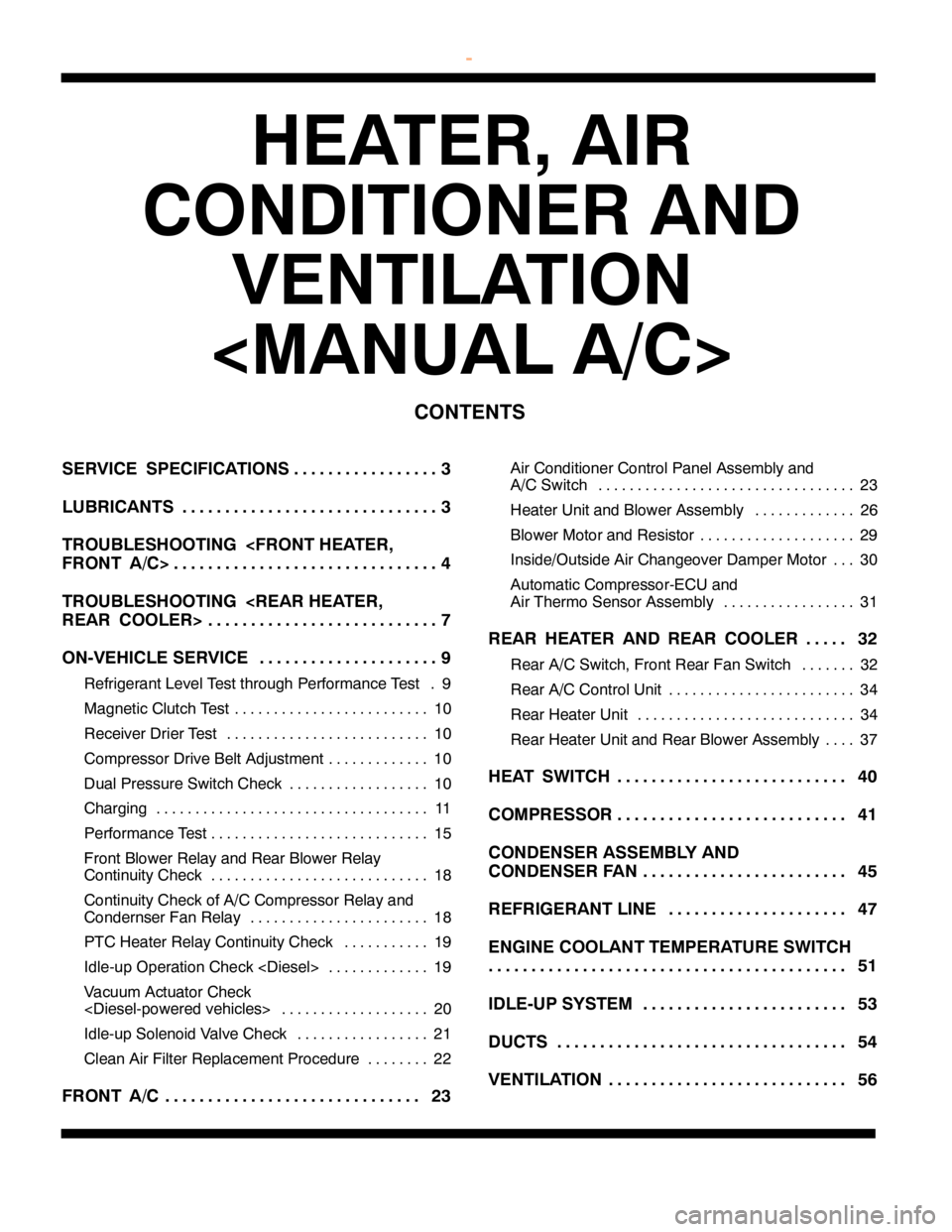

55A-2

HEATER, AIR

CONDITIONER AND

VENTILATION

CONTENTS

SERVICE SPECIFICATIONS 3.................

LUBRICANTS 3..............................

TROUBLESHOOTING

TROUBLESHOOTING

ON-VEHICLE SERVICE 9.....................

Refrigerant Level Test through Performance Test 9.

Magnetic Clutch Test 10.........................

Receiver Drier Test 10..........................

Compressor Drive Belt Adjustment 10.............

Dual Pressure Switch Check 10..................

Charging 11...................................

Performance Test 15............................

Front Blower Relay and Rear Blower Relay

Continuity Check 18............................

Continuity Check of A/C Compressor Relay and

Condernser Fan Relay 18.......................

PTC Heater Relay Continuity Check 19...........

Idle-up Operation Check

Vacuum Actuator Check

Idle-up Solenoid Valve Check 21.................

Clean Air Filter Replacement Procedure 22........

FRONT A/C 23..............................

Air Conditioner Control Panel Assembly and

A/C Switch 23.................................

Heater Unit and Blower Assembly 26.............

Blower Motor and Resistor 29....................

Inside/Outside Air Changeover Damper Motor 30...

Automatic Compressor-ECU and

Air Thermo Sensor Assembly 31.................

REAR HEATER AND REAR COOLER 32.....

Rear A/C Switch, Front Rear Fan Switch 32.......

Rear A/C Control Unit 34........................

Rear Heater Unit 34............................

Rear Heater Unit and Rear Blower Assembly 37....

HEAT SWITCH 40...........................

COMPRESSOR 41...........................

CONDENSER ASSEMBLY AND

CONDENSER FAN 45........................

REFRIGERANT LINE 47.....................

ENGINE COOLANT TEMPERATURE SWITCH

51 ..........................................

IDLE-UP SYSTEM 53........................

DUCTS 54..................................

VENTILATION 56............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1749 of 1839

HEATER, AIR CONDITIONER AND VENTILATION - Service Specifications/Lubricants55A-3

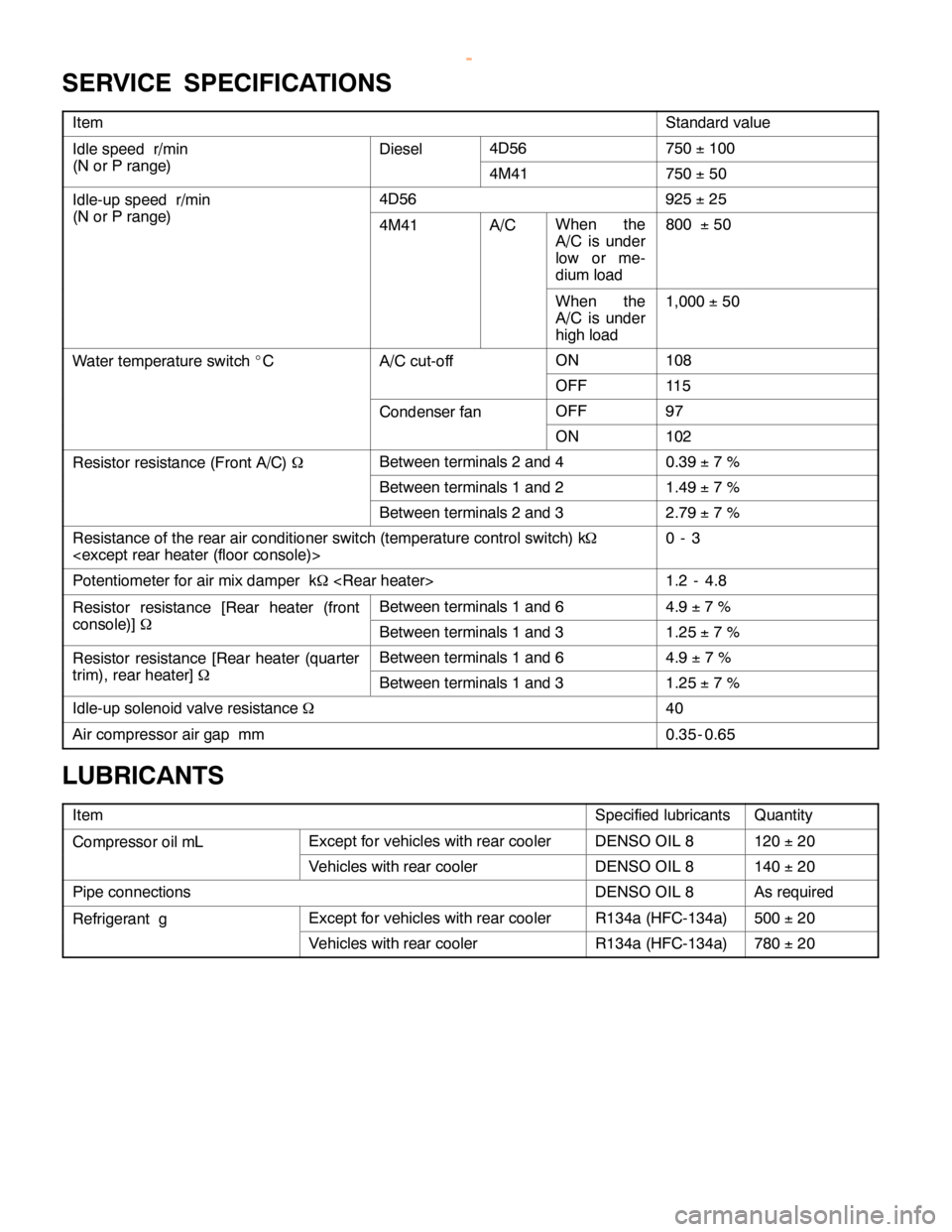

SERVICE SPECIFICATIONS

ItemStandard value

Idle speed r/minDiesel4D56750±100

(N or P range)4M41750±50

Idle-up speed r/min4D56925±25

(N or P range)4M41A/CWhen the

A/C is under

low or me-

dium load800±50

When the1,000±50

A/C is under

high load

Water temperature switch_CA/C cut-offON108

OFF11 5

Condenser fanOFF97

ON102

Resistor resistance (Front A/C)WBetween terminals 2 and 40.39±7%

Between terminals 1 and 21.49±7%

Between terminals 2 and 32.79±7%

Resistance of the rear air conditioner switch (temperature control switch) kW

Potentiometer for air mix damper kW

Resistor resistance [Rear heater (frontBetween terminals 1 and 64.9±7%

console)]WBetween terminals 1 and 31.25±7%

Resistor resistance [Rear heater (quarterBetween terminals 1 and 64.9±7%

trim), rear heater]WBetween terminals 1 and 31.25±7%

Idle-up solenoid valve resistanceW40

Air compressor air gap mm0.35 - 0.65

LUBRICANTS

ItemSpecified lubricantsQuantity

Compressor oil mLExcept for vehicles with rear coolerDENSO OIL 8120±20

Vehicles with rear coolerDENSO OIL 8140±20

Pipe connectionsDENSO OIL 8As required

Refrigerant gExcept for vehicles with rear coolerR134a (HFC-134a)500±20

Vehicles with rear coolerR134a (HFC-134a)780±20

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1750 of 1839

HEATER, AIR CONDITIONER AND VENTILATION - Troubleshooting55A-4

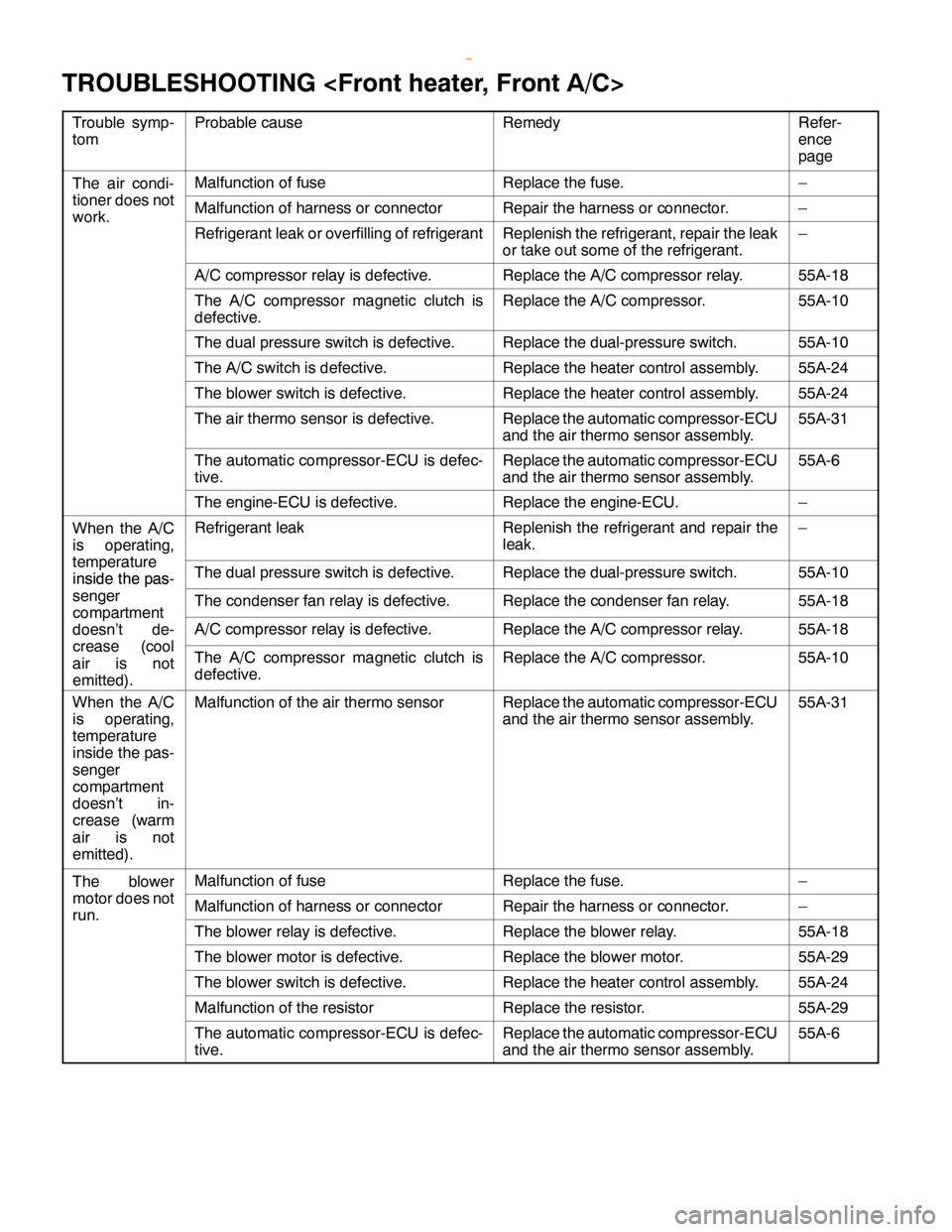

TROUBLESHOOTING

Trouble symp-

tomProbable causeRemedyRefer-

ence

page

The air condi-Malfunction of fuseReplace the fuse.–

tioner does notMalfunction of harness or connectorRepair the harness or connector.–work.

Refrigerant leak or overfilling of refrigerantReplenish the refrigerant, repair the leak

or take out some of the refrigerant.–

A/C compressor relay is defective.Replace the A/C compressor relay.55A-18

The A/C compressor magnetic clutch is

defective.Replace the A/C compressor.55A-10

The dual pressure switch is defective.Replace the dual-pressure switch.55A-10

The A/C switch is defective.Replace the heater control assembly.55A-24

The blower switch is defective.Replace the heater control assembly.55A-24

The air thermo sensor is defective.Replace the automatic compressor-ECU

and the air thermo sensor assembly.55A-31

The automatic compressor-ECU is defec-

tive.Replace the automatic compressor-ECU

and the air thermo sensor assembly.55A-6

The engine-ECU is defective.Replace the engine-ECU.–

When the A/C

is operating,Refrigerant leakReplenish the refrigerant and repair the

leak.–

temperature

inside the pas-The dual pressure switch is defective.Replace the dual-pressure switch.55A-10inside the pas-

senger

The condenser fan relay is defective.Replace the condenser fan relay.55A-18compartment

doesn’t de-

A/C compressor relay is defective.Replace the A/C compressor relay.55A-18

crease (cool

air is not

emitted).The A/C compressor magnetic clutch is

defective.Replace the A/C compressor.55A-10

When the A/C

is operating,

temperature

inside the pas-

senger

compartment

doesn’t in-

crease (warm

air is not

emitted).Malfunction of the air thermo sensorReplace the automatic compressor-ECU

and the air thermo sensor assembly.55A-31

The blowerMalfunction of fuseReplace the fuse.–

motor does notMalfunction of harness or connectorRepair the harness or connector.–run.

The blower relay is defective.Replace the blower relay.55A-18

The blower motor is defective.Replace the blower motor.55A-29

The blower switch is defective.Replace the heater control assembly.55A-24

Malfunction of the resistorReplace the resistor.55A-29

The automatic compressor-ECU is defec-

tive.Replace the automatic compressor-ECU

and the air thermo sensor assembly.55A-6

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1763 of 1839

HEATER, AIR CONDITIONER AND VENTILATION - On-vehicle Service55A-17

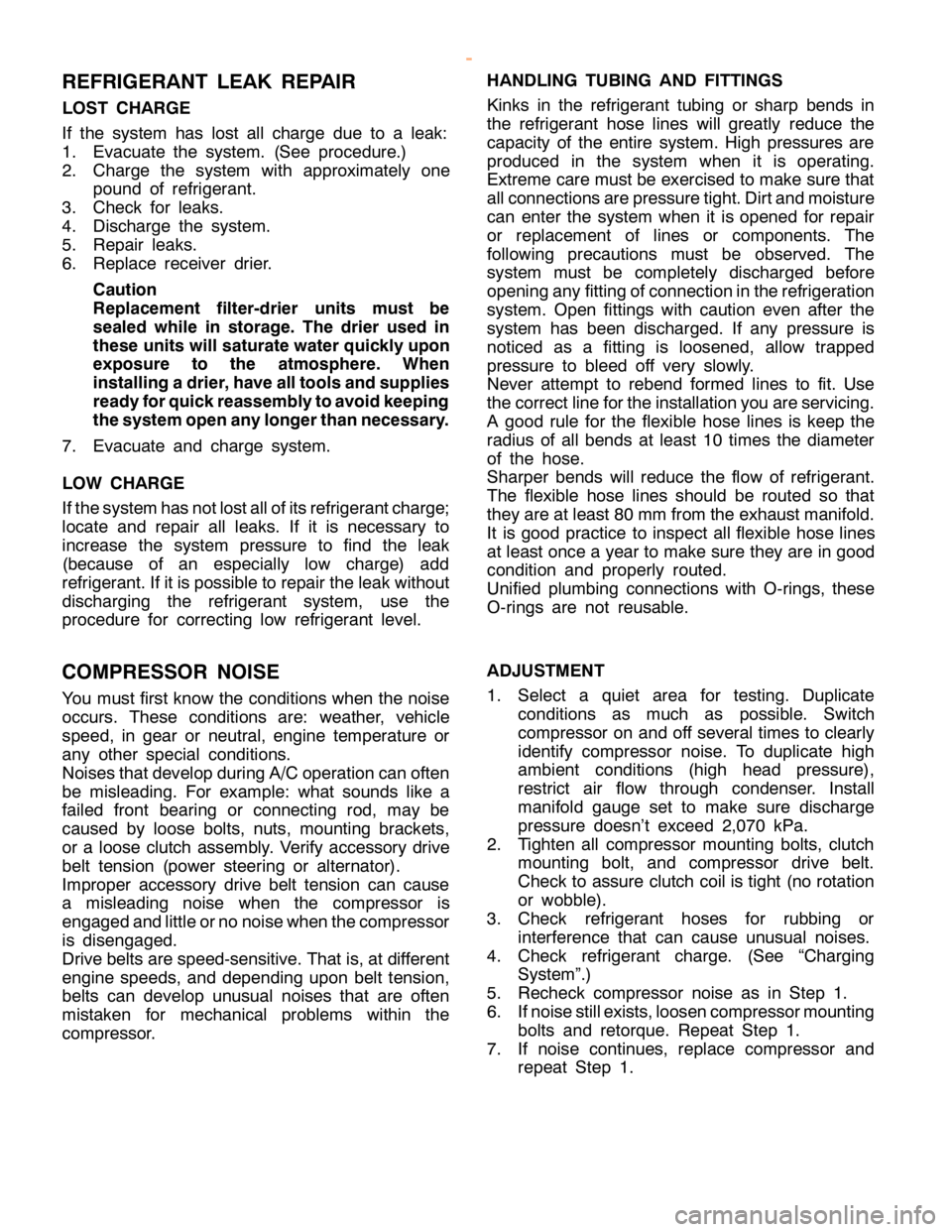

REFRIGERANT LEAK REPAIR

LOST CHARGE

If the system has lost all charge due to a leak:

1. Evacuate the system. (See procedure.)

2. Charge the system with approximately one

pound of refrigerant.

3. Check for leaks.

4. Discharge the system.

5. Repair leaks.

6. Replace receiver drier.

Caution

Replacement filter-drier units must be

sealed while in storage. The drier used in

these units will saturate water quickly upon

exposure to the atmosphere. When

installing a drier, have all tools and supplies

ready for quick reassembly to avoid keeping

the system open any longer than necessary.

7. Evacuate and charge system.

LOW CHARGE

If the system has not lost all of its refrigerant charge;

locate and repair all leaks. If it is necessary to

increase the system pressure to find the leak

(because of an especially low charge) add

refrigerant. If it is possible to repair the leak without

discharging the refrigerant system, use the

procedure for correcting low refrigerant level.HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are

produced in the system when it is operating.

Extreme care must be exercised to make sure that

all connections are pressure tight. Dirt and moisture

can enter the system when it is opened for repair

or replacement of lines or components. The

following precautions must be observed. The

system must be completely discharged before

opening any fitting of connection in the refrigeration

system. Open fittings with caution even after the

system has been discharged. If any pressure is

noticed as a fitting is loosened, allow trapped

pressure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use

the correct line for the installation you are servicing.

A good rule for the flexible hose lines is keep the

radius of all bends at least 10 times the diameter

of the hose.

Sharper bends will reduce the flow of refrigerant.

The flexible hose lines should be routed so that

they are at least 80 mm from the exhaust manifold.

It is good practice to inspect all flexible hose lines

at least once a year to make sure they are in good

condition and properly routed.

Unified plumbing connections with O-rings, these

O-rings are not reusable.

COMPRESSOR NOISE

You must first know the conditions when the noise

occurs. These conditions are: weather, vehicle

speed, in gear or neutral, engine temperature or

any other special conditions.

Noises that develop during A/C operation can often

be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be

caused by loose bolts, nuts, mounting brackets,

or a loose clutch assembly. Verify accessory drive

belt tension (power steering or alternator).

Improper accessory drive belt tension can cause

a misleading noise when the compressor is

engaged and little or no noise when the compressor

is disengaged.

Drive belts are speed-sensitive. That is, at different

engine speeds, and depending upon belt tension,

belts can develop unusual noises that are often

mistaken for mechanical problems within the

compressor.ADJUSTMENT

1. Select a quiet area for testing. Duplicate

conditions as much as possible. Switch

compressor on and off several times to clearly

identify compressor noise. To duplicate high

ambient conditions (high head pressure),

restrict air flow through condenser. Install

manifold gauge set to make sure discharge

pressure doesn’t exceed 2,070 kPa.

2. Tighten all compressor mounting bolts, clutch

mounting bolt, and compressor drive belt.

Check to assure clutch coil is tight (no rotation

or wobble).

3. Check refrigerant hoses for rubbing or

interference that can cause unusual noises.

4. Check refrigerant charge. (See “Charging

System”.)

5. Recheck compressor noise as in Step 1.

6. If noise still exists, loosen compressor mounting

bolts and retorque. Repeat Step 1.

7. If noise continues, replace compressor and

repeat Step 1.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1804 of 1839

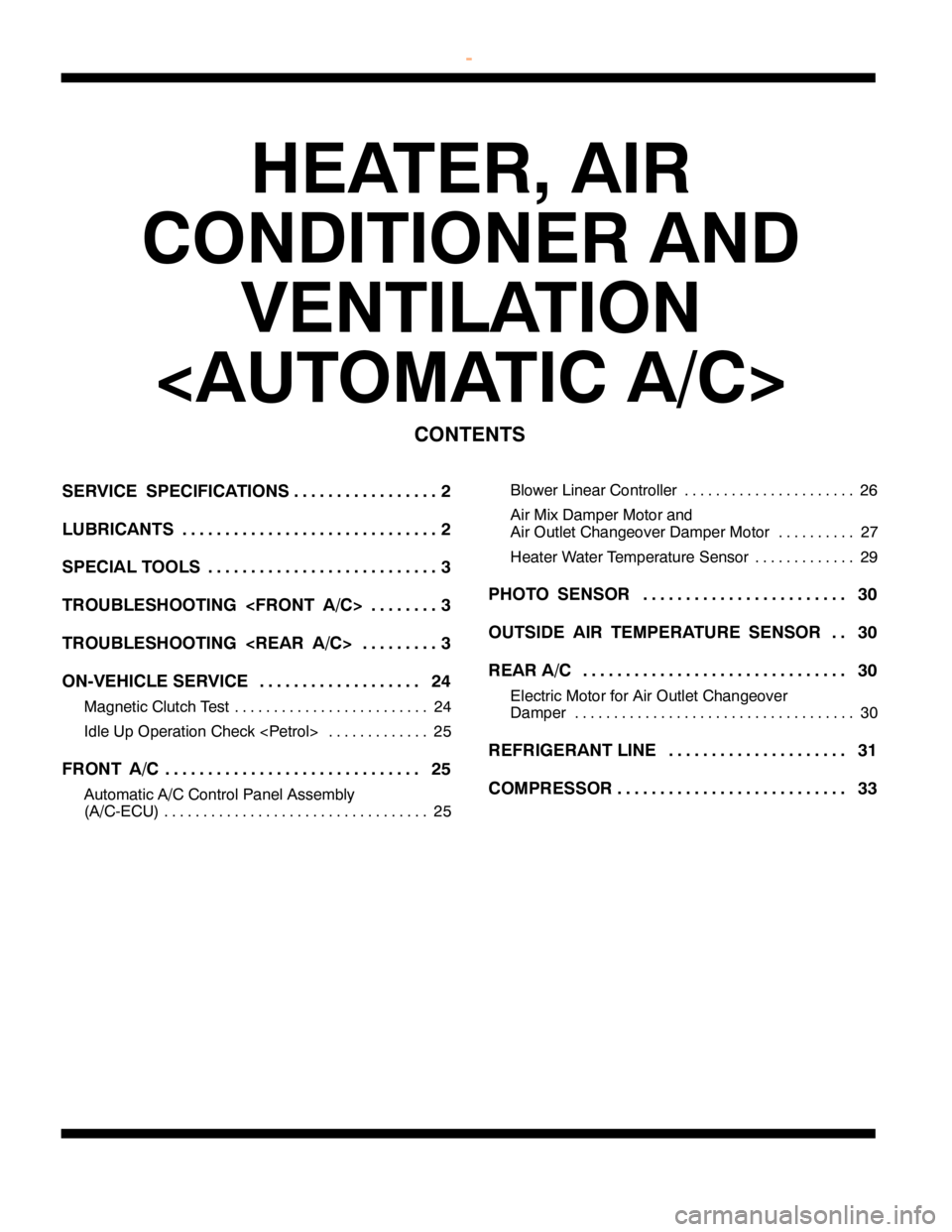

55B-1

HEATER, AIR

CONDITIONER AND

VENTILATION

CONTENTS

SERVICE SPECIFICATIONS 2.................

LUBRICANTS 2..............................

SPECIAL TOOLS 3...........................

TROUBLESHOOTING

TROUBLESHOOTING

ON-VEHICLE SERVICE 24...................

Magnetic Clutch Test 24.........................

Idle Up Operation Check

FRONT A/C 25..............................

Automatic A/C Control Panel Assembly

(A/C-ECU) 25..................................Blower Linear Controller 26......................

Air Mix Damper Motor and

Air Outlet Changeover Damper Motor 27..........

Heater Water Temperature Sensor 29.............

PHOTO SENSOR 30........................

OUTSIDE AIR TEMPERATURE SENSOR 30..

REAR A/C 30...............................

Electric Motor for Air Outlet Changeover

Damper 30....................................

REFRIGERANT LINE 31.....................

COMPRESSOR 33...........................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1805 of 1839

HEATER, AIR CONDITIONER AND VENTILATION -Service Specifications/Lubricants55B-2

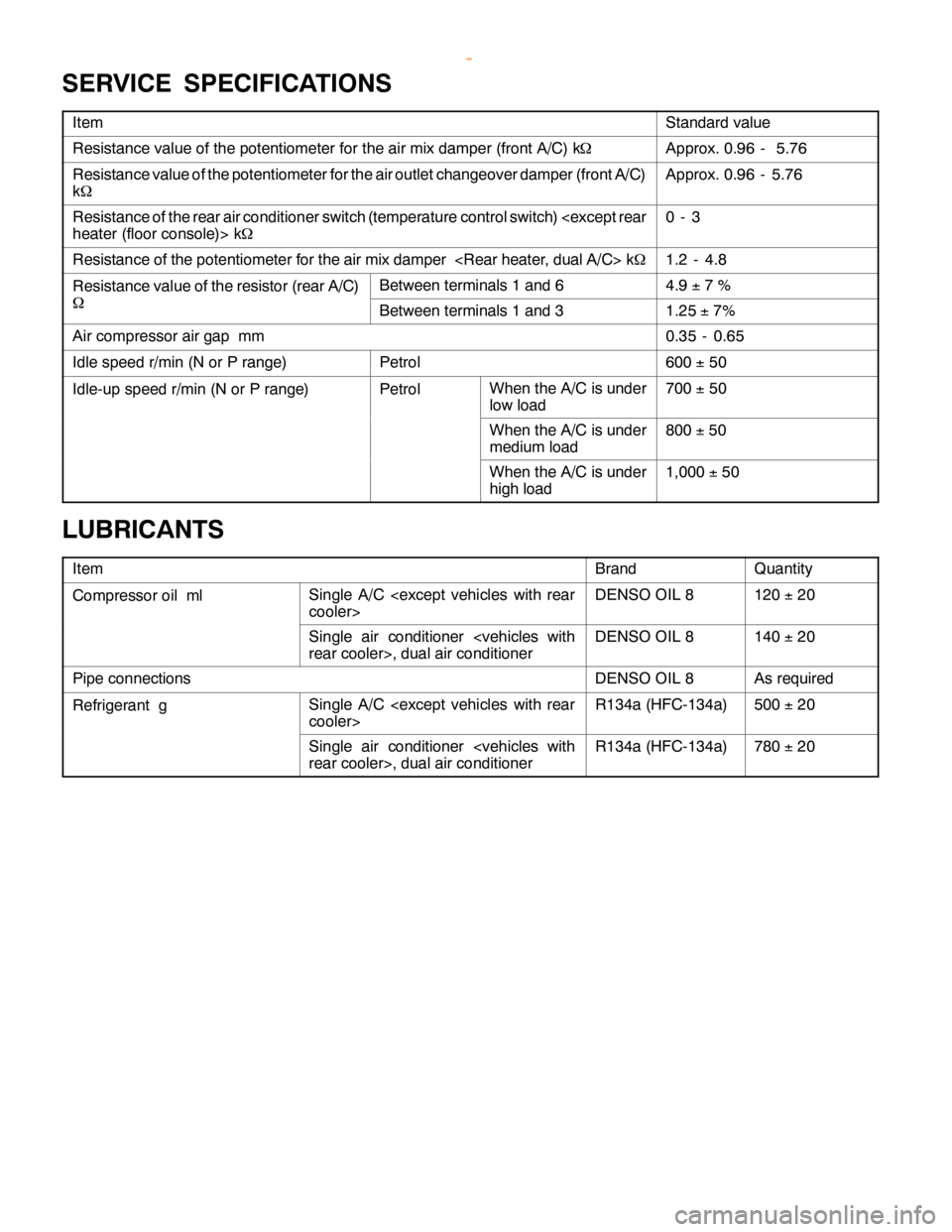

SERVICE SPECIFICATIONS

ItemStandard value

Resistance value of the potentiometer for the air mix damper (front A/C) kWApprox. 0.96 - 5.76

Resistance value of the potentiometer for the air outlet changeover damper (front A/C)

kWApprox. 0.96 - 5.76

Resistance of the rear air conditioner switch (temperature control switch)

Resistance of the potentiometer for the air mix damper

Resistance value of the resistor (rear A/C)Between terminals 1 and 64.9±7%

WBetween terminals 1 and 31.25±7%

Air compressor air gap mm0.35 - 0.65

Idle speed r/min (N or P range)Petrol600±50

Idle-up speed r/min (N or P range)PetrolWhen the A/C is under

low load700±50

When the A/C is under

medium load800±50

When the A/C is under

high load1,000±50

LUBRICANTS

ItemBrandQuantity

Compressor oil mlSingle A/C

Single air conditioner

Pipe connectionsDENSO OIL 8As required

Refrigerant gSingle A/C

Single air conditioner

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1820 of 1839

HEATER, AIR CONDITIONER AND VENTILATION -Troubleshooting

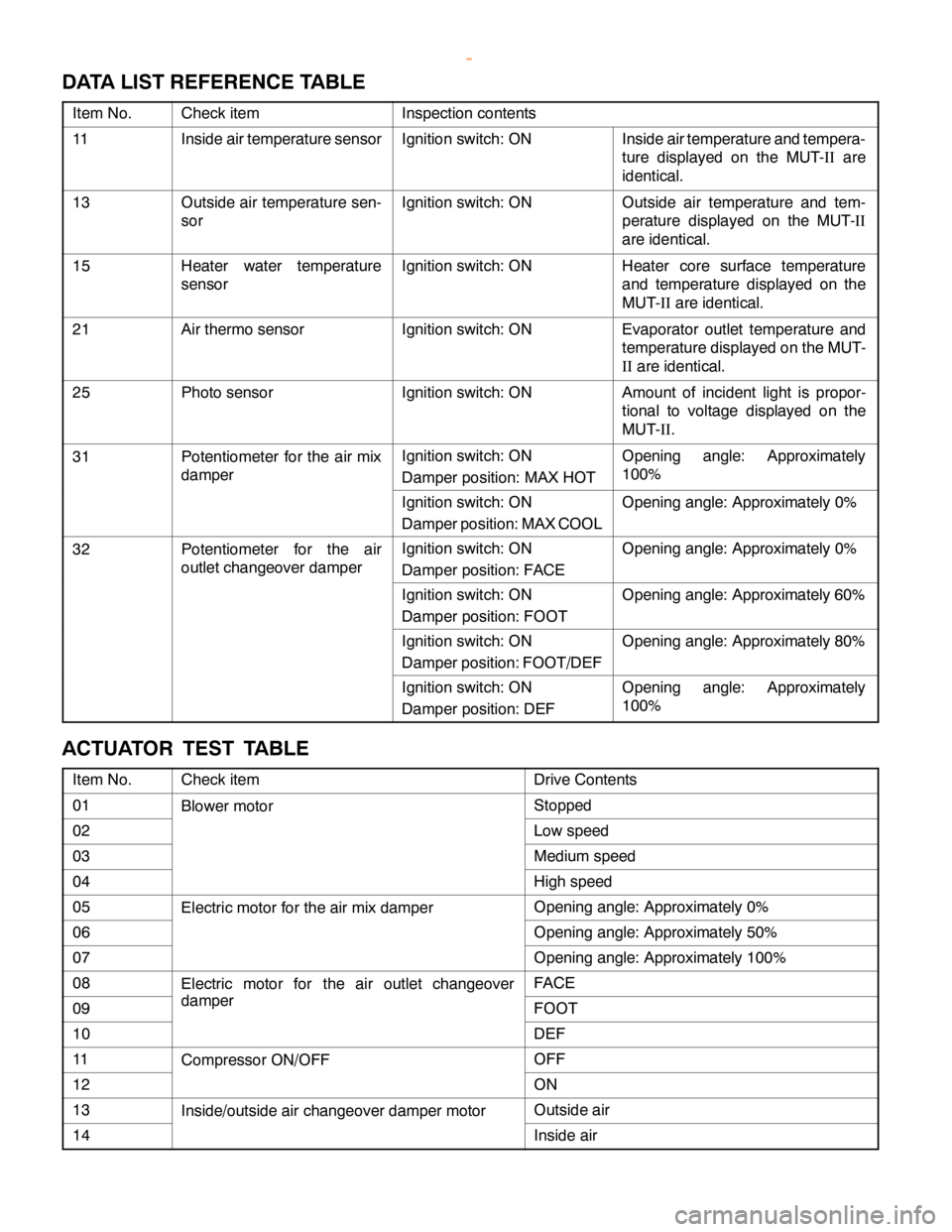

DATA LIST REFERENCE TABLE

Item No.Check itemInspection contents

11Inside air temperature sensorIgnition switch: ONInside air temperature and tempera-

ture displayed on the MUT-IIare

identical.

13Outside air temperature sen-

sorIgnition switch: ONOutside air temperature and tem-

perature displayed on the MUT-II

are identical.

15Heater water temperature

sensorIgnition switch: ONHeater core surface temperature

and temperature displayed on the

MUT-IIare identical.

21Air thermo sensorIgnition switch: ONEvaporator outlet temperature and

temperature displayed on the MUT-

IIare identical.

25Photo sensorIgnition switch: ONAmount of incident light is propor-

tional to voltage displayed on the

MUT-II.

31Potentiometer for the air mix

damperIgnition switch: ON

Damper position: MAX HOTOpening angle: Approximately

100%

Ignition switch: ON

Damper position: MAX COOLOpening angle: Approximately 0%

32Potentiometer for the air

outlet changeover damperIgnition switch: ON

Damper position: FACEOpening angle: Approximately 0%

Ignition switch: ON

Damper position:FOOTOpening angle: Approximately 60%

Ignition switch: ON

Damper position: FOOT/DEFOpening angle: Approximately 80%

Ignition switch: ON

Damper position: DEFOpening angle: Approximately

100%

ACTUATOR TEST TABLE

Item No.Check itemDrive Contents

01Blower motorStopped

02Low speed

03Medium speed

04High speed

05Electric motor for the air mix damperOpening angle: Approximately 0%

06Opening angle: Approximately 50%

07Opening angle: Approximately 100%

08Electric motor for the air outlet changeoverFACE

09damperFOOT

10DEF

11Compressor ON/OFFOFF

12ON

13Inside/outside air changeover damper motorOutside air

14Inside air

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk