check oil MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 56 of 1839

11A-2

ENGINE <6G7>

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 3.................

SEALANT 4..................................

SPECIAL TOOLS 4..........................

ON-VEHICLE SERVICE 6.....................

Drive Belt Tension Check and Adjustment 6......

Auto-tensioner Check 6.........................

Ignition Timing Check 6........................

Idle Speed Check 7............................

Idle Mixture Check 8...........................Compression Pressure Check 9.................

Intake Manifold Vacuum Check 10...............

Lash Adjuster Check 10........................

OIL PAN AND OIL SCREEN 13..............

TIMING BELT 15............................

CRANKSHAFT OIL SEAL 23.................

CAMSHAFT OIL SEAL 25...................

CYLINDER HEAD GASKET 27...............

ENGINE ASSEMBLY 30.....................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 88 of 1839

11B-1

ENGINE <4D5>

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

SEALANTS 3................................

SPECIAL TOOLS 4..........................

ON-VEHICLE SERVICE 5.....................

Drive Belt Tension Check and Adjustment 5......

Auto-tensioner check 7.........................

Valve Clearance Check and Adjustment 8........

Injection Timing Check and Adjustment 9........

Idle Speed Check and Adjustment 12............

Idle-up Mechanism Check and

Adjustment-For A/C 12.........................Compression Pressure Check 13................

Timing Belt Tension Adjustment 14..............

Timing Belt B Tension Adjustment 15............

OIL PAN AND OIL SCREEN 17..............

TIMING BELT AND TIMING BELT B 19......

CRANKSHAFT OIL SEAL 25.................

CAMSHAFT AND CAMSHAFT OIL SEAL 27..

CYLINDER HEAD GASKET 30...............

ENGINE ASSEMBLY 34.....................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 124 of 1839

11B-1

ENGINE <4D5>

CONTENTS

GENERAL 2.................................

Outline of Changes 2...........................

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

SEALANT 2..................................

SPECIAL TOOLS 3...........................ON-VEHICLE SERVICE 4.....................

Injection Timing Check and Adjustment 4.........

Idle Speed Check 4............................

OIL PAN AND OIL SCREEN 5................

TIMING BELT AND TIMING BELT B 7........

CYLINDER HEAD GASKET 13................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 125 of 1839

