ignition MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 1735 of 1839

SWS -Troubleshooting54B-49

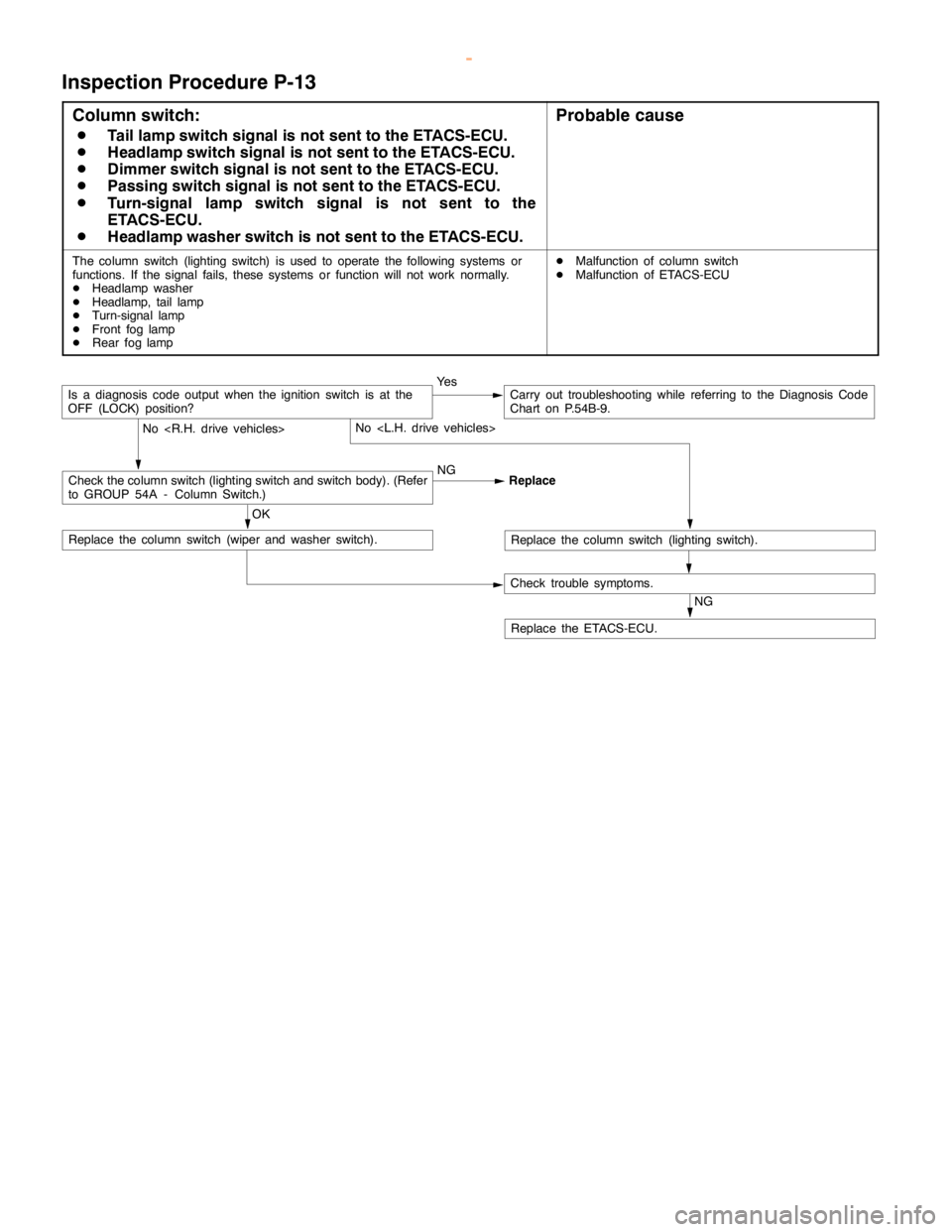

Inspection Procedure P-13

Column switch:

D

Tail lamp switch signal is not sent to the ETACS-ECU.

D

Headlamp switch signal is not sent to the ETACS-ECU.

D

Dimmer switch signal is not sent to the ETACS-ECU.

D

Passing switch signal is not sent to the ETACS-ECU.

D

Turn-signal lamp switch signal is not sent to the

ETACS-ECU.

D

Headlamp washer switch is not sent to the ETACS-ECU.

Probable cause

The column switch (lighting switch) is used to operate the following systems or

functions. If the signal fails, these systems or function will not work normally.

DHeadlamp washer

DHeadlamp, tail lamp

DTurn-signal lamp

DFront fog lamp

DRear foglampDMalfunction of column switch

DMalfunction of ETACS-ECU

NG

Replace the ETACS-ECU.

Ye sCarry out troubleshooting while referring to the Diagnosis Code

Chart on P.54B-9.

Check trouble symptoms.

No

Replace the column switch (lighting switch).

OK

Replace the column switch (wiper and washer switch).

No

Check the column switch (lighting switch and switch body). (Refer

to GROUP 54A - Column Switch.)NG

Replace

Is a diagnosis code output when the ignition switch is at the

OFF (LOCK) position?

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1736 of 1839

SWS -Troubleshooting54B-50

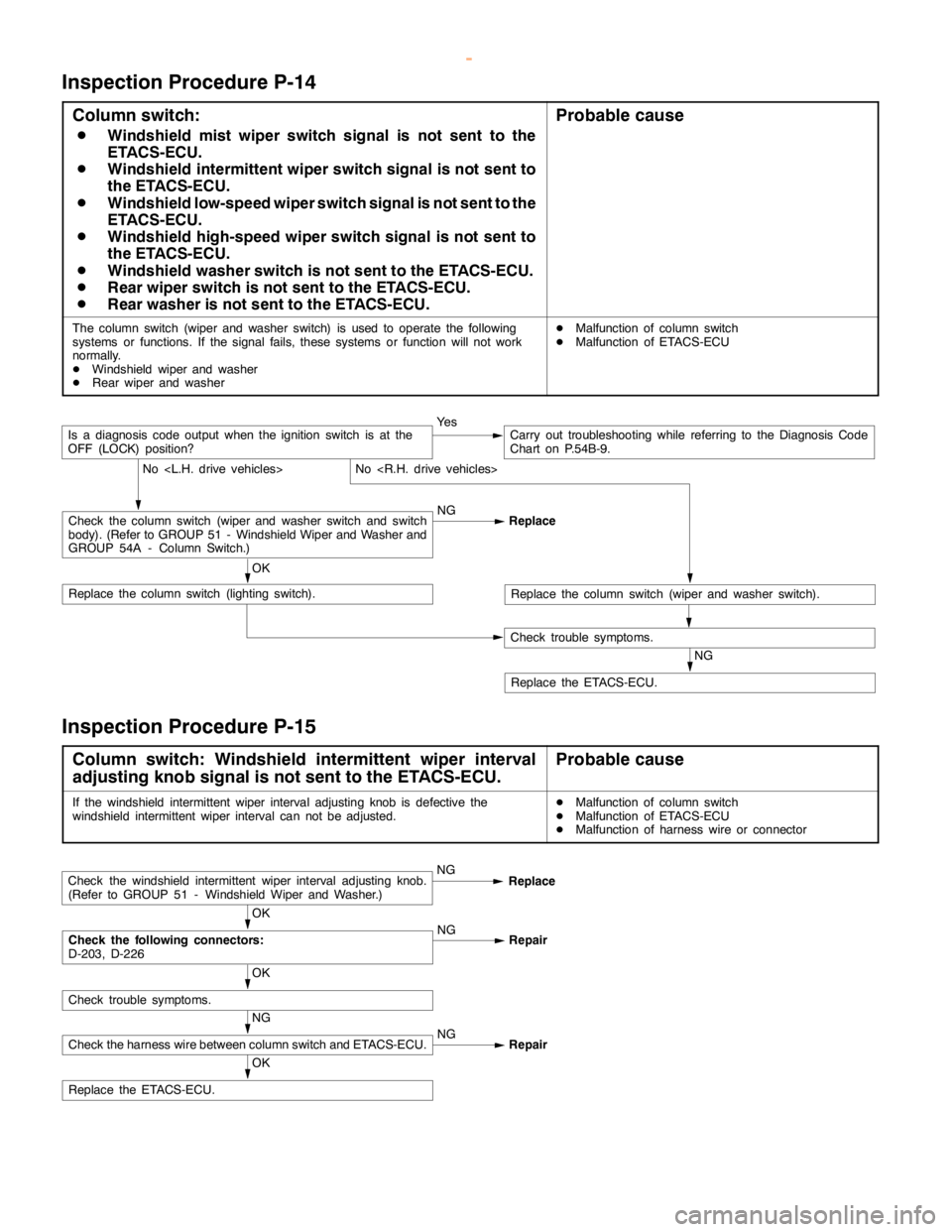

Inspection Procedure P-14

Column switch:

D

Windshield mist wiper switch signal is not sent to the

ETACS-ECU.

D

Windshield intermittent wiper switch signal is not sent to

the ETACS-ECU.

D

Windshield low-speed wiper switch signal is not sent to the

ETACS-ECU.

D

Windshield high-speed wiper switch signal is not sent to

the ETACS-ECU.

D

Windshield washer switch is not sent to the ETACS-ECU.

D

Rear wiper switch is not sent to the ETACS-ECU.

D

Rear washer is not sent to the ETACS-ECU.

Probable cause

The column switch (wiper and washer switch) is used to operate the following

systems or functions. If the signal fails, these systems or function will not work

normally.

DWindshield wiper and washer

DRear wiper and washerDMalfunction of column switch

DMalfunction of ETACS-ECU

NG

Replace the ETACS-ECU.

Ye sCarry out troubleshooting while referring to the Diagnosis Code

Chart on P.54B-9.

Check trouble symptoms.

No

Replace the column switch (wiper and washer switch).

OK

Replace the column switch (lighting switch).

No

Check the column switch (wiper and washer switch and switch

body). (Refer to GROUP 51 - Windshield Wiper and Washer and

GROUP 54A - Column Switch.)NG

Replace

Is a diagnosis code output when the ignition switch is at the

OFF (LOCK) position?

Inspection Procedure P-15

Column switch: Windshield intermittent wiper interval

adjusting knob signal is not sent to the ETACS-ECU.Probable cause

If the windshield intermittent wiper interval adjusting knob is defective the

windshield intermittent wiper interval can not be adjusted.DMalfunction of column switch

DMalfunction of ETACS-ECU

DMalfunction of harness wire or connector

OK

Replace the ETACS-ECU.

NG

Check the harness wire between column switch and ETACS-ECU.NG

Repair

OK

Check trouble symptoms.

OK

Check the following connectors:

D-203, D-226NG

Repair

Check the windshield intermittent wiper interval adjusting knob.

