engine MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 828 of 1839

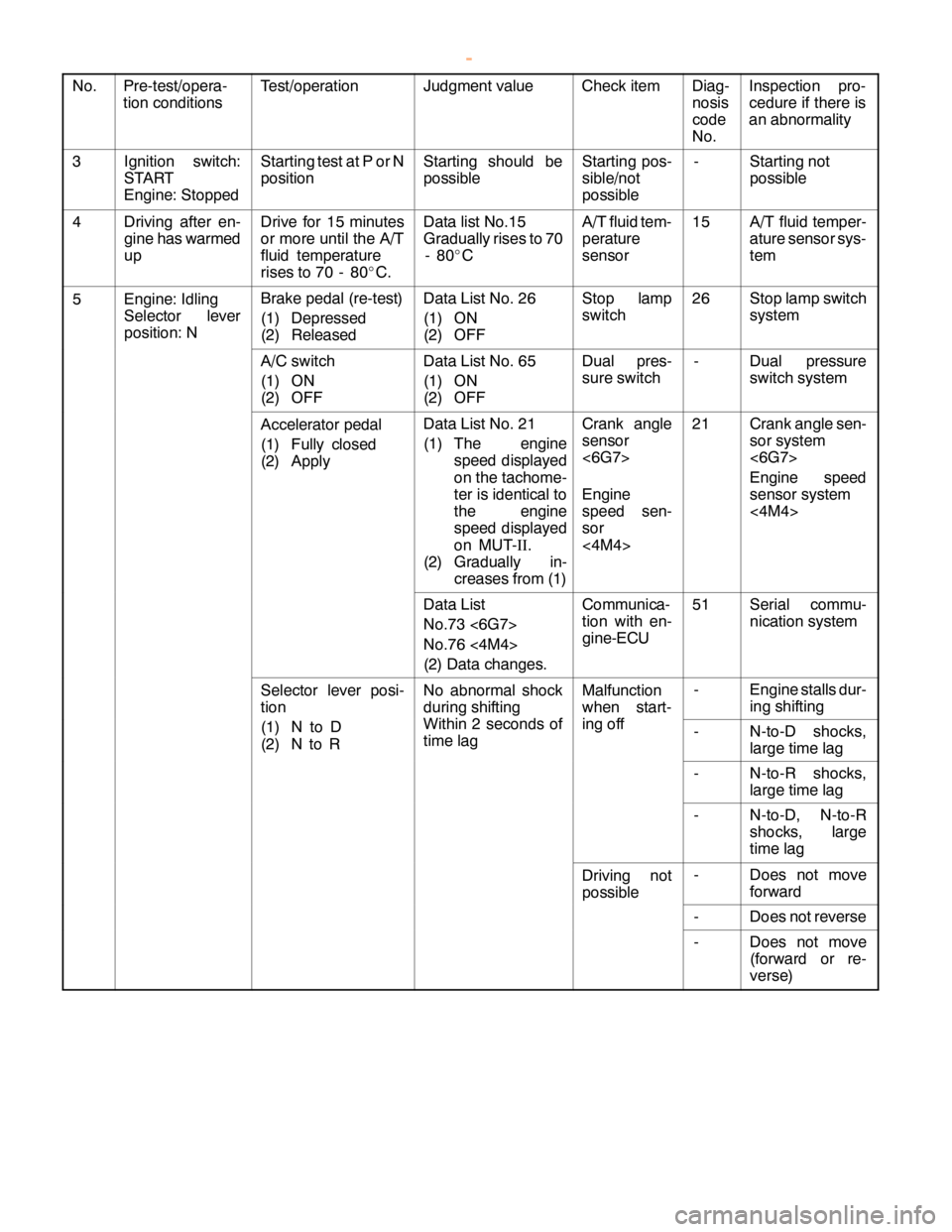

ENGINE AND EMISSION CONTROL -Auto-cruise Control System17-26

Terminal

No.Normal condition Check conditions Check item

11Throttle position sensorAccelerator pedal: Fully depressed450 - 800 mV

Accelerator pedal: DepressedThe more deeply the

pedal is depressed, the

higher value the MUT-

IIdisplay

Accelerator pedal: Release4,200 - 4,900 mV

12Accelerator pedalAccelerator pedal: Fully depressed985 - 1,085 mV

position sensorAccelerator pedal: DepressedThe more deeply the

pedal is depressed, the

higher value the MUT-

IIdisplay

Accelerator pedal: Release4,000 mV or more

<4M4>

Terminal

No.Check itemCheck conditionsNormal condition

01Auto-cruiseMAINMAIN switch: ONON

control

switchMAIN switch: OFFOFF

02SETMAIN switch:SET switch: ONON

(COAST)ONSET switch: OFFOFF

03RESUMERESUME switch: ONON

(ACCEL)RESUME switch: OFFOFF

04CANCELCANCEL switch: ONON

CANCEL switch: OFFOFF

05Stop lamp switchBrake pedal: DepressedON

(for stop lamp circuit)Brake pedal: ReleasedOFF

06Stop lamp switchBrake pedal: DepressedOFF

(for auto-cruise control

circuit)

Brake pedal: ReleasedON

07Clutch switch

Brake pedal: ReleasedOFF

Inhibitor switchSelector lever: “N”, “P” positionON

Selector lever: Other than “N”, “P” positionOFF

08Accelerator switchAccelerator pedal: ReleasedON

(Idle position switch)Accelerator pedal: DepressedOFF

09Auto-cruise controlAuto-cruise control system: ActivatedON

systemAuto-cruise control system: Not activatedOFF

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 833 of 1839

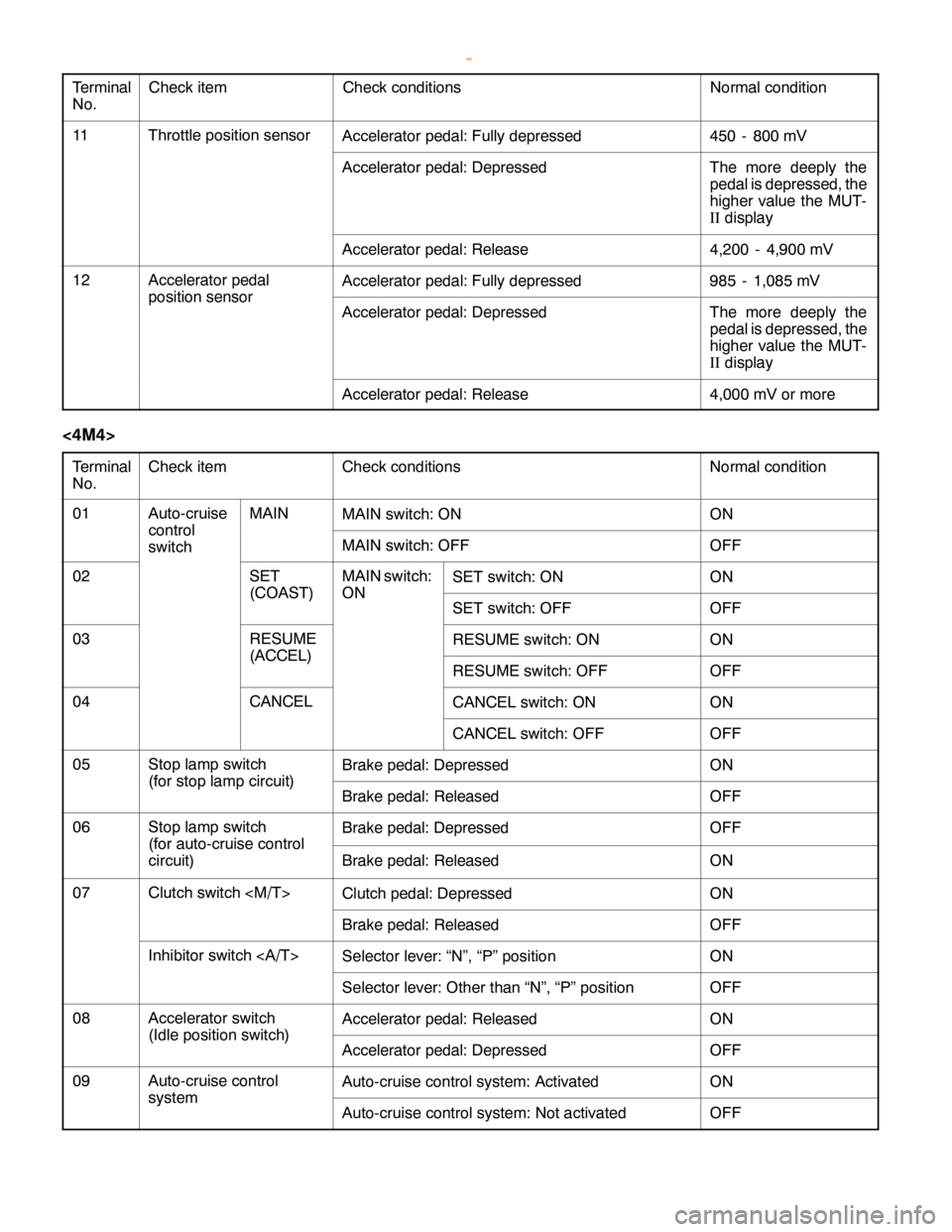

ENGINE AND EMISSION CONTROL -Emission Control System <6G7>17-31

EMISSION CONTROL SYSTEM <6G7>

GENERAL INFORMATION

The emission control system consists of the following subsystems:

DCrankcase emission control system

DEvaporative emission control system

DExhaust emission control system

ItemsNameSpecification

Crankcase emission

control systemPositive crankcase ventilation (PCV) valveVariable flow type

(Purpose: HC reduction)

Evaporative emission

control systemCanister

Purge control solenoid valveEquipped

Duty cycle type solenoid valve

(Purpose: HC reduction)

Exhaust emission

control systemAir-fuel ratio control device - GDI systemOxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Exhaust gas recirculation system

DEGR valveEquipped

Stepper motor type

(Purpose: NOx reduction)

Catalytic converterMonolith type

(Purpose: CO, HC, NOx reduction)

EMISSION CONTROL DEVICE REFERENCE TABLE

Related partsCrankcase

emission

control

systemEvaporative

emission

control

systemAir/fuel

ratio

control

systemCatalytic

converterExhaust

gas

recirculation

systemReference

page

PCV valve´17-35

Purge control solenoid valve´17-38

GDI system component´´GROUP

13A

Catalytic converter´17-44

EGR valve´17-40

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 854 of 1839

ENGINE AND EMISSION CONTROL -Emission Control System

<4M4-Vehicles with EGR>17-52

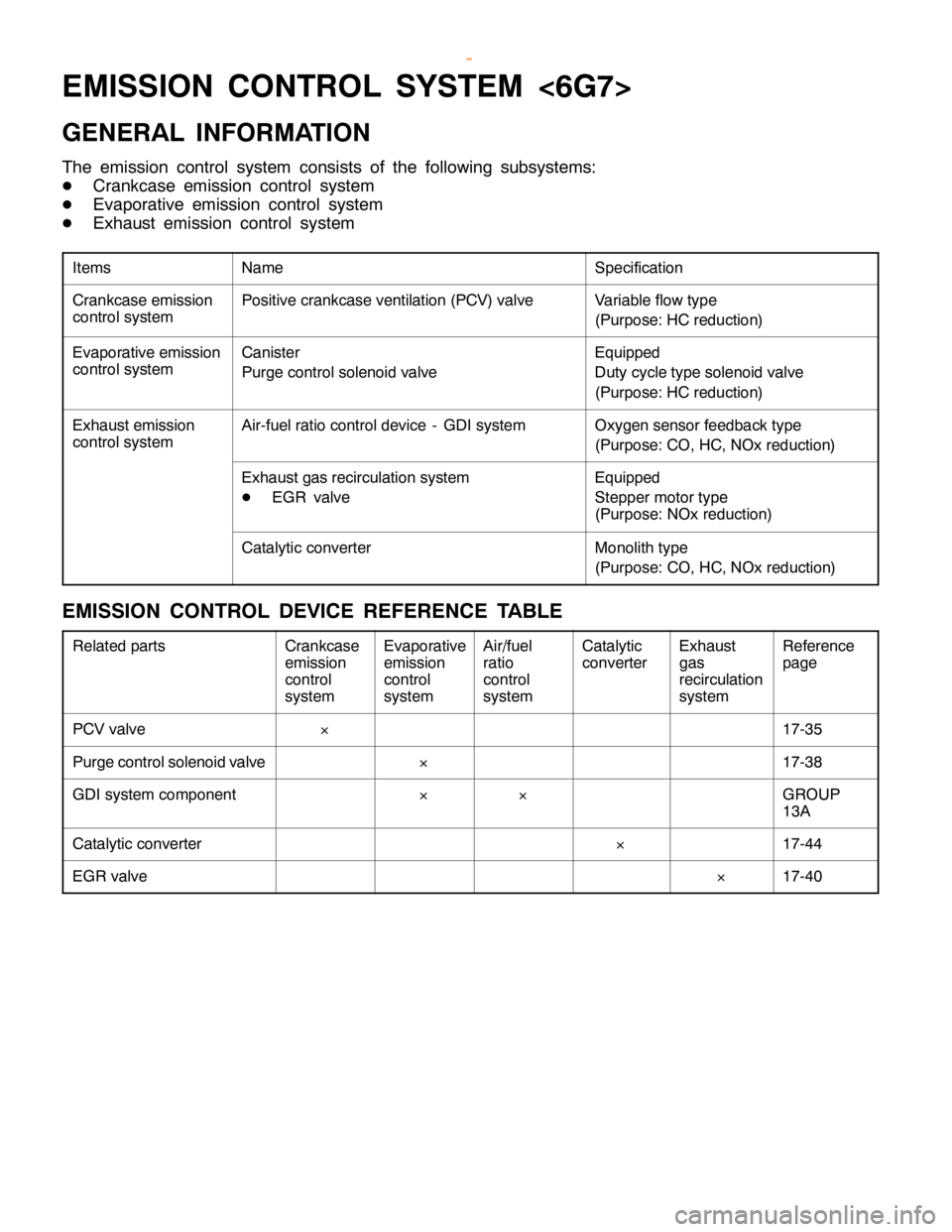

EMISSION CONTROL SYSTEM <4M4-VEHICLES WITH

EGR>

GENERAL INFORMATION

The electronically-controlled EGR system and the

fuel injection timing control system (load timer)

reduce the level of exhaust gases (NO

x).

ItemsNameSpecification

Exhaust emission

control systemExhaust gas recirculation system

DEGR valve

DEGR solenoid valve No.1

DEGR solenoid valve No.2Electronically-controlled EGR system

Single type

Duty cycle solenoid valve

ON-OFFsolenoid valve

SERVICE SPECIFICATIONS

ItemsStandard value

EGR solenoid valve No.1/No. 2 resistance (at 20_C)W36 - 44

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 859 of 1839

17-1

ENGINE AND

EMISSION

CONTROL

CONTENTS

ENGINE CONTROL SYSTEM 2........

GENERAL 2...............................

Outline of Change 2.........................

EMISSION CONTROL SYSTEM

<4D5-STEPIII>

2 .....................................

GENERAL 2...............................

Outline of Changes 2........................

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 2..............

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 3................................EGR VALVE AND EGR COOLER 6.........

CATALYTIC CONVERTER 8................

EMISSION CONTROL SYSTEM <4M4>

9 .....................................

GENERAL 9...............................

Outline of Change 9.........................

SERVICE SPECIFICATIONS 9..............

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 9................................

EGR VALVE AND EGR COOLER 11........

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 860 of 1839

ENGINE AND EMISSION CONTROL -EngineControlSystem/EmissionControl

System <4D5-Step III>17-2

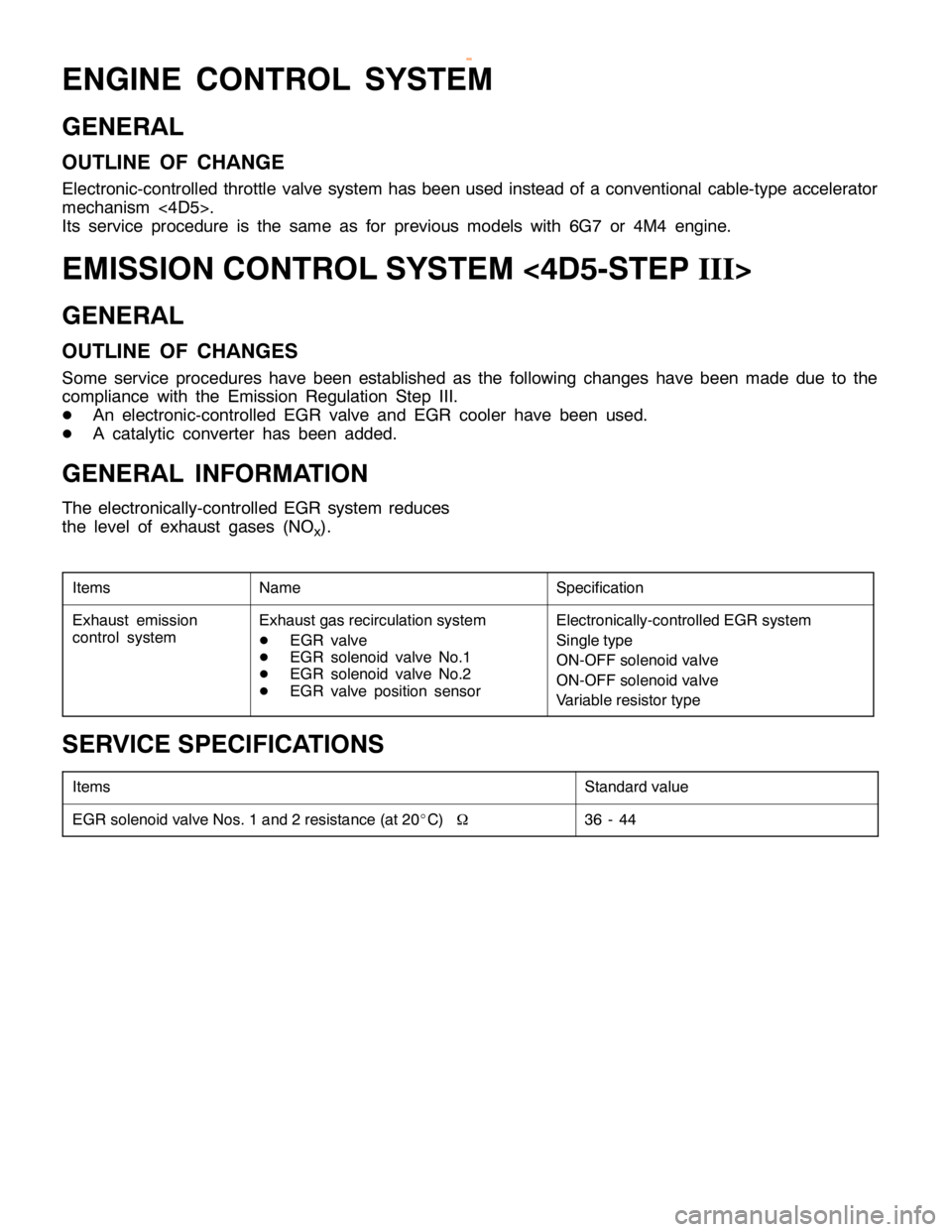

ENGINE CONTROL SYSTEM

GENERAL

OUTLINE OF CHANGE

Electronic-controlled throttle valve system has been used instead of a conventional cable-type accelerator

mechanism <4D5>.

Its service procedure is the same as for previous models with 6G7 or 4M4 engine.

EMISSION CONTROL SYSTEM <4D5-STEP

III>

GENERAL

OUTLINE OF CHANGES

Some service procedures have been established as the following changes have been made due to the

compliance with the Emission Regulation Step III.

DAn electronic-controlled EGR valve and EGR cooler have been used.

DA catalytic converter has been added.

GENERAL INFORMATION

The electronically-controlled EGR system reduces

the level of exhaust gases (NO

x).

ItemsNameSpecification

Exhaust emission

control systemExhaust gas recirculation system

DEGR valve

DEGR solenoid valve No.1

DEGR solenoid valve No.2

DEGR valve position sensorElectronically-controlled EGR system

Single type

ON-OFF solenoid valve

ON-OFF solenoid valve

Variable resistor type

SERVICE SPECIFICATIONS

ItemsStandard value

EGR solenoid valve Nos. 1 and 2 resistance (at 20_C)Ω36 - 44

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 885 of 1839

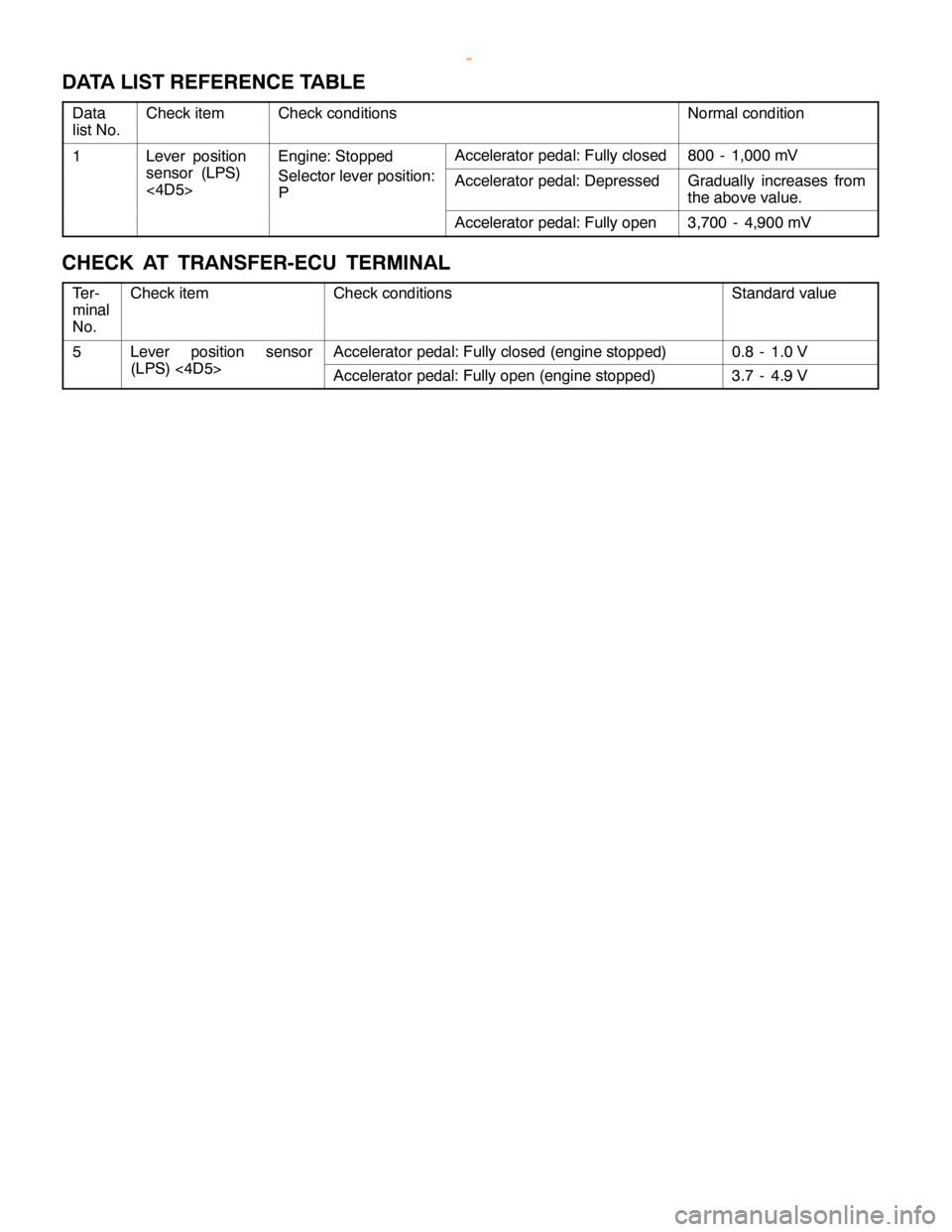

MANUAL TRANSMISSION -Troubleshooting

DATA LIST REFERENCE TABLE

Data

list No.Check itemCheck conditionsNormal condition

1Lever positionEngine: StoppedAccelerator pedal: Fully closed800 - 1,000 mV

sensor (LPS)

<4D5>Selector lever position:

PAccelerator pedal: DepressedGradually increases from

the above value.

Accelerator pedal: Fully open3,700 - 4,900 mV

CHECK AT TRANSFER-ECU TERMINAL

Ter-

minal

No.Check itemCheck conditionsStandard value

5Lever position sensorAccelerator pedal: Fully closed (engine stopped)0.8 - 1.0 V

(LPS) <4D5>Accelerator pedal: Fully open (engine stopped)3.7 - 4.9 V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 899 of 1839

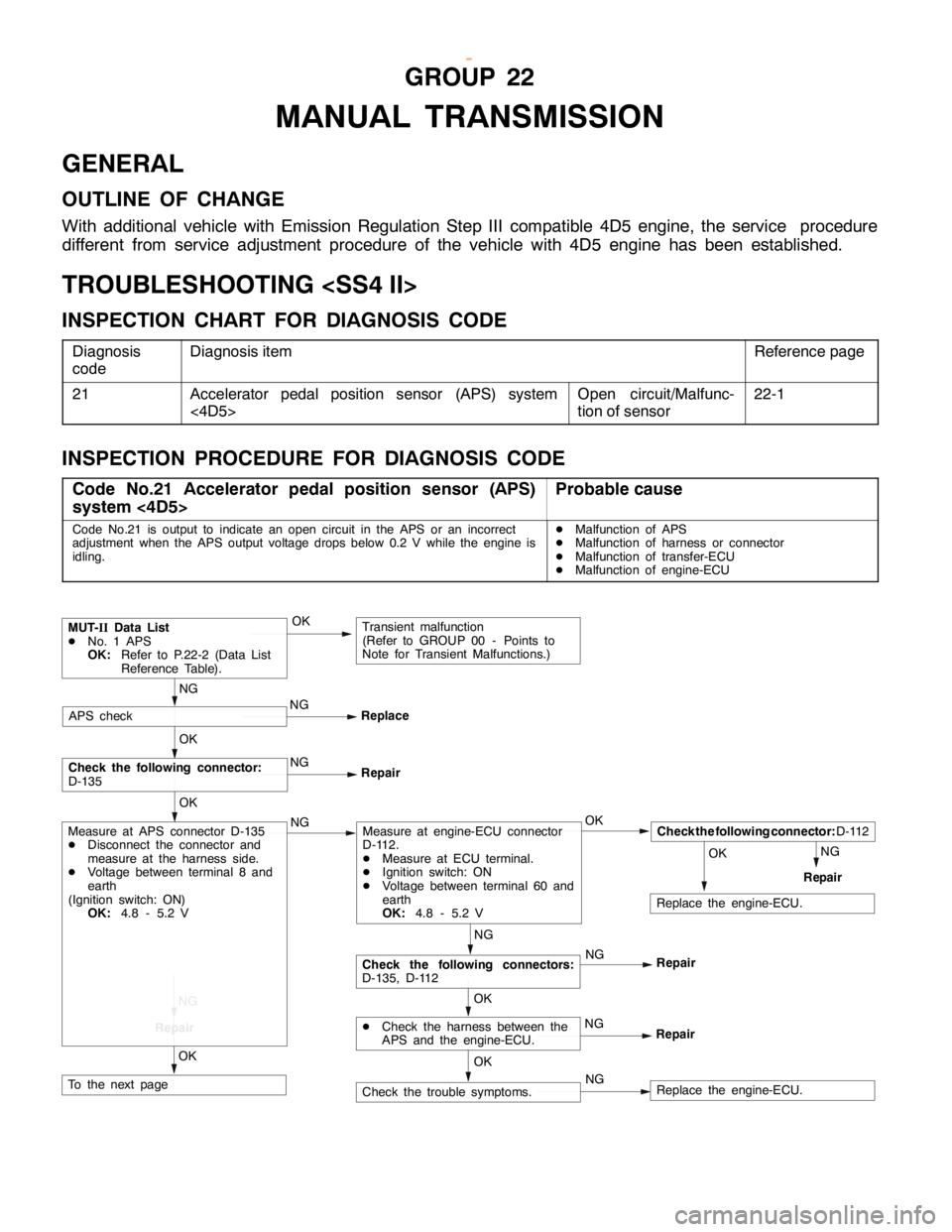

MANUAL TRANSMISSION -Gneral/Troubleshooting

GROUP 22

MANUAL TRANSMISSION

GENERAL

OUTLINE OF CHANGE

With additional vehicle with Emission Regulation Step III compatible 4D5 engine, the service procedure

different from service adjustment procedure of the vehicle with 4D5 engine has been established.

TROUBLESHOOTING

INSPECTION CHART FOR DIAGNOSIS CODE

Diagnosis

codeDiagnosis itemReference page

21Accelerator pedal position sensor (APS) system

<4D5>Open circuit/Malfunc-

tion of sensor22-1

INSPECTION PROCEDURE FOR DIAGNOSIS CODE

Code No.21 Accelerator pedal position sensor (APS)

system <4D5>Probable cause

Code No.21 is output to indicate an open circuit in the APS or an incorrect

adjustment when the APS output voltage drops below 0.2 V while the engine is

idling.DMalfunction of APS

DMalfunction of harness or connector

DMalfunction of transfer-ECU

DMalfunction of engine-ECU

NGNG

NG

Repair

MUT-IIData List

DNo. 1 APS

OK:Refer to P.22-2 (Data List

Reference Table).

NG

ReplaceAPS check

OK

NG

Repair

OK

Check the following connector:

D-135

OK

OK

Check the following connector:D-112

Repair

NG

Repair

NG

Repair

OK

DCheck the harness between the

APS and the engine-ECU.

OK

Check the following connectors:

D-135, D-112

Measure at engine-ECU connector

D-112.

DMeasure at ECU terminal.

DIgnition switch: ON

DVoltage between terminal 60 and

earth

OK:4.8 - 5.2 V

NGNG

NGCheck the trouble symptoms.Replace the engine-ECU.

OK

Measure at APS connector D-135

DDisconnect the connector and

measure at the harness side.

DVoltage between terminal 8 and

earth

(Ignition switch: ON)

OK:4.8 - 5.2 V

To the next page

Transient malfunction

(Refer to GROUP 00 - Points to

Note for Transient Malfunctions.)

OK

Replace the engine-ECU.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 900 of 1839

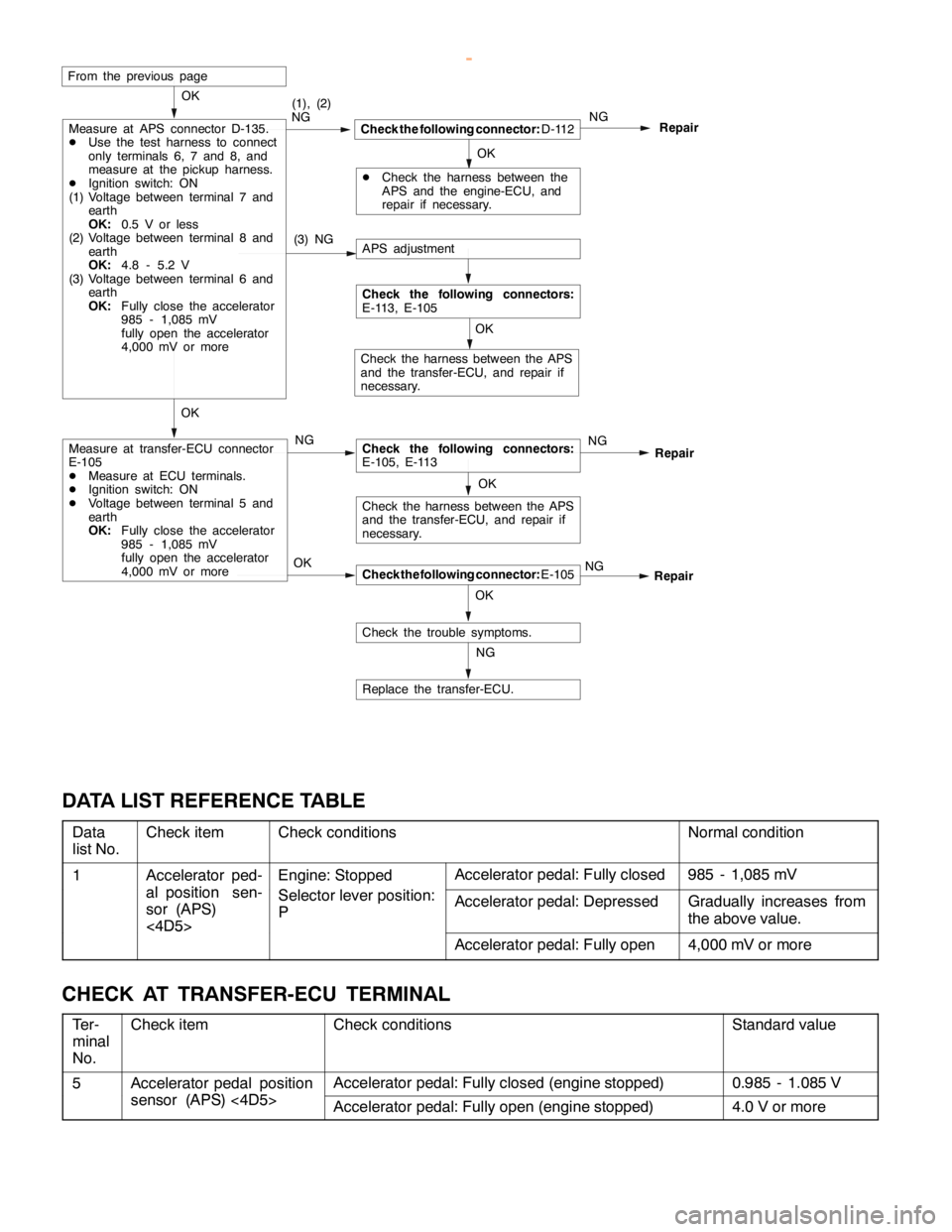

MANUAL TRANSMISSION -Troubleshooting

OKOK OK

NG

NG

NG(1), (2)

NG

Check the following connector:D-112Repair OK

DCheck the harness between the

APS and the engine-ECU, and

repair if necessary.OK

Measure at transfer-ECU connector

E-105

DMeasure at ECU terminals.

DIgnition switch: ON

DVoltage between terminal 5 and

earth

OK:Fully close the accelerator

985 - 1,085 mV

fully open the accelerator

4,000 mV or more

Check the following connector:E-105

Check the trouble symptoms.OK

Check the following connectors:

E-105, E-113 NG

Replace the transfer-ECU. OK

NGRepair

Check the harness between the APS

and the transfer-ECU, and repair if

necessary.

Check the harness between the APS

and the transfer-ECU, and repair if

necessary.

From the previous page

(3) NG

Measure at APS connector D-135.

DUse the test harness to connect

only terminals 6, 7 and 8, and

measure at the pickup harness.

DIgnition switch: ON

(1) Voltage between terminal 7 and

earth

OK:0.5 V or less

(2) Voltage between terminal 8 and

earth

OK:4.8 - 5.2 V

(3) Voltage between terminal 6 and

earth

OK:Fully close the accelerator

985 - 1,085 mV

fully open the accelerator

4,000 mV or more

APS adjustment

Check the following connectors:

E-113, E-105

Repair

DATA LIST REFERENCE TABLE

Data

list No.Check itemCheck conditionsNormal condition

1Accelerator ped-

alpositionsen

Engine: Stopped

Sllii

Accelerator pedal: Fully closed985 - 1,085 mV

al position sen-

sor (APS)

<4D5>Selector lever position:

PAccelerator pedal: DepressedGradually increases from

the above value.

<4D5>

Accelerator pedal: Fully open4,000 mV or more

CHECK AT TRANSFER-ECU TERMINAL

Ter-

minal

No.Check itemCheck conditionsStandard value

5Accelerator pedal position

(APS)4D5

Accelerator pedal: Fully closed (engine stopped)0.985 - 1.085 Vpp

sensor (APS) <4D5>Accelerator pedal: Fully open (engine stopped)4.0 V or more

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 906 of 1839

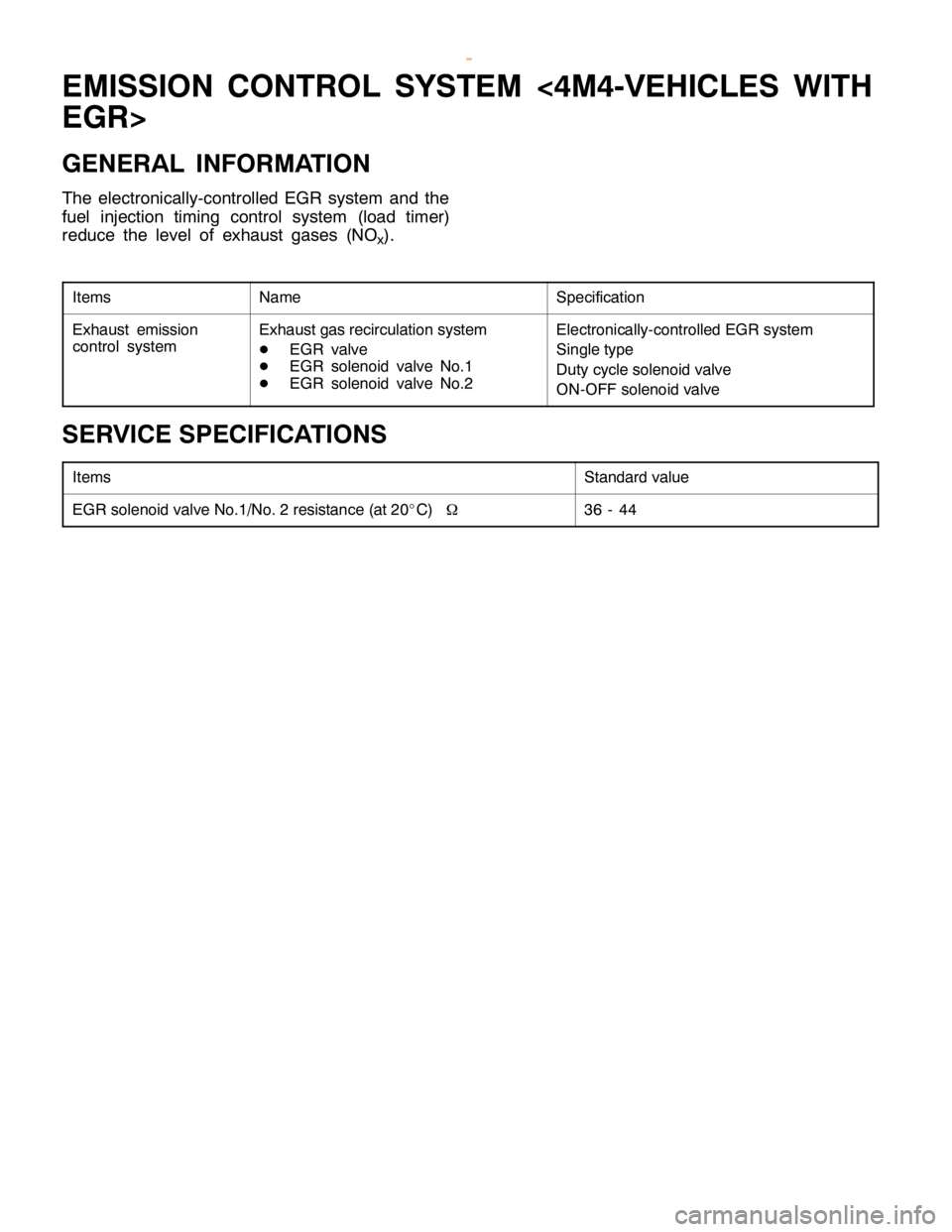

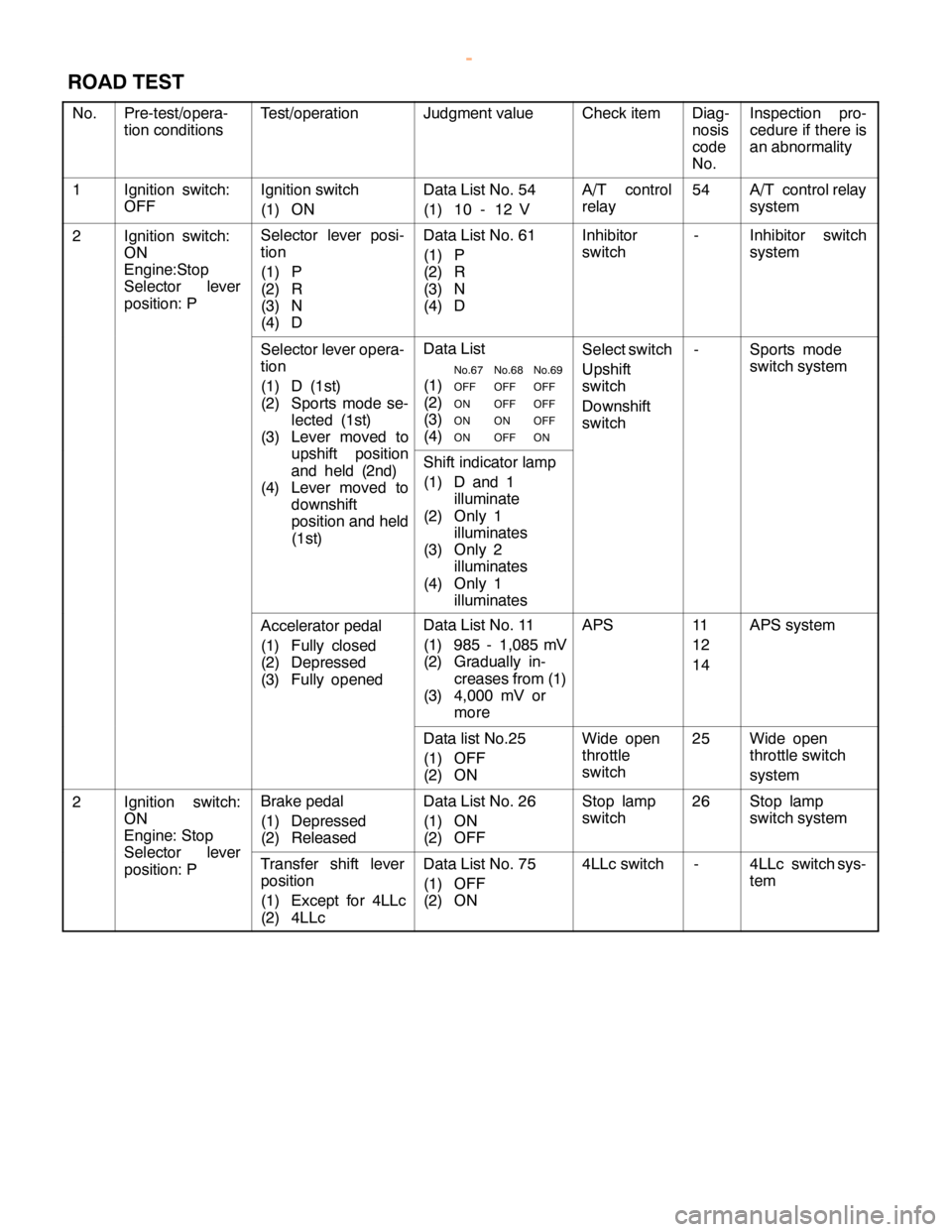

AUTOMATIC TRANSMISSION -Troubleshooting AUTOMATIC TRANSMISSION -Troubleshooting 23-5

ROAD TEST

No.Pre-test/opera-

tion conditionsTest/operationJudgment valueCheck itemDiag-

nosis

code

No.Inspection pro-

cedure if there is

an abnormality

1Ignition switch:

OFFIgnition switch

(1) ONData List No. 54

(1) 10 - 12 VA/T control

relay54A/T control relay

system

2Ignition switch:

ON

Engine:Stop

Selector lever

position: PSelector lever posi-

tion

(1) P

(2) R

(3) N

(4) DData List No. 61

(1) P

(2) R

(3) N

(4) DInhibitor

switch-Inhibitor switch

system

Selector lever opera-

tion

(1) D (1st)

(2) Sports mode se-

lected (1st)

(3) Lever moved toData List

No.67 No.68 No.69

(1)OFF OFF OFF

(2)ON OFF OFF

(3)ON ON OFF

(4)ON OFF ON

Select switch

Upshift

switch

Downshift

switch-Sports mode

switch system

upshift position

and held (2nd)

(4) Lever moved to

downshift

position and held

(1st)Shift indicator lamp

(1) D and 1

illuminate

(2) Only 1

illuminates

(3) Only 2

illuminates

(4) Only 1

illuminates

Accelerator pedal

(1) Fully closed

(2) Depressed

(3) Fully openedData List No. 11

(1) 985 - 1,085 mV

(2) Gradually in-

creases from (1)

(3) 4,000 mV or

moreAPS11

12

14APS system

Data list No.25

(1) OFF

(2) ONWide open

throttle

switch25Wide open

throttle switch

system

2Ignition switch:

ON

Engine: StopBrake pedal

(1) Depressed

(2) ReleasedData List No. 26

(1) ON

(2) OFFStop lamp

switch26Stop lamp

switch system

Selector lever

position: PTransfer shift lever

position

(1) Except for 4LLc

(2) 4LLcData List No. 75

(1) OFF

(2) ON4LLc switch-4LLc switch sys-

tem

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 907 of 1839