ENGINE <4D5> -General/General Information/Service Specifications/Sealant11B-2

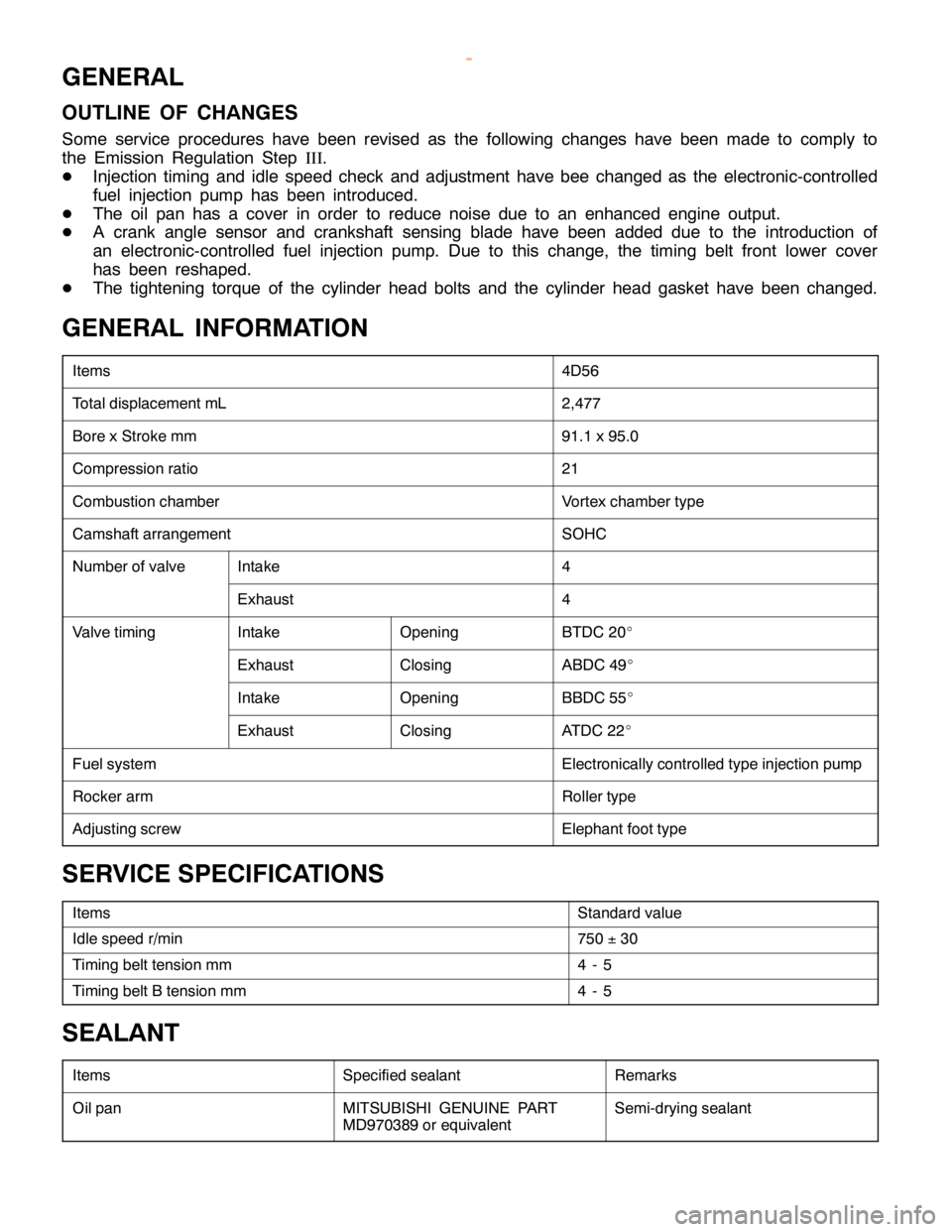

GENERAL

OUTLINE OF CHANGES

Some service procedures have been revised as the following changes have been made to comply to

the Emission Regulation StepIII.

DInjection timing and idle speed check and adjustment have bee changed as the electronic-controlled

fuel injection pump has been introduced.

DThe oil pan has a cover in order to reduce noise due to an enhanced engine output.

DA crank angle sensor and crankshaft sensing blade have been added due to the introduction of

an electronic-controlled fuel injection pump. Due to this change, the timing belt front lower cover

has been reshaped.

DThe tightening torque of the cylinder head bolts and the cylinder head gasket have been changed.

GENERAL INFORMATION

Items4D56

Total displacement mL2,477

Bore x Stroke mm91.1 x 95.0

Compression ratio21

Combustion chamberVortex chamber type

Camshaft arrangementSOHC

Number of valveIntake4

Exhaust4

Valve timingIntakeOpeningBTDC 20_

ExhaustClosingABDC 49_

IntakeOpeningBBDC 55_

ExhaustClosingATDC 22_

Fuel systemElectronically controlled type injection pump

Rocker armRoller type

Adjusting screwElephant foot type

SERVICE SPECIFICATIONS

ItemsStandard value

Idle speed r/min750±30

Timing belt tension mm4-5

Timing belt B tension mm4-5

SEALANT

ItemsSpecified sealantRemarks

Oil panMITSUBISHI GENUINE PART

MD970389 or equivalentSemi-drying sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 142 of 1839

11C-1

ENGINE <4M4>

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

SEALANTS AND ADHESIVES 3..............

SPECIAL TOOLS 3..........................

ON-VEHICLE SERVICE 5.....................

Drive Belt Tension Check and Adjustment 5......

Valve Clearance Check and Adjustment 8........

Injection Timing Check and Adjustment 9........

Idle Speed Check 12...........................Compression Pressure Check 12................

OIL PAN 14.................................

VACUUM PUMP 16..........................

TIMING CHAIN 17...........................

CRANKSHAFT OIL SEAL 21.................

CAMSHAFT 23..............................

CYLINDER HEAD GASKET 27...............

ENGINE ASSEMBLY 33.....................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 168 of 1839

ENGINE <4M4> -Cylinder Head Gasket11C-27

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

DEngine Coolant Drain and Refill

(Refer to GROUP 14 - On-vehicle Service.)

DEngine Oil Check andRefill

(Refer to GROUP 12 - On-vehicle Service.)

DFuel Line Air-bleeding

(Refer to GROUP 13C - On-vehicle Service.)

DDrive Belt TensionCheck and Adjustment

(Refer to P.11C-5.)

(Refer to P.11C-20.)

DCooling Fan and Fan Clutch Assembly Removal and

Installation (Refer to GROUP 14.)

DIntake Manifold Removal and Installation

(Refer to GROUP15.)

DTurbocharger Removal and Installation

(Refer to GROUP15.)

DExhaust Manifold Removal and Installation

(Refer to GROUP15.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 202 of 1839

12-1

ENGINE

LUBRICATION

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

SEALANT 3..................................

LUBRICANTS 3..............................

SPECIAL TOOLS 3..........................ON-VEHICLE SERVICE 4.....................

Engine Oil Check 4............................

Engine Oil Replacement 4......................

Oil Filter Replacement 5........................

Oil Pressure Check 6..........................

ENGINE OIL COOLER 9.....................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 205 of 1839

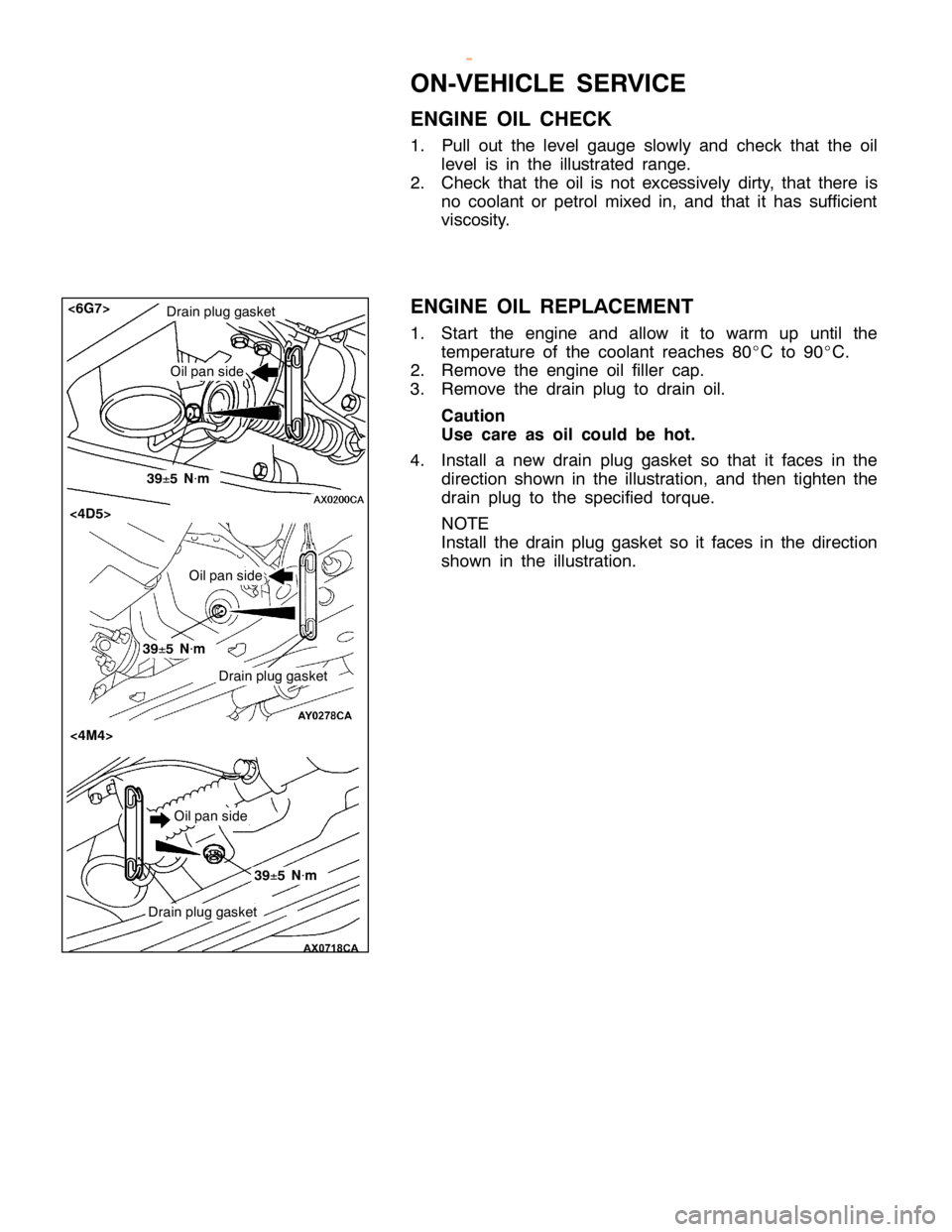

O

N-V EH IC LE SER VIC E

E N G IN E OIL CHEC K

1 . Pull out th e le ve l gauge slo w ly and ch eck th at th e oil

l e ve l is in th e illu str a te d ra nge.

2 . Check th at th e oil is not exce ssiv e ly dir ty , th at th ere is

n o co ola nt or petr o l m ix e d in , and th at it has su ff ic ie nt

v is co sit y .

E N G IN E OIL REPLA CEM EN T

1 . Sta rt th e engin e and allo w it to warm up until th e

t e m pera tu re of th e co ola nt re ach es 80 _C to 90 _C .

2 . Rem ove th e engin e oil fille r ca p.

3 . Rem ove th e dra in plu g to dra in oil.

C au tio n

U se care as oil co uld be hot.

4 . In sta ll a new dra in plu g gaske t so th at it fa ce s in th e

d ir e ctio n sh ow n in th e illu str a tio n, and th en tig hte n th e

d ra in plu g to th e sp ecif ie d to rq ue.

N O TE

I n sta ll th e dra in plu g gaske t so it fa ce s in th e dir e ctio n

s h ow n in th e illu str a tio n. <

4M 4> <

4D 5> O

il p an sid e O

il p an sid e D

ra in plu g gask e t

Page 267 of 1839

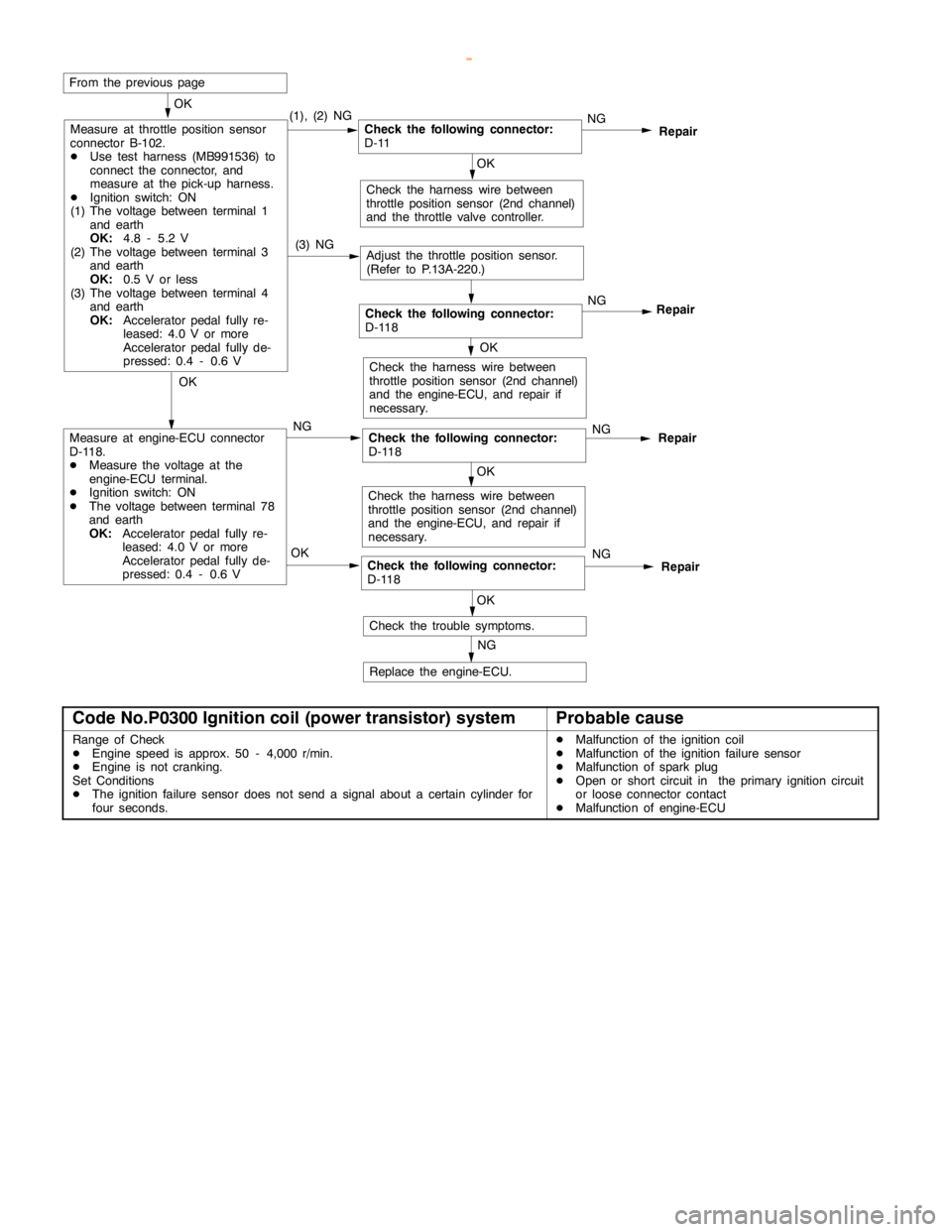

GDI -Troubleshooting

OK

Measure at throttle position sensor

connector B-102.

DUse test harness (MB991536) to

connect the connector, and

measure at the pick-up harness.

DIgnition switch: ON

(1) The voltage between terminal 1

and earth

OK:

4.8 - 5.2 V

(2) The voltage between terminal 3

and earth

OK:

0.5 V or less

(3) The voltage between terminal 4

and earth

OK:

Acceleratorpedalfully re-

leased: 4.0 V or more

Acceleratorpedalfully de-

pressed: 0.4 - 0.6 V(1), (2) NG

NGRepair

Check the following connector:

D-118NG

Repair

OK

Check the harness wire between

throttle position sensor (2nd channel)

and the throttle valve controller.

From the previouspage

(3) NG

Adjust the throttle position sensor.

(Refer to P.13A-220.)

OK

Check the harness wire between

throttle position sensor (2nd channel)

and the engine-ECU, and repair if

necessary.OK

Measure at engine-ECU connector

D-118.

DMeasure the voltage at the

engine-ECU terminal.

DIgnition switch: ON

DThe voltage between terminal 78

and earth

OK:

Acceleratorpedalfully re-

leased: 4.0 V or more

Acceleratorpedalfully de-

pressed: 0.4 - 0.6 VNGCheck the following connector:

D-118NGRepair

OK

Check the harness wire between

throttle position sensor (2nd channel)

and the engine-ECU, and repair if

necessary.

OKCheck the following connector:

D-118NGRepair

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

Check the following connector:

D-11

Code No.P0300 Ignition coil (power transistor) systemProbable cause

Range of Check

DEngine speed is approx. 50 - 4,000 r/min.

DEngine is not cranking.

Set Conditions

DThe ignition failure sensor does not send a signal about a certain cylinder for

four seconds.DMalfunction of the ignition coil

DMalfunction of the ignition failure sensor

DMalfunction of sparkplug

DOpen or short circuit in the primary ignition circuit

or loose connector contact

DMalfunction of engine-ECU

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 268 of 1839

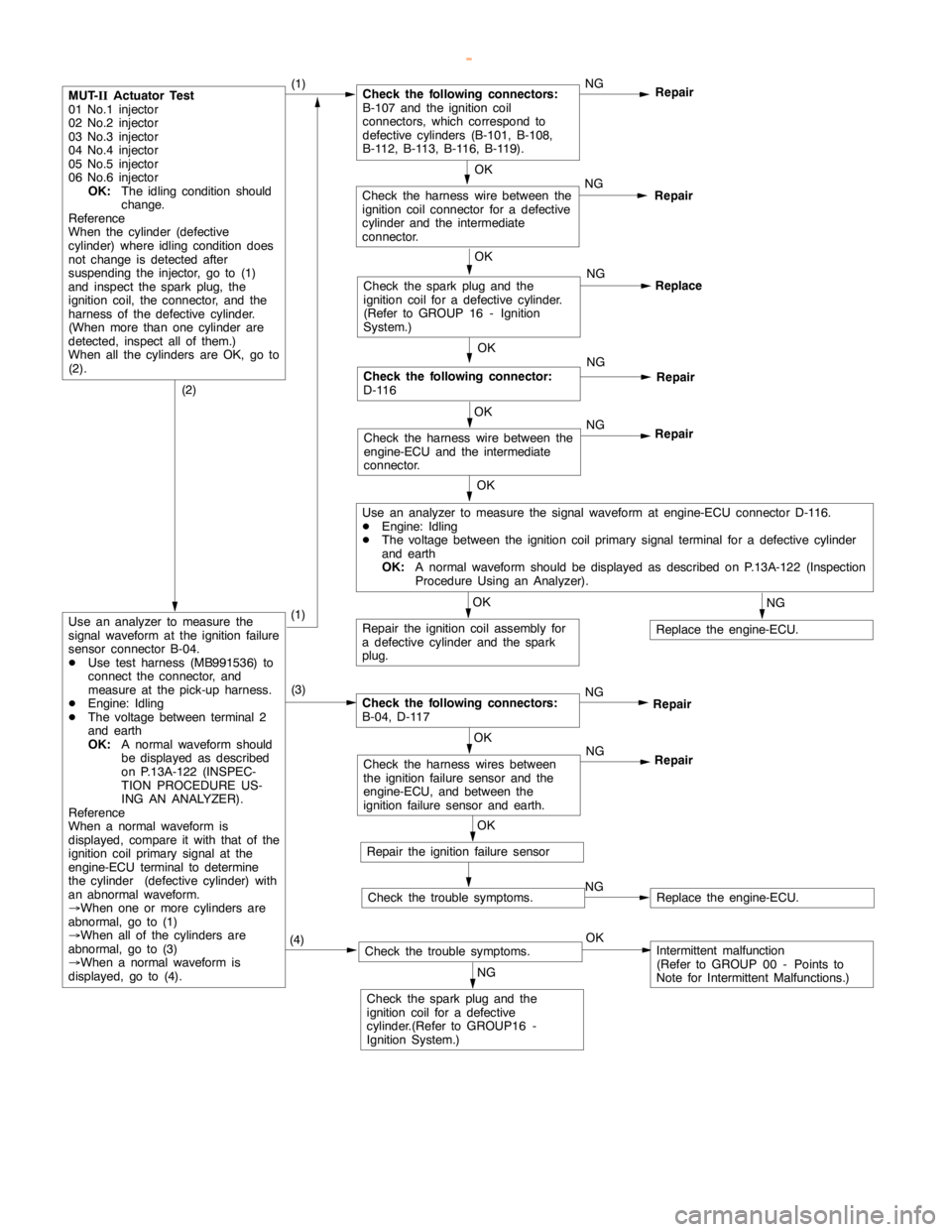

GDI -Troubleshooting

OK

Check the harness wire between the

engine-ECU and the intermediate

connector.NG

Repair

OK

Check the following connector:

D-116NG

Repair

OK

Check the harness wire between the

ignition coil connector for a defective

cylinder and the intermediate

connector.NG

Repair

MUT-

IIActuator Test

01 No.1 injector

02 No.2 injector

03 No.3 injector

04 No.4 injector

05 No.5 injector

06 No.6 injector

OK:

The idling condition should

change.

Reference

When the cylinder (defective

cylinder) whereidling conditiondoes

not change is detected after

suspending the injector, go to (1)

and inspect the spark plug, the

ignition coil, the connector, and the

harness of the defective cylinder.

(When more than one cylinder are

detected, inspect all of them.)

When all the cylinders are OK, go to

(2).(1)Check the following connectors:

B-107 and the ignition coil

connectors, which correspond to

defective cylinders (B-101, B-108,

B-112, B-113, B-116, B-119).NG

Repair

OK

Check the sparkplug and the

ignition coil for a defective cylinder.

(Refer to GROUP 16 - Ignition

System.)NG

Replace

OK

Use an analyzer to measure the signal waveform at engine-ECU connector D-116.

DEngine: Idling

DThe voltage between the ignition coil primary signal terminal for a defective cylinder

and earth

OK:

A normal waveform should be displayed as described on P.13A-122 (Inspection

Procedure Using an Analyzer).

OK

Repair the ignition coil assembly for

a defective cylinder and the spark

plug.

NG

Replace the engine-ECU.

(2)

Use an analyzer to measure the

signal waveform at the ignition failure

sensor connector B-04.

DUse test harness (MB991536) to

connect the connector, and

measure at the pick-up harness.

DEngine: Idling

DThe voltage between terminal 2

and earth

OK:

A normal waveform should

be displayed as described

on P.13A-122 (INSPEC-

TION PROCEDURE US-

ING AN ANALYZER).

Reference

When a normal waveform is

displayed, compare it with that of the

ignition coil primary signal at the

engine-ECU terminal to determine

the cylinder (defective cylinder) with

an abnormal waveform.

®When one or more cylinders are

abnormal, go to (1)

®When all of the cylinders are

abnormal, go to (3)

®When a normal waveform is

displayed, go to (4).(3)

Check the following connectors:

B-04, D-117NG

Repair

OK

Check the harness wires between

the ignition failure sensor and the

engine-ECU, and between the

ignition failure sensor and earth.NG

Repair

OK

Repair the ignition failure sensor

Check the trouble symptoms.NGReplace the engine-ECU.

(4)Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

Check the sparkplug and the

ignition coil for a defective

cylinder.(Refer to GROUP16 -

Ignition System.)

(1)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk