compressor MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 90 of 1839

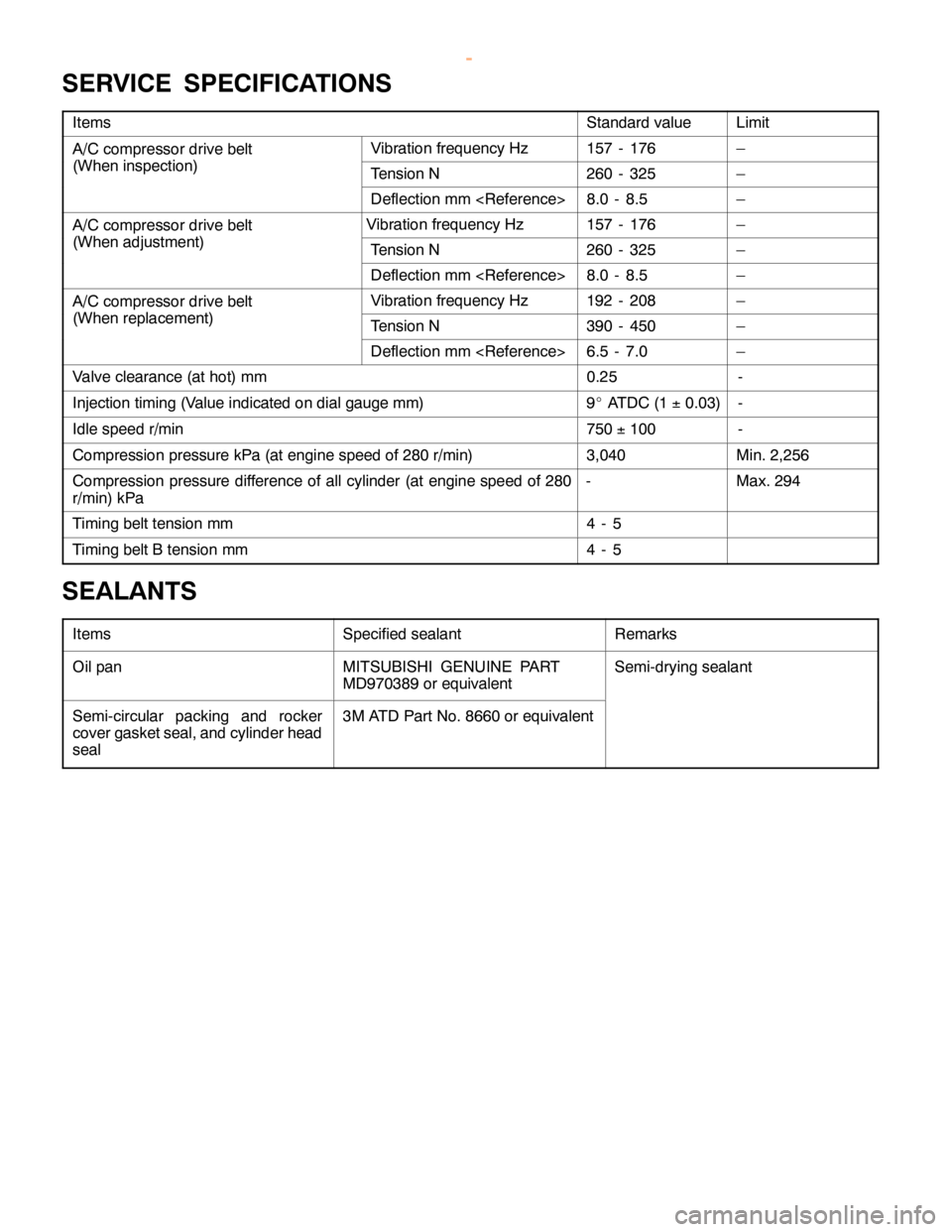

ENGINE <4D5> -Service Specifications/Sealants11B-3

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

A/C compressor drive beltVibration frequency Hz157 - 176–

(When inspection)Tension N260 - 325–

Deflection mm

A/C compressor drive beltVibration frequency Hz157 - 176–

(When adjustment)Tension N260 - 325–

Deflection mm

A/C compressor drive beltVibration frequency Hz192 - 208–

(When replacement)Tension N390 - 450–

Deflection mm

Valve clearance (at hot) mm0.25-

Injection timing (Value indicated on dial gauge mm)9_ATDC (1±0.03)-

Idle speed r/min750±100-

Compression pressure kPa (at engine speed of 280 r/min)3,040Min. 2,256

Compression pressure difference of all cylinder (at engine speed of 280

r/min) kPa-Max. 294

Timing belt tension mm4-5

Timing belt B tension mm4-5

SEALANTS

ItemsSpecified sealantRemarks

Oil panMITSUBISHI GENUINE PART

MD970389 or equivalentSemi-drying sealant

Semi-circular packing and rocker

cover gasket seal, and cylinder head

seal3M ATD Part No. 8660 or equivalent

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 143 of 1839

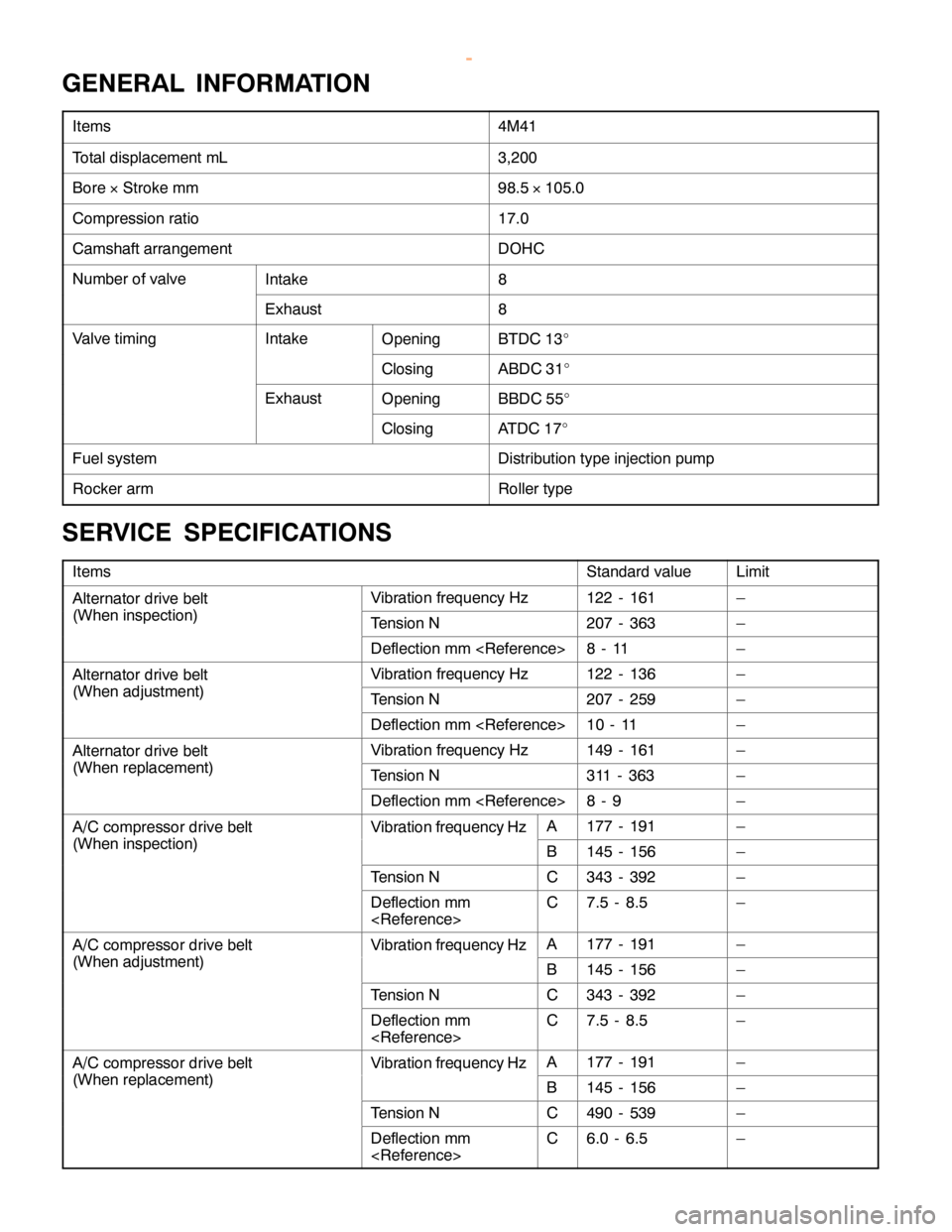

ENGINE <4M4> -General Information/Service Specifications11C-2

GENERAL INFORMATION

Items4M41

Total displacement mL3,200

Bore´Stroke mm98.5´105.0

Compression ratio17.0

Camshaft arrangementDOHC

Number of valveIntake8

Exhaust8

Valve timingIntakeOpeningBTDC 13_

ClosingABDC 31_

ExhaustOpeningBBDC 55_

ClosingATDC 17_

Fuel systemDistribution type injection pump

Rocker armRoller type

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Alternator drive beltVibration frequency Hz122 - 161–

(When inspection)Tension N207 - 363–

Deflection mm

Alternator drive beltVibration frequency Hz122 - 136–

(When adjustment)Tension N207 - 259–

Deflection mm

Alternator drive beltVibration frequency Hz149 - 161–

(When replacement)Tension N311 - 363–

Deflection mm

A/C compressor drive beltVibration frequency HzA177 - 191–

(When inspection)B145 - 156–

Tension NC343 - 392–

Deflection mm

A/C compressor drive beltVibration frequency HzA177 - 191–

(When adjustment)B145 - 156–

Tension NC343 - 392–

Deflection mm

A/C compressor drive beltVibration frequency HzA177 - 191–

(When replacement)B145 - 156–

Tension NC490 - 539–

Deflection mm

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 190 of 1839

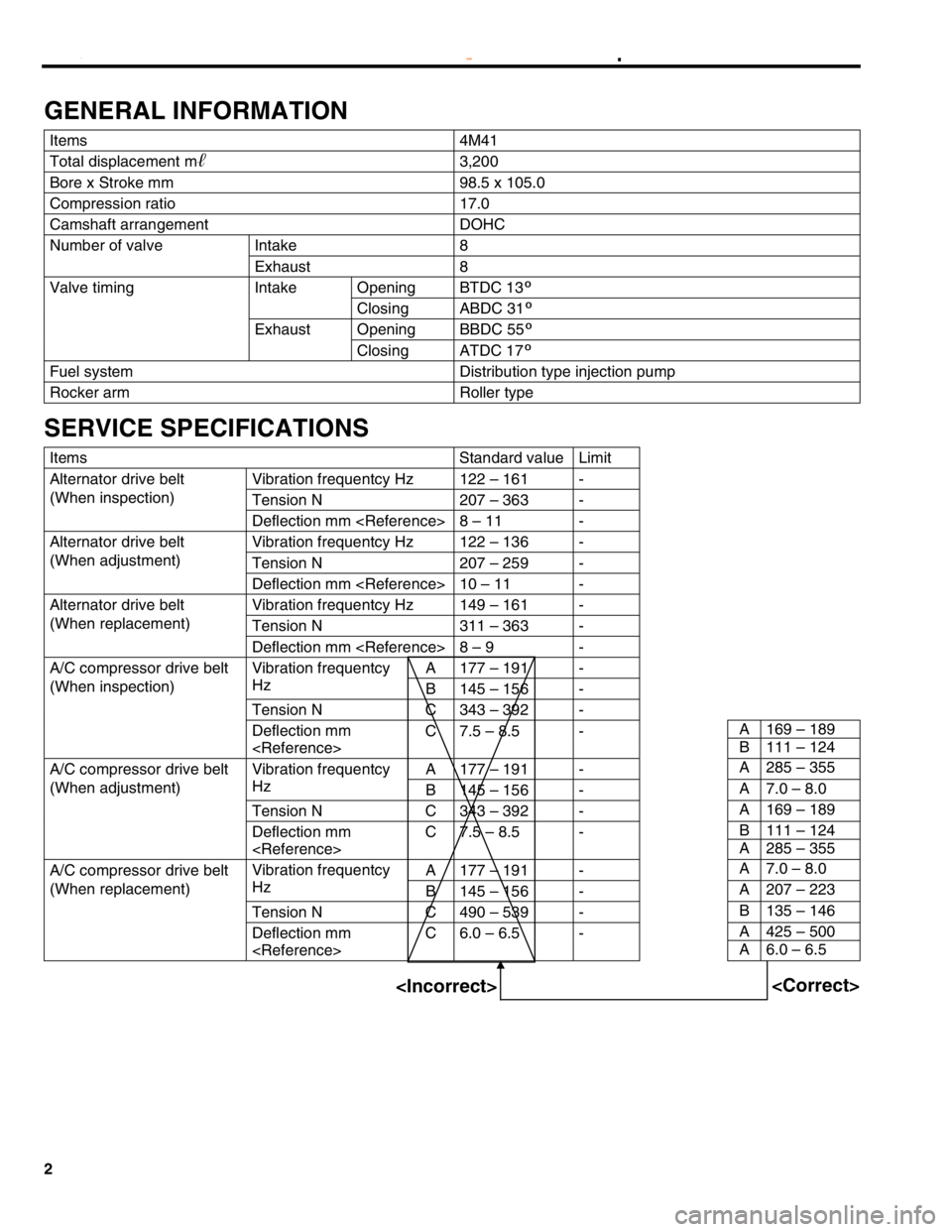

2

GENERAL INFORMATION

Items 4M41

Total displacement mℓ

3,200

Bore x Stroke mm 98.5 x 105.0

Compression ratio 17.0

Camshaft arrangement DOHC

Intake 8Number of valve

Exhaust 8

Opening BTDC 13ºIntake

Closing ABDC 31º

Opening BBDC 55º

Valve timing

Exhaust

Closing ATDC 17º

Fuel system Distribution type injection pump

Rocker arm Roller type

SERVICE SPECIFICATIONS

Items Standard value Limit

Vibration frequentcy Hz 122 – 161 -

Tension N 207 – 363 -

Alternator drive belt

(When inspection)

Deflection mm

Vibration frequentcy Hz 122 – 136 -

Tension N 207 – 259 -

Alternator drive belt

(When adjustment)

Deflection mm

Vibration frequentcy Hz 149 – 161 -

Tension N 311 – 363 -

Alternator drive belt

(When replacement)

Deflection mm

A 177 – 191 -Vibration frequentcy

Hz

B 145 – 156 -

Tension N C 343 – 392 -

A 169 – 189

A/C compressor drive belt

(When inspection)

Deflection mm

B 111 – 124

A 177 – 191 -A 285 – 355Vibration frequentcy

Hz

B 145 – 156 -A 7.0 – 8.0

Tension N C 343 – 392 -A 169 – 189

B 111 – 124

A/C compressor drive belt

(When adjustment)

Deflection mm

A 285 – 355

A 177 – 191 -A 7.0 – 8.0Vibration frequentcy

Hz

B 145 – 156 -A 207 – 223

Tension N C 490 – 539 -B 135 – 146

A 425 – 500

A/C compressor drive belt

(When replacement)

Deflection mm

A 6.0 – 6.5

11C-2ENGINE <4M4> - General Information/Service Specifications

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 218 of 1839

GDI -General Information13A-4

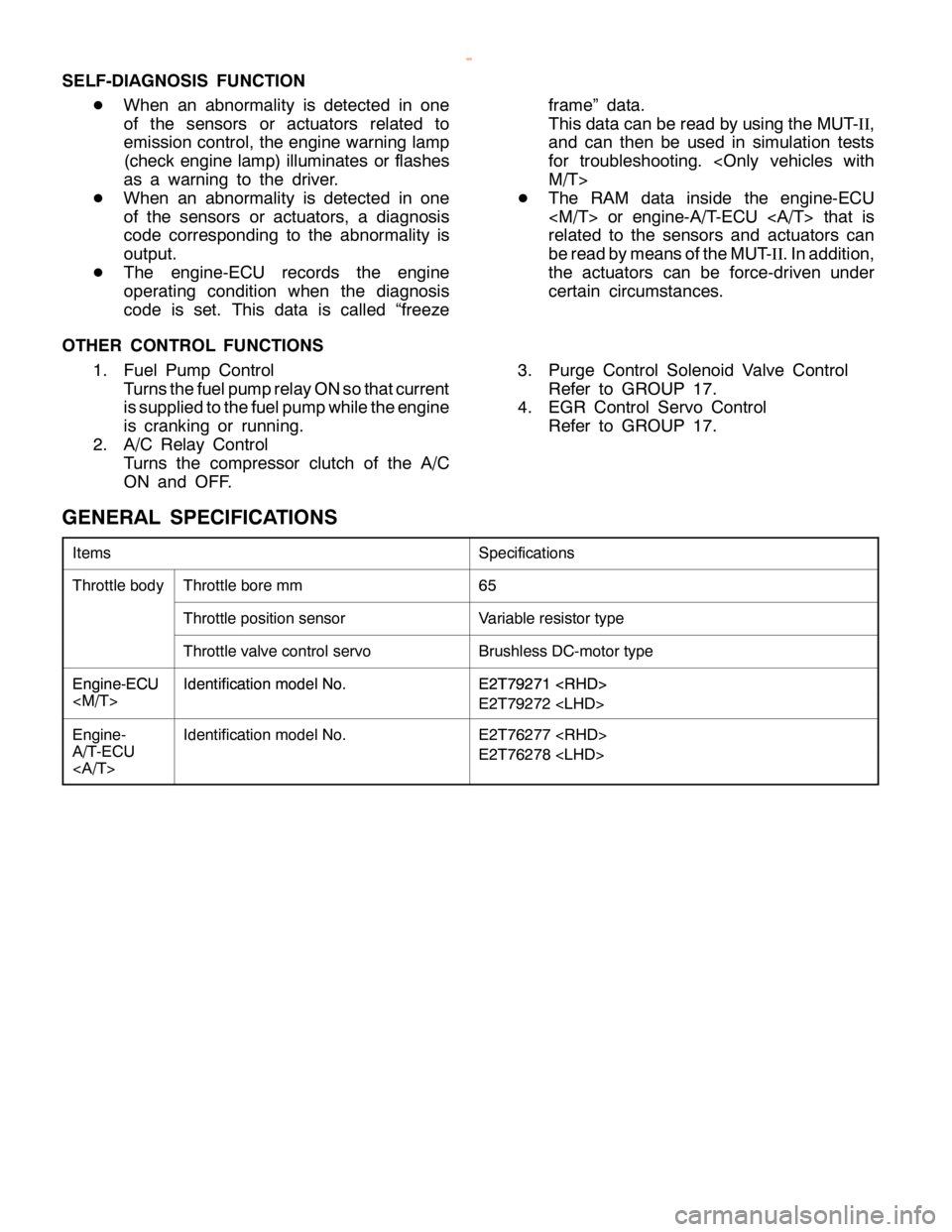

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in one

of the sensors or actuators related to

emission control, the engine warning lamp

(check engine lamp) illuminates or flashes

as a warning to the driver.

DWhen an abnormality is detected in one

of the sensors or actuators, a diagnosis

code corresponding to the abnormality is

output.

DThe engine-ECU records the engine

operating condition when the diagnosis

code is set. This data is called “freezeframe” data.

This data can be read by using the MUT-II,

and can then be used in simulation tests

for troubleshooting.

DThe RAM data inside the engine-ECU

related to the sensors and actuators can

be read by means of the MUT-II. In addition,

the actuators can be force-driven under

certain circumstances.

OTHER CONTROL FUNCTIONS

1. Fuel Pump Control

Turns the fuel pump relay ON so that current

is supplied to the fuel pump while the engine

is cranking or running.

2. A/C Relay Control

Turns the compressor clutch of the A/C

ON and OFF.3. Purge Control Solenoid Valve Control

Refer to GROUP 17.

4. EGR Control Servo Control

Refer to GROUP 17.

GENERAL SPECIFICATIONS

ItemsSpecifications

Throttle bodyThrottle bore mm65

Throttle position sensorVariable resistor type

Throttle valve control servoBrushless DC-motor type

Engine-ECUIdentification model No.E2T79271

E2T79272

Engine-Identification model No.E2T76277

A/T-ECU

E2T76278

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 316 of 1839

GDI -Troubleshooting

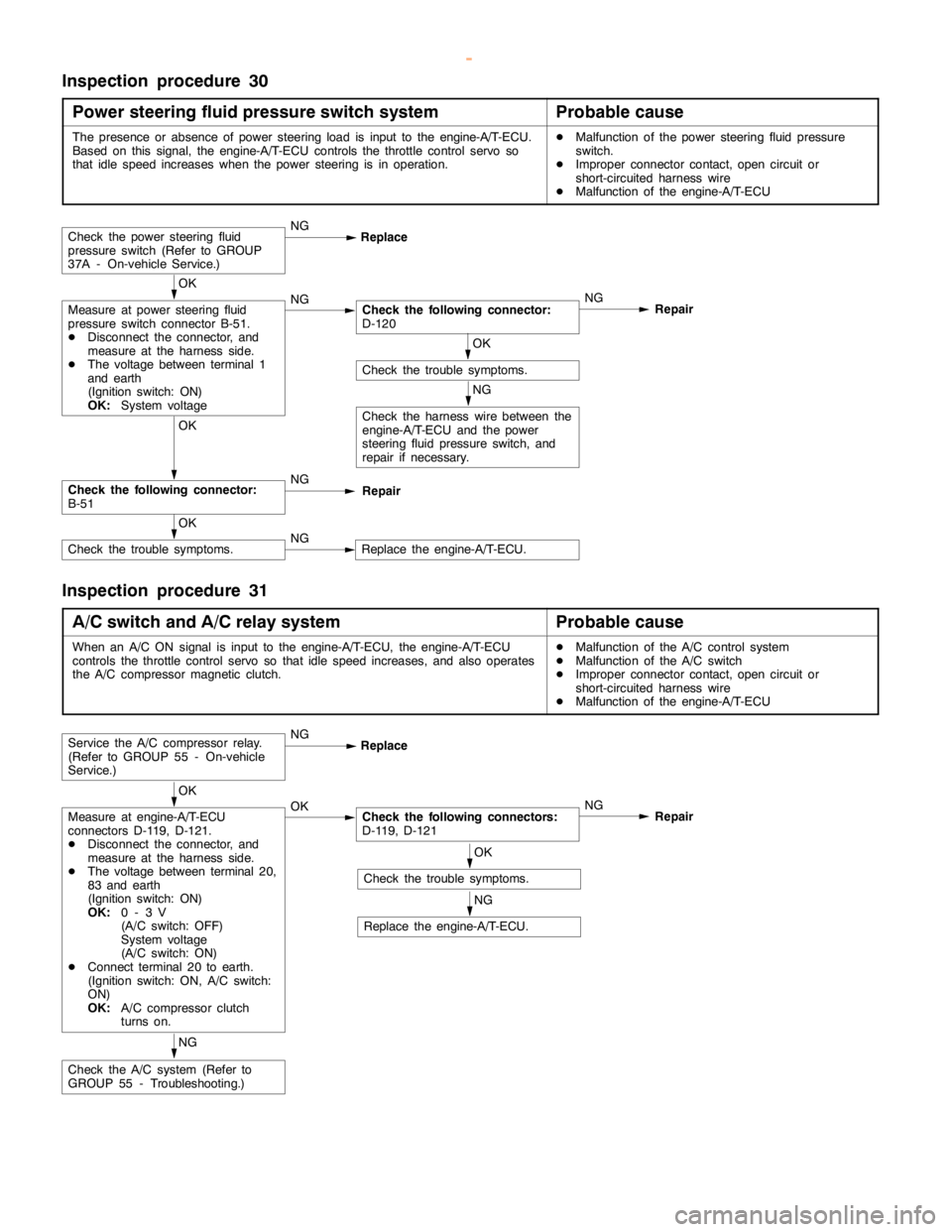

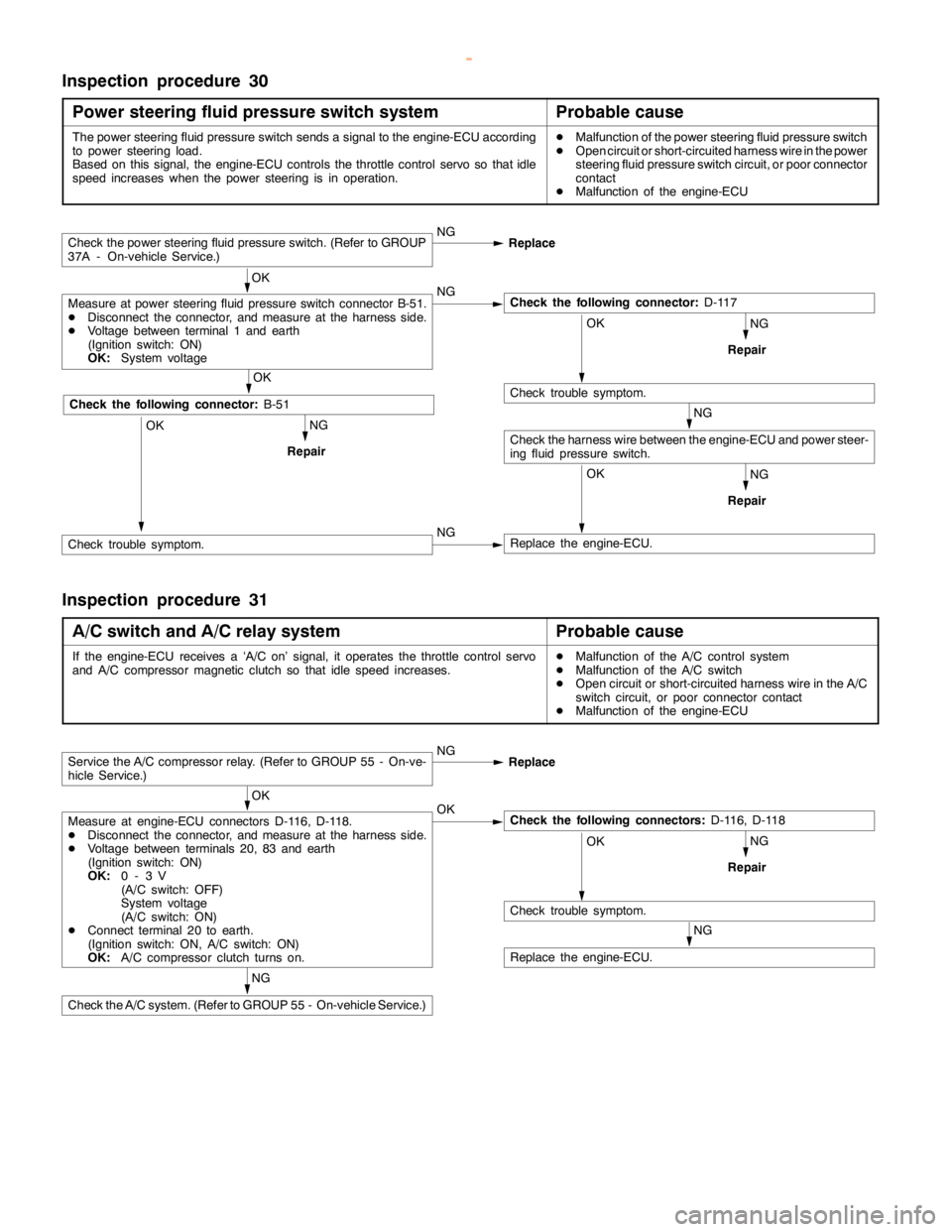

Inspection procedure 30

Power steering fluid pressure switch system

Probable cause

The power steering fluid pressure switch sends a signal to the engine-ECU according

to power steering load.

Based on this signal, the engine-ECU controls the throttle control servo so thatidle

speed increases when the power steering is in operation.DMalfunction of the power steering fluid pressure switch

DOpen circuit or short-circuited harness wire in the power

steering fluid pressure switch circuit, or poor connector

contact

DMalfunction of the engine-ECU

NG

NG

RepairOK

Replace the engine-ECU.

NG

Repair

Check the power steering fluid pressure switch. (Refer to GROUP

37A - On-vehicle Service.)NG

Replace

OK

Measure at power steering fluid pressure switch connector B-51.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminal 1 and earth

(Ignition switch: ON)

OK:

System voltageNGCheck the following connector:

D-117

OK

Check trouble symptom.

Check the harness wire between the engine-ECU and power steer-

ing fluid pressure switch.NG

RepairOK

OK

Check the following connector:

B-51

Check trouble symptom.NG

Inspection procedure 31

A/C switch and A/C relay system

Probable cause

If the engine-ECU receives a ‘A/C on’ signal, it operates the throttle control servo

and A/C compressor magnetic clutch so thatidlespeed increases.DMalfunction of the A/C control system

DMalfunction of the A/C switch

DOpen circuit or short-circuited harness wire in the A/C

switch circuit, or poor connector contact

DMalfunction of the engine-ECU

NG

NG

RepairOK

Check trouble symptom.

NG

Replace the engine-ECU.

Service the A/C compressor relay. (Refer to GROUP 55 - On-ve-

hicle Service.)NG

Replace

OK

Measure at engine-ECU connectors D-116, D-118.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminals 20, 83 and earth

(Ignition switch: ON)

OK:

0-3V

(A/C switch: OFF)

System voltage

(A/C switch: ON)

DConnect terminal 20 to earth.

(Ignition switch: ON, A/C switch: ON)

OK:

A/C compressor clutch turns on.OKCheck the following connectors:

D-116, D-118

Check the A/C system. (Refer to GROUP 55 - On-vehicle Service.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 321 of 1839

GDI -Troubleshooting

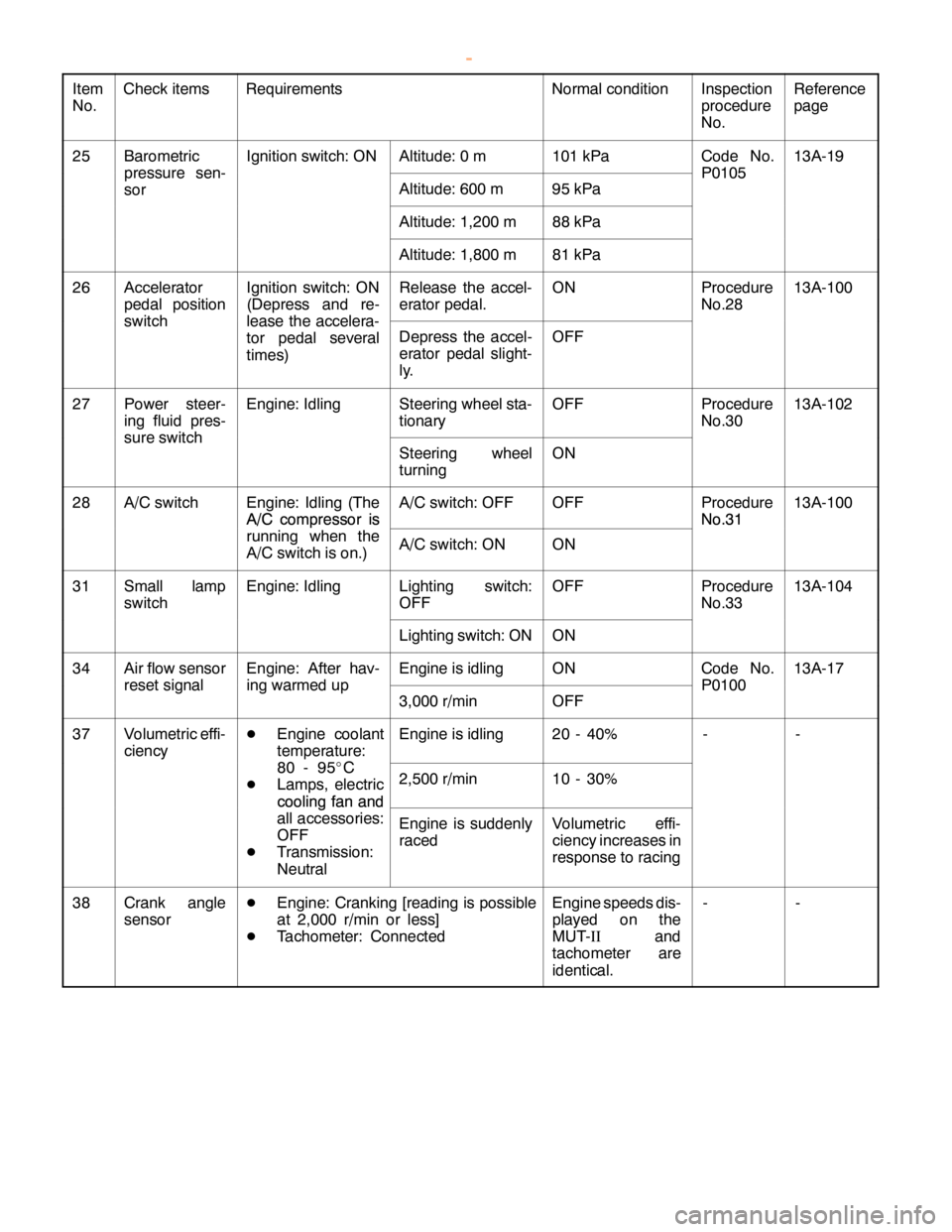

Item

No.Reference

page Inspection

procedure

No. Normal condition Requirements Check items

25BarometricIgnition switch: ONAltitude: 0 m101 kPaCode No.13A-19

pressure sen-

sor

Altitude: 600 m95 kPa

P0105

Altitude: 1,200 m88 kPa

Altitude: 1,800 m81 kPa

26Accelerator

pedal positionIgnition switch: ON

(Depress and re-Release the accel-

erator pedal.ONProcedure

No.2813A-100

switchlease the accelera-

tor pedal several

times)

Depress the accel-

erator pedal slight-

ly.OFF

27Power steer-

ing fluid pres-Engine: IdlingSteering wheel sta-

tionaryOFFProcedure

No.3013A-102

sure switch

Steering wheel

turningON

28A/C switchEngine: Idling (The

A/C compressor isA/C switch: OFFOFFProcedure

No.3113A-100

A/C compressor is

running when the

A/C switch is on.)

A/C switch: ONON

No.31

31Small lamp

switchEngine: IdlingLighting switch:

OFFOFFProcedure

No.3313A-104

Lighting switch: ONON

34Air flow sensorEngine: After hav-Engine is idlingONCode No.13A-17

reset signaling warmed up

3,000 r/minOFF

P0100

37Volumetric effi-

ciencyDEngine coolant

temperature:Engine is idling20 - 40%--

80 - 95_C

DLamps, electric

cooling fan and2,500 r/min10 - 30%

cooling fan and

all accessories:

OFF

DTransmission:

Neutral

Engine is suddenly

racedVolumetric effi-

ciency increases in

response to racing

38Crank angle

sensorDEngine: Cranking [reading is possible

at 2,000 r/min or less]

DTachometer: ConnectedEngine speeds dis-

played on the

MUT-IIand

tachometer are

identical.--

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 322 of 1839

GDI -Troubleshooting

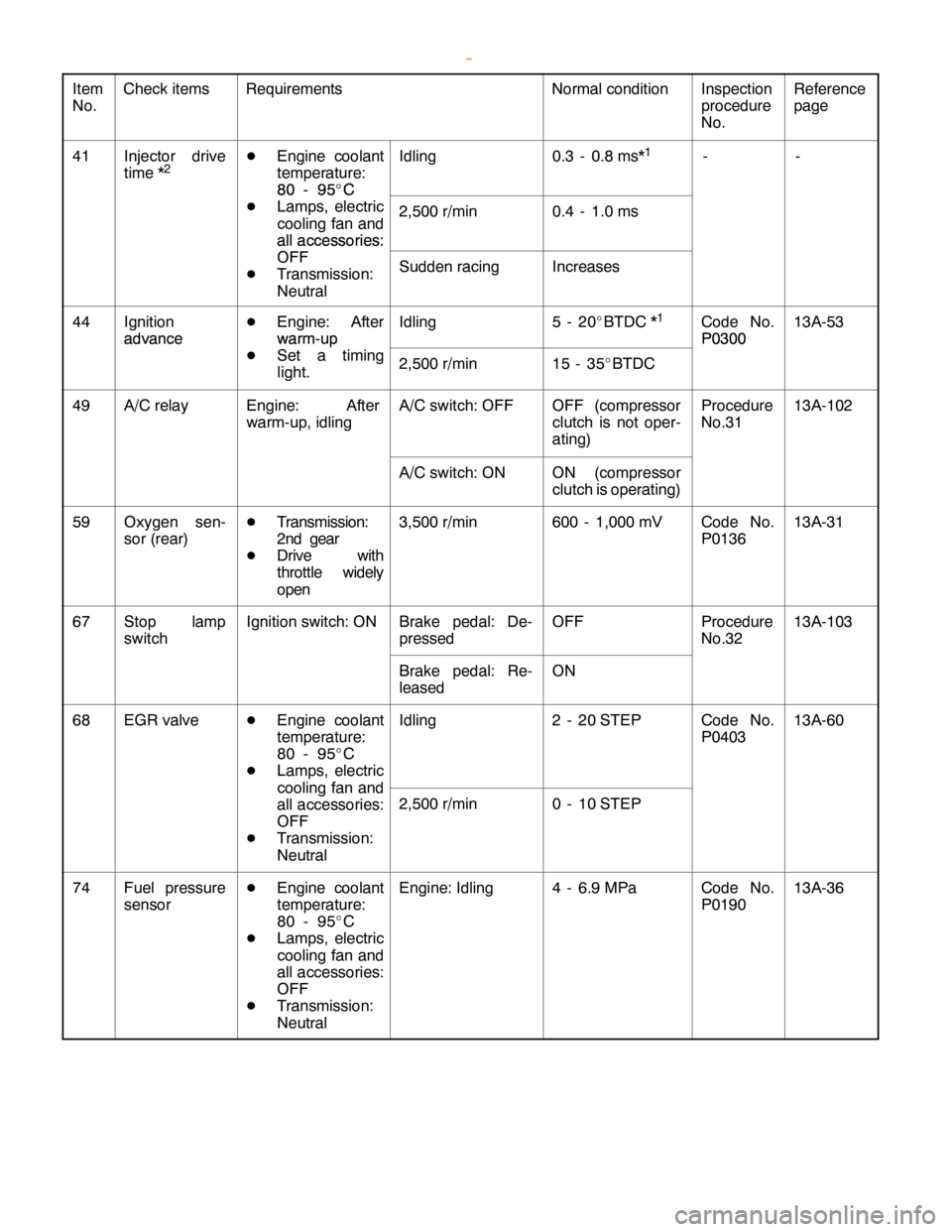

Item

No.Reference

page Inspection

procedure

No. Normal condition Requirements Check items

41Injector drive

time *2DEngine coolant

temperature:

80 - 95_CIdling0.3 - 0.8 ms*1--

80 - 95_C

DLamps, electric

cooling fan and

all accessories:

2,500 r/min0.4 - 1.0 ms

all accessories:

OFF

DTransmission:

Neutral

Sudden racingIncreases

44Ignition

advanceDEngine: After

warm-upIdling5-20_BTDC *1Code No.

P030013A-53

advancewarm-up

DSet a timing

light.

2,500 r/min15 - 35_BTDC

P0300

49A/C relayEngine: After

warm-up, idlingA/C switch: OFFOFF (compressor

clutch is not oper-

ating)Procedure

No.3113A-102

A/C switch: ONON (compressor

clutch is operating)

59Oxygen sen-

sor (rear)DTransmission:

2nd gear

DDrive with

throttle widely

open3,500 r/min600 - 1,000 mVCode No.

P013613A-31

67Stop lamp

switchIgnition switch: ONBrake pedal: De-

pressedOFFProcedure

No.3213A-103

Brake pedal: Re-

leasedON

68EGR valveDEngine coolant

temperature:

80 - 95_C

DLamps, electricIdling2 - 20 STEPCode No.

P040313A-60

cooling fan and

all accessories:

OFF

DTransmission:

Neutral

2,500 r/min0 - 10 STEP

74Fuel pressure

sensorDEngine coolant

temperature:

80 - 95_C

DLamps, electric

cooling fan and

all accessories:

OFF

DTransmission:

NeutralEngine: Idling4 - 6.9 MPaCode No.

P019013A-36

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 326 of 1839

GDI -Troubleshooting

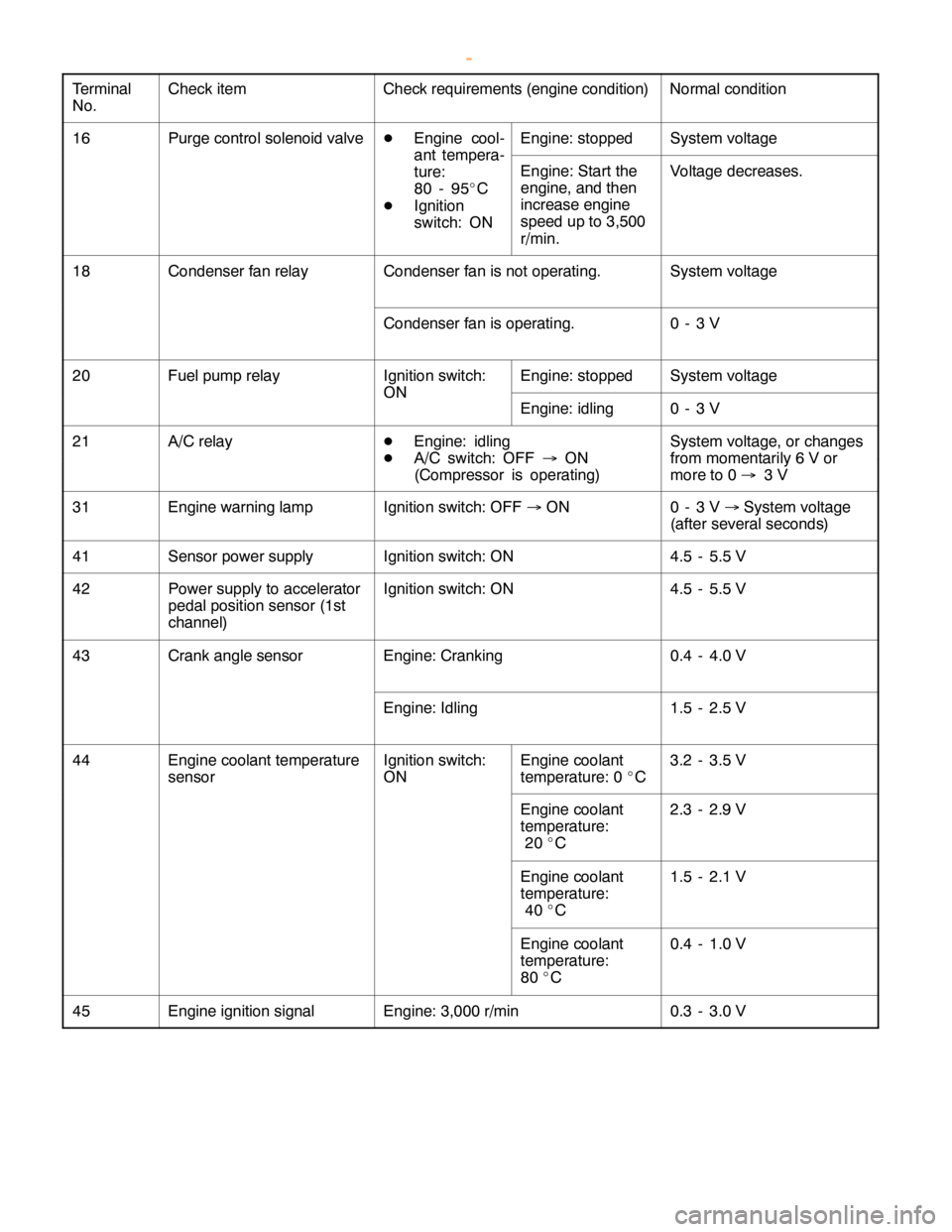

Terminal

No.Normal condition Check requirements (engine condition) Check item

16Purge control solenoid valveDEngine cool-Engine: stoppedSystem voltage

ant tempera-

ture:

80 - 95_C

DIgnition

switch: ON

Engine: Start the

engine, and then

increase engine

speed up to 3,500

r/min.Voltage decreases.

18Condenser fan relayCondenser fan is not operating.System voltage

Condenser fan is operating.0-3V

20Fuel pump relayIgnition switch:Engine: stoppedSystem voltage

ON

Engine: idling0-3V

21A/C relayDEngine: idlingSystem voltage, or changes

DA/C switch: OFF®ON

(Compressor is operating)from momentarily 6 V or

more to 0®3V

31Engine warning lampIgnition switch: OFF®ON0-3V®System voltage

(after several seconds)

41Sensor power supplyIgnition switch: ON4.5 - 5.5 V

42Power supply to accelerator

pedal position sensor (1st

channel)Ignition switch: ON4.5 - 5.5 V

43Crank angle sensorEngine: Cranking0.4 - 4.0 V

Engine: Idling1.5 - 2.5 V

44Engine coolant temperature

sensorIgnition switch:

ONEngine coolant

temperature: 0_C3.2 - 3.5 V

Engine coolant

temperature:

20_C2.3 - 2.9 V

Engine coolant

temperature:

40_C1.5 - 2.1 V

Engine coolant

temperature:

80_C0.4 - 1.0 V

45Engine ignition signalEngine: 3,000 r/min0.3 - 3.0 V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 328 of 1839

GDI -Troubleshooting

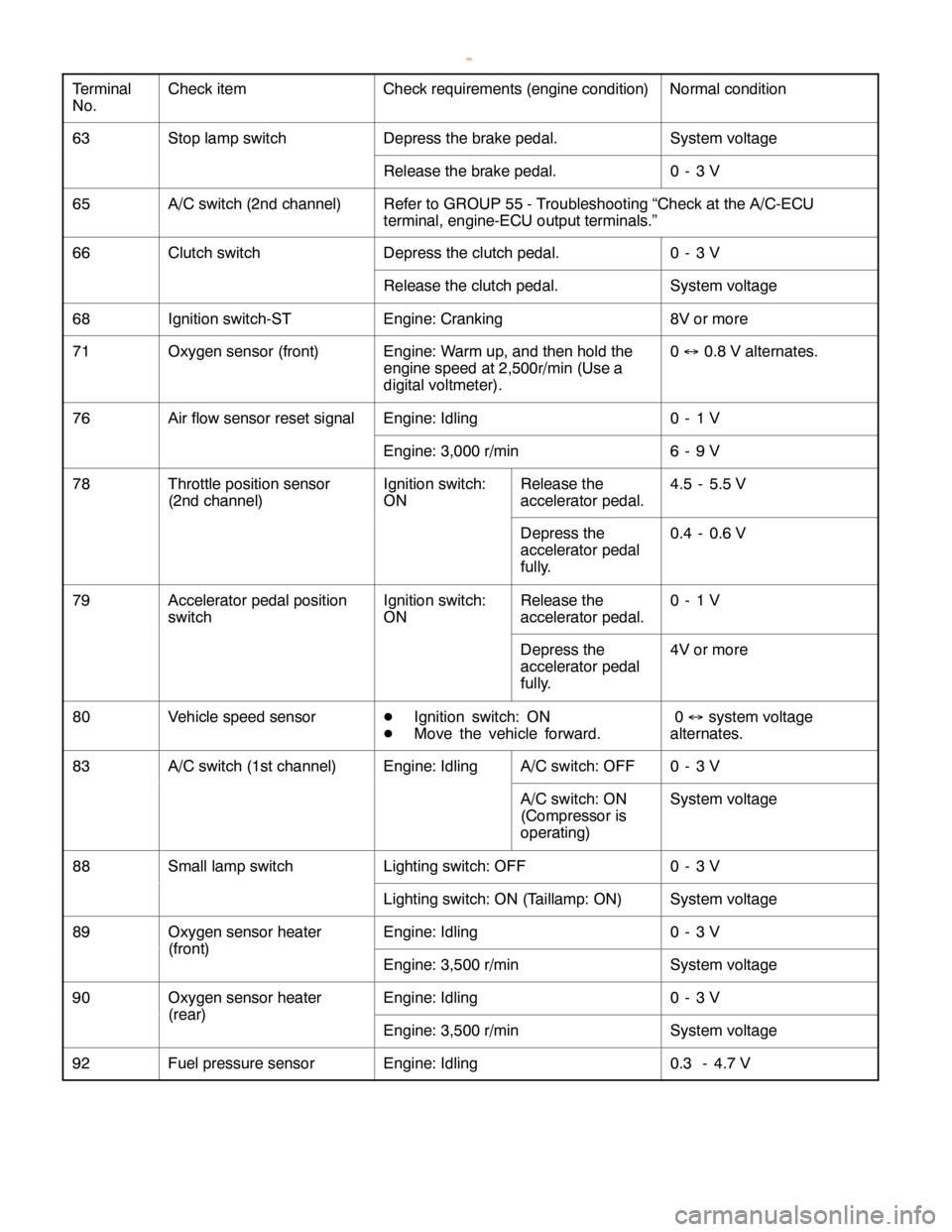

Terminal

No.Normal condition Check requirements (engine condition) Check item

63Stop lamp switchDepress the brake pedal.System voltage

Release the brake pedal.0-3V

65A/C switch (2nd channel)Refer to GROUP 55 - Troubleshooting “Check at the A/C-ECU

terminal, engine-ECU output terminals.”

66Clutch switchDepress the clutch pedal.0-3V

Release the clutch pedal.System voltage

68Ignition switch-STEngine: Cranking8V or more

71Oxygen sensor (front)Engine: Warm up, and then hold the

engine speed at 2,500r/min (Use a

digital voltmeter).0«0.8 V alternates.

76Air flow sensor reset signalEngine: Idling0-1V

Engine: 3,000 r/min6-9V

78Throttle position sensor

(2nd channel)Ignition switch:

ONRelease the

accelerator pedal.4.5 - 5.5 V

Depress the

accelerator pedal

fully.0.4 - 0.6 V

79Accelerator pedal position

switchIgnition switch:

ONRelease the

accelerator pedal.0-1V

Depress the

accelerator pedal

fully.4V or more

80Vehicle speed sensorDIgnition switch: ON

DMove the vehicle forward.0«system voltage

alternates.

83A/C switch (1st channel)Engine: IdlingA/C switch: OFF0-3V

A/C switch: ON

(Compressor is

operating)System voltage

88Small lamp switchLighting switch: OFF0-3V

Lighting switch: ON (Taillamp: ON)System voltage

89Oxygen sensor heaterEngine: Idling0-3V

(front)

Engine: 3,500 r/minSystem voltage

90Oxygen sensor heaterEngine: Idling0-3V

(rear)

Engine: 3,500 r/minSystem voltage

92Fuel pressure sensorEngine: Idling0.3 - 4.7 V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 408 of 1839