(Refer to GROUP 51 - Windshield Wiper and Washer.)NG

Replace

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1737 of 1839

SWS -Troubleshooting54B-51

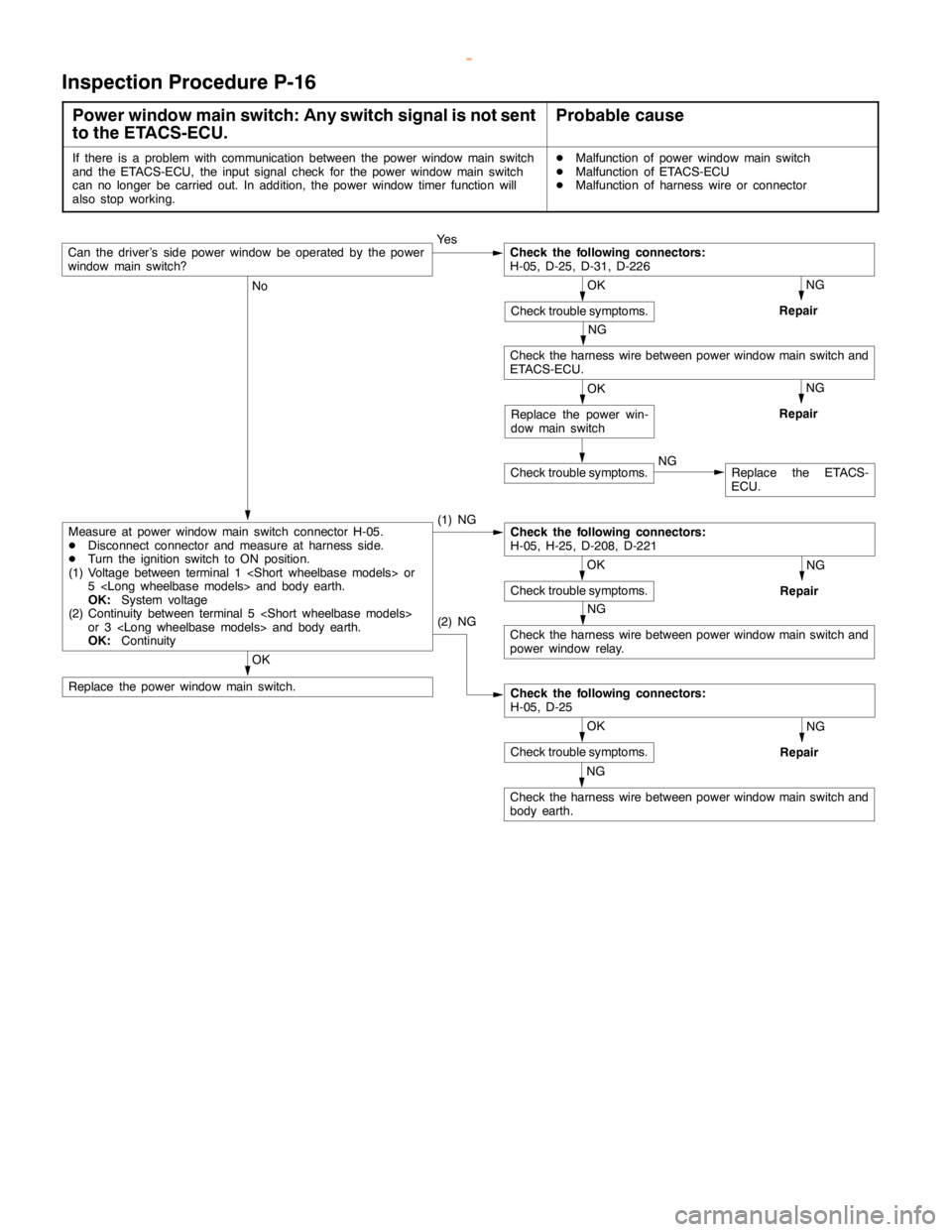

Inspection Procedure P-16

Power window main switch: Any switch signal is not sent

to the ETACS-ECU.Probable cause

If there is a problem with communication between the power windowmainswitch

and the ETACS-ECU, the input signal check for the power windowmainswitch

can no longer be carried out. In addition, the power window timer function will

also stop working.DMalfunction of power windowmainswitch

DMalfunction of ETACS-ECU

DMalfunction of harness wire or connector

Ye s

NG

Repair

NG

No

(1) NG

NG

Repair

NG

Check the harness wire between power windowmainswitch and

power window relay.

OK

Replace the power windowmainswitch.

NG

Repair

NG

Check the harness wire between power windowmainswitch and

body earth.

NG

Repair

Check trouble symptoms.NGReplace the ETACS-

ECU.

OK

Check trouble symptoms.

(2) NG

Check the following connectors:

H-05, D-25

OK

Check trouble symptoms.

Check the following connectors:

H-05, H-25, D-208, D-221Measure at power windowmainswitch connector H-05.

DDisconnect connector and measure at harness side.

DTurn the ignition switch to ON position.

(1) Voltage between terminal 1

5

OK:System voltage

(2) Continuity between terminal 5

or 3

OK:Continuity

OK

Replace the power win-

dow mainswitch

Check the harness wire between power windowmainswitch and

ETACS-ECU.

OK

Check trouble symptoms.

Check the following connectors:

H-05, D-25, D-31, D-226Can the driver’s side power window be operated by the power

window mainswitch?

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1739 of 1839

SWS -Troubleshooting54B-53

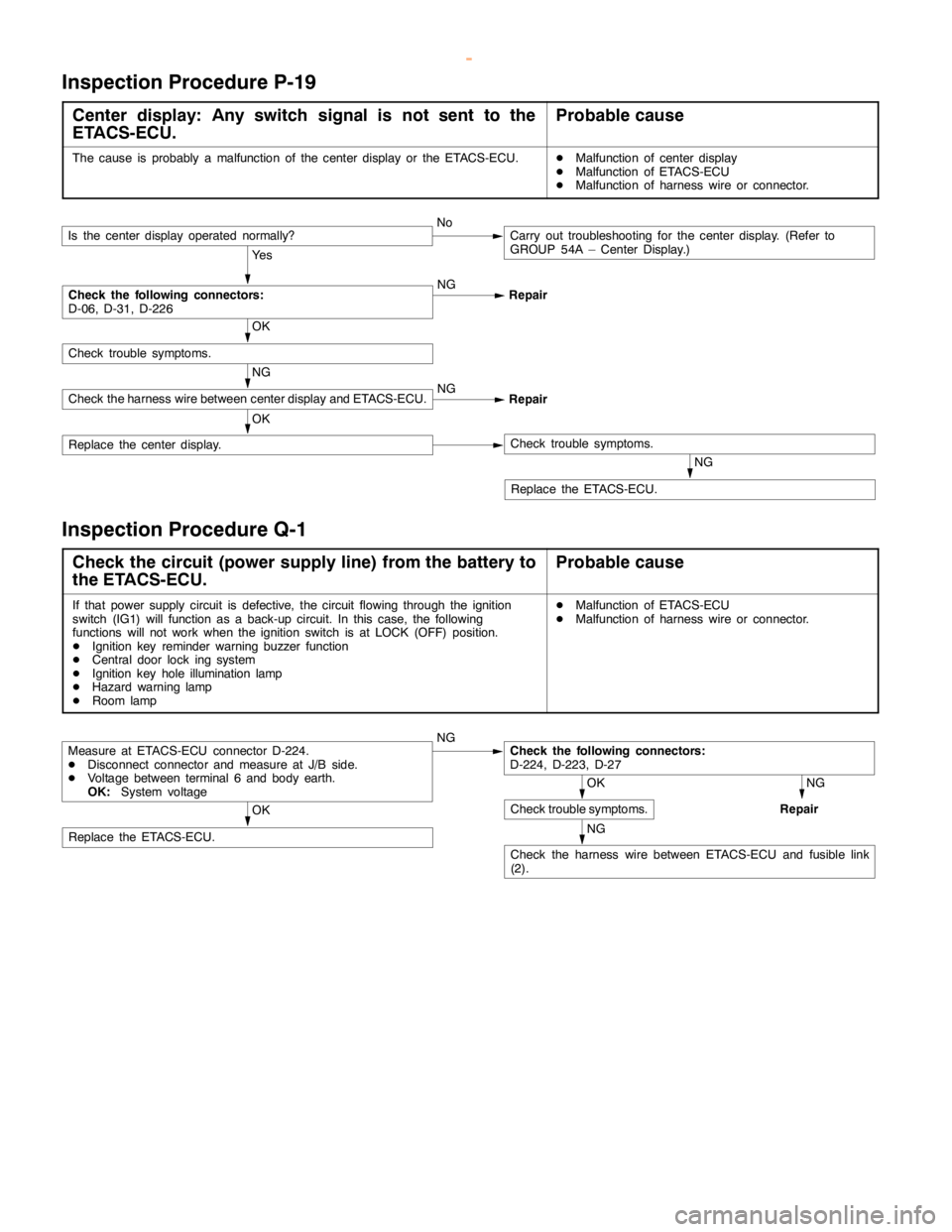

Inspection Procedure P-19

Center display: Any switch signal is not sent to the

ETACS-ECU.Probable cause

The cause is probably a malfunction of the center display or the ETACS-ECU.DMalfunction of center display

DMalfunction of ETACS-ECU

DMalfunction of harness wire or connector.

Ye s

NG

Repair

NG

Replace the ETACS-ECU.

OK

Replace the center display.Check trouble symptoms.

NG

Check the harness wire between center display and ETACS-ECU.NG

Repair

OK

Check trouble symptoms.

Check the following connectors:

D-06, D-31, D-226

Is the center display operated normally?NoCarry out troubleshooting for the center display. (Refer to

GROUP 54A – Center Display.)

Inspection Procedure Q-1

Check the circuit (power supply line) from the battery to

the ETACS-ECU.Probable cause

If that power supply circuit is defective, the circuit flowing through the ignition

switch (IG1) will function as a back-up circuit. In this case, the following

functions will not work when the ignition switch is at LOCK (OFF) position.

DIgnition key reminder warning buzzer function

DCentral door lock ing system

DIgnition key hole illumination lamp

DHazard warninglamp

DRoom lampDMalfunction of ETACS-ECU

DMalfunction of harness wire or connector.

NG

NG

Repair

NG

Check the harness wire between ETACS-ECU and fusible link

(2).

OK

Replace the ETACS-ECU.

OK

Check trouble symptoms.

Check the following connectors:

D-224, D-223, D-27Measure at ETACS-ECU connector D-224.

DDisconnect connector and measure at J/B side.

DVoltage between terminal 6 and body earth.

OK:System voltage

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1741 of 1839

SWS -Troubleshooting54B-55

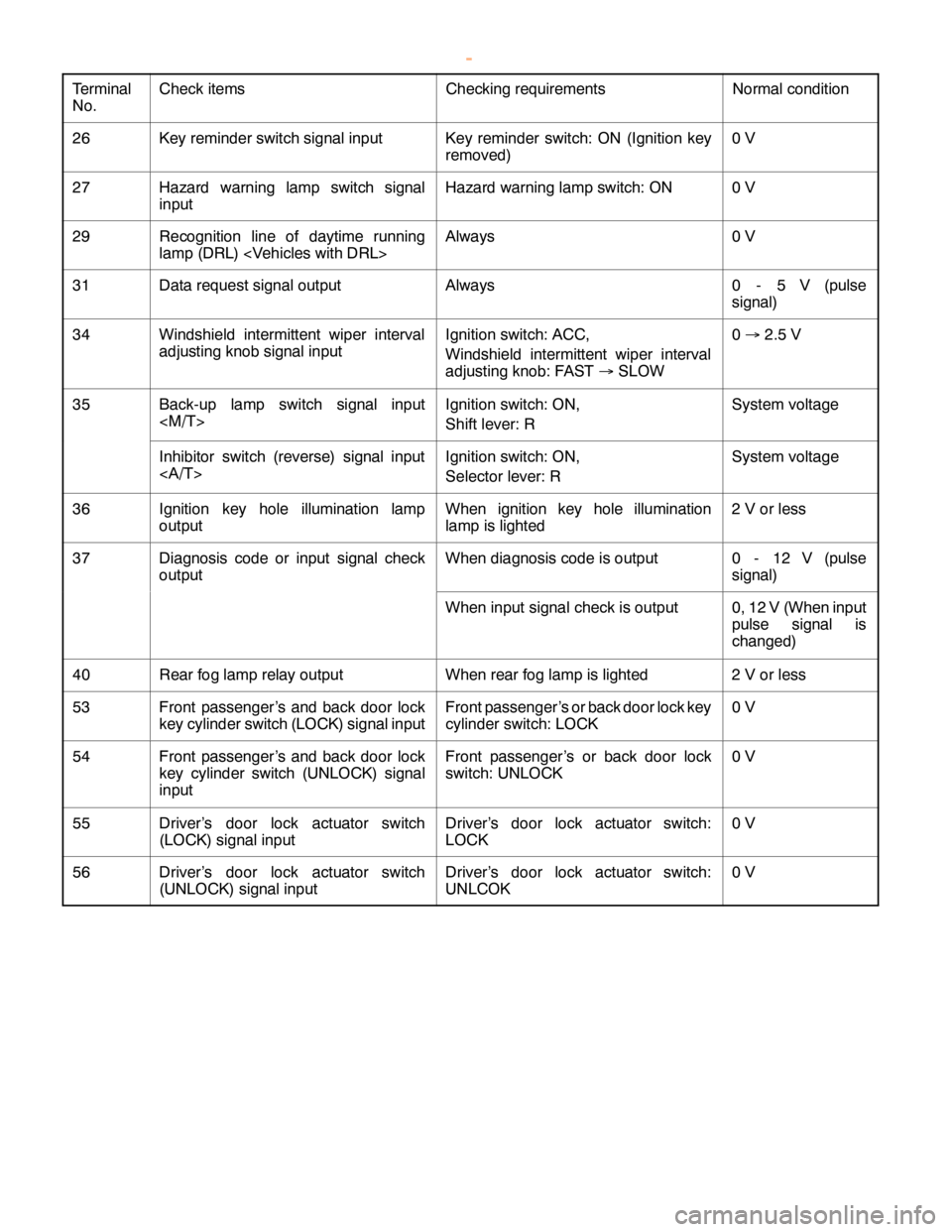

Terminal

No.Normal condition Checking requirements Check items

26Key reminder switch signal inputKey reminder switch: ON (Ignition key

removed)0V

27Hazard warning lamp switch signal

inputHazard warning lamp switch: ON0V

29Recognition line of daytime running

lamp (DRL)

31Data request signal outputAlways0 - 5 V (pulse

signal)

34Windshield intermittent wiper interval

adjusting knob signal inputIgnition switch: ACC,

Windshield intermittent wiper interval

adjusting knob: FAST®SLOW0®2.5 V

35Back-up lamp switch signal input

Shift lever: RSystem voltage

Inhibitor switch (reverse) signal input

Ignition switch: ON,

Selector lever: RSystem voltage

36Ignition key hole illumination lamp

outputWhen ignition key hole illumination

lamp is lighted2 V or less

37Diagnosis code or input signal check

outputWhen diagnosis code is output0 - 12 V (pulse

signal)

When input signal check is output0, 12 V (When input

pulse signal is

changed)

40Rear fog lamp relay outputWhen rear fog lamp is lighted2 V or less

53Front passenger’s and back door lock

key cylinder switch (LOCK) signal inputFront passenger’s or back door lock key

cylinder switch: LOCK0V

54Front passenger’s and back door lock

key cylinder switch (UNLOCK) signal

inputFront passenger’s or back door lock

switch: UNLOCK0V

55Driver’s door lock actuator switch

(LOCK) signal inputDriver’s door lock actuator switch:

LOCK0V

56Driver’s door lock actuator switch

(UNLOCK) signal inputDriver’s door lock actuator switch:

UNLCOK0V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1746 of 1839

SWS -On-vehicle Service54B-60

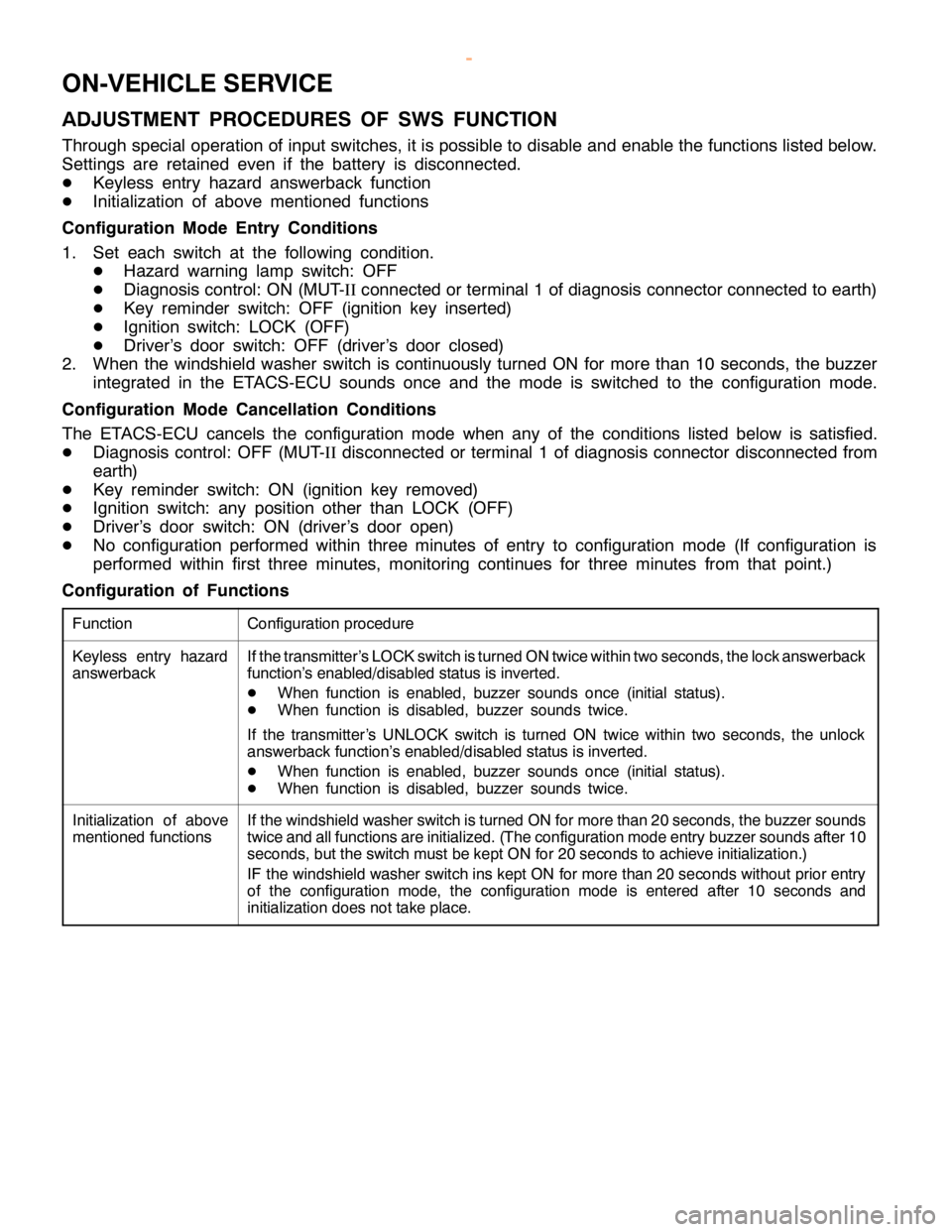

ON-VEHICLE SERVICE

ADJUSTMENT PROCEDURES OF SWS FUNCTION

Through special operation of input switches, it is possible to disable and enable the functions listed below.

Settings are retained even if the battery is disconnected.

DKeyless entry hazard answerback function

DInitialization of above mentioned functions

Configuration Mode Entry Conditions

1. Set each switch at the following condition.

DHazard warning lamp switch: OFF

DDiagnosis control: ON (MUT-II

connected or terminal 1 of diagnosis connector connected to earth)

DKey reminder switch: OFF (ignition key inserted)

DIgnition switch: LOCK (OFF)

DDriver’s door switch: OFF (driver’s door closed)

2. When the windshield washer switch is continuously turned ON for more than 10 seconds, the buzzer

integrated in the ETACS-ECU sounds once and the mode is switched to the configuration mode.

Configuration Mode Cancellation Conditions

The ETACS-ECU cancels the configuration mode when any of the conditions listed below is satisfied.

DDiagnosis control: OFF (MUT-II

disconnected or terminal 1 of diagnosis connector disconnected from

earth)

DKey reminder switch: ON (ignition key removed)

DIgnition switch: any position other than LOCK (OFF)

DDriver’s door switch: ON (driver’s door open)

DNo configuration performed within three minutes of entry to configuration mode (If configuration is

performed within first three minutes, monitoring continues for three minutes from that point.)

Configuration of Functions

FunctionConfiguration procedure

Keyless entry hazard

answerbackIf the transmitter’s LOCK switch is turned ON twice within two seconds, the lock answerback

function’s enabled/disabled status is inverted.

D

When function is enabled, buzzer sounds once (initial status).

D

When function is disabled, buzzer sounds twice.

If the transmitter’s UNLOCK switch is turned ON twice within two seconds, the unlock

answerback function’s enabled/disabled status is inverted.

D

When function is enabled, buzzer sounds once (initial status).

D

When function is disabled, buzzer sounds twice.

Initialization of above

mentioned functionsIf the windshield washer switch is turned ON for more than 20 seconds, the buzzer sounds

twice and all functions are initialized. (The configuration mode entry buzzer sounds after 10

seconds, but the switch must be kept ON for 20 seconds to achieve initialization.)

IF the windshield washer switch ins kept ON for more than 20 seconds without prior entry

of the configuration mode, the configuration mode is entered after 10 seconds and

initialization does not take place.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1809 of 1839

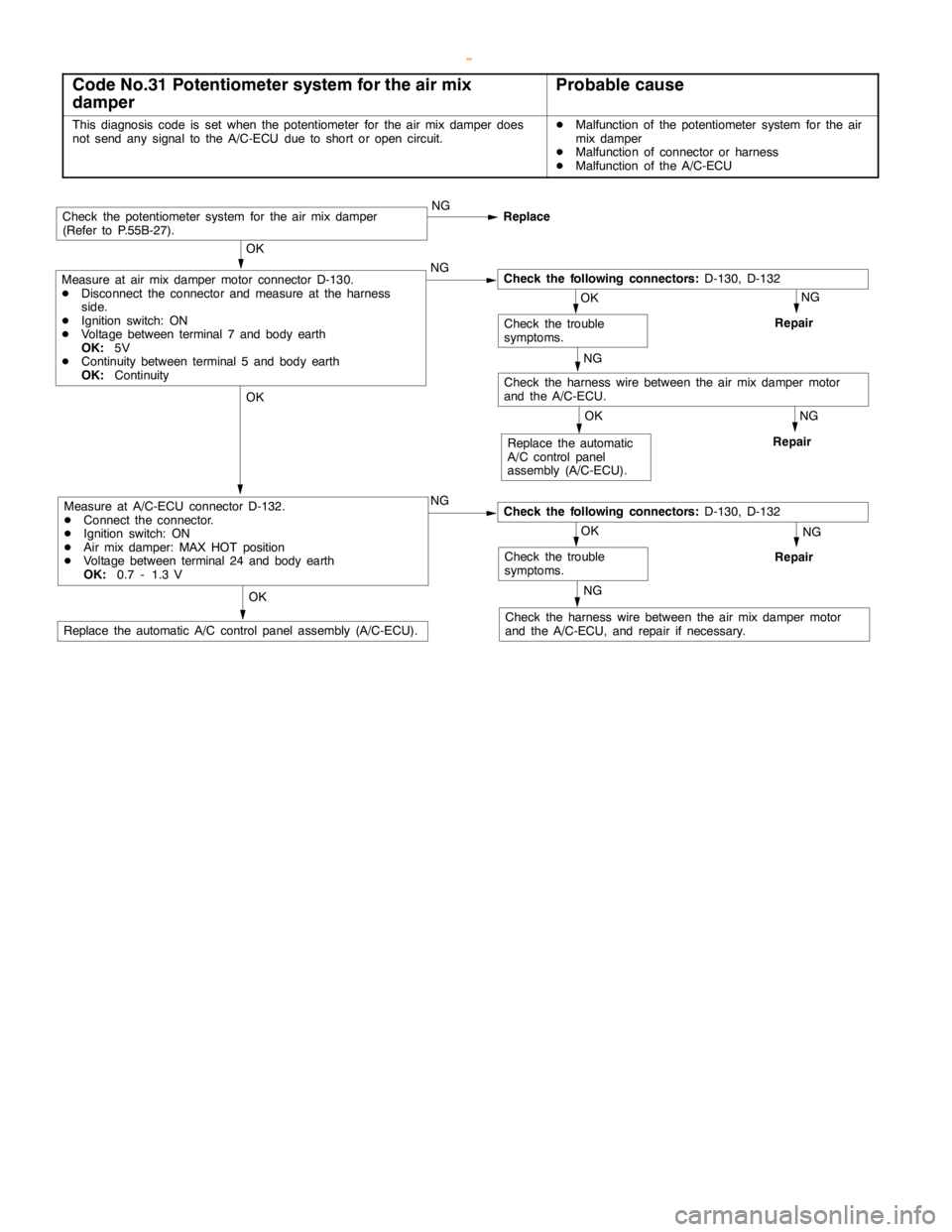

HEATER, AIR CONDITIONER AND VENTILATION -Troubleshooting

Code No.31 Potentiometer system for the air mix

damperProbable cause

This diagnosis code is set when the potentiometer for the air mix damper does

not send any signal to the A/C-ECU due to short oropencircuit.DMalfunction of the potentiometer system for the air

mix damper

DMalfunction of connector or harness

DMalfunction of the A/C-ECU

NG

Repair

NG

Repair

NG

Check the harness wire between the air mix damper motor

and the A/C-ECU, and repair if necessary.

OK

Replace the automatic A/C control panelassembly (A/C-ECU).

NG

Repair

OK

Replace the automatic

A/C control panel

assembly (A/C-ECU).

OK

Check the trouble

symptoms.

OK

Measure at A/C-ECU connector D-132.

DConnect the connector.

DIgnition switch: ON

DAir mix damper: MAX HOT position

DVoltage between terminal 24 and body earth

OK:0.7 - 1.3 VNGCheck the following connectors:D-130, D-132

NG

Check the harness wire between the air mix damper motor

and the A/C-ECU.

OK

Check the trouble

symptoms.

OK

Measure at air mix damper motor connector D-130.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DVoltage between terminal 7 and body earth

OK:5V

DContinuity between terminal 5 and body earth

OK:ContinuityNGCheck the following connectors:D-130, D-132

Check the potentiometer system for the air mix damper

(Refer to P.55B-27).NG

Replace

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1810 of 1839

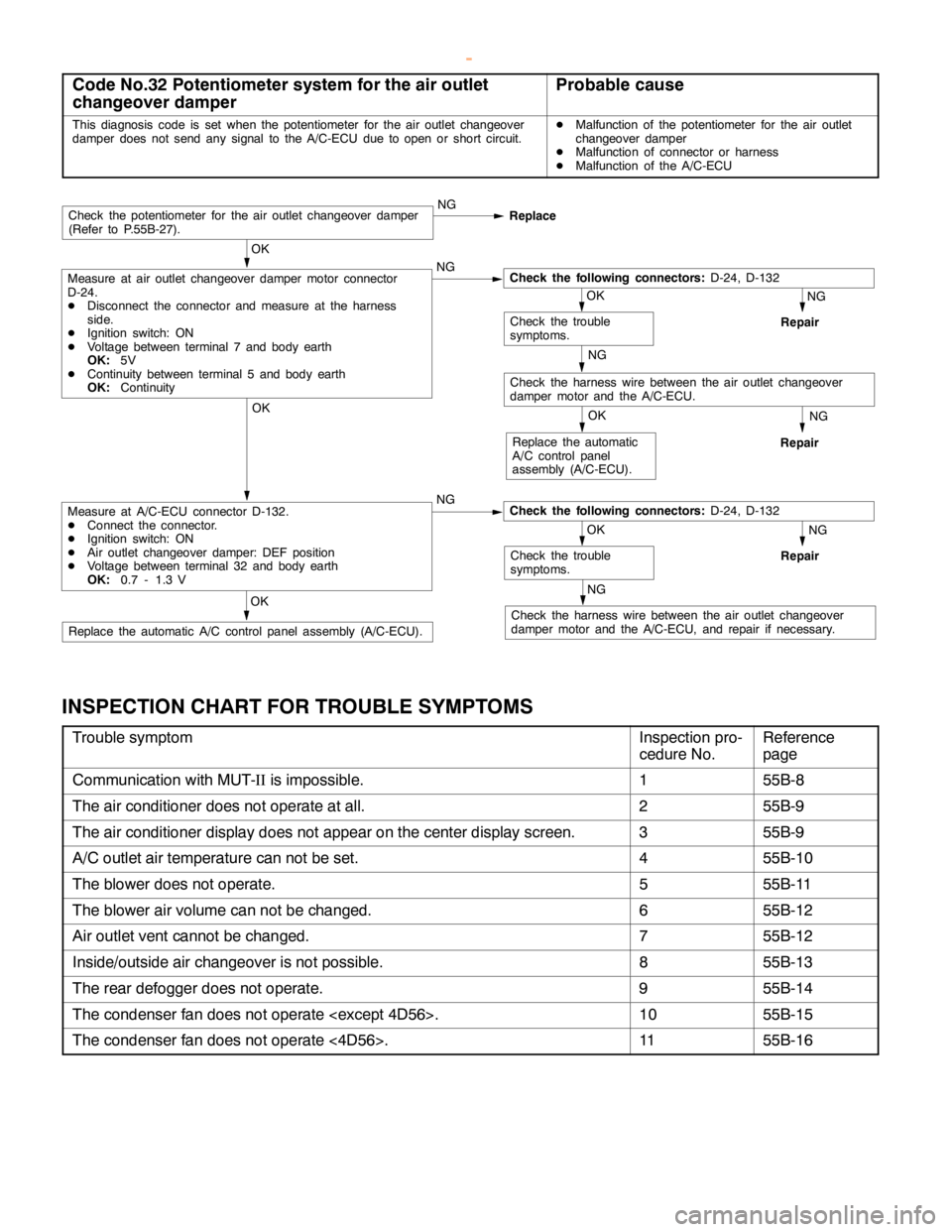

HEATER, AIR CONDITIONER AND VENTILATION -Troubleshooting

Code No.32 Potentiometer system for the air outlet

changeover damperProbable cause

This diagnosis code is set when the potentiometer for the air outlet changeover

damper does not send any signal to the A/C-ECU due toopen orshort circuit.DMalfunction of the potentiometer for the air outlet

changeover damper

DMalfunction of connector or harness

DMalfunction of the A/C-ECU

NG

Repair

NG

Repair

NG

Check the harness wire between the air outlet changeover

damper motor and the A/C-ECU, and repair if necessary.OK

Replace the automatic A/C control panelassembly (A/C-ECU).

NG

Repair

OK

Replace the automatic

A/C control panel

assembly (A/C-ECU).

OK

Check the trouble

symptoms.

OK

Measure at A/C-ECU connector D-132.

DConnect the connector.

DIgnition switch: ON

DAir outlet changeover damper: DEF position

DVoltage between terminal 32 and body earth

OK:0.7 - 1.3 VNGCheck the following connectors:D-24, D-132

NG

Check the harness wire between the air outlet changeover

damper motor and the A/C-ECU.

OK

Check the trouble

symptoms.

OK

Measure at air outlet changeover damper motor connector

D-24.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DVoltage between terminal 7 and body earth

OK:5V

DContinuity between terminal 5 and body earth

OK:ContinuityNGCheck the following connectors:D-24, D-132

Check the potentiometer for the air outlet changeover damper

(Refer to P.55B-27).NG

Replace

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection pro-

cedure No.Reference

page

Communication with MUT-IIis impossible.155B-8

The air conditioner does not operate at all.255B-9

The air conditioner display does not appear on the center display screen.355B-9

A/C outlet air temperature can not be set.455B-10

The blower does not operate.555B-11

The blower air volume can not be changed.655B-12

Air outlet vent cannot be changed.755B-12

Inside/outside air changeover is not possible.855B-13

The rear defogger does not operate.955B-14

The condenser fan does not operate

The condenser fan does not operate <4D56>.1155B-16

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1812 of 1839

HEATER, AIR CONDITIONER AND VENTILATION -Troubleshooting

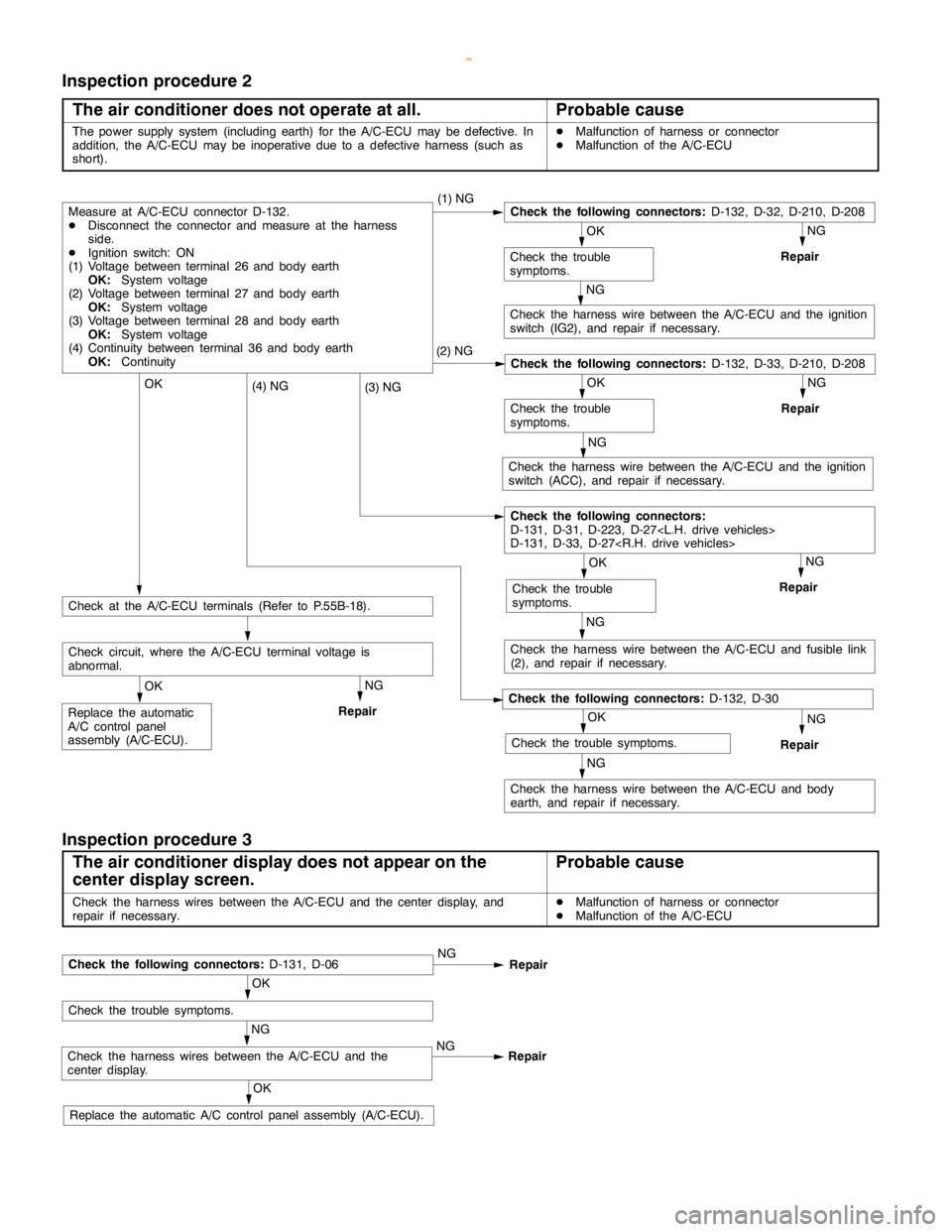

Inspection procedure 2

The air conditioner does not operate at all.

Probable cause

The power supply system (including earth) for the A/C-ECU may be defective. In

addition, the A/C-ECU may be inoperative due to a defective harness (such as

short).DMalfunction of harness or connector

DMalfunction of the A/C-ECU

NG

Repair

NG

Check the harness wire between the A/C-ECU and the ignition

switch (IG2), and repair if necessary.

NG

Repair

NG

Check the harness wire between the A/C-ECU and the ignition

switch (ACC), and repair if necessary.

NG

Repair

NG

Check the harness wire between the A/C-ECU and fusible link

(2), and repair if necessary.

NG

Repair

NG

Check the harness wire between the A/C-ECU and body

earth, and repair if necessary.

OK

Replace the automatic

A/C control panel

assembly (A/C-ECU).

NG

Repair

Check circuit, where the A/C-ECU terminal voltage is

abnormal.

OK

Check at the A/C-ECU terminals (Refer to P.55B-18).

OK

Check the trouble symptoms.

Check the following connectors:D-132, D-30

(4) NG

OK

Check the trouble

symptoms.

Check the following connectors:

D-131, D-31, D-223, D-27

D-131, D-33, D-27

(3) NGOK

Check the trouble

symptoms.

Check the following connectors:D-132, D-33, D-210, D-208(2) NG

OK

Check the trouble

symptoms.

Measure at A/C-ECU connector D-132.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

(1) Voltage between terminal 26 and body earth

OK:System voltage

(2) Voltage between terminal 27 and body earth

OK:System voltage

(3) Voltage between terminal 28 and body earth

OK:System voltage

(4) Continuity between terminal 36 and body earth

OK:Continuity(1) NGCheck the following connectors:D-132, D-32, D-210, D-208

Inspection procedure 3

The air conditioner display does not appear on the

center display screen.

Probable cause

Check the harness wires between the A/C-ECU and the center display, and

repair if necessary.DMalfunction of harness or connector

DMalfunction of the A/C-ECU

OK

Replace the automatic A/C control panelassembly (A/C-ECU).

NG

Check the harness wires between the A/C-ECU and the

center display.NG

Repair

OK

Check the trouble symptoms.

Check the following connectors:D-131, D-06NG

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1814 of 1839

HEATER, AIR CONDITIONER AND VENTILATION -Troubleshooting

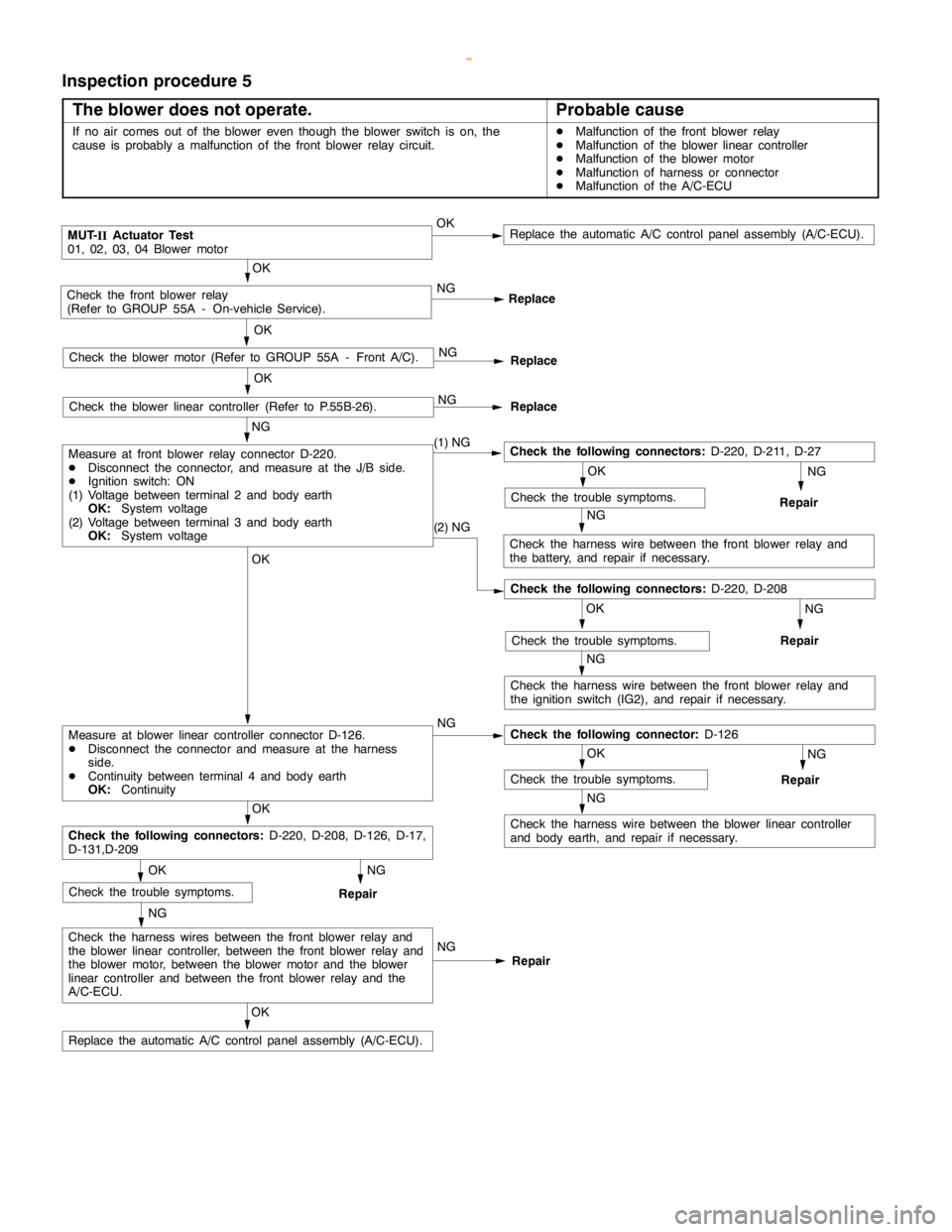

Inspection procedure 5

The blower does not operate.

Probable cause

If no air comes out of the blower even though the blower switch is on, the

cause is probably a malfunction of the front blower relay circuit.DMalfunction of the front blower relay

DMalfunction of the blower linear controller

DMalfunction of the blower motor

DMalfunction of harness or connector

DMalfunction of the A/C-ECU

NG

Repair

NG

Repair

NG

Repair

NG

Check the harness wire between the front blower relay and

the ignition switch (IG2), and repair if necessary.

NG

Check the harness wire between the front blower relay and

the battery, and repair if necessary.

NG

Repair

NG

Check the harness wire between the blower linear controller

and body earth, and repair if necessary.

OK

Replace the automatic A/C control panelassembly (A/C-ECU).

NG

Check the harness wires between the front blower relay and

the blower linear controller, between the front blower relay and

the blower motor, between the blower motor and the blower

linear controller and between the front blower relay and the

A/C-ECU.NG

Repair

OK

Check the trouble symptoms.

OK

Check the following connectors:D-220, D-208, D-126, D-17,

D-131,D-209

OK

Check the trouble symptoms.

OK

Measure at blower linear controller connector D-126.

DDisconnect the connector and measure at the harness

side.

DContinuity between terminal 4 and body earth

OK:ContinuityNGCheck the following connector:D-126

OK

Check the trouble symptoms.

Check the following connectors:D-220, D-208

(2) NG

OK

Check the trouble symptoms.

NG

Measure at front blower relay connector D-220.

DDisconnect the connector, and measure at the J/B side.

DIgnition switch: ON

(1) Voltage between terminal 2 and body earth

OK:System voltage

(2) Voltage between terminal 3 and body earth

OK:System voltage(1) NGCheck the following connectors:D-220, D-211, D-27

OK

Check the blower linear controller (Refer to P.55B-26).NG

Replace

OK

Check the blower motor (Refer to GROUP 55A - Front A/C).NG

Replace

OK

Check the front blower relay

(Refer to GROUP 55A - On-vehicle Service).NG

Replace

MUT-

IIActuator Test

01, 02, 03, 04 Blower motorOKReplace the automatic A/C control panelassembly (A/C-ECU).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk