engine MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 700 of 1839

14-1

ENGINE COOLING

CONTENTS

GENERAL 2.................................

Outline of Changes 2...........................

WATER HOSE AND WATER PIPE <4D5> 3....

WATER HOSE AND WATER PIPE <4M4> 5...

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 701 of 1839

ENGINE COOLING -General14-2

GENERAL

OUTLINE OF CHANGES

Some service procedures have been established as the following changes have been made due to the

compliance with the Emission Regulation Step III.

DThe turbocharger has been changed to a Variable Geometry (VG) type. Due to this change, an

EGR cooler has been added and section ”Water hose and water pipe” has been changed. <4D5>

DThe section ”Water hose and water pipe” has been changed due to the addition of the EGR cooler.

<4M4>

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 719 of 1839

INTAKE AND EXHAUST -Intake and Exhaust Manifold,

Turbocharger <4D5>15-13

INSTALLATION SERVICE POINT

"

AA

TURBOCHARGER ASSEMBLY INSTALLATION

1. Check the internal surface, the eye bolt and the

mating surface of the oil pipe and water pipe for

clogging, and clean if necessary.

2. If deposits of carbon are accumulated on the

turbocharger oil passage, remove them and clean

using the compressed air.

Caution

Be careful not to allow foreign material to enter the

turbocharger.

3. Add clean engine oil through the oil feed pipe port

on the turbocharger.

INSPECTION

TURBOCHARGER ASSEMBLY CHECK

DVisually check the turbine wheel and the compressor

wheel for cracking or other damage.

DCheck whether the turbine wheel and the compressor

wheel can be easily turned by hand.

DCheck for oil leakage from the turbocharger assembly.

DCheck whether or not the waste gate valve remains open.

If any problem is found, replace the part after disassembly.

OIL PIPE AND OIL RETURN PIPE CHECK

Check the oil pipe and oil return pipe for clogging, bending,

or other damage. If there is clogging, clean it.

EXHAUST MANIFOLD CHECK

Damage or cracking of any part.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 721 of 1839

INTAKE AND EXHAUST -Turbocharger and Exhaust

Manifold <4M4>15-15

INSTALLATION SERVICE POINT

"

AA

TURBOCHARGER ASSEMBLY INSTALLATION

1. Check the internal surface, the eye bolt and the

mating surface of the oil pipe and water pipe for

clogging, and clean if necessary.

2. If deposits of carbon are accumulated on the

turbocharger oil passage, remove them and clean

using the compressed air.

Caution

Be careful not to allow foreign material to enter the

turbocharger.

3. Add clean engine oil through the oil feed pipe port

on the turbocharger.

INSPECTION

Check the following points; replace the part if a problem is

found.

EXHAUST MANIFOLD CHECK

1. Check for damage or cracking of any part.

2. Using a straight edge and a thickness gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

TURBOCHARGER ASSEMBLY CHECK

DVisually check the turbine wheel and the compressor

wheel for cracking or other damage.

DCheck whether the turbine wheel and the compressor

wheel can be easily turned by hand.

DCheck for oil leakage from the turbocharger assembly.

DCheck whether or not the waste gate valve remains open.

If any problem is found, replace the part after disassembly.

OIL PIPE AND OIL RETURN PIPE CHECK

Check the oil pipe and oil return pipe for clogging, bending,

or other damage. If there is clogging, clean it.

EXHAUST MANIFOLD CHECK

Damage or cracking of any part.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 735 of 1839

INTAKE AND EXHAUST -General Information/Service Specifications/Sealant15-3

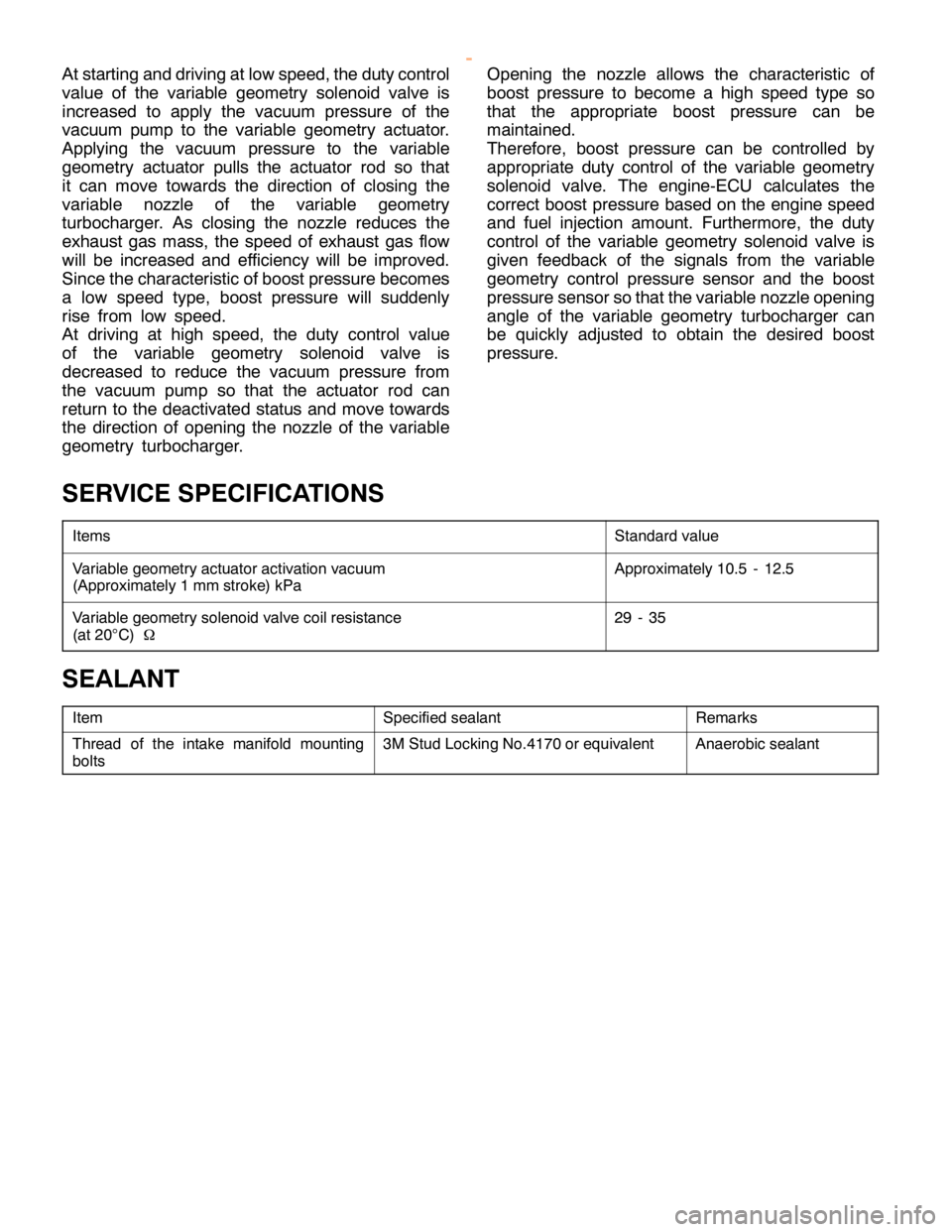

At starting and driving at low speed, the duty control

value of the variable geometry solenoid valve is

increased to apply the vacuum pressure of the

vacuum pump to the variable geometry actuator.

Applying the vacuum pressure to the variable

geometry actuator pulls the actuator rod so that

it can move towards the direction of closing the

variable nozzle of the variable geometry

turbocharger. As closing the nozzle reduces the

exhaust gas mass, the speed of exhaust gas flow

will be increased and efficiency will be improved.

Since the characteristic of boost pressure becomes

a low speed type, boost pressure will suddenly

rise from low speed.

At driving at high speed, the duty control value

of the variable geometry solenoid valve is

decreased to reduce the vacuum pressure from

the vacuum pump so that the actuator rod can

return to the deactivated status and move towards

the direction of opening the nozzle of the variable

geometry turbocharger.Opening the nozzle allows the characteristic of

boost pressure to become a high speed type so

that the appropriate boost pressure can be

maintained.

Therefore, boost pressure can be controlled by

appropriate duty control of the variable geometry

solenoid valve. The engine-ECU calculates the

correct boost pressure based on the engine speed

and fuel injection amount. Furthermore, the duty

control of the variable geometry solenoid valve is

given feedback of the signals from the variable

geometry control pressure sensor and the boost

pressure sensor so that the variable nozzle opening

angle of the variable geometry turbocharger can

be quickly adjusted to obtain the desired boost

pressure.

SERVICE SPECIFICATIONS

ItemsStandard value

Variable geometry actuator activation vacuum

(Approximately 1 mm stroke) kPaApproximately 10.5 - 12.5

Variable geometry solenoid valve coil resistance

(at 20°C)Ω29 - 35

SEALANT

ItemSpecified sealantRemarks

Thread of the intake manifold mounting

bolts3M Stud Locking No.4170 or equivalentAnaerobic sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 745 of 1839

INTAKE AND EXHAUST -Turbocharger and Exhaust

Manifold <4M4>15-13

INSTALLATION SERVICE POINT

"AATURBOCHARGER ASSEMBLY INSTALLATION

1. Check the internal surface, the eye bolt and the

mating surface of the oil pipe and water pipe for

clogging, and clean if necessary.

2. If deposits of carbon are accumulated on the

turbocharger oil passage, remove them and clean

using the compressed air.

Caution

Be careful not to allow foreign material to enter the

turbocharger.

3. Add clean engine oil through the oil feed pipe port

on the turbocharger.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 748 of 1839

ENGINE ELECTRICAL

Click on the applicable bookmark to selected the required model year.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 749 of 1839

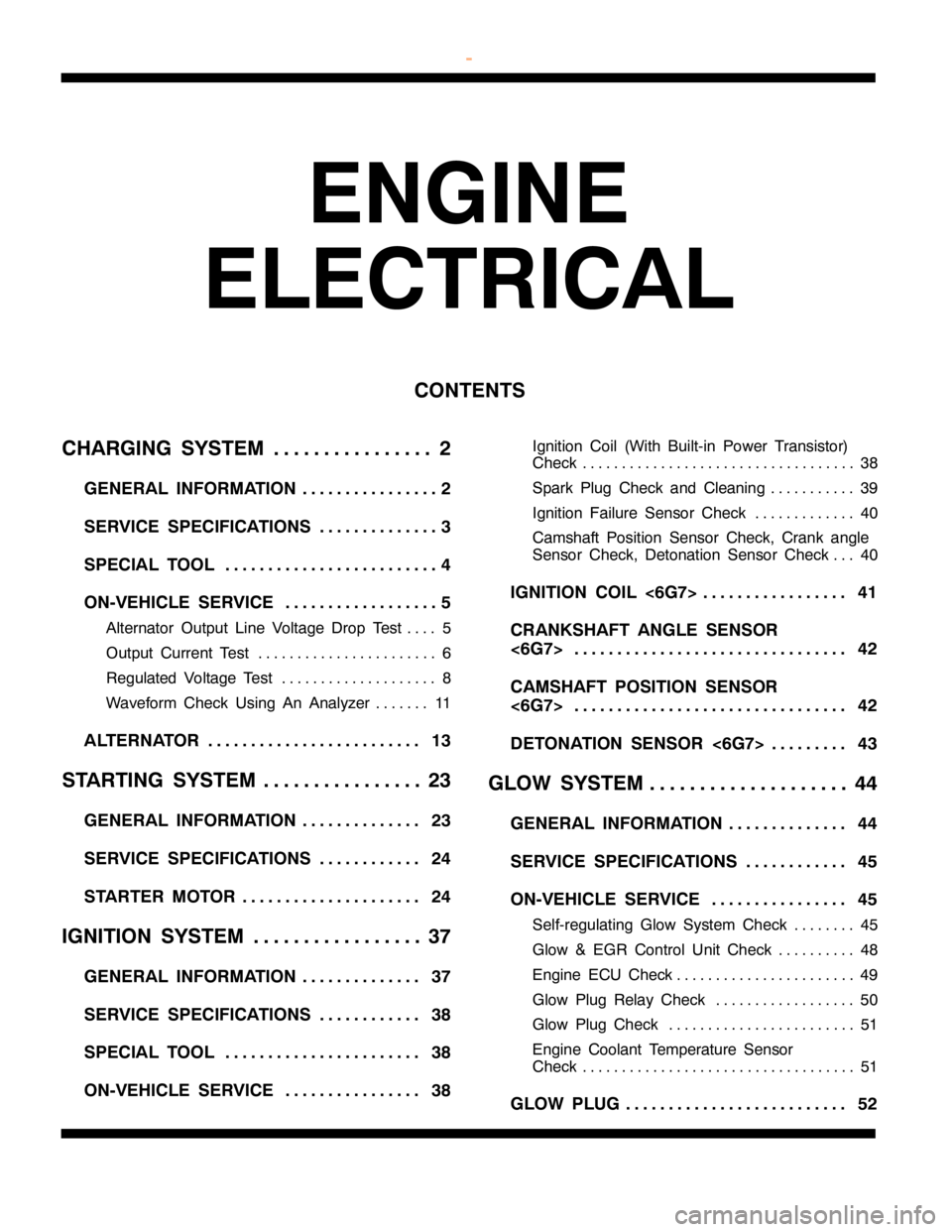

16-1

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM 2................

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 3..............

SPECIAL TOOL 4.........................

ON-VEHICLE SERVICE 5..................

Alternator Output Line Voltage Drop Test 5....

Output Current Test 6.......................

Regulated Voltage Test 8....................

Waveform Check Using An Analyzer 11.......

ALTERNATOR 13.........................

STARTING SYSTEM 23................

GENERAL INFORMATION 23..............

SERVICE SPECIFICATIONS 24............

STARTER MOTOR 24.....................

IGNITION SYSTEM 37.................

GENERAL INFORMATION 37..............

SERVICE SPECIFICATIONS 38............

SPECIAL TOOL 38.......................

ON-VEHICLE SERVICE 38................

Ignition Coil (With Built-in Power Transistor)

Check 38...................................

Spark Plug Check and Cleaning 39...........

Ignition Failure Sensor Check 40.............

Camshaft Position Sensor Check, Crank angle

Sensor Check, Detonation Sensor Check 40...

IGNITION COIL <6G7> 41.................

CRANKSHAFT ANGLE SENSOR

<6G7> 42................................

CAMSHAFT POSITION SENSOR

<6G7> 42................................

DETONATION SENSOR <6G7> 43.........

GLOW SYSTEM 44....................

GENERAL INFORMATION 44..............

SERVICE SPECIFICATIONS 45............

ON-VEHICLE SERVICE 45................

Self-regulating Glow System Check 45........

Glow & EGR Control Unit Check 48..........

Engine ECU Check 49.......................

Glow Plug Relay Check 50..................

Glow Plug Check 51........................

Engine Coolant Temperature Sensor

Check 51...................................

GLOW PLUG 52..........................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 758 of 1839

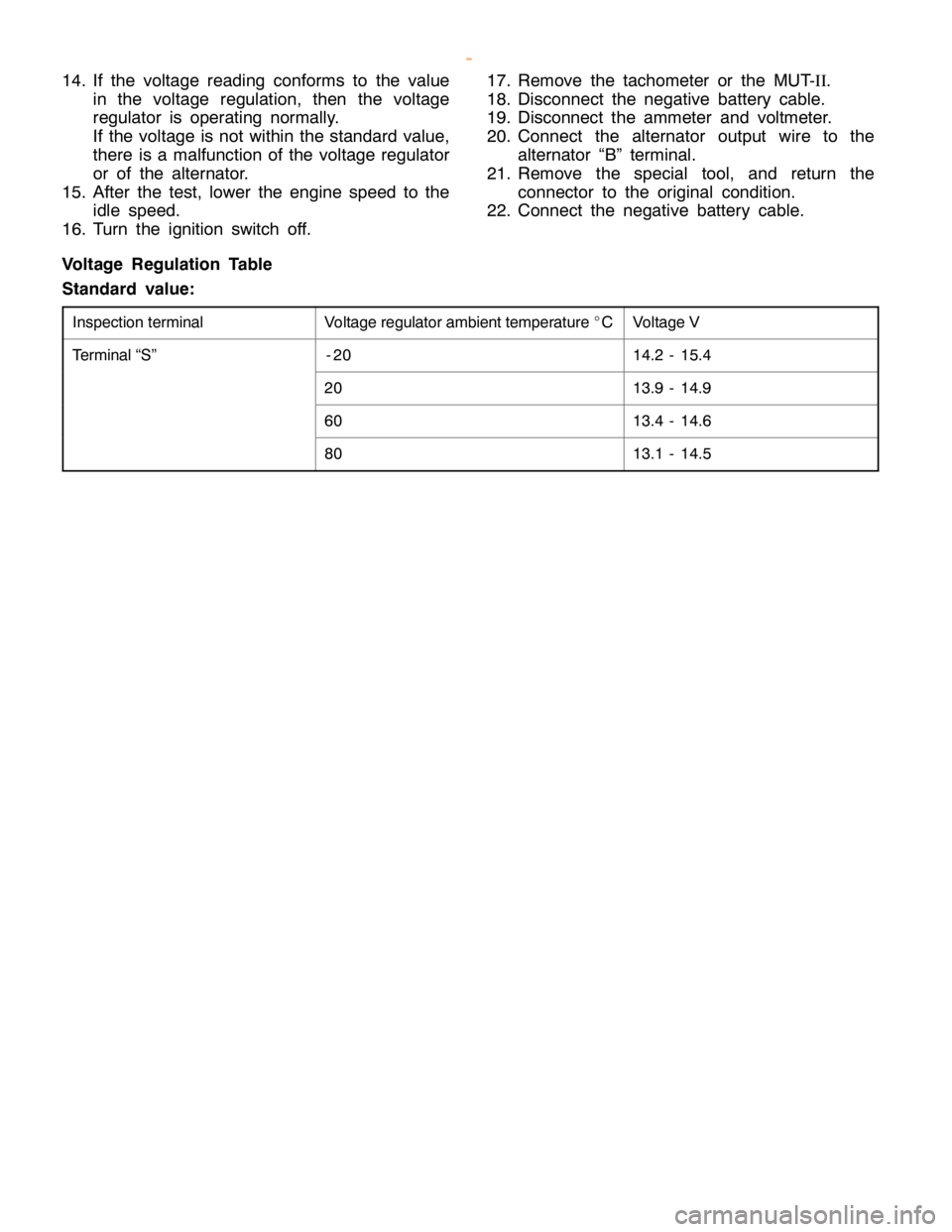

ENGINE ELECTRICAL -Charging System16-10

14. If the voltage reading conforms to the value

in the voltage regulation, then the voltage

regulator is operating normally.

If the voltage is not within the standard value,

there is a malfunction of the voltage regulator

or of the alternator.

15. After the test, lower the engine speed to the

idle speed.

16. Turn the ignition switch off.17. Remove the tachometer or the MUT-II.

18. Disconnect the negative battery cable.

19. Disconnect the ammeter and voltmeter.

20. Connect the alternator output wire to the

alternator “B” terminal.

21. Remove the special tool, and return the

connector to the original condition.

22. Connect the negative battery cable.

Voltage Regulation Table

Standard value:

Inspection terminalVoltage regulator ambient temperature_

CVoltage V

Terminal “S”-2014.2 - 15.4

2013.9 - 14.9

6013.4 - 14.6

8013.1 - 14.5

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 787 of 1839

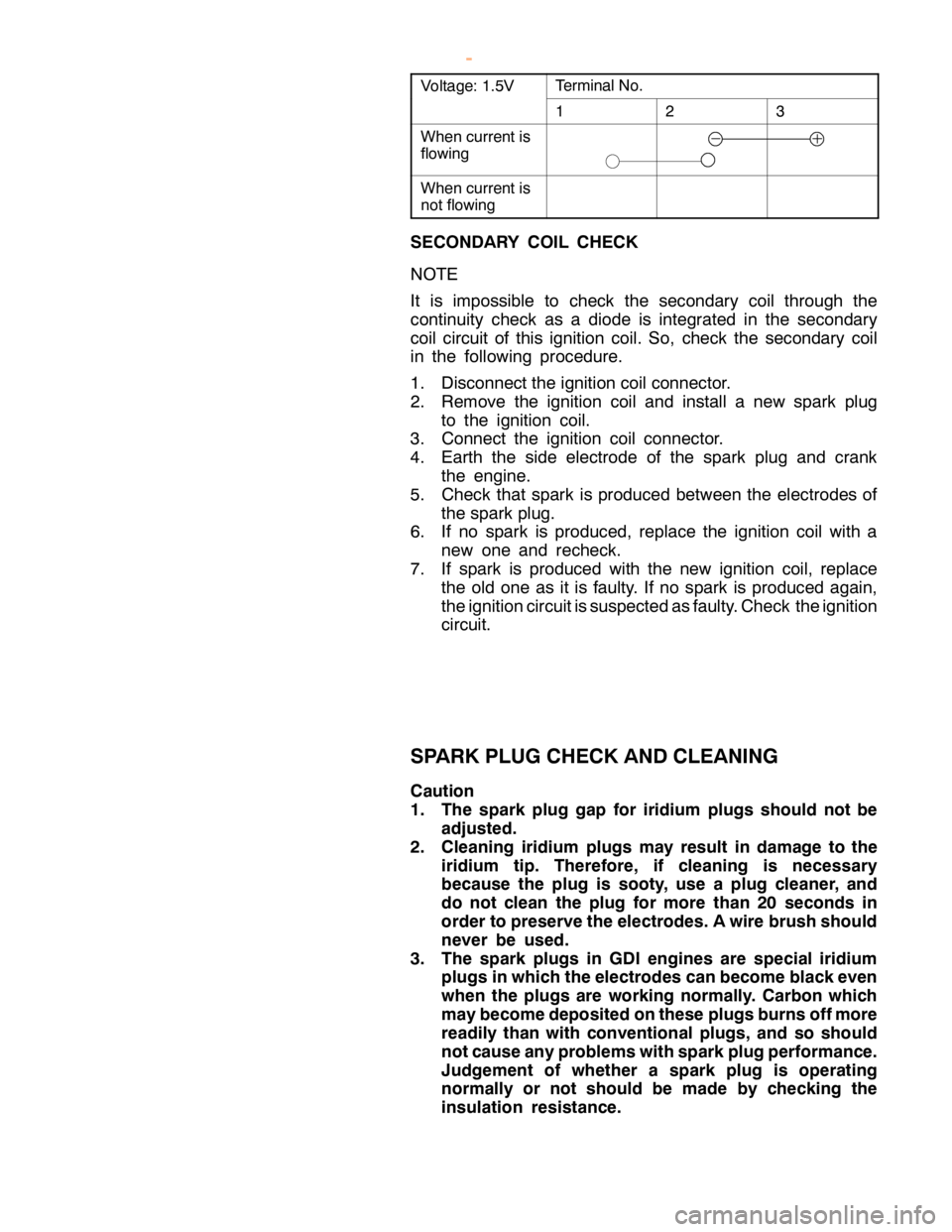

ENGINE ELECTRICAL -Ignition System16-39

Voltage: 1.5VTerminal No.

123

When current is

flowing

When current is

not flowing

SECONDARY COIL CHECK

NOTE

It is impossible to check the secondary coil through the

continuity check as a diode is integrated in the secondary

coil circuit of this ignition coil. So, check the secondary coil

in the following procedure.

1. Disconnect the ignition coil connector.

2. Remove the ignition coil and install a new spark plug

to the ignition coil.

3. Connect the ignition coil connector.

4. Earth the side electrode of the spark plug and crank

the engine.

5. Check that spark is produced between the electrodes of

the spark plug.

6. If no spark is produced, replace the ignition coil with a

new one and recheck.

7. If spark is produced with the new ignition coil, replace

the old one as it is faulty. If no spark is produced again,

the ignition circuit is suspected as faulty. Check the ignition

circuit.

SPARK PLUG CHECK AND CLEANING

Caution

1. The spark plug gap for iridium plugs should not be

adjusted.

2. Cleaning iridium plugs may result in damage to the

iridium tip. Therefore, if cleaning is necessary

because the plug is sooty, use a plug cleaner, and

do not clean the plug for more than 20 seconds in

order to preserve the electrodes. A wire brush should

never be used.

3. The spark plugs in GDI engines are special iridium

plugs in which the electrodes can become black even

when the plugs are working normally. Carbon which

may become deposited on these plugs burns off more

readily than with conventional plugs, and so should

not cause any problems with spark plug performance.

Judgement of whether a spark plug is operating

normally or not should be made by checking the

insulation resistance.